fuel pump DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 942 of 1502

•

FUEL

SYSTEM

14 - 123

SPECIFICATIONS

GENERAL

INFORMATION

The following specifications

are

published from

the

latest information available

at the

time

of

publica

tion.

If

anything differs between

the

specifica

tions found

on the

Vehicle Emission Control Information (VECI) label

and the

following spec

ifications,

use

specifications

on

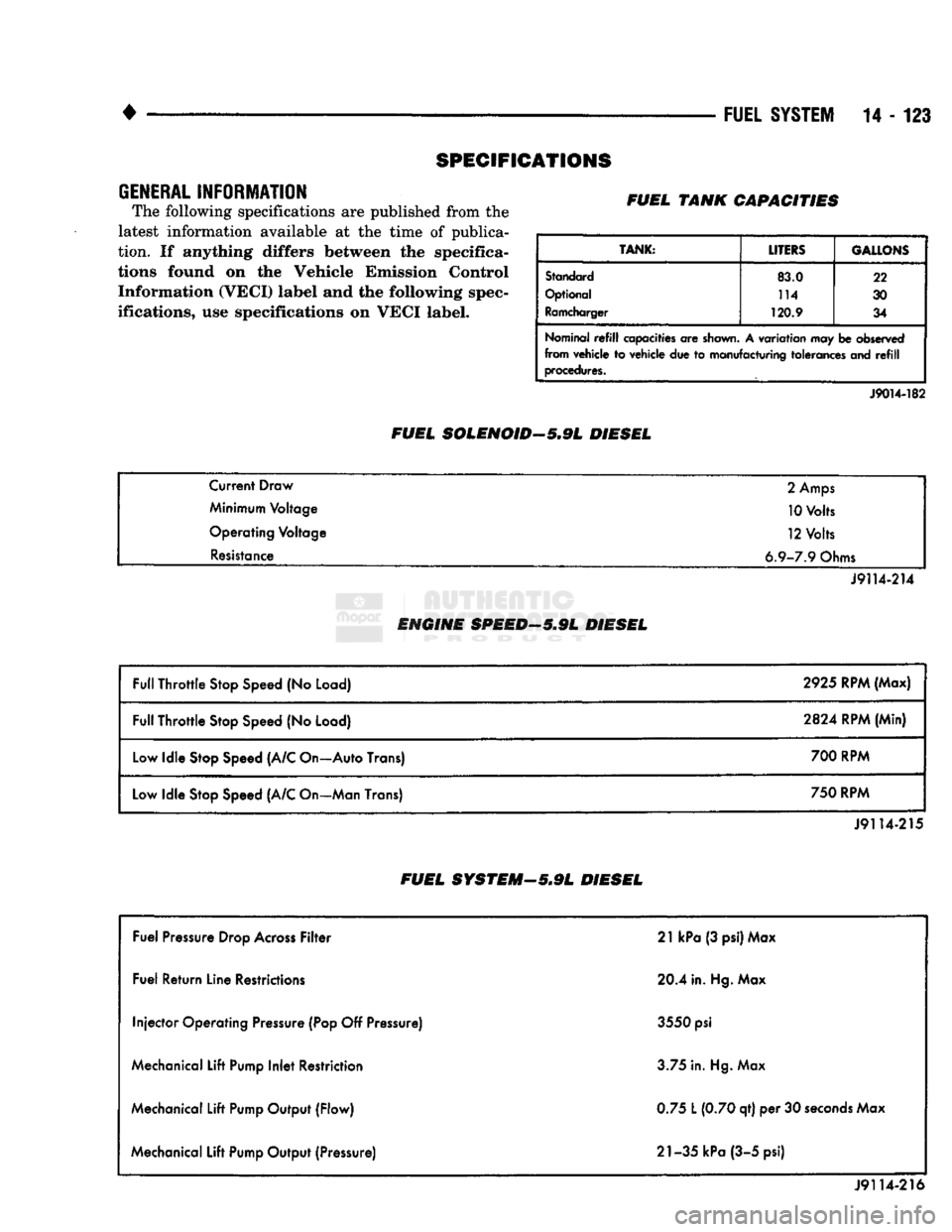

VECI label. FUEL TANK CAPACITIES

TANK:

LITERS GALLONS

Standard

83.0 22

Optional 114

30

Ramcharger

120.9

34

Nominal

refill

capacities

are

shown.

A

variation

may be

observed

from vehicle

to

vehicle

due to

manufacturing tolerances

and refill

procedures.

FUEL SOLENOID-5.9L DIESEL

J9014-182

Current Draw

2

Amps

Minimum Voltage 10 Volts

Operating Voltage 12 Volts

Resistance 6.9-7.9 Ohms

J9114-214

ENGINE SPEED—5.9L DIESEL

Full Throttle Stop Speed

(No

Load) 2925 RPM (Max)

Full Throttle Stop Speed

(No

Load)

2824

RPM (Min)

Low Idle Stop Speed (A/C On—Auto Trans) 700 RPM

Low Idle Stop Speed (A/C On—Man Trans) 750 RPM

J9114-215

FUEL SYSTEM—5*9L DIESEL

Fuel Pressure Drop Across Filter 21

kPa

(3 psi) Max

Fuel Return Line Restrictions 20.4 in. Hg. Max

Injector Operating Pressure (Pop

Off

Pressure) 3550

psi

Mechanical Lift Pump Inlet Restriction 3.75 in. Hg. Max

Mechanical Lift Pump Output (Flow) 0.75

L

(0.70 qt)

per 30

seconds Max

Mechanical Lift Pump Output (Pressure) 21-35 kPa (3-5 psi)

J9114-216

Page 944 of 1502

• —_ —_

FUEL

SYSTEM

14 - 125

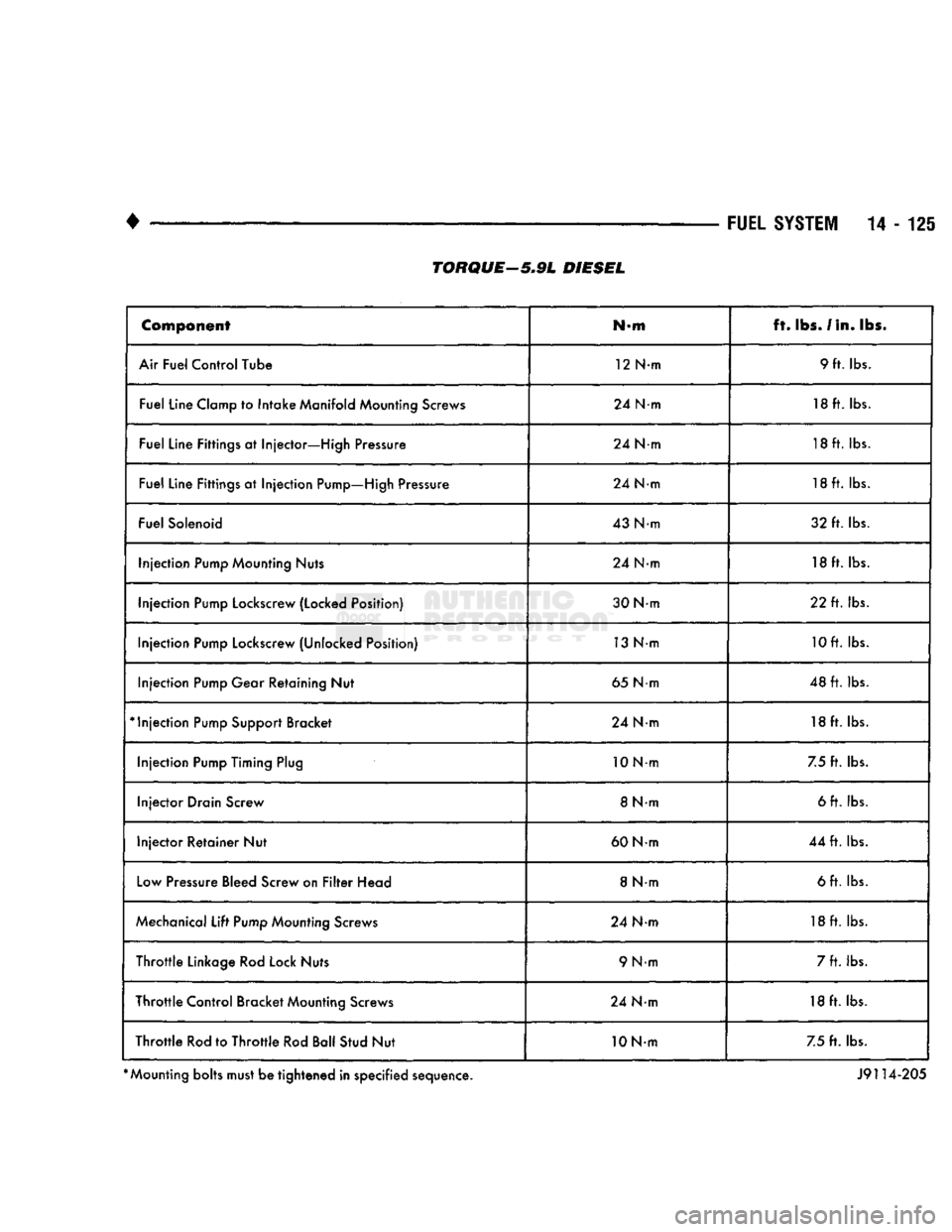

Component

N-m ft.

lbs.

/In. lbs.

Air Fuel Control Tube 12 N-m 9 ft. lbs.

Fuel Line Clamp to Intake Manifold Mounting Screws 24 N-m 18 ft. lbs.

Fuel Line Fittings at Injector—High Pressure 24 N-m 18ft. lbs.

Fuel Line Fittings at Injection Pump—High Pressure 24 N-m 18ft. lbs.

Fuel Solenoid 43 Nm 32 ft. lbs.

Injection Pump Mounting Nuts 24 N-m 18ft. lbs.

Injection Pump Lockscrew (Locked Position) 30 Nm 22 ft. lbs.

Injection Pump Lockscrew (Unlocked Position) 13 Nm 10ft. lbs.

Injection Pump Gear Retaining Nut 65 Nm 48 ft. lbs.

*

Injection Pump Support Bracket 24 Nm 18 ft. lbs.

Injection Pump Timing Plug 10Nm

7.5 ft. lbs.

Injector Drain Screw 8 N-m 6 ft. lbs.

Injector Retainer Nut 60 Nm 44 ft. lbs.

Low Pressure Bleed Screw on Filter Head 8 Nm 6 ft. lbs.

Mechanical Lift Pump Mounting Screws 24 Nm 18ft. lbs.

Throttle Linkage Rod Lock Nuts 9 N-m 7 ft. lbs.

Throttle Control Bracket Mounting Screws 24 Nm 18 ft. lbs.

Throttle Rod to Throttle Rod Ball Stud Nut 10 Nm 7.5 ft. lbs.

*

Mounting bolts must be tightened in specified sequence. J9114-205

TORQUE—5.9L

DIESEL

Page 1082 of 1502

•

AUTOMATIC

TRANSMISSION—32RH/36RH/37RH/42RH/46RH

21 - 81

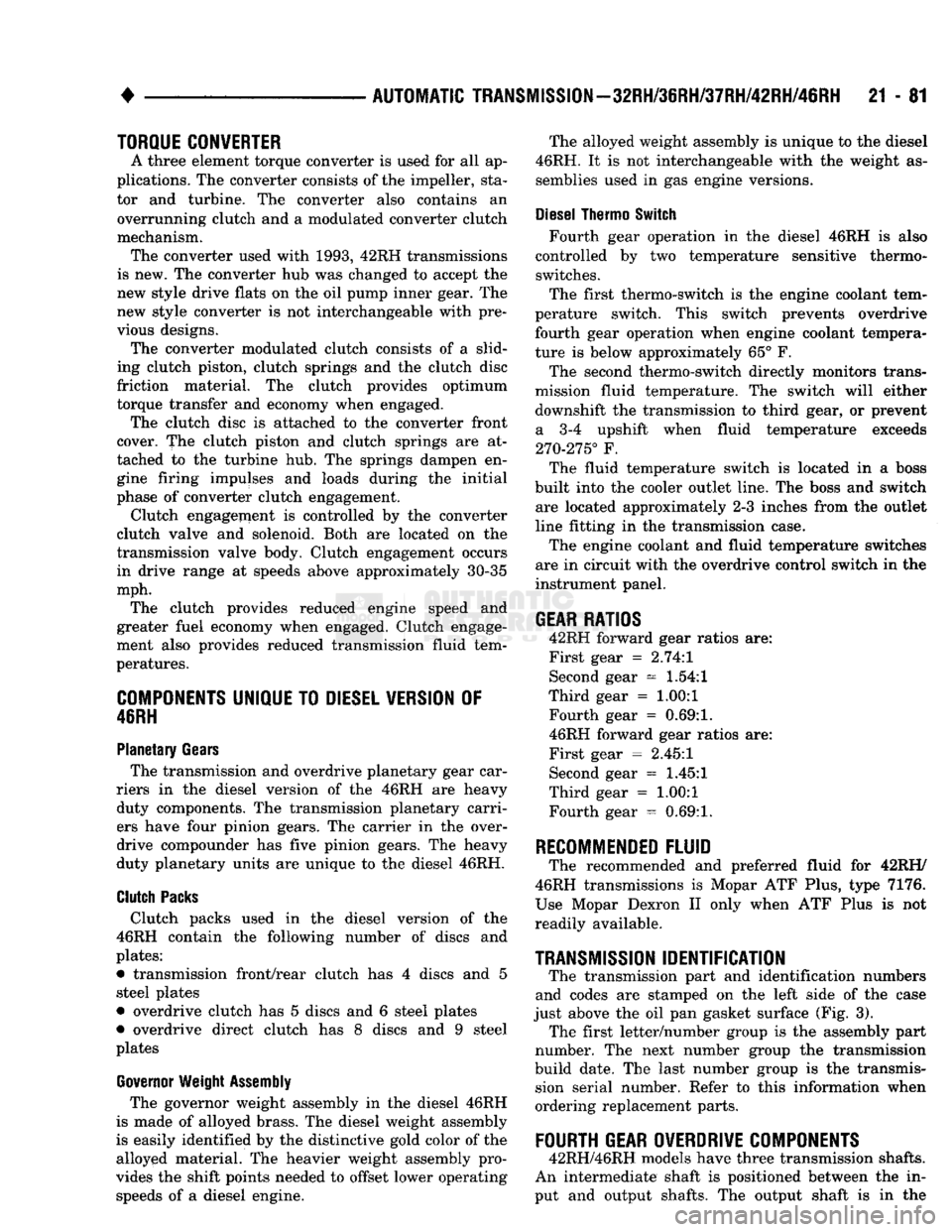

TORQUE

CONVERTER

A three element torque converter

is

used

for all ap

plications.

The

converter consists

of the

impeller,

sta-

tor

and

turbine.

The

converter also contains

an

overrunning clutch

and a

modulated converter clutch

mechanism.

The converter used with

1993,

42RH transmissions

is

new. The

converter

hub was

changed

to

accept

the

new style drive flats

on the oil

pump inner gear.

The

new style converter

is not

interchangeable with pre

vious designs.

The converter modulated clutch consists

of a

slid

ing clutch piston, clutch springs

and the

clutch disc

friction material.

The

clutch provides optimum

torque transfer

and

economy when engaged.

The clutch disc

is

attached

to the

converter front

cover.

The

clutch piston

and

clutch springs

are at

tached

to the

turbine

hub. The

springs dampen

en

gine firing impulses

and

loads during

the

initial

phase

of

converter clutch engagement.

Clutch engagement

is

controlled

by the

converter

clutch valve

and

solenoid. Both

are

located

on the

transmission valve body. Clutch engagement occurs in drive range

at

speeds above approximately 30-35

mph.

The clutch provides reduced engine speed

and

greater fuel economy when engaged. Clutch engage

ment also provides reduced transmission fluid tem

peratures.

COMPONENTS

UNIQUE

TO

DIESEL VERSION

OF

46RH

Planetary

Gears

The transmission

and

overdrive planetary gear car

riers

in the

diesel version

of the

46RH

are

heavy duty components.

The

transmission planetary carriers have four pinion gears.

The

carrier

in the

over

drive compounder

has

five pinion gears.

The

heavy

duty planetary units

are

unique

to the

diesel 46RH.

Clutch

Packs

Clutch packs used

in the

diesel version

of the

46RH contain

the

following number

of

discs

and

plates:

• transmission front/rear clutch

has 4

discs

and 5

steel plates

• overdrive clutch

has 5

discs

and 6

steel plates

• overdrive direct clutch

has 8

discs

and 9

steel

plates

Governor

Weight

Assembly

The governor weight assembly

in the

diesel 46RH

is made

of

alloyed brass.

The

diesel weight assembly

is easily identified

by the

distinctive gold color

of the

alloyed material.

The

heavier weight assembly pro

vides

the

shift points needed

to

offset lower operating speeds

of a

diesel engine. The alloyed weight assembly

is

unique

to the

diesel

46RH.

It is not

interchangeable with

the

weight

as

semblies used

in gas

engine versions.

Diesel

Thermo

Switch

Fourth gear operation

in the

diesel 46RH

is

also

controlled

by two

temperature sensitive thermo- switches.

The first thermo-switch

is the

engine coolant tem

perature switch. This switch prevents overdrive fourth gear operation when engine coolant tempera

ture

is

below approximately

65° F.

The second thermo-switch directly monitors trans

mission fluid temperature.

The

switch will either

downshift

the

transmission

to

third gear,

or

prevent a

3-4

upshift when fluid temperature exceeds

270-275°

F.

The fluid temperature switch

is

located

in a

boss

built into

the

cooler outlet line.

The

boss

and

switch are located approximately

2-3

inches from

the

outlet

line fitting

in the

transmission case.

The engine coolant

and

fluid temperature switches

are

in

circuit with

the

overdrive control switch

in the

instrument panel.

GEAR RATIOS

42RH forward gear ratios

are:

First gear

=

2.74:1

Second gear

= 1.54:1

Third gear

= 1.00:1

Fourth gear

=

0.69:1.

46RH forward gear ratios

are:

First gear

=

2.45:1 Second gear

= 1.45:1

Third gear

= 1.00:1

Fourth gear

=

0.69:1.

RECOMMENDED

FLUID

The recommended

and

preferred fluid

for

42RH/

46RH transmissions

is

Mopar

ATF

Plus, type

7176.

Use Mopar Dexron

II

only when

ATF

Plus

is not

readily available.

TRANSMISSION

IDENTIFICATION

The transmission part

and

identification numbers

and codes

are

stamped

on the

left side

of the

case

just above

the oil pan

gasket surface

(Fig. 3).

The first letter/number group

is the

assembly part

number.

The

next number group

the

transmission

build date.

The

last number group

is the

transmis sion serial number. Refer

to

this information when

ordering replacement parts.

FOURTH

GEAR OVERDRIVE COMPONENTS

42RH/46RH models have three transmission shafts.

An intermediate shaft

is

positioned between

the in

put

and

output shafts.

The

output shaft

is in the

Page 1478 of 1502

•

EMISSION

CONTROL

SYSTEMS

25

- 1

CONTENTS

page page

AIR INJECTION

SYSTEM-o

9L

HDC-GAS EVAPORATIVE EMISSION CONTROLS

6

ENGINE

15

EXHAUST EMISSION CONTROLS

10

COMPONENT

REMOVAL/INSTALLATION

17

GENERAL INFORMATION

1

GENERAL

INFORMATION

Throughout this group, references are made

to

par

ticular vehicle models

by

alphabetical designation

or

by the particular vehicle nameplate.

A

chart showing a breakdown

of

alphabetical designations

is

included

in

the

Introduction section

at

the

beginning

of

this

manual.

The 5.9L (V-8) gas powered engine will

be

referred

to

in

this group

as

either the: LDC (Light Duty Cy cle)

or

HDC (Heavy Duty Cycle) engine.

The

HDC

engine can

be

easily identified

by

the

use

of

an en

gine mounted

air

injection pump. The 3.9L/5.2L/5.9L

LDC engine will not use

an

air

injection pump.

Maintenance requirements for LDC and HDC emis

sion systems differ because

of

different load

and

op

erating conditions. This section will cover emission control systems

for

the 3.9L (V-6), 5.2L (V-8), 5.9L LDC (V-8), 5.9L HDC (V-8) and 5.9L (in-line six cylinder) diesel engines.

SERVICE

REMINDER INDICATOR

(SRI)

LIGHT

The instrument panel mounted SRI light was for

merly referred

to as the

emission maintenance

re

minder (EMR) light.

It is

used with 5.9L HDC-gas

powered engines only.

It is

not

used with diesel

en

gines.

The SRI system

is

incorporated into the powertrain

control module (PCM)

(the

PCM

was

formerly

re

ferred

to as the

engine controller

or

SBEC).

The

PCM records

the

vehicles mileage and stores

it

into

memory every

8

miles. At that time, the PCM checks

for the 60,000 and 82,500 mileage trip points. When

the current mileage matches one

of

the above men

tioned trip points,

the

SRI light

is

activated.

The following parts are

to

be replaced

at

either the

indicated mileage

or

when the SRI light remains

on

when the key

is in

the ON position. After performing

the required maintenance,

the

SRI light must

be

re set

to

turn the light

off.

96,000

km

(60,000 miles):

• Replace EGR Valve

• Clean EGR passage • Replace PCV Valve

132,000

km

(82,500 miles):

• Replace Oxygen Sensor

Refer

to

Group

0,

Lubrication and Maintenance

for

all required maintenance schedules.

Failure

to

perform

the

required maintenance

and

only reset the SRI light may be

a

violation of federal

law. Only after performing

the

required mainte

nance, should the SRI light

be

reset.

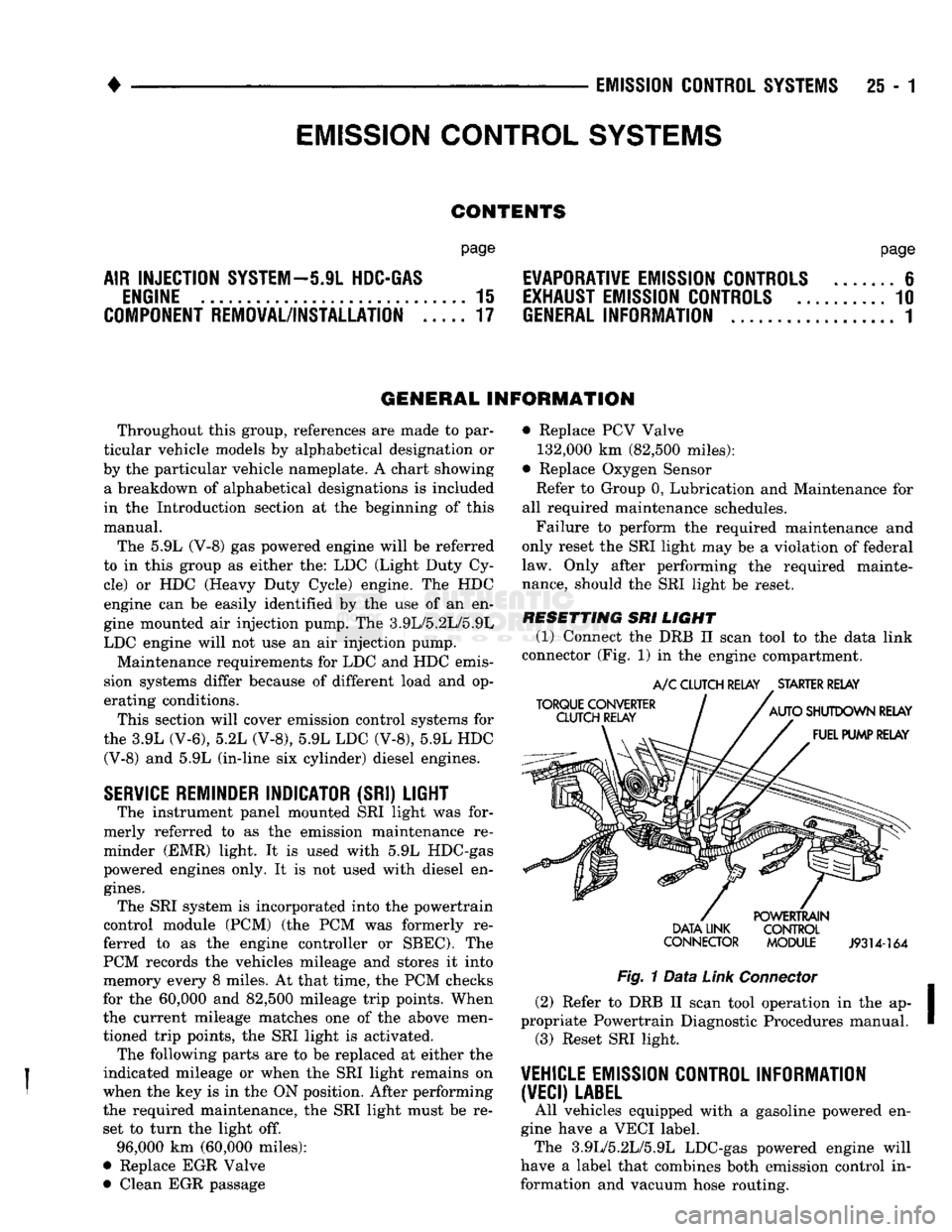

RESETTING

SRI

LIGHT

(1) Connect

the

DRB

II

scan tool

to

the

data link

connector (Fig.

1)

in

the engine compartment.

TORQUE CONVERTER

CLUTCH RELAY

A/C

CLUTCH RELAY

.

STARTER RELAY

AUTO

SHUTDOWN RELAY FUEL PUMP RELAY DATA LINK

CONNECTOR POWERTRAIN

CONTROL

MODULE

J9314-164

Fig.

1

Data

Link

Connector

(2) Refer

to

DRB

II

scan tool operation

in

the ap

propriate Powertrain Diagnostic Procedures manual. (3) Reset SRI light.

VEHICLE

EMISSION CONTROL INFORMATION

(VECI)

LABEL

All vehicles equipped with

a

gasoline powered

en

gine have

a

VECI label. The 3.9L/5.2L/5.9L LDC-gas powered engine will

have

a

label that combines both emission control

in

formation and vacuum hose routing.

EMISSION CONTROL

SYSTEMS

Page 1488 of 1502

•

EMISSION

CONTROL

SYSTEMS

25 - 11 • The electrical solenoid portion of the EET is not

energized.

• The engine back pressure entering the EGR valve

inlet is strong enough to close the transducer bleed

valve.

If back pressure is not strong enough to close the

transducer bleed valve, the transducer will bleed off the vacuum preventing EGR operation.

When the electrical solenoid portion of the EET is

de-energized by the powertrain control module (PCM), vacuum flows to the transducer. The trans

ducer is connected to the engine exhaust system by a small hose that connects to the base of the EGR

valve.

The vacuum section of the transducer is controlled

by exhaust system back pressure. When back pres sure is high enough it will close a bleed valve in the

transducer allowing vacuum to actuate the EGR

valve. If back pressure does not close the bleed valve,

vacuum will be bled off.

For more information, refer to Group 14, Fuel Sys

tems.

Refer to the Component Removal/Installation sec

tion of this group for EGR valve replacement proce

dures.

EGR SYSTEM ON-BOARD DIAGNOSTICS

(CALIFORNIA VEHICLES

ONLY)

The powertrain control module (PCM) performs an

On-Board Diagnostic (OBD) check of the EGR system

on all California vehicles. The diagnostic system uses

the electric EGR transducer (EET) for the system

tests.

The OBD check activates only during selected en

gine/driving conditions. When the conditions are met,

the PCM energizes the EET solenoid to disable the EGR. The PCM checks for a change in the oxygen sensor signal. If the air-fuel mixture goes lean, the

PCM will attempt to enrichen the mixture. The PCM

registers a diagnostic trouble code (DTC) if the EGR system has failed or degraded. After registering a

DTC,

the PCM turns the malfunction indicator

lamp (MIL) on. (The malfunction indicator lamp was formerly referred to as the check engine lamp). The

malfunction indicator lamp indicates the need for im

mediate service.

If a malfunction is indicated by the malfunction in

dicator lamp and a DTC for the EGR system was set,

check for proper operation of EGR system. Use the

following: System Test, EGR Gas Flow Test and EGR

Diagnosis Chart.

If the EGR system tests properly, check the system

using the DRB II scan tool. For use of the DRB II,

refer to the appropriate Powertrain Diagnostics Pro cedure service manual. EGR SYSTEM SERVICE

A malfunctioning EGR system can cause engine

spark knock, sags or hesitation, rough idle, engine

stalling and poor driveability. To be sure of proper

operation of the EGR system, inspect all passages for

blockage. Check moving parts for binding. Inspect

the complete system for leaks. Replace system com ponents or hoses that are leaking.

Inspect all hose connections between throttle body,

intake manifold, EGR valve and EGR purge solenoid.

Replace any vacuum harness components that are

leaking or damaged. Refer to EGR Control System Test and EGR Gas

Flow Test to check EGR System operation.

EGR GAS FLOW TEST (1) Disconnect hose from EGR valve and connect a

hand vacuum pump to EGR valve nipple. Apply a

minimum of 12 inches vacuum the valve.

(2) The engine should now idle roughly or stall. If

this occurs, the valve is performing correctly. Proceed

to Electric EGR Transducer Test.

(3) If the engine idle speed did not change, remove

the EGR valve and inspect the valve and the exhaust passage in the manifold for blockage. Repair as nec

essary. If blockage is not present, replace the EGR

valve.

ELECTRIC EGR TRANSDUCER (EET)

TESTING ELECTRIC SOLENOID PORTION OF TRANSDUCER

(1) Bring the engine to normal operating tempera

ture.

Operate at idle speed. Test the EET as follows: (2) Check vacuum at EET vacuum source. Discon

nect the hose and attach a vacuum gauge to it.

(3) Vacuum should be a minimum of 15 inches:

• If vacuum is low, check the line for kinks, twists

or a loose connection at vacuum connector or intake

manifold.

• If vacuum is correct, remove gauge. Connect the

vacuum line and proceed to next step. (4) Check EET operation using the appropriate

Powertrain Diagnostic Procedures service manual.

Refer to this manual for use of the DRB II scan tool and repair EET as necessary.

TESTING VACUUM PORTION

OF

TRANSDUCER

(1) Disconnect the EET vacuum lines, back pres

sure line and electrical connector. Remove trans

ducer.

(2) Plug the EET EGR valve port.

(3) Apply 1-2 pounds air pressure to exhaust back

pressure port. Air pressure can be supplied with a

hand operated air pump or compressed air (regulated

to correct psi).

(4) Apply a minimum of 12 inches of vacuum to

vacuum supply port.

Replace the EET if it will not hold vacuum.

Page 1494 of 1502

•

EMISSION

CONTROL SYSTEMS

25 - 17

COMPONENT REMOVAL/INSTALLATION

INDEI

page

Air

Filter/Filter

Housing—Diesel Engines

17

Air

Filter/Filter

Housing—Gas Engines

17

Air

Injection

Pump

17

Air

Injection

Pump Relief Valve

18

Check

Valve—Air

Injection

Tube

18

Coolant Temperature

Sensor

. 18

EGR

Tube—Gas Powered Engines

19

EGR

Valve

19

AIR FILTER/FILTER HOUSING-GAS ENGINES

REMOVAL/INSTALLATION Remove crankcase breather/filter hose at side of air

filter housing. Remove wingnut (Fig. 1) and remove

housing from engine. Check condition of gasket at

throttle body and replace as necessary. To replace air filter element only: Remove wingnut

and air filter housing cover (Fig. 1). Clean inside of

housing before replacing filter. Housing removal is not necessary for filter replacement.

^

WING NUT

COVER

:

GASKET

| I

MOUNTING

STUD

Fig.

1 Air

Filter

Housing—Gas

Powered

Engines—Typical

page

Electric

EGR Transducer (EET)

20

EVAP

Canister

20

EVAP

Canister Purge Solenoid

20

Fuel Tank

Filler

Tube

Cap . 21

Oxygen

(02)

Sensor

21

Powertrain Control Module (PCM)

21

Pressure

Relief/Rollover Valve

21

If housing-to-throttle body mounting stud is being

installed, tighten to 10 N»m (90 in. lbs.) torque. In stall housing to engine and tighten wingnut to 1.5

N»m (15 in. lbs.) torque.

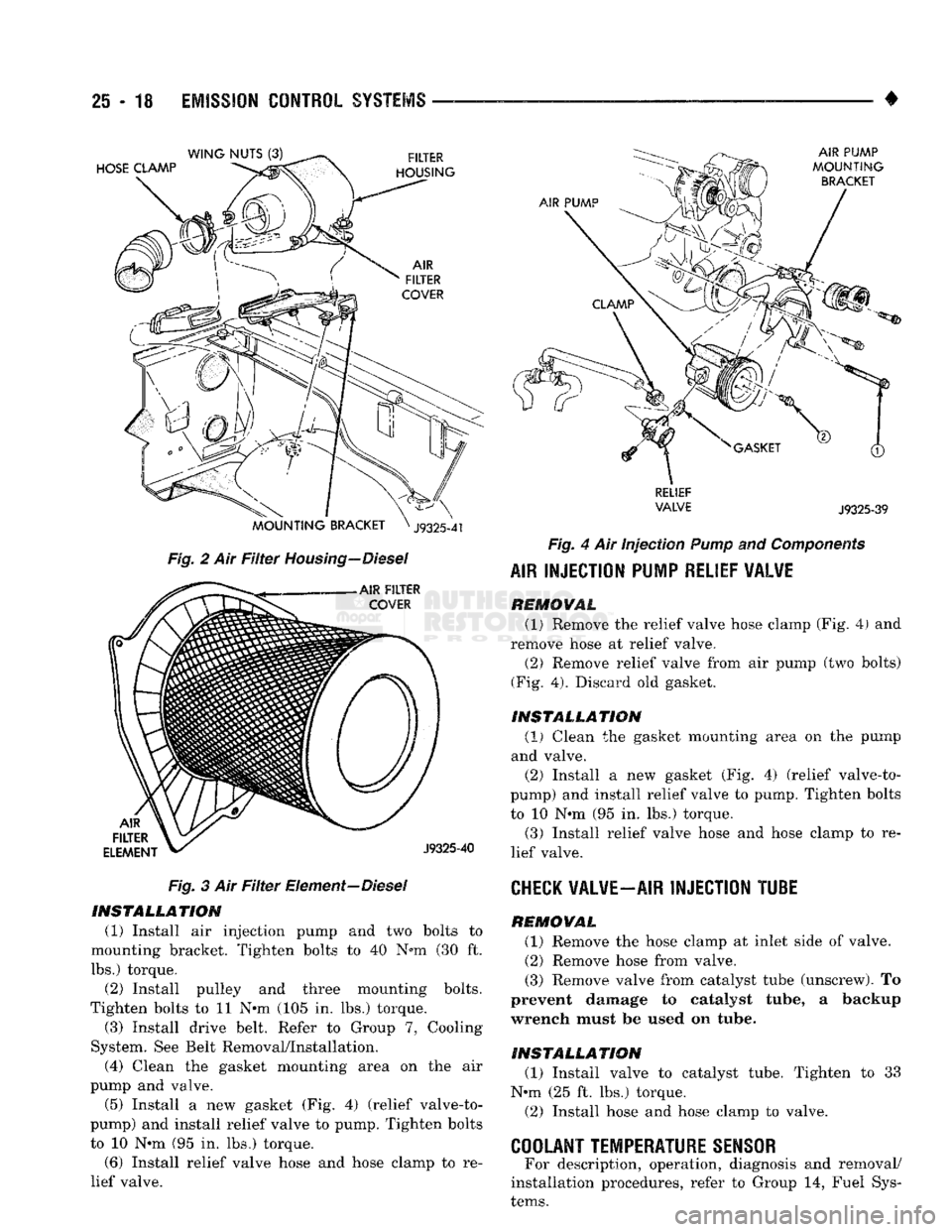

AIR FILTER/FILTER HOUSING-DIESEL ENGINES

REMO

VAL/INSTALLA

TION Remove the hose clamp at air filter housing (Fig.

2).

Remove mounting nuts and remove air filter

housing from vehicle.

To replace air filter element only: Remove hose clamp

and hose at air filter housing inlet tube. Remove three

wingnuts and air filter housing cover (Figs. 2 and 3). Clean inside of housing before replacing filter. Housing

removal is not necessary for filter replacement.

When installing a new air filter element, push el

ement into cover. Be sure it is pushed into tabs in

back of filter housing. Install wing nuts.

If housing had been removed, install mounting

nuts and tighten to 10 N»m (95 in. lbs.) torque.

AIR INJECTION PUMP

REMOVAL (1) Remove the relief valve hose clamp (Fig. 4) and

remove hose at relief valve.

(2) Remove relief valve from air pump (two bolts)

(Fig. 4). (3) Loosen (but do not remove at this time) the

three air pump pulley mounting bolts (number 2—figure 4).

(4) Relax the automatic belt tensioner and remove

the engine accessory drive belt. Refer to Group 7, Cooling System. See Belt Removal/Installation.

(5) Remove the three air pump pulley bolts and re

move pulley from pump.

(6) Remove the two air pump mounting bolts

(number

1—figure

4) and remove pump from mount

ing bracket.

Page 1495 of 1502

25

- 18

EMISSION

CONTROL

SYSTEMS

Fig. 2 Air Filter Housing—Diesel Fig. 3 Air Filter Element—Diesel INSTALLATION

(1) Install air injection pump and two bolts to

mounting bracket. Tighten bolts to 40 N*m (30 ft.

lbs.) torque. (2) Install pulley and three mounting bolts.

Tighten bolts to 11 N*m (105 in. lbs.) torque.

(3) Install drive belt. Refer to Group 7, Cooling

System. See Belt Removal/Installation.

(4) Clean the gasket mounting area on the air

pump and valve. (5) Install a new gasket (Fig. 4) (relief valve-to-

pump) and install relief valve to pump. Tighten bolts to 10 N*m (95 in. lbs.) torque.

(6) Install relief valve hose and hose clamp to re

lief valve. •

RELIEF

VALVE

J9325-39

Fig. 4 Air Injection

Pump

and

Components

AIR

INJECTION PUMP RELIEF VALVE REMOVAL

(1) Remove the relief valve hose clamp (Fig. 4) and

remove hose at relief valve.

(2) Remove relief valve from air pump (two bolts)

(Fig. 4). Discard old gasket.

INSTALLATION (1)

Clean the gasket mounting area on the pump

and valve. (2) Install a new gasket (Fig. 4) (relief valve-to-

pump) and install relief valve to pump. Tighten bolts

to 10 N*m (95 in. lbs.) torque. (3) Install relief valve hose and hose clamp to re

lief valve.

CHECK

VALVE—AIR INJECTION TUBE REMOVAL

(1) Remove the hose clamp at inlet side of valve.

(2) Remove hose from valve.

(3) Remove valve from catalyst tube (unscrew). To

prevent damage to catalyst tube, a backup

wrench must be used on tube.

INSTALLATION

(1) Install valve to catalyst tube. Tighten to 33

N«m (25 ft. lbs.) torque.

(2) Install hose and hose clamp to valve.

COOLANT TEMPERATURE SENSOR

For description, operation, diagnosis and removal/

installation procedures, refer to Group 14, Fuel Sys

tems.

Page 1500 of 1502

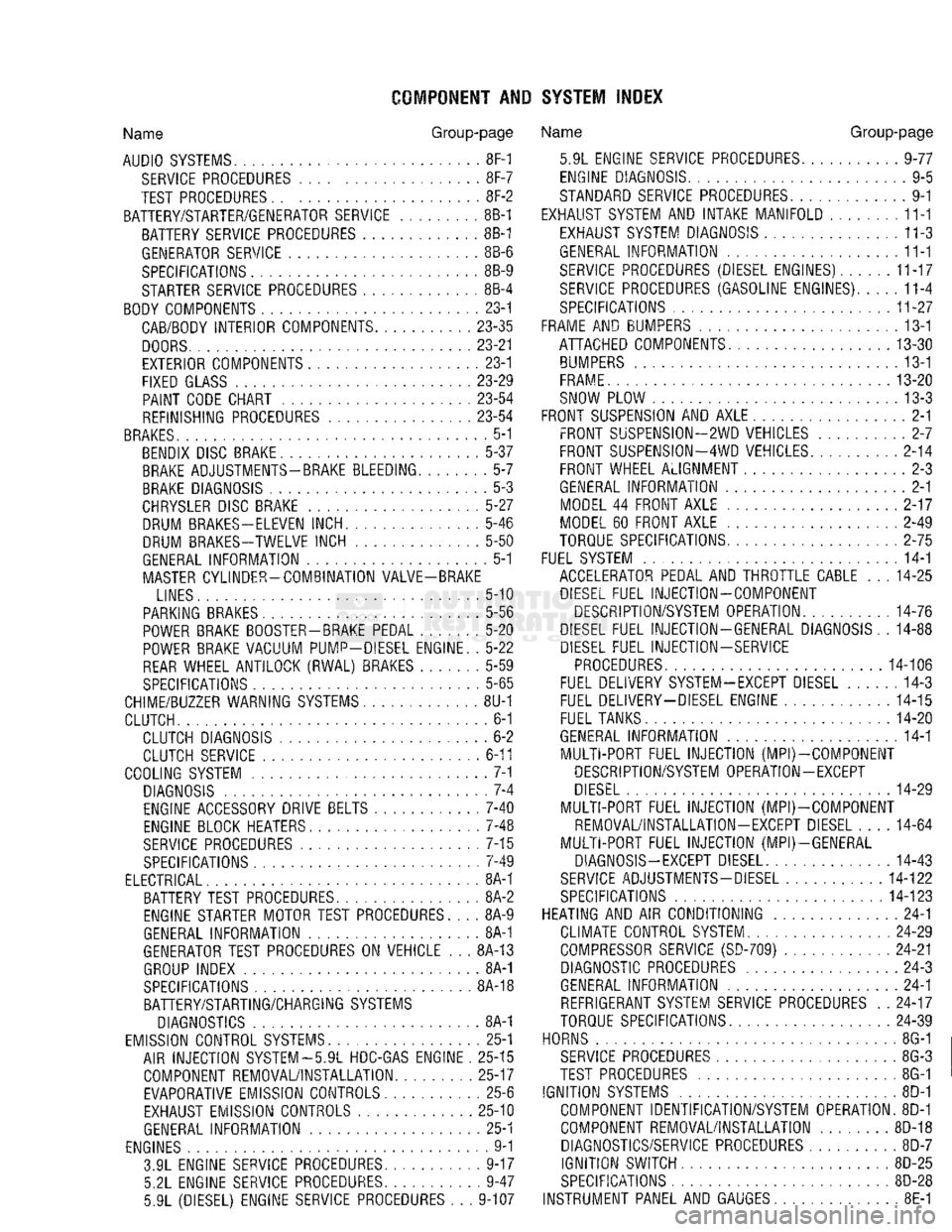

COMPONENT AND SYSTEM INDEX

Name

Group-page

AUDIO

SYSTEMS

8F-1

SERVICE

PROCEDURES 8F-7

TEST PROCEDURES 8F-2

BATTERY/STARTER/GENERATOR SERVICE 8B-1 BATTERY SERVICE PROCEDURES 8B-1

GENERATOR SERVICE 8B-6

SPECIFICATIONS 8B-9

STARTER SERVICE PROCEDURES 8B-4

BODY COMPONENTS 23-1 CAB/BODY INTERIOR COMPONENTS

23-35

DOORS

23-21

EXTERIOR COMPONENTS 23-1

FIXED GLASS

23-29

PAINT

CODE CHART

23-54

REFINISHING PROCEDURES

23-54

BRAKES

5-1 BENDIX DISC BRAKE 5-37 BRAKE ADJUSTMENTS-BRAKE BLEEDING 5-7

BRAKE DIAGNOSIS 5-3

CHRYSLER

DISC BRAKE 5-27 DRUM BRAKES—ELEVEN INCH 5-46

DRUM BRAKES-TWELVE INCH 5-50

GENERAL INFORMATION 5-1 MASTER CYLINDER—COMBINATION VALVE-BRAKE

LINES 5-10

PARKING BRAKES 5-56

POWER BRAKE BOOSTER-BRAKE PEDAL 5-20 POWER BRAKE VACUUM PUMP-DIESEL ENGINE. . 5-22

REAR

WHEEL ANTILOCK

(RWAL)

BRAKES 5-59

SPECIFICATIONS 5-65

CHIME/BUZZER WARNING

SYSTEMS

8U-1

CLUTCH 6-1 CLUTCH DIAGNOSIS 6-2 CLUTCH SERVICE 6-11

COOLING SYSTEM 7-1

DIAGNOSIS 7-4

ENGINE ACCESSORY DRIVE BELTS 7-40

ENGINE BLOCK HEATERS 7-48

SERVICE

PROCEDURES 7-15 SPECIFICATIONS 7-49

ELECTRICAL 8A-1 BATTERY TEST PROCEDURES 8A-2

ENGINE STARTER MOTOR TEST PROCEDURES.... 8A-9

GENERAL INFORMATION 8A-1

GENERATOR TEST PROCEDURES ON VEHICLE . . . 8A-13

GROUP INDEX 8A-1

SPECIFICATIONS 8A-18

BATTERY/STARTING/CHARGING

SYSTEMS

DIAGNOSTICS 8A-1

EMISSION

CONTROL

SYSTEMS.

25-1 AIR INJECTION SYSTEM—5.9L HDC-GAS ENGINE . 25-15 COMPONENT REMOVAL/INSTALLATION 25-17 EVAPORATIVE EMISSION CONTROLS 25-6

EXHAUST EMISSION CONTROLS 25-10

GENERAL INFORMATION 25-1

ENGINES 9-1 3.9L ENGINE SERVICE PROCEDURES 9-17 5.2L ENGINE SERVICE PROCEDURES 9-47

5.9L (DIESEL) ENGINE SERVICE PROCEDURES . . . 9-107

Name

Group-page

5.9L ENGINE SERVICE PROCEDURES 9-77 ENGINE DIAGNOSIS 9-5

STANDARD SERVICE PROCEDURES 9-1

EXHAUST SYSTEM AND INTAKE MANIFOLD 11-1

EXHAUST SYSTEM DIAGNOSIS 11-3

GENERAL INFORMATION 11-1

SERVICE

PROCEDURES (DIESEL ENGINES) 11-17

SERVICE

PROCEDURES (GASOLINE ENGINES) 11-4

SPECIFICATIONS 11-27

FRAME AND BUMPERS 13-1 ATTACHED COMPONENTS 13-30

BUMPERS

13-1

FRAME 13-20

SNOW PLOW 13-3

FRONT SUSPENSION AND AXLE 2-1 FRONT SUSPENSION—2WD VEHICLES 2-7

FRONT SUSPENSION—4WD VEHICLES 2-14 FRONT WHEEL ALIGNMENT 2-3

GENERAL INFORMATION 2-1 MODEL 44 FRONT AXLE 2-17

MODEL 60 FRONT AXLE 2-49

TORQUE SPECIFICATIONS 2-75

FUEL SYSTEM 14-1 ACCELERATOR PEDAL AND THROTTLE CABLE . . . 14-25

DIESEL

FUEL INJECTION—COMPONENT DESCRIPTION/SYSTEM OPERATION 14-76

DIESEL

FUEL INJECTION-GENERAL DIAGNOSIS. . 14-88

DIESEL

FUEL INJECTION-SERVICE

PROCEDURES

14-106

FUEL DELIVERY SYSTEM-EXCEPT DIESEL 14-3

FUEL DELIVERY-DIESEL ENGINE 14-15 FUEL TANKS 14-20

GENERAL INFORMATION 14-1 MULTI-PORT FUEL INJECTION (MPI)-COMPONENT DESCRIPTION/SYSTEM OPERATION-EXCEPT

DIESEL

14-29

MULTI-PORT FUEL INJECTION

(MPlj-COMPONENT

REMOVAL/INSTALLATION-EXCEPT DIESEL .... 14-64

MULTI-PORT FUEL INJECTION (MPI)—GENERAL DIAGNOSIS-EXCEPT DIESEL 14-43

SERVICE

ADJUSTMENTS-DIESEL

14-122

SPECIFICATIONS

14-123

HEATING AND AIR CONDITIONING 24-1 CLIMATE CONTROL SYSTEM

24-29

COMPRESSOR

SERVICE

(SD-709)

24-21 DIAGNOSTIC PROCEDURES 24-3

GENERAL INFORMATION 24-1 REFRIGERANT SYSTEM SERVICE PROCEDURES . . 24-17

TORQUE SPECIFICATIONS

24-39

HORNS 8G-1

SERVICE

PROCEDURES 8G-3

TEST PROCEDURES 8G-1

IGNITION

SYSTEMS

8D-1 COMPONENT IDENTIFICATION/SYSTEM OPERATION. 8D-1

COMPONENT REMOVAL/INSTALLATION 8D-18 DIAGNOSTICS/SERVICE PROCEDURES 8D-7

IGNITION

SWITCH

8D-25

SPECIFICATIONS

8D-28

INSTRUMENT PANEL AND GAUGES 8E-1