ad blue DODGE TRUCK 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 867 of 1502

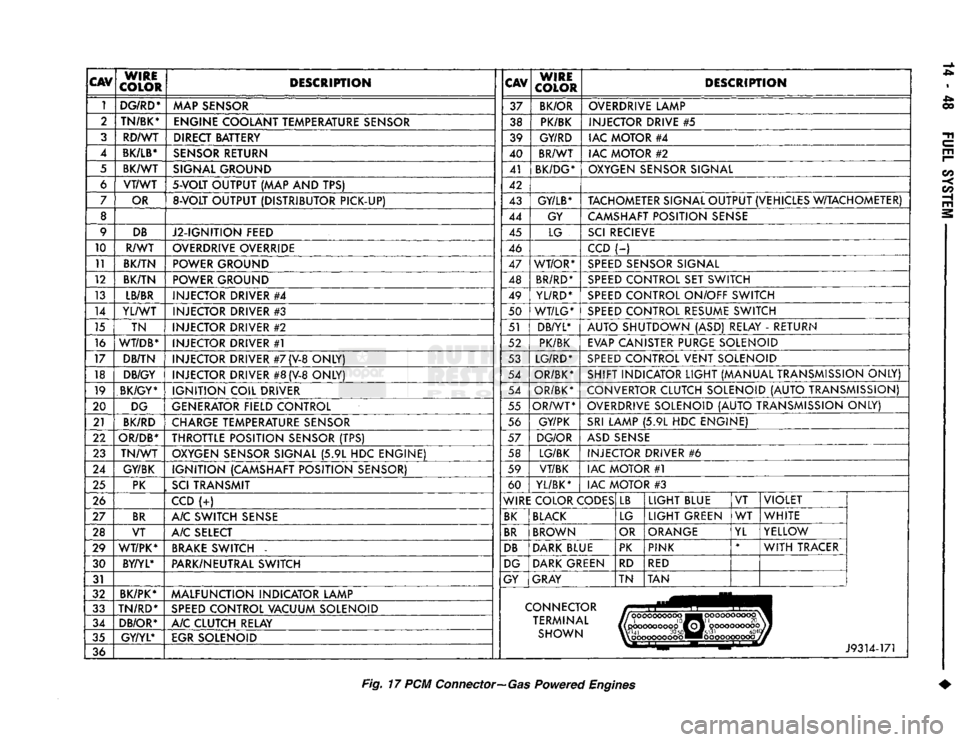

CAV

WIRE

COLOR DESCRIPTION

CAV

WIRE

COLOR DESCRIPTION

1 DG/RD*

MAP SENSOR 37

BK/OR OVERDRIVE LAMP

2 TN/BK*

ENGINE COOLANT TEMPERATURE SENSOR 38 PK/BK INJECTOR DRIVE

#5

3 RD/WT DIRECT BATTERY 39 GY/RD IAC MOTOR

#4

4

BK/LB*

SENSOR RETURN 40 BR/WT

IAC MOTOR

#2

5 BK/WT SIGNAL GROUND 41

BK/DG* OXYGEN SENSOR SIGNAL

6 VT/WT

5-VOLT

OUTPUT

(MAP AND TPS)

42

7 OR

8-VOLT

OUTPUT (DISTRIBUTOR PICK-UP) 43

GY/LB*

TACHOMETER SIGNAL OUTPUT (VEHICLES W/TACHOMETER)

8 44 GY CAMSHAFT POSITION SENSE

9 DB

J2-IGNITION FEED 45

LG SCI RECIEVE

10 R/WT OVERDRIVE OVERRIDE

46 CCD

(-)

11 BK/TN POWER GROUND 47 WT/OR* SPEED SENSOR SIGNAL

12 BK/TN POWER GROUND 48 BR/RD* SPEED CONTROL

SET

SWITCH

13 LB/BR

INJECTOR DRIVER

#4

49

YL/RD* SPEED CONTROL ON/OFF SWITCH

14 YL/WT

INJECTOR DRIVER

#3

50 WT/LG* SPEED CONTROL RESUME SWITCH

15 TN INJECTOR DRIVER

#2

51 DB/YL*

AUTO SHUTDOWN

(ASD)

RELAY

-

RETURN

16

WT/DB*

INJECTOR DRIVER

#1

52 PK/BK

EVAP CANISTER PURGE SOLENOID

17 DB/TN INJECTOR DRIVER

#7

(V-8

ONLY) 53 LG/RD* SPEED CONTROL VENT SOLENOID

18 DB/GY

INJECTOR DRIVER

#8

(V-8

ONLY) 54

OR/BK* SHIFT INDICATOR LIGHT (MANUAL TRANSMISSION ONLY)

19 BK/GY*

IGNITION COIL DRIVER 54

OR/BK* CONVERTOR CLUTCH SOLENOID (AUTO TRANSMISSION)

20 DG

GENERATOR FIELD CONTROL 55

OR/WT OVERDRIVE SOLENOID (AUTO TRANSMISSION ONLY)

21 BK/RD

CHARGE TEMPERATURE SENSOR 56

GY/PK SRI LAMP

(5.9L HDC

ENGINE)

22

OR/DB*

THROTTLE POSITION SENSOR

(TPS)

57

DG/OR ASD SENSE

23 TN/WT

OXYGEN SENSOR SIGNAL

(5.9L HDC

ENGINE) 58 LG/BK

INJECTOR DRIVER

#6

24 GY/BK IGNITION (CAMSHAFT POSITION SENSOR) 59

VT/BK IAC MOTOR

#1

25 PK

,

SCI

TRANSMIT 60

YL/BK* IAC MOTOR

#3

26 CCD

(-:-)

WIRE COLOR CODES LB

LIGHT BLUE

VT VIOLET

27 BR

A/C SWITCH SENSE BK BLACK

LG LIGHT GREEN

WT

WHITE

28 VT A/C SELECT BR BROWN

OR ORANGE

YL YELLOW

29 WT/PK* BRAKE SWITCH

-

DB DARK BLUE PK

PINK *

WITH TRACER

30 BY/YL*

PARK/NEUTRAL SWITCH DG DARK GREEN

RD

RED

31 GY

GRAY TN TAN

32 BK/PK*

MALFUNCTION INDICATOR LAMP

33 TN/RD*

SPEED CONTROL VACUUM SOLENOID CONNECTOR

34 DB/OR* A/C CLUTCH RELAY TERMINAL

|(pcKX>coooop0ffoj'

oooooooooojj

35 GY/YL*

EGR SOLENOID SHOWN W'41

30

50«M#5l31

604

%\

oooooooooo ••ooooooooooj

36 J9314-171

Fig.

17 PCM

Connector—Gas

Powered

Engines

Page 910 of 1502

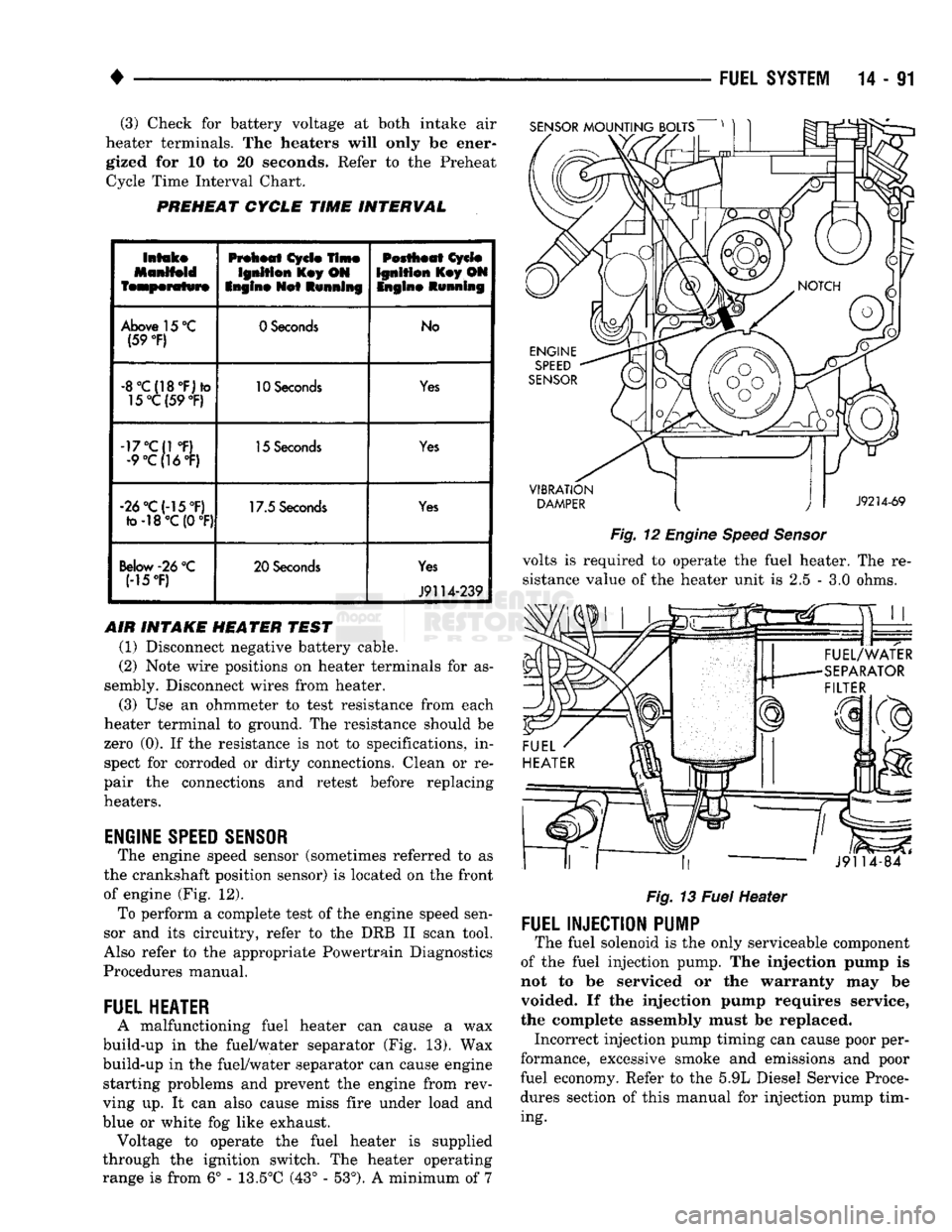

(3) Check for battery voltage at both intake air

heater terminals. The heaters will only be ener gized for 10 to 20 seconds. Refer to the Preheat Cycle Time Interval Chart.

PREHEAT

CYCLE

TIME

INTERVAL

SENSOR

MOUNTING

BOLTS

Intake

Manifold

temperature

Preheat

Cycle

Time

Ignition

Key ON

Engine

Net

Running

Pestheat

Cycle

Ignition

Key ON Ingin©

Running

Above 15 °C (59

°F)

0 Seconds

No

-8°C{18°F)*o 15°C(59

°F)

10 Seconds

Yes

-17°C{1 °F) •9°C(16°F) 15 Seconds

Yes

-26°C(-15°F) fo-18°C (0

°F)

17.5 Seconds

Yes

Below

-26

°C

(15T) 20 Seconds

Yes

J9114-239

AIR INTAKE HEATER TEST (1) Disconnect negative battery cable.

(2) Note wire positions on heater terminals for as

sembly. Disconnect wires from heater.

(3) Use an ohmmeter to test resistance from each

heater terminal to ground. The resistance should be

zero (0). If the resistance is not to specifications, in spect for corroded or dirty connections. Clean or re

pair the connections and retest before replacing

heaters.

ENGINE

SPEED

SENSOR

The engine speed sensor (sometimes referred to as

the crankshaft position sensor) is located on the front

of engine (Fig. 12). To perform a complete test of the engine speed sen

sor and its circuitry, refer to the DRB II scan tool.

Also refer to the appropriate Powertrain Diagnostics

Procedures manual.

FUEL

HEATER

A malfunctioning fuel heater can cause a wax

build-up in the fuel/water separator (Fig. 13). Wax

build-up in the fuel/water separator can cause engine starting problems and prevent the engine from rev

ving up. It can also cause miss fire under load and

blue or white fog like exhaust. Voltage to operate the fuel heater is supplied

through the ignition switch. The heater operating

range is from 6° - 13.5°C (43° - 53°). A minimum of 7

VIBRATION

DAMPER

J9214-69

Fig.

12

Engine

Speed

Sensor

volts is required to operate the fuel heater. The re

sistance value of the heater unit is 2.5 - 3.0 ohms.

««.

* rr ,,

J9114-84

Fig.

13

Fuel

Heater

FUEL

INJECTION

PUMP

The fuel solenoid is the only serviceable component

of the fuel injection pump. The injection pump is

not to be serviced or the warranty may be

voided. If the injection pump requires service,

the complete assembly must be replaced. Incorrect injection pump timing can cause poor per

formance, excessive smoke and emissions and poor

fuel economy. Refer to the 5.9L Diesel Service Proce

dures section of this manual for injection pump tim

ing.

Page 911 of 1502

14-92

FUEL

SYSTEM

• A broken injection pump timing mechanism spring

will cause the timing to be fully advanced resulting

in torque loss, a fuel knock and possible engine over

heating.

An improperly operating KSB (cold start) solenoid

will cause white smoke during engine warm-up. The

KSB solenoid is not serviceable.

A defective or non-adjustable fuel injection pump

can cause starting problems or prevent the engine

from revving up. It can also cause:

• Engine surge at idle • Rough idle (warm engine)

• Engine miss under load

• Low power

• Excessive fuel consumption

• Poor performance

• Low power

• Black smoke from the exhaust • Blue or white fog like exhaust

• Incorrect idle or maximum speed A worn fuel injection pump plunger can effect fuel

pressure and the amount of fuel injected. This results in reduced engine power. In most cases, if the injec

tion pump is delivering fuel from one outlet, it will deliver fuel from all outlets. If the internal plunger is defective, the fuel injection pump must be re

placed.

Engine power is also effected by the governor set

ting and performance. Do not attempt to adjust the governor. If the governor seals on the external adjustment screw are broken, the fuel rate may

be out of adjustment. The warranty of the injec tion pump and the engine may be void if the

seals have been tampered with or removed.

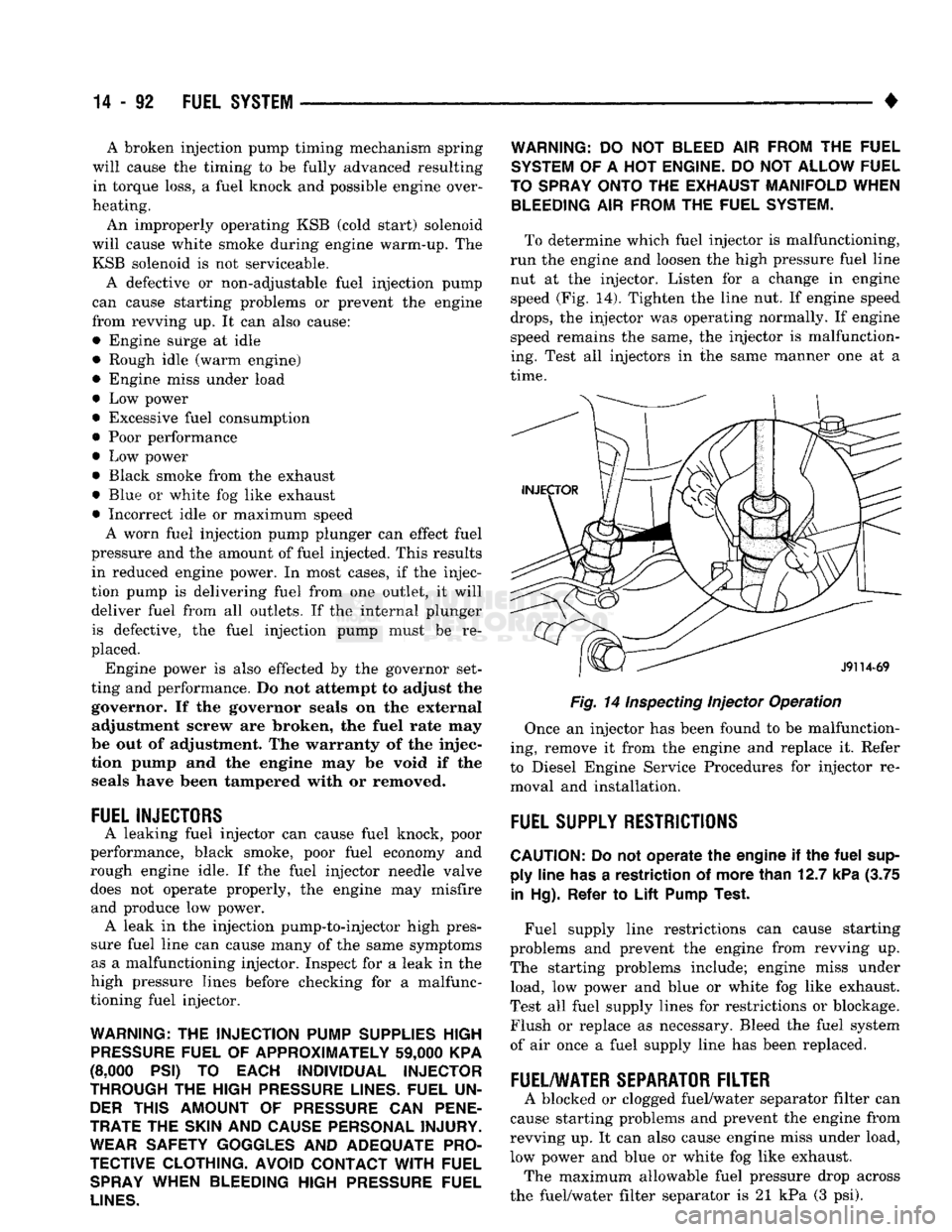

FUEL

INJECTORS

A leaking fuel injector can cause fuel knock, poor

performance, black smoke, poor fuel economy and

rough engine idle. If the fuel injector needle valve

does not operate properly, the engine may misfire and produce low power. A leak in the injection pump-to-injector high pres

sure fuel line can cause many of the same symptoms as a malfunctioning injector. Inspect for a leak in the

high pressure lines before checking for a malfunc

tioning fuel injector.

WARNING:

THE

INJECTION PUMP SUPPLIES HIGH

PRESSURE

FUEL

OF

APPROXIMATELY

59,000

KPA

(8,000

PSI) TO

EACH INDIVIDUAL INJECTOR

THROUGH THE HIGH

PRESSURE

LINES. FUEL UN

DER

THIS AMOUNT

OF

PRESSURE

CAN

PENE

TRATE THE SKIN AND CAUSE PERSONAL INJURY,

WEAR

SAFETY GOGGLES

AND

ADEQUATE PRO

TECTIVE CLOTHING. AVOID CONTACT

WITH

FUEL

SPRAY

WHEN BLEEDING HIGH

PRESSURE

FUEL

LINES.

WARNING:

DO NOT

BLEED

AIR

FROM

THE

FUEL

SYSTEM

OF A

HOT ENGINE.

DO

NOT ALLOW FUEL

TO SPRAY ONTO THE EXHAUST MANIFOLD WHEN

BLEEDING

AIR

FROM THE FUEL SYSTEM.

To determine which fuel injector is malfunctioning,

run the engine and loosen the high pressure fuel line nut at the injector. Listen for a change in engine

speed (Fig. 14). Tighten the line nut. If engine speed

drops,

the injector was operating normally. If engine

speed remains the same, the injector is malfunction

ing. Test all injectors in the same manner one at a

time.

Fig. 14

Inspecting

Injector Operation

Once an injector has been found to be malfunction

ing, remove it from the engine and replace it. Refer

to Diesel Engine Service Procedures for injector re moval and installation.

FUEL

SUPPLY

RESTRICTIONS

CAUTION:

Do not

operate

the

engine

if the

fuel

sup ply

line

has

a

restriction

of

more

than

12.7

kPa

(3.75

in

Hg).

Refer

to

Lift

Pump

Test.

Fuel supply line restrictions can cause starting

problems and prevent the engine from revving up.

The starting problems include; engine miss under load, low power and blue or white fog like exhaust.

Test all fuel supply lines for restrictions or blockage.

Flush or replace as necessary. Bleed the fuel system

of air once a fuel supply line has been replaced.

FUEL/WATER

SEPARATOR

FILTER

A blocked or clogged fuel/water separator filter can

cause starting problems and prevent the engine from

revving up. It can also cause engine miss under load,

low power and blue or white fog like exhaust. The maximum allowable fuel pressure drop across

the fuel/water filter separator is 21 kPa (3 psi).

Page 918 of 1502

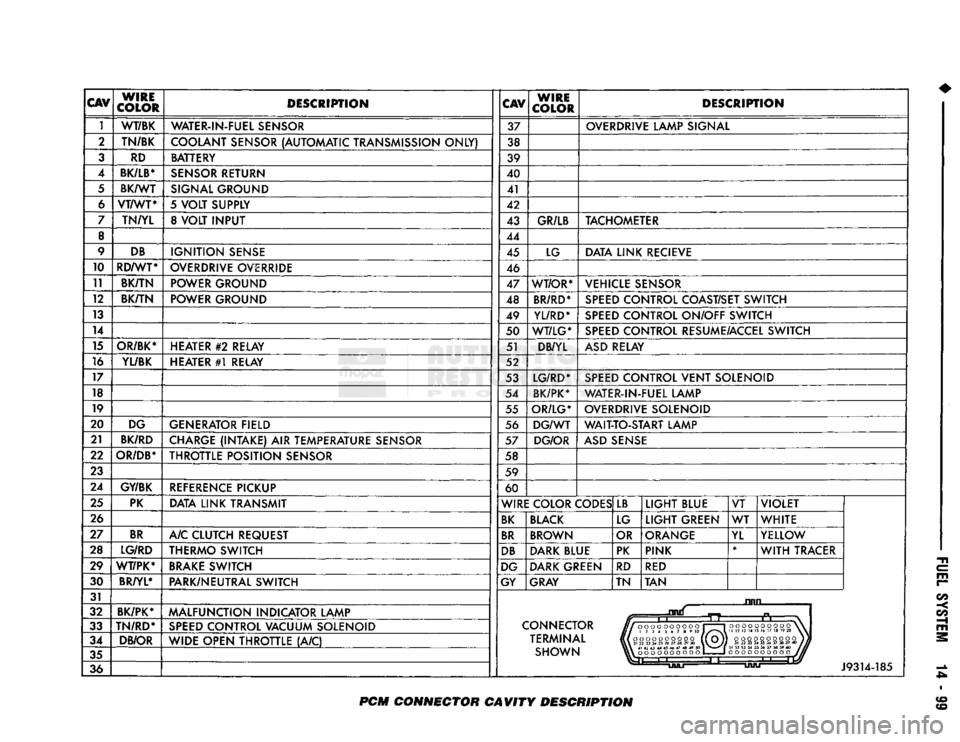

CAV

WIRE

COLOR DESCRIPTION

CAV

WIRE

COLOR DESCRIPTION

1 WT/BK

WATER-IN-FUEL SENSOR 37 OVERDRIVE LAMP SIGNAL

2 TN/BK

COOLANT SENSOR (AUTOMATIC TRANSMISSION ONLY) 38

3 RD BATTERY

39

4

BK/LB*

SENSOR RETURN 40

5 BK/WT

SIGNAL GROUND 41

6 VT/WT*

5 VOLT SUPPLY 42

7 TN/YL 8 VOLT INPUT 43 GR/LB TACHOMETER

8 44

9 DB

IGNITION SENSE 45 LG DATA LINK RECIEVE

10 RD/WT*

OVERDRIVE OVERRIDE 46

11 BK/TN POWER GROUND

47 WT/OR* VEHICLE SENSOR

12 BK/TN

POWER GROUND 48 BR/RD* SPEED CONTROL COAST/SET SWITCH

13 49 YL/RD* SPEED CONTROL ON/OFF SWITCH

14 50 WT/LG* SPEED CONTROL RESUME/ACCEL SWITCH

15 OR/BK* HEATER

#2

RELAY 51 DB/YL ASD RELAY

16 YL/BK HEATER #1 RELAY 52

17 53 LG/RD* SPEED CONTROL VENT SOLENOID

18 54 BK/PK* WATER-IN-FUEL LAMP

19 55 OR/LG* OVERDRIVE SOLENOID

20 DG GENERATOR FIELD 56 DG/WT WAIT-TO-START LAMP

21 BK/RD

CHARGE (INTAKE) AIR TEMPERATURE SENSOR 57 DG/OR ASD SENSE

22

OR/DB*

THROTTLE POSITION SENSOR 58

23 59

24 GY/BK

REFERENCE PICKUP 60

25 PK

DATA LINK TRANSMIT WIRE COLOR CODES LB

LIGHT BLUE VT VIOLET

26 BK BLACK LG LIGHT GREEN WT

WHITE

27 BR

A/C CLUTCH REQUEST BR BROWN OR ORANGE

YL YELLOW

28 LG/RD THERMO SWITCH DB DARK BLUE PK PINK *

WITH TRACER

29 WT/PK* BRAKE SWITCH DG DARK GREEN

RD RED

30 BR/YL*

PARK/NEUTRAL SWITCH GY GRAY TN TAN

31 ruin

32 BK/PK*

MALFUNCTION INDICATOR LAMP

n

33 TN/RD*

SPEED CONTROL VACUUM SOLENOID CONNECTOR

J//000OOOOOOO

1 1

HI

173456789

10 J/^"*\

Hi

oooooooooo (1 Oj]

VlX

21

22

23

24

25

26

27

28

29

30

\V~V//

oooooooooo

\

II

12 13

14 15

16 17 18

19 20

\

34 DB/OR

WIDE OPEN THROTTLE (A/C) TERMINAL

J//000OOOOOOO

1 1

HI

173456789

10 J/^"*\

Hi

oooooooooo (1 Oj]

VlX

21

22

23

24

25

26

27

28

29

30

\V~V//

oooooooooo)}

31

32 33 34 35 36 37 38 39 40

1JU

35 SHOWN \\\

41 42 43 44 45 46 47 48 49

SO

1

^m^^

|

oooooooooo

1

1

oooooooooo

J//

36

Li

J9314-185

PCM

CONNECTOR CAVITY DESCRIPTION

Page 923 of 1502

14-104

FUEL

SYSTEM

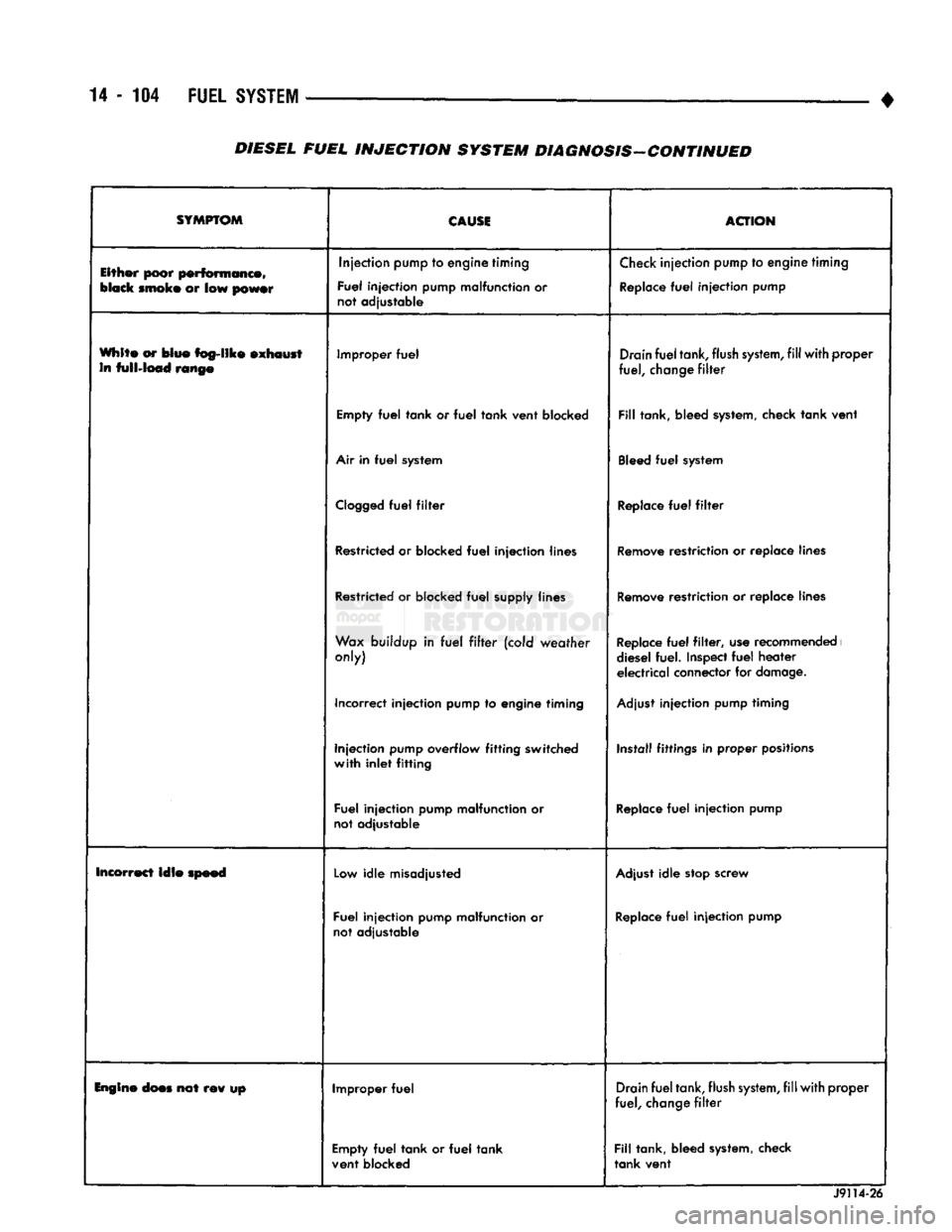

• DIESEL FUEL INJECTION SYSTEM DIAGNOSIS-CONTINUED

SYMPTOM

CAUSE

ACTION

Either poor performance,

black

smoke

or low

power

Injection

pump

to engine timing

Fuel injection pump malfunction or

not adjustable

Check

injection

pump

to

engine

timing

Replace

fuel

injection pump

White or blue fog-like exhaust in full-load range Improper

fuel

Drain

fuel

tank,

flush

system,

fill

with proper

fuel,

change

filter

Empty

fuel

tank or

fuel

tank vent blocked

Fill

tank, bleed

system,

check tank vent

Air

in

fuel

system

Bleed

fuel

system

Clogged

fuel

filter

Replace

fuel

filter

Restricted

or blocked

fuel

injection lines

Remove

restriction or replace lines

Restricted

or blocked

fuel

supply lines

Remove

restriction or replace lines

Wax

buildup in

fuel

filter

(cold weather

only)

Replace

fuel

filter,

use

recommended

i

diesel fuel.

Inspect

fuel

heater electrical connector for

damage.

Incorrect injection pump to engine timing

Adjust

injection pump timing

Injection pump overflow fitting switched

with inlet fitting Install fittings in

proper

positions

Fuel injection pump malfunction or

not adjustable

Replace

fuel

injection pump

Incorrect lale speed

Low

idle misadjusted

Adjust

idle

stop

screw

Fuel injection pump malfunction or

not adjustable

Replace

fuel

injection pump

Engine

does

not rev up Improper

fuel

Drain

fuel

tank,

flush

system,

fill

with proper

fuel,

change

filter

Empty

fuel

tank or

fuel

tank

vent blocked

Fill

tank, bleed

system,

check

tank vent J9114-26

Page 1437 of 1502

23 - 54

BODY COMPONENTS

•

REFINISHING PROCEDURES

SERVICE

INFORMATION

Exterior vehicle body colors are identified on the

Body Code plate. The plate is attached to the top, right side of the cowl below the cowl grille. The color

code location is described in the manual introduction. OEM paint colors are generally available from all

of the major paint suppliers. They are supplied in the

form of either mixing formulas or factory packaged (pre-mixed) paint. The exterior colors and corresponding Ram Truck,

Chassis Cab and Ramcharger paint codes are listed

in the following chart.

BASE

COAT/CLEAR COAT FINISH

On most vehicles a two part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects

base coat from ultraviolet light. It also provides a du

rable high gloss finish.

WET SANDING, BUFFING

AND

POLISHING

Minor acid etching, orange peel or smudging in

clear coat can be reduced with light wet sanding,

hand buffing and polishing. If the finish has been wet sanded in the past, it cannot be repeated. Wet sanding operation should be performed by a trained

automotive painter.

CAUTION:

Do not remove clear

coat

finish,

if

equipped.

Base

coat

paint

must

retain

clear

coat

to

shine.

ble.

For best results, use Mopar®Scratch Filler/

Primer, Touch-up Paints and Clear Top Coat. Refer

to Introduction group of this manual for Body Code

Plate information.

TOUCH-UP

PROCEDURE \l)

Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with Mopar®Tar/Road Oil

Remover and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur

face finish. The applicator should be wet enough to

puddle/fill the defect without running. Do not stroke

brush applicator on body surface. Allow the filler/ primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap color touch-up onto the original color coat. Butt the new color to the original color if

possible. Do not stroke applicator brush on body sur

face.

Allow touch-up paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly (600 grit) wet sanded and pol

ished with rubbing compound.

(6) On vehicles with clear coat, apply clear top coat

to touch-up paint with the same technique as de scribed in step 4. Allow clear top coat to dry hard. If

desired, step 5 can be performed on clear top coat.

PAINTED SURFACE TOUCH-UP

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

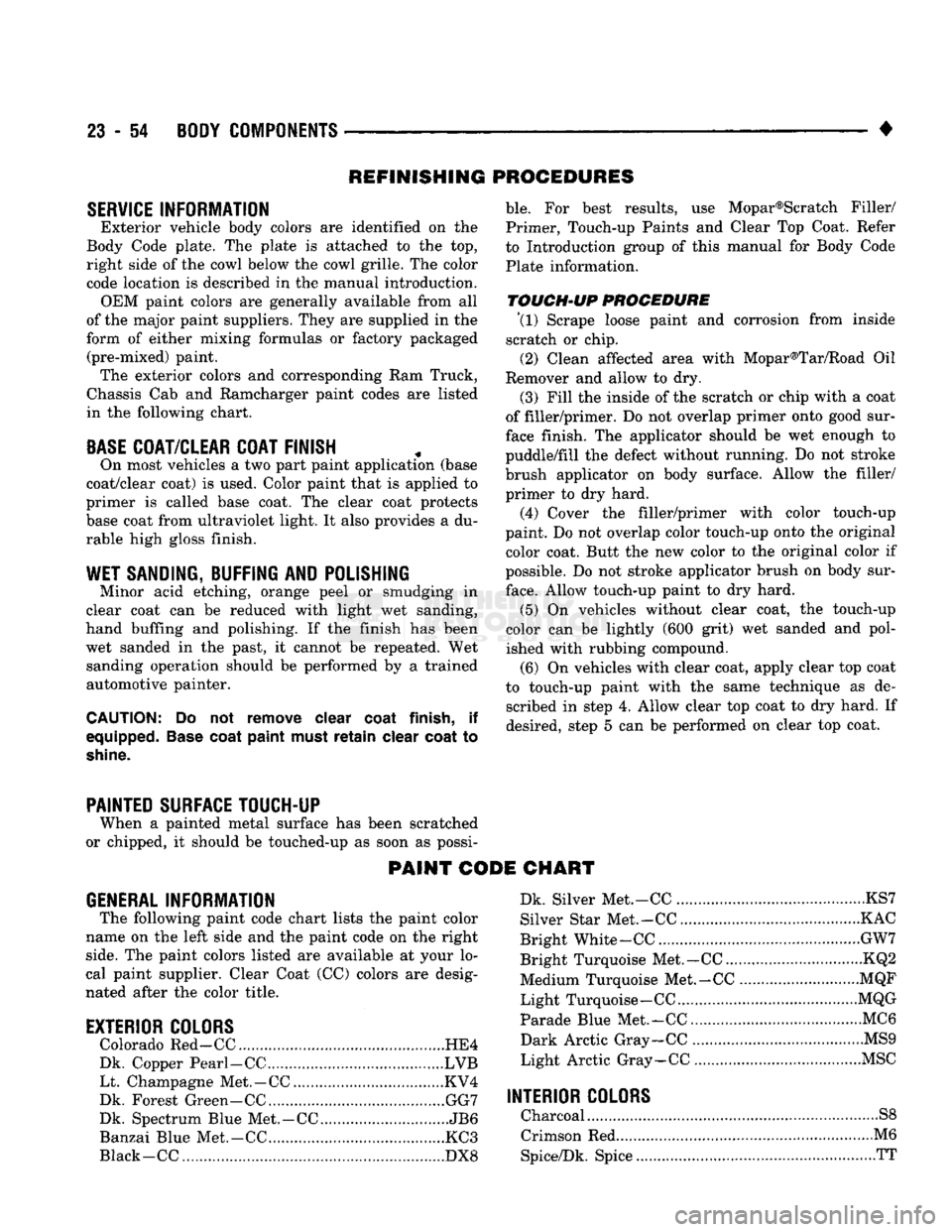

PAINT CODE CHART

GENERAL

INFORMATION

The following paint code chart lists the paint color

name on the left side and the paint code on the right

side.

The paint colors listed are available at your lo

cal paint supplier. Clear Coat (CO colors are desig

nated after the color title.

EXTERIOR COLORS

Colorado Red-CC HE4

Dk. Copper Pearl-CC LVB Lt. Champagne Met.-CC KV4

Dk. Forest Green-CC GG7

Dk. Spectrum Blue Met.-CC JB6

Banzai Blue Met.-CC KC3

Black -CC DX8 Dk. Silver Met.-CC KS7

Silver Star Met.-CC KAC

Bright White-CC GW7

Bright Turquoise Met.-CC KQ2

Medium Turquoise Met.-CC MQF

Light Turquoise-CC MQG

Parade Blue Met.-CC... MC6

Dark Arctic Gray-CC MS9

Light Arctic Gray-CC MSC

INTERIOR COLORS

Charcoal S8

Crimson Red M6

Spice/Dk. Spice TT