ESP DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 15 of 1502

10 INTRODUCTION

•

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

ID

HIGH

BEAM P

FOG UGHTS -&

HEADLIGHTS,

PARKING UGHTS, PANEL UGHTS TURN SIGNAL A

HAZARD WARNING WINDSHIELD

WASHER

WINDSHIELD WIPER WINDSHIELD WIPER

AND WASHER

AND DEFROSTING *

VENTILATING

FAN 8

M f

REAR

WINDOW DEFOGGER

sp

REARWINLX)W WIPER

CD

l

m

REAR

WINDOW WASHER FUEL ENGINE COOLANT

TEMPERATURE BATTERY CHARGING

CONDITION ENGINE OIL

SEAT

BELT

(©) (®) ky

11 J

LIGHTER

BRAKE

FAILURE

PARKING

BRAKE

FRONT HOOD

REAR

HOOD

(TRUNK)

HORN

11 J

LIGHTER

93IN-9

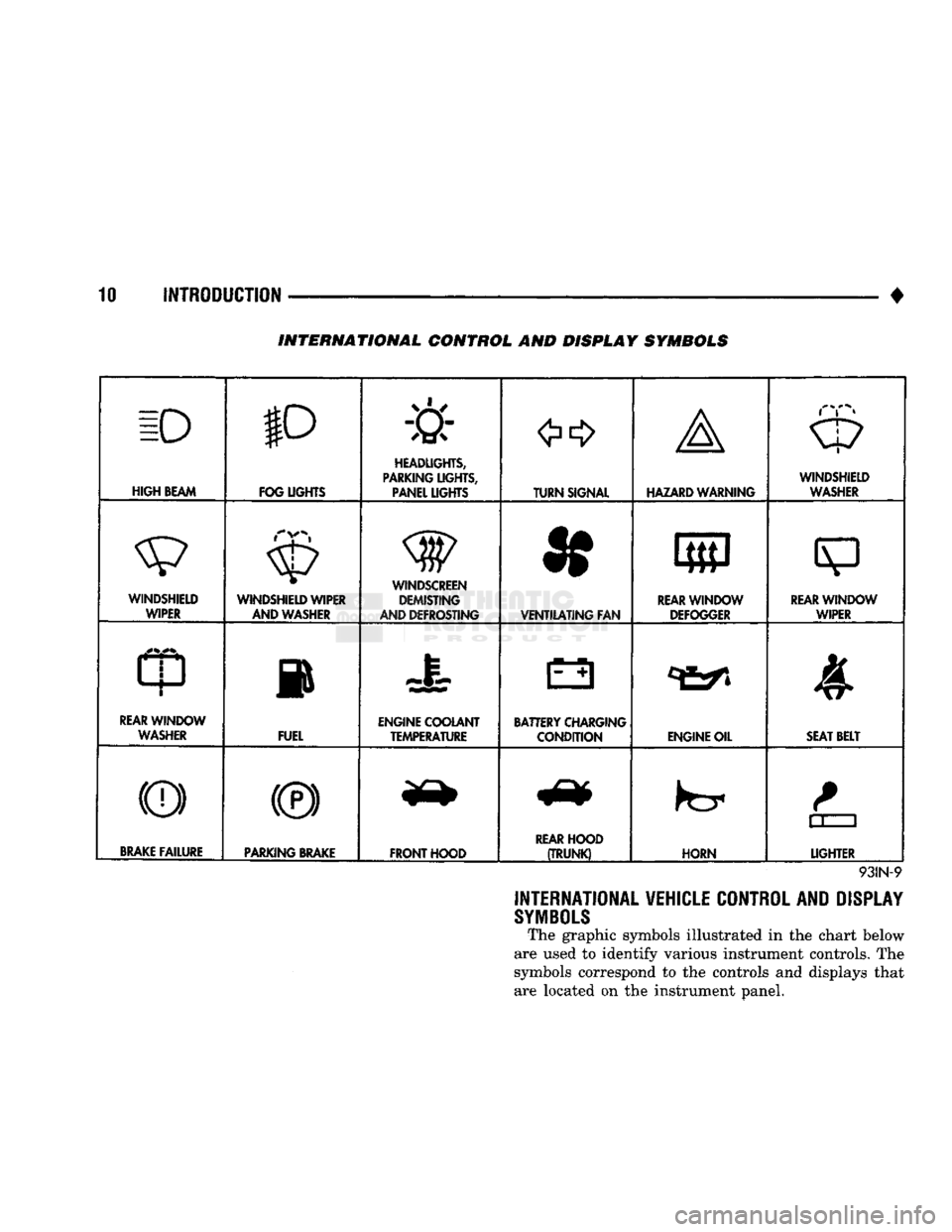

INTERNATIONAL VEHICLE CONTROL AND DISPLAY

SYMBOLS

The graphic symbols illustrated in the chart below

are used to identify various instrument controls. The

symbols correspond to the controls and displays that are located on the instrument panel.

Page 16 of 1502

•

INTRODUCTION

11

MEASUREMENT

AND

TORQUE SPECIFICATIONS

INDEX

page

Metric

and

English/SAE

Conversion

11

Specification

Notations

11

SPECIFICATION NOTATIONS

WARNING:

THE USE OF

INCORRECT

ATTACHING

HARDWARE

CAN

RESULT

IN

COMPONENT

DAM

AGE

AND/OR

PERSONAL

INJURY.

It is important to retain the original attaching

hardware for assembly of the components. If the at

taching hardware is not reusable, hardware with

equivalent specifications must be used.

METRIC

AND

ENGLISH/SAE

CONVERSION

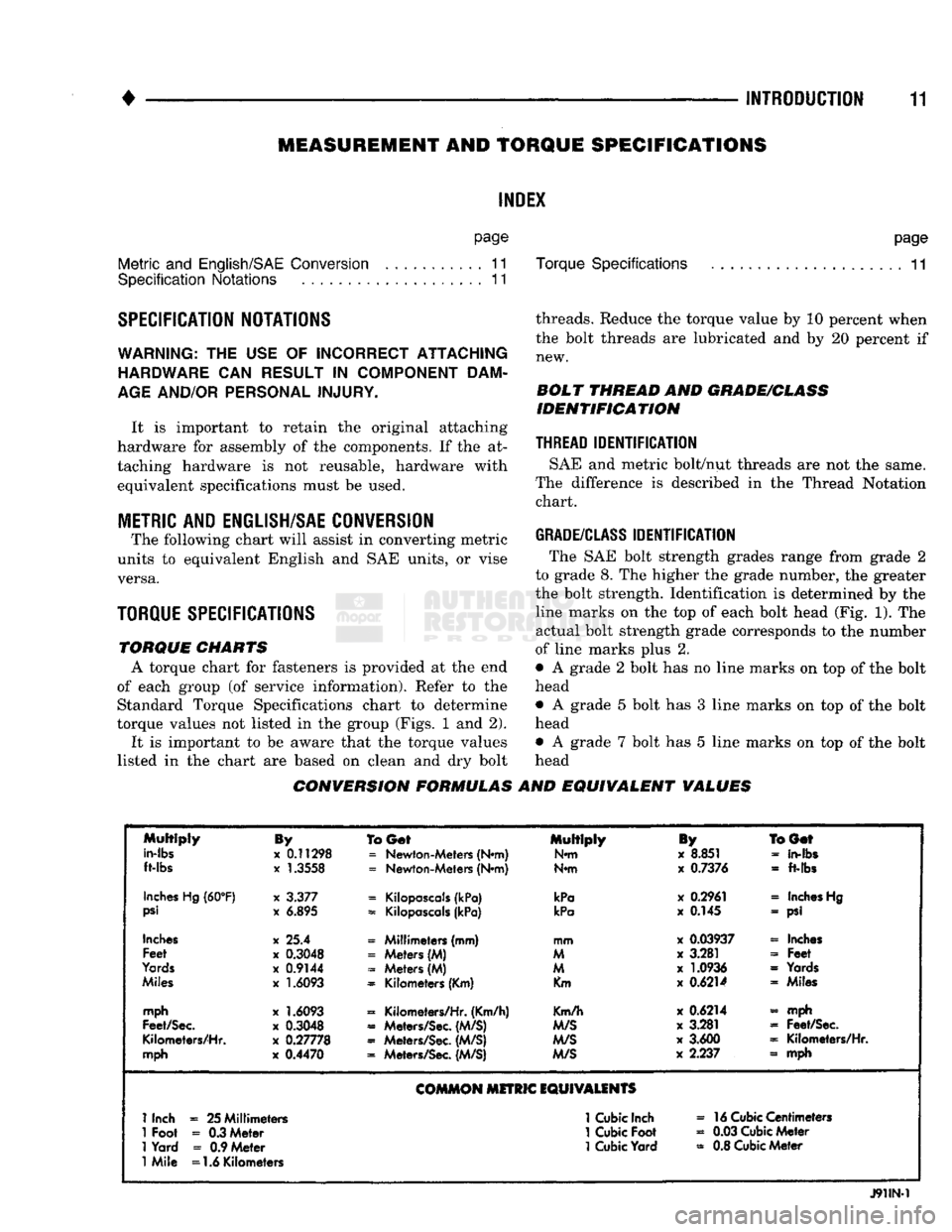

The following chart will assist in converting metric

units to equivalent English and SAE units, or vise versa.

TORQUE SPECIFICATIONS

TORQUE

CHARTS

A torque chart for fasteners is provided at the end

of each group (of service information). Refer to the Standard Torque Specifications chart to determine

torque values not listed in the group (Figs. 1 and 2).

It is important to be aware that the torque values

listed in the chart are based on clean and dry bolt

page

Torque Specifications

11

threads. Reduce the torque value by 10 percent when the bolt threads are lubricated and by 20 percent if new.

BOLT

THREAD

AND

GRADE/CLASS

IDENTIFICATION

THREAD

IDENTIFICATION

SAE and metric bolt/nut threads are not the same.

The difference is described in the Thread Notation chart.

GRADE/CLASS

IDENTIFICATION

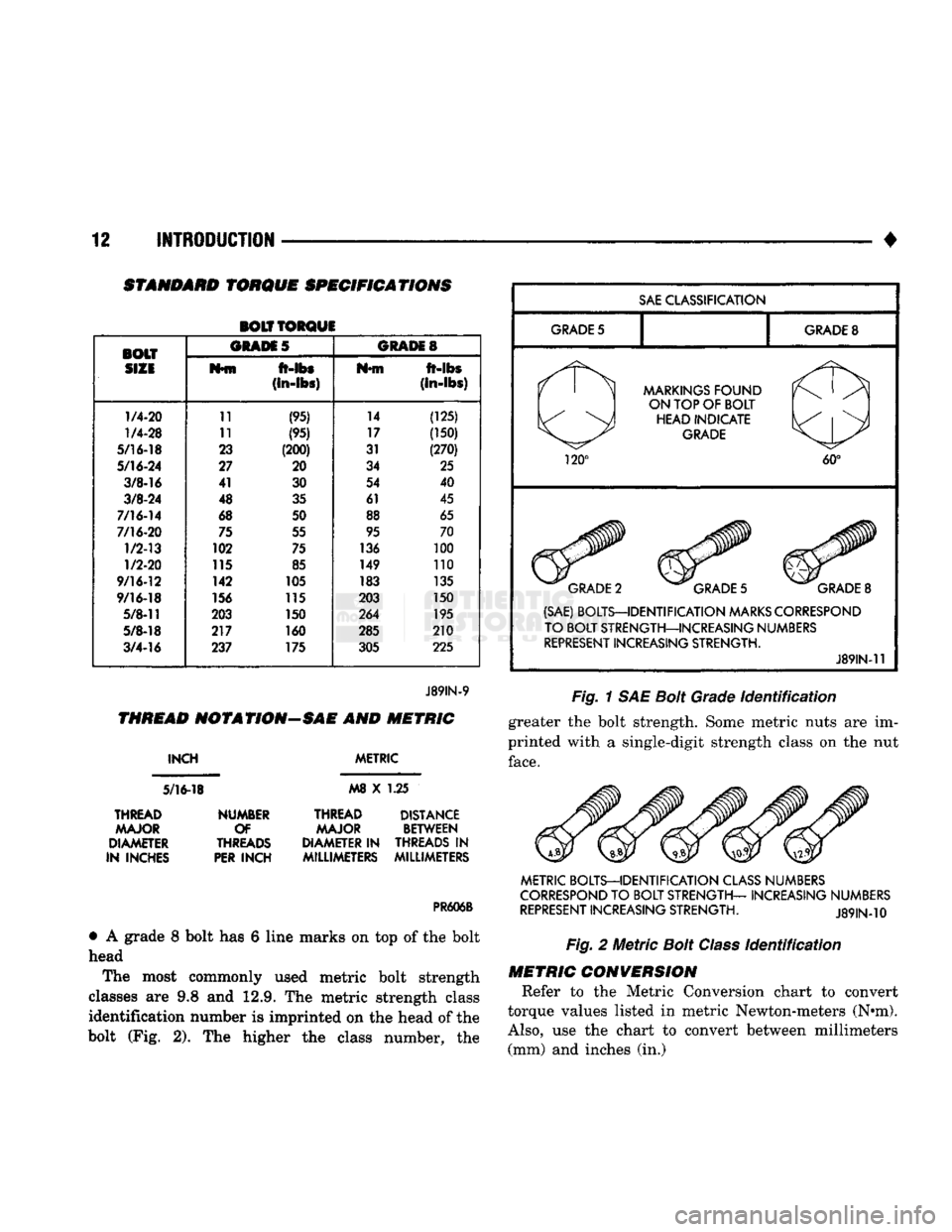

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the line marks on the top of each bolt head (Fig. 1). The

actual bolt strength grade corresponds to the number

of line marks plus 2.

• A grade 2 bolt has no line marks on top of the bolt

head

• A grade 5 bolt has 3 line marks on top of the bolt

head • A grade 7 bolt has 5 line marks on top of the bolt

head

CONVERSION FORMULAS

AND

EQUIVALENT

VALUES

Multiply

in-lbs

ft-lbs

By

x

0.11298

x

1.3558

To

Get

=

Newton-Meters (N*m)

=

Newton-Meters (N*m) Multiply

N*m

iy

x

8.851

x

0.7376

BGef

-

in-fbs

-

ft-lbs

Inches

Hg

(60°F)

psi

x

3.377

x

6.895

=

Kilopascals

(kPa)

=

Kilopascals

(kPa)

kPa

kPa

x

0.2961

x

0.145

«

Inches

Hg

- psi

Inches

Feet

Yards

Miles

x 25.4

x

0.3048

x

0.9144

x

1.6093

« Millimeters (mm)

=

Meters (M)

-

Meters (M)

=

Kilometers (Km) mm

M

M

Km

x

0.03937

x

3.281

x

1.0936

x

0.6214

« Inches

-

Feet

=

Yards « Miles

mph

Feet/Sec.

Kilometers/Hr.

mph

x

1.6093

x

0.3048

x

0.27778

x

0.4470

=

Kilometers/Hr. (Km/h)

«

Meters/Sec.

(M/S)

«

Meters/Sec.

(M/S)

=

Meters/Sec.

(M/S)

Km/h

M/S

M/S

M/S

x

0.6214

x

3.281

x

3.600

x

2.237 - mph

=

Feet/Sec.

=

Kilometers/Hr.

» mph

COMMON

MITRIC

EQUIVALENTS

1

Inch

=

25 Millimeters

1

Cubic

Inch

»

16

Cubic

Centimeters

1

Foot

-

0.3 Meter

1

Cubic

Foot

«

0.03

Cubic

Meter

1

Yard

=

0.9 Meter

1

Cubic

Yard

=

0.8

Cubic

Meter

1

Mile =1.6 Kilometers

J91IN-1

Page 17 of 1502

12

INTRODUCTION

STANDARD

TORQUE

SPECIFICATIONS

BOLT TORQUE

BOLT ORAM

5

GRADES

SIZE

M*fn

ft-lbs

Nfft

ft-abs

(in-lbs)

(In-lbs)

1/4-20

11

(95) 14

(125)

1/4-28

11 (95) 17 (150)

5/16-18

23 (200) 31 (270)

5/16-24

27 20 34 25

3/8-16

41

30 54

40

3/8-24

48 35 61 45

7/16-14

68

50 88 65

7/16-20

75 55 95 70

1/2-13

102

75 136 100

1/2-20

115 85 149 110

9/16-12

142

105 183 135

9/16-18

156 115 203 150

5/8-11

203 150 264 195

5/8-18

217 160 285 210

3/4-16

237 175

305 225

J89IN-9

THREAD

NOT A

TION—SAE

AND

METRIC

INCH

5/16-18

METRIC

M8

X 1.25

THREAD MAJOR

DIAMETER

IN INCHES NUMBER

OF

THREADS

PER

INCH

THREAD DISTANCE

MAJOR BETWEEN

DIAMETER IN THREADS

IN

MILLIMETERS MILLIMETERS

PR606B

•

A grade 8 bolt has 6 line marks on top of the bolt

head

The most commonly used metric bolt strength

classes are 9.8 and 12.9. The metric strength class identification number is imprinted on the head of the

bolt (Fig. 2). The higher the class number, the

SAE

CLASSIFICATION

GRADE

5

GRADE

8

MARKINGS

FOUND

ON TOP OF BOLT HEAD INDICATE

GRADE

120°

60°

GRADE

2

GRADE

5

GRADE

8

(SAE) BOLTS—IDENTIFICATION

MARKS

CORRESPOND

TO BOLT STRENGTH—INCREASING NUMBERS

REPRESENT

INCREASING STRENGTH.

J89IN-11

Fig.

1 SAE

Bolt

Grade

Identification

greater the bolt strength. Some metric nuts are im

printed with a single-digit strength class on the nut

face.

METRIC BOLTS—IDENTIFICATION

CLASS

NUMBERS

CORRESPOND

TO BOLT STRENGTH— INCREASING NUMBERS

REPRESENT

INCREASING STRENGTH.

J89IN-10

Fig.

2

Metric

Bolt

Class

Identification

METRIC

CONVERSION

Refer to the Metric Conversion chart to convert

torque values listed in metric Newton-meters (N»m).

Also,

use the chart to convert between millimeters (mm) and inches (in.)

Page 20 of 1502

•

• —

LUiRICATlON

AND

MAINTENANCE

0 - 1

CONTENTS

page

page

CHASSIS

AND

BODY

28

ENGINE MAINTENANCE

14

DRIVETRAIN

.,,, 22

GENERAL INFORMATION

1

GENERAL

INFORMATION INDEl

page

Classification

of

Lubricants

. 3

Components

Requiring

No

Lubrication

4

Fuel Requirements

. 2

Introduction

1

Lubrication

and

Replacement Parts Recommendation

3

page

Routine Maintenance

2

Starting

Assistance (Jump Starting)

9

Vehicle

Lifting

Recommendations

............ 10

Vehicle Noise

Control

2

Vehicle Towing Recommendations

11

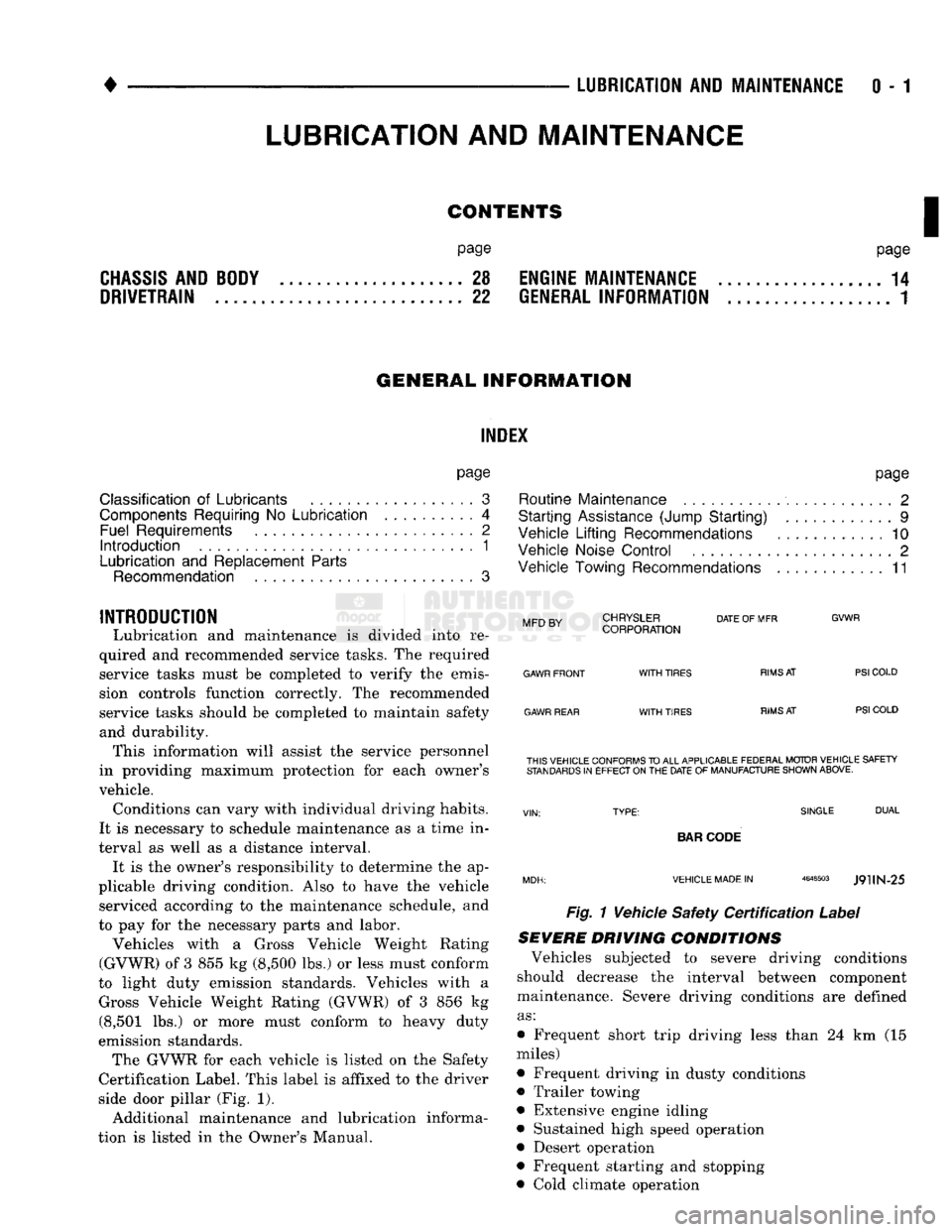

INTRODUCTION

Lubrication and maintenance is divided into re

quired and recommended service tasks. The required service tasks must be completed to verify the emis

sion controls function correctly. The recommended

service tasks should be completed to maintain safety

and durability. This information will assist the service personnel

in providing maximum protection for each owner's

vehicle. Conditions can vary with individual driving habits.

It is necessary to schedule maintenance as a time in

terval as well as a distance interval. It is the owner's responsibility to determine the ap

plicable driving condition. Also to have the vehicle serviced according to the maintenance schedule, and

to pay for the necessary parts and labor. Vehicles with a Gross Vehicle Weight Rating

(GVWR) of 3 855 kg (8,500 lbs.) or less must conform

to light duty emission standards. Vehicles with a Gross Vehicle Weight Rating (GVWR) of 3 856 kg

(8,501 lbs.) or more must conform to heavy duty

emission standards. The GVWR for each vehicle is listed on the Safety

Certification Label. This label is affixed to the driver

side door pillar (Fig. 1).

Additional maintenance and lubrication informa

tion is listed in the Owner's Manual.

Mm

rv

CHRYSLER

DATE

OF MFR

MFD BY CORPORATION

GVWR

GAWR FRONT

GAWR REAR

WITH

TIRES

WITH

TIRES

RIMS

AT

RIMS

AT

PSI

COLD

PSI

COLD THIS VEHICLE CONFORMS

TO

ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFETY

STANDARDS

IN

EFFECT ON

THE

DATE

OF

MANUFACTURE SHOWN ABOVE.

SINGLE

DUAL

BAR

CODE

VEHICLE MADE

IN

4648503

J9UN-25

Fig. 1 Vehicle Safety

Certification

Label

SEVERE DRIVING

CONDITIONS

Vehicles subjected to severe driving conditions

should decrease the interval between component

maintenance. Severe driving conditions are defined

as:

• Frequent short trip driving less than 24 km (15

miles)

• Frequent driving in dusty conditions

• Trailer towing

• Extensive engine idling

• Sustained high speed operation

• Desert operation

• Frequent starting and stopping

• Cold climate operation

LUBRICATION

AND

MAINTENANCE

Page 59 of 1502

2

- 6

FRONT

SUSPENSION

AND

AXLE

•

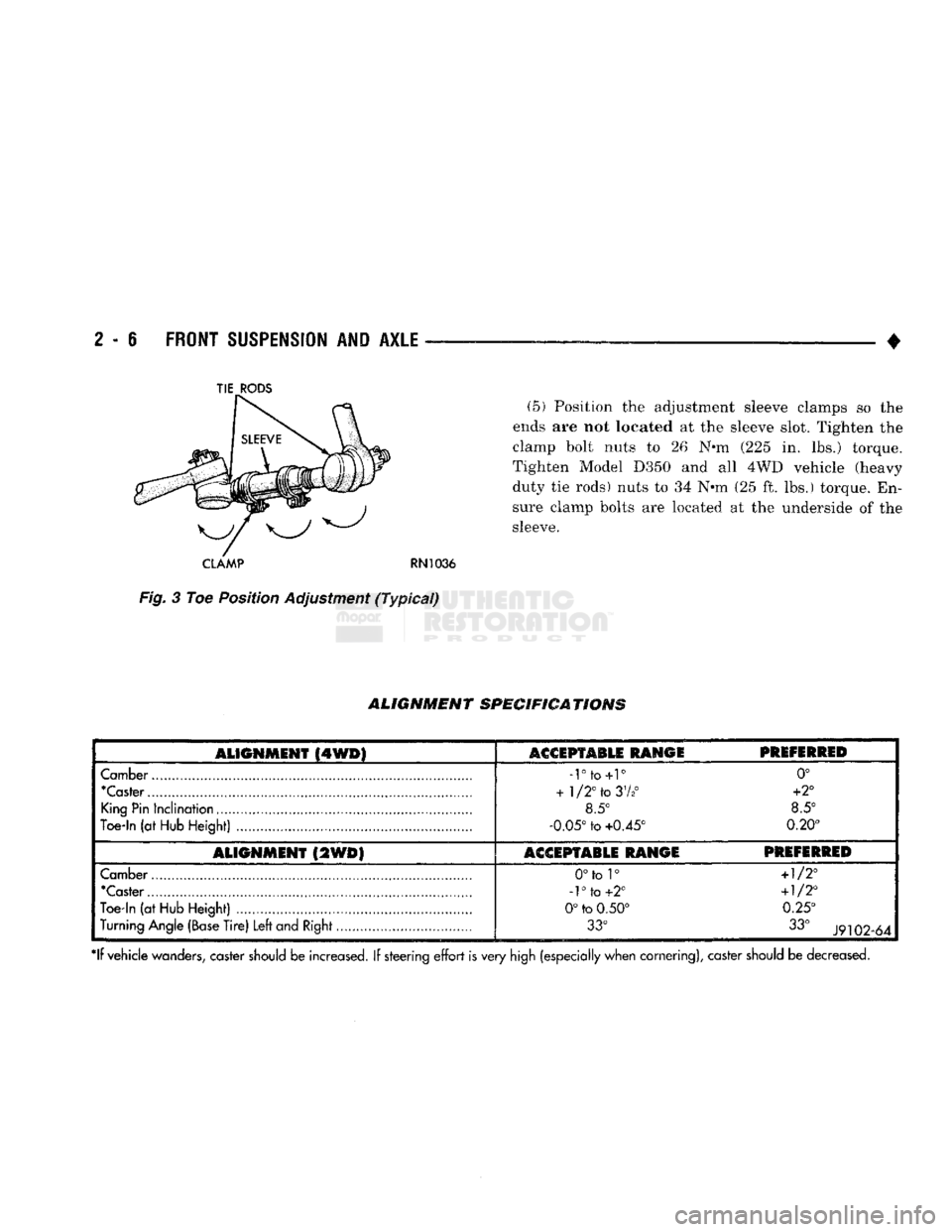

(5) Position the adjustment sleeve clamps so the

ends are not located at the sleeve slot. Tighten the

clamp bolt nuts to 26 N*m (225 in. lbs.) torque.

Tighten Model D350 and all 4WD vehicle (heavy

duty tie rods) nuts to 34 N*m (25 ft. lbs.) torque. En

sure clamp bolts are located at the underside of the

sleeve.

CLAMP

RN1036

Fig.

3 Toe Position Adjustment

(Typical)

ALIGNMENT

SPECIFICATIONS

ALIGNMENT

(4WD)

ASGSPTABLE RANGE

PREFERRED

Camber

-rto+r

0°

"Caster

+

1/2°

to

37*°

+2°

King

Pin

Inclination

8.5° 8.5°

Toe-In

(at

Hub

Height)

-0.05°

to

+0.45° 0.20°

ALIGNMENT

(2WD)

ACCEPTABLE RANGE PREFERRED

Camber

0°to 1°

+1/2°

'Caster

-1°

to

+2°

+1/2°

Toe-in

(at

Hub

Height)

0°

to

0.50° 0.25°

Turning

Angle

(Base

Tire)

Left

and

Right

33°

33°

J9102-64

*lf vehicle

wanders,

caster

should

be increased. If steering

effort

is very

high

(especially when cornering), caster

should

be decreased.

TIE

RODS

Page 63 of 1502

2

- 10

FRONT SUSPENSION

AND

AXLE

• INSTALLATION

(1) Position the spring and isolation pad on the

suspension arm. Install the spring compressor tool.

Compress the spring until the lower suspension arm

can be properly positioned in the steering knuckle.

(2) Install the nuts on the ball studs. Tighten the

upper nut to 142 Nnn (105 ft. lbs.) torque. Tighten

the lower nut.

* 11/16-16 bolt, to 183 Nnn (135 ft. lbs.) torque

• 3/4-16 bolt, to 237 Nnn (175 ft. lbs.) torque Install replacement cotter pins.

(3) Install the strut.

(4) Connect the stabilizer bar.

(5) Install the shock absorber.

(6) Install the brake splash shield on the steering

knuckle. Tighten the screws to 23 Nnn (200 in. lbs.)

torque.

(7) Carefully install the hub/rotor and bearings.

(8) Install the brake caliper, refer to Group 5, Brakes.

(9) Install the wheel and tire, refer to Wheel and Tire

Installation within this section. Lower the vehicle. (10) Test the vehicle brakes and the suspension for

proper operation.

LOWER SUSPENSION

ARM

REMOVAL

(1) Follow procedure under Coil Spring Removal.

(2) Remove hex-head mounting bolt from the cross-

member. (3) Remove the lower suspension arm from vehicle.

INSTALLATION (1) Position lower suspension arm on vehicle.

(2) Install mounting bolt, tighten finger-tight.

(3) Follow procedure under Coil Spring Installa

tion.

(4) Lower the vehicle to the surface with the

wheels/tires supporting the vehicle weight. Tighten

the lower suspension arm mounting bolt to 305 Nnn (225 ft. lbs.) torque.

LOWER

BALL

STUD

INSPECTION

(1) Raise the front of the vehicle. Install safety

floor stands under both lower suspension arms as far outboard as possible. The upper suspension arms

must not contact the rebound bumpers. (2) Install a dial indicator and clamp assembly to

the lower suspension arm. (3) Position indicator plunger against knuckle arm

and zero indicator. (4) Raise and lower the wheel with a pry bar under

the center of the tire. Measure the axial movement of

the knuckle with respect to the suspension arm.

(5) If the travel of the suspension arm is 0.020

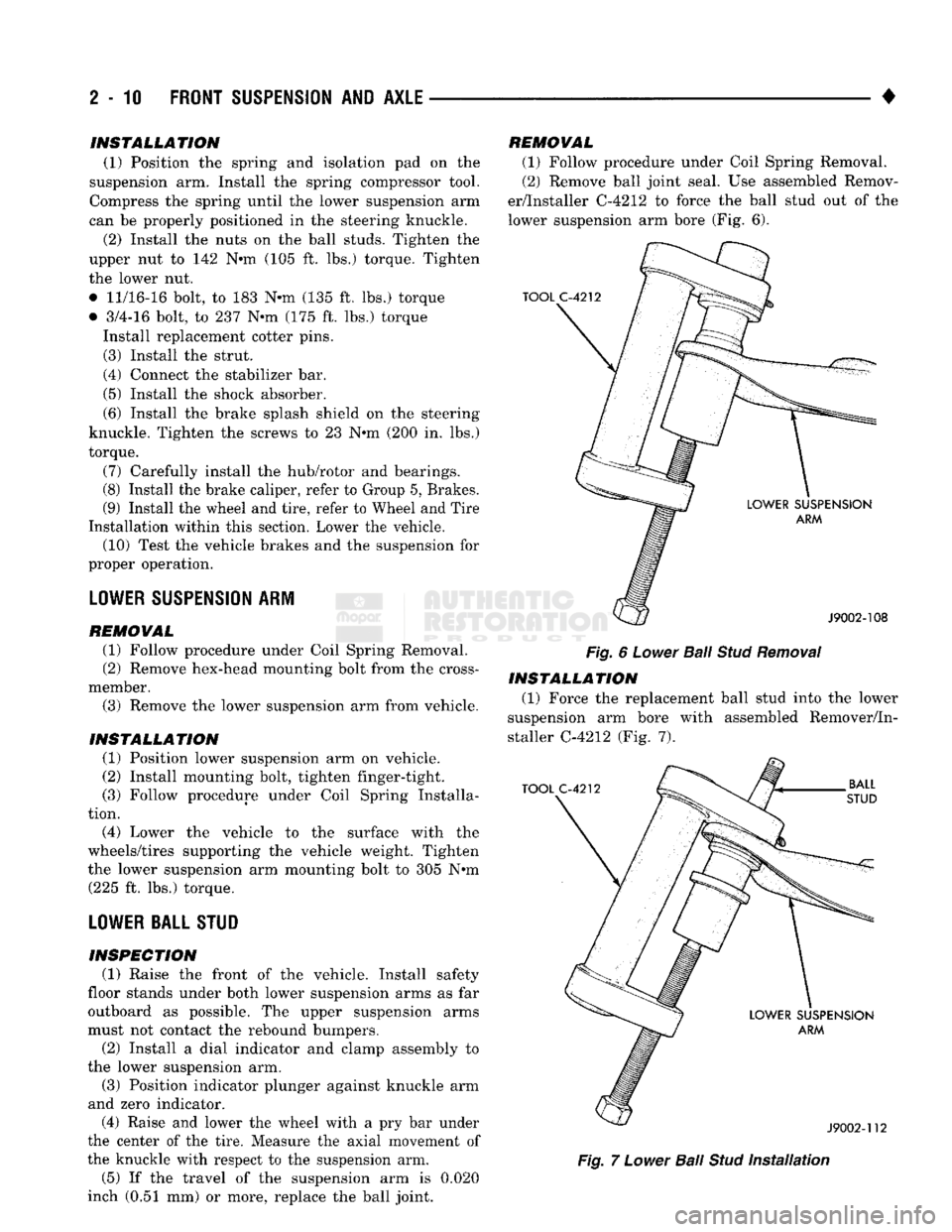

inch (0.51 mm) or more, replace the ball joint. REMOVAL

(1) Follow procedure under Coil Spring Removal.

(2) Remove ball joint seal. Use assembled Remov

er/Installer C-4212 to force the ball stud out of the

lower suspension arm bore (Fig. 6).

Fig.

6

Lower

Bail

Stud

Removal

INSTALLATION (1) Force the replacement ball stud into the lower

suspension arm bore with assembled Remover/In

staller C-4212 (Fig. 7).

Fig.

7

Lower

Ball

Stud

Installation

Page 144 of 1502

REAR SUSPENSION

ANi

AXLE

3 - 17

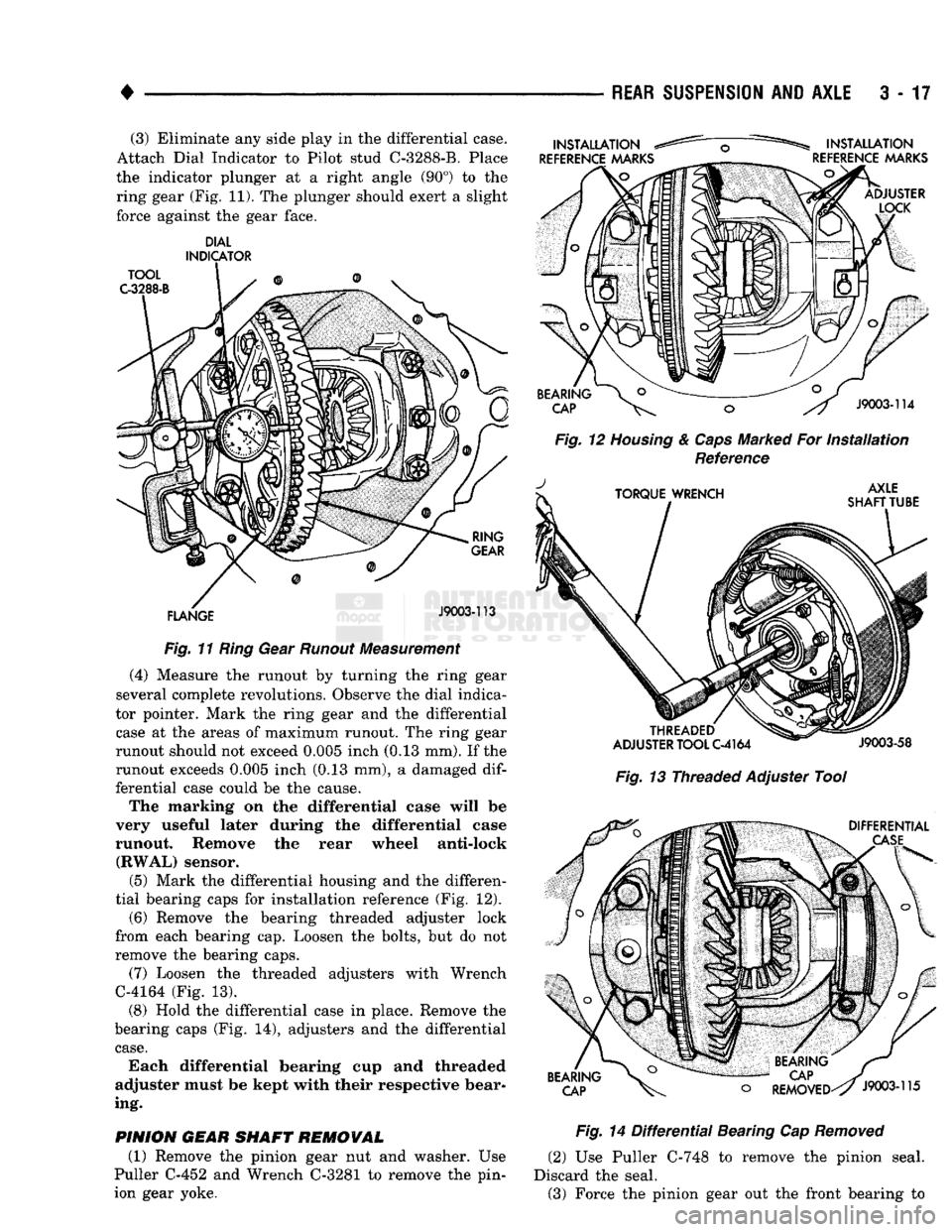

(3) Eliminate any side play in the differential case.

Attach Dial Indicator to Pilot stud C-3288-B. Place

the indicator plunger at a right angle (90°) to the ring gear (Fig. 11). The plunger should exert a slight

force against the gear face.

DIAL

INDICATOR

Fig.

11

Ring

Gear

Runout

Measurement

(4) Measure the runout by turning the ring gear

several complete revolutions. Observe the dial indica

tor pointer. Mark the ring gear and the differential

case at the areas of maximum runout. The ring gear

runout should not exceed 0.005 inch (0.13 mm). If the

runout exceeds 0.005 inch (0.13 mm), a damaged

dif

ferential case could be the cause.

The marking on the differential case will be

very useful later during the differential case

runout. Remove the rear wheel anti-lock (RWAL) sensor.

(5) Mark the differential housing and the differen

tial bearing caps for installation reference (Fig. 12).

(6) Remove the bearing threaded adjuster lock

from each bearing cap. Loosen the bolts, but do not

remove the bearing caps.

(7) Loosen the threaded adjusters with Wrench

C-4164 (Fig. 13).

(8) Hold the differential case in place. Remove the

bearing caps (Fig. 14), adjusters and the differential

case.

Each differential bearing cup and threaded

adjuster must be kept with their respective bear

ing.

PINION

GEAR

SHAFT

REMOVAL

(1) Remove the pinion gear nut and washer. Use

Puller C-452 and Wrench C-3281 to remove the pin

ion gear yoke.

Fig.

12

Housing

&

Caps

Marked For

Installation

Reference

Fig.

13 Threaded Adjuster Tool

Fig.

14

Differential

Bearing Cap

Removed

(2) Use Puller C-748 to remove the pinion seal.

Discard the seal. (3) Force the pinion gear out the front bearing to

Page 151 of 1502

3

- 24

REAR SUSPENSION

AND

AXLE

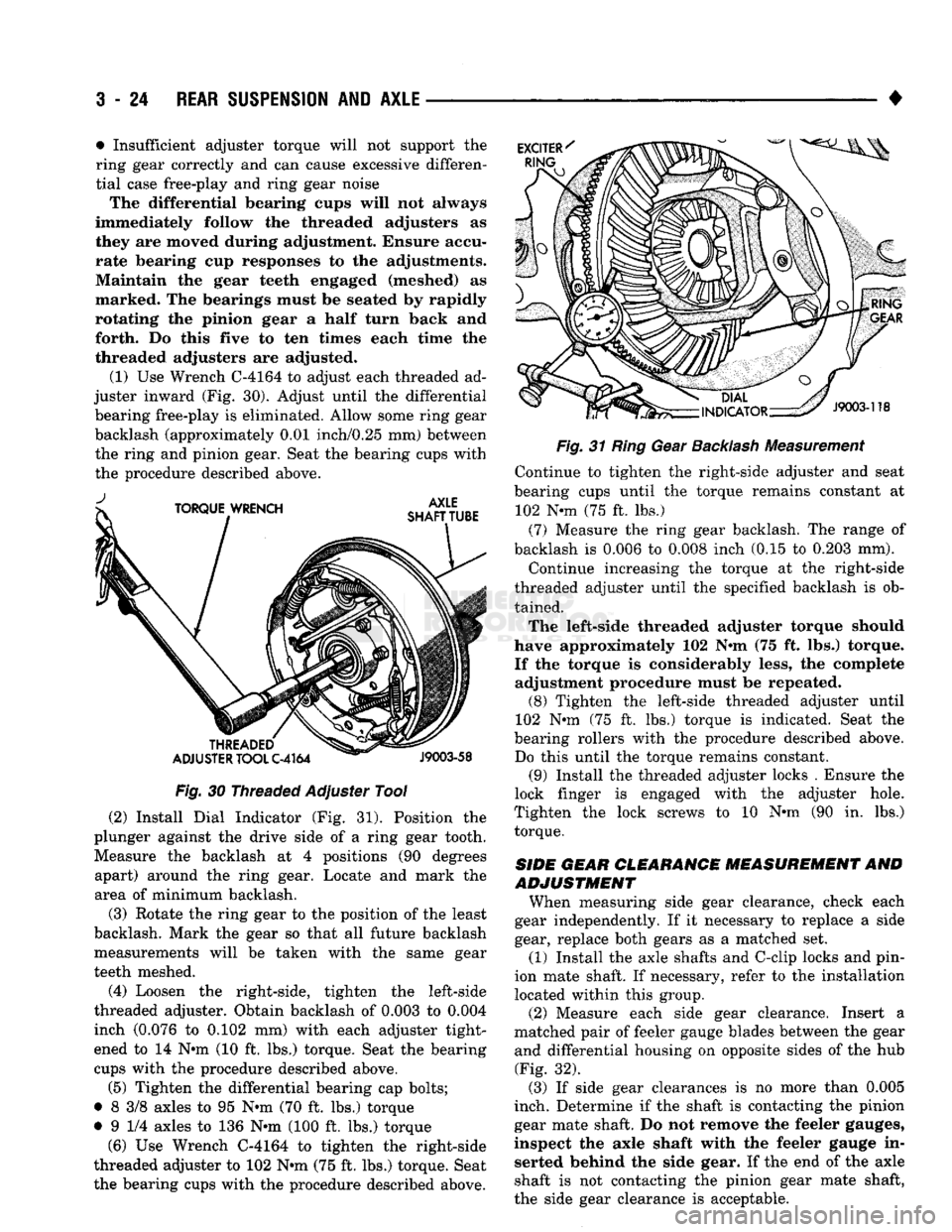

Fig.

30 Threaded Adjuster Tool

(2) Install Dial Indicator (Fig. 31). Position the

plunger against the drive side of a ring gear tooth. Measure the backlash at 4 positions (90 degrees apart) around the ring gear. Locate and mark the

area of minimum backlash.

(3) Rotate the ring gear to the position of the least

backlash. Mark the gear so that all future backlash

measurements will be taken with the same gear

teeth meshed.

(4) Loosen the right-side, tighten the left-side

threaded adjuster. Obtain backlash of 0.003 to 0.004

inch (0.076 to 0.102 mm) with each adjuster tight

ened to 14 N-m (10 ft. lbs.) torque. Seat the bearing

cups with the procedure described above.

(5) Tighten the differential bearing cap bolts;

• 8 3/8 axles to 95 N-m (70 ft. lbs.) torque

• 9 1/4 axles to 136 N-m (100 ft. lbs.) torque

(6) Use Wrench C-4164 to tighten the right-side

threaded adjuster to 102 N-m (75 ft. lbs.) torque. Seat the bearing cups with the procedure described above. •

Fig.

31

Ring

Gear

Backlash

Measurement Continue to tighten the right-side adjuster and seat

bearing cups until the torque remains constant at 102 N-m (75 ft. lbs.)

(7) Measure the ring gear backlash. The range of

backlash is 0.006 to 0.008 inch (0.15 to 0.203 mm).

Continue increasing the torque at the right-side

threaded adjuster until the specified backlash is ob tained.

The left-side threaded adjuster torque should

have approximately 102 N-m (75 ft. lbs.) torque. If the torque is considerably less, the complete adjustment procedure must be repeated. (8) Tighten the left-side threaded adjuster until

102 N-m (75 ft. lbs.) torque is indicated. Seat the

bearing rollers with the procedure described above. Do this until the torque remains constant. (9) Install the threaded adjuster locks . Ensure the

lock finger is engaged with the adjuster hole.

Tighten the lock screws to 10 N-m (90 in. lbs.) torque.

SIDE

GEAR CLEARANCE

MEASUREMENT

AND

ADJUSTMENT

When measuring side gear clearance, check each

gear independently. If it necessary to replace a side

gear, replace both gears as a matched set.

(1) Install the axle shafts and C-clip locks and pin

ion mate shaft. If necessary, refer to the installation

located within this group. (2) Measure each side gear clearance. Insert a

matched pair of feeler gauge blades between the gear

and differential housing on opposite sides of the hub (Fig. 32).

(3) If side gear clearances is no more than 0,005

inch. Determine if the shaft is contacting the pinion

gear mate shaft. Do not remove the feeler gauges,

inspect the axle shaft with the feeler gauge in serted behind the side gear. If the end of the axle

shaft is not contacting the pinion gear mate shaft,

the side gear clearance is acceptable.

• Insufficient adjuster torque will not support the

ring gear correctly and can cause excessive differen

tial case free-play and ring gear noise

The differential bearing cups will not always

immediately follow the threaded adjusters as they are moved during adjustment. Ensure accu

rate bearing cup responses to the adjustments. Maintain the gear teeth engaged (meshed) as

marked. The bearings must be seated by rapidly

rotating the pinion gear a half turn back and forth. Do this five to ten times each time the

threaded adjusters are adjusted.

(1) Use Wrench C-4164 to adjust each threaded ad

juster inward (Fig. 30). Adjust until the differential bearing free-play is eliminated. Allow some ring gear

backlash (approximately 0.01 inch/0.25 mm) between

the ring and pinion gear. Seat the bearing cups with

the procedure described above.

Page 190 of 1502

•

BRAKES

i - 3 BRAKE DIAGNOSIS

INDEX

page

Brake

Warning Lights

3

Diagnosing

Brake Problems .................

4

Diagnosis

Procedures

3

Low

Vacuum

Switch—Diesel

Models

3

page

Master

Cylinder/Power Booster Test

5

Power

Booster

Check

Valve Test .............

6

Power

Booster

Vacuum

Test .................

6

Testing Diesel

Engine

Vacuum

Pump

Output

.... 6

DIAGNOSIS

PROCEDURES

Brake diagnosis involves determining

if the

prob

lem

is

related

to a

mechanical, hydraulic

or

vacuum

operated component.

A

preliminary check, road test

ing

and

component inspection

can all be

used

to de

termine

a

problem cause. Road testing will either verify proper brake opera

tion

or

confirm

the

existence

of a

problem. Compo nent inspection will,

in

most cases, identify

the

actual part causing

a

problem. The first diagnosis step

is the

preliminary check. This

involves inspecting fluid level, parking brake action,

wheel

and

tire condition, checking

for

obvious leaks

or

component damage

and

testing brake pedal response. A road test will confirm

the

existence

of a

problem.

Final diagnosis procedure involves road test analysis and

a

visual inspection

of

brake components.

BRAKE

WARNING LIGHTS

The

red

brake warning light

is

connected

to the

parking brake switch

and to the

pressure differential switch

in the

combination valve. The

red

light will illuminate when

the

parking

brakes

are

applied

or

when

a

fluid pressure drop

oc

curs

in the

front

or

rear brake circuit.

The

light will

also illuminate

for

approximately

2-4

seconds

at en

gine start

up.

This

is a

self test feature designed

to

check bulb

and

circuit operation each time

the en

gine

is

started. The amber antilock light

is

connected

to the

anti-

lock rear brake hydraulic valve.

The

light will illu

minate

if a

fault occurs within

the

antilock system.

LOW VACUUM SWITCH-DIESEL MODELS

On diesel models,

the red

brake warning light

is

also

used

to

alert

the

driver

of a low

brake booster vacuum

condition.

The

warning light

is in

circuit with

a

vacuum

warning switch mounted

on the

driver side fender

panel.

The

vacuum side

of the

switch

is

connected

to the

power brake booster.

The

electrical side

of the

switch

is

connected

to the

brake warning light. The

low

vacuum switch monitors booster vacuum

level whenever

the

engine

is

running.

If

booster vac

uum falls below

8.5

inches vacuum

for a

minimum

of

10 seconds,

the

switch completes

the

circuit

to the

warning light causing

it to

illuminate.

The

warning light

is

designed

to

differentiate between

a low

vac

uum condition

and a

hydraulic circuit fault.

PRELIMINARY

BRAKE CHECK

(1) Check condition

of

tires

and

wheels. Damaged

wheels

and

worn, damaged,

or

underinflated tires

can

cause pull, shudder, tramp,

and a

condition similar

to

grab.

(2)

If

complaint

was

based

on

noise when braking,

check suspension components. Jounce front

and

rear

of

vehicle

and

listen

for

noise that might

be

caused

by

loose, worn

or

damaged suspension

or

steering compo

nents.

(3) Inspect brake fluid level

and

condition. Note

that

the

front disc brake reservoir fluid level will drop

in

proportion

to

normal lining wear. Also note

that brake fluid tends

to

darken over time. This

is normal

and

should

not be

mistaken

for

con

tamination.

If the

fluid

is

still clear

and

free

of

foreign material,

it is OK.

(a)

If

fluid level

is

abnormally

low,

look

for

evi

dence

of

leaks

at

calipers, wheel cylinders, brake-

lines

and

master cylinder.

(b)

If

fluid appears contaminated, drain

out a

sample.

If

fluid

is

separated into layers,

or

obvi

ously contains

oil or a

substance other than brake

fluid,

the

system seals

and

cups will have

to be re

placed

and the

hydraulic system flushed.

(4) Check parking brake operation. Verify free

movement

and

full release

of

cables

and

pedal. Also

note

if

vehicle

was

being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does

not

bind

and has

adequate free play.

If

pedal

lacks free play, check pedal

and

power booster

for be

ing loose

or for

bind condition.

Do not

road test until

condition

is

corrected.

(6)

If

components checked appear

OK,

road test

the

vehicle.

ROAD

TESTING (1)

If

complaint involved

low

brake pedal, pump

the pedal

and

note

if the

pedal comes back

up to

nor mal height.

(2) Check brake pedal response with transmission

in Neutral

and

engine running. Pedal should remain

firm under steady foot pressure.

Page 200 of 1502

•

BRAKES

5 - 13

COMBINATION VALVE OPERATION

METERING (HOLD-OFF) VALVE The metering valve is used to balance brake action

between the front disc and rear drum brakes. The

valve meters (holds-off) full apply pressure to the front disc brakes until the rear brakeshoes are in full

contact with the drums.

The valve is designed to maintain front brake fluid

pressure at 3-30 psi until the hold-off limit of 117 psi is reached. At this point, the metering valve opens completely permitting full fluid apply pressure to the

front disc brakes.

PRESSURE DIFFERENTIAL SWITCH AND VALVE The pressure differential switch is connected to the

brake warning light. The switch is triggered by movement of the switch valve. The purpose of the switch is to monitor fluid pressure in the separate

front/rear brake hydraulic circuits.

A decrease or loss of fluid pressure in either hy

draulic circuit will cause the switch valve to shuttle

forward or rearward in response to a pressure differ ential.

Movement of the switch valve will push the switch

plunger upward. This closes the switch internal con tacts completing the electrical circuit to the warning light. The switch valve will remain in an actuated

position until repair restores system pressures to nor mal levels.

COMBINATION VALVE TESTING

TESTING METERING VALVE Metering valve operation can be checked visually

and with the aid of a helper.

Observe the metering valve stem while a helper

applies and releases the brakes. If the valve is oper

ating correctly, the stem will extend slightly when

the brakes are applied and retract when the brakes are released.

If the valve is faulty, replace the entire combina

tion valve as an assembly.

TESTING PRESSURE DIFFERENTIAL SWITCH (1) Have helper sit in drivers seat to observe brake

warning light and to operate brake pedal.

(2) Raise vehicle on hoist.

(3) Connect bleed hose to left or right rear wheel

cylinder. Then immerse hose end in glass jar par

tially filled with brake fluid.

(4) Have helper press and hold brake pedal all the

way down and observe warning light.

(a) If warning light illuminates, switch is operat

ing correctly. (b) If light fails to illuminate, check circuit fuse,

bulb and wiring. Repair as necessary and repeat test steps (3) and (4). (5) If warning light still fails to illuminate, check

brakelight and park brake switches (and wiring) with test lamp. Repair or replace parts as necessary and test differential pressure switch operation again.

(6) If warning light still does not illuminate,

switch is faulty. Replace combination valve, bleed

brakes and verify proper switch and valve operation.

COMBINATION VALVE REMOVAL/INSTALLATION

VALVE REMOVAL (1) Raise vehicle on hoist.

(2) Mark or tag brake lines connected to valve for

assembly reference.

(3) Disconnect lines at valve (Fig. 8).

(4) Disconnect wires from differential pressure

switch.

(5) Remove bolts attaching valve to frame bracket

and remove valve.

VALVE INSTALLATION (1) Mount new valve on bracket and tighten valve

and bracket screws/nuts securely.

(2) Connect brakelines to valve. Tighten fittings to

16 N*m (145 in. lbs.)

(3) Connect wires to pressure differential switch

terminal. (4) Bleed brakes.

(5) Lower vehicle and verify proper brake opera

tion.

BRAKE

LINES AND

HOSES

BRAKE LINE AND HOSE INSPECTION Flexible rubber hose is used at both front brakes

and at the rear axle junction block. Inspect the hoses

whenever the brake system is serviced, at every en gine oil change, or whenever the vehicle is in for ser

vice.

Inspect the hoses for surface cracking, scuffing, or

worn spots. Replace any brake hose immediately if

the fabric casing of the hose is exposed by cracks or abrasion.

Also check brake hose installation. Faulty installa

tion can result in kinked, twisted hoses, or contact with the wheels and tires or other chassis compo

nents.

All of these conditions can lead to scuffing,

cracking and eventual failure.

The steel brake lines should be inspected periodi

cally for evidence of corrosion, twists, kinks, leaks, or

other damage. Heavily corroded lines will eventually

rust through causing leaks. In any case, corroded or damaged brake lines should be replaced.