light DODGE RAM SRT-10 2006 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 290 of 5267

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on and engine running with no MAP Sensor DTCs.

Set Condition:

PCM calculated MAP value is greater than actual MAP value plus an offset value. One trip fault. Three good

trips to turn of the mil. ETC light will flash.

Possible Causes

RESTRICTED AIR INLET SYSTEM

RESISTANCE IN THE (F856) 5-VOLT SUPPLY CIRCUIT

(F856) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K1) MAP SIGNAL CIRCUIT

(K1) MAP SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN (K900) SENSOR GROUND CIRCUIT

RESISTANCE IN THE (F855) 5-VOLT SUPPLY CIRCUIT

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE TP SENSOR SIGNAL CIRCUIT

TP SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K922) TP SENSOR RETURN CIRCUIT

MAP SENSOR

TP SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: The most likely cause of this DTC is a plugged intake air system or Dirty Throttle Body. Check for

TSB’s before continuing.

NOTE: Diagnose any 5-Volt Supply, TP Sensor, Fuel System Lean or Rich, or MAP Sensor DTCs before con-

tinuing.

NOTE: The throttle plate should be free from binding and carbon build up.

NOTE: Question the customer about weather conditions, as ICE build up on the blade can cause this fault

when ambient is around +4 to -10 Celsius range.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 300 of 5267

When Monitored:

Ignition on and engine running with no MAP Sensor DTCs.

Set Condition:

PCM calculated MAP value is greater than actual MAP value plus an offset value. One trip fault and the code

will set within 5 seconds. Three good trips to turn of the mil. ETC light willflash.

Possible Causes

RESTRICTED AIR INLET SYSTEM

RESISTANCE IN THE (F856) 5-VOLT SUPPLY CIRCUIT

(F856) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K1) MAP SIGNAL CIRCUIT

(K1) MAP SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN (K900) SENSOR GROUND CIRCUIT

RESISTANCE IN THE (F855) 5-VOLT SUPPLY CIRCUIT

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE TP SENSOR SIGNAL CIRCUIT

TP SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K922) TP SENSOR RETURN CIRCUIT

MAP SENSOR

TP SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: The most likely cause of this DTC is a plugged intake air system or dirty Throttle Body. Check for

any TSB’s before continuing.

NOTE: Diagnose any 5-Volt Supply, TP Sensor, Oxygen Sensor, Fuel related or MAP Sensor DTCs before

continuing.

NOTE: The throttle plate should be free from binding and carbon build up.

NOTE: Question the customer about weather conditions, as ICE build up on the blade can cause this fault

when ambient is around +4 to -10 Celsius range.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 310 of 5267

When Monitored:

Ignition on, Engine running, and no ECT DTCs present.

Set Condition:

PCM recognizes that the ECT has failed its self coherence test. The coolanttemp should only change at a

certain rate, if this rate is too slow or too fast this fault will set. Two trip fault. Three good trips to clear MIL.

ETC light will illuminate on first trip failure.

Possible Causes

LOW COOLANT LEVEL

(K2) ECT SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

(K2) ECT SIGNAL CIRCUIT OPEN

(K900) SENSOR GROUND CIRCUIT OPEN

(K2) ECT SIGNAL CIRCUIT SHORTED TO GROUND

(K2) ECT SIGNAL CIRCUIT SHORTED TO THE (K900) SENSOR GROUND

THERMOSTAT

ECT SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

NOTE: If this code sets during extreme ambient temperatures, improper installation of a block heater could

be the cause of this DTC.

With a scan tool, read DTCs.

Diagnose all other ECT and Cooling System codes before continuing.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.LOW COOLANT LEVEL

NOTE: If a Engine Coolant Temperature (ECT) DTC is set along with this code,diagnose the ECT DTC first.

NOTE: Inspect the ECT terminals and related PCM terminals. Ensure the terminals are free from corrosion

and damage.

NOTE: The best way to diagnose this DTC is to allow the vehicle to sit overnight outside in order to have

a totally cold soaked engine.

NOTE: Extremely cold outside ambient temperatures may have caused this DTCtoset.

NOTE: Need to make sure that no Cooling System DTCs are set or changes that would make the warm up

much slower or much faster: broken water pump can set this, addition of aftermarket auxiliary cooler can

set this DTC.

WARNING: Never open the cooling system when the engine is hot. The system isunder pressure. Failure to

follow these instructions can result in personal injury or death. Allow the engine to cool before opening the

cooling system.

Page 316 of 5267

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on. No Break or APPS faults present.

Set Condition:

The PCM recognizes a brake application following the APPS showing a fixed pedal opening. Temporary or

permanent. Internally the PCM will reduce throttle opening below driver demand. One trip fault and the code

will be set within 5 seconds. ETC light will illuminate, the light will onlystay illuminated while DTC is active.

Possible Causes

CUSTOMER PRESSING ACCLERATOR PEDAL, THEN PRESSING BRAKE PEDAL, AND CONTINUES

HOLDING THEM DOWN SIMULTANEOUSLY

STOP LAMP SWITCH

APP SENSOR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.DTC INFORMATION

NOTE: If a pedal assembly becomes mechanically stuck the voltage output will stay fixed, if this is also

Followed by a long application of the brakes this code will set.

NOTE: When this code sets the pedal position in the PCM software will ramp toidle. If the Pedal voltage

changes OR the brake pedal is released, the pedal position in the PCM software will ramp up to the pedal

position and the ETC light will go out.

With a scan tool, read DTCs and record the related Freeze Frame data.

Diagnose all other Stop Lamp Switch and APP Sensor codes before continuing.

This code can be set by a driver who uses both feet while driving, one for the Accelerator Pedal and the other for

the Brake Pedal.

NOTE: The most likely cause of this DTC is caused by the customer Brake Torquing the engine by pressing

the Accelerator pedal and the pressing the Brake Pedal.

Ask the driver of the vehicle if these conditions apply to their driving habits.

Are the listed conditions part of the customers driving habits?

Ye s>>

Advise the customer of what caused the DTC. This is normal operation of a ETCequipped vehicle

because of safety issues.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.STOP LAMP SWITCH OPERATION

With a scan tool, read both Stop Lamp Switch statuses while pressing and releasing the Brake Pedal.

Does the scan tool display the Pressed and Released while pressing and releasing the Pedal?

Ye s>>

Go To 3

No>>

Check the Stop Lamp Switch for proper installation and check the related circuits for opens and shorts

using the appropriate wiring diagram. If OK, replace the Stop Lamp Switch assembly.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 319 of 5267

When Monitored:

Engine running and battery voltage greater than 10 volts.

Set Condition:

If PCM detects that the secondary ignition burn time is incorrect, too short, or not present, an error is detected.

One Trip Fault. Three good trips to turn off the MIL.

Possible Causes

(K342) ASD CONTROL OUTPUT CIRCUIT

(K19) COIL CONTROL NO.1 CIRCUIT OPEN

(K19) COIL CONTROL NO.1 CIRCUIT SHORTED TO GROUND

COIL ON PLUG

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Diagnose any ASD related DTC’s before continuing.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

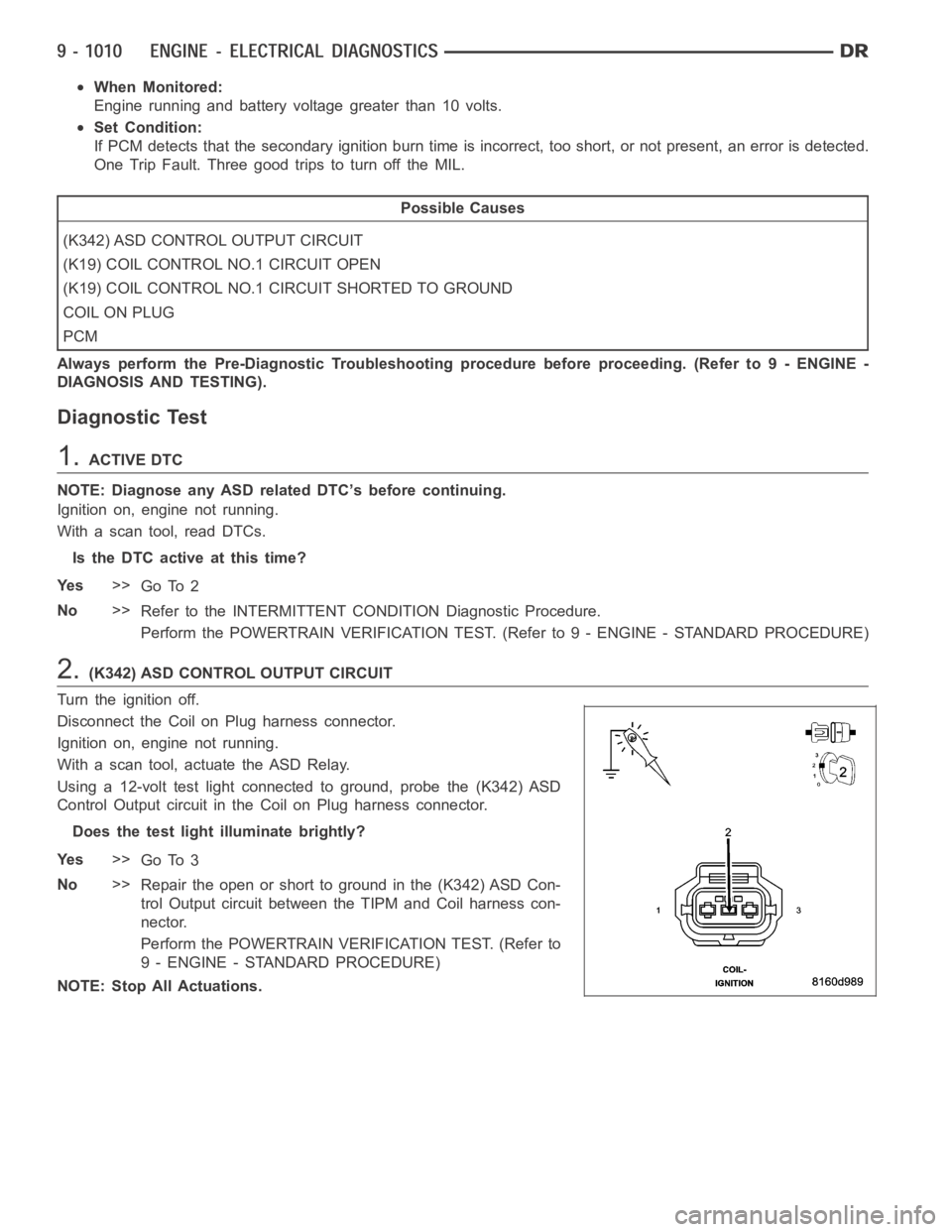

2.(K342) ASD CONTROL OUTPUT CIRCUIT

Turn the ignition off.

Disconnect the Coil on Plug harness connector.

Ignition on, engine not running.

With a scan tool, actuate the ASD Relay.

Using a 12-volt test light connected to ground, probe the (K342) ASD

Control Output circuit in the Coil on Plug harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the open or short to ground in the (K342) ASD Con-

trol Output circuit between the TIPM and Coil harness con-

nector.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

NOTE: Stop All Actuations.

Page 320 of 5267

3.COIL ON PLUG RESISTANCE

Turn the ignition off.

NOTE: The following resistance measurement should be taken between 70° and80°F.

Measure the resistance of the Coil on Plug.

4.7L and 3.7L Primary Ignition Coil resistance is 0.6 to 0.9 of an ohm at 77°F(25°C).

5.7L Primary Ignition Coil resistance is 0.558 to 0.682 of an ohm at 77°F (25°C).

Is the resistance within the given specification for the Ignition Coil being tested?

Ye s>>

Go To 4

No>>

Replace the Coil on plug.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

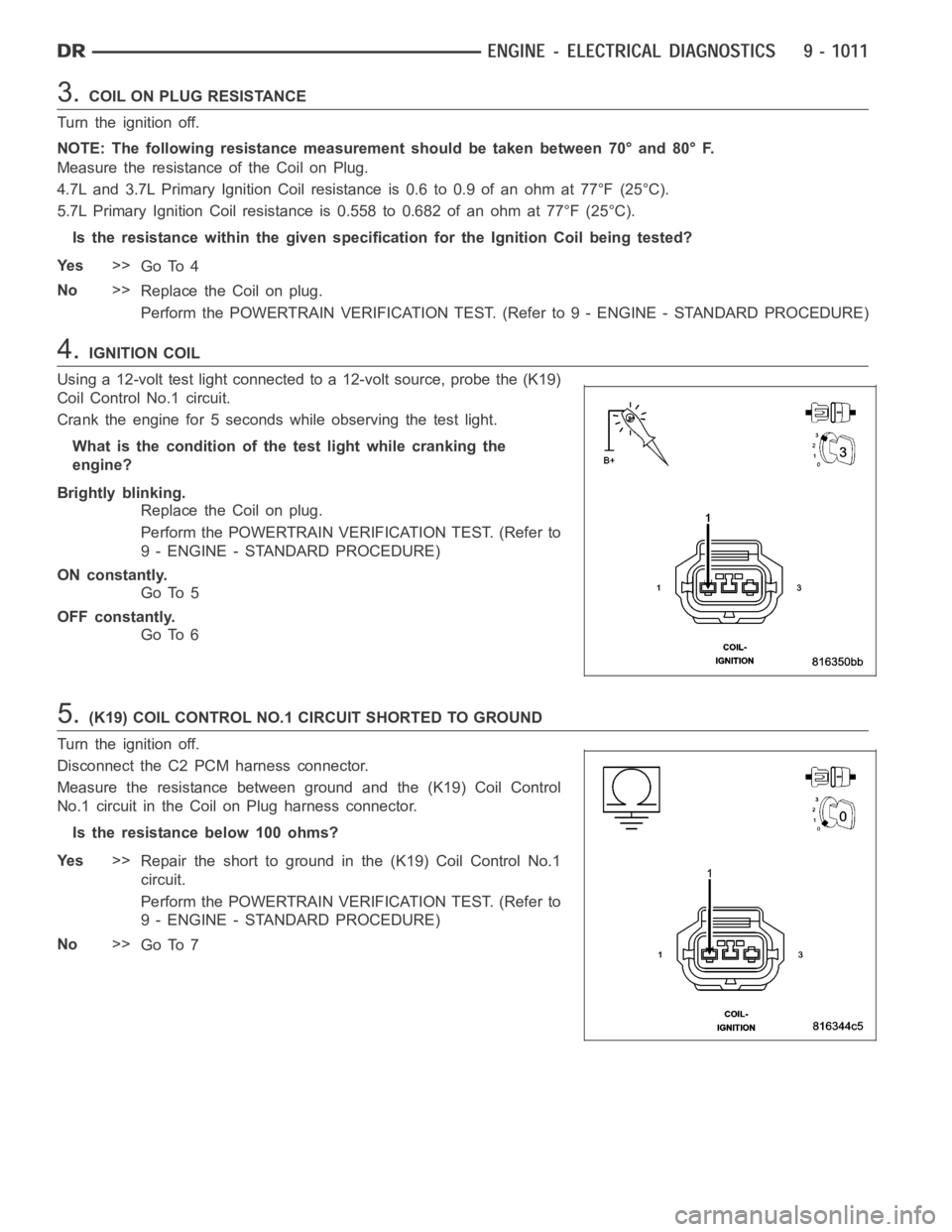

4.IGNITION COIL

Using a 12-volt test light connected to a 12-volt source, probe the (K19)

Coil Control No.1 circuit.

Crank the engine for 5 seconds while observing the test light.

What is the condition of the test light while cranking the

engine?

Brightly blinking.

Replace the Coil on plug.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

ON constantly.

Go To 5

OFF constantly.

Go To 6

5.(K19) COIL CONTROL NO.1 CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the C2 PCM harness connector.

Measure the resistance between ground and the (K19) Coil Control

No.1 circuit in the Coil on Plug harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K19) Coil Control No.1

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 7

Page 323 of 5267

When Monitored:

Engine running and battery voltage greater than 10 volts.

Set Condition:

If PCM detects that the secondary ignition burn time is incorrect, too short, or not present, an error is detected.

One Trip Fault. Three good trips to turn off the MIL.

Possible Causes

(K342) ASD CONTROL OUTPUT CIRCUIT

(K17) COIL CONTROL NO.2 CIRCUIT OPEN

(K17) COIL CONTROL NO.2 CIRCUIT SHORTED TO GROUND

COIL ON PLUG

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

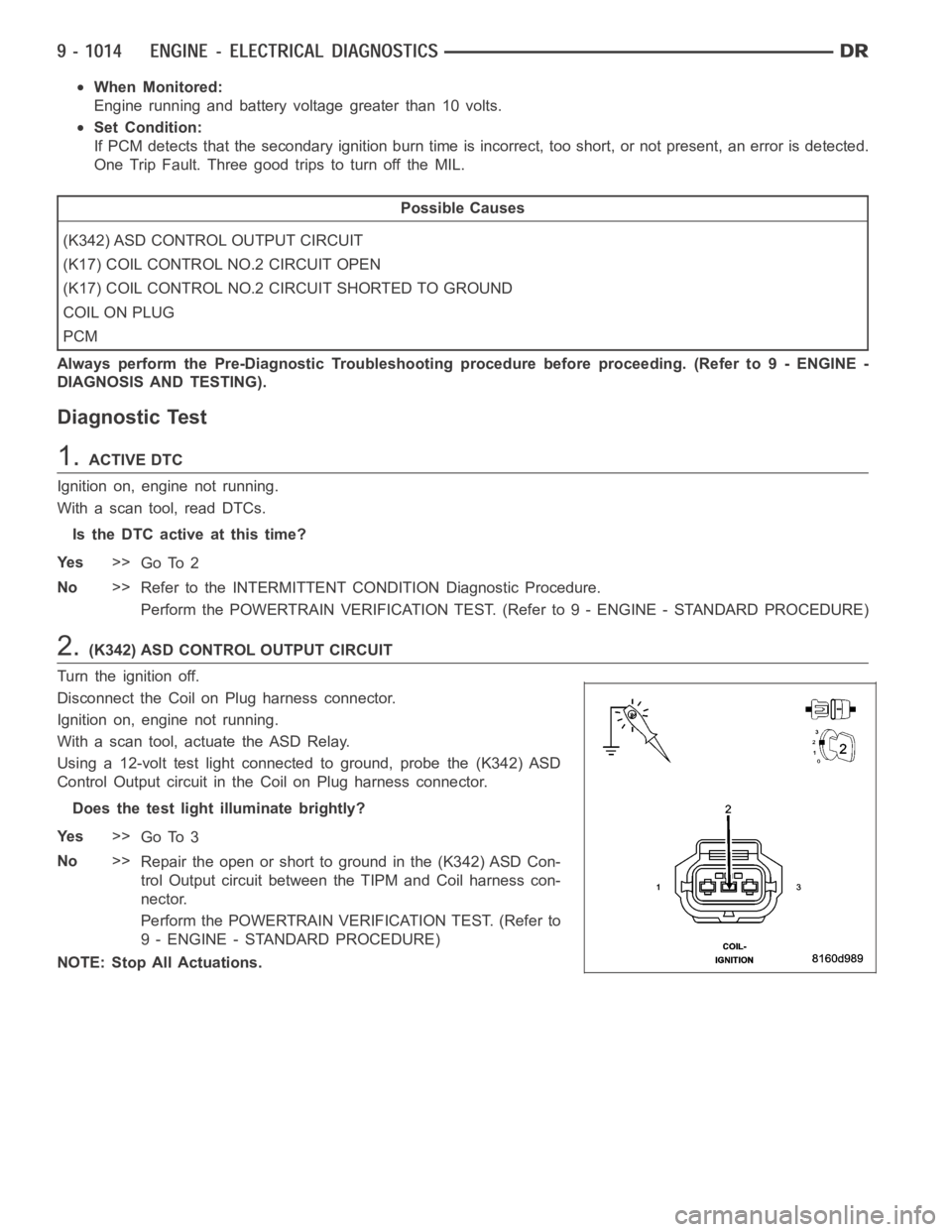

2.(K342) ASD CONTROL OUTPUT CIRCUIT

Turn the ignition off.

Disconnect the Coil on Plug harness connector.

Ignition on, engine not running.

With a scan tool, actuate the ASD Relay.

Using a 12-volt test light connected to ground, probe the (K342) ASD

Control Output circuit in the Coil on Plug harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the open or short to ground in the (K342) ASD Con-

trol Output circuit between the TIPM and Coil harness con-

nector.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

NOTE: Stop All Actuations.

Page 324 of 5267

3.COIL ON PLUG RESISTANCE

Turn the ignition off.

NOTE: The following resistance measurement should be taken between 70° and80°F.

Measure the resistance of the Coil on Plug.

4.7L and 3.7L Primary Ignition Coil resistance is 0.6 to 0.9 of an ohm at 77°F(25°C).

5.7L Primary Ignition Coil resistance is 0.558 to 0.682 of an ohm at 77°F (25°C).

Is the resistance within the given specification for the Ignition Coil being tested?

Ye s>>

Go To 4

No>>

Replace the Coil on plug.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

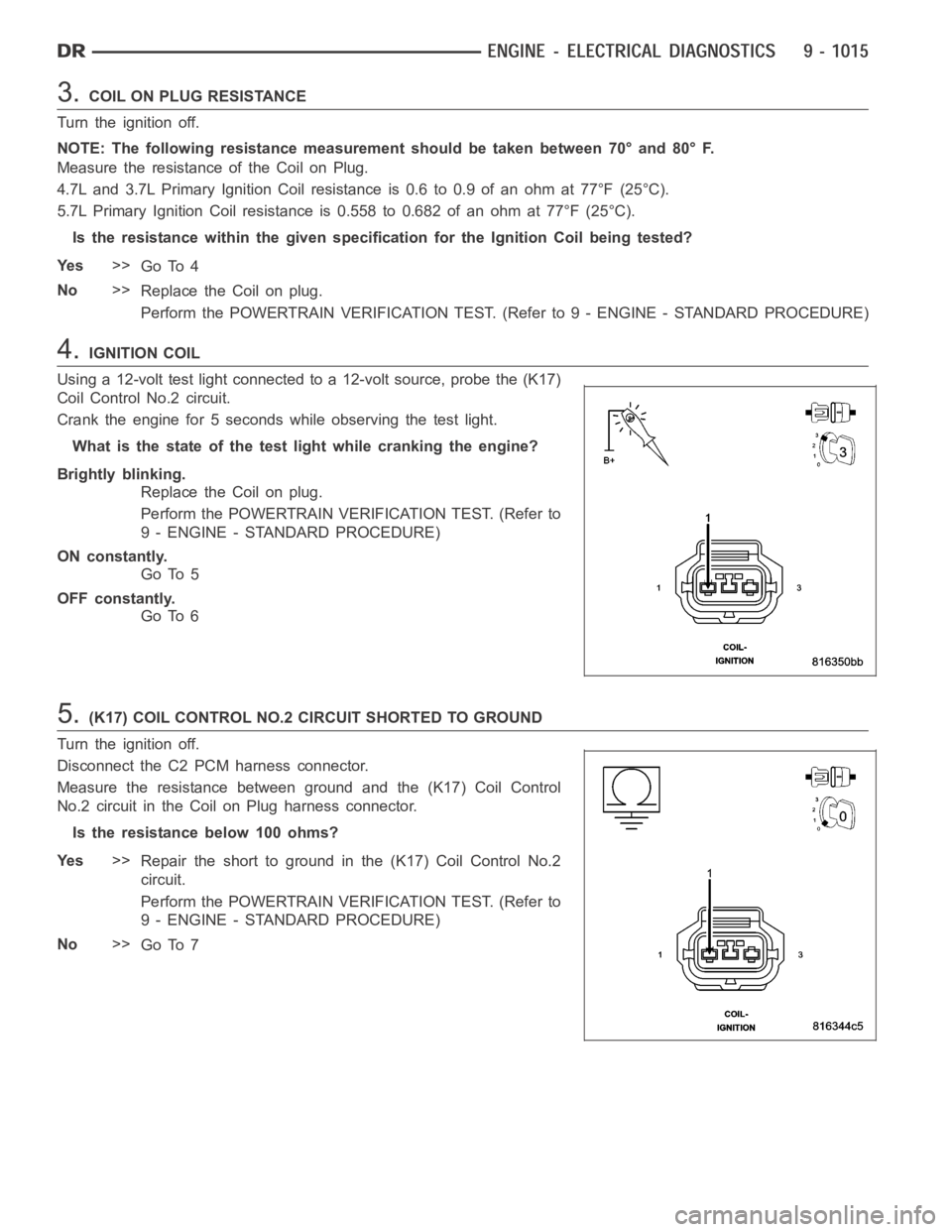

4.IGNITION COIL

Using a 12-volt test light connected to a 12-volt source, probe the (K17)

Coil Control No.2 circuit.

Crank the engine for 5 seconds while observing the test light.

What is the state of the test light while cranking the engine?

Brightly blinking.

Replace the Coil on plug.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

ON constantly.

Go To 5

OFF constantly.

Go To 6

5.(K17) COIL CONTROL NO.2 CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the C2 PCM harness connector.

Measure the resistance between ground and the (K17) Coil Control

No.2 circuit in the Coil on Plug harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K17) Coil Control No.2

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 7

Page 327 of 5267

When Monitored:

Engine running and battery voltage greater than 10 volts.

Set Condition:

If PCM detects that the secondary ignition burn time is incorrect, too short, or not present, an error is detected.

One Trip Fault. Three good trips to turn off the MIL.

Possible Causes

(K342) ASD CONTROL OUTPUT CIRCUIT

(K18) COIL CONTROL NO.3 CIRCUIT OPEN

(K18) COIL CONTROL NO.3 CIRCUIT SHORTED TO GROUND

COIL ON PLUG

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Diagnose any ASD related DTC’s before continuing.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

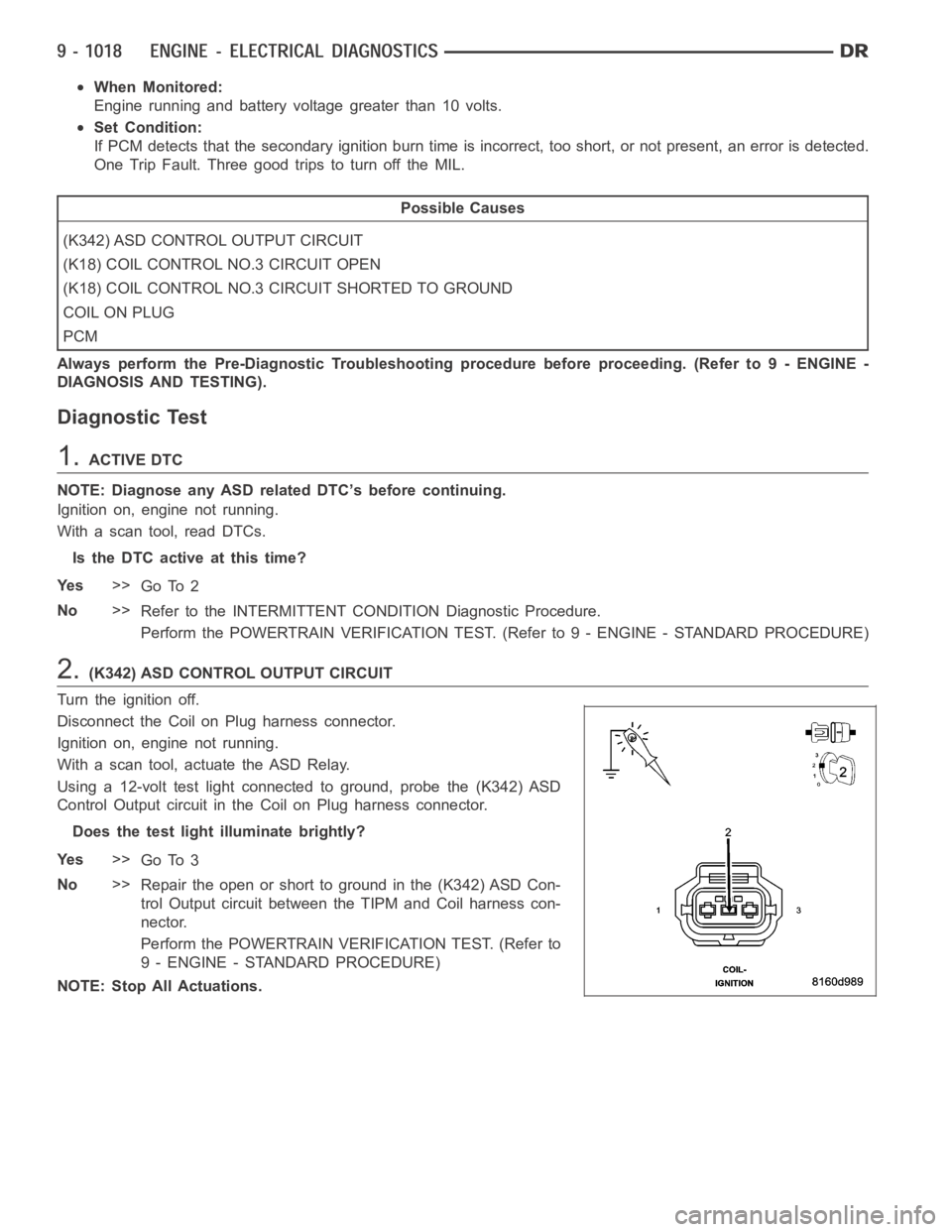

2.(K342) ASD CONTROL OUTPUT CIRCUIT

Turn the ignition off.

Disconnect the Coil on Plug harness connector.

Ignition on, engine not running.

With a scan tool, actuate the ASD Relay.

Using a 12-volt test light connected to ground, probe the (K342) ASD

Control Output circuit in the Coil on Plug harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the open or short to ground in the (K342) ASD Con-

trol Output circuit between the TIPM and Coil harness con-

nector.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

NOTE: Stop All Actuations.

Page 328 of 5267

3.COIL ON PLUG RESISTANCE

Turn the ignition off.

NOTE: The following resistance measurement should be taken between 70° and80°F.

Measure the resistance of the Coil on Plug.

4.7L and 3.7L Primary Ignition Coil resistance is 0.6 to 0.9 of an ohm at 77°F(25°C).

5.7L Primary Ignition Coil resistance is 0.558 to 0.682 of an ohm at 77°F (25°C).

Is the resistance within the given specification for the Ignition Coil being tested?

Ye s>>

Go To 4

No>>

Replace the Coil on plug.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

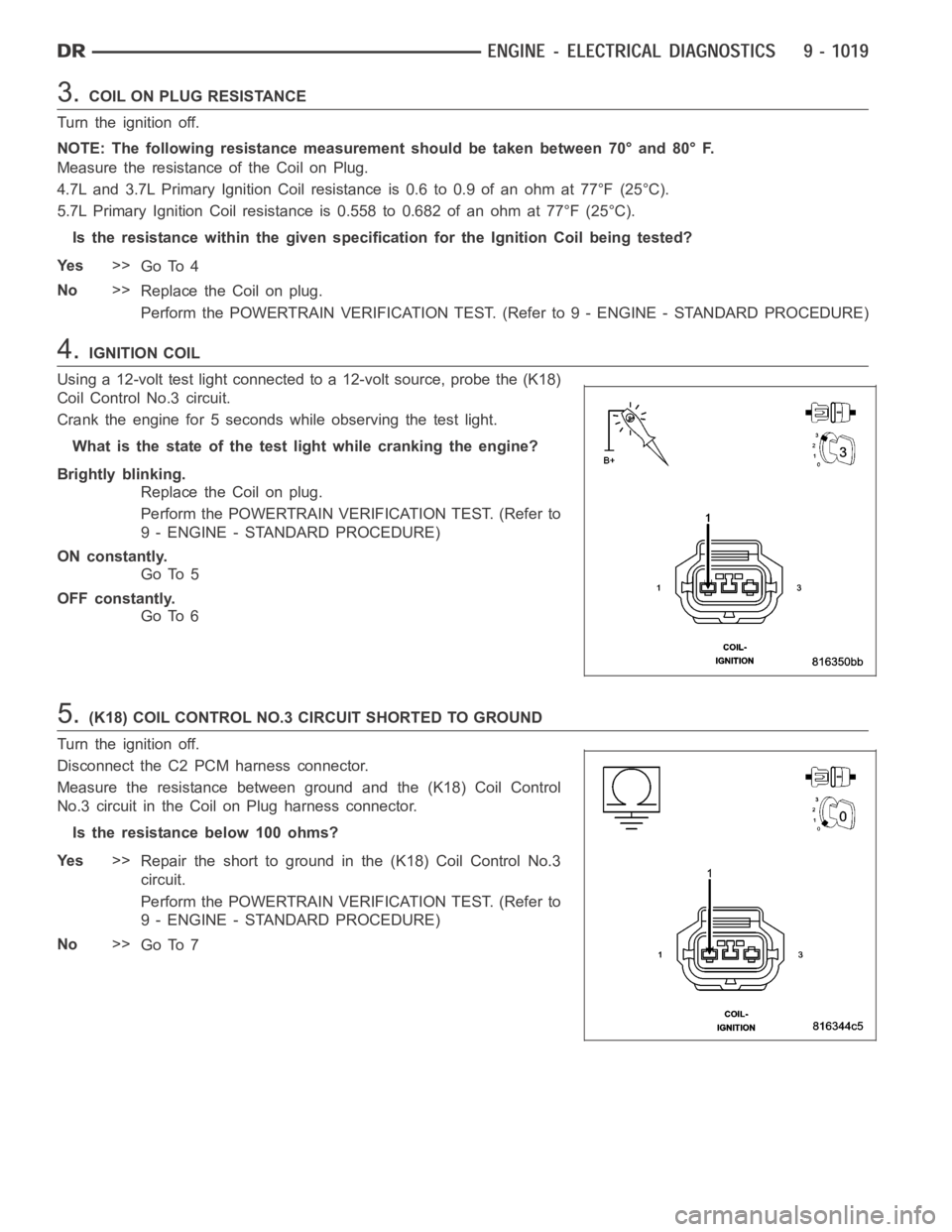

4.IGNITION COIL

Using a 12-volt test light connected to a 12-volt source, probe the (K18)

Coil Control No.3 circuit.

Crank the engine for 5 seconds while observing the test light.

What is the state of the test light while cranking the engine?

Brightly blinking.

Replace the Coil on plug.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

ON constantly.

Go To 5

OFF constantly.

Go To 6

5.(K18) COIL CONTROL NO.3 CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the C2 PCM harness connector.

Measure the resistance between ground and the (K18) Coil Control

No.3 circuit in the Coil on Plug harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K18) Coil Control No.3

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 7