torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3894 of 5267

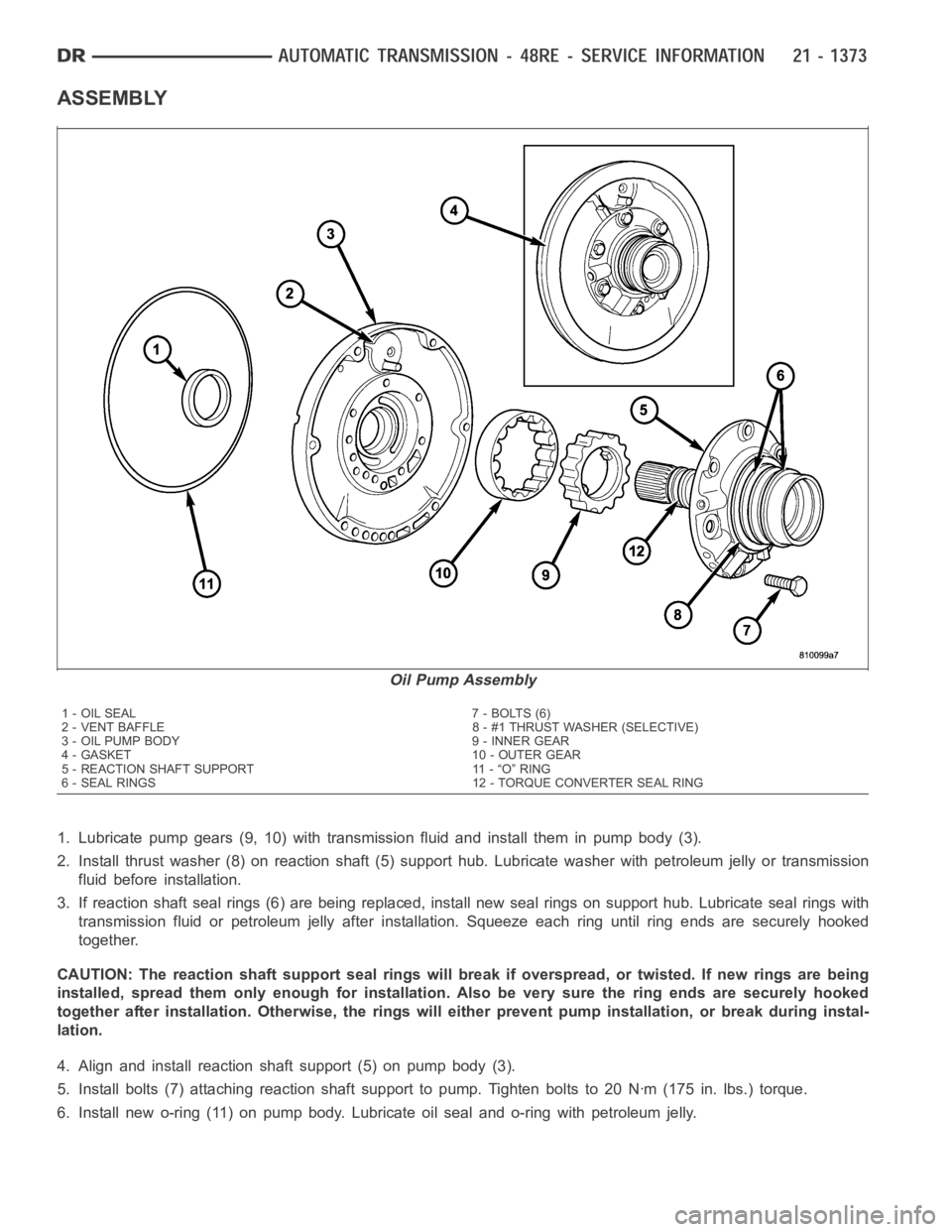

ASSEMBLY

1. Lubricate pump gears (9, 10) with transmission fluid and install them inpump body (3).

2. Install thrust washer (8) on reaction shaft (5) support hub. Lubricate washer with petroleum jelly or transmission

fluid before installation.

3. If reaction shaft seal rings (6) are being replaced, install new seal rings on support hub. Lubricate seal rings with

transmission fluid or petroleum jelly after installation. Squeeze each ring until ring ends are securely hooked

together.

CAUTION: The reaction shaft support seal rings will break if overspread, or twisted. If new rings are being

installed, spread them only enough forinstallation. Also be very sure thering ends are securely hooked

together after installation. Otherwise, the rings will either prevent pump installation, or break during instal-

lation.

4. Align and install reaction shaft support (5) on pump body (3).

5. Install bolts (7) attaching reaction shaft support to pump. Tighten bolts to 20 Nꞏm (175 in. lbs.) torque.

6. Install new o-ring (11) on pump body. Lubricate oil seal and o-ring with petroleum jelly.

Oil Pump Assembly

1 - OIL SEAL 7 - BOLTS (6)

2 - VENT BAFFLE 8 - #1 THRUST WASHER (SELECTIVE)

3 - OIL PUMP BODY 9 - INNER GEAR

4 - GASKET 10 - OUTER GEAR

5 - REACTION SHAFT SUPPORT 11 - “O” RING

6 - SEAL RINGS 12 - TORQUE CONVERTER SEAL RING

Page 3898 of 5267

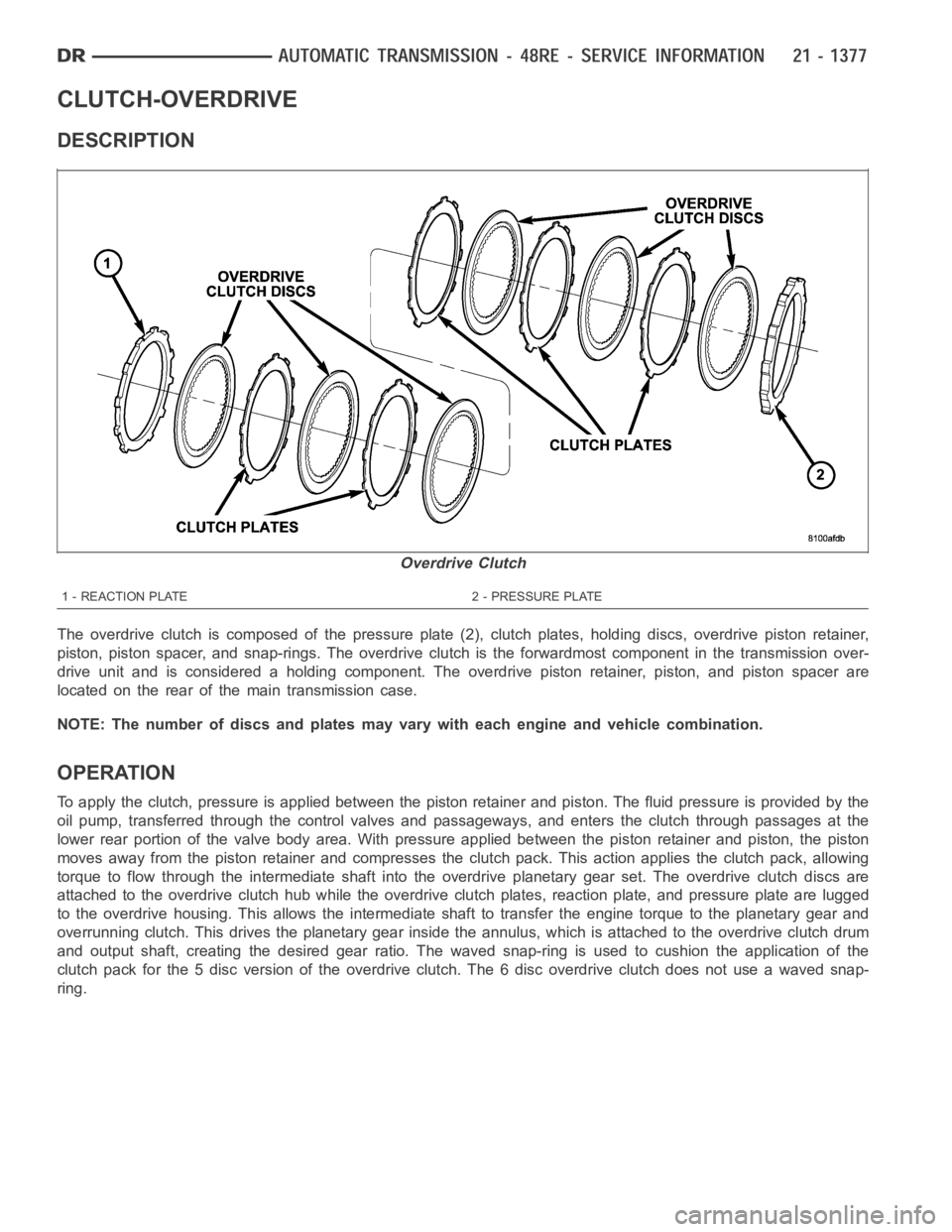

CLUTCH-OVERDRIVE

DESCRIPTION

The overdrive clutch is composed of the pressure plate (2), clutch plates,holding discs, overdrive piston retainer,

piston, piston spacer, and snap-rings. The overdrive clutch is the forwardmost component in the transmission over-

drive unit and is considered a holding component. The overdrive piston retainer, piston, and piston spacer are

located on the rear of the main transmission case.

NOTE: The number of discs and plates may vary with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between the piston retainer and piston. The fluid pressure is provided by the

oil pump, transferred through the control valves and passageways, and enters the clutch through passages at the

lower rear portion of the valve body area. With pressure applied between the piston retainer and piston, the piston

moves away from the piston retainer and compresses the clutch pack. This action applies the clutch pack, allowing

torque to flow through the intermediate shaft into the overdrive planetary gear set. The overdrive clutch discs are

attached to the overdrive clutch hub while the overdrive clutch plates, reaction plate, and pressure plate are lugged

to the overdrive housing. This allows the intermediate shaft to transfer the engine torque to the planetary gear and

overrunning clutch. This drives the planetary gear inside the annulus, which is attached to the overdrive clutch drum

and output shaft, creating the desired gear ratio. The waved snap-ring is used to cushion the application of the

clutch pack for the 5 disc version of the overdrive clutch. The 6 disc overdrive clutch does not use a waved snap-

ring.

Overdrive Clutch

1 - REACTION PLATE 2 - PRESSURE PLATE

Page 3917 of 5267

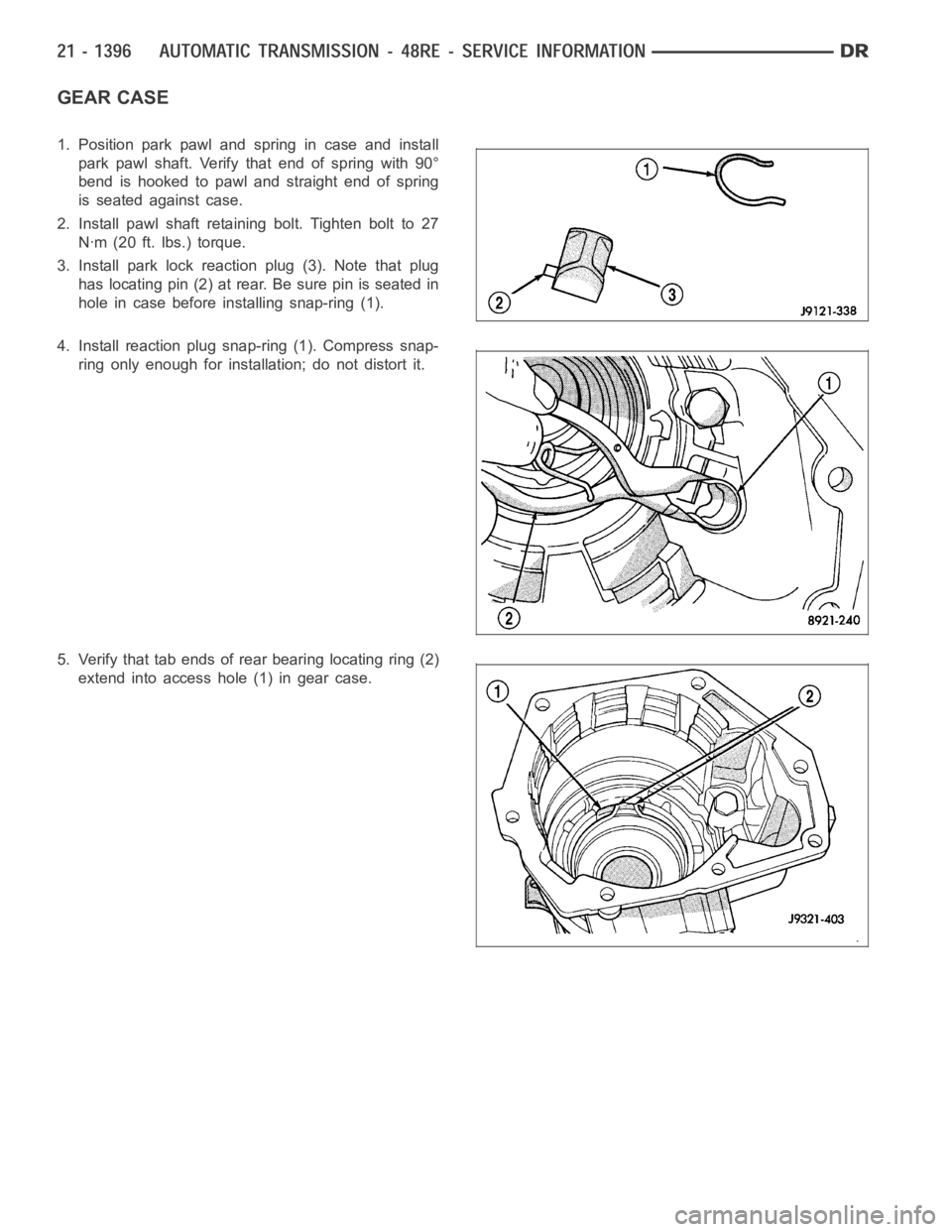

GEAR CASE

1. Position park pawl and spring in case and install

park pawl shaft. Verify that end of spring with 90°

bend is hooked to pawl and straight end of spring

is seated against case.

2. Install pawl shaft retaining bolt. Tighten bolt to 27

Nꞏm (20 ft. lbs.) torque.

3. Install park lock reaction plug (3). Note that plug

has locating pin (2) at rear. Be sure pin is seated in

hole in case before installing snap-ring (1).

4. Install reaction plug snap-ring (1). Compress snap-

ring only enough for installation; do not distort it.

5. Verify that tab ends of rear bearing locating ring (2)

extend into access hole (1) in gear case.

Page 3927 of 5267

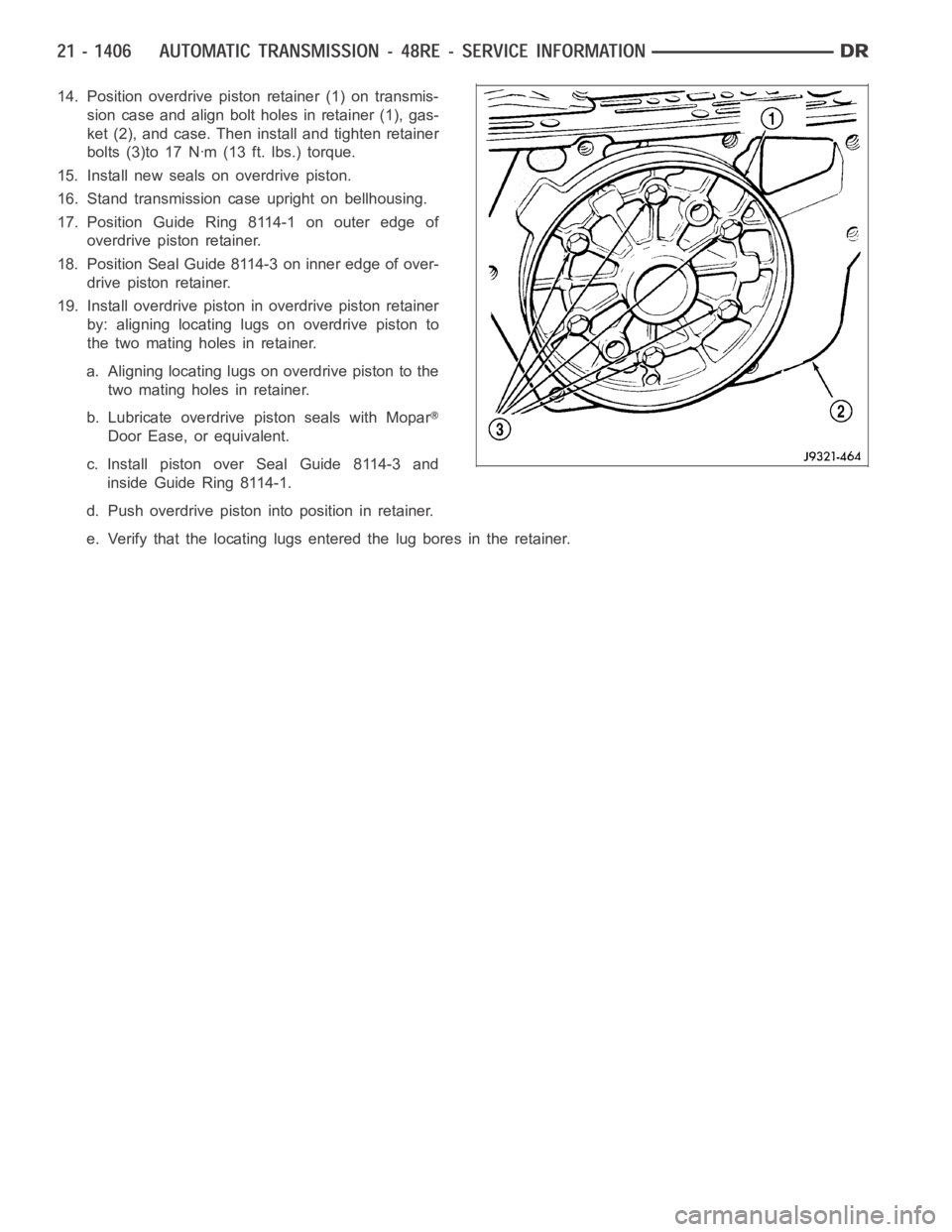

14. Position overdrive piston retainer (1) on transmis-

sion case and align bolt holes in retainer (1), gas-

ket (2), and case. Then install and tighten retainer

bolts (3)to 17 Nꞏm (13 ft. lbs.) torque.

15. Install new seals on overdrive piston.

16. Stand transmission case upright on bellhousing.

17. Position Guide Ring 8114-1 on outer edge of

overdrive piston retainer.

18. Position Seal Guide 8114-3 on inner edge of over-

drive piston retainer.

19. Install overdrive piston in overdrive piston retainer

by: aligning locating lugs on overdrive piston to

the two mating holes in retainer.

a. Aligning locating lugs on overdrive piston to the

two mating holes in retainer.

b. Lubricate overdrive piston seals with Mopar

Door Ease, or equivalent.

c. Install piston over Seal Guide 8114-3 and

inside Guide Ring 8114-1.

d. Push overdrive piston into position in retainer.

e. Verify that the locating lugs entered the lug bores in the retainer.

Page 3937 of 5267

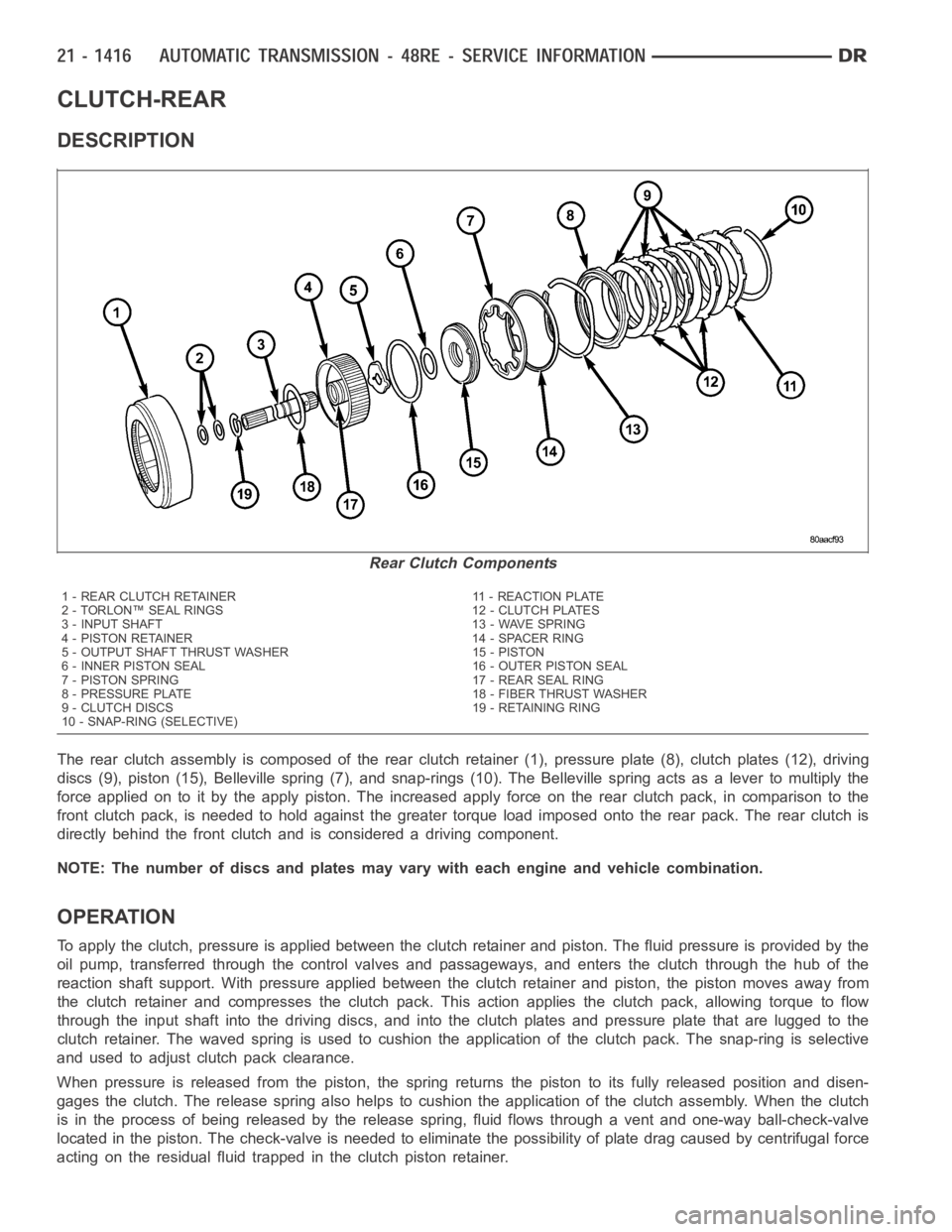

CLUTCH-REAR

DESCRIPTION

The rear clutch assembly is composed of the rear clutch retainer (1), pressure plate (8), clutch plates (12), driving

discs (9), piston (15), Belleville spring (7), and snap-rings (10). The Belleville spring acts as a lever to multiply the

force applied on to it by the apply piston. The increased apply force on the rear clutch pack, in comparison to the

front clutch pack, is needed to hold against the greater torque load imposed onto the rear pack. The rear clutch is

directly behind the front clutch and is considered a driving component.

NOTE: The number of discs and plates may vary with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between the clutch retainer and piston. The fluid pressure is provided by the

oil pump, transferred through the control valves and passageways, and enters the clutch through the hub of the

reaction shaft support. With pressure applied between the clutch retainer and piston, the piston moves away from

the clutch retainer and compresses the clutch pack. This action applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and into the clutch plates and pressure plate that are lugged to the

clutch retainer. The waved spring is used to cushion the application of theclutch pack. The snap-ring is selective

and used to adjust clutch pack clearance.

When pressure is released from the piston, the spring returns the piston toits fully released position and disen-

gages the clutch. The release spring also helps to cushion the applicationof the clutch assembly. When the clutch

is in the process of being released by the release spring, fluid flows through a vent and one-way ball-check-valve

located in the piston. The check-valve is needed to eliminate the possibility of plate drag caused by centrifugal force

acting on the residual fluid trapped in the clutch piston retainer.

Rear Clutch Components

1 - REAR CLUTCH RETAINER 11 - REACTION PLATE

2 - TORLON™ SEAL RINGS 12 - CLUTCH PLATES

3 - INPUT SHAFT 13 - WAVE SPRING

4 - PISTON RETAINER 14 - SPACER RING

5 - OUTPUT SHAFT THRUST WASHER 15 - PISTON

6 - INNER PISTON SEAL 16 - OUTER PISTON SEAL

7 - PISTON SPRING 17 - REAR SEAL RING

8 - PRESSURE PLATE 18 - FIBER THRUST WASHER

9 - CLUTCH DISCS 19 - RETAINING RING

10 - SNAP-RING (SELECTIVE)

Page 3952 of 5267

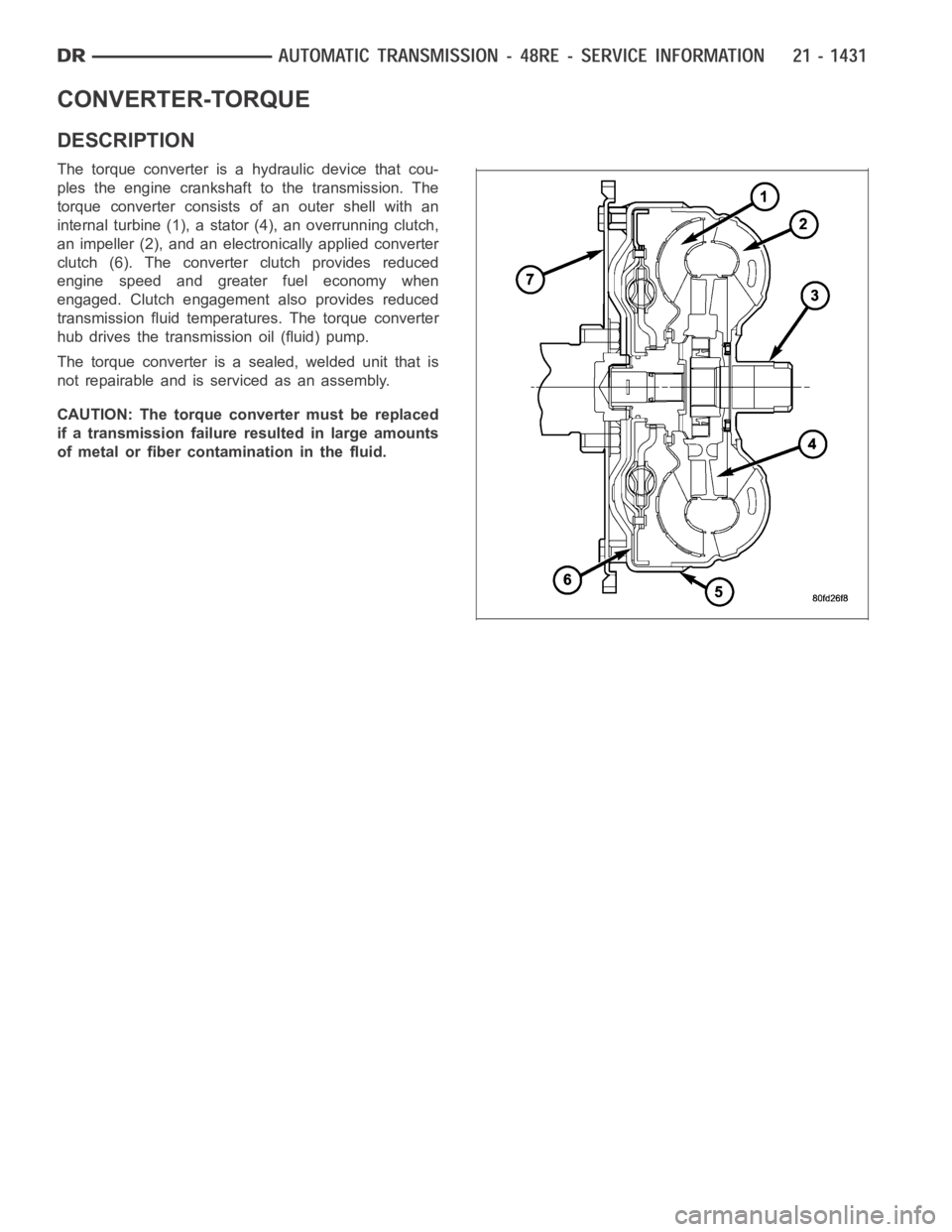

CONVERTER-TORQUE

DESCRIPTION

The torque converter is a hydraulic device that cou-

ples the engine crankshaft to the transmission. The

torque converter consists of an outer shell with an

internal turbine (1), a stator (4), an overrunning clutch,

an impeller (2), and an electronically applied converter

clutch (6). The converterclutch provides reduced

engine speed and greater fuel economy when

engaged. Clutch engagement also provides reduced

transmission fluid temperatures. The torque converter

hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that is

not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced

if a transmission failure resulted in large amounts

of metal or fiber contamination in the fluid.

Page 3954 of 5267

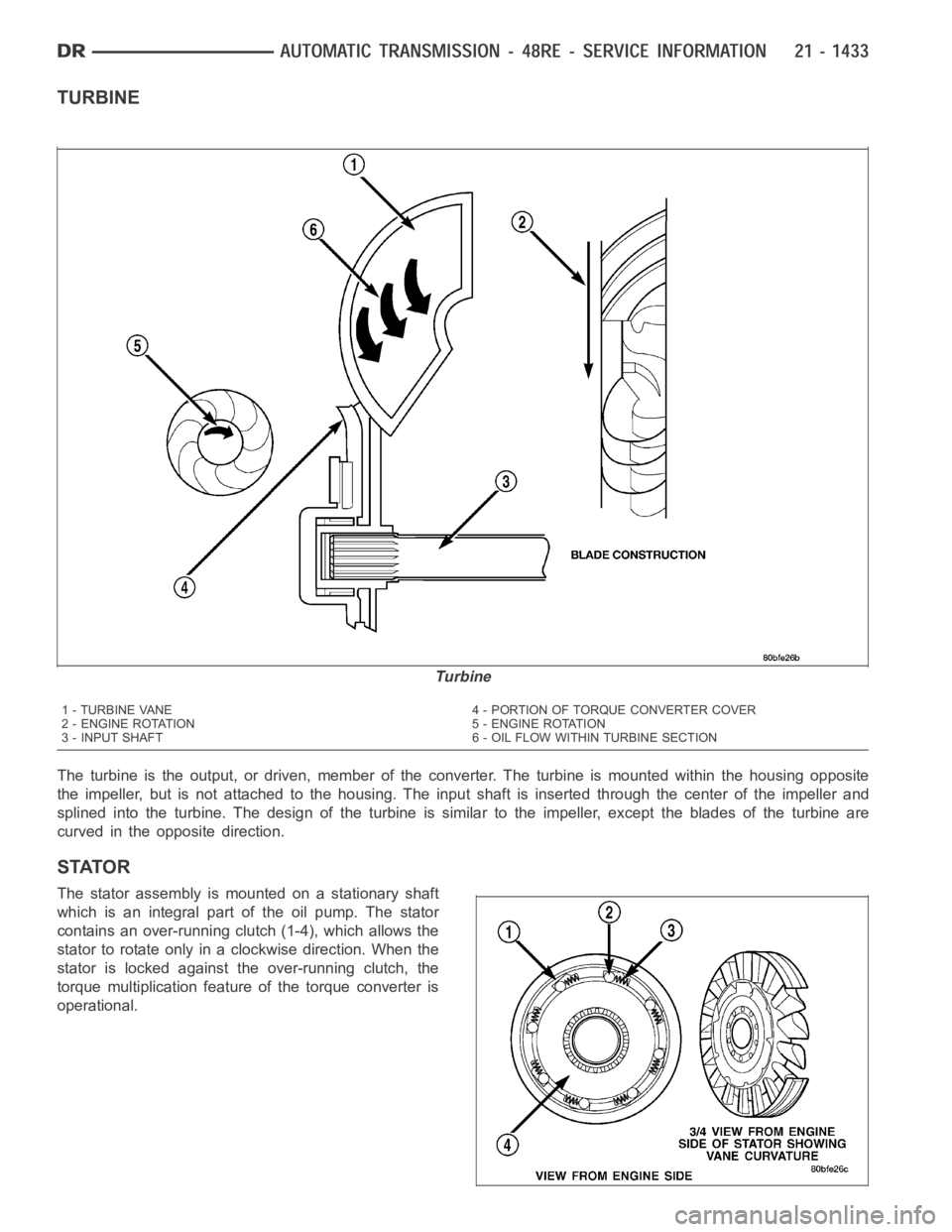

TURBINE

The turbine is the output, or driven, member of the converter. The turbine is mounted within the housing opposite

the impeller, but is not attached to the housing. The input shaft is inserted through the center of the impeller and

splined into the turbine. The design of the turbine is similar to the impeller, except the blades of the turbine are

curved in the opposite direction.

STATOR

The stator assembly is mounted on a stationary shaft

which is an integral part of the oil pump. The stator

contains an over-running clutch (1-4), which allows the

stator to rotate only in a clockwise direction. When the

stator is locked against theover-runningclutch,the

torque multiplication feature of the torque converter is

operational.

Turbine

1 - TURBINE VANE 4 - PORTION OF TORQUE CONVERTER COVER

2 - ENGINE ROTATION 5 - ENGINE ROTATION

3 - INPUT SHAFT 6 - OIL FLOW WITHIN TURBINE SECTION

Page 3955 of 5267

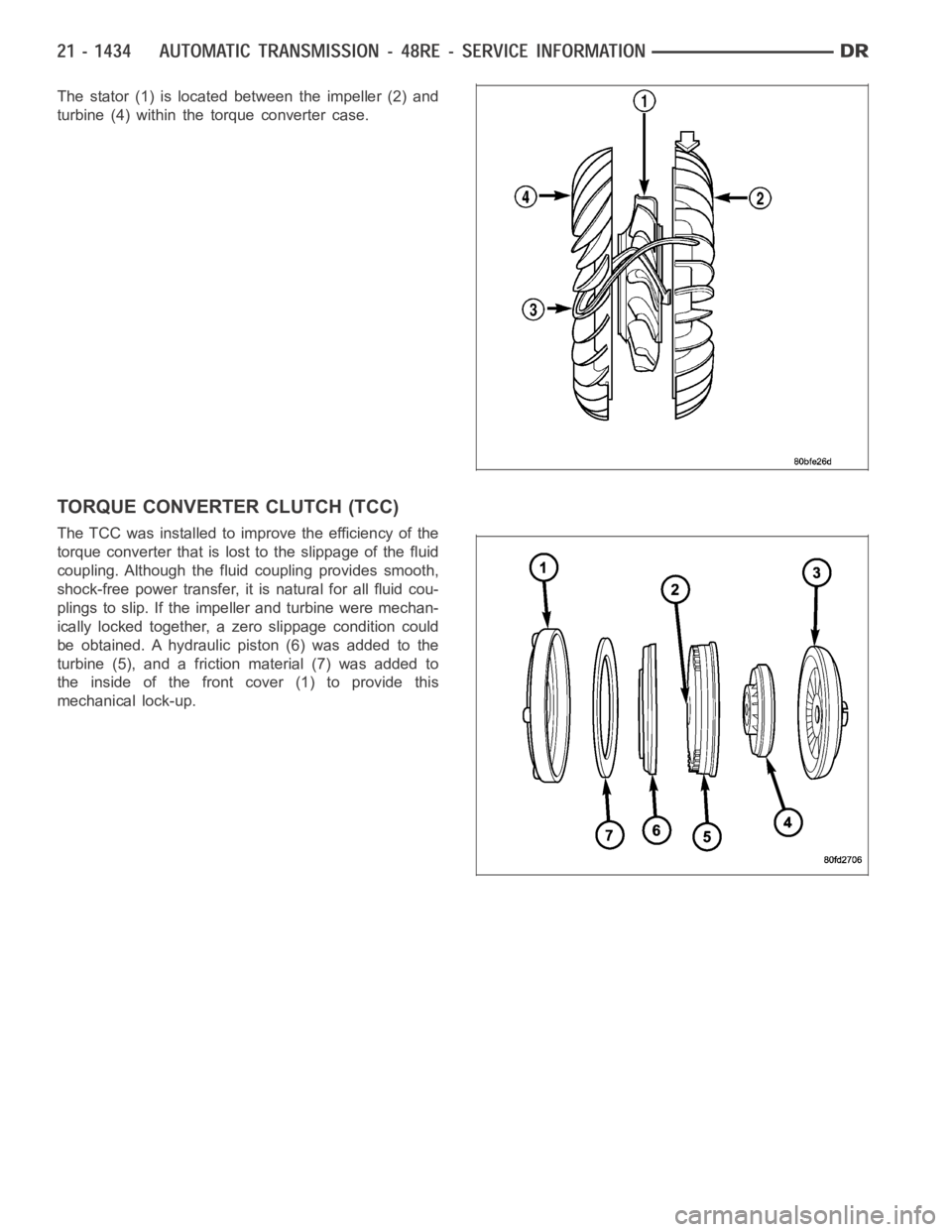

The stator (1) is located between the impeller (2) and

turbine (4) within the torque converter case.

TORQUE CONVERTER CLUTCH (TCC)

The TCC was installed to improve the efficiency of the

torque converter that is lost to the slippage of the fluid

coupling. Although the fluid coupling provides smooth,

shock-free power transfer, it is natural for all fluid cou-

plings to slip. If the impeller and turbine were mechan-

ically locked together, a zero slippage condition could

be obtained. A hydraulic piston (6) was added to the

turbine (5), and a friction material (7) was added to

the inside of the front cover (1) to provide this

mechanical lock-up.

Page 3956 of 5267

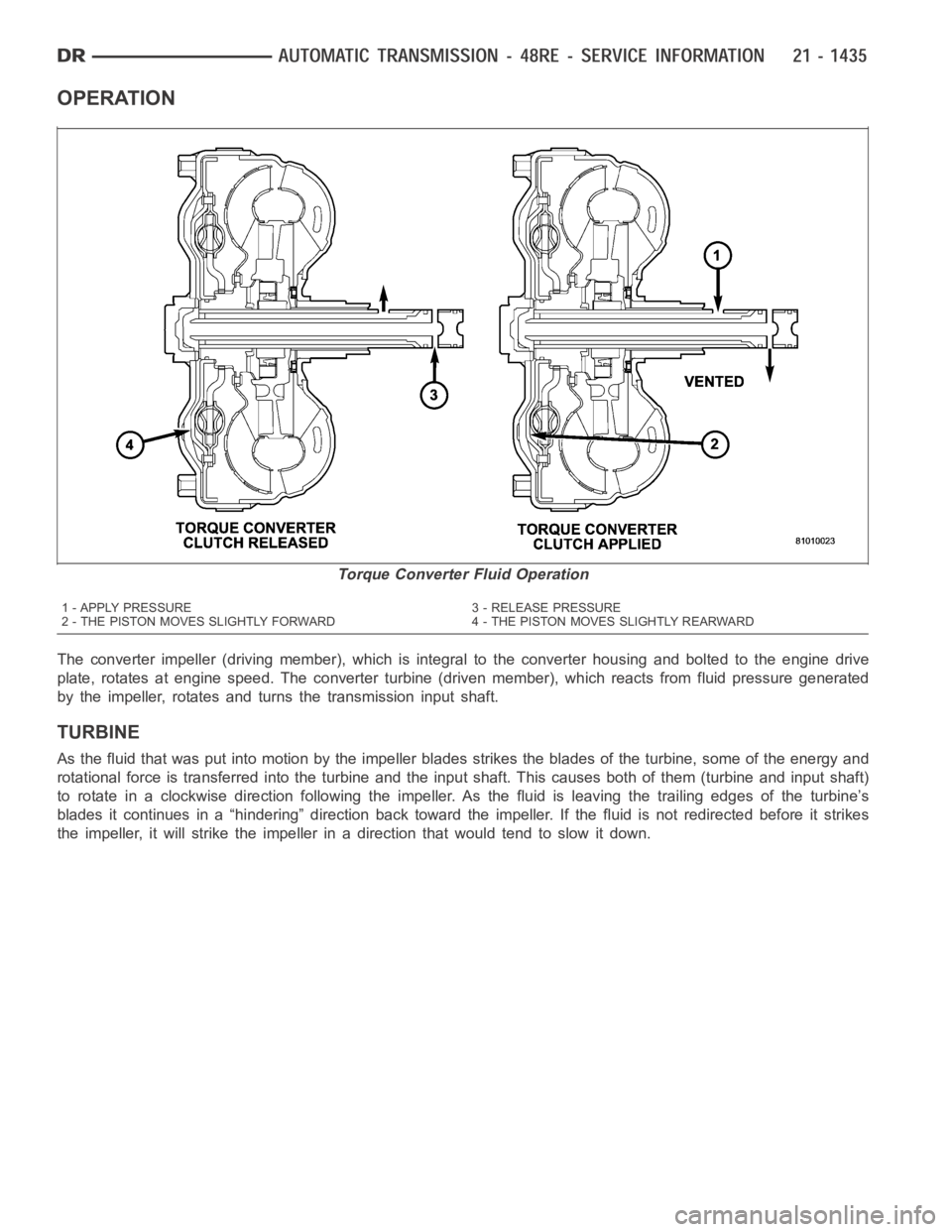

OPERATION

The converter impeller (driving member), which is integral to the converter housing and bolted to the engine drive

plate, rotates at engine speed. The converter turbine (driven member), which reacts from fluid pressure generated

by the impeller, rotates and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion bythe impeller blades strikes the blades of the turbine, some of the energy and

rotational force is transferred into the turbine and the input shaft. Thiscauses both of them (turbine and input shaft)

to rotate in a clockwise direction following the impeller. As the fluid is leaving the trailing edges of the turbine’s

blades it continues in a “hindering” direction back toward the impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in a direction that would tend to slow it down.

Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

Page 3957 of 5267

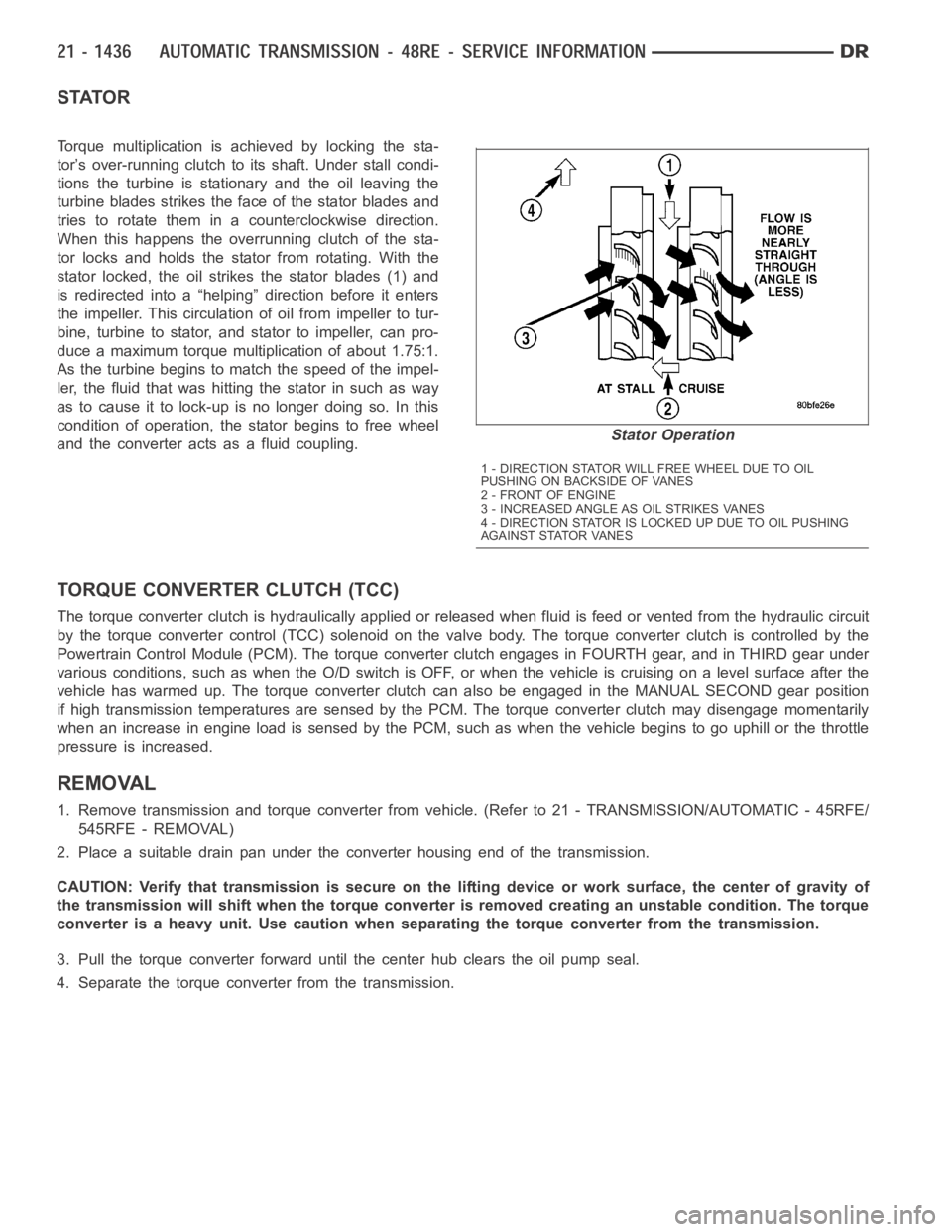

STATOR

Torque multiplication is achieved by locking the sta-

tor’s over-running clutch to its shaft. Under stall condi-

tions the turbine is stationary and the oil leaving the

turbine blades strikes the face of the stator blades and

tries to rotate them in a counterclockwise direction.

When this happens the overrunning clutch of the sta-

tor locks and holds the stator from rotating. With the

stator locked, the oil strikes the stator blades (1) and

is redirected into a “helping” direction before it enters

the impeller. This circulation of oil from impeller to tur-

bine, turbine to stator, and stator to impeller, can pro-

duce a maximum torque multiplication of about 1.75:1.

As the turbine begins to match the speed of the impel-

ler, the fluid that was hitting the stator in such as way

as to cause it to lock-up is no longer doing so. In this

condition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

The torque converter clutch is hydraulically applied or released when fluid is feed or vented from the hydraulic circuit

by the torque converter control (TCC) solenoid on the valve body. The torque converter clutch is controlled by the

Powertrain Control Module (PCM). The torque converter clutch engages in FOURTH gear, and in THIRD gear under

various conditions, such as when the O/D switch is OFF, or when the vehicle is cruising on a level surface after the

vehicle has warmed up. The torque converter clutch can also be engaged in the MANUAL SECOND gear position

if high transmission temperatures are sensed by the PCM. The torque converter clutch may disengage momentarily

when an increase in engine load is sensed by the PCM, such as when the vehiclebegins to go uphill or the throttle

pressure is increased.

REMOVAL

1. Remove transmission and torque converter from vehicle. (Refer to 21 - TRANSMISSION/AUTOMATIC - 45RFE/

545RFE - REMOVAL)

2. Place a suitable drain pan under the converter housing end of the transmission.

CAUTION: Verify that transmission is secure on the lifting device or work surface, the center of gravity of

the transmission will shift when the torque converter is removed creatingan unstable condition. The torque

converter is a heavy unit. Use caution when separating the torque converter from the transmission.

3. Pull the torque converter forward until the center hub clears the oil pumpseal.

4. Separate the torque converter from the transmission.

Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2-FRONTOFENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES