lock DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3973 of 5267

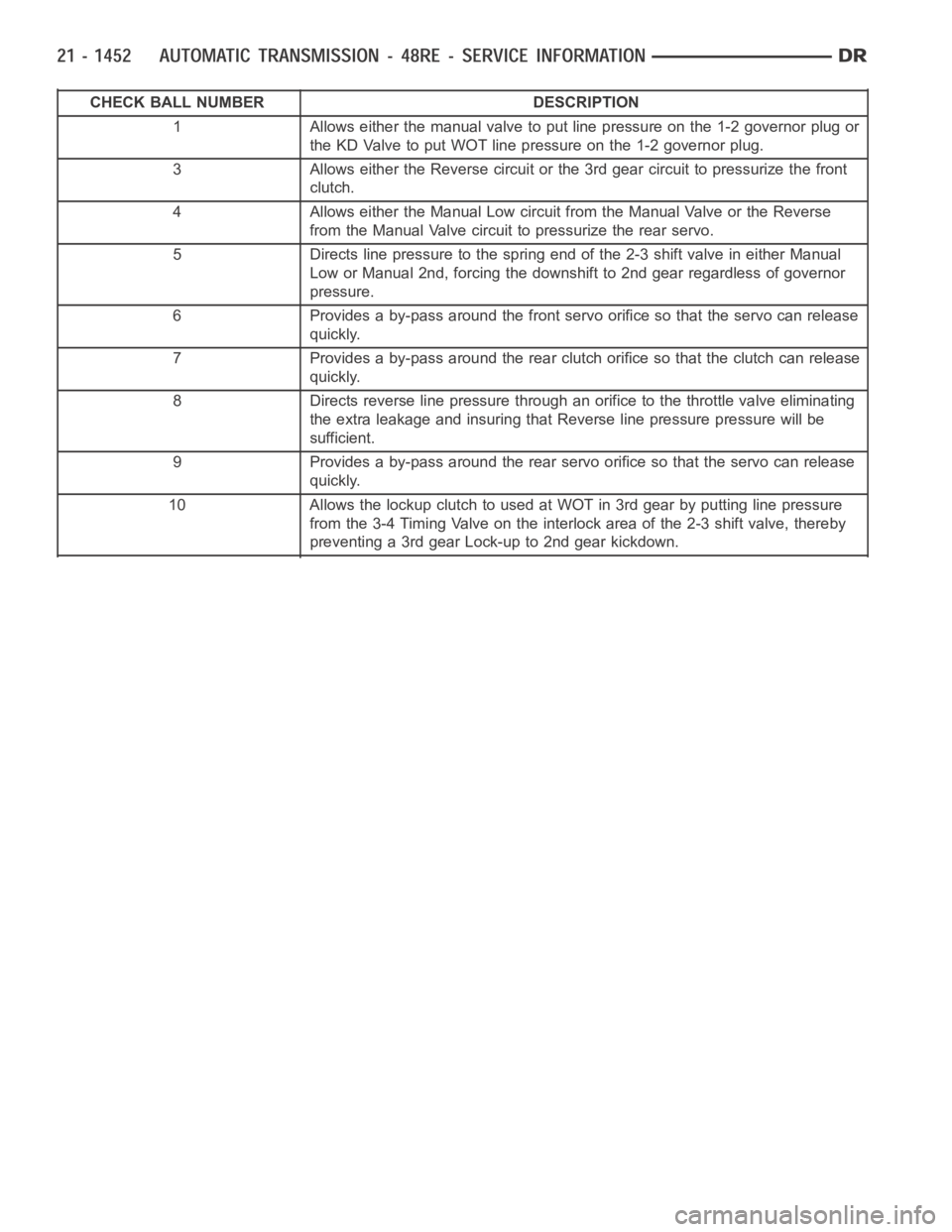

CHECK BALL NUMBER DESCRIPTION

1 Allows either the manual valve to put line pressure on the 1-2 governor plugor

the KD Valve to put WOT line pressure on the 1-2 governor plug.

3 Allows either the Reverse circuit or the 3rd gear circuit to pressurize thefront

clutch.

4 Allows either the Manual Low circuit from the Manual Valve or the Reverse

from the Manual Valve circuit to pressurize the rear servo.

5 Directs line pressure to the spring end of the 2-3 shift valve in either Manual

Low or Manual 2nd, forcing the downshift to 2nd gear regardless of governor

pressure.

6 Provides a by-pass around the front servo orifice so that the servo can release

quickly.

7 Provides a by-pass around the rear clutch orifice so that the clutch can release

quickly.

8 Directs reverse line pressure through an orifice to the throttle valve eliminating

the extra leakage and insuring that Reverse line pressure pressure will be

sufficient.

9 Provides a by-pass around the rear servo orifice so that the servo can release

quickly.

10 AllowsthelockupclutchtousedatWOTin3rdgearbyputtinglinepressure

from the 3-4 Timing Valve on the interlock area of the 2-3 shift valve, thereby

preventing a 3rd gear Lock-up to 2nd gear kickdown.

Page 3977 of 5267

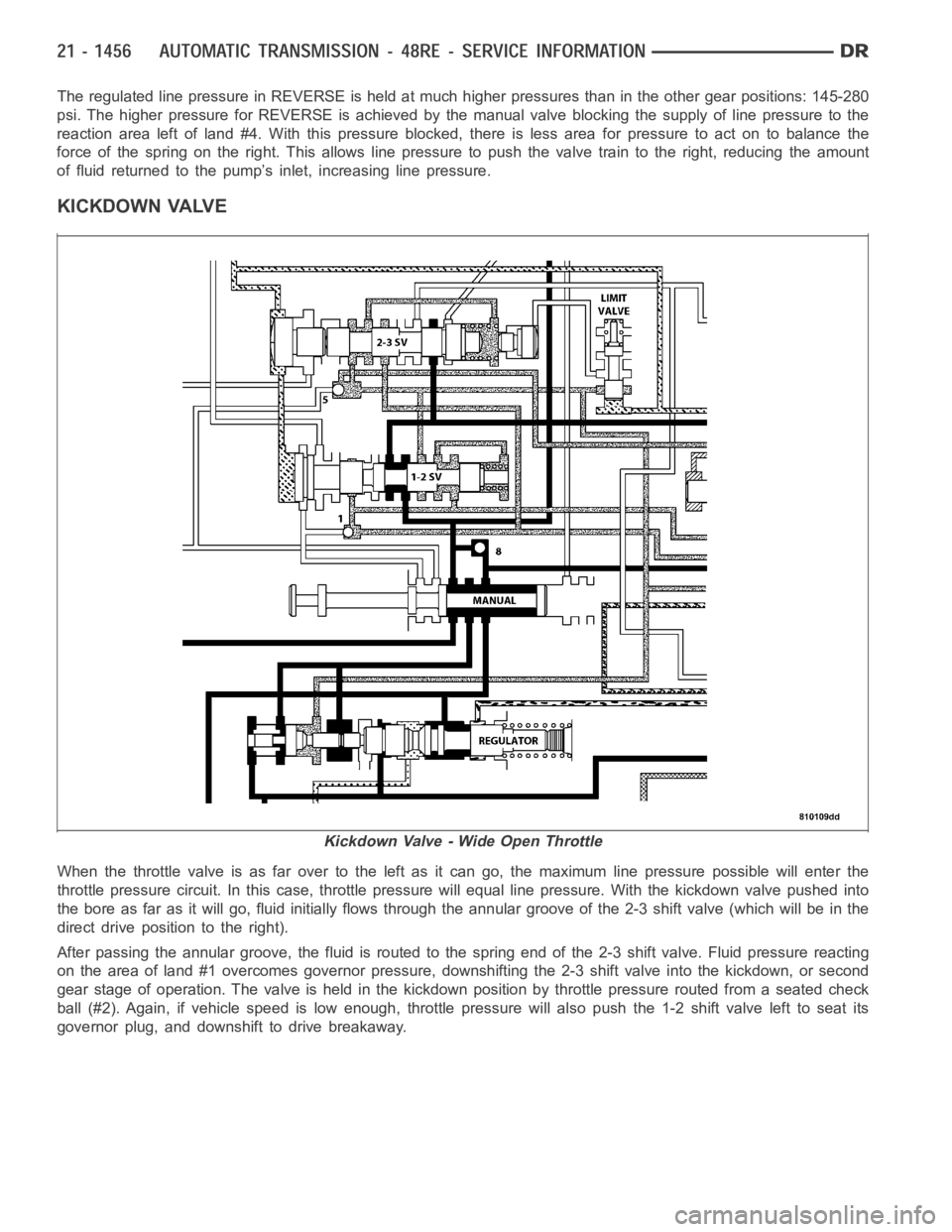

The regulated line pressure in REVERSEis held at much higher pressures than in the other gear positions: 145-280

psi. The higher pressure for REVERSE isachieved by the manual valve blocking the supply of line pressure to the

reaction area left of land #4. With this pressure blocked, there is less area for pressure to act on to balance the

force of the spring on the right. This allows line pressure to push the valvetrain to the right, reducing the amount

of fluid returned to the pump’s inlet, increasing line pressure.

KICKDOWN VALVE

When the throttle valve is as far over to the left as it can go, the maximum line pressure possible will enter the

throttle pressure circuit. In this case, throttle pressure will equal line pressure. With the kickdown valve pushed into

the bore as far as it will go, fluid initially flows through the annular groove of the 2-3 shift valve (which will be in the

direct drive position to the right).

After passing the annular groove, the fluid is routed to the spring end of the 2-3 shift valve. Fluid pressure reacting

on the area of land #1 overcomes governor pressure, downshifting the 2-3 shift valve into the kickdown, or second

gear stage of operation. The valve is held in the kickdown position by throttle pressure routed from a seated check

ball (#2). Again, if vehicle speed is low enough, throttle pressure will also push the 1-2 shift valve left to seat its

governor plug, and downshift to drive breakaway.

Kickdown Valve - Wide Open Throttle

Page 3979 of 5267

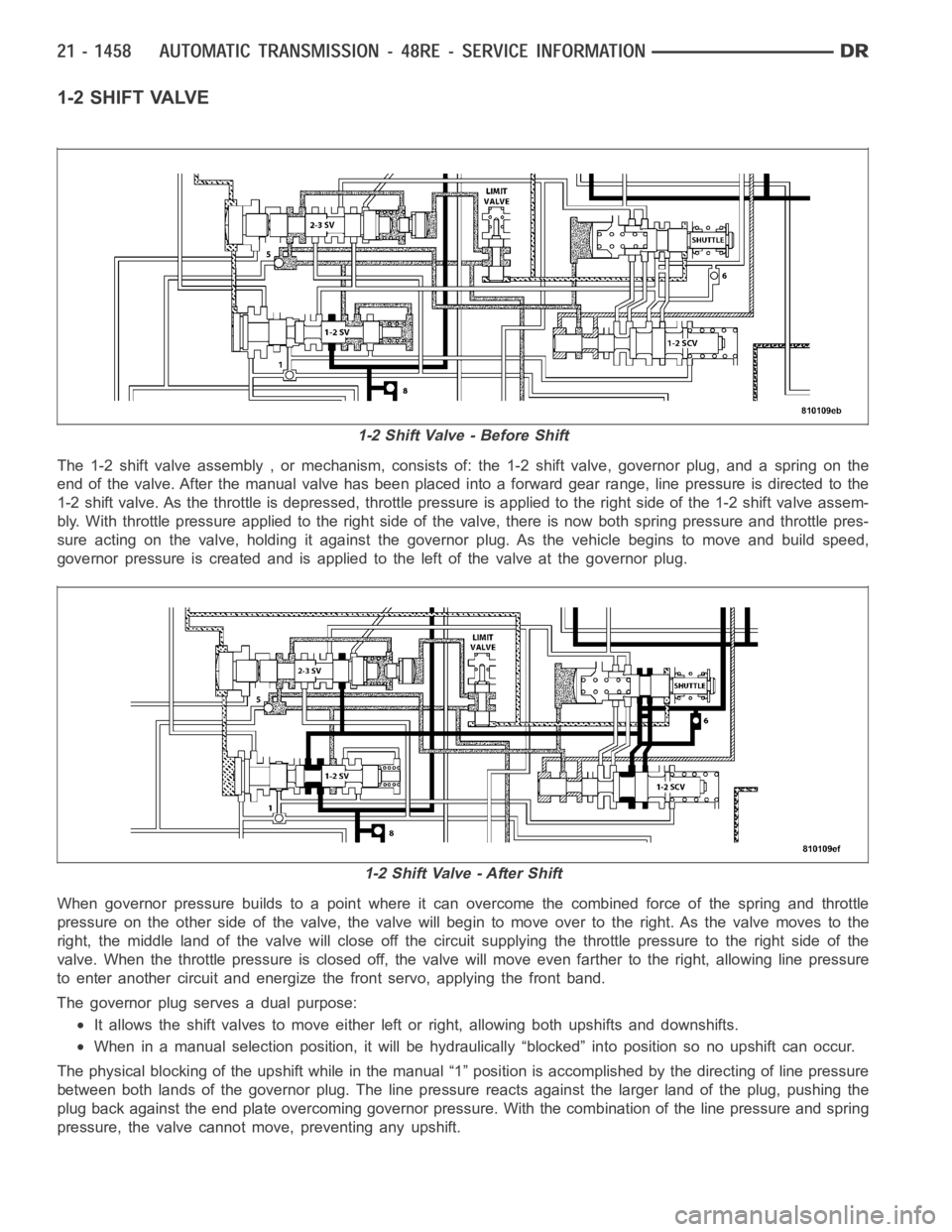

1-2 SHIFT VALVE

The 1-2 shift valve assembly , or mechanism, consists of: the 1-2 shift valve, governor plug, and a spring on the

end of the valve. After the manual valve has been placed into a forward gear range, line pressure is directed to the

1-2 shift valve. As the throttle is depressed, throttle pressure is applied to the right side of the 1-2 shift valve assem-

bly. With throttle pressure applied to the right side of the valve, there isnow both spring pressure and throttle pres-

sure acting on the valve, holding it against the governor plug. As the vehicle begins to move and build speed,

governor pressure is created and is applied to the left of the valve at the governor plug.

When governor pressure builds to a point where it can overcome the combinedforce of the spring and throttle

pressureontheothersideofthevalve,thevalvewillbegintomoveovertothe right. As the valve moves to the

right, the middle land of the valve will close off the circuit supplying thethrottle pressure to the right side of the

valve. When the throttle pressure is closed off, the valve will move even farther to the right, allowing line pressure

to enter another circuit and energize the front servo, applying the front band.

The governor plug serves a dual purpose:

It allows the shift valves to move either left or right, allowing both upshifts and downshifts.

When in a manual selection position, it will be hydraulically “blocked” into position so no upshift can occur.

The physical blocking of the upshift while in the manual “1” position is accomplished by the directing of line pressure

between both lands of the governor plug. The line pressure reacts against the larger land of the plug, pushing the

plug back against the end plate overcoming governor pressure. With the combination of the line pressure and spring

pressure, the valve cannot move, preventing any upshift.

1-2 Shift Valve - Before Shift

1-2ShiftValve-AfterShift

Page 3982 of 5267

2-3 shift valve is larger in diameter than the 1-2 shift valve, the 2-3 shiftwill always happen at a greater speed than

the 1-2 shift. When this happens, the governor plug is forced against the shift valve moving it to the right. The shift

valve causes land #4 to close the passage supplying throttle pressure to the 2-3 shift valve. Without throttle pres-

sure present in the circuit now, the governor plug will push the valve over far enough to bottom the valve in its bore.

This allows land #2 to direct line pressure to the front clutch.

After the shift , line pressure is directed to the release side of the kickdown servo. This releases the front band and

applies the front clutch, shifting into third gear or direct drive. The rear clutch remains applied, as it has been in the

other gears. During a manual “1” or manual “2” gear selection, line pressure is sent between the two lands of the

2-3 governor plug. This line pressure at the governor plug locks the shift valve into the second gear position, pre-

venting an upshift into direct drive. The theory for the blocking of the valve is the same as that of the 1-2 shift valve.

If the manual “2” or manual “1” gear position is selected from the drive position, the PCM will control the timing of

the downshift by targeting for a high governor pressure. When a safe vehicle speed is reached, the PCM will switch

to its normal control governor curve and the downshift will occur.

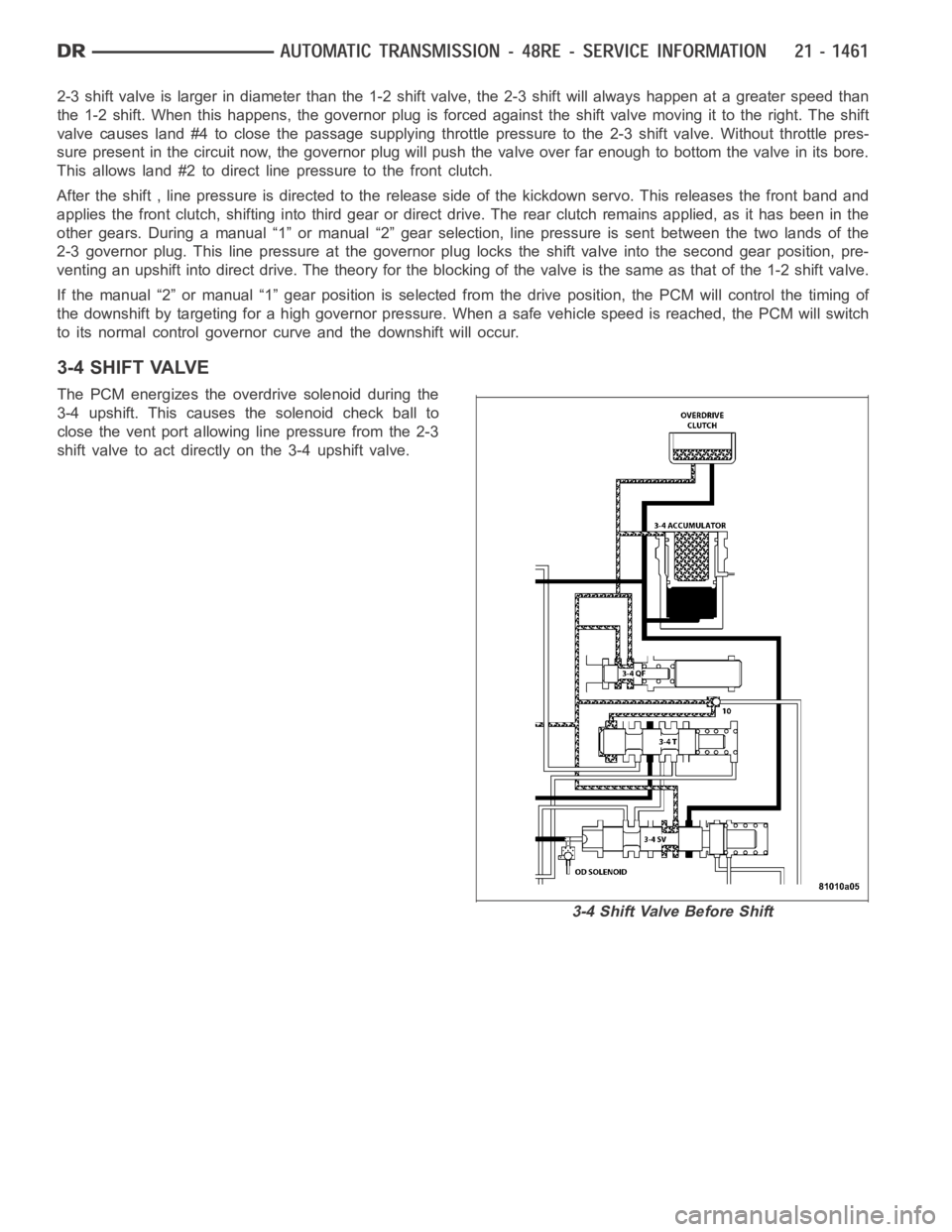

3-4 SHIFT VALVE

The PCM energizes the overdrive solenoid during the

3-4 upshift. This causes the solenoid check ball to

close the vent port allowing line pressure from the 2-3

shift valve to act directly on the 3-4 upshift valve.

3-4ShiftValveBeforeShift

Page 3989 of 5267

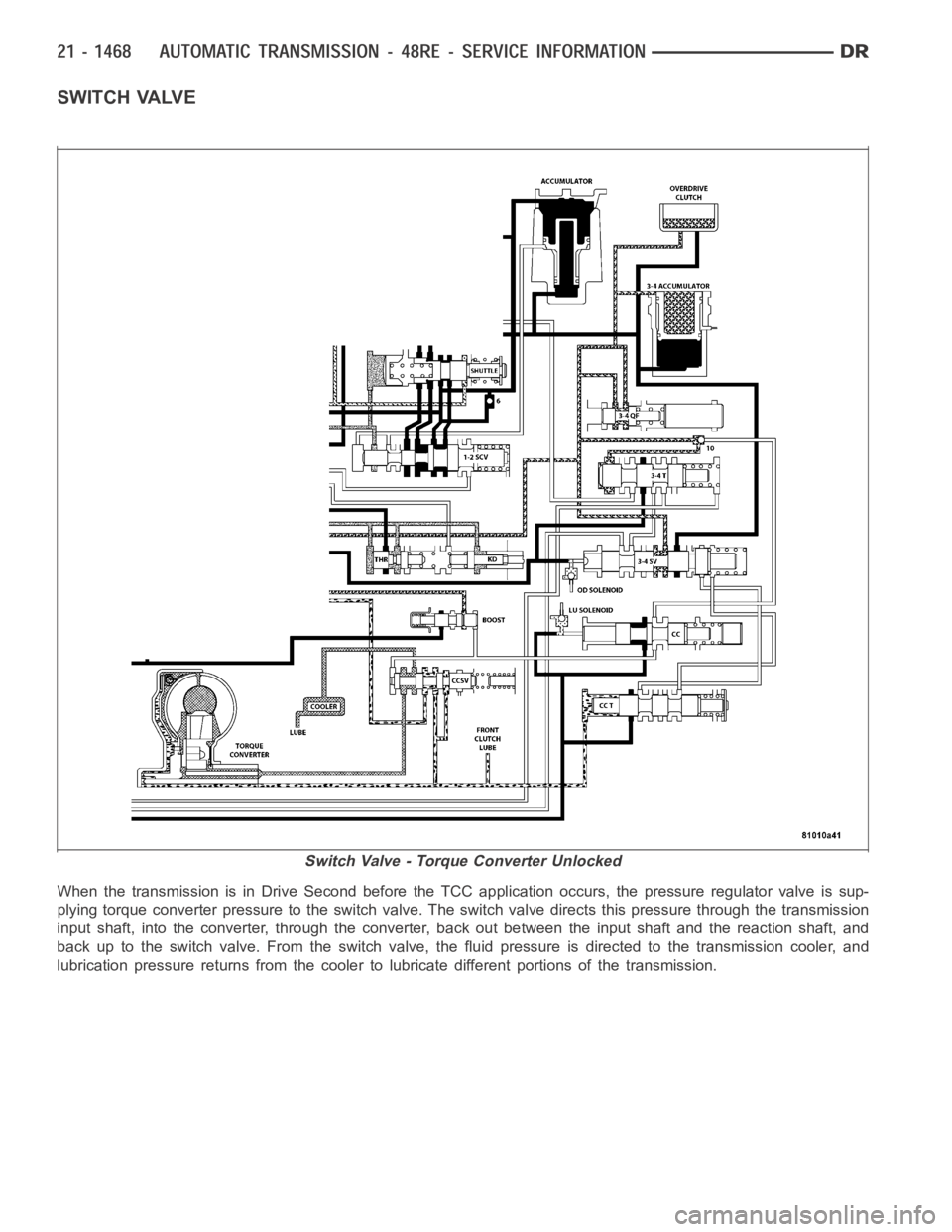

SWITCH VALVE

When the transmission is in Drive Second before the TCC application occurs, the pressure regulator valve is sup-

plying torque converter pressure to the switch valve. The switch valve directs this pressure through the transmission

input shaft, into the converter, through the converter, back out between the input shaft and the reaction shaft, and

back up to the switch valve. From the switch valve, the fluid pressure is directed to the transmission cooler, and

lubrication pressure returns from the cooler to lubricate different portions of the transmission.

Switch Valve - Torque Converter Unlocked

Page 3990 of 5267

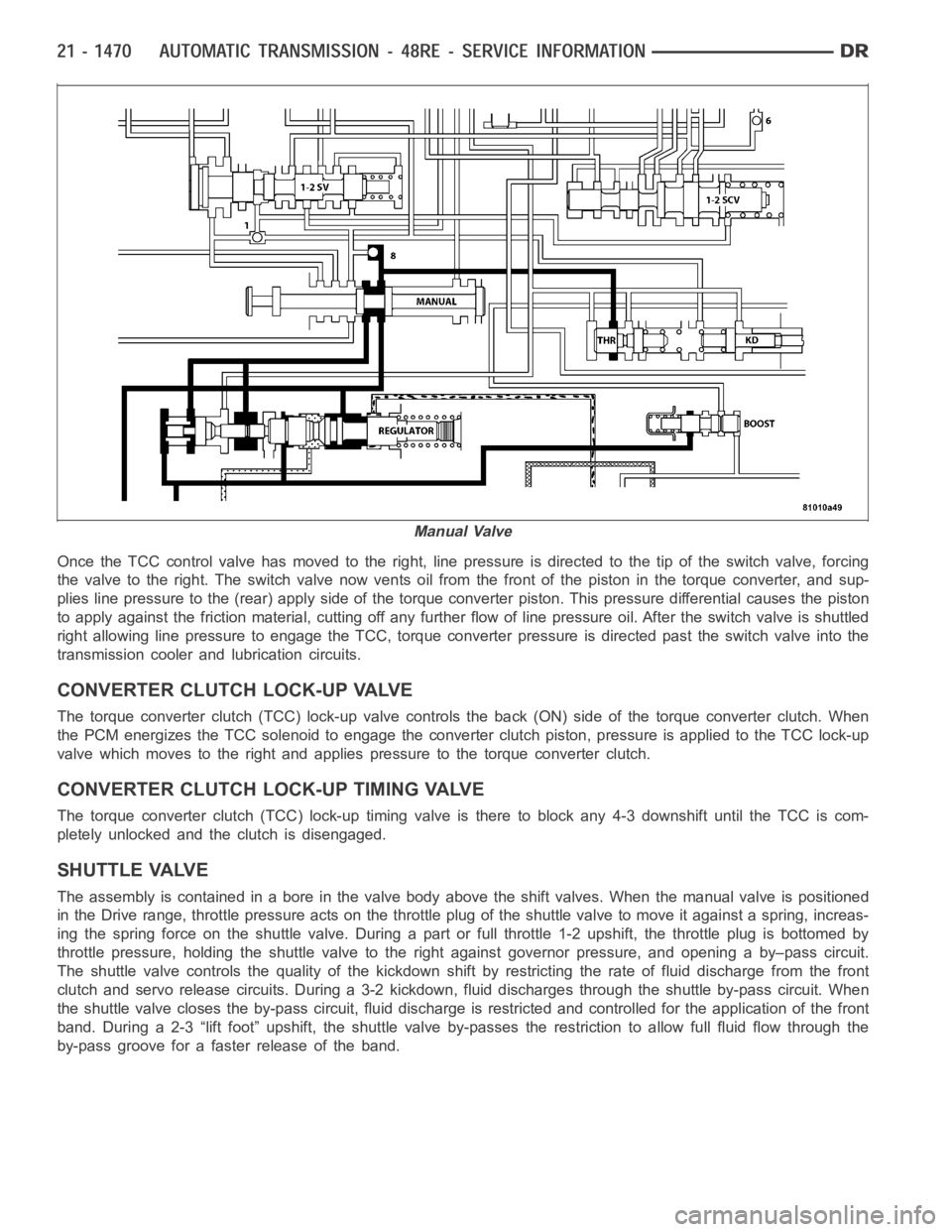

MANUAL VALVE

The manual valve is a relay valve. The purpose of the manual valve is to direct fluid to the correct circuit needed

for a specific gear or driving range. The manual valve, as the name implies,is manually operated by the driver with

a lever located on the side of the valve body. The valve is connected mechanically by either a cable or linkage to

the gearshift mechanism. The valve is held in each of its positions by a spring-loaded roller or ball that engages the

“roostercomb” of the manual valve lever.

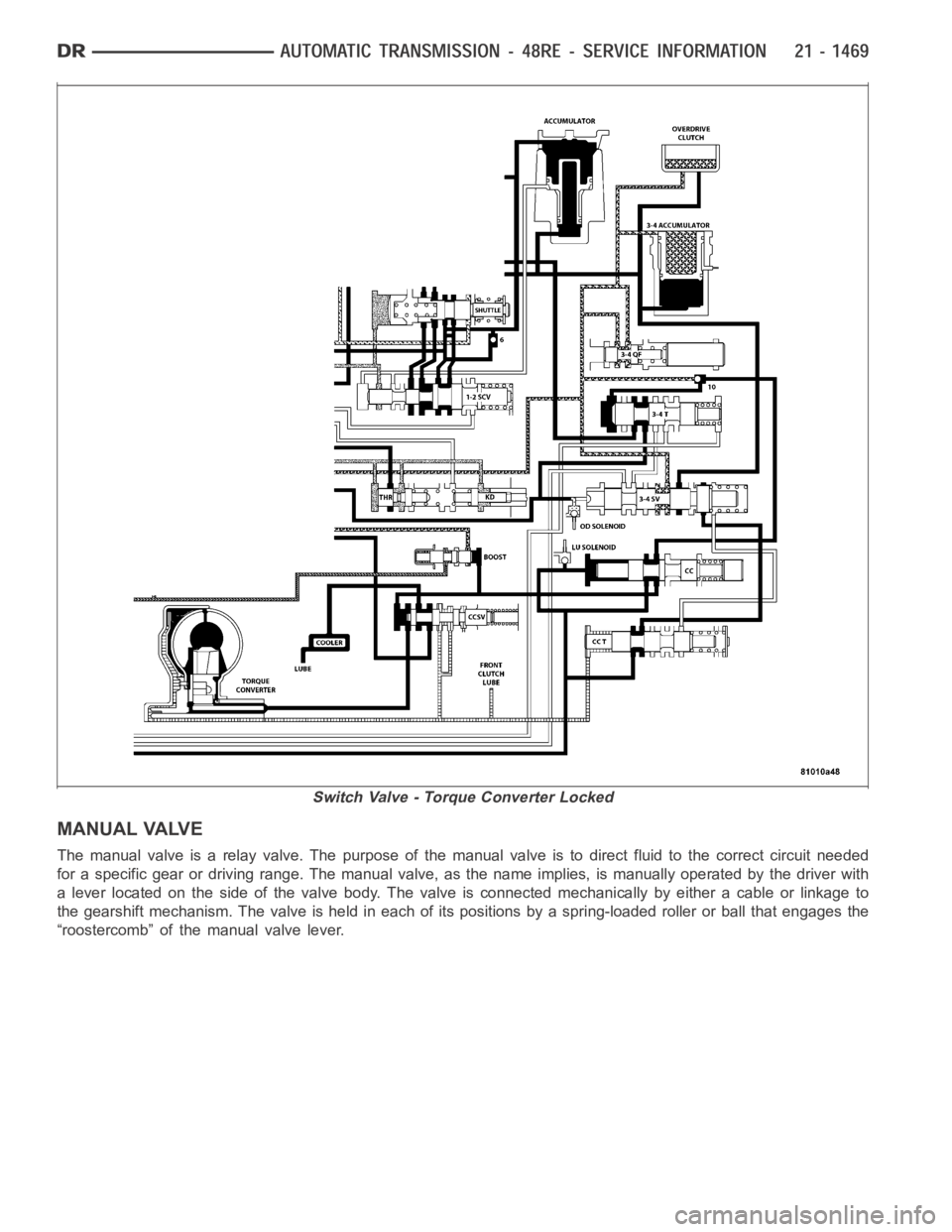

Switch Valve - Torque Converter Locked

Page 3991 of 5267

Once the TCC control valve has moved to the right, line pressure is directedto the tip of the switch valve, forcing

the valve to the right. The switch valve now vents oil from the front of the piston in the torque converter, and sup-

plies line pressure to the (rear) apply side of the torque converter piston. This pressure differential causes the piston

to apply against the friction material, cutting off any further flow of line pressure oil. After the switch valve is shuttled

right allowing line pressure to engage the TCC, torque converter pressureis directed past the switch valve into the

transmission cooler and lubrication circuits.

CONVERTER CLUTCH LOCK-UP VALVE

The torque converter clutch (TCC) lock-up valve controls the back (ON) side of the torque converter clutch. When

the PCM energizes the TCC solenoid to engage the converter clutch piston, pressure is applied to the TCC lock-up

valve which moves to the right and applies pressure to the torque converterclutch.

CONVERTER CLUTCH LOCK-UP TIMING VALVE

The torque converter clutch (TCC) lock-up timing valve is there to block any 4-3 downshift until the TCC is com-

pletely unlocked and the clutch is disengaged.

SHUTTLE VALVE

The assembly is contained in a bore in the valve body above the shift valves.When the manual valve is positioned

in the Drive range, throttle pressure acts on the throttle plug of the shuttle valve to move it against a spring, increas-

ing the spring force on the shuttle valve. During a part or full throttle 1-2upshift, the throttle plug is bottomed by

throttle pressure, holding the shuttle valve to the right against governor pressure, and opening a by–pass circuit.

The shuttle valve controls the quality of the kickdown shift by restricting the rate of fluid discharge from the front

clutch and servo release circuits. During a 3-2 kickdown, fluid discharges through the shuttle by-pass circuit. When

the shuttle valve closes the by-pass circuit, fluid discharge is restricted and controlled for the application of the front

band. During a 2-3 “lift foot” upshift, the shuttle valve by-passes the restriction to allow full fluid flow through the

by-pass groove for a faster release of the band.

Manual Valve

Page 3992 of 5267

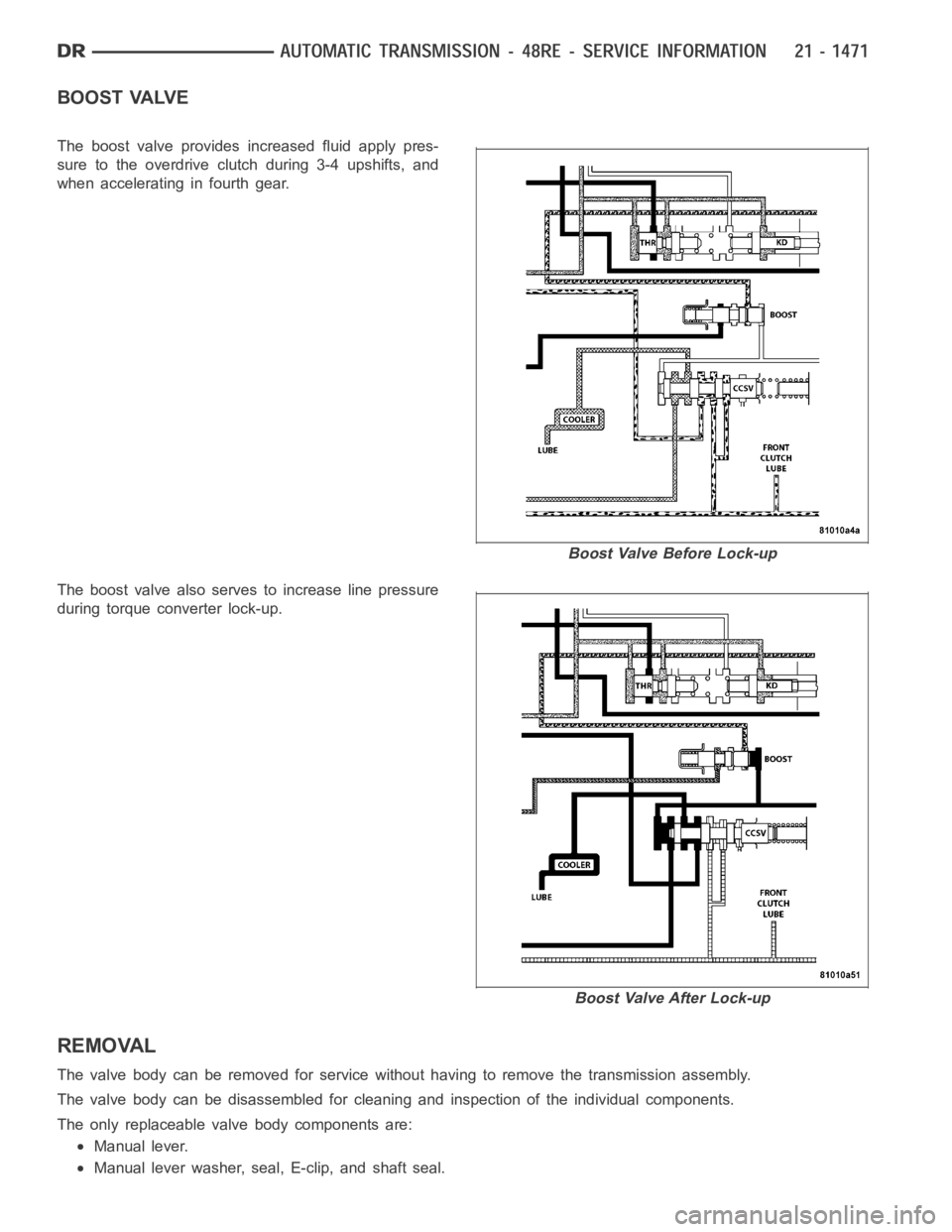

BOOST VALVE

The boost valve provides increased fluid apply pres-

sure to the overdrive clutch during 3-4 upshifts, and

when accelerating in fourth gear.

Theboostvalvealsoservestoincreaselinepressure

during torque converter lock-up.

REMOVAL

The valve body can be removed for service without having to remove the transmission assembly.

The valve body can be disassembled for cleaning and inspection of the individual components.

The only replaceable valve body components are:

Manual lever.

Manual lever washer, seal, E-clip, and shaft seal.

Boost Valve Before Lock-up

Boost Valve After Lock-up

Page 4006 of 5267

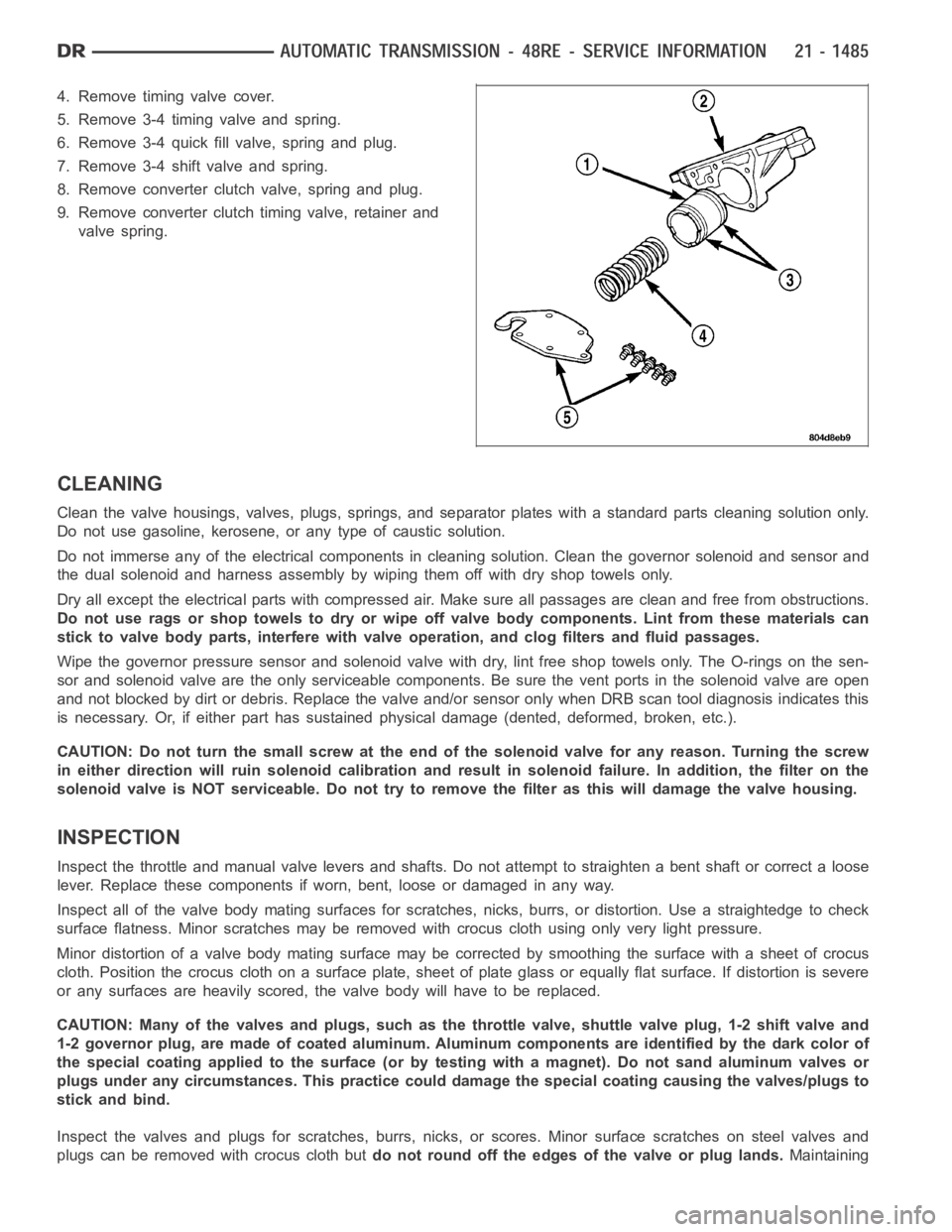

4. Remove timing valve cover.

5. Remove 3-4 timing valve and spring.

6. Remove 3-4 quick fill valve, spring and plug.

7. Remove 3-4 shift valve and spring.

8. Remove converter clutch valve, spring and plug.

9. Remove converter clutch timing valve, retainer and

valve spring.

CLEANING

Clean the valve housings, valves, plugs, springs, and separator plates with a standard parts cleaning solution only.

Do not use gasoline, kerosene, or any type of caustic solution.

Do not immerse any of the electrical components in cleaning solution. Clean the governor solenoid and sensor and

the dual solenoid and harness assembly by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed air. Make sure all passages are clean and free from obstructions.

Do not use rags or shop towels to dry or wipe off valve body components. Lint from these materials can

stick to valve body parts, interfere with valve operation, and clog filters and fluid passages.

Wipe the governor pressure sensor and solenoid valve with dry, lint free shop towels only. The O-rings on the sen-

sor and solenoid valve are the only serviceable components. Be sure the vent ports in the solenoid valve are open

and not blocked by dirt or debris. Replace the valve and/or sensor only whenDRB scan tool diagnosis indicates this

is necessary. Or, if either part has sustained physical damage (dented, deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of the solenoid valve for any reason. Turning the screw

in either direction will ruin solenoid calibration and result in solenoidfailure. In addition, the filter on the

solenoid valve is NOT serviceable. Do not try to remove the filter as this will damage the valve housing.

INSPECTION

Inspect the throttle and manual valve levers and shafts. Do not attempt to straighten a bent shaft or correct a loose

lever. Replace these components if worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for scratches, nicks, burrs,or distortion. Use a straightedge to check

surface flatness. Minor scratches may be removed with crocus cloth using only very light pressure.

Minor distortion of a valve body mating surface may be corrected by smoothing the surface with a sheet of crocus

cloth. Position the crocus cloth on a surface plate, sheet of plate glass orequally flat surface. If distortion is severe

or any surfaces are heavily scored, the valve body will have to be replaced.

CAUTION: Many of the valves and plugs, such as the throttle valve, shuttle valve plug, 1-2 shift valve and

1-2 governor plug, are made of coated aluminum. Aluminum components are identified by the dark color of

thespecialcoatingappliedtothesurface(orbytestingwithamagnet).Donot sand aluminum valves or

plugs under any circumstances. This practice could damage the special coating causing the valves/plugs to

stick and bind.

Inspect the valves and plugs for scratches, burrs, nicks, or scores. Minorsurface scratches on steel valves and

plugs can be removed with crocus cloth butdo not round off the edges of the valve or plug lands.Maintaining

Page 4007 of 5267

sharpness of these edges is vitally important. The edges prevent foreign matter from lodging between the valves

and plugs and the bore.

Inspect all the valve and plug bores in the valve body. Use a penlight to viewthe bore interiors. Replace the valve

body if any bores are distorted or scored. Inspect all of the valve body springs. The springs must be free of dis-

tortion, warpage or broken coils.

Check the two separator plates for distortion or damage of any kind. Inspect the upper housing, lower housing, 3-4

accumulator housing, and transfer plate carefully. Be sure all fluid passages are clean and clear. Check condition of

the upper housing and transfer plate check balls as well. The check balls and ball seats must not be worn or dam-

aged.

Trial fit each valve and plug in its bore to check freedom of operation. Whenclean and dry, the valves and plugs

shoulddropfreelyintothebores.

Valve body bores do not change dimensionally with use. If the valve body functioned correctly when new, it will

continue to operate properly after cleaning and inspection. It should notbe necessary to replace a valve body

assembly unless it is damaged in handling.

The only serviceable valve body components are listed below. The remaining valve body components are serviced

only as part of a complete valve body assembly. Serviceable parts are:

dual solenoid and harness assembly

solenoid gasket

solenoid case connector O-rings and shoulder bolt

switch valve and spring

pressure adjusting screw and bracket assembly

throttle lever

manual lever and shaft seal

throttle lever shaft seal, washer, and E-clip

fluid filter and screws

detent ball and spring

valve body screws

governor pressure solenoid

governor pressure sensor and retaining clip

park lock rod and E-clip

ASSEMBLY

CAUTION: Do not force valves or plugs into place during reassembly. If the valve body bores, valves and

plugs are free of distortion or burrs, the valve body components should allslide into place easily. In addi-

tion, do not overtighten the transfer plate and valve body screws during reassembly. Overtightening can

distort the housings resulting in valve sticking, cross leakage and unsatisfactory operation. Tighten valve

body screws to recommended torque only.