light DODGE SPRINTER 2006 1.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: SPRINTER, Model: DODGE SPRINTER 2006 1.GPages: 330, PDF Size: 10.82 MB

Page 193 of 330

STARTING AND OPERATING 193

5

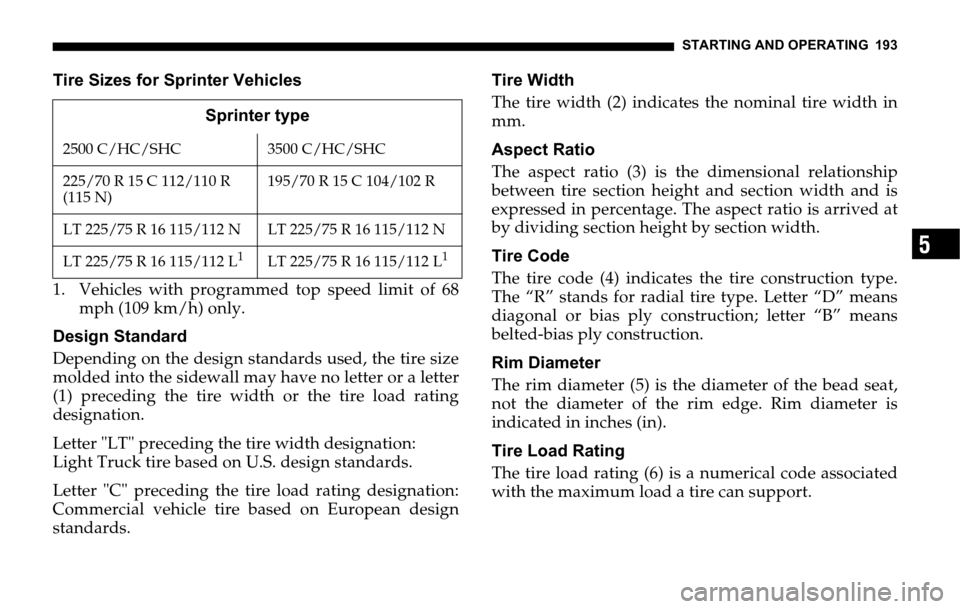

Tire Sizes for Sprinter Vehicles

1. Vehicles with programmed top speed limit of 68

mph (109 km/h) only.

Design Standard

Depending on the design standards used, the tire size

molded into the sidewall may have no letter or a letter

(1) preceding the tire width or the tire load rating

designation.

Letter "LT" preceding the tire width designation:

Light Truck tire based on U.S. design standards.

Letter "C" preceding the tire load rating designation:

Commercial vehicle tire based on European design

standards.Tire Width

The tire width (2) indicates the nominal tire width in

mm.

Aspect Ratio

The aspect ratio (3) is the dimensional relationship

between tire section height and section width and is

expressed in percentage. The aspect ratio is arrived at

by dividing section height by section width.

Tire Code

The tire code (4) indicates the tire construction type.

The “R” stands for radial tire type. Letter “D” means

diagonal or bias ply construction; letter “B” means

belted-bias ply construction.

Rim Diameter

The rim diameter (5) is the diameter of the bead seat,

not the diameter of the rim edge. Rim diameter is

indicated in inches (in).

Tire Load Rating

The tire load rating (6) is a numerical code associated

with the maximum load a tire can support. Sprinter type

2500 C/HC/SHC 3500 C/HC/SHC

225/70 R 15 C 112/110 R

(115 N)195/70 R 15 C 104/102 R

LT 225/75 R 16 115/112 N LT 225/75 R 16 115/112 N

LT 225/75 R 16 115/112 L

1LT 225/75 R 16 115/112 L1

Page 214 of 330

214 STARTING AND OPERATING

BLEEDING DIESEL FUEL SYSTEM

If the fuel tank was run empty, the diesel fuel system

must be bled after refueling before starting the engine.

Turn the key in the ignition lock to position 2 for at

least 30 seconds.

Return the key to position 0.

Start the engine three to four times.

The malfunction indicator light (MIL) ± must go

out.

NOTE: Too many attempts to start the engine could

drain the battery. If the engine does not start after

several attempts, consult an authorized Sprinter

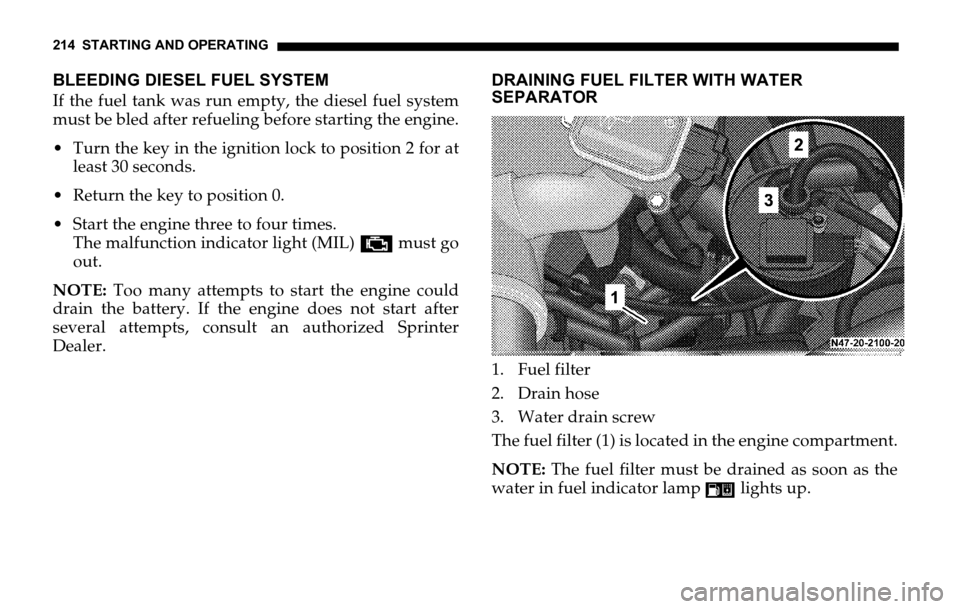

Dealer.DRAINING FUEL FILTER WITH WATER

SEPARATOR

1. Fuel filter

2. Drain hose

3. Water drain screw

The fuel filter (1) is located in the engine compartment.

NOTE: The fuel filter must be drained as soon as the

water in fuel indicator lamp lights up.

Page 215 of 330

STARTING AND OPERATING 215

5

NOTE: Prior to opening water drain screw (3), place a

suitable receptacle underneath the drain hose (2). Turn

water drain screw (3) on and off only by hand.

Diesel fuels and diesel fuel mixtures must be disposed

of properly; we recommend water be drained from fuel

filters by an authorized Sprinter Dealer.

Draining Fuel Filter

Stop the engine.

Shift gear selector lever to ‘‘P’’ position.

Open the hood.

Place a suitable receptacle underneath the drain

hose (2).

Turn the key in the ignition lock to position 2. Open immediately the water drain screw (3) about 1

turn (counterclockwise) until fluid emerges. Ensure

that the fluid is collected in the receptacle.

Close the water drain screw (3) as soon as about 0.25

US qt (0.2 liters) are emerged.

After draining, return the key in the ignition lock to

position 0.

Dispose of the collected fluid in an environmentally

responsible manner.

If the filter is still saturated, drain the filter once

more.

After draining, the engine may run briefly but stall for

lack of fuel. If this occurs, bleed the system.

NOTE: Should the water in the fuel indicator lamp

still not go out after the fuel filter has been drained

twice, the cause should be examined by an authorized

Sprinter Dealer.

CAUTION!

Delaying draining of the fuel filter for a

considerable time after the indicator lamp lights

up may lead to engine damage.

Page 225 of 330

STARTING AND OPERATING 225

5

Towing a Trailer

There are many different laws, including speed limit

restrictions, having to do with trailer towing. Make

sure that your vehicle-trailer combination will be legal,

not only for where you reside, but also for where you

will be driving. A good source for this information can

be the police or local authorities.

Before you start driving with the trailer, check the

trailer hitch, break-away switch, safety chains,

electrical connections, lighting and tires. Also adjust

the mirrors to permit unobstructed view beyond rear

of trailer.

If the trailer has electric brakes, start your vehicle and

trailer moving slowly, and then apply only the trailer

brake controller by hand to be sure the brakes are

working properly.

When towing a trailer, check occasionally to be sure

that the load is secure, and that lighting and trailer

brakes (if so equipped) are functioning properly.

Always secure items in the trailer to prevent load shifts

while driving.Take into consideration that when towing a trailer, the

handling characteristics are different and less stable

from those when operating the vehicle without a

trailer. It is important to avoid sudden maneuvers. The

vehicle and trailer combination is heavier, and

therefore is limited in acceleration and climbing ability,

and requires longer stopping distances. It is more

prone to reacting to side wind gusts, and requires more

sensitive steering input.

In order to gain skill and an understanding of the

vehicle’s behavior, you should practice turning, stopping

and backing up in an area which is free from traffic.

If possible, do not brake abruptly, but rather engage

the brake slightly at first to permit the trailer to activate

its brake. Then increase the braking force.

Page 232 of 330

232 WHAT TO DO IN EMERGENCIES

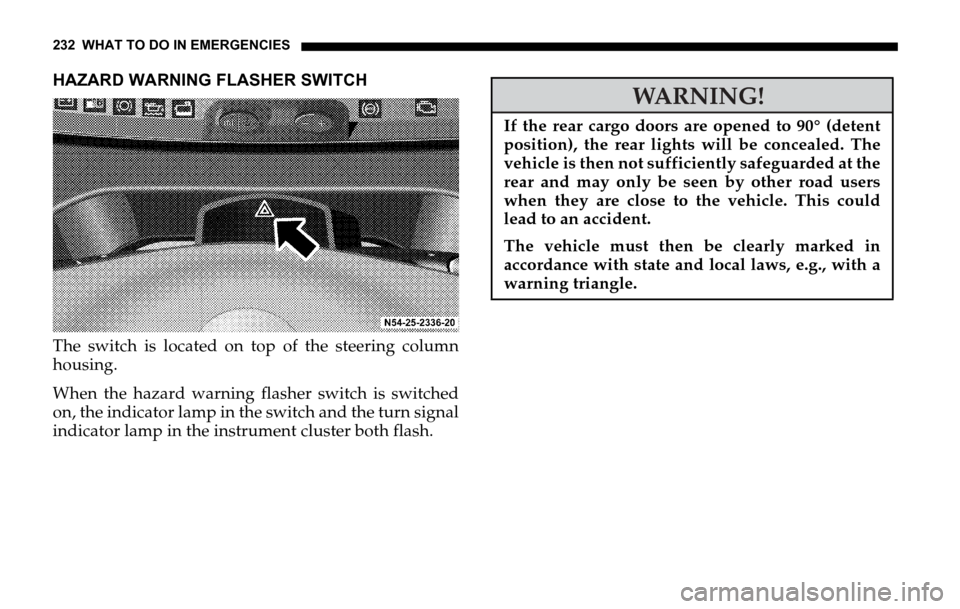

HAZARD WARNING FLASHER SWITCH

The switch is located on top of the steering column

housing.

When the hazard warning flasher switch is switched

on, the indicator lamp in the switch and the turn signal

indicator lamp in the instrument cluster both flash.

WARNING!

If the rear cargo doors are opened to 90° (detent

position), the rear lights will be concealed. The

vehicle is then not sufficiently safeguarded at the

rear and may only be seen by other road users

when they are close to the vehicle. This could

lead to an accident.

The vehicle must then be clearly marked in

accordance with state and local laws, e.g., with a

warning triangle.

Page 236 of 330

236 WHAT TO DO IN EMERGENCIES

Spare Wheel Location

NOTE: Lug wrench and jack, refer to "Vehicle Tool

Kit". For reasons of safety, check at regular intervals

that the spare wheel is properly secured.

WARNING!

If the rear cargo doors are opened to 90° (detent

position), the rear lights will be concealed. The ve-

hicle is then not sufficiently safeguarded at the

rear and may only be seen by other road users

when they are close to the vehicle. This could lead

to an accident.

The vehicle must then be clearly marked in

accordance with state and local laws, e.g., with a

warning triangle.

WARNING!

The spare wheel holder should be reattached once

the wheel has been changed.

Regularly check the spare wheel fastening.

A loose spare wheel or spare wheel holder could

be loosen or could move around the vehicle

interior uncontrollably in the event of sudden

braking, a rapid change in direction or an

accident. This increases the risk of injury to

vehicle occupants and other road users in these

situations.

Do not use retreaded/remolded tires. This process

does not always permit previous damage to be

detected. Therefore vehicle safety cannot be

guaranteed if retreaded/remolded tires are fitted.

Page 242 of 330

242 WHAT TO DO IN EMERGENCIES

REMOVING A WHEEL

1. Loosen the wheel bolts/nuts.

2. Jack up the vehicle until the wheel is clear of the

ground.

3. Unscrew the wheel bolts and remove the wheel

(keep the wheel bolts clean).

NOTE: If the vehicle moves forwards or backwards

while it is being jacked-up, lower it again and

reposition the jack. When the vehicle is jacked-up, the

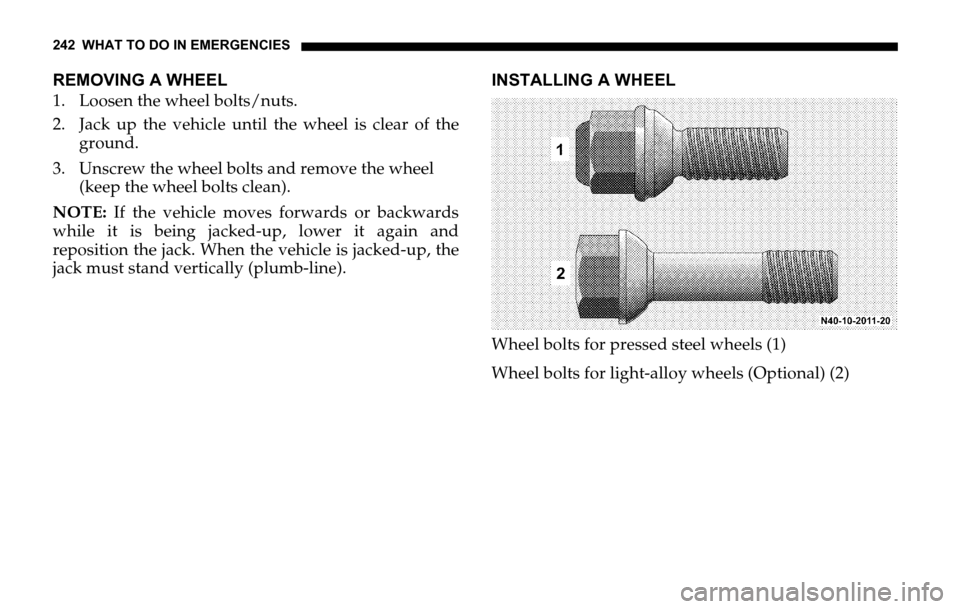

jack must stand vertically (plumb-line).INSTALLING A WHEEL

Wheel bolts for pressed steel wheels (1)

Wheel bolts for light-alloy wheels (Optional) (2)

Page 243 of 330

WHAT TO DO IN EMERGENCIES 243

6NOTE: The optional light alloy wheels are supplied

with 5 short wheel lug bolts enclosed for the steel spare

wheel in the vehicle tool kit.

Before fitting the spare wheel, clean rust and dirt off

the contact surfaces of the wheel and the wheel hub,

and from the wheel bolts.

Note the specified wheel and tire size, tire load

capacity and speed code.

Do not change the tire’s direction of rotation.

Do not damage, grease or oil wheel bolts or their

threads.

WARNING!

Different wheel bolts are required for pressed

steel and light-alloy wheels.

Incorrect wheel lug bolts for the wheels could

work loose, thereby causing you to lose control of

the vehicle. This could cause an accident resulting

in severe personal injuries and and property

damage.

WARNING!

Incorrect mounting bolts or improperly tightened

mounting bolts can cause the wheel to come off.

To avoid the risk of serious or fatal injuries or ve-

hicle damage, please bear the following points in

mind:

Always replace wheel bolts that are damaged or

rusted.

Never apply oil or grease to wheel bolts

If a wheel hub thread is damaged, you must not

drive the vehicle. Consult a qualified specialist

workshop.

Only use genuine DaimlerChrysler wheel bolts

specified for your vehicle’s rims.

Page 244 of 330

244 WHAT TO DO IN EMERGENCIES

Centering wheels with wheel bolts/nuts

If dual assemblies are used, before placement the

inner wheel should be inspected to ensure that all

ball bearing rings are in proper position.

Install the wheel and snug the wheel bolts/nuts.

Slightly tighten wheel bolts/nuts.

Slowly open jack release valve to lower vehicle until

tire is resting on ground.

WARNING!

Do not tighten the wheel bolts and wheel nuts

completely while the vehicle is still jacked up.

The vehicle could tip.

Page 245 of 330

WHAT TO DO IN EMERGENCIES 245

6

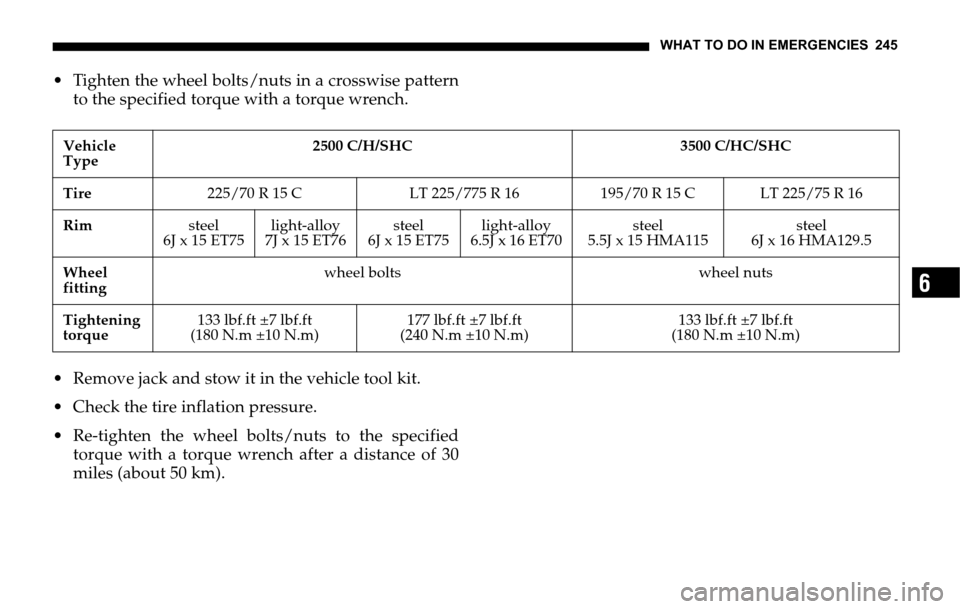

Tighten the wheel bolts/nuts in a crosswise pattern

to the specified torque with a torque wrench.

Remove jack and stow it in the vehicle tool kit.

Check the tire inflation pressure.

Re-tighten the wheel bolts/nuts to the specified

torque with a torque wrench after a distance of 30

miles (about 50 km).

Vehicle

Type2500 C/H/SHC 3500 C/HC/SHC

Tire225/70 R 15 C LT 225/775 R 16 195/70 R 15 C LT 225/75 R 16

Rimsteel

6J x 15 ET75light-alloy

7J x 15 ET76steel

6J x 15 ET75light-alloy

6.5J x 16 ET70steel

5.5J x 15 HMA115steel

6J x 16 HMA129.5

Wheel

fittingwheel bolts wheel nuts

Tightening

torque133 lbf.ft ±7 lbf.ft

(180 N.m ±10 N.m)177 lbf.ft ±7 lbf.ft

(240 N.m ±10 N.m)133 lbf.ft ±7 lbf.ft

(180 N.m ±10 N.m)