check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2267 of 5267

INSTALLATION

3.7L

1. If fuel injectors are to be installed, (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - INSTALLATION).

2. Clean out fuel injector machined bores in intake

manifold.

3. Apply a small amount of engine oil to each fuel

injector O-ring. This will helpin fuel rail installation.

4. Position fuel rail/fuel injector assembly to machined

injector openings in cylinder head.

5. Guide each injector into cylinder head. Be careful

not to tear injector O-rings.

6. Pushrightside of fuel rail down until fuel injectors

have bottomed on cylinder head shoulder. Push

leftfuel rail down until injectors have bottomed on

cylinder head shoulder.

7. Install 4 fuel rail mounting bolts and tighten. (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - SPECI-

FICATIONS)

8. Install 6 ignition coils. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL - INSTALLA-

TION)

9. Connect electrical connectors to throttle body.

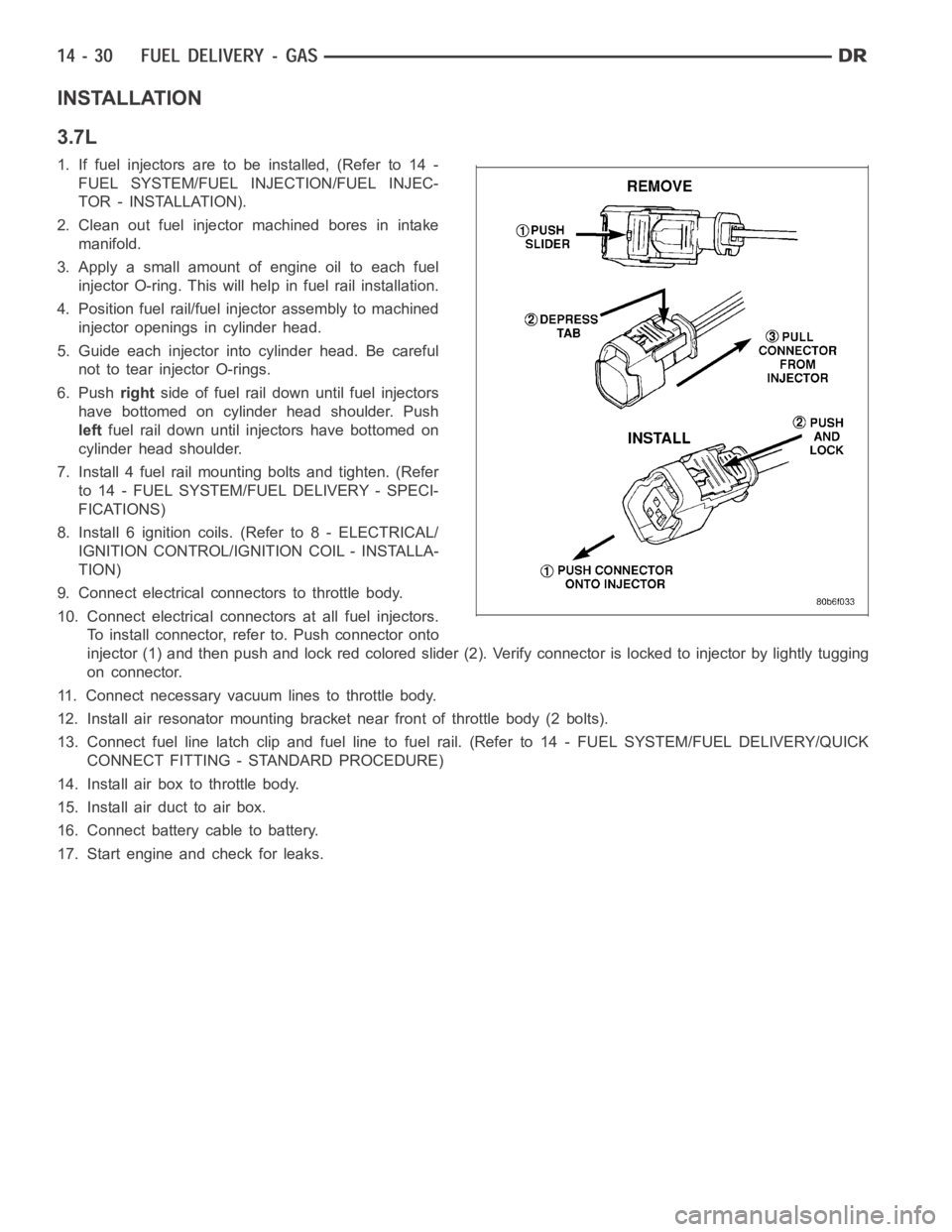

10. Connect electrical connectors at all fuel injectors.

To install connector, refer to. Push connector onto

injector (1) and then push and lock red colored slider (2). Verify connector is locked to injector by lightly tugging

on connector.

11. Connect necessary vacuum lines to throttle body.

12. Install air resonator mounting bracket near front of throttle body (2 bolts).

13. Connect fuel line latch clip and fuel line to fuel rail. (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/QUICK

CONNECT FITTING - STANDARD PROCEDURE)

14. Install air box to throttle body.

15. Install air duct to air box.

16. Connect battery cable to battery.

17. Start engine and check for leaks.

Page 2268 of 5267

4.7L

1. If fuel injectors are to be installed, (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - INSTALLATION).

2. Clean out fuel injector machined bores in intake

manifold.

3. Apply a small amount of engine oil to each fuel

injector O-ring. This will helpin fuel rail installation.

4. Position fuel rail/fuel injector assembly to machined

injector openings in cylinder head.

5. Guide each injector into cylinder head. Be careful

not to tear injector O-rings.

6. Pushrightside of fuel rail down until fuel injectors

have bottomed on cylinder head shoulder. Push

leftfuel rail down until injectors have bottomed on

cylinder head shoulder.

7. Install 4 fuel rail mounting bolts and tighten. (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - SPECI-

FICATIONS)

8. Install 8 ignition coils. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL - INSTALLA-

TION)

9. Connect electrical connectors to throttle body.

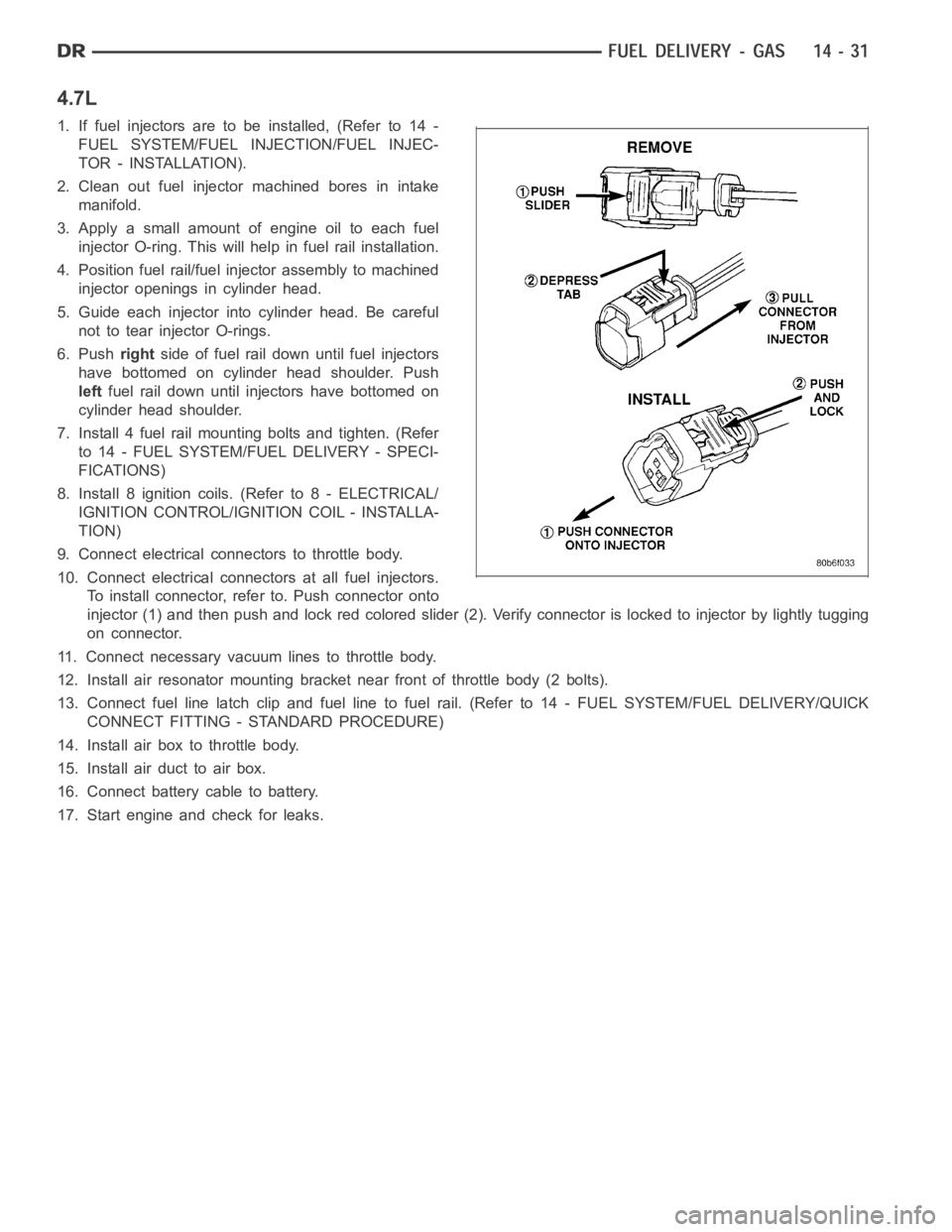

10. Connect electrical connectors at all fuel injectors.

To install connector, refer to. Push connector onto

injector (1) and then push and lock red colored slider (2). Verify connector is locked to injector by lightly tugging

on connector.

11. Connect necessary vacuum lines to throttle body.

12. Install air resonator mounting bracket near front of throttle body (2 bolts).

13. Connect fuel line latch clip and fuel line to fuel rail. (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/QUICK

CONNECT FITTING - STANDARD PROCEDURE)

14. Install air box to throttle body.

15. Install air duct to air box.

16. Connect battery cable to battery.

17. Start engine and check for leaks.

Page 2269 of 5267

5.7L

1. If fuel injectors are to be installed, (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - INSTALLATION).

2. Clean out fuel injector machined bores in intake

manifold.

3. Apply a small amount of engine oil to each fuel

injector O-ring. This will helpin fuel rail installation.

4. Position fuel rail/fuel injector assembly to machined

injector openings in intake manifold.

5. Guide each injector into intake manifold. Be careful

not to tear injector O-rings.

6. Pushrightside of fuel rail down until fuel injectors

have bottomed on shoulders. Pushleftfuel rail

down until injectors have bottomed on shoulders.

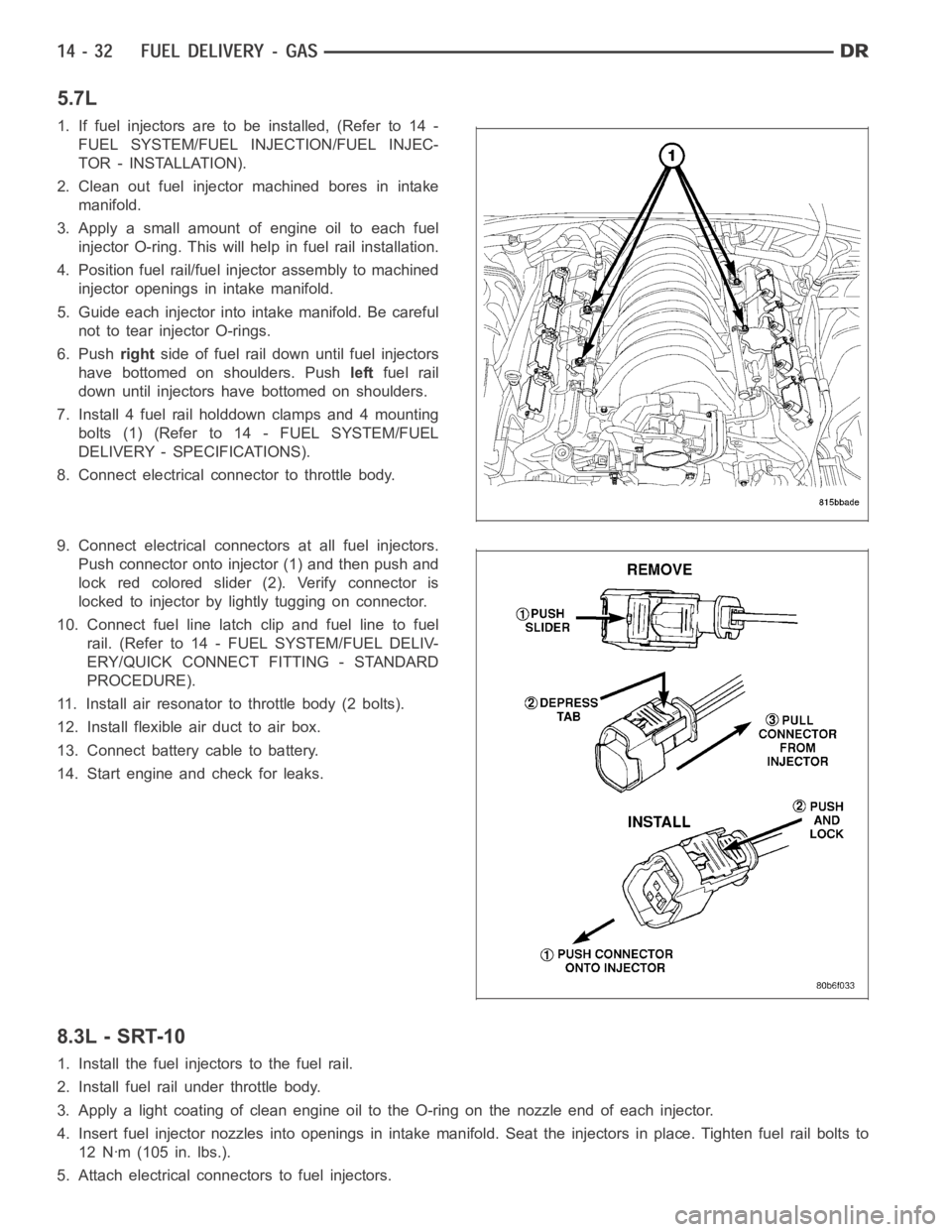

7. Install 4 fuel rail holddown clamps and 4 mounting

bolts (1) (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - SPECIFICATIONS).

8. Connect electrical connector to throttle body.

9. Connect electrical connectors at all fuel injectors.

Push connector onto injector (1) and then push and

lock red colored slider (2). Verify connector is

locked to injector by lightly tugging on connector.

10. Connect fuel line latch clip and fuel line to fuel

rail. (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY/QUICK CONNECT FITTING - STANDARD

PROCEDURE).

11. Install air resonator to throttle body (2 bolts).

12. Install flexible air duct to air box.

13. Connect battery cable to battery.

14. Start engine and check for leaks.

8.3L - SRT-10

1. Install the fuel injectors to the fuel rail.

2. Install fuel rail under throttle body.

3. Apply a light coating of clean engine oiltotheO-ringonthenozzleendofeach injector.

4. Insert fuel injector nozzles into openings in intake manifold. Seat theinjectors in place. Tighten fuel rail bolts to

12 Nꞏm (105 in. lbs.).

5. Attach electrical connectors to fuel injectors.

Page 2270 of 5267

6. Connect the electrical connector to the MAP sensor and Coolant Temperature sensor.

7. Connect the electrical connector to the TPS and Idle Air Control.

8. Install the wiring harness to the wiring clips under the throttle body.

9. Connect fuel supply tube to fuel rail. Refer to Quick Connect Fittings inthe Fuel Delivery section.

10. Install the negative battery cable.

11. Install the air cleaner assembly, refer to the Engine/Air Intake System/Air Cleaner Housing for more information.

12. Use the DRBIII

scan tool ASD Fuel System Test to pressurize the fuel system. Check for leaks.

Page 2271 of 5267

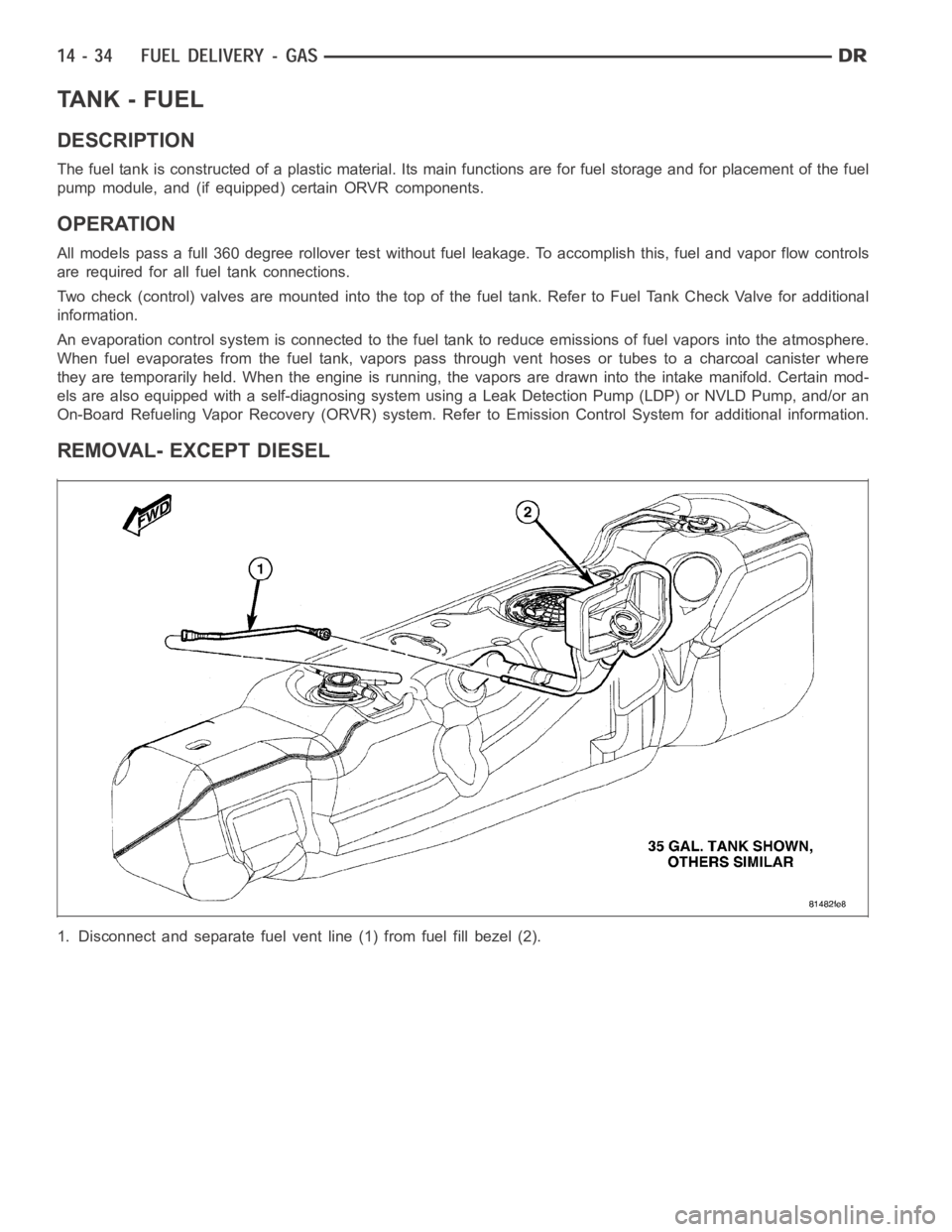

TA N K - F U E L

DESCRIPTION

The fuel tank is constructed of a plastic material. Its main functions are for fuel storage and for placement of the fuel

pump module, and (if equipped) certain ORVR components.

OPERATION

All models pass a full 360 degree rollover test without fuel leakage. To accomplish this, fuel and vapor flow controls

are required for all fuel tank connections.

Two check (control) valves are mounted into the top of the fuel tank. Refer to Fuel Tank Check Valve for additional

information.

An evaporation control system is connected to the fuel tank to reduce emissions of fuel vapors into the atmosphere.

When fuel evaporates from the fuel tank, vapors pass through vent hoses or tubes to a charcoal canister where

they are temporarily held. When the engine is running, the vapors are drawninto the intake manifold. Certain mod-

els are also equipped with a self-diagnosing system using a Leak DetectionPump (LDP) or NVLD Pump, and/or an

On-Board Refueling Vapor Recovery (ORVR) system. Refer to Emission Control System for additional information.

REMOVAL- EXCEPT DIESEL

1. Disconnect and separate fuel vent line (1) from fuel fill bezel (2).

Page 2279 of 5267

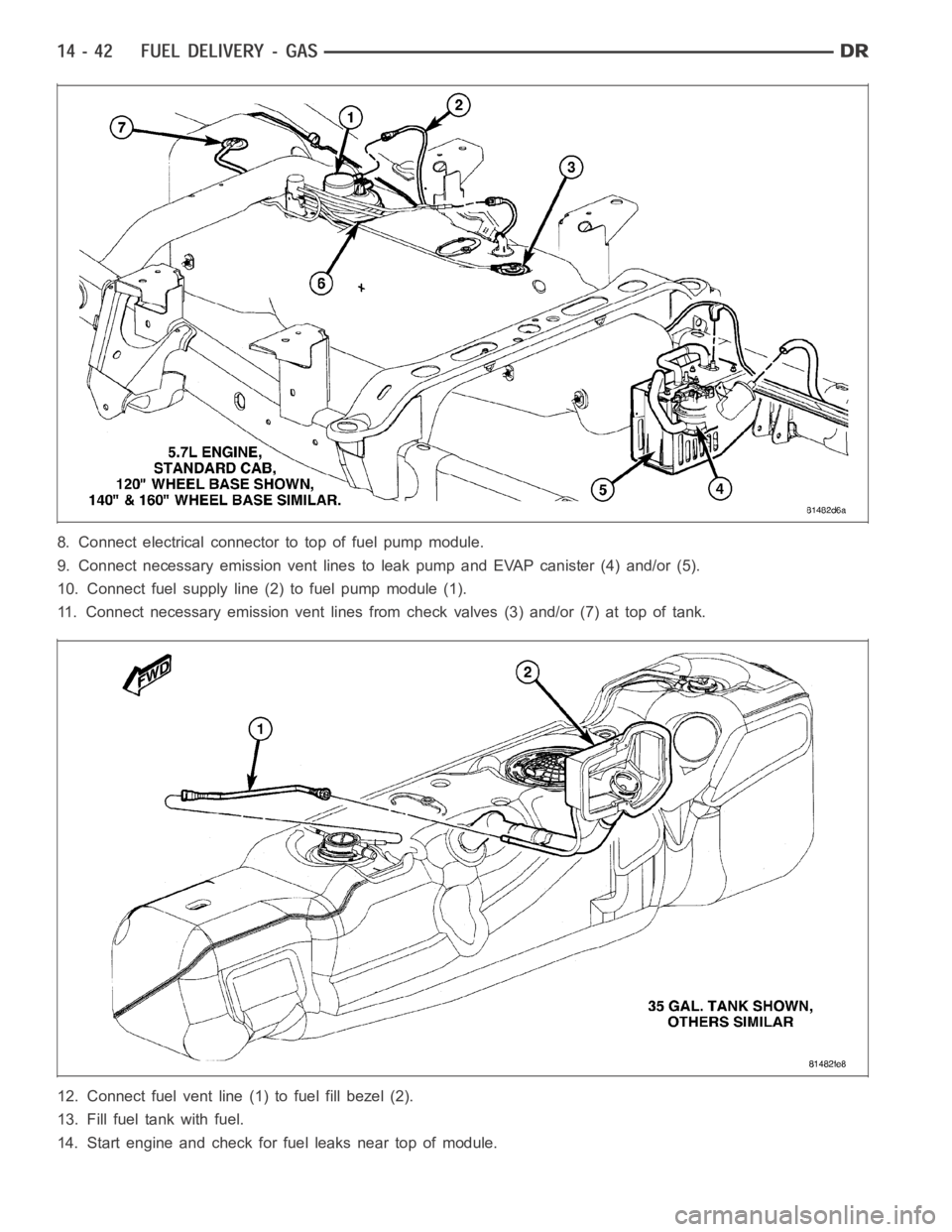

8. Connect electrical connector to top of fuel pump module.

9. Connect necessary emission vent lines to leak pump and EVAP canister (4)and/or (5).

10. Connect fuel supply line (2) to fuel pump module (1).

11. Connect necessary emission vent lines from check valves (3) and/or (7)at top of tank.

12. Connect fuel vent line (1) to fuel fill bezel (2).

13. Fill fuel tank with fuel.

14. Start engine and check for fuel leaks near top of module.

Page 2283 of 5267

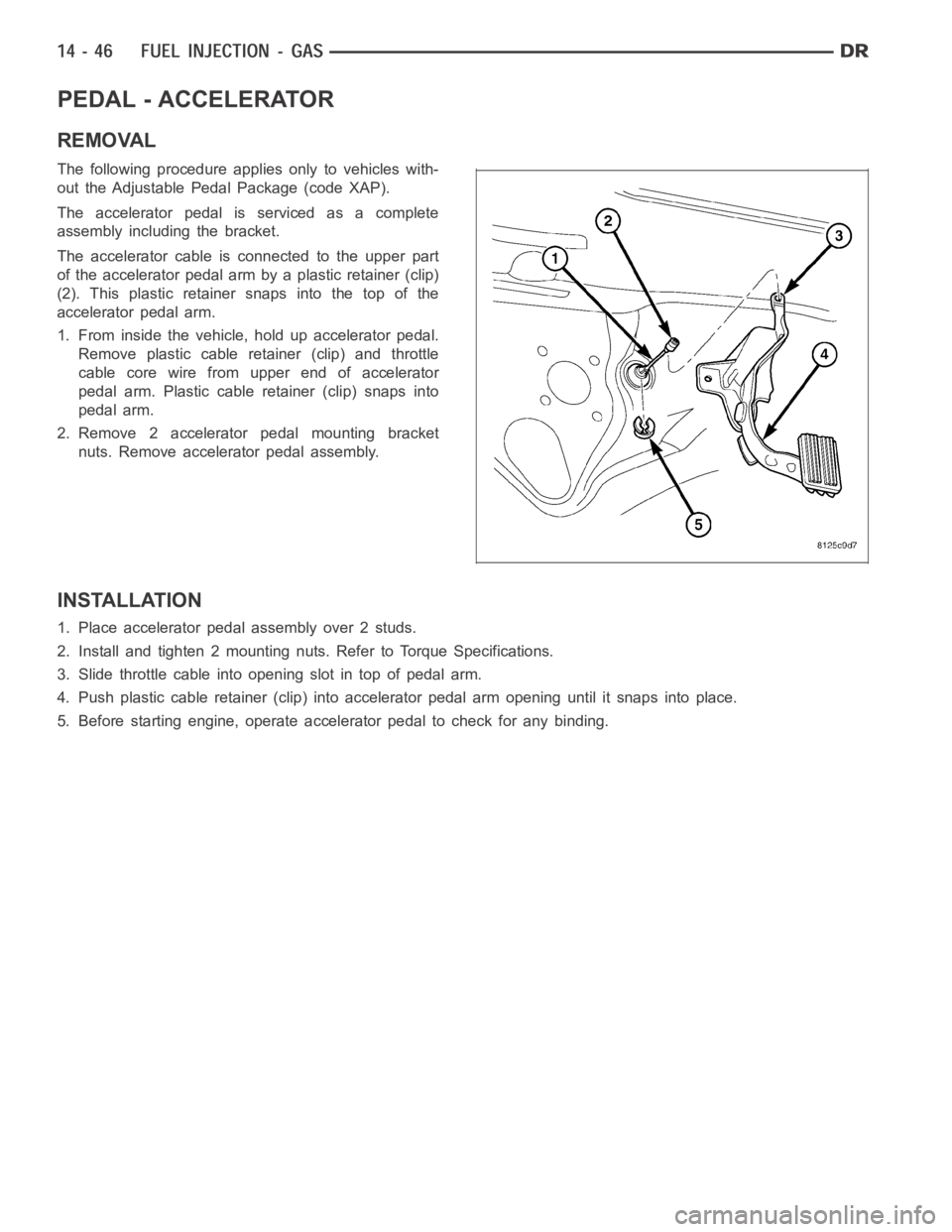

PEDAL - ACCELERATOR

REMOVAL

The following procedure applies only to vehicles with-

out the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

The accelerator cable is connected to the upper part

of the accelerator pedal arm by a plastic retainer (clip)

(2). This plastic retainer snaps into the top of the

accelerator pedal arm.

1. From inside the vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle

cable core wire from upper end of accelerator

pedal arm. Plastic cable retainer (clip) snaps into

pedal arm.

2. Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.

INSTALLATION

1. Place accelerator pedal assembly over 2 studs.

2. Install and tighten 2 mounting nuts. Refer to Torque Specifications.

3. Slide throttle cable into opening slot in top of pedal arm.

4. Push plastic cable retainer (clip) into accelerator pedal arm opening until it snaps into place.

5. Before starting engine, operate accelerator pedal to check for any binding.

Page 2289 of 5267

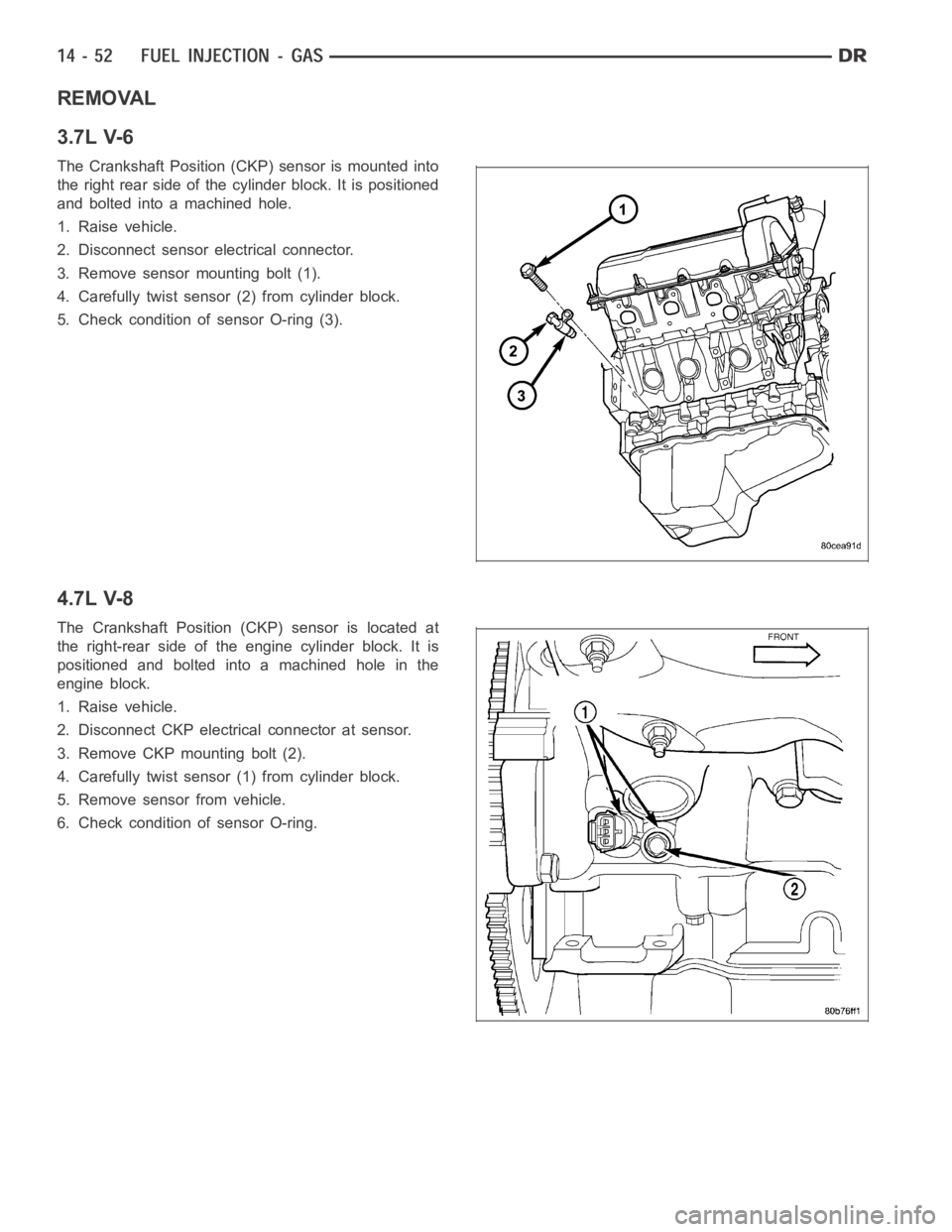

REMOVAL

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted into

the right rear side of the cylinder block. It is positioned

and bolted into a machined hole.

1. Raise vehicle.

2. Disconnect sensor electrical connector.

3. Remove sensor mounting bolt (1).

4. Carefully twist sensor (2) from cylinder block.

5. Check condition of sensor O-ring (3).

4.7L V-8

The Crankshaft Position (CKP) sensor is located at

the right-rear side of the engine cylinder block. It is

positioned and bolted into a machined hole in the

engine block.

1. Raise vehicle.

2. Disconnect CKP electrical connector at sensor.

3. Remove CKP mounting bolt (2).

4. Carefully twist sensor (1) from cylinder block.

5. Remove sensor from vehicle.

6. Check condition of sensor O-ring.

Page 2290 of 5267

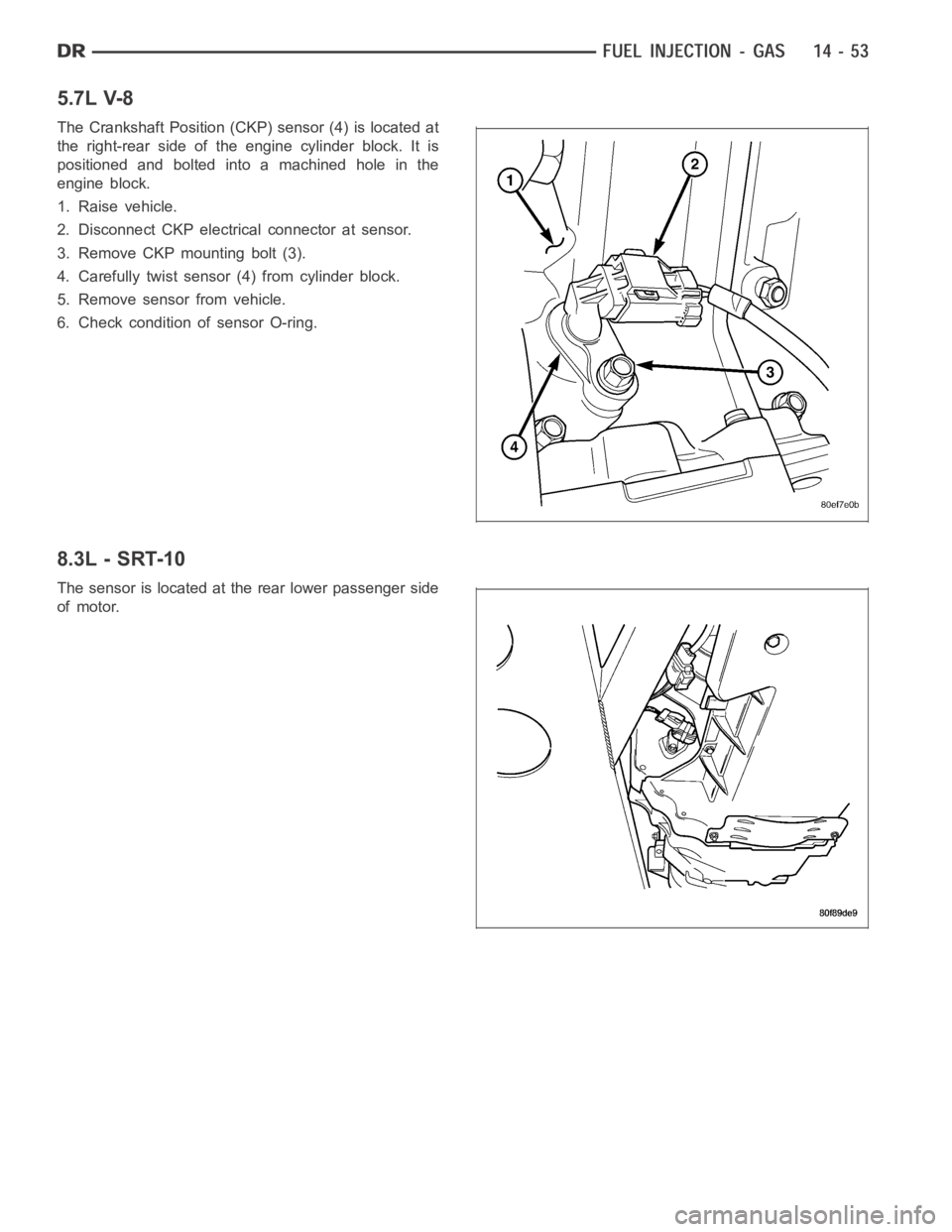

5.7L V-8

The Crankshaft Position (CKP) sensor (4) is located at

the right-rear side of the engine cylinder block. It is

positioned and bolted into a machined hole in the

engine block.

1. Raise vehicle.

2. Disconnect CKP electrical connector at sensor.

3. Remove CKP mounting bolt (3).

4. Carefully twist sensor (4) from cylinder block.

5. Remove sensor from vehicle.

6. Check condition of sensor O-ring.

8.3L - SRT-10

The sensor is located at the rear lower passenger side

of motor.

Page 2297 of 5267

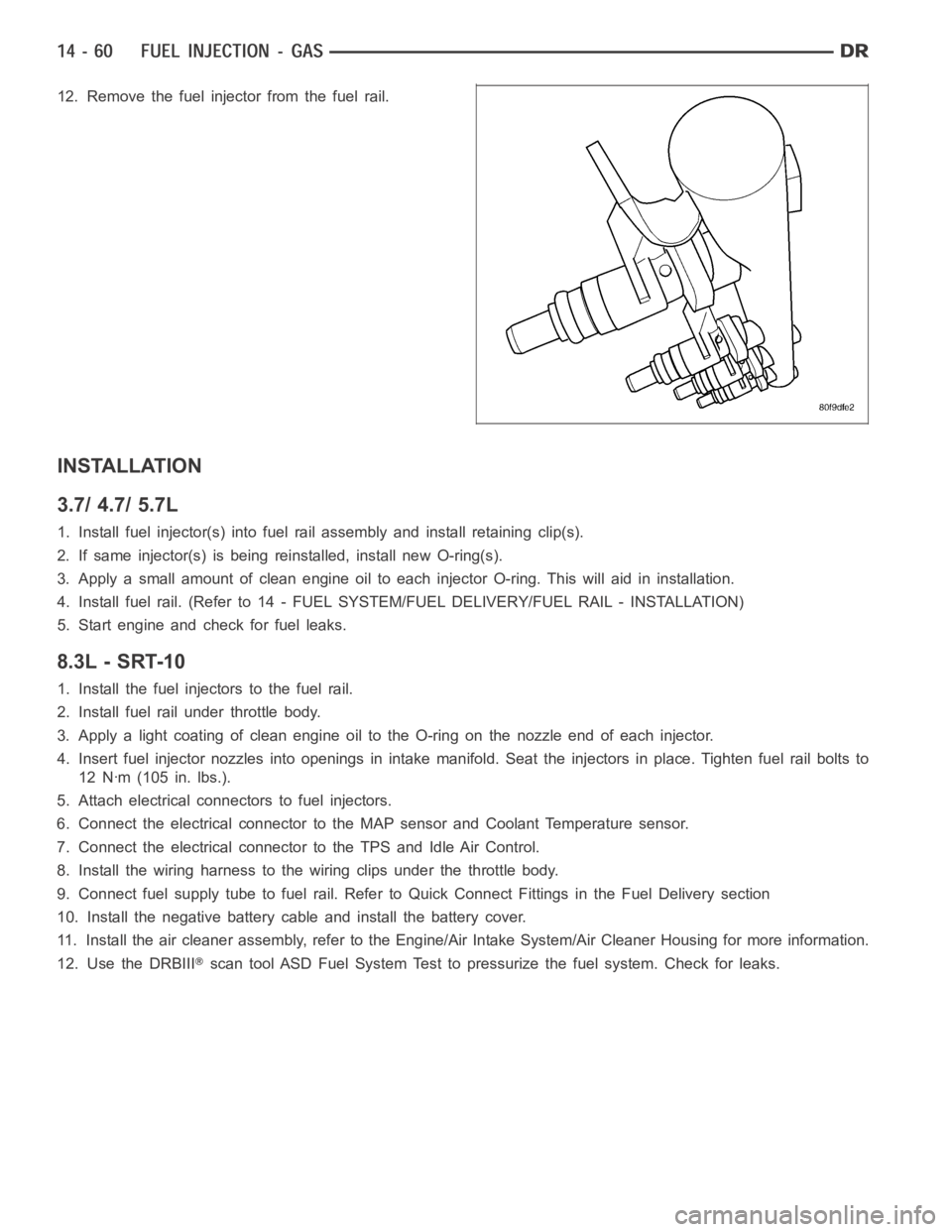

12. Remove the fuel injector from the fuel rail.

INSTALLATION

3.7/ 4.7/ 5.7L

1. Install fuel injector(s) into fuel rail assembly and install retainingclip(s).

2. If same injector(s) is being reinstalled, install new O-ring(s).

3. Apply a small amount of clean engine oil to each injector O-ring. This will aid in installation.

4. Install fuel rail. (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/FUEL RAIL - INSTALLATION)

5. Start engine and check for fuel leaks.

8.3L - SRT-10

1. Install the fuel injectors to the fuel rail.

2. Install fuel rail under throttle body.

3. Apply a light coating of clean engine oiltotheO-ringonthenozzleendofeach injector.

4. Insert fuel injector nozzles into openings in intake manifold. Seat theinjectors in place. Tighten fuel rail bolts to

12 Nꞏm (105 in. lbs.).

5. Attach electrical connectors to fuel injectors.

6. Connect the electrical connector to the MAP sensor and Coolant Temperature sensor.

7. Connect the electrical connector to the TPS and Idle Air Control.

8. Install the wiring harness to the wiring clips under the throttle body.

9. Connect fuel supply tube to fuel rail. Refer to Quick Connect Fittings inthe Fuel Delivery section

10. Install the negative battery cable and install the battery cover.

11. Install the air cleaner assembly, refer to the Engine/Air Intake System/Air Cleaner Housing for more information.

12. Use the DRBIII

scan tool ASD Fuel System Test to pressurize the fuel system. Check for leaks.