torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4326 of 5267

STANDARD PROCEDURE

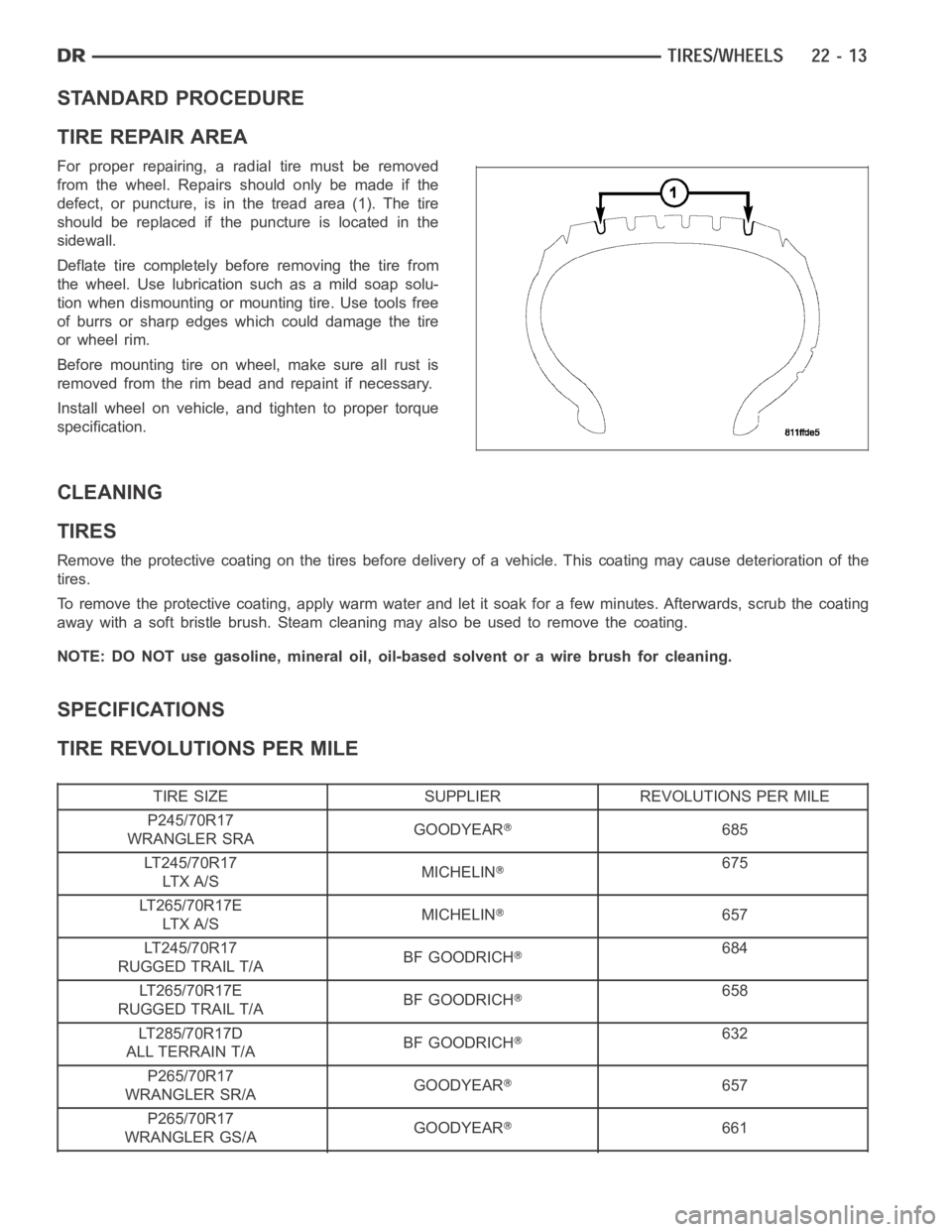

TIRE REPAIR AREA

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (1). The tire

should be replaced if the puncture is located in the

sidewall.

Deflate tire completely before removing the tire from

the wheel. Use lubrication such as a mild soap solu-

tion when dismounting or mounting tire. Use tools free

of burrs or sharp edges which could damage the tire

or wheel rim.

Before mounting tire on wheel, make sure all rust is

removed from the rim bead and repaint if necessary.

Install wheel on vehicle, and tighten to proper torque

specification.

CLEANING

TIRES

Remove the protective coating on the tires before delivery of a vehicle. This coating may cause deterioration of the

tires.

To remove the protective coating, apply warm water and let it soak for a few minutes. Afterwards, scrub the coating

away with a soft bristle brush. Steam cleaning may also be used to remove thecoating.

NOTE: DO NOT use gasoline, mineral oil, oil-based solvent or a wire brush for cleaning.

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE

TIRE SIZE SUPPLIER REVOLUTIONS PER MILE

P245/70R17

WRANGLER SRAGOODYEAR

685

LT245/70R17

LT X A / SMICHELIN

675

LT265/70R17E

LT X A / SMICHELIN

657

LT245/70R17

RUGGED TRAIL T/ABF GOODRICH

684

LT265/70R17E

RUGGED TRAIL T/ABF GOODRICH

658

LT285/70R17D

ALL TERRAIN T/ABF GOODRICH

632

P265/70R17

WRANGLER SR/AGOODYEAR

657

P265/70R17

WRANGLER GS/AGOODYEAR

661

Page 4330 of 5267

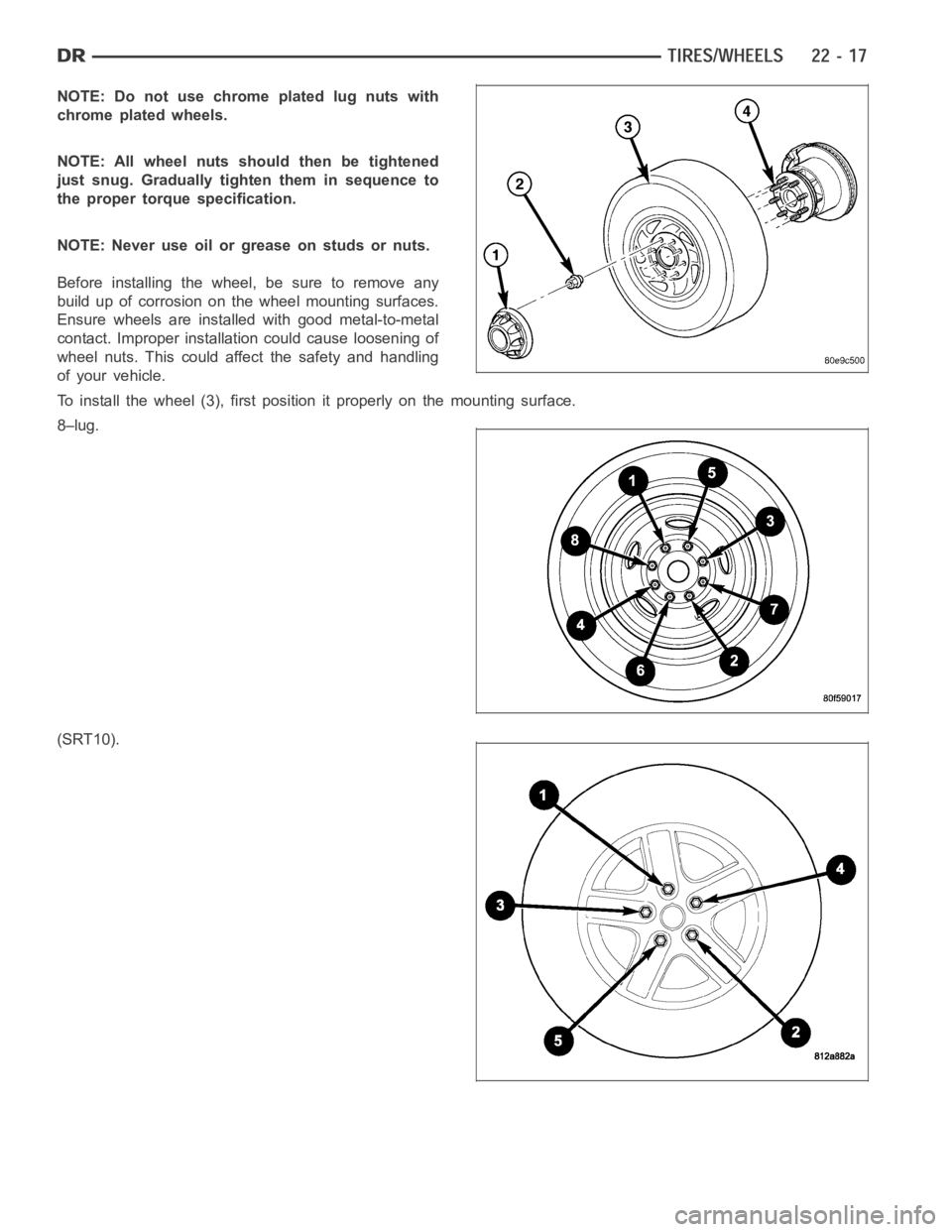

NOTE: Do not use chrome plated lug nuts with

chrome plated wheels.

NOTE: All wheel nuts should then be tightened

just snug. Gradually tighten them in sequence to

the proper torque specification.

NOTE: Never use oil or grease on studs or nuts.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening of

wheel nuts. This could affect the safety and handling

of your vehicle.

To install the wheel (3), first position it properly on the mounting surface.

8–lug.

(SRT10).

Page 4332 of 5267

Tighten the wheel lug nuts in the numbered sequential pattern until they are snug tight. Then tighten lug nut to

specified torque following same number sequence, (Refer to 22 - TIRES/WHEELS/WHEELS - SPECIFICA-

TIONS).

Tighten lug nuts in same numbered sequence a second time to the specified torque. This will ensure that the

wheels are thoroughly mated.

Check lug nut specified torque after 100 miles (160 kilometers). Also after 500 miles (800 kilometers) of vehicle

operation.

NOTE: Wheel lug nuts should be tightened to specified torque at every maintenance interval thereafter.

Page 4338 of 5267

BODY

TABLE OF CONTENTS

page page

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS ..... 2

DIAGNOSIS AND TESTING

WATER LEAKS .............................. 2

WIND NOISE ................................ 3

STANDARD PROCEDURE

BODY LUBRICATION ......................... 4

HEAT STAKING .............................. 4

BUZZ, SQUEAK & RATTLE ................... 4

PLASTIC BODY PANEL REPAIR ............... 5

SPECIFICATIONS

TORQUE ................................... 14

SPECIAL TOOLS

BODY ...................................... 16TA I L G AT E..............................17

DOOR - FRONT.........................28

DOORS - REAR.........................56

EXTERIOR.............................86

HOOD................................126

INSTRUMENT PANEL....................138

INTERIOR.............................176

PA I N T................................215

SEATS...............................221

STATIONARY GLASS....................256

SUNROOF - SERVICE INFORMATION.......270

WEATHERSTRIP/SEALS..................300

WINCH...............................320

BODY STRUCTURE.....................361

Page 4351 of 5267

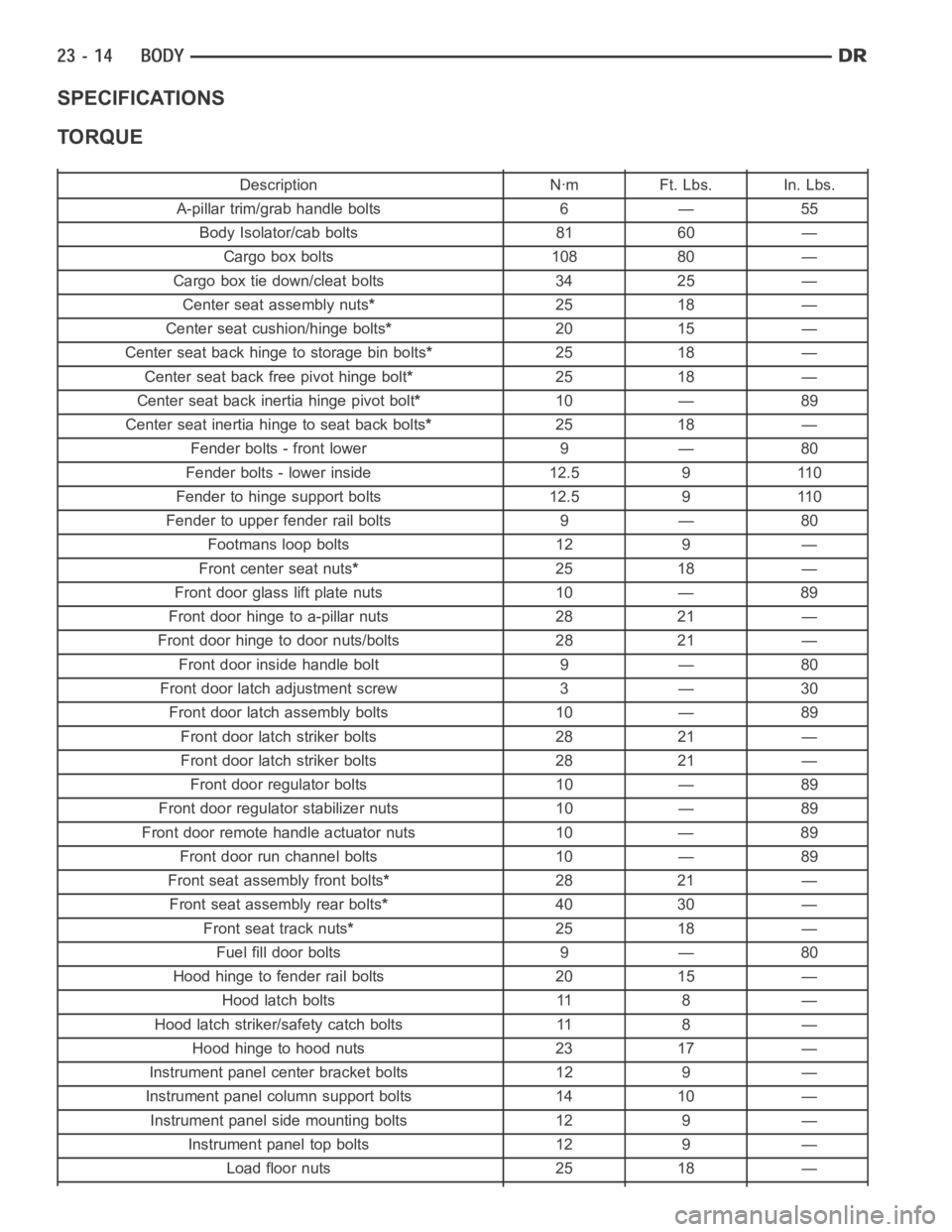

SPECIFICATIONS

TORQUE

Description Nꞏm Ft. Lbs. In. Lbs.

A-pillar trim/grab handle bolts 6 — 55

Body Isolator/cab bolts 81 60 —

Cargo box bolts 108 80 —

Cargo box tie down/cleat bolts 34 25 —

Center seat assembly nuts*25 18 —

Center seat cushion/hinge bolts*20 15 —

Center seat back hinge to storage bin bolts*25 18 —

Center seat back free pivot hinge bolt*25 18 —

Center seat back inertia hinge pivot bolt*10 — 89

Center seat inertia hinge to seat back bolts*25 18 —

Fender bolts - front lower 9 — 80

Fender bolts - lower inside 12.5 9 110

Fender to hinge support bolts 12.5 9 110

Fender to upper fender rail bolts 9 — 80

Footmans loop bolts 12 9 —

Front center seat nuts*25 18 —

Front door glass lift plate nuts 10 — 89

Front door hinge to a-pillar nuts 28 21 —

Front door hinge to door nuts/bolts 28 21 —

Front door inside handle bolt 9 — 80

Front door latch adjustment screw 3 — 30

Front door latch assembly bolts 10 — 89

Front door latch striker bolts 28 21 —

Front door latch striker bolts 28 21 —

Front door regulator bolts 10 — 89

Front door regulator stabilizer nuts 10 — 89

Front door remote handle actuator nuts 10 — 89

Front door run channel bolts 10 — 89

Front seat assembly front bolts*28 21 —

Front seat assembly rear bolts*40 30 —

Frontseattracknuts*25 18 —

Fuel fill door bolts 9 — 80

Hood hinge to fender rail bolts 20 15 —

Hood latch bolts 11 8 —

Hood latch striker/safety catch bolts 11 8 —

Hood hinge to hood nuts 23 17 —

Instrument panel center bracket bolts 12 9 —

Instrument panel column support bolts 14 10 —

Instrument panel side mounting bolts 12 9 —

Instrument panel top bolts 12 9 —

Load floor nuts 25 18 —

Page 4366 of 5267

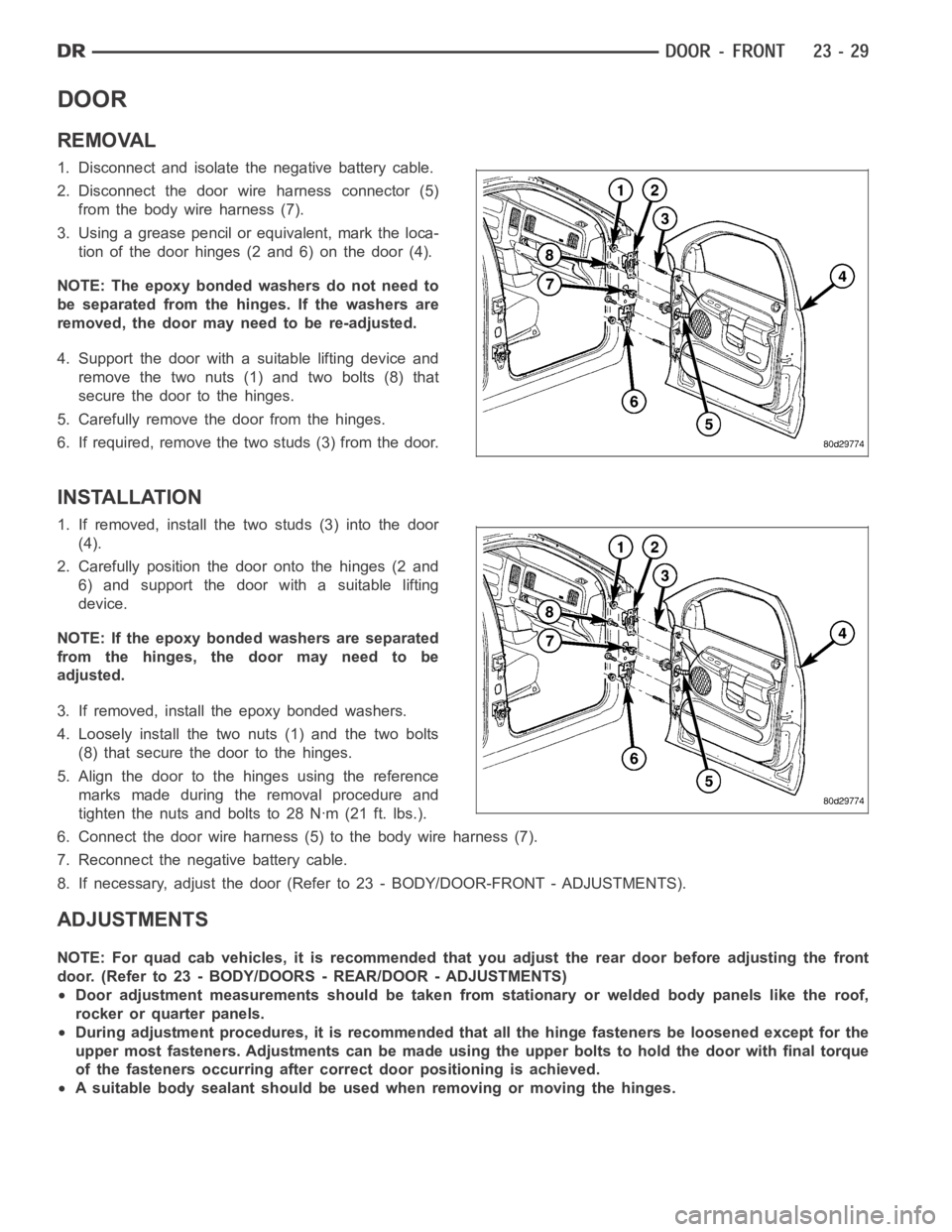

DOOR

REMOVAL

1. Disconnect and isolate the negative battery cable.

2. Disconnect the door wire harness connector (5)

from the body wire harness (7).

3. Using a grease pencil or equivalent, mark the loca-

tion of the door hinges (2 and 6) on the door (4).

NOTE: The epoxy bonded washers do not need to

be separated from the hinges. If the washers are

removed,thedoormayneedtobere-adjusted.

4. Support the door with a suitable lifting device and

remove the two nuts (1) and two bolts (8) that

secure the door to the hinges.

5. Carefully remove the door from the hinges.

6. If required, remove the two studs (3) from the door.

INSTALLATION

1. If removed, install the two studs (3) into the door

(4).

2. Carefully position the door onto the hinges (2 and

6) and support the door with a suitable lifting

device.

NOTE: If the epoxy bonded washers are separated

from the hinges, the door may need to be

adjusted.

3. If removed, install the epoxy bonded washers.

4. Loosely install the two nuts (1) and the two bolts

(8) that secure the door to the hinges.

5. Align the door to the hinges using the reference

marks made during the removal procedure and

tighten the nuts and bolts to 28 Nꞏm (21 ft. lbs.).

6. Connect the door wire harness (5) to the body wire harness (7).

7. Reconnect the negative battery cable.

8. If necessary, adjust the door (Refer to 23 - BODY/DOOR-FRONT - ADJUSTMENTS).

ADJUSTMENTS

NOTE: For quad cab vehicles, it is recommended that you adjust the rear doorbefore adjusting the front

door. (Refer to 23 - BODY/DOORS - REAR/DOOR - ADJUSTMENTS)

Door adjustment measurements should be taken from stationary or welded body panels like the roof,

rocker or quarter panels.

During adjustment procedures, it is recommended that all the hinge fasteners be loosened except for the

upper most fasteners. Adjustments can be made using the upper bolts to holdthe door with final torque

of the fasteners occurring after correct door positioning is achieved.

A suitable body sealant should be used when removing or moving the hinges.

Page 4395 of 5267

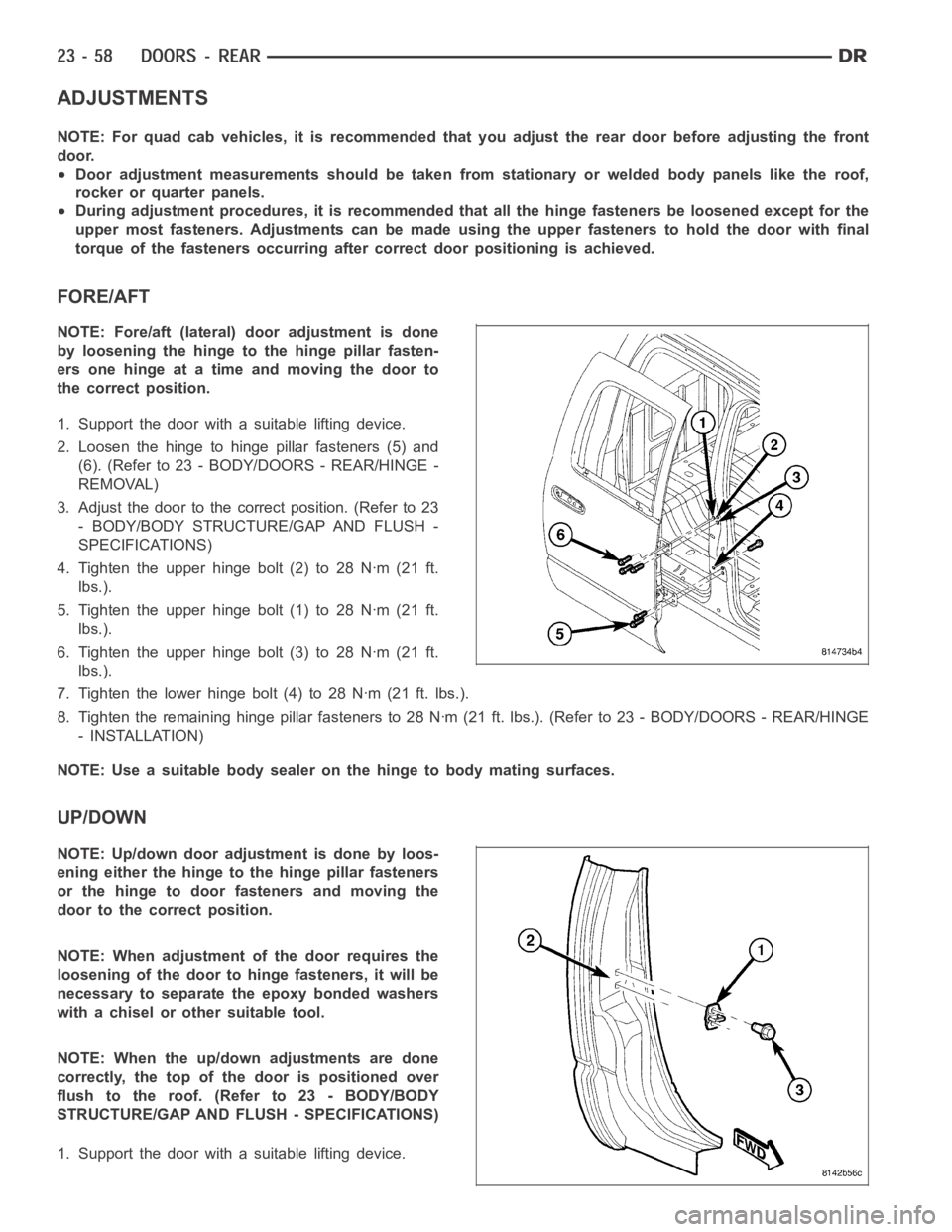

ADJUSTMENTS

NOTE: For quad cab vehicles, it is recommended that you adjust the rear doorbefore adjusting the front

door.

Door adjustment measurements should be taken from stationary or welded body panels like the roof,

rocker or quarter panels.

During adjustment procedures, it is recommended that all the hinge fasteners be loosened except for the

upper most fasteners. Adjustments can be made using the upper fasteners tohold the door with final

torque of the fasteners occurring after correct door positioning is achieved.

FORE/AFT

NOTE: Fore/aft (lateral) door adjustment is done

by loosening the hinge to the hinge pillar fasten-

ers one hinge at a time and moving the door to

the correct position.

1. Support the door with a suitable lifting device.

2. Loosen the hinge to hinge pillar fasteners (5) and

(6). (Refer to 23 - BODY/DOORS - REAR/HINGE -

REMOVAL)

3. Adjust the door to the correct position. (Refer to 23

- BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

4. Tighten the upper hinge bolt (2) to 28 Nꞏm (21 ft.

lbs.).

5. Tighten the upper hinge bolt (1) to 28 Nꞏm (21 ft.

lbs.).

6. Tighten the upper hinge bolt (3) to 28 Nꞏm (21 ft.

lbs.).

7. Tighten the lower hinge bolt (4) to 28 Nꞏm (21 ft. lbs.).

8. Tighten the remaining hinge pillar fasteners to 28 Nꞏm (21 ft. lbs.). (Refer to 23 - BODY/DOORS - REAR/HINGE

- INSTALLATION)

NOTE: Use a suitable body sealer on the hinge to body mating surfaces.

UP/DOWN

NOTE: Up/down door adjustment is done by loos-

ening either the hinge to the hinge pillar fasteners

or the hinge to door fasteners and moving the

door to the correct position.

NOTE: When adjustment of the door requires the

loosening of the door to hinge fasteners, it will be

necessary to separate the epoxy bonded washers

with a chisel or other suitable tool.

NOTE: When the up/down adjustments are done

correctly, the top of the door is positioned over

flush to the roof. (Refer to 23 - BODY/BODY

STRUCTURE/GAP AND FLUSH - SPECIFICATIONS)

1. Support the door with a suitable lifting device.

Page 5049 of 5267

page page

HVAC - SERVICE INFORMATION

DESCRIPTION ............................... 209

OPERATION ................................. 209

DIAGNOSIS AND TESTING

HEATING-A/C SYSTEM DIAGNOSTICS ...... 211

A/C PERFORMANCE ....................... 212

HEATER PERFORMANCE .................. 215

SPECIFICATIONS

A/C SYSTEM .............................. 216TORQUE .................................. 216

SPECIAL TOOLS

A/C SYSTEM .............................. 218

CONTROLS............................219

DISTRIBUTION.........................253

PLUMBING............................284

Page 5057 of 5267

Improper heater hose routing.

Plugged heater hoses or supply and return ports at the cooling system connections.

Plugged heater core.

If proper coolant flow through the cooling system is verified, and heater outlet air temperature is low, a mechanical

problem may exist.

MECHANICAL PROBLEMS

Possible locations or causes of insufficient heat due to mechanical problems are as follows:

Obstructed cowl air intake.

Obstructed heater system outlets.

Blend-air door(s) or actuator(s) not functioning properly.

Faulty blower motor system

Faulty A/C-heater control

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be adjusted with the temperature control on the A/C-heater control, the

following could require service:

Faulty A/C-heater control.

Faulty blend door actuator(s).

Faulty, obstructed or improperly installed blend-air door.

Faulty related wiring harness or connectors.

Improper engine coolant temperature.

SPECIFICATIONS

A/C SYSTEM

Item Description Notes

A/C Compressor Denso 10S17 (3.7L/4.7L/5.7L/8.3L

engines)ND-8 PAG oil

Visteon HS-18 (5.9L engine) VC-46 PAG oil

Freeze–up Control Evaporator Temperature Sensor A/C evaporator mounted

High psi Control A/C pressure transducer A/C discharge line mounted

Refrigerant Charge Capacity Refer to the A/C Underhood

Specification Label located in the

engine compartment.R134a refrigerant

A/C Clutch Field Coil Draw 3.2 - 3.3 amps @ 12V ± 0.5V @

21° C (70° F)3.7L/4.7L/5.7L/8.3L engines

3.1 - 4 amps @ 12V ± 0.5V @ 21°

C(70°F)5.9L engine

A/C Clutch Air Gap 0.35 - 0.60 mm (0.014 - 0.024 in.) 3.7L/4.7L/5.7L/8.3L engines

0.35 - 0.75 mm (0.014 - 0.030 in.) 5.9L engine

TORQUE

Page 5074 of 5267

TESTS

1. Verify the battery state of charge (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BATTERY - DIAGNOSIS AND

TESTING).

2. Connect an ammeter (0 to 10 ampere scale selected) in series with the clutch coil feed terminal. Connect a

voltmeter (0 to 20 volt scale selected) to measure voltage across the battery and the clutch coil.

3. With the A/C-heater control in the A/C mode and the blower motor at low speed, start the engine and allow it to

run at a normal idle speed.

4. The A/C compressor clutch should engage immediately, and the clutch coil supply voltage should be within two

volts of the battery voltage. If the coil supply voltage is OK, go to Step 5. If the coil supply voltage is not within

two volts of battery voltage, test the clutch coil feed circuit for excessive voltage drop and repair as necessary.

5. For the acceptable A/C clutch coil current draw specifications refer to24 - HEATING & AIR CONDITIONING -

SPECIFICATIONS. Specifications apply for a work area temperature of 21° C(70° F). If voltage is more than

12.5 volts, add electrical loads by turning on electrical accessories until voltage reads below 12.5 volts.

STANDARD PROCEDURE

A/C CLUTCH PLATE INSPECTION

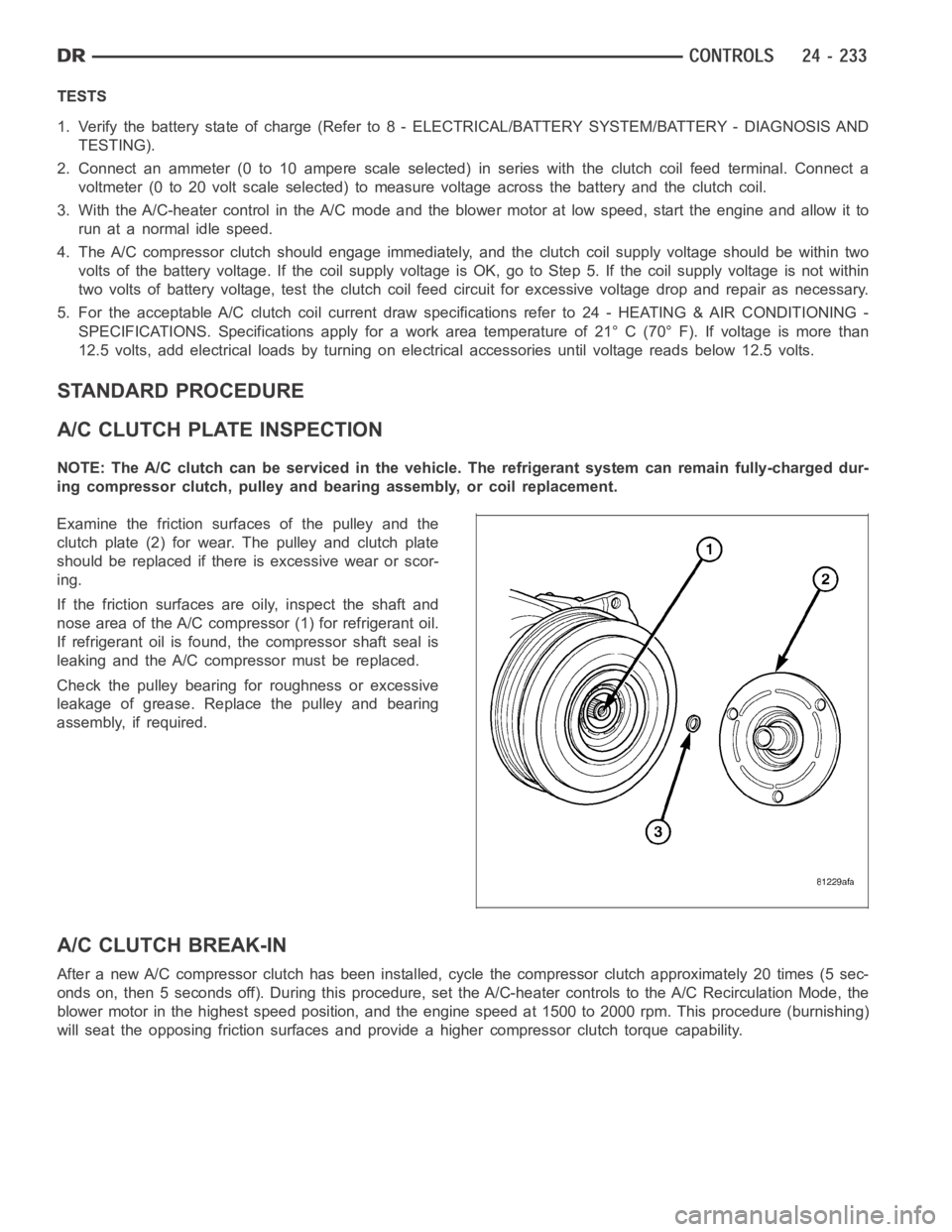

NOTE: The A/C clutch can be serviced inthe vehicle. The refrigerant systemcan remain fully-charged dur-

ing compressor clutch, pulley and bearing assembly, or coil replacement.

Examine the friction surfaces of the pulley and the

clutch plate (2) for wear. The pulley and clutch plate

should be replaced if there is excessive wear or scor-

ing.

If the friction surfaces are oily, inspect the shaft and

nose area of the A/C compressor (1) for refrigerant oil.

If refrigerant oil is found, the compressor shaft seal is

leaking and the A/C compressor must be replaced.

Check the pulley bearing for roughness or excessive

leakage of grease. Replace the pulley and bearing

assembly, if required.

A/C CLUTCH BREAK-IN

After a new A/C compressor clutch hasbeen installed, cycle the compressorclutch approximately 20 times (5 sec-

onds on, then 5 seconds off). During this procedure, set the A/C-heater controls to the A/C Recirculation Mode, the

blower motor in the highest speed position, and the engine speed at 1500 to 2000 rpm. This procedure (burnishing)

will seat the opposing friction surfaces and provide a higher compressor clutch torque capability.