ad blue DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 590 of 1502

![DODGE TRUCK 1993 Service User Guide

•

WIRING DIAGRAMS 8W - 115 RIGHT DOOR SWITCH CONNECTOR

P33

160R/BK (LOCK)

P35

160R/VT

] —E

FORWARD

TERMINAL END

-BLUE

P36 16PK/VT

• F35 16RD

P34 1BPK/BK (UNLOCK)

t

UP

y- DODGE TRUCK 1993 Service User Guide

•

WIRING DIAGRAMS 8W - 115 RIGHT DOOR SWITCH CONNECTOR

P33

160R/BK (LOCK)

P35

160R/VT

] —E

FORWARD

TERMINAL END

-BLUE

P36 16PK/VT

• F35 16RD

P34 1BPK/BK (UNLOCK)

t

UP

y-](/img/12/56922/w960_56922-589.png)

•

WIRING DIAGRAMS 8W - 115 RIGHT DOOR SWITCH CONNECTOR

P33

160R/BK (LOCK)

P35

160R/VT

] —E

FORWARD

TERMINAL END

-BLUE

P36 16PK/VT

• F35 16RD

P34 1BPK/BK (UNLOCK)

t

UP

y-—•

• •—'

RIGHT FRONT DOOR SWITCH /

(VIEW FROM /

TERMINAL END) / BLACK—^

fTOPl

/

VLK

P36 P34

16PK 16PK VT BK F35 16RD-

P36 16PK/VT -J

P35

160R/VT-

P33

160R/BK- P34 16PK/BK

J938W-11 P34

16PK

BK

F35

16RD P35

160R VT

P33

160R/BK-P34 16PK/BK

POWER

DOOR LOCKS RIGHT FRONT

DOOR

MOTOR

^ LK X—\UNLK

to AD 74

Page 594 of 1502

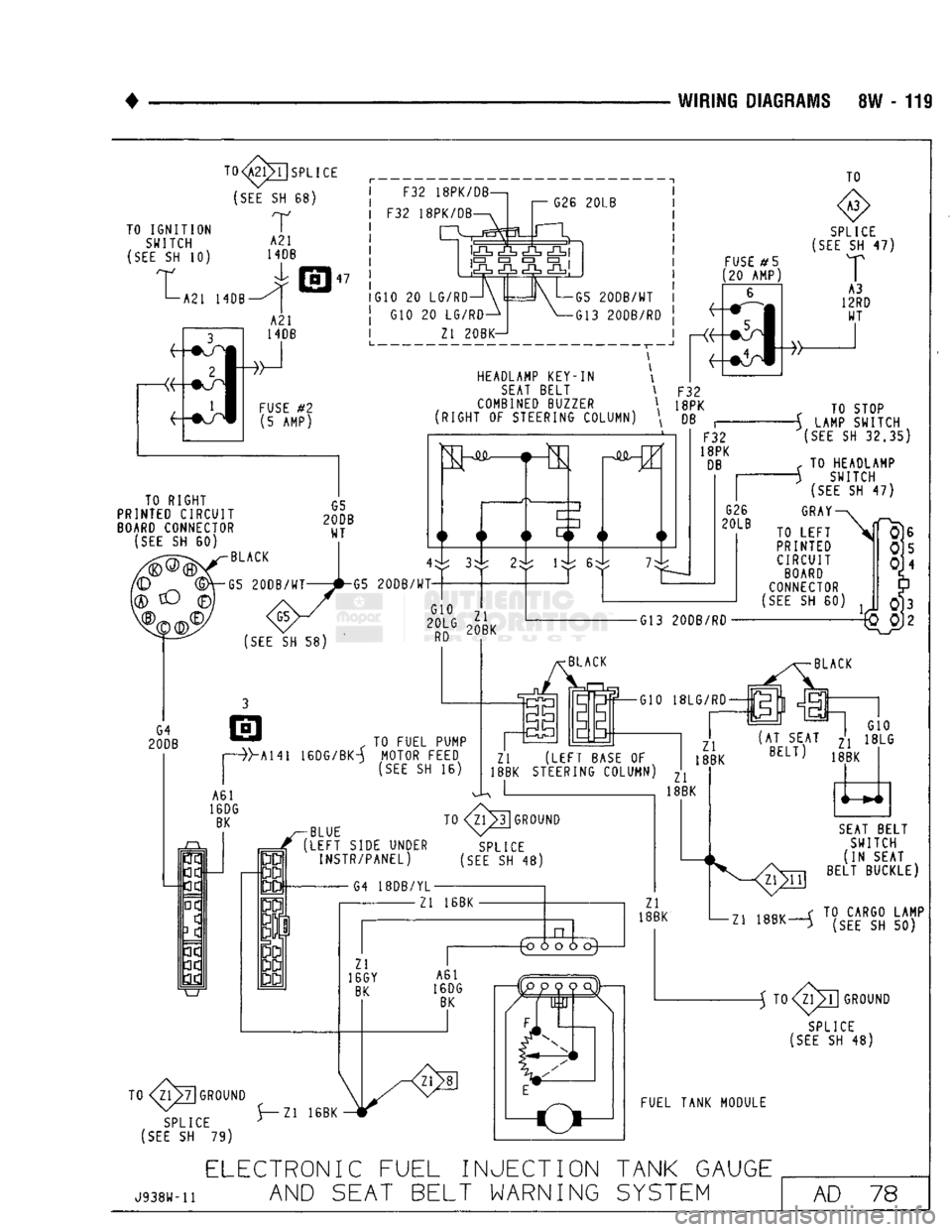

WIRING

DIAGRAMS SW - 119

TO IGNITION SWITCH

(SEE

SH 10)

t 1—A21 HOB TO

1| SPLICE

(SEE

SH 68)

r

A21

HOB

47 F32 18PK/DB—,

F32 18PK/DB G26

20LB

lc£L

iCZD

• • • G10 20 LG/RD-

G10 20 LG/RD- Zl 20BK- ~1

G5

20DB/WT

G13 20DB/RD TO

FUSE

#5

[20 AMP)

SPLICE

(SEE

SH 47)

HEADLAMP KEY-IN

SEAT

BELT

COMBINED

BUZZER \ F32

\ 18PK

RIGHT OF STEERING COLUMN \ DB TO RIGHT

PRINTED CIRCUIT

BOARD

CONNECTOR

(SEE

SH 60)

(SEE

SH 58)

BLACK

G5

20DB/WT

G5

20DB/WT-

G10

20LG

Zl

20BK F32

18PK

DB

G26

20LB

TO STOP

-\ LAMP SWITCH

(SEE

SH

32,35)

< TO HEADLAMP

S SWITCH

(SEE

SH 47)

GRAY

TO LEFT

PRINTED CIRCUIT

BOARD

CONNECTOR

(SEE

SH 60)

•G13 20DB/RD

, TO FUEL PUMP

Hi41 16DG/BK-A MOTOR FEED

(SEE

SH 16) G10

Zl

(LEFT

BASE

OF

18BK STEERING COLUMN) ^ I , 18BK Zl

8BK (AT SEAT ^ 18LG

BELT>

18BK

^BLUE

r

(LEFT

SIDE UNDER INSTR/PANEL)

G4 18DB/YL- TO

GROUND

SPLICE

[SEE

SH 48)

Zl 16BK XL Zl

16GY

BK

TO

SPLICE

(SEE

SH 79) \ z^20

5~Zl 16BK -HT A61

16DG

BK

4o

o o d

) c

F. it

JJ Zl

18BK Z1>11

SEAT

BELT

SWITCH

(IN SEAT

BELT BUCKLE) 71 1ftR. f TO CARGO LAMP

-Zl 18BK—^ (SEE SH 50) -5 TO

SPLICE

(SEE

SH 48)

FUEL TANK MODULE

J938W-11

ELECTRONIC

FUEL INJECTION TANK GAUGE

AND

SEAT BELT WARNING

SYSTEM

AD

78

Page 595 of 1502

![DODGE TRUCK 1993 Service User Guide

8W - 120 WIRING

DIAGRAMS

TO TRANSMISSION

WIRING r

(SEE

SH 7 DIESEL)J

(SEE

SH 9 GAS)

TO<L7^T]

SPLICE

(SEE

SH 47) S

TO TURN

SIGNAL SWITCH

(SEE

SH 56)

T0<Z1>3

[SPLICE

(SEE

SH DODGE TRUCK 1993 Service User Guide

8W - 120 WIRING

DIAGRAMS

TO TRANSMISSION

WIRING r

(SEE

SH 7 DIESEL)J

(SEE

SH 9 GAS)

TO<L7^T]

SPLICE

(SEE

SH 47) S

TO TURN

SIGNAL SWITCH

(SEE

SH 56)

T0<Z1>3

[SPLICE

(SEE

SH](/img/12/56922/w960_56922-594.png)

8W - 120 WIRING

DIAGRAMS

TO TRANSMISSION

WIRING r

(SEE

SH 7 DIESEL)J

(SEE

SH 9 GAS)

TO

(SEE

SH 47) S

TO TURN

SIGNAL SWITCH

(SEE

SH 56)

T0

[SPLICE

(SEE

SH 48)

SPORT

UTILITY

LEFT

TAIL.

STOP

i TURN X2

SIGNAL 18GY

LAMP

LEFT

BACK-UP LAMP CAB I

CHASSIS

SWEPT

LINE

BOX

LEFT

TAIL.

STOP

I

TURN

SIGNAL LAMP -

LEFT

BACK-UP LAMP

LEFT

TAIL,

STOP

I

TURN Y9

SIGNAL ,ppv LAMP 18fY

LEFT

BACK-UP LAMP BLUE

(LEFT

SIDE UNDER I/P)

TO

SPLICE

(SEE

SH

77.78)

B2

18VT/BK

AD

79

REAR

LIGHTING

J938W-11

Page 598 of 1502

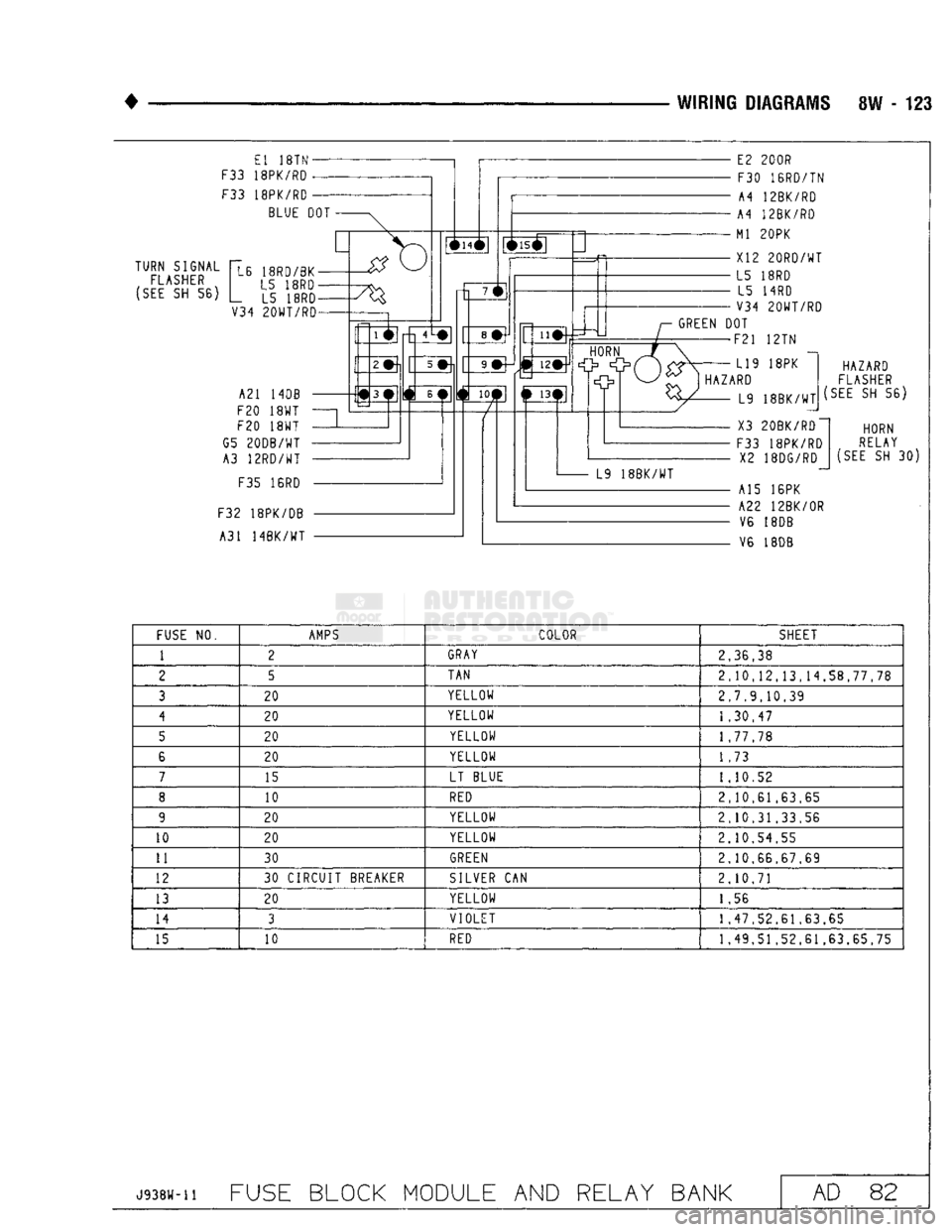

•

WIRING DIAGRAMS 8W - 123 F33

F33 El 18TN

18PK/RD

18PK/RD BLUE DOT TURN SIGNAL

FLASHER

(SEE

SH 56) L6 18RD/BK

L5 18RD

_ L5 18RD

V34

20WT/RD

A21 14DB

F20 18WT

F20 18WT

G5 20DB/WT

A3 12RD/WT

F35 16RD

F32 A31 18PK/DB

14BK/WT

GREEN

DOT

F21

E2

200R

F30 16RD/TN A4 12BK/RD

A4 12BK/RD

Ml 20PK

X12 20RD/WT

L5 18RD L5 14RD

V34 20WT/RD

12TN L19 18PK

HAZARD

L9 18BK/WT

X3

20BK/RD

F33 18PK/RD X2 18DG/RD_

A15 16PK

A22 12BK/0R V6 18DB

V6 18DB HAZARD

FLASHER

(SEE

SH 56)

HORN

RELAY

(SEE

SH 30)

FUSE

NO.

AMPS

COLOR

SHEET

1 2

GRAY

2,36,38

2

5

TAN

2, 10,

12.13,14,58,77,78

3 20 YELLOW

2.7,9,10,39

4 20 YELLOW

1.30.47

5

20 YELLOW

1

.77.78

6 20 YELLOW

1 ,73

7 15 LT BLUE

1,10.52

8 10

RED

2,10,61.63.65

9 20 YELLOW

2.10,31.33.56

10 20 YELLOW

2.10.54.55

11 30

GREEN

2.10.66,67.69

12 30 CIRCUIT BREAKER

SILVER

CAN

2,10,71

13 20 YELLOW

1 ,56

14 3 VIOLET

1.47,52.61.63,65

15 10

RED

1,49,51.52,61,63,65,75

J938W-H

FUSE BLOCK MODULE AND RELAY BANK

AD 82

Page 617 of 1502

9

- 12

ENGINES

•

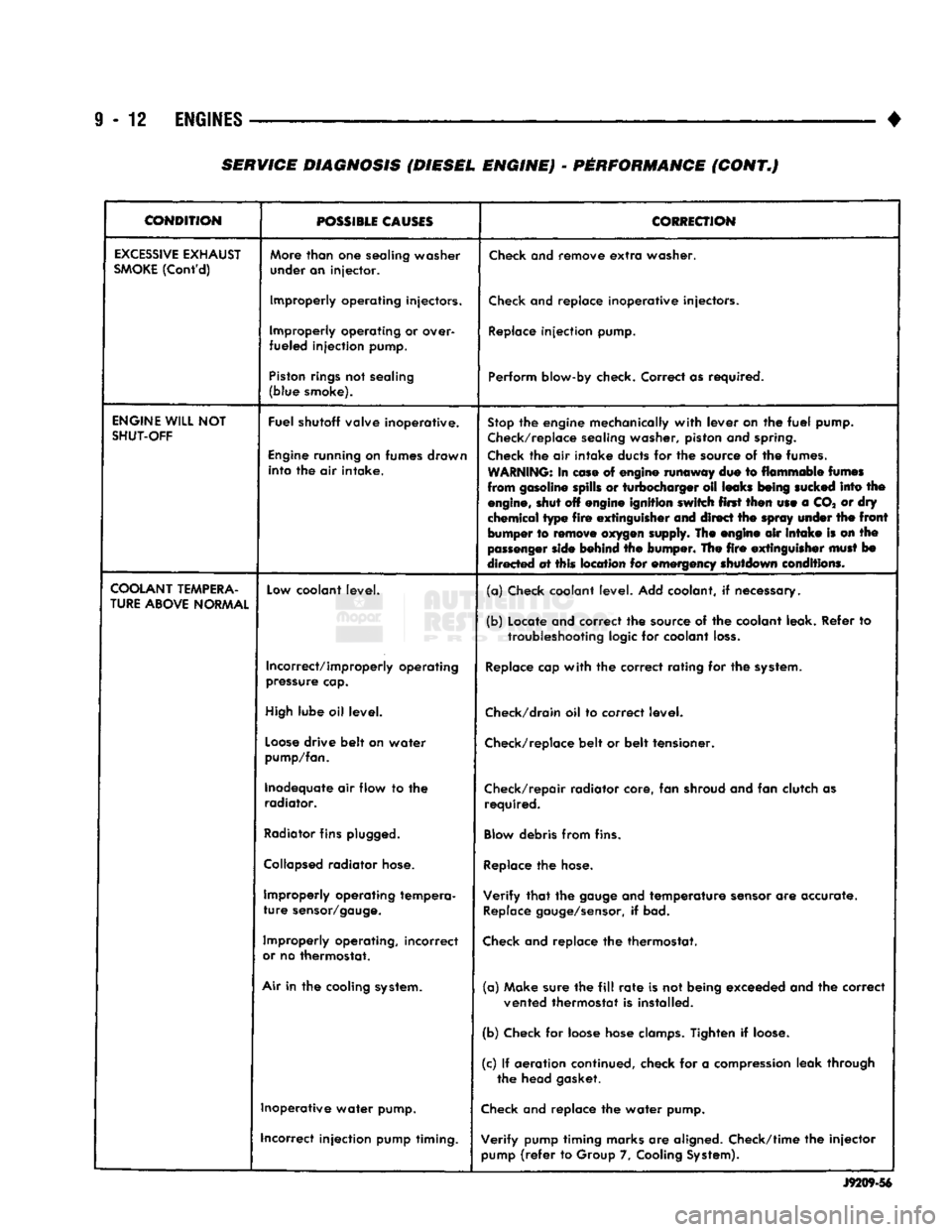

CONDITION

POSSIBLE

CAUSES

CORRECTION

EXCESSIVE

EXHAUST

SMOKE

(Cont'd)

More

than

one

sealing washer

under an injector.

Check

and remove

extra

washer.

Improperly operating injectors.

Check

and replace inoperative injectors.

Improperly operating or over-

fueled injection pump.

Replace

injection pump.

Piston

rings

not sealing

(blue smoke). Perform blow-by check. Correct as required.

ENGINE

WILL

NOT

SHUT-OFF

Fuel shutoff valve inoperative.

Engine

running on fumes drawn into the air intake.

Stop

the engine mechanically

with

lever on the

fuel

pump.

Check/replace

sealing washer, piston and

spring.

Check

the air intake ducts for the source of the fumes.

WARNING:

In

ease

of engine runaway due to flammable

fumes

from gasoline spills or turbocharger oil leaks

being

sucked

into the

engine,

shut off engine ignition switch first then use a CO* or dry

chemical type

fire

extinguisher

and direct the

spray

under

the

front

bumper to

remove

oxygen

supply. The engine air

intake

is on the

passenger

side

behind the bumper. The

fire

extinguisher

must

bo

directed at this location for emergency shutdown conditions.

COOLANT

TEMPERA

TURE

ABOVE

NORMAL

Low

coolant level.

(a) Check coolant level. Add coolant, if necessary.

(b) Locate and correct the source of the coolant leak. Refer to

troubleshooting

logic for coolant

loss.

Incorrect/improperly operating

pressure

cap.

Replace

cap

with

the correct rating for the

system.

High

lube oil level.

Check/drain

oil to correct level.

Loose

drive belt on water

pump/fan.

Check/replace

belt or belt tensioner.

Inadequate air flow to the radiator. Check/repair radiator core, fan shroud and fan clutch as

required.

Radiator

fins

plugged.

Blow

debris from fins.

Collapsed

radiator

hose.

Replace

the

hose.

Improperly operating tempera

ture

sensor/gauge.

Verify

that

the

gauge

and temperature

sensor

are accurate.

Replace

gauge/sensor,

if bad.

Improperly operating, incorrect

or

no thermostat.

Check

and replace the thermostat.

Air

in the cooling

system.

(a) Make sure the

fill

rate

is not being exceeded and the correct

vented thermostat is installed.

(b) Check for loose hose

clamps.

Tighten if

loose.

(c) If aeration continued, check for a

compression

leak through the head gasket.

Inoperative water pump.

Check

and replace the water pump.

incorrect injection pump timing. Verify pump timing marks are aligned. Check/time the injector

pump

(refer

to Group 7,

Cooling

System).

J9209-56

SERVICE DIAGNOSIS (DIESEL ENGINE) - PERFORMANCE (CONT.)

Page 631 of 1502

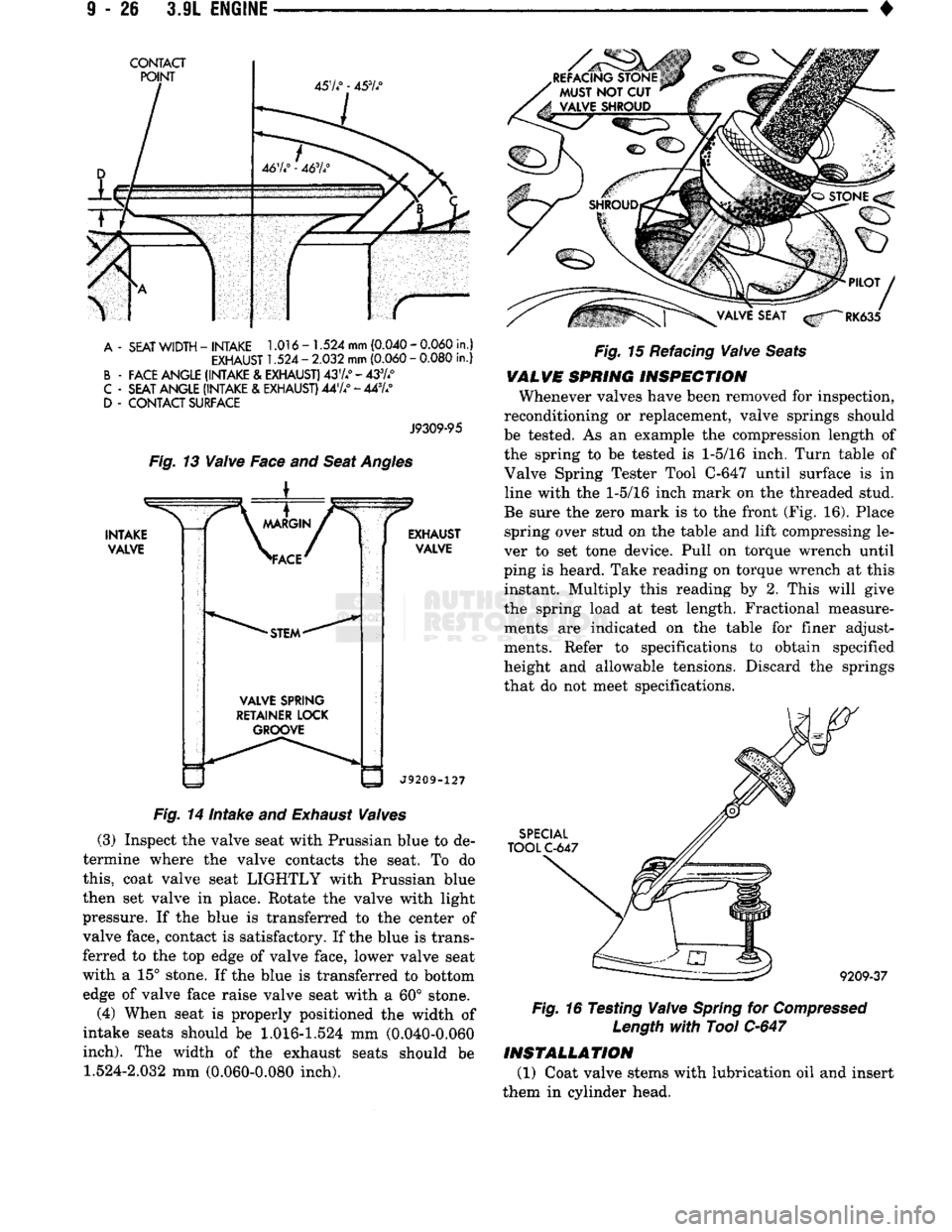

A

-

SEAT

WIDTH

-

INTAKE

1.016

-

1.524

mm

(0.040

-

0.060

in.)

EXHAUST

1.524

-

2.032

mm

(0.060

-

0.080

in.)

B

-

FACE

ANGLE

(INTAKE

& EXHAUST)

4374°

-

433A°

C

-

SEAT

ANGLE

(INTAKE

& EXHAUST)

4474°

-

44%°

D

-

CONTACT SURFACE

J9309-95

Fig.

13

Valve

Face and

Seat

Angles

i

INTAKE

VALVE

\

MARGIN

/ "

>FACE'

•STEM"

VALVE SPRING

RETAINER LOCK GROOVE EXHAUST

VALVE

J9209-127

Fig.

14 Intake and

Exhaust

Valves

(3) Inspect

the

valve seat with Prussian blue

to de

termine where

the

valve contacts

the

seat.

To do

this,

coat valve seat LIGHTLY with Prussian blue

then

set

valve

in

place. Rotate

the

valve with light

pressure.

If the

blue

is

transferred

to the

center

of

valve face, contact

is

satisfactory.

If

the blue

is

trans

ferred

to the top

edge

of

valve face, lower valve seat

with

a 15°

stone.

If

the blue

is

transferred

to

bottom edge

of

valve face raise valve seat with

a 60°

stone.

(4)

When seat

is

properly positioned

the

width

of

intake seats should

be 1.016-1.524 mm (0.040-0.060

inch).

The

width

of the

exhaust seats should

be 1.524-2.032 mm (0.060-0.080

inch).

Fig.

15 Refacing

Valve

Seats

VALVE

SPRING

INSPECTION

Whenever valves have been removed

for

inspection,

reconditioning

or

replacement, valve springs should

be tested.

As an

example

the

compression length

of

the spring

to be

tested

is 1-5/16

inch. Turn table

of

Valve Spring Tester Tool

C-647

until surface

is in

line with

the 1-5/16

inch mark

on the

threaded stud.

Be sure

the

zero mark

is to the

front (Fig.

16).

Place spring over stud

on the

table

and

lift compressing

le

ver

to set

tone device. Pull

on

torque wrench until

ping

is

heard. Take reading

on

torque wrench

at

this instant. Multiply this reading

by 2.

This will give

the spring load

at

test length. Fractional measure ments

are

indicated

on the

table

for

finer adjustments. Refer

to

specifications

to

obtain specified

height

and

allowable tensions. Discard

the

springs

that

do not

meet specifications.

SPECIAL

TOOL

C-647

9209-37

Fig.

16 Testing

Valve

Spring

for

Compressed

Length

with

Tool

C-647

INSTALLATION

(1)

Coat valve stems with lubrication

oil and

insert

them

in

cylinder head.

Page 660 of 1502

•

5.2L

ENGINE

I - 55

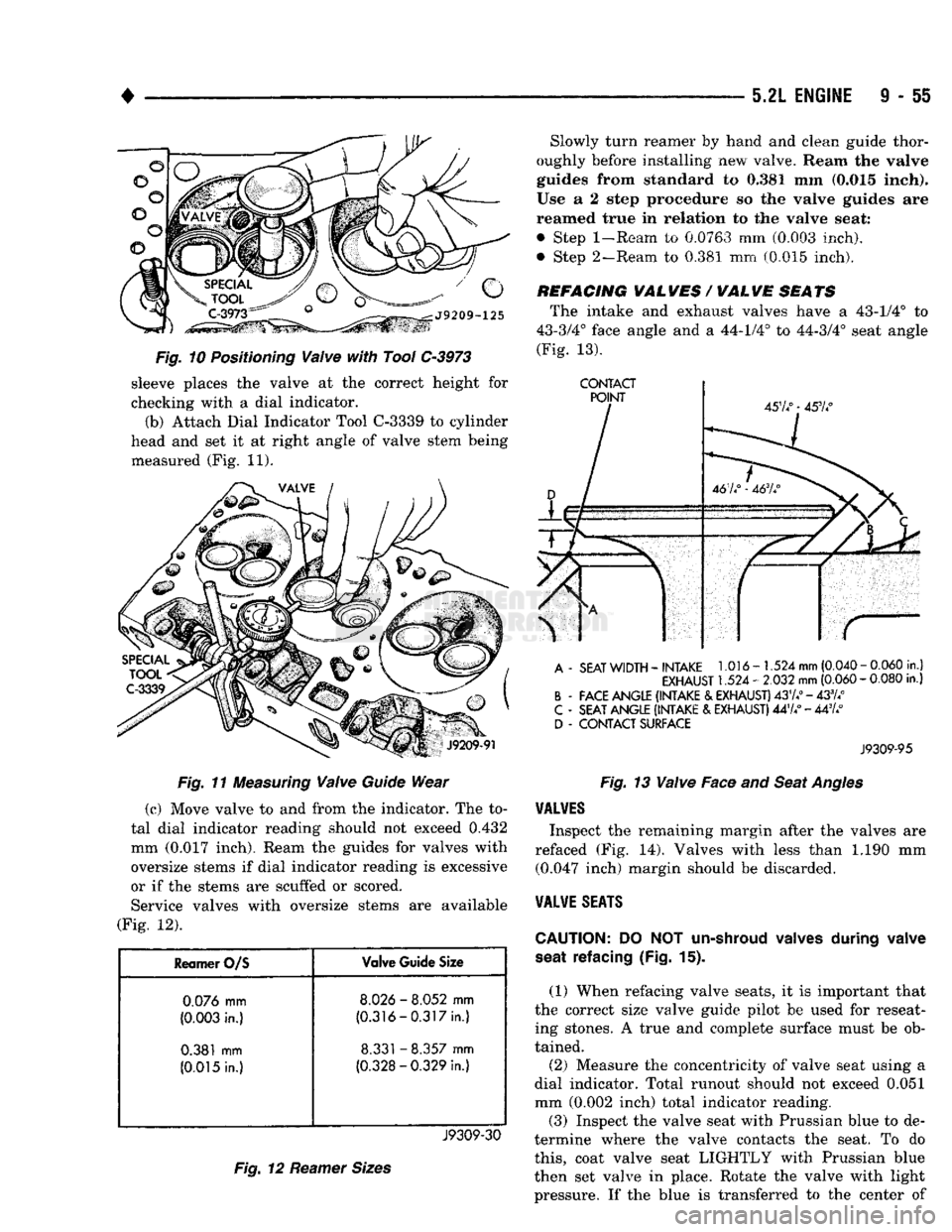

Fig. 10 Positioning Valve with Tool C-3973 sleeve places the valve at the correct height for

checking with a dial indicator.

(b) Attach Dial Indicator Tool C-3339 to cylinder

head and set it at right angle of valve stem being measured (Fig. 11).

Fig. 11 Measuring Valve Guide Wear

(c) Move valve to and from the indicator. The to

tal dial indicator reading should not exceed

0.432

mm

(0.017

inch). Ream the guides for valves with

oversize stems if dial indicator reading is excessive

or if the stems are scuffed or scored. Service valves with oversize stems are available

(Fig. 12).

Reamer

O/S

Valve

Guide

Size

0.076

mm

8.026

-

8.052

mm

(0.003

in.)

(0.316-0.317in.)

0.381

mm

8.331

-

8.357

mm

(0.015

In.)

(0.328-0.329

In.)

J9309-30

Fig. 12 Reamer Sizes

Slowly turn reamer

by

hand

and

clean guide thor

oughly before installing

new

valve. Ream

the valve

guides from standard

to 0,381 mm

(0.015 Inch).

Use

a 2

step procedure

so the

valve guides

are

reamed true

in

relation

to the

valve seat:

• Step

1-Ream

to 0.0763 mm (0.003 inch),

• Step 2—Ream, to 0.381 mm (0.015 inch).

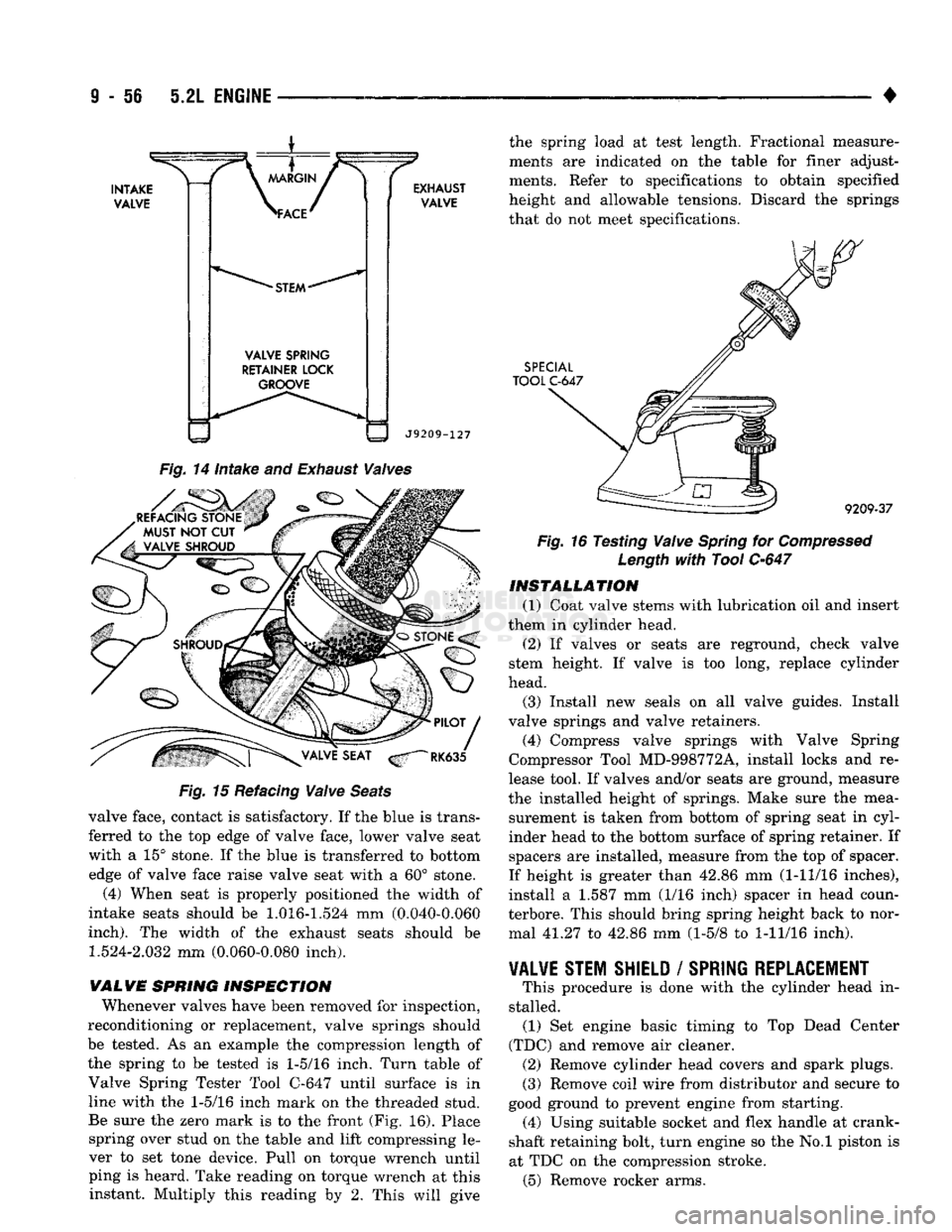

REFACING

VAL

WES

/

WAL

WE

SEATS

The intake and exhaust valves have a 43-1/4° to

43-3/4° face angle and a 44-1/4° to 44-3/4° seat angle

(Fig.

13).

CONTACT

A

-

SEAT

WIDTH

-

INTAKE

1.016-1.524

mm

(0.040

-

0.060

in.)

EXHAUST

1.524 -

2.032

mm

(0.060

-

0.080

in.)

B

-

FACE ANGLE (INTAKE

&

EXHAUST)

437.°

-433//

C

-

SEAT ANGLE (INTAKE

&

EXHAUST)

447/ - 447/

D

-

CONTACT SURFACE

J9309-95

Fig. 13 Valve Face and Seat Angles

VALVES

Inspect the remaining margin after the valves are

refaced (Fig. 14). Valves with less than 1.190 mm (0.047 inch) margin should be discarded.

VALVE

SEATS

CAUTION:

DO NOT

un-shroud valves

during

valve

seat

refacing (Fig.

15).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat ing stones. A true and complete surface must be ob

tained.

(2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.051

mm (0.002 inch) total indicator reading. (3) Inspect the valve seat with Prussian blue to de

termine where the valve contacts the seat. To do

this,

coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

Page 661 of 1502

9

- 56 5.2L

ENGINE

•

VALVE

SPRING

RETAINER LOCK GROOVE

EXHAUST

VALVE

J9209-127 the spring load at test length. Fractional measure

ments are indicated on the table for finer adjust

ments. Refer to specifications to obtain specified

height and allowable tensions. Discard the springs

that do not meet specifications.

SPECIAL

TOOL

C-647

Fig.

14 Intake and

Exhaust

Valves

Fig.

15 Refacing

Valve

Seats

valve face, contact is satisfactory. If the blue is trans

ferred to the top edge of valve face, lower valve seat

with a 15° stone. If the blue is transferred to bottom edge of valve face raise valve seat with a 60° stone.

(4) When seat is properly positioned the width of

intake seats should be

1.016-1.524

mm (0.040-0.060

inch).

The width of the exhaust seats should be

1.524-2.032

mm (0.060-0.080 inch).

WALVE SPRING INSPECTION Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested. As an example the compression length of

the spring to be tested is

1-5/16

inch. Turn table of Valve Spring Tester Tool C-647 until surface is in line with the

1-5/16

inch mark on the threaded stud.

Be sure the zero mark is to the front (Fig. 16). Place spring over stud on the table and lift compressing le

ver to set tone device. Pull on torque wrench until ping is heard. Take reading on torque wrench at this instant. Multiply this reading by 2. This will give ^

9209-37

Fig.

16 Testing

Valve

Spring

for

Compressed

Length

with

Tool

C-647

INSTALLATION

(1) Coat valve stems with lubrication oil and insert

them in cylinder head.

(2) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(3) Install new seals on all valve guides. Install

valve springs and valve retainers.

(4) Compress valve springs with Valve Spring

Compressor Tool MD-998772A, install locks and re

lease tool. If valves and/or seats are ground, measure

the installed height of springs. Make sure the mea surement is taken from bottom of spring seat in cyl

inder head to the bottom surface of spring retainer. If spacers are installed, measure from the top of spacer.

If height is greater than 42.86 mm (1-11/16 inches),

install a 1.587 mm (1/16 inch) spacer in head coun-

terbore. This should bring spring height back to nor mal 41.27 to 42.86 mm (1-5/8 to

1-11/16

inch).

VALVE STEM SHIELD

/

SPRING REPLACEMENT

# This procedure is done with the cylinder head in

stalled. (1) Set engine basic timing to Top Dead Center

(TDC) and remove air cleaner. (2) Remove cylinder head covers and spark plugs.

(3) Remove coil wire from distributor and secure to

good ground to prevent engine from starting. (4) Using suitable socket and flex handle at crank

shaft retaining bolt, turn engine so the No.l piston is

at TDC on the compression stroke. (5) Remove rocker arms.

Page 690 of 1502

•

5.9L

ENGINE

9 - 85 sleeve places the valve at the correct height for

checking with a dial indicator.

Fig.

11

Measuring

Valve

Guide

Wear

(c) Move valve to and from the indicator. The to

tal dial indicator reading should not exceed 0.432

mm (0.017 inch). Ream the guides for valves with

oversize stems if dial indicator reading is excessive

or if the stems are scuffed or scored. Service valves with oversize stems are available

(Fig. 12).

Reamer O/S Valve Guide Size

0.076

mm

8.026

-

8.052

mm

(0.003

in.)

(0.316-0.317

in.)

0.381

mm

8.331

-

8.357

mm

(0.015

in.)

(0.328-0.329

in.)

J9309-30

Fig.

12

Reamer

Sizes

Slowly turn reamer by hand and clean guide thor

oughly before installing new valve. Ream the valve

guides from standard to 0.381 mm (0.015 inch).

Use a 2 step procedure so the valve guides are

reamed true in relation to the valve seat:

• Step

1-Ream

to 0.0763 mm (0.003 inch).

• Step 2-Ream to 0.381 mm (0.015 inch).

REFACING VALVES / VALVE SEATS The intake and exhaust valves have a 43-1/4° to

43-3/4° face angle and a 44-1/4° to 44-3/4° seat angle (Fig. 13).

CONTACT

A

-

SEAT

WIDTH

-

INTAKE

1.016-1.524

mm

(0.040

-

0.060

in.)

EXHAUST

1.524 -

2.032

mm

(0.060

-

0.080

in.)

B

-

FACE ANGLE (INTAKE

&

EXHAUST)

4374°-433/4°

C

-

SEAT ANGLE (INTAKE

&

EXHAUST)

447/ - 443A°

D

-

CONTACT SURFACE

J9309-95

Fig.

13

Valve

Face and

Seat

Angles

VALVES

Inspect the remaining margin after the valves are

refaced (Fig. 14). Valves with less than 1.190 mm (0.047 inch) margin should be discarded.

VALVE

SEATS

CAUTION:

DO NOT

un-shroud valves during valve

seat refacing

(Fig. 15).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat ing stones. A true and complete surface must be ob

tained.

(2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.051

mm (0.002 inch) total indicator reading.

(3)

Inspect the valve seat with Prussian blue to de

termine where the valve contacts the seat. To do

this,

coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light pressure. If the blue is transferred to the center of

Page 691 of 1502

9

• 86 5.9L

ENGINE

•

INTAKE

VALVE

\

MARGIN

/ >

\ACE^

*

STEM

*

VALVE

SPRING

RETAINER

LOCK

GROOVE EXHAUST

VALVE

J9209-127

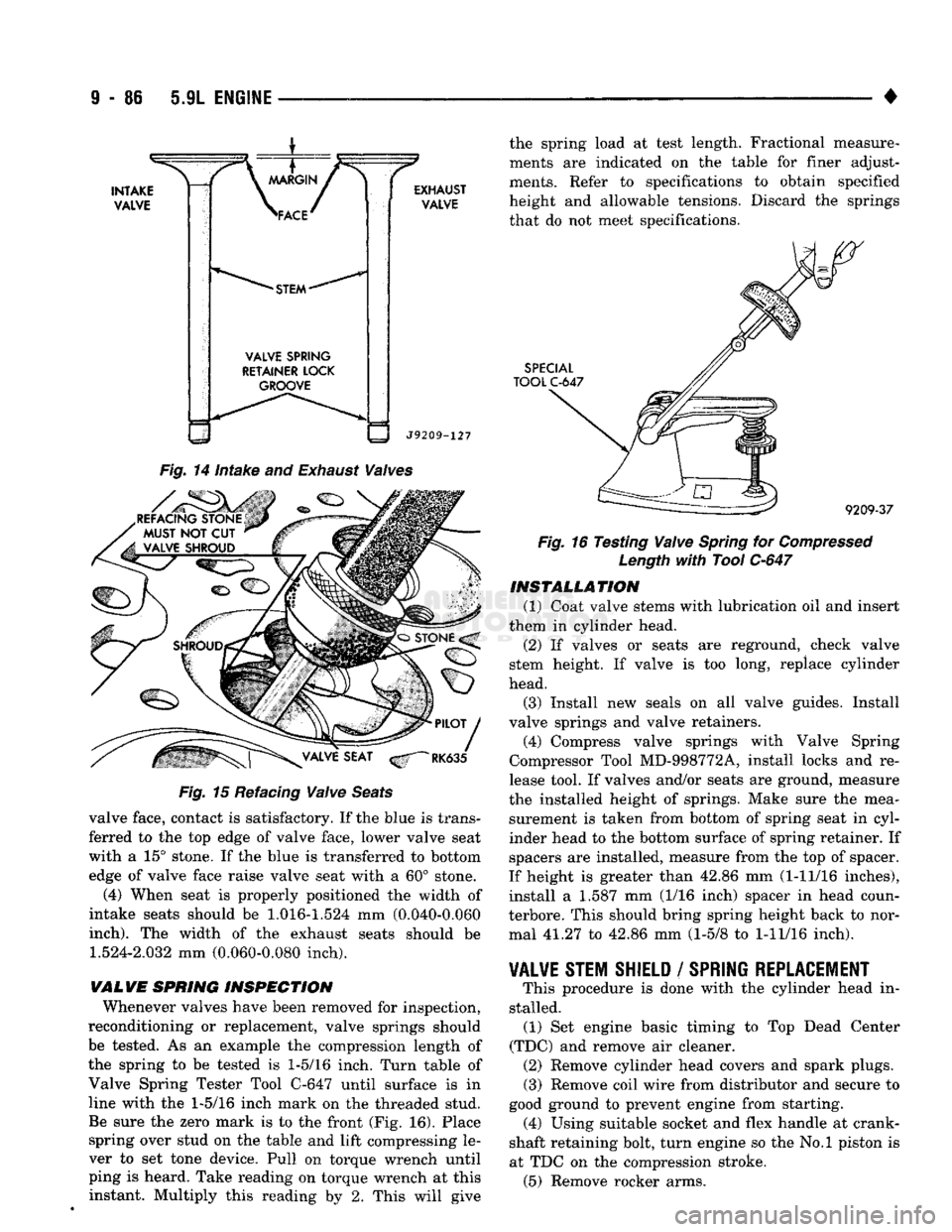

Fig.

14

intake

and

Exhaust

Waives

REFACING STONE MUST

NOT CUT

VALVE SHROUD Fig.

15 Refacing

Waive

Seats

valve face, contact is satisfactory. If the blue is trans ferred to the top edge of valve face, lower valve seat

with a 15° stone. If the blue is transferred to bottom edge of valve face raise valve seat with a 60° stone.

(4) When seat is properly positioned the width of

intake seats should be

1.016-1.524

mm (0.040-0.060

inch).

The width of the exhaust seats should be

1.524-2.032

mm (0.060-0.080 inch).

VALVE

SPRING

INSPECTION

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should be tested. As an example the compression length of

the spring to be tested is

1-5/16

inch. Turn table of

Valve Spring Tester Tool C-647 until surface is in

line with the

1-5/16

inch mark on the threaded stud. Be sure the zero mark is to the front (Fig. 16). Place spring over stud on the table and lift compressing le

ver to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this instant. Multiply this reading by 2. This will give the spring load at test length. Fractional measure

ments are indicated on the table for finer adjust

ments. Refer to specifications to obtain specified

height and allowable tensions. Discard the springs that do not meet specifications.

SPECIAL

TOOL

C-647

9209-37

Fig.

16 Testing

Waive

Spring

for

Compressed

Length

with

Tool

C-647

INSTALLATION

(1) Coat valve stems with lubrication oil and insert

them in cylinder head.

(2) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(3) Install new seals on all valve guides. Install

valve springs and valve retainers.

(4) Compress valve springs with Valve Spring

Compressor Tool MD-998772A, install locks and re

lease tool. If valves and/or seats are ground, measure

the installed height of springs. Make sure the mea surement is taken from bottom of spring seat in cyl

inder head to the bottom surface of spring retainer. If

spacers are installed, measure from the top of spacer.

If height is greater than 42.86 mm (1-11/16 inches),

install a 1.587 mm (1/16 inch) spacer in head coun-

terbore. This should bring spring height back to nor mal 41.27 to 42.86 mm (1-5/8 to

1-11/16

inch).

¥AL¥E

STEM SHIELD

/

SPRING REPLACEMENT

This procedure is done with the cylinder head in

stalled. (1) Set engine basic timing to Top Dead Center

(TDC) and remove air cleaner. (2) Remove cylinder head covers and spark plugs. (3) Remove coil wire from distributor and secure to

good ground to prevent engine from starting. (4) Using suitable socket and flex handle at crank

shaft retaining bolt, turn engine so the No.l piston is

at TDC on the compression stroke. (5) Remove rocker arms.