torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4010 of 5267

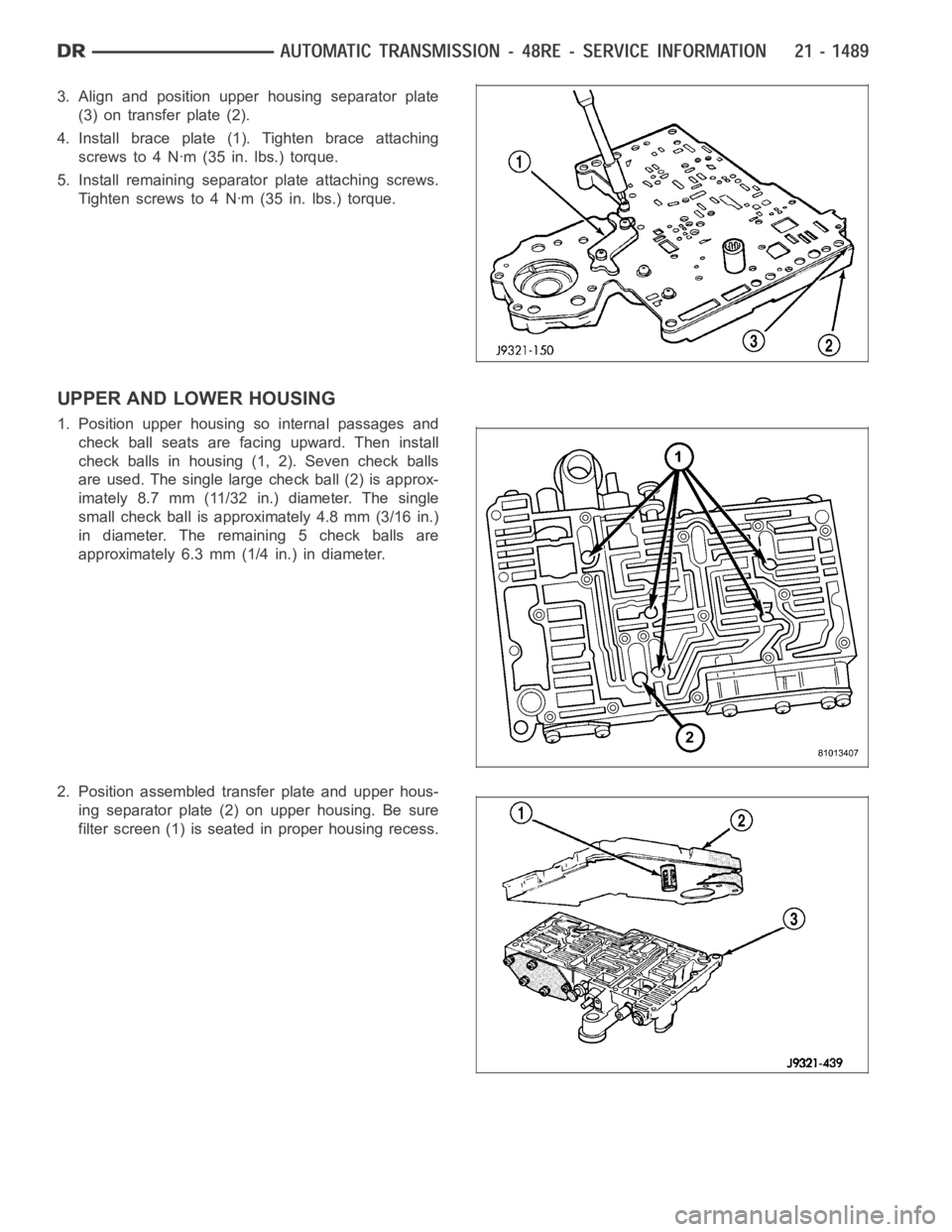

3. Align and position upper housing separator plate

(3) on transfer plate (2).

4. Install brace plate (1). Tighten brace attaching

screws to 4 Nꞏm (35 in. lbs.) torque.

5. Install remaining separator plate attaching screws.

Tighten screws to 4 Nꞏm (35 in. lbs.) torque.

UPPER AND LOWER HOUSING

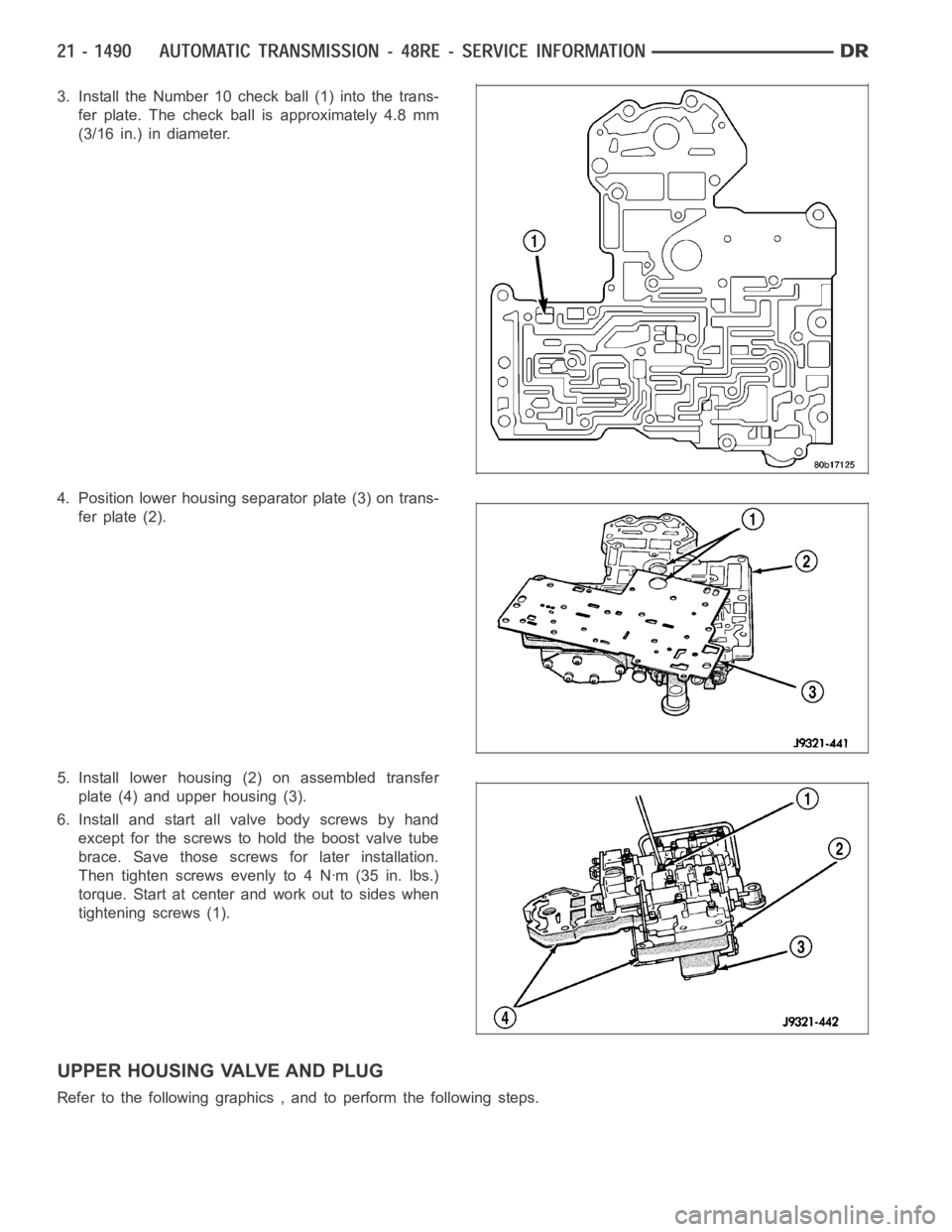

1. Position upper housing so internal passages and

check ball seats are facing upward. Then install

check balls in housing (1, 2). Seven check balls

are used. The single large check ball (2) is approx-

imately 8.7 mm (11/32 in.) diameter. The single

small check ball is approximately 4.8 mm (3/16 in.)

in diameter. The remaining 5 check balls are

approximately 6.3 mm (1/4 in.) in diameter.

2. Position assembled transfer plate and upper hous-

ing separator plate (2) on upper housing. Be sure

filter screen (1) is seated in proper housing recess.

Page 4011 of 5267

3. Install the Number 10 check ball (1) into the trans-

fer plate. The check ball is approximately 4.8 mm

(3/16 in.) in diameter.

4. Position lower housing separator plate (3) on trans-

fer plate (2).

5. Install lower housing (2) on assembled transfer

plate (4) and upper housing (3).

6. Install and start all valve body screws by hand

except for the screws to hold the boost valve tube

brace. Save those screws for later installation.

Then tighten screws evenly to 4 Nꞏm (35 in. lbs.)

torque. Start at center and work out to sides when

tightening screws (1).

UPPER HOUSING VALVE AND PLUG

Refer to the following graphics , and to perform the following steps.

Page 4012 of 5267

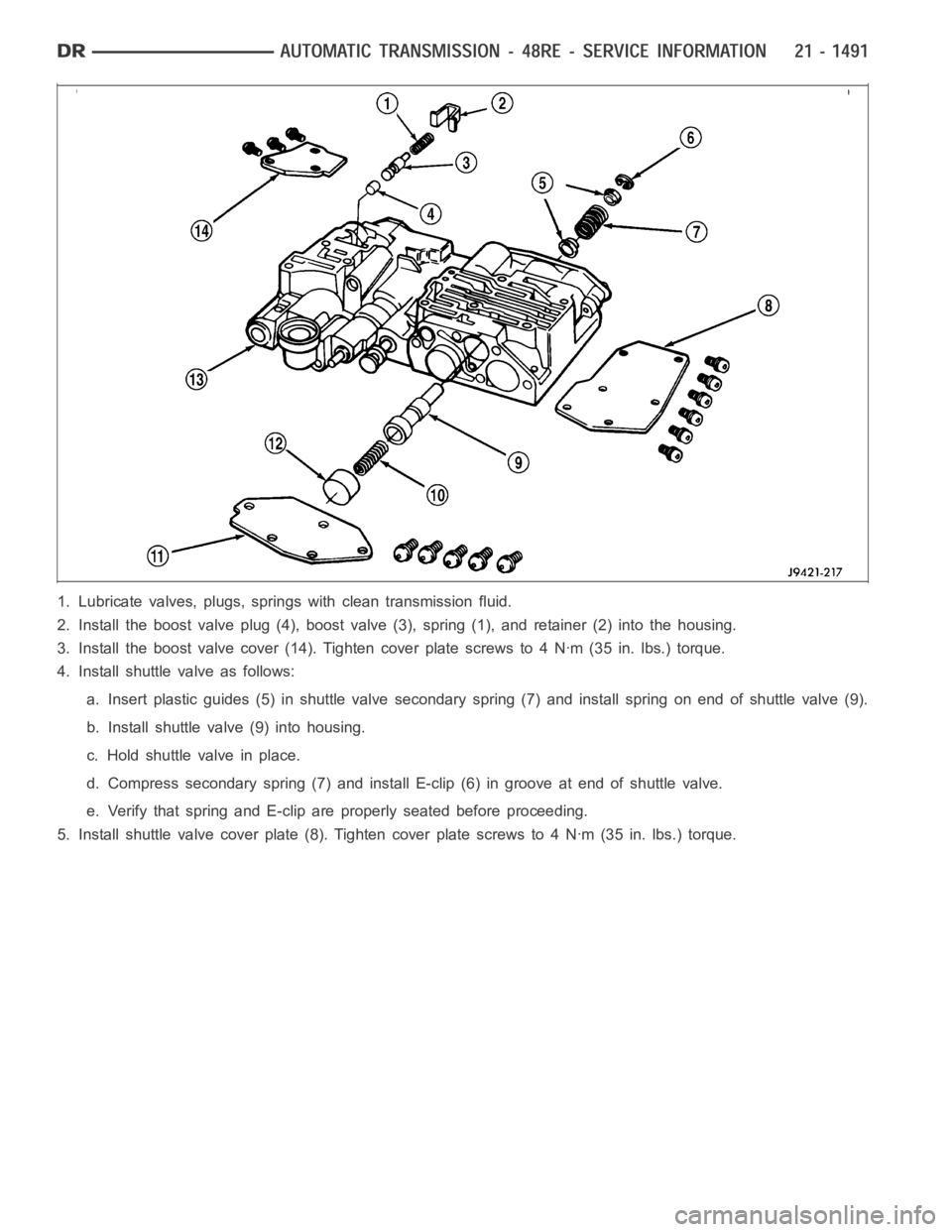

1. Lubricate valves, plugs, springs with clean transmission fluid.

2. Install the boost valve plug (4), boost valve (3), spring (1), and retainer (2) into the housing.

3. Install the boost valve cover (14). Tighten cover plate screws to 4 Nꞏm (35 in. lbs.) torque.

4. Install shuttle valve as follows:

a. Insert plastic guides (5) in shuttle valve secondary spring (7) and install spring on end of shuttle valve (9).

b. Install shuttle valve (9) into housing.

c. Hold shuttle valve in place.

d. Compress secondary spring (7) and install E-clip (6) in groove at end of shuttle valve.

e. Verify that spring and E-clip are properly seated before proceeding.

5. Install shuttle valve cover plate (8). Tighten cover plate screws to 4 Nꞏm (35 in. lbs.) torque.

Page 4013 of 5267

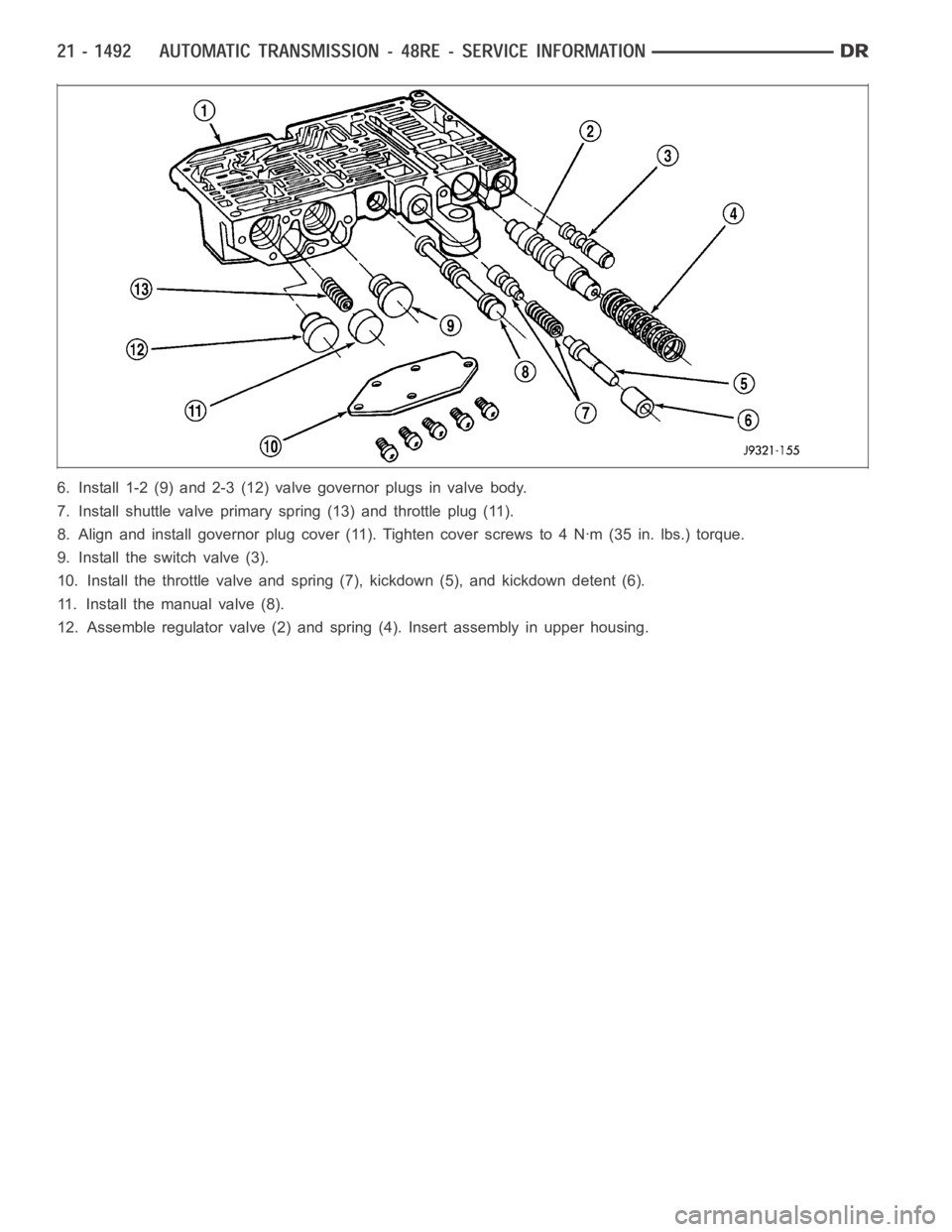

6. Install 1-2 (9) and 2-3 (12) valve governor plugs in valve body.

7. Install shuttle valve primary spring (13) and throttle plug (11).

8. Align and install governor plug cover (11). Tighten cover screws to 4 Nꞏm(35 in. lbs.) torque.

9. Install the switch valve (3).

10. Install the throttle valve and spring (7), kickdown (5), and kickdown detent (6).

11. Install the manual valve (8).

12. Assemble regulator valve (2) and spring (4). Insert assembly in upper housing.

Page 4015 of 5267

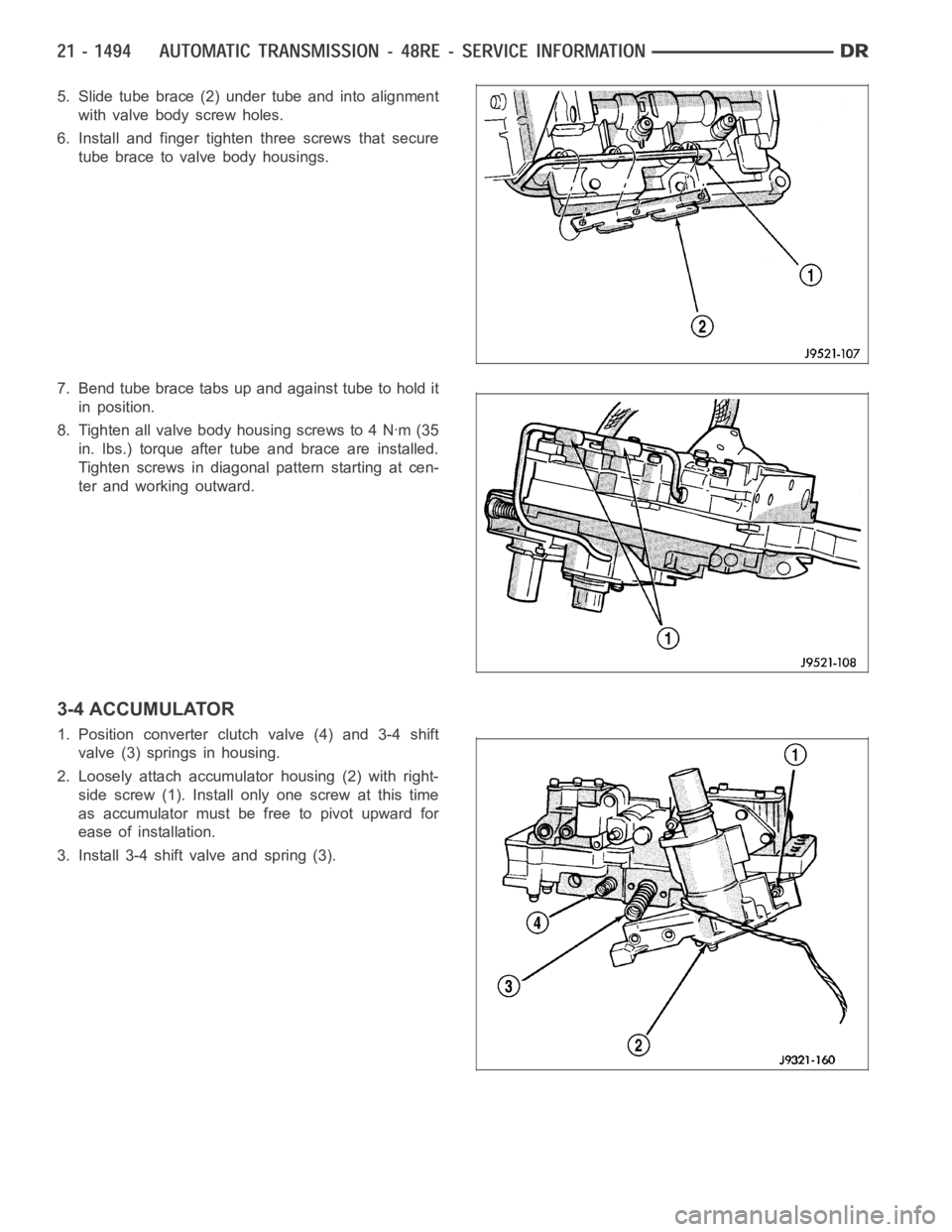

5. Slide tube brace (2) under tube and into alignment

with valve body screw holes.

6. Install and finger tighten three screws that secure

tube brace to valve body housings.

7. Bend tube brace tabs up and against tube to hold it

in position.

8. Tighten all valve body housing screws to 4 Nꞏm (35

in. lbs.) torque after tube and brace are installed.

Tighten screws in diagonal pattern starting at cen-

ter and working outward.

3-4 ACCUMULATOR

1. Position converter clutch valve (4) and 3-4 shift

valve (3) springs in housing.

2. Loosely attach accumulator housing (2) with right-

side screw (1). Install only one screw at this time

as accumulator must be free to pivot upward for

ease of installation.

3. Install 3-4 shift valve and spring (3).

Page 4017 of 5267

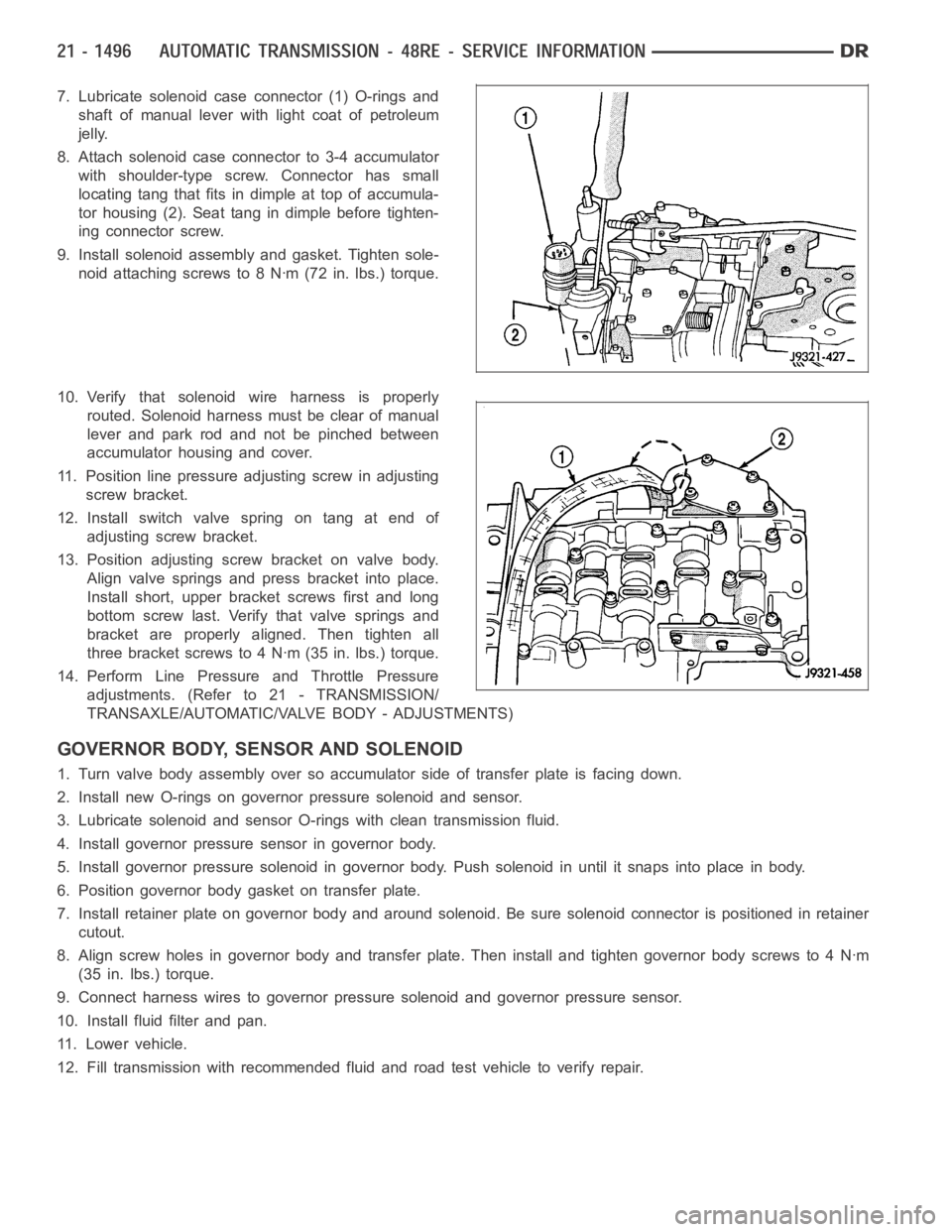

7. Lubricate solenoid case connector (1) O-rings and

shaft of manual lever with light coat of petroleum

jelly.

8. Attach solenoid case connector to 3-4 accumulator

with shoulder-type screw. Connector has small

locating tang that fits indimple at top of accumula-

tor housing (2). Seat tang in dimple before tighten-

ing connector screw.

9. Install solenoid assembly and gasket. Tighten sole-

noid attaching screws to 8 Nꞏm (72 in. lbs.) torque.

10. Verify that solenoid wire harness is properly

routed. Solenoid harness must be clear of manual

lever and park rod and not be pinched between

accumulator housing and cover.

11. Position line pressure adjusting screw in adjusting

screw bracket.

12. Install switch valve spring on tang at end of

adjusting screw bracket.

13. Position adjusting screw bracket on valve body.

Align valve springs and press bracket into place.

Install short, upper bracket screws first and long

bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all

three bracket screws to 4 Nꞏm (35 in. lbs.) torque.

14. Perform Line Pressure and Throttle Pressure

adjustments. (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC/VALVE BODY - ADJUSTMENTS)

GOVERNOR BODY, SENSOR AND SOLENOID

1. Turn valve body assembly over so accumulator side of transfer plate is facing down.

2. Install new O-rings on governor pressure solenoid and sensor.

3. Lubricate solenoid and sensor O-rings with clean transmission fluid.

4. Install governor pressure sensor in governor body.

5. Install governor pressure solenoid in governor body. Push solenoid in until it snaps into place in body.

6. Position governor body gasket on transfer plate.

7. Install retainer plate on governor body and around solenoid. Be sure solenoid connector is positioned in retainer

cutout.

8. Align screw holes in governor body and transfer plate. Then install and tighten governor body screws to 4 Nꞏm

(35 in. lbs.) torque.

9. Connect harness wires to governor pressure solenoid and governor pressure sensor.

10. Install fluid filter and pan.

11. Lower vehicle.

12. Fill transmission with recommended fluid and road test vehicle to verify repair.

Page 4018 of 5267

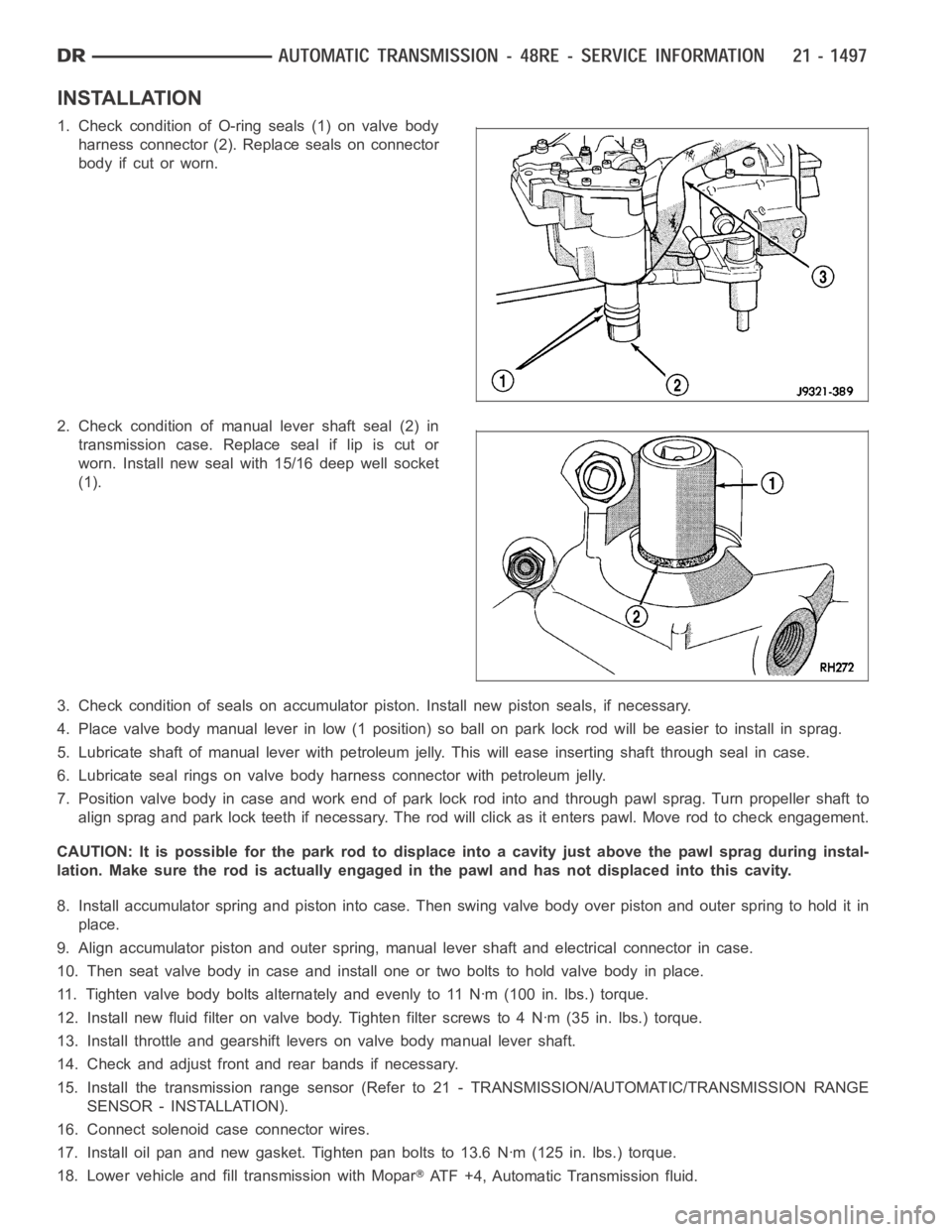

INSTALLATION

1. Check condition of O-ring seals (1) on valve body

harness connector (2). Replace seals on connector

body if cut or worn.

2. Check condition of manual lever shaft seal (2) in

transmission case. Replace seal if lip is cut or

worn. Install new seal with 15/16 deep well socket

(1).

3. Check condition of seals on accumulator piston. Install new piston seals, if necessary.

4. Place valve body manual lever in low (1 position) so ball on park lock rod will be easier to install in sprag.

5. Lubricate shaft of manual lever with petroleum jelly. This will ease inserting shaft through seal in case.

6. Lubricate seal rings on valve body harness connector with petroleum jelly.

7. Position valve body in case and work end of park lock rod into and through pawl sprag. Turn propeller shaft to

align sprag and park lock teeth if necessary. The rod will click as it enterspawl. Move rod to check engagement.

CAUTION: It is possible for the park rod to displace into a cavity just abovethe pawl sprag during instal-

lation. Make sure the rod is actually engaged in the pawl and has not displaced into this cavity.

8. Install accumulator spring and piston into case. Then swing valve body overpistonandouterspringtoholditin

place.

9. Align accumulator piston and outer spring, manual lever shaft and electrical connector in case.

10. Then seat valve body in case and install one or two bolts to hold valve bodyinplace.

11. Tighten valve body bolts alternately and evenly to 11 Nꞏm (100 in. lbs.)torque.

12. Install new fluid filter on valve body. Tighten filter screws to 4 Nꞏm (35 in. lbs.) torque.

13. Install throttle and gearshift levers on valve body manual lever shaft.

14. Check and adjust front and rear bands if necessary.

15. Install the transmission range sensor (Refer to 21 - TRANSMISSION/AUTOMATIC/TRANSMISSION RANGE

SENSOR - INSTALLATION).

16. Connect solenoid case connector wires.

17. Install oil pan and new gasket. Tighten pan bolts to 13.6 Nꞏm (125 in. lbs.) torque.

18. Lower vehicle and fill transmission with Mopar

ATF +4, Automatic Transmission fluid.

Page 4085 of 5267

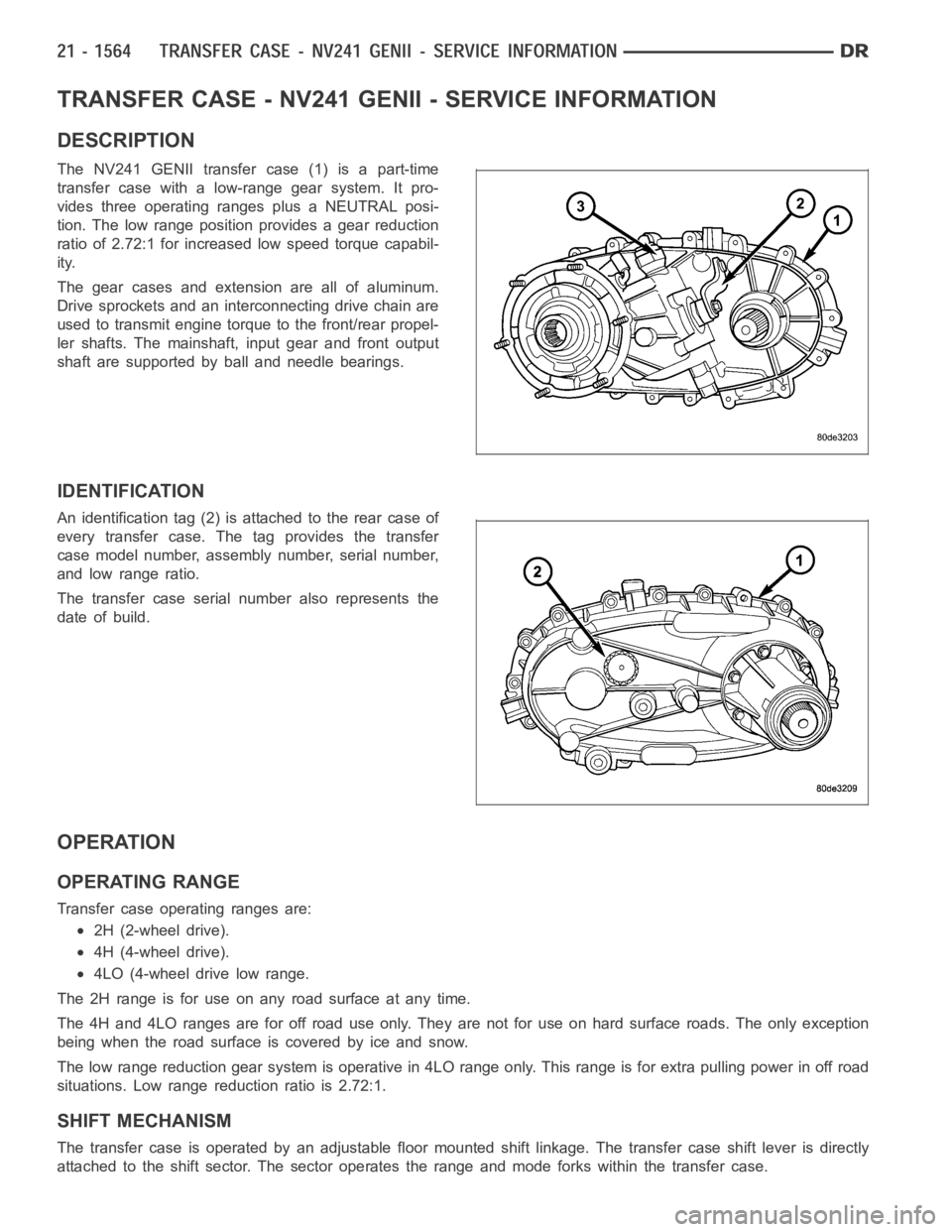

TRANSFER CASE - NV241 GENII - SERVICE INFORMATION

DESCRIPTION

The NV241 GENII transfer case (1) is a part-time

transfer case with a low-range gear system. It pro-

vides three operating ranges plus a NEUTRAL posi-

tion. The low range position provides a gear reduction

ratio of 2.72:1 for increased low speed torque capabil-

ity.

The gear cases and extension are all of aluminum.

Drive sprockets and an interconnecting drive chain are

used to transmit engine torque to the front/rear propel-

ler shafts. The mainshaft, input gear and front output

shaft are supported by ball and needle bearings.

IDENTIFICATION

An identification tag (2) is attached to the rear case of

every transfer case. The tag provides the transfer

case model number, assembly number, serial number,

and low range ratio.

The transfer case serial number also represents the

date of build.

OPERATION

OPERATING RANGE

Transfer case operating ranges are:

2H (2-wheel drive).

4H (4-wheel drive).

4LO (4-wheel drive low range.

The 2H range is for use on any road surface at any time.

The 4H and 4LO ranges are for off road use only. They are not for use on hard surface roads. The only exception

being when the road surface is covered by ice and snow.

The low range reduction gear system is operative in 4LO range only. This range is for extra pulling power in off road

situations. Low range reduction ratio is 2.72:1.

SHIFT MECHANISM

The transfer case is operated by an adjustable floor mounted shift linkage. The transfer case shift lever is directly

attached to the shift sector. The sector operates the range and mode forks within the transfer case.

Page 4086 of 5267

A straight line shift pattern is used with a NEUTRAL detent. Lever range positions are imprinted in the shift knob.

SHIFTING

The transfer case can be shifted between the 2H and 4H operating ranges while the vehicle is in motion. The vehi-

cle must have the transmission placed in NEUTRAL, or the clutch depressed in the case of a manual transmission,

and be moving less than 2-3 MPH when shifting into and out of the 4L operatingrange.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV241 GENII

Before beginning repair on a suspected transfer case malfunction, check all other driveline components beforehand.

The actual cause of a problem may be related to such items as: front hubs, axles, propeller shafts, wheels and tires,

transmission, or clutch instead. If all other driveline components are ingood condition and operating properly, refer

to the Diagnosis Chart for further information.

DIAGNOSIS CHART

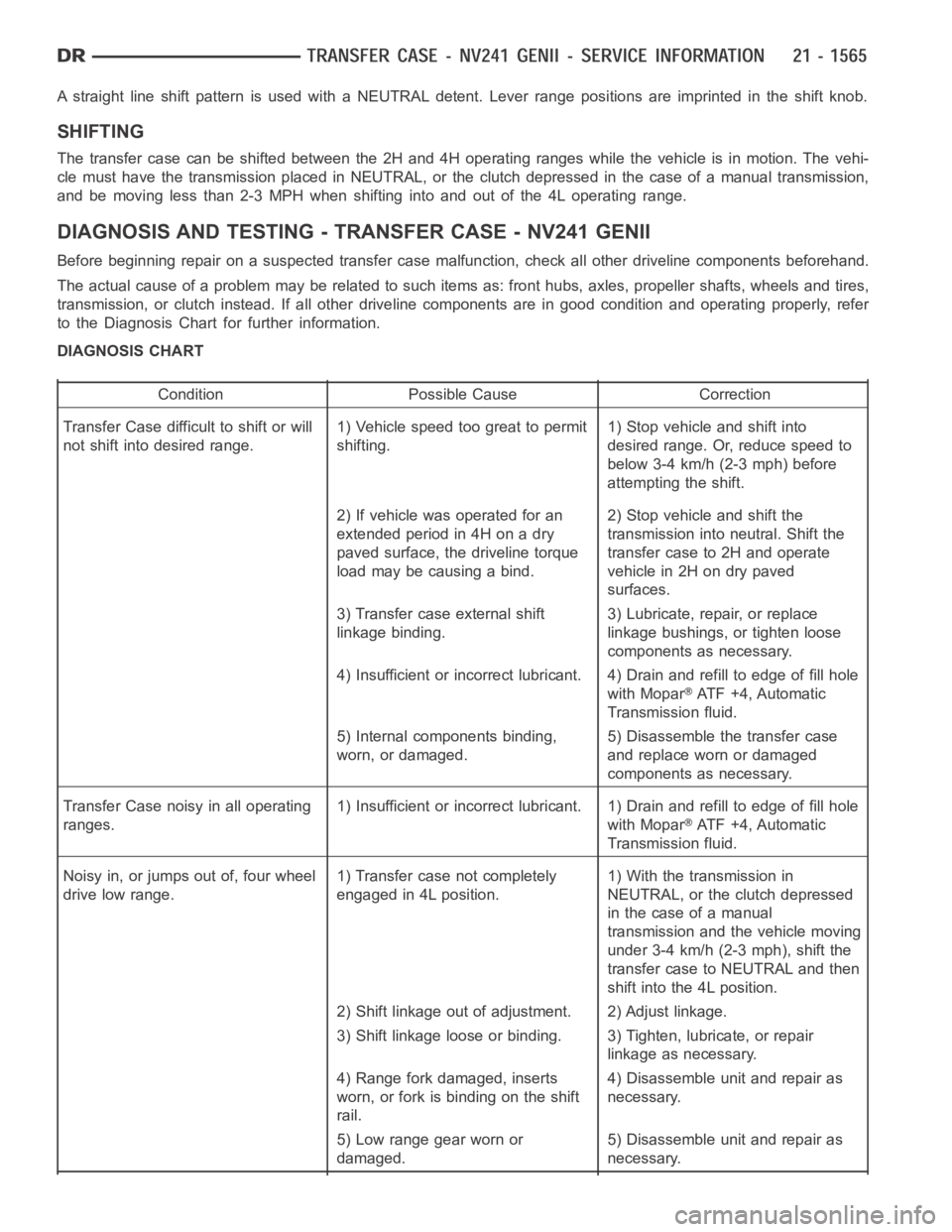

Condition Possible Cause Correction

Transfer Case difficult to shift or will

not shift into desired range.1) Vehicle speed too great to permit

shifting.1) Stop vehicle and shift into

desired range. Or, reduce speed to

below 3-4 km/h (2-3 mph) before

attempting the shift.

2) If vehicle was operated for an

extended period in 4H on a dry

paved surface, the driveline torque

load may be causing a bind.2) Stop vehicle and shift the

transmission into neutral. Shift the

transfer case to 2H and operate

vehicle in 2H on dry paved

surfaces.

3) Transfer case external shift

linkage binding.3) Lubricate, repair, or replace

linkage bushings, or tighten loose

components as necessary.

4) Insufficient or incorrect lubricant. 4) Drain and refill to edge of fillhole

with Mopar

ATF +4, Automatic

Transmission fluid.

5) Internal components binding,

worn, or damaged.5) Disassemble the transfer case

and replace worn or damaged

components as necessary.

Transfer Case noisy in all operating

ranges.1) Insufficient or incorrect lubricant. 1) Drain and refill to edge of fillhole

with Mopar

ATF +4, Automatic

Transmission fluid.

Noisy in, or jumps out of, four wheel

drive low range.1) Transfer case not completely

engaged in 4L position.1) With the transmission in

NEUTRAL, or the clutch depressed

in the case of a manual

transmission and the vehicle moving

under 3-4 km/h (2-3 mph), shift the

transfer case to NEUTRAL and then

shift into the 4L position.

2) Shift linkage out of adjustment. 2) Adjust linkage.

3) Shift linkage loose or binding. 3) Tighten, lubricate, or repair

linkage as necessary.

4) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.4) Disassemble unit and repair as

necessary.

5) Low range gear worn or

damaged.5) Disassemble unit and repair as

necessary.

Page 4111 of 5267

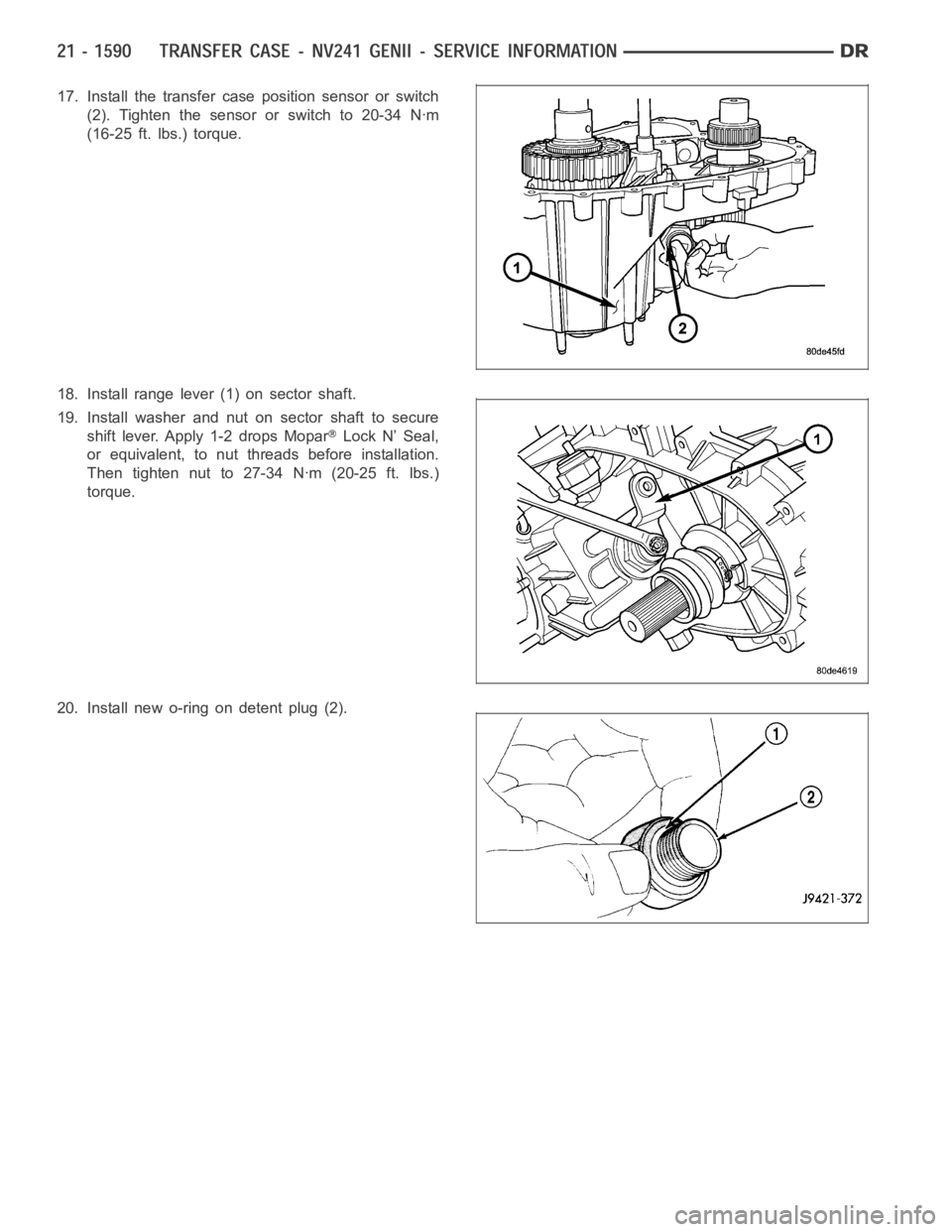

17. Install the transfer case position sensor or switch

(2). Tighten the sensor or switch to 20-34 Nꞏm

(16-25 ft. lbs.) torque.

18. Install range lever (1) on sector shaft.

19. Install washer and nut on sector shaft to secure

shift lever. Apply 1-2 drops Mopar

Lock N’ Seal,

or equivalent, to nut threads before installation.

Then tighten nut to 27-34 Nꞏm (20-25 ft. lbs.)

torque.

20. Install new o-ring on detent plug (2).