DODGE STRATUS COUPE 2005 2.G Owners Manual

Manufacturer: DODGE, Model Year: 2005, Model line: STRATUS COUPE, Model: DODGE STRATUS COUPE 2005 2.GPages: 396

Page 331 of 396

Special additives

DaimlerChrysler does not recommend the addition of

any fluid additives to the transaxle.

MANUAL TRANSAXLE

Add oil to maintain the proper level. Refill or change oil

according to the scheduled maintenance table.

Lubricant Gear Oil Classification GL-4

Viscosity range SAE75W-90 or 75W-85W

DISC BRAKE PADS, REAR DRUM BRAKE

LININGS AND REAR WHEEL CYLINDERS

Proper brakes are essential to safe operation of your

vehicle. Check brake pads and rear brake linings for

wear, and check rear wheel cylinders for leakage.

For proper braking performance, replace brake pads with

original equipment type pads.

BRAKE HOSES

Brake hoses and tubing should be checked for:

1. Severe surface cracking, scuffing or worn spots. If the

casing of the hose is exposed by cracks or abrasions in therubber hose cover, the hose should be replaced. Deterio-

ration of the hose could cause brake failure.

2. Faulty installation may cause twisting, or wheel, tire

or chassis interference.

BALL JOINT, STEERING LINKAGE SEAL AND

DRIVE SHAFT BOOTS

Check the following parts for damage and grease leak-

age:

1. Ball joint boots of the front suspension and steering

linkage

2. Bellows on both ends of the drive shaft

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

The entire SRS system must be inspected by an autho-

rized dealer 10 years after the vehicle manufacture date

shown on the certification label. [See ªSRS servicingº on

page 101.]

MAINTENANCE 331

9

Page 332 of 396

HOOD LOCK RELEASE MECHANISM AND

SAFETY CATCH

The door hinges, trunk hinges, hood lock release mecha-

nism and hood safety catch should be inspected, cleaned,

and lubricated as required to maintain ease of operation

and to provide protection against rust and wear. Apply

Multipurpose Grease NLGI Grade 2 sparingly to all

sliding contact areas of the hood latch and release lever.

Work lubricant into the hood lock mechanism until all

frictional surfaces are covered.

Also, apply a film of the same lubricant to the pivot

contact areas of the safety catch.

EXHAUST SYSTEM

WARNING!

Carbon monoxide gas found in the vehicle's exhaust

is poisonous. Inhalation of exhaust fumes can cause

unconsciousness or death.

The best protection against carbon monoxide entry into

the vehicle interior is a properly maintained engineexhaust system.

Whenever a change is noticed in the sound of the exhaust

system; when exhaust fumes can be detected inside the

vehicle; or when the underside or rear of the vehicle is

damaged, have a competent technician inspect the com-

plete exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts.

In addition inspect the exhaust system each time the

vehicle is raised for lubrication or oil change. Replace as

required.

Open seams or loose connections could permit danger-

ous exhaust fumes to seep into the trunk and passenger

compartments.

Do this service when performing underbody service.

Check for any of the following conditions:

1. Check for holes or exhaust gas leakage caused by

corrosion or damage.

2. Check the joints and connections for looseness or

exhaust gas leakage.

3. Check the rubber hangers and brackets for damage.

332 MAINTENANCE

Page 333 of 396

WINDSHIELD WIPER BLADES

Check the wiper blades occasionally. Periodic cleaning of

the wiper blades is suggested to remove the accumula-

tion of salt and road film. The wiper blade arms and glass

areas should be cleaned with a sponge or cloth and a

mild detergent or non-abrasive cleaner.

If the blades continue to streak or smear, they should be

replaced.

NOTE: Do not operate wipers for long periods on dry

glass; this accelerates deterioration of the rubber and

could scratch the glass.

Windshield washers

The windshield washer reservoir is in the engine com-

partment. Check the fluid level at regular intervals and

replenish the fluid if necessary.

NOTE: When freezing weather is anticipated flush out

the water in the reservoir by operating the pump. Fill the

reservoir with windshield antifreeze (not radiator anti-

freeze) and operate the system for a few seconds to flush

out any residual water.

M31A0730

MAINTENANCE 333

9

Page 334 of 396

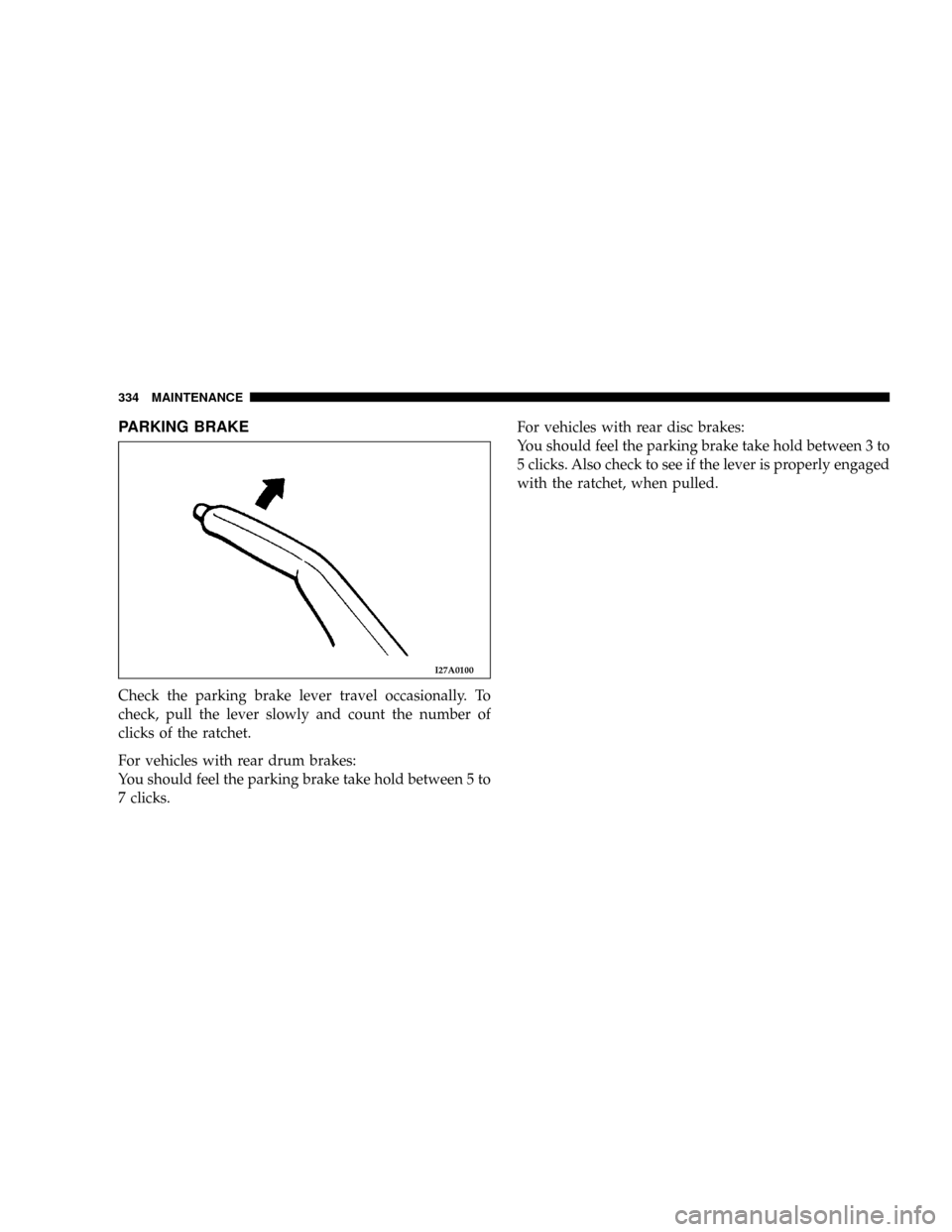

PARKING BRAKE

Check the parking brake lever travel occasionally. To

check, pull the lever slowly and count the number of

clicks of the ratchet.

For vehicles with rear drum brakes:

You should feel the parking brake take hold between 5 to

7 clicks.For vehicles with rear disc brakes:

You should feel the parking brake take hold between 3 to

5 clicks. Also check to see if the lever is properly engaged

with the ratchet, when pulled.

I27A0100

334 MAINTENANCE

Page 335 of 396

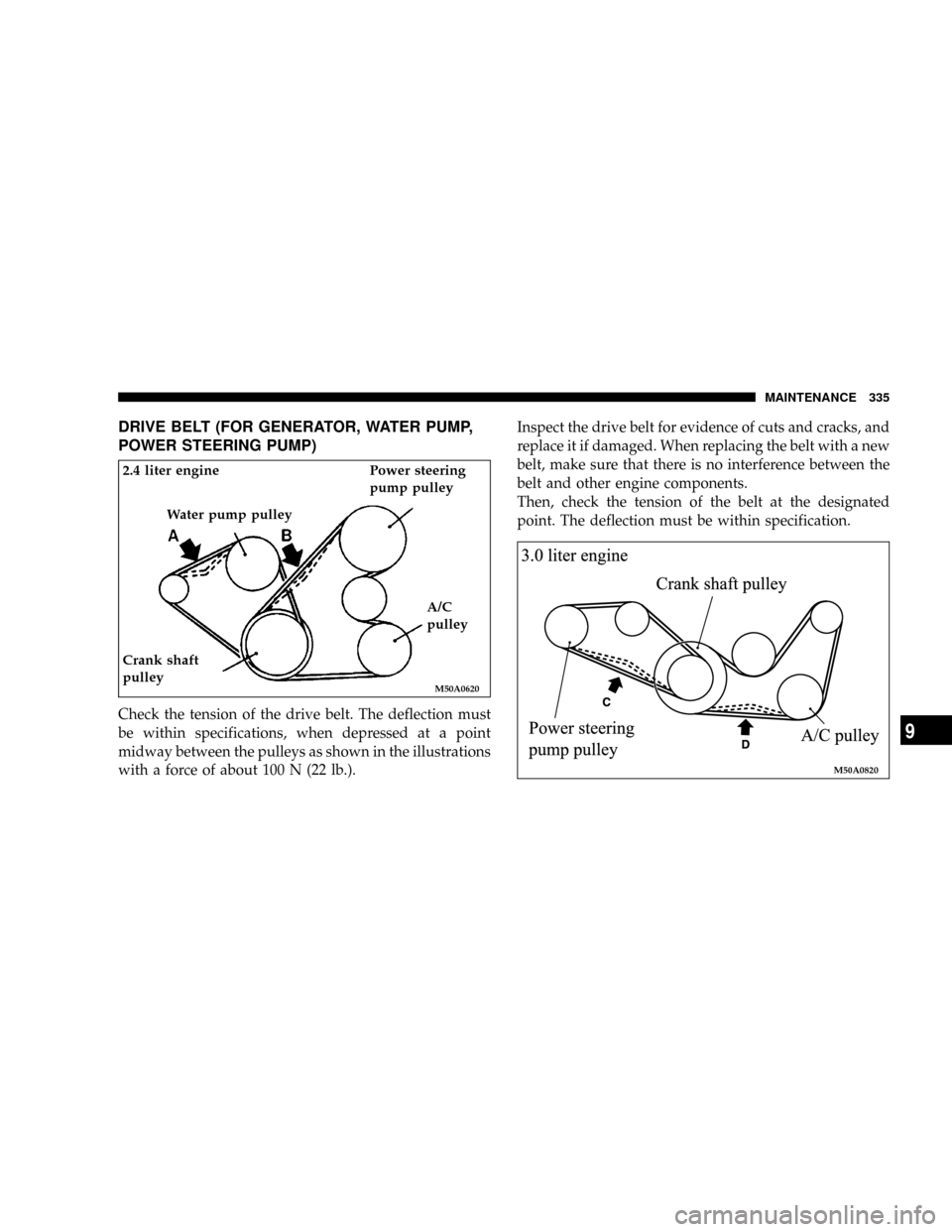

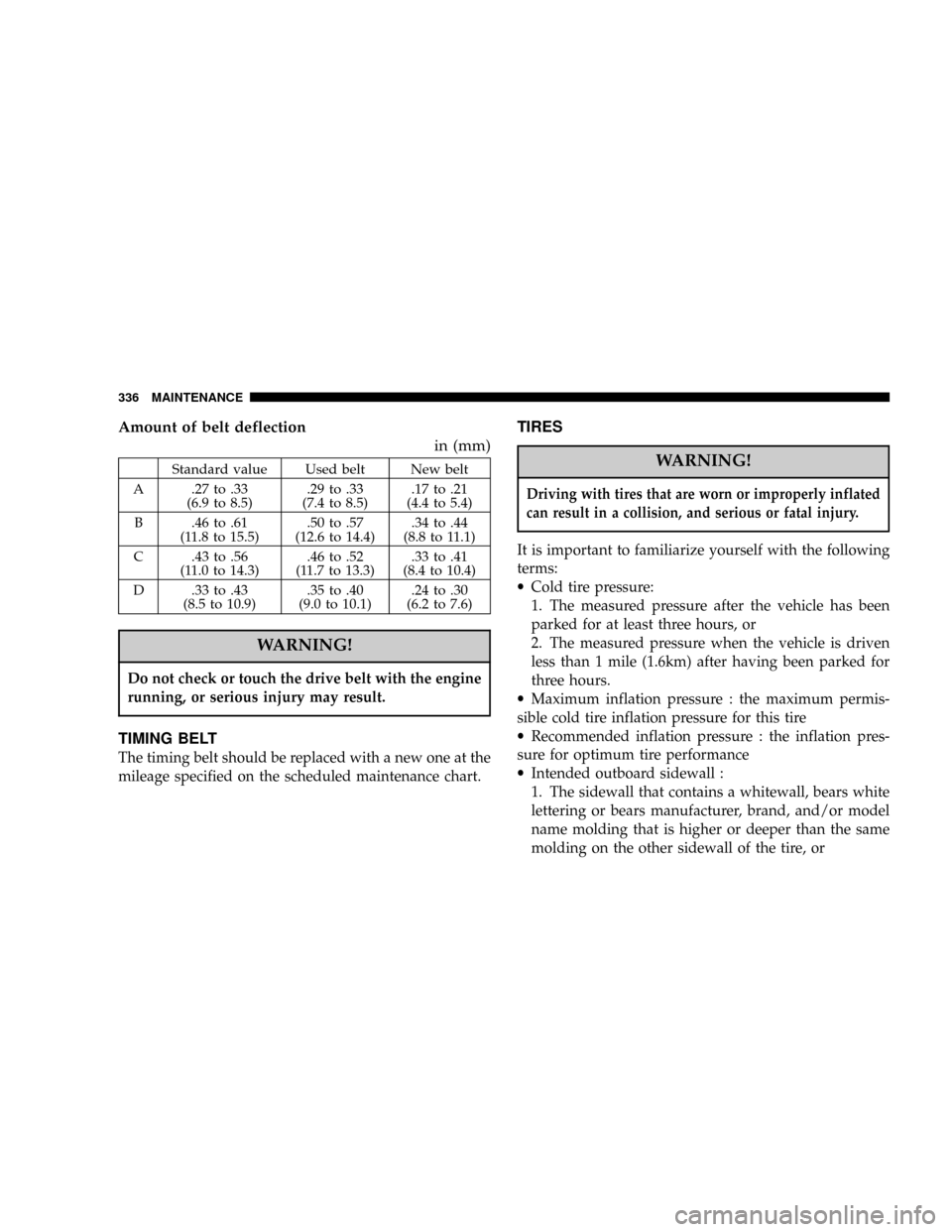

DRIVE BELT (FOR GENERATOR, WATER PUMP,

POWER STEERING PUMP)

Check the tension of the drive belt. The deflection must

be within specifications, when depressed at a point

midway between the pulleys as shown in the illustrations

with a force of about 100 N (22 lb.).Inspect the drive belt for evidence of cuts and cracks, and

replace it if damaged. When replacing the belt with a new

belt, make sure that there is no interference between the

belt and other engine components.

Then, check the tension of the belt at the designated

point. The deflection must be within specification.

M50A0620

Water pump pulley

Crank shaft

pulleyPower steering

pump pulley

A/C

pulley 2.4 liter engine

M50A0820

MAINTENANCE 335

9

Page 336 of 396

Amount of belt deflection

in (mm)

Standard value Used belt New belt

A .27 to .33

(6.9 to 8.5).29 to .33

(7.4 to 8.5).17 to .21

(4.4 to 5.4)

B .46 to .61

(11.8 to 15.5).50 to .57

(12.6 to 14.4).34 to .44

(8.8 to 11.1)

C .43 to .56

(11.0 to 14.3).46 to .52

(11.7 to 13.3).33 to .41

(8.4 to 10.4)

D .33 to .43

(8.5 to 10.9).35 to .40

(9.0 to 10.1).24 to .30

(6.2 to 7.6)

WARNING!

Do not check or touch the drive belt with the engine

running, or serious injury may result.

TIMING BELT

The timing belt should be replaced with a new one at the

mileage specified on the scheduled maintenance chart.

TIRES

WARNING!

Driving with tires that are worn or improperly inflated

can result in a collision, and serious or fatal injury.

It is important to familiarize yourself with the following

terms:

·Cold tire pressure:

1. The measured pressure after the vehicle has been

parked for at least three hours, or

2. The measured pressure when the vehicle is driven

less than 1 mile (1.6km) after having been parked for

three hours.

·Maximum inflation pressure : the maximum permis-

sible cold tire inflation pressure for this tire

·Recommended inflation pressure : the inflation pres-

sure for optimum tire performance

·Intended outboard sidewall :

1. The sidewall that contains a whitewall, bears white

lettering or bears manufacturer, brand, and/or model

name molding that is higher or deeper than the same

molding on the other sidewall of the tire, or

336 MAINTENANCE

Page 337 of 396

2. The outward facing sidewall of an asymmetrical tire

that has a particular side that must always face out-

ward when mounted on a vehicle.

·Rim : a metal support for a tire or a tire and tube

assembly upon which the tire beads are seated.

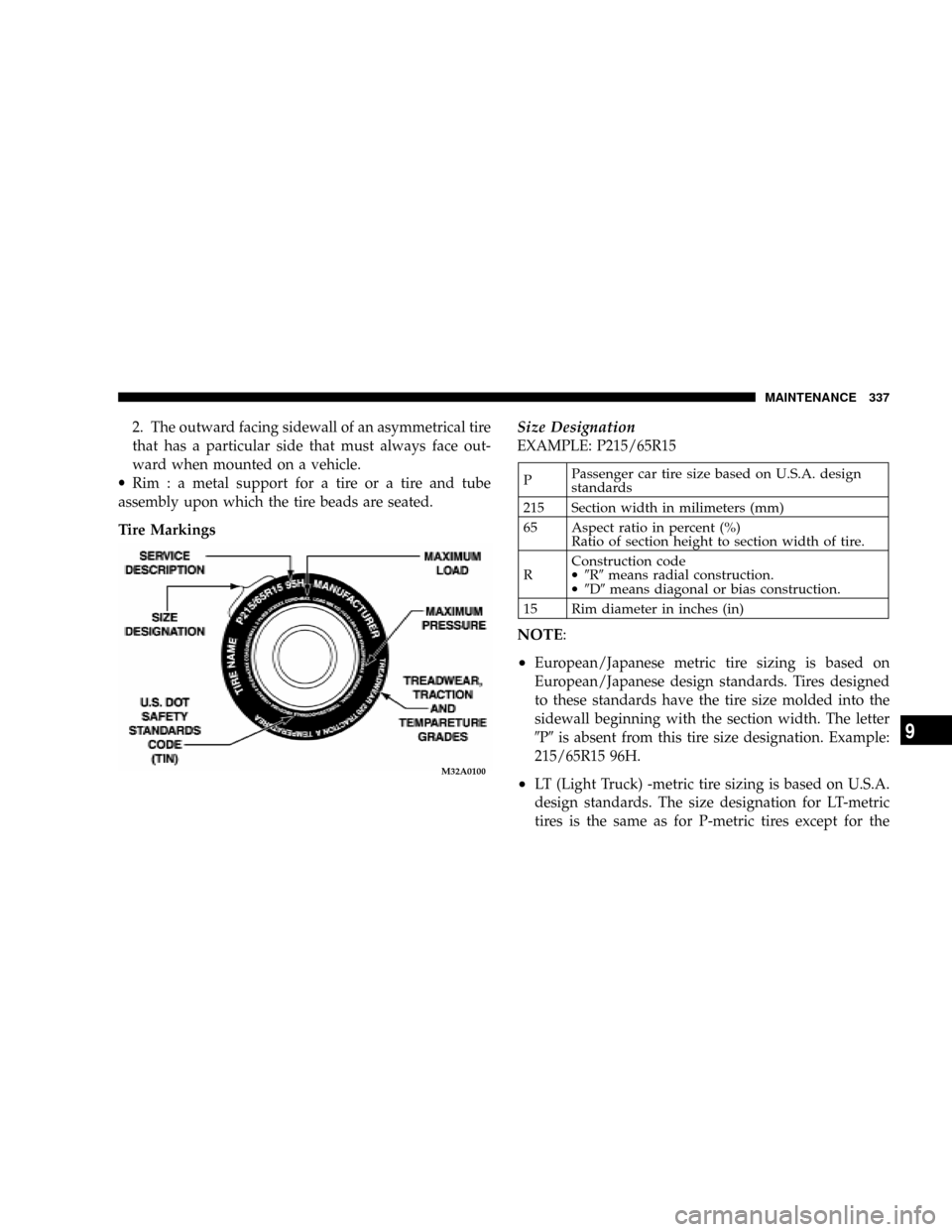

Tire MarkingsSize Designation

EXAMPLE: P215/65R15

PPassenger car tire size based on U.S.A. design

standards

215 Section width in milimeters (mm)

65 Aspect ratio in percent (%)

Ratio of section height to section width of tire.

RConstruction code

·9R9means radial construction.

·9D9means diagonal or bias construction.

15 Rim diameter in inches (in)

NOTE:

²European/Japanese metric tire sizing is based on

European/Japanese design standards. Tires designed

to these standards have the tire size molded into the

sidewall beginning with the section width. The letter

9P9is absent from this tire size designation. Example:

215/65R15 96H.

²LT (Light Truck) -metric tire sizing is based on U.S.A.

design standards. The size designation for LT-metric

tires is the same as for P-metric tires except for theM32A0100

MAINTENANCE 337

9

Page 338 of 396

letters9LT9that are molded into the sidewall preceding

the size designation. Example: LT235/85R16.

²Temporary spare tires are high pressure compact

spares designed for temporary emergency use only.

Tires designed to this standard have the letter9T9

molded into the sidewall preceding the size designa-

tion. Example: T145/80D18 103M.

Service Description

EXAMPLE: 95H

95Load index

A numerical code associated with the maximum

load a tire can carry.

HSpeed symbol

A symbol indicating the range of speeds at which

a tire can carry a load corresponding to its load

index under certain operating conditions.

The maximum speed corresponding to the speed

symbol should only be achieved under specified

operating conditions. (i.e. tire pressure, vehicle

loading, road conditions and posted speed limits).

Maximum Load

Maximum load indicates the maximum load this tire is

designed to carry

Maximum Pressure

Maximum Pressure indicates the maximum permissible

cold tire inflation pressure for this tire.

Tire Identification Number (TIN)

The TIN may be found on one or both sides of the tire,

but the date code may only be on one side. Tires with

white sidewalls will have the full TIN including date

code located on the white sidewall side of the tire. Look

for the TIN on the outboard side of black sidewall tires as

mounted on the vehicle. If the TIN is not found on the

outboard side then you will find it on the inboard side of

the tire.

338 MAINTENANCE

Page 339 of 396

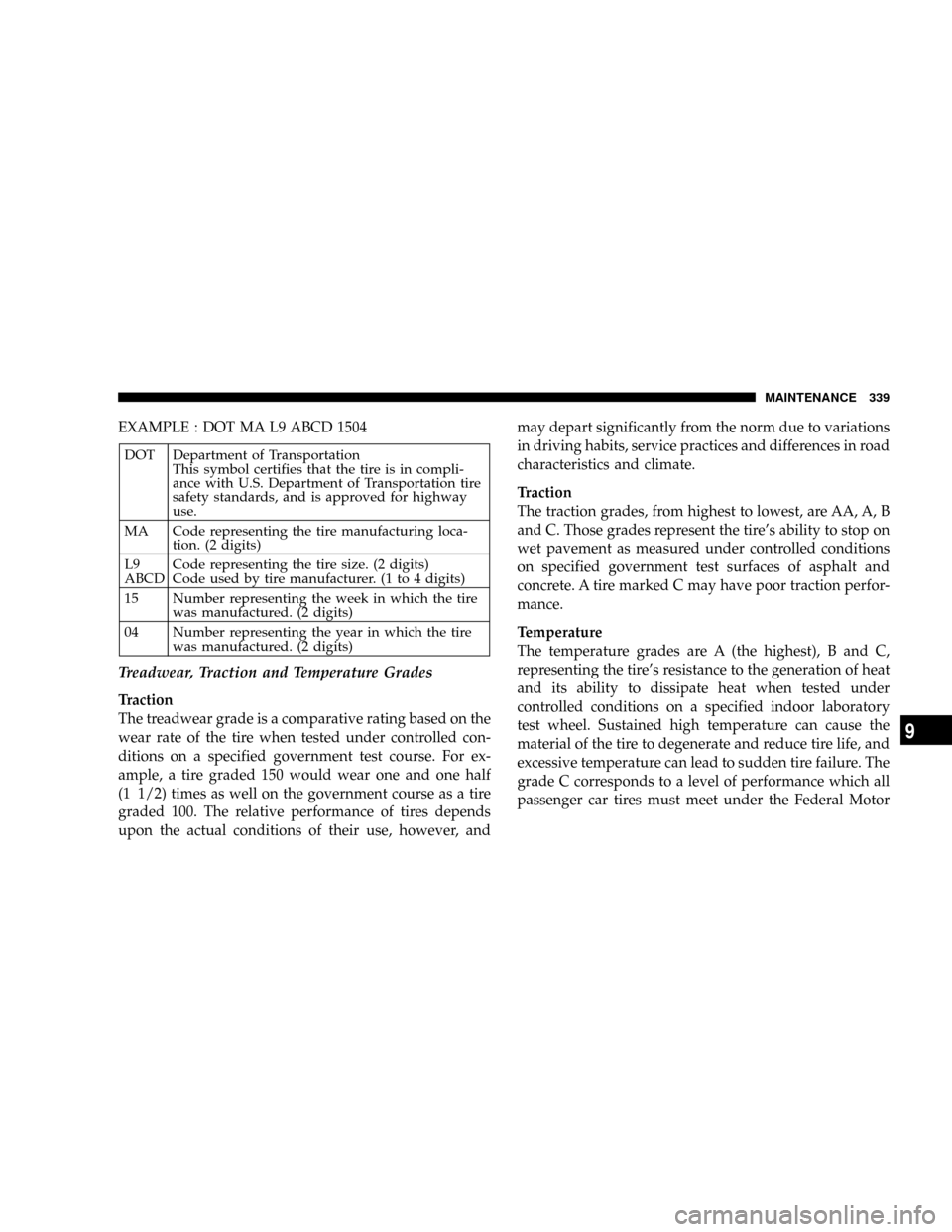

EXAMPLE : DOT MA L9 ABCD 1504

DOT Department of Transportation

This symbol certifies that the tire is in compli-

ance with U.S. Department of Transportation tire

safety standards, and is approved for highway

use.

MA Code representing the tire manufacturing loca-

tion. (2 digits)

L9

ABCDCode representing the tire size. (2 digits)

Code used by tire manufacturer. (1 to 4 digits)

15 Number representing the week in which the tire

was manufactured. (2 digits)

04 Number representing the year in which the tire

was manufactured. (2 digits)

Treadwear, Traction and Temperature Grades

Traction

The treadwear grade is a comparative rating based on the

wear rate of the tire when tested under controlled con-

ditions on a specified government test course. For ex-

ample, a tire graded 150 would wear one and one half

(1 1/2) times as well on the government course as a tire

graded 100. The relative performance of tires depends

upon the actual conditions of their use, however, andmay depart significantly from the norm due to variations

in driving habits, service practices and differences in road

characteristics and climate.

Traction

The traction grades, from highest to lowest, are AA, A, B

and C. Those grades represent the tire's ability to stop on

wet pavement as measured under controlled conditions

on specified government test surfaces of asphalt and

concrete. A tire marked C may have poor traction perfor-

mance.

Temperature

The temperature grades are A (the highest), B and C,

representing the tire's resistance to the generation of heat

and its ability to dissipate heat when tested under

controlled conditions on a specified indoor laboratory

test wheel. Sustained high temperature can cause the

material of the tire to degenerate and reduce tire life, and

excessive temperature can lead to sudden tire failure. The

grade C corresponds to a level of performance which all

passenger car tires must meet under the Federal Motor

MAINTENANCE 339

9

Page 340 of 396

Vehicle Safety Standard No. 109. Grades B and A repre-

sent higher levels of performance on the laboratory test

wheel than the minimum required by law.

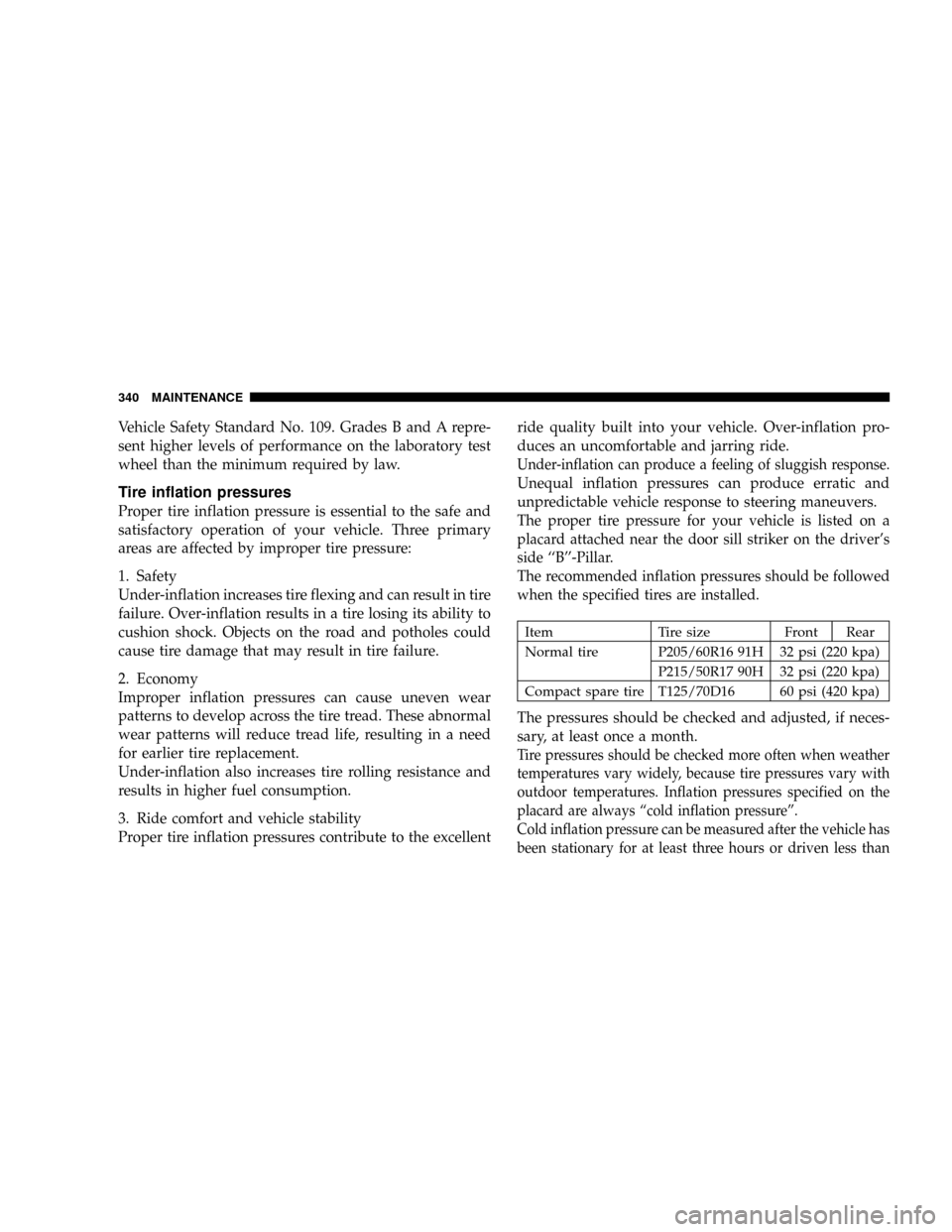

Tire inflation pressures

Proper tire inflation pressure is essential to the safe and

satisfactory operation of your vehicle. Three primary

areas are affected by improper tire pressure:

1. Safety

Under-inflation increases tire flexing and can result in tire

failure. Over-inflation results in a tire losing its ability to

cushion shock. Objects on the road and potholes could

cause tire damage that may result in tire failure.

2. Economy

Improper inflation pressures can cause uneven wear

patterns to develop across the tire tread. These abnormal

wear patterns will reduce tread life, resulting in a need

for earlier tire replacement.

Under-inflation also increases tire rolling resistance and

results in higher fuel consumption.

3. Ride comfort and vehicle stability

Proper tire inflation pressures contribute to the excellentride quality built into your vehicle. Over-inflation pro-

duces an uncomfortable and jarring ride.

Under-inflation can produce a feeling of sluggish response.

Unequal inflation pressures can produce erratic and

unpredictable vehicle response to steering maneuvers.

The proper tire pressure for your vehicle is listed on a

placard attached near the door sill striker on the driver's

side ``B''-Pillar.

The recommended inflation pressures should be followed

when the specified tires are installed.

Item Tire size Front Rear

Normal tire P205/60R16 91H 32 psi (220 kpa)

P215/50R17 90H 32 psi (220 kpa)

Compact spare tire T125/70D16 60 psi (420 kpa)

The pressures should be checked and adjusted, if neces-

sary, at least once a month.

Tire pressures should be checked more often when weather

temperatures vary widely, because tire pressures vary with

outdoor temperatures. Inflation pressures specified on the

placard are always ªcold inflation pressureº.

Cold inflation pressure can be measured after the vehicle has

been stationary for at least three hours or driven less than

340 MAINTENANCE