width DODGE TRUCK 1993 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 1376 of 1502

•

WHEELS

AND

TIRES

22 - 7 move and install dual rear wheels only when the

proper wrench is available.

INSTALLATION

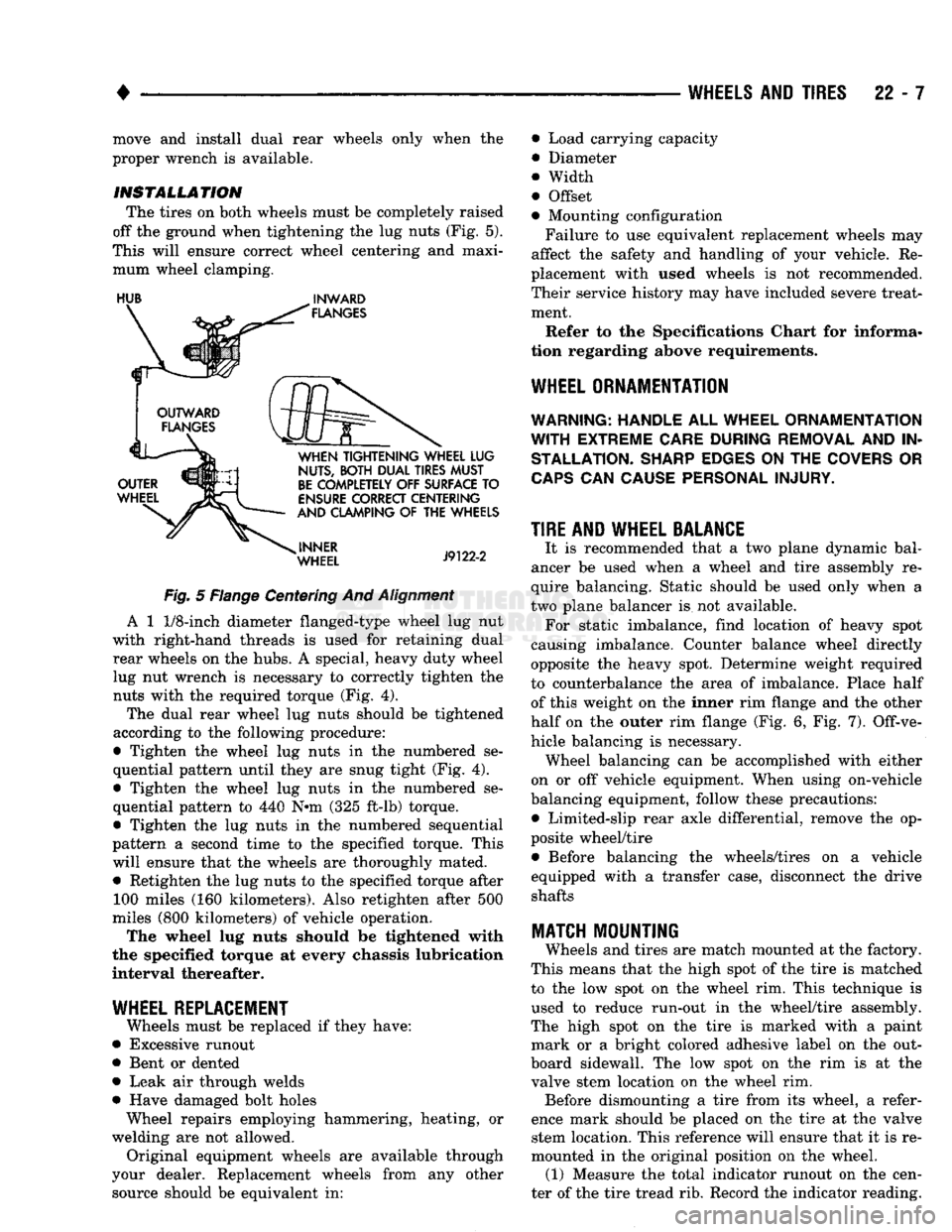

The tires on both wheels must be completely raised

off the ground when tightening the lug nuts (Fig. 5).

This will ensure correct wheel centering and maxi mum wheel clamping.

HUB

^

INWARD

Fig.

5 Flange Centering And

Alignment

A 1

1/8-inch

diameter flanged-type wheel lug nut

with right-hand threads is used for retaining dual rear wheels on the hubs. A special, heavy duty wheel lug nut wrench is necessary to correctly tighten the nuts with the required torque (Fig. 4).

The dual rear wheel lug nuts should be tightened

according to the following procedure:

• Tighten the wheel lug nuts in the numbered se

quential pattern until they are snug tight (Fig. 4).

• Tighten the wheel lug nuts in the numbered se

quential pattern to 440 N#m (325 ft-lb) torque.

• Tighten the lug nuts in the numbered sequential

pattern a second time to the specified torque. This will ensure that the wheels are thoroughly mated. • Retighten the lug nuts to the specified torque after 100 miles (160 kilometers). Also retighten after 500

miles (800 kilometers) of vehicle operation.

The wheel lug nuts should be tightened with

the specified torque at every chassis lubrication

interval thereafter.

WHEEL REPLACEMENT

Wheels must be replaced if they have:

• Excessive runout

• Bent or dented

• Leak air through welds

• Have damaged bolt holes Wheel repairs employing hammering, heating, or

welding are not allowed. Original equipment wheels are available through

your dealer. Replacement wheels from any other source should be equivalent in: • Load carrying capacity

• Diameter

® Width

• Offset

• Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle. Re

placement with used wheels is not recommended.

Their service history may have included severe treat ment.

Refer to the Specifications Chart for informa

tion regarding above requirements.

WHEEL ORNAMENTATION

WARNING; HANDLE

ALL

WHEEL ORNAMENTATION

WITH

EXTREME CARE DURING REMOVAL

AND IN

STALLATION. SHARP EDGES

ON THE

COVERS

OR

CAPS

CAN

CAUSE PERSONAL INJURY.

TIRE AND WHEEL BALANCE

It is recommended that a two plane dynamic bal

ancer be used when a wheel and tire assembly re

quire balancing. Static should be used only when a

two plane balancer is not available. For static imbalance, find location of heavy spot

causing imbalance. Counter balance wheel directly

opposite the heavy spot. Determine weight required

to counterbalance the area of imbalance. Place half of this weight on the inner rim flange and the other

half on the outer rim flange (Fig. 6, Fig. 7). Off-ve

hicle balancing is necessary. Wheel balancing can be accomplished with either

on or off vehicle equipment. When using on-vehicle

balancing equipment, follow these precautions: • Limited-slip rear axle differential, remove the op

posite wheel/tire • Before balancing the wheels/tires on a vehicle

equipped with a transfer case, disconnect the drive shafts

MATCH

MOUNTING

Wheels and tires are match mounted at the factory.

This means that the high spot of the tire is matched

to the low spot on the wheel rim. This technique is used to reduce run-out in the wheel/tire assembly.

The high spot on the tire is marked with a paint mark or a bright colored adhesive label on the out

board sidewall. The low spot on the rim is at the

valve stem location on the wheel rim. Before dismounting a tire from its wheel, a refer

ence mark should be placed on the tire at the valve stem location. This reference will ensure that it is re

mounted in the original position on the wheel. (1) Measure the total indicator runout on the cen

ter of the tire tread rib. Record the indicator reading.