lock DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4018 of 5267

INSTALLATION

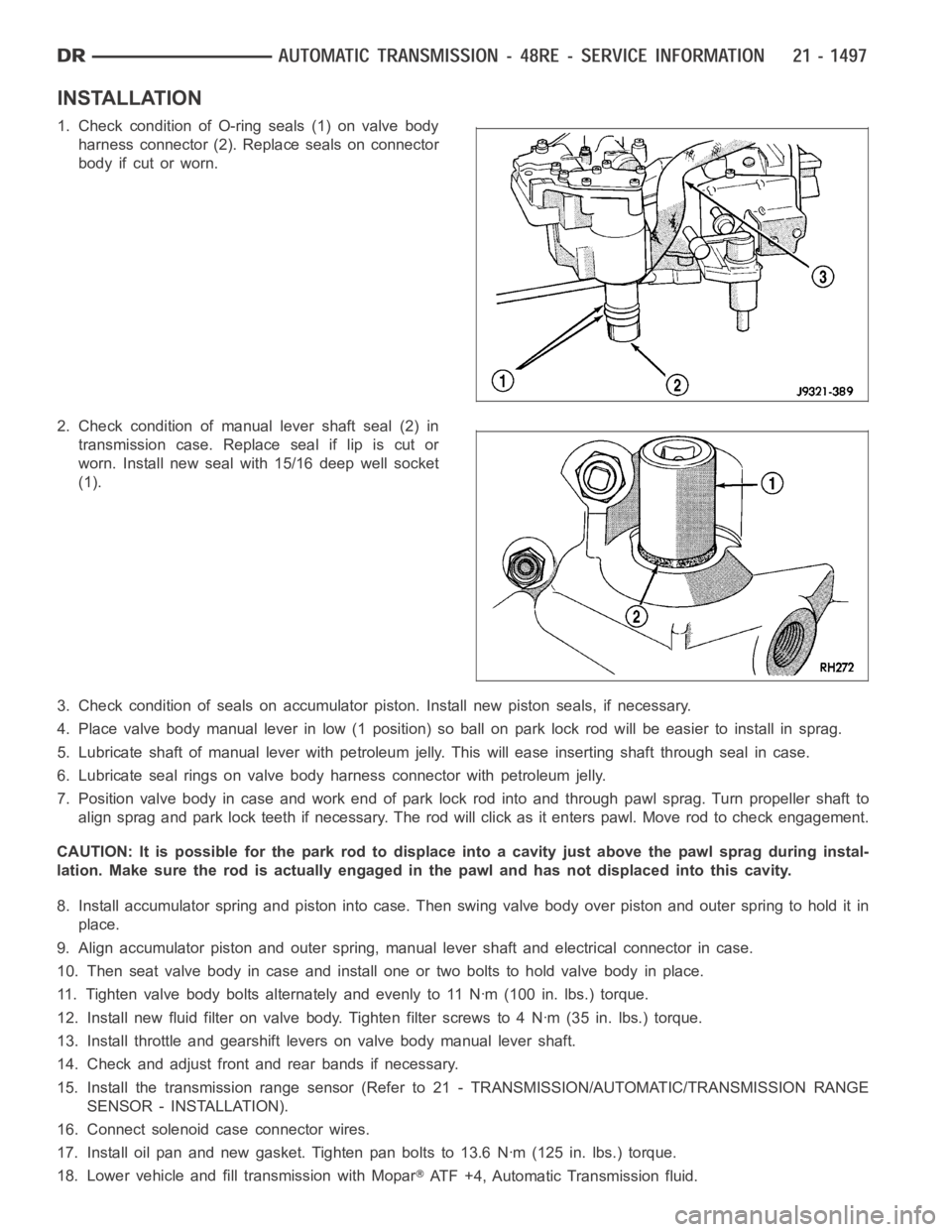

1. Check condition of O-ring seals (1) on valve body

harness connector (2). Replace seals on connector

body if cut or worn.

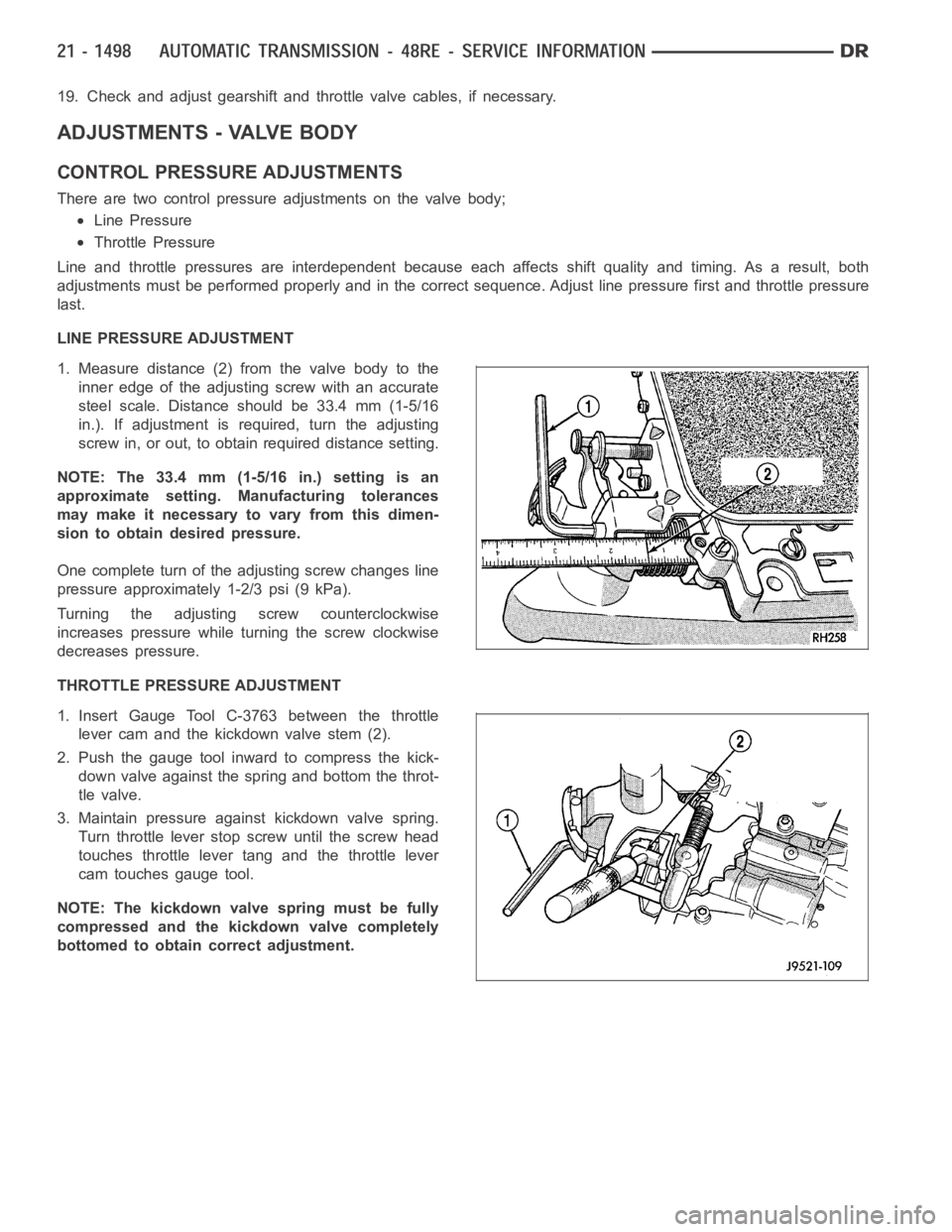

2. Check condition of manual lever shaft seal (2) in

transmission case. Replace seal if lip is cut or

worn. Install new seal with 15/16 deep well socket

(1).

3. Check condition of seals on accumulator piston. Install new piston seals, if necessary.

4. Place valve body manual lever in low (1 position) so ball on park lock rod will be easier to install in sprag.

5. Lubricate shaft of manual lever with petroleum jelly. This will ease inserting shaft through seal in case.

6. Lubricate seal rings on valve body harness connector with petroleum jelly.

7. Position valve body in case and work end of park lock rod into and through pawl sprag. Turn propeller shaft to

align sprag and park lock teeth if necessary. The rod will click as it enterspawl. Move rod to check engagement.

CAUTION: It is possible for the park rod to displace into a cavity just abovethe pawl sprag during instal-

lation. Make sure the rod is actually engaged in the pawl and has not displaced into this cavity.

8. Install accumulator spring and piston into case. Then swing valve body overpistonandouterspringtoholditin

place.

9. Align accumulator piston and outer spring, manual lever shaft and electrical connector in case.

10. Then seat valve body in case and install one or two bolts to hold valve bodyinplace.

11. Tighten valve body bolts alternately and evenly to 11 Nꞏm (100 in. lbs.)torque.

12. Install new fluid filter on valve body. Tighten filter screws to 4 Nꞏm (35 in. lbs.) torque.

13. Install throttle and gearshift levers on valve body manual lever shaft.

14. Check and adjust front and rear bands if necessary.

15. Install the transmission range sensor (Refer to 21 - TRANSMISSION/AUTOMATIC/TRANSMISSION RANGE

SENSOR - INSTALLATION).

16. Connect solenoid case connector wires.

17. Install oil pan and new gasket. Tighten pan bolts to 13.6 Nꞏm (125 in. lbs.) torque.

18. Lower vehicle and fill transmission with Mopar

ATF +4, Automatic Transmission fluid.

Page 4019 of 5267

19. Check and adjust gearshift and throttle valve cables, if necessary.

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the valve body;

Line Pressure

Throttle Pressure

Line and throttle pressures are interdependent because each affects shift quality and timing. As a result, both

adjustments must be performed properly and in the correct sequence. Adjust line pressure first and throttle pressure

last.

LINE PRESSURE ADJUSTMENT

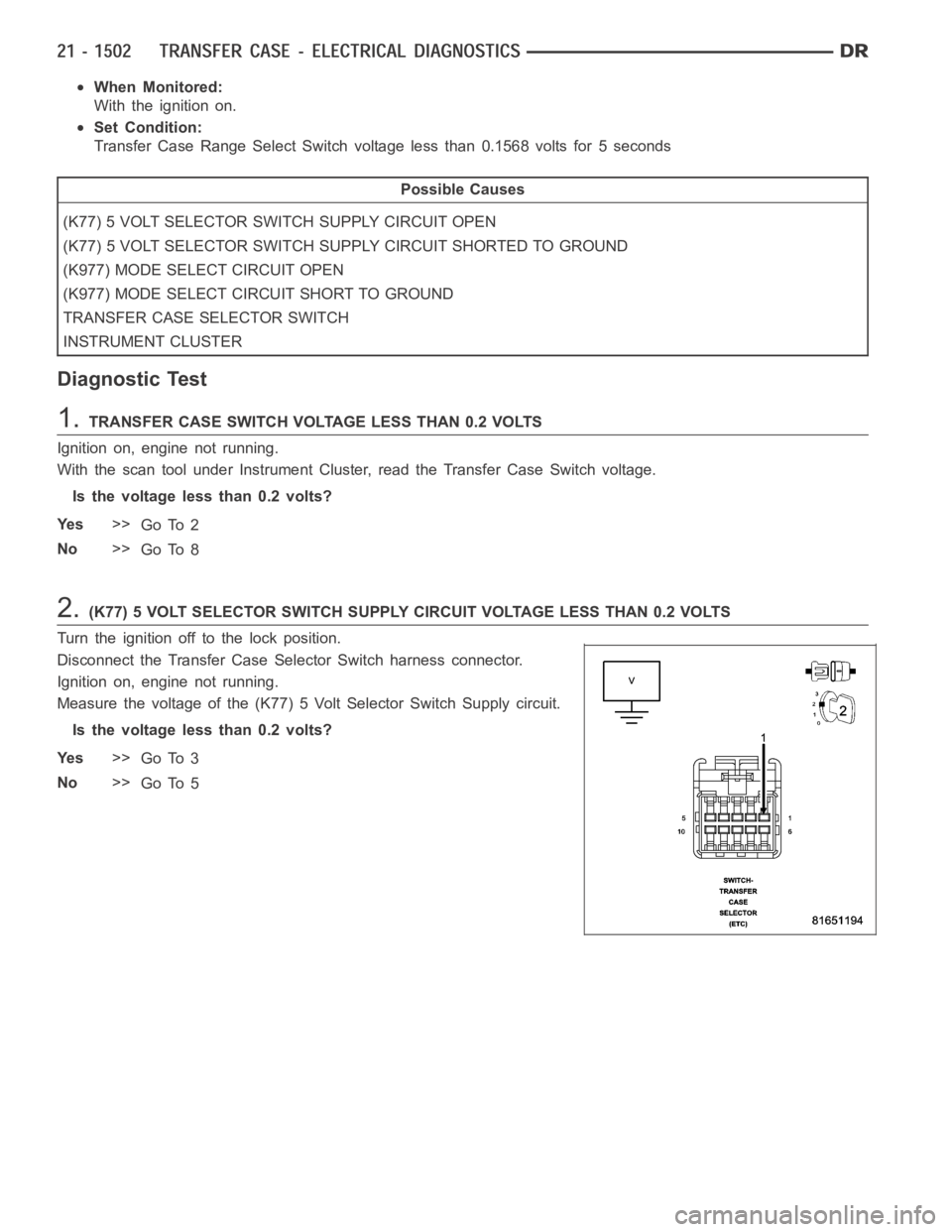

1. Measure distance (2) from the valve body to the

inner edge of the adjusting screw with an accurate

steel scale. Distance should be 33.4 mm (1-5/16

in.). If adjustment is required, turn the adjusting

screw in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances

may make it necessary to vary from this dimen-

sion to obtain desired pressure.

One complete turn of the adjusting screw changes line

pressure approximately 1-2/3 psi (9 kPa).

Turning the adjustingscrew counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.

THROTTLE PRESSURE ADJUSTMENT

1. Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (2).

2. Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

3. Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever

cam touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Page 4023 of 5267

When Monitored:

With the ignition on.

Set Condition:

Transfer Case Range Select Switch voltage less than 0.1568 volts for 5 seconds

Possible Causes

(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT OPEN

(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT SHORTED TO GROUND

(K977) MODE SELECT CIRCUIT OPEN

(K977) MODE SELECT CIRCUIT SHORT TO GROUND

TRANSFER CASE SELECTOR SWITCH

INSTRUMENT CLUSTER

Diagnostic Test

1.TRANSFER CASE SWITCH VOLTAGE LESS THAN 0.2 VOLTS

Ignition on, engine not running.

With the scan tool under Instrument Cluster, read the Transfer Case Switchvoltage.

Is the voltage less than 0.2 volts?

Ye s>>

Go To 2

No>>

Go To 8

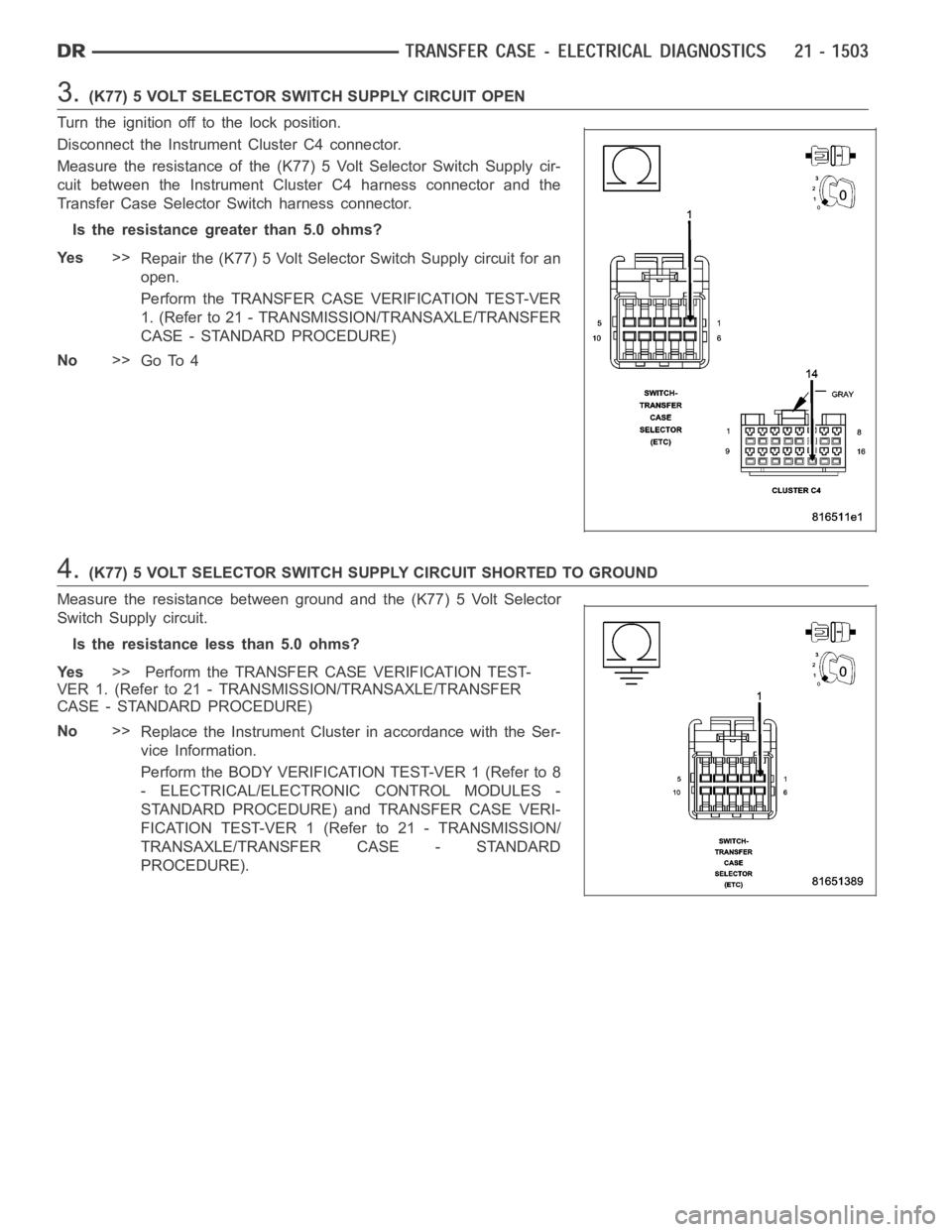

2.(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT VOLTAGE LESS THAN 0.2 VOLTS

Turn the ignition off to the lock position.

Disconnect the Transfer Case Selector Switch harness connector.

Ignition on, engine not running.

Measure the voltage of the (K77) 5 Volt Selector Switch Supply circuit.

Is the voltage less than 0.2 volts?

Ye s>>

Go To 3

No>>

Go To 5

Page 4024 of 5267

3.(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT OPEN

Turn the ignition off to the lock position.

Disconnect the Instrument Cluster C4 connector.

Measure the resistance of the (K77) 5 Volt Selector Switch Supply cir-

cuit between the Instrument Cluster C4 harness connector and the

Transfer Case Selector Switch harness connector.

Is the resistance greater than 5.0 ohms?

Ye s>>

Repair the (K77) 5 Volt Selector Switch Supply circuit for an

open.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go To 4

4.(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (K77) 5 Volt Selector

Switch Supply circuit.

Is the resistance less than 5.0 ohms?

Ye s>> Perform the TRANSFER CASE VERIFICATION TEST-

VER 1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Replace the Instrument Cluster in accordance with the Ser-

vice Information.

Perform the BODY VERIFICATION TEST-VER 1 (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE) and TRANSFER CASE VERI-

FICATION TEST-VER 1 (Refer to 21 - TRANSMISSION/

TRANSAXLE/TRANSFER CASE - STANDARD

PROCEDURE).

Page 4025 of 5267

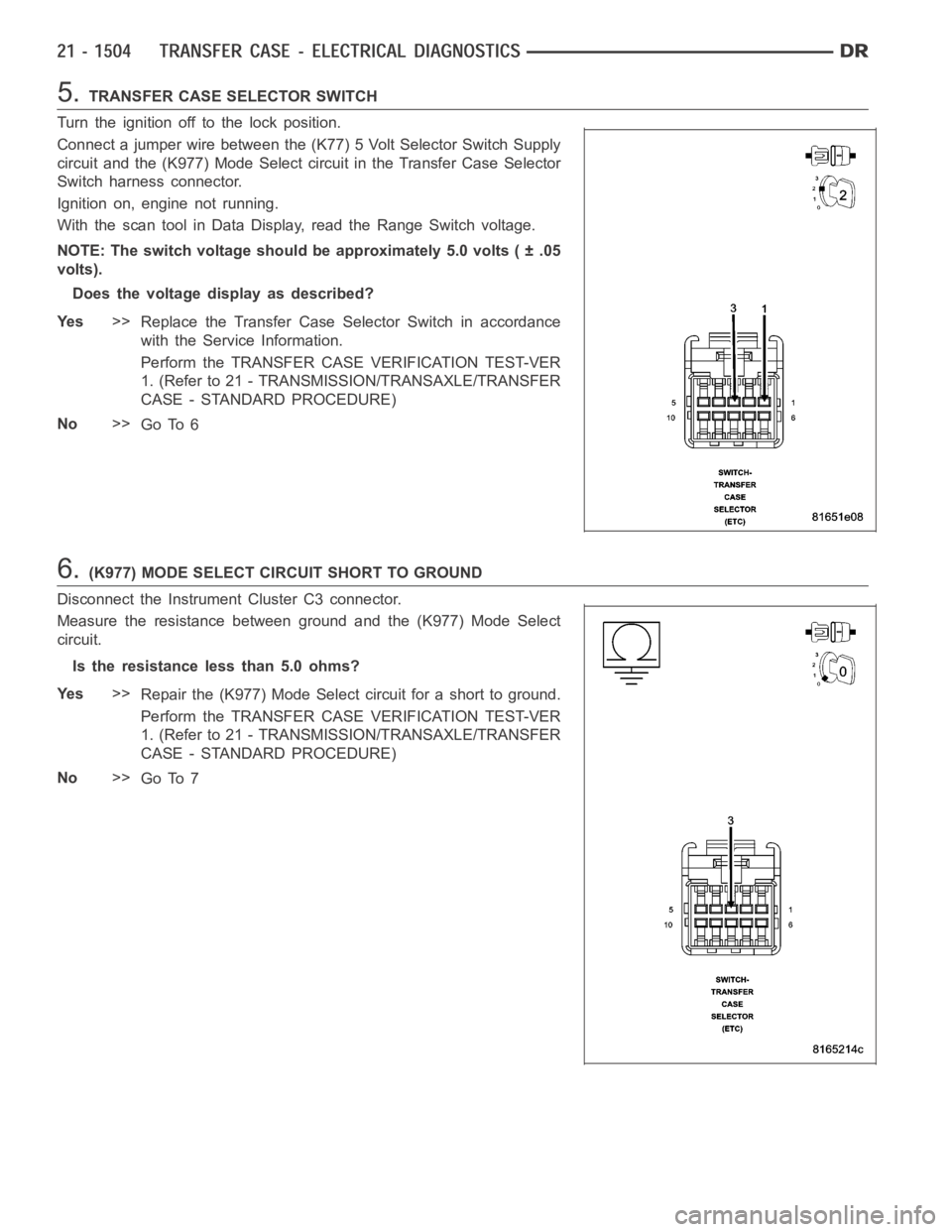

5.TRANSFER CASE SELECTOR SWITCH

Turn the ignition off to the lock position.

Connect a jumper wire between the (K77) 5 Volt Selector Switch Supply

circuit and the (K977) Mode Select circuit in the Transfer Case Selector

Switch harness connector.

Ignition on, engine not running.

With the scan tool in Data Display, read the Range Switch voltage.

NOTE: The switch voltage should be approximately 5.0 volts ( ± .05

volts).

Does the voltage display as described?

Ye s>>

Replace the Transfer Case Selector Switch in accordance

with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go To 6

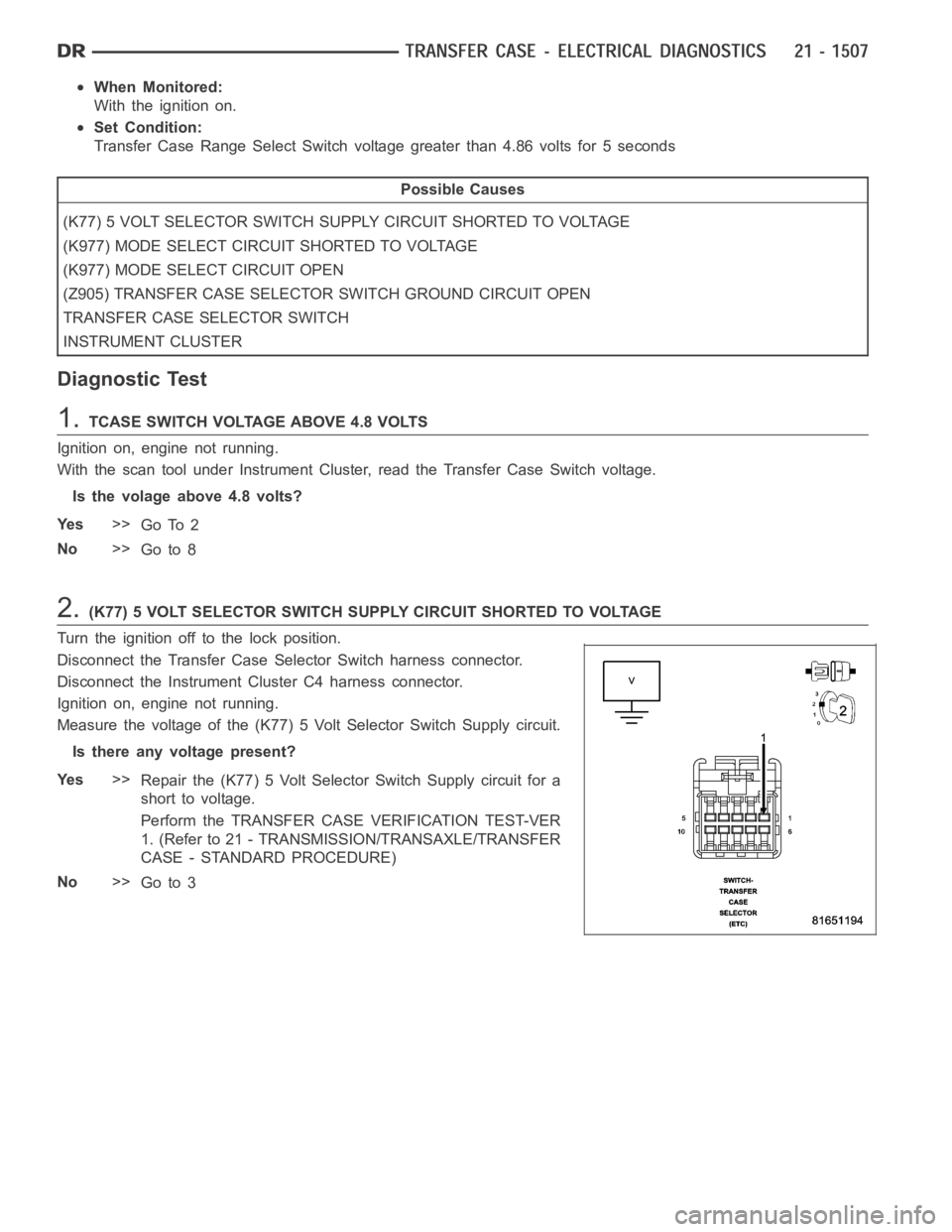

6.(K977) MODE SELECT CIRCUIT SHORT TO GROUND

Disconnect the Instrument Cluster C3 connector.

Measure the resistance between ground and the (K977) Mode Select

circuit.

Is the resistance less than 5.0 ohms?

Ye s>>

Repair the (K977) Mode Select circuit for a short to ground.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go To 7

Page 4028 of 5267

When Monitored:

With the ignition on.

Set Condition:

Transfer Case Range Select Switch voltage greater than 4.86 volts for 5 seconds

Possible Causes

(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT SHORTED TO VOLTAGE

(K977) MODE SELECT CIRCUIT SHORTED TO VOLTAGE

(K977) MODE SELECT CIRCUIT OPEN

(Z905) TRANSFER CASE SELECTOR SWITCH GROUND CIRCUIT OPEN

TRANSFER CASE SELECTOR SWITCH

INSTRUMENT CLUSTER

Diagnostic Test

1.TCASE SWITCH VOLTAGE ABOVE 4.8 VOLTS

Ignition on, engine not running.

With the scan tool under Instrument Cluster, read the Transfer Case Switchvoltage.

Is the volage above 4.8 volts?

Ye s>>

Go To 2

No>>

Go to 8

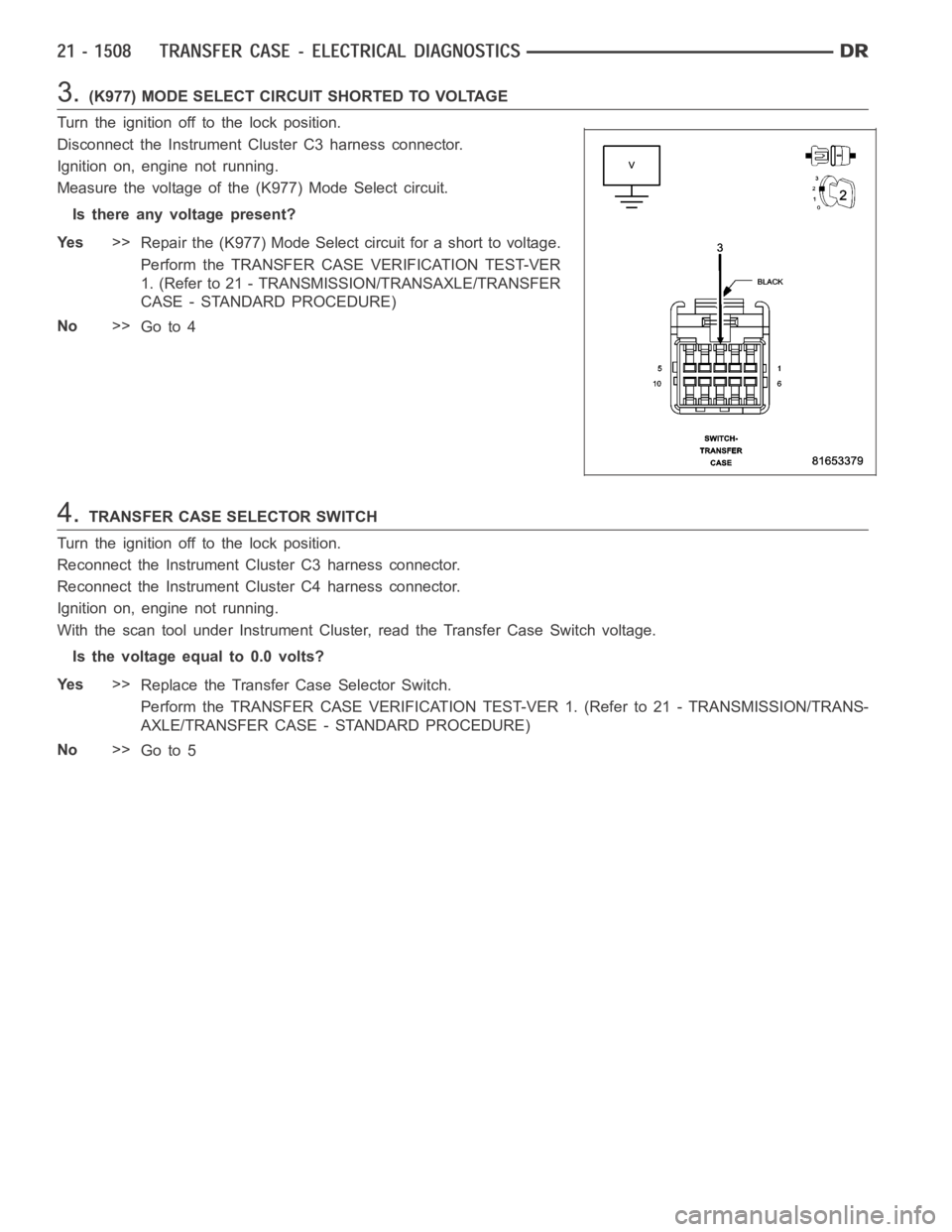

2.(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT SHORTED TO VOLTAGE

Turn the ignition off to the lock position.

Disconnect the Transfer Case Selector Switch harness connector.

Disconnect the Instrument Cluster C4 harness connector.

Ignition on, engine not running.

Measure the voltage of the (K77) 5 Volt Selector Switch Supply circuit.

Is there any voltage present?

Ye s>>

Repair the (K77) 5 Volt Selector Switch Supply circuit for a

short to voltage.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 3

Page 4029 of 5267

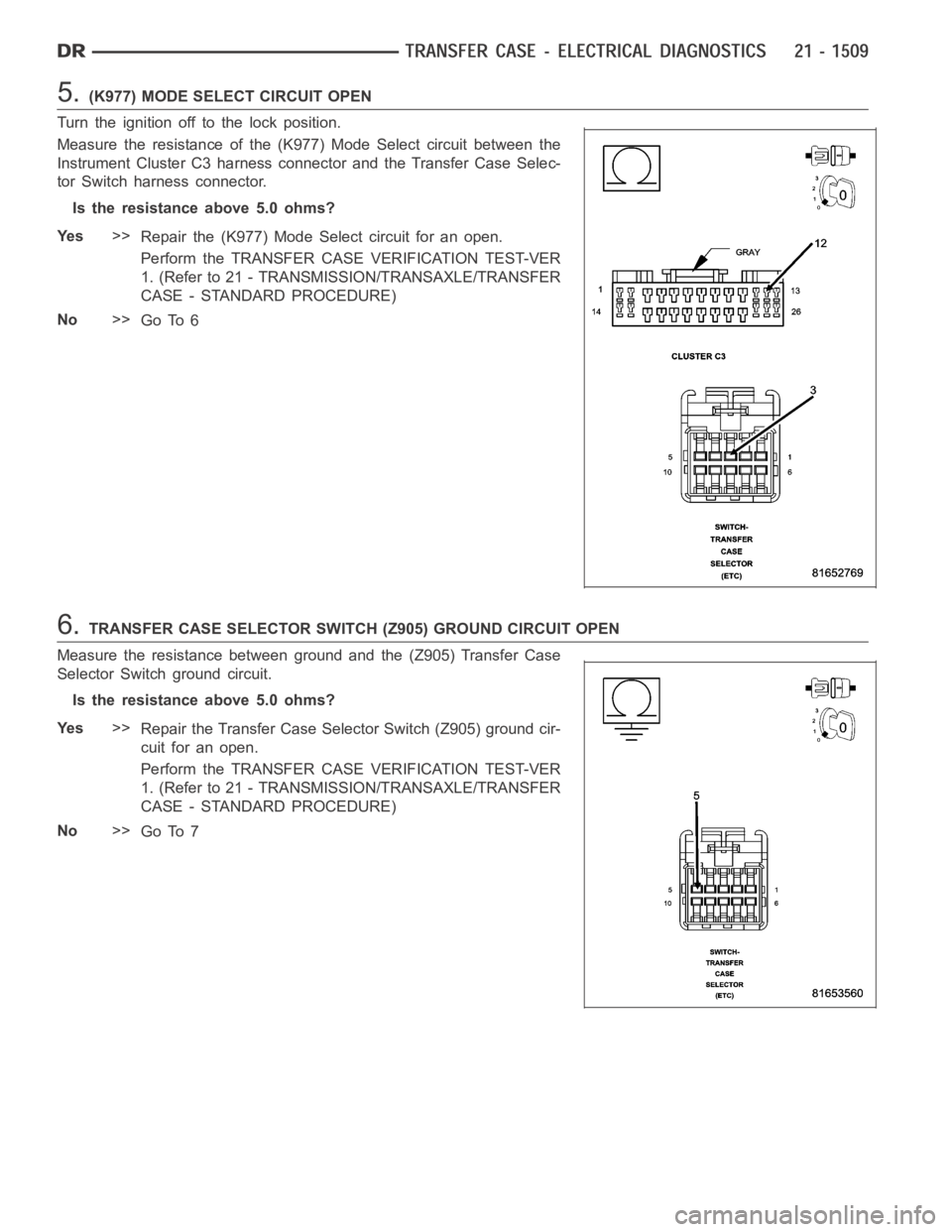

3.(K977) MODE SELECT CIRCUIT SHORTED TO VOLTAGE

Turn the ignition off to the lock position.

Disconnect the Instrument Cluster C3 harness connector.

Ignition on, engine not running.

Measure the voltage of the (K977) Mode Select circuit.

Is there any voltage present?

Ye s>>

Repair the (K977) Mode Select circuit for a short to voltage.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 4

4.TRANSFER CASE SELECTOR SWITCH

Turn the ignition off to the lock position.

Reconnect the Instrument Cluster C3 harness connector.

Reconnect the Instrument Cluster C4 harness connector.

Ignition on, engine not running.

With the scan tool under Instrument Cluster, read the Transfer Case Switchvoltage.

Is the voltage equal to 0.0 volts?

Ye s>>

Replace the Transfer Case Selector Switch.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Go to 5

Page 4030 of 5267

5.(K977) MODE SELECT CIRCUIT OPEN

Turn the ignition off to the lock position.

Measure the resistance of the (K977) Mode Select circuit between the

Instrument Cluster C3 harness connector and the Transfer Case Selec-

tor Switch harness connector.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (K977) Mode Select circuit for an open.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go To 6

6.TRANSFER CASE SELECTOR SWITCH (Z905) GROUND CIRCUIT OPEN

Measure the resistance between ground and the (Z905) Transfer Case

Selector Switch ground circuit.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the Transfer Case Selector Switch (Z905) ground cir-

cuit for an open.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go To 7

Page 4033 of 5267

When Monitored:

Ignition on. Battery voltage between 9.0 and 16.0 volts.

Set Condition:

The TIPM detects a short to ground on the Transfer Case Position Sensor Signal circuit for 2.0 seconds.

Possible Causes

(T103) 5 VOLT SUPPLY CIRCUIT OPEN

(T103) 5 VOLT SUPPLY CIRCUIT SHORTED TO GROUND

(D201) MODE SENSOR A CIRCUIT SHORTED TO GROUND

(D201) MODE SENSOR A CIRCUIT SHORTED TO (G180) SENSOR RETURN CIRCUIT

SHIFT MOTOR/MODE SENSOR ASSEMBLY

TOTALLY INTERGRATED POWER MODULE (TIPM)

Diagnostic Test

1.T-CASE POSITION SENSOR VOLTAGE BELOW 0.2 VOLTS

Ignition on, engine not running.

With the scan tool under TIPM, read the T-Case Position Sensor voltage.

Is the voltage below 0.2 volts?

Ye s>>

Go to 2

No>>

Go to 8

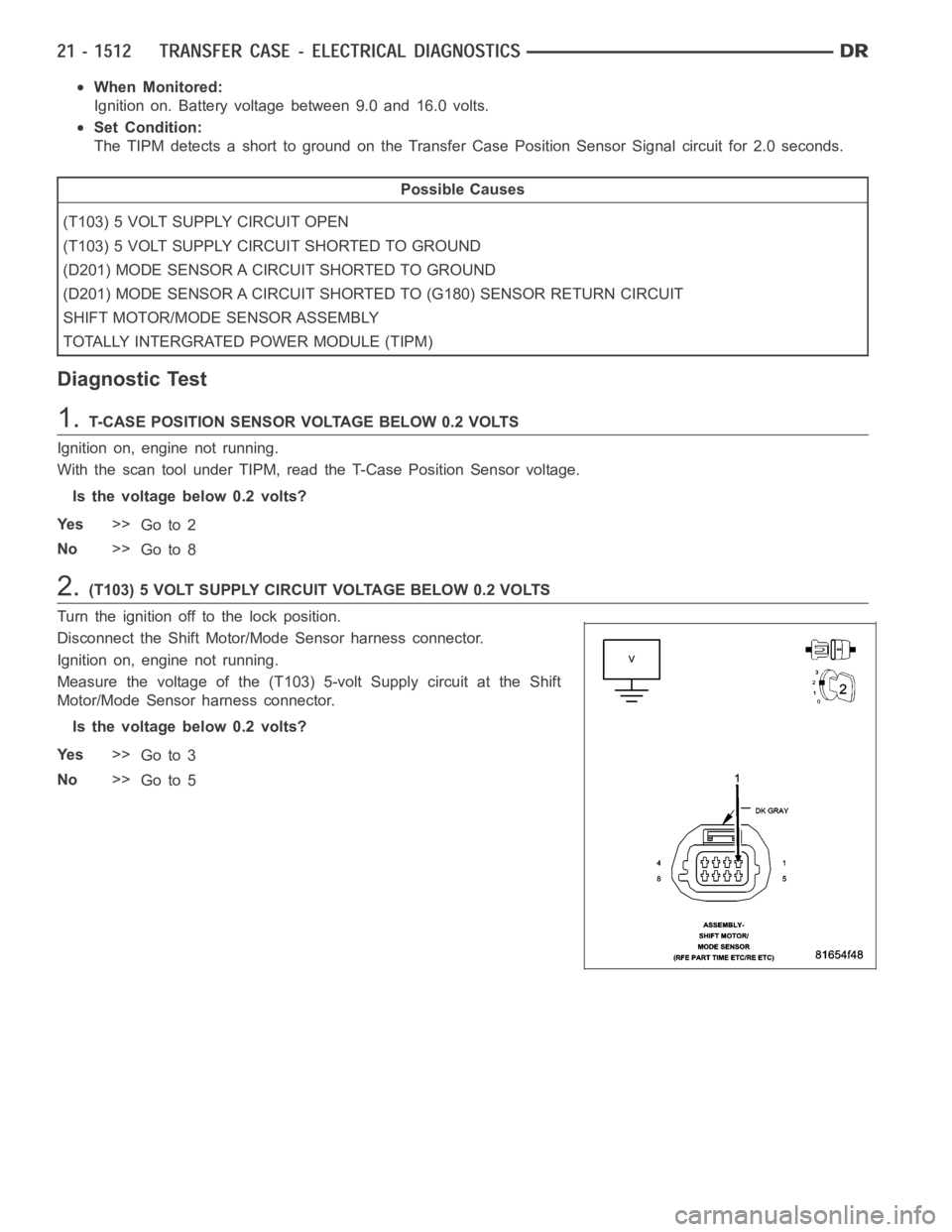

2.(T103) 5 VOLT SUPPLY CIRCUIT VOLTAGE BELOW 0.2 VOLTS

Turn the ignition off to the lock position.

Disconnect the Shift Motor/Mode Sensor harness connector.

Ignition on, engine not running.

Measure the voltage of the (T103) 5-volt Supply circuit at the Shift

Motor/Mode Sensor harness connector.

Is the voltage below 0.2 volts?

Ye s>>

Go to 3

No>>

Go to 5

Page 4034 of 5267

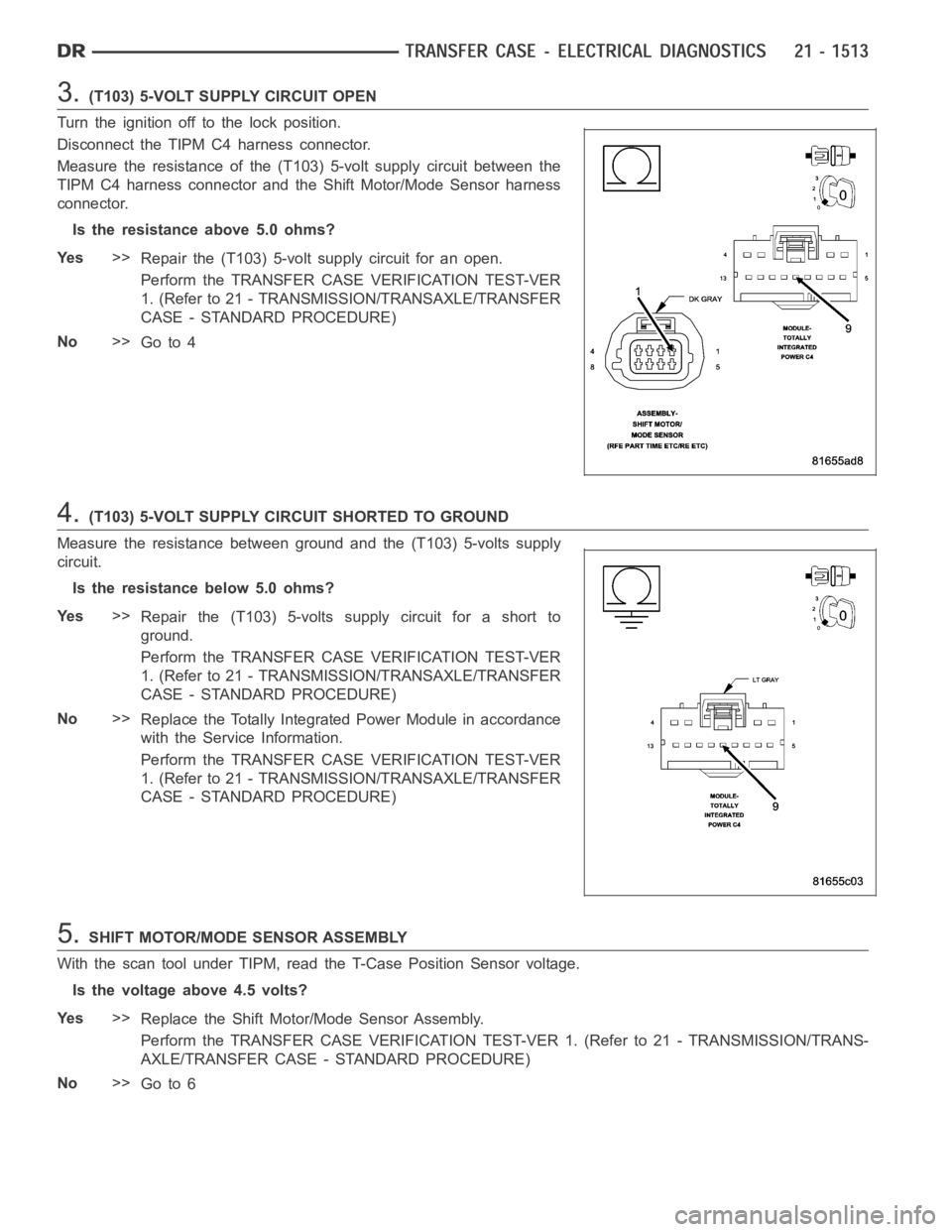

3.(T103) 5-VOLT SUPPLY CIRCUIT OPEN

Turn the ignition off to the lock position.

Disconnect the TIPM C4 harness connector.

Measure the resistance of the (T103) 5-volt supply circuit between the

TIPM C4 harness connector and the Shift Motor/Mode Sensor harness

connector.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T103) 5-volt supply circuit for an open.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 4

4.(T103) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (T103) 5-volts supply

circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (T103) 5-volts supply circuit for a short to

ground.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module in accordance

with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

5.SHIFT MOTOR/MODE SENSOR ASSEMBLY

With the scan tool under TIPM, read the T-Case Position Sensor voltage.

Is the voltage above 4.5 volts?

Ye s>>

Replace the Shift Motor/Mode Sensor Assembly.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Go to 6