width DODGE TRUCK 1993 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 612 of 1502

•

ENGINES

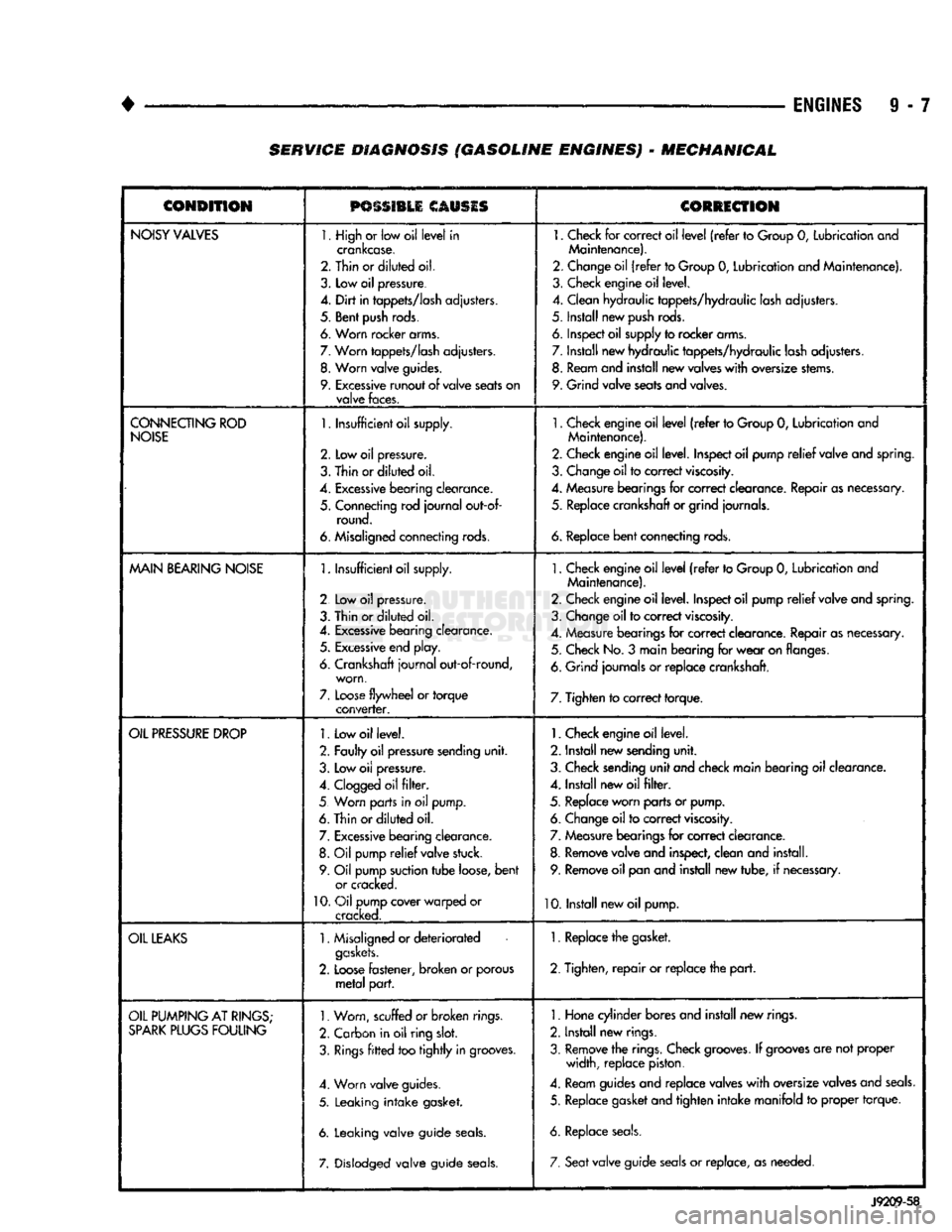

9 - 7 SERVICE DIAGNOSIS (GASOLINE ENGINES) - MECHANICAL

CONDITION

PSSSI1LI

CAUSIS

CORRECTION

NOISY

VALVES

1. High

or

low oil

level

in

crankcase.

2. Thin or

diluted

oil.

3.

Low

oil

pressure.

4.

Dirt

in

tappets/lash

adjusters.

5. Bent

push

rods.

6. Worn rocker arms.

7.

Worn

tappets/lash

adjusters.

8.

Worn

valve

guides.

9.

Excessive

runout

of

valve

seats

on

valve

faces.

1.

Check

for

correct oil

level

(refer

to

Group

0,

Lubrication and

Maintenance).

2. Change oil

(refer

to Group

0,

Lubrication and Maintenance).

3. Check engine oil level.

4. Clean hydraulic tappets/hydraulic lash adjusters.

5. Install new

push

rods.

6. Inspect oil supply to rocker arms.

7. Install new hydraulic tappets/hydraulic lash adjusters. 8. Ream and install new valves

with

oversize stems.

9. Grind valve seats and valves.

CONNECTING

ROD

NOISE

1.

Insufficient oil supply.

2.

Low oil

pressure.

3.

Thin

or

diluted

oil.

4.

Excessive

bearing

clearance.

5. Connecting rod

journal

out-of- round.

6. Misaligned connecting rods.

1.

Check engine oil

level

(refer

to Group

0,

Lubrication and

Maintenance).

2. Check engine oil level. Inspect oil pump

relief

valve and spring.

3. Change oil to correct

viscosity.

4. Measure bearings for correct clearance. Repair as necessary, 5. Replace crankshaft or grind journals.

6.

Replace

bent

connecting rods.

MAIN

BEARING

NOISE

1.

Insufficient oil supply.

2 Low

oil

pressure.

3. Thin or

diluted

oil.

4.

Excessive

bearing clearance. 5.

Excessive

end play.

6. Crankshaft

journal

out-of-round, worn,

7.

Loose

flywheel

or

torque

converter.

1.

Check engine oil

level

(refer

to Group

0,

Lubrication and

Maintenance).

2. Check engine oil level. Inspect oil pump

relief

valve and spring.

3. Change oil to correct

viscosity.

4. Measure bearings for correct clearance. Repair as necessary. 5. Check No.

3

main bearing for

wear

on flanges.

6. Grind journals

or

replace crankshaft.

7. Tighten to correct torque.

OIL

PRESSURE

DROP

1.

Low oil level.

2. Faulty oil pressure sending

unit.

3. Low

oil

pressure.

4.

Clogged

oil

filter.

5 Worn parts in

oil

pump.

6. Thin or

diluted

oil.

7.

Excessive

bearing clearance. 8.

Oil

pump

relief

valve stuck.

9. Oil pump suction

tube

loose,

bent

or cracked.

10.

Oil pump cover warped

or

cracked.

1.

Check engine oil level.

2. Install new sending

unit.

3. Check sending

unit

and check main bearing oil clearance.

4. Install new oil

filter.

5. Replace worn parts or pump. 6. Change oil to correct

viscosity.

7. Measure bearings for correct clearance.

8. Remove valve and inspect, clean and install. 9. Remove oil pan and install new tube,

if

necessary.

10. Install new oil pump.

OIL

LEAKS

1.

Misaligned or

deteriorated

gaskets.

2.

Loose

fastener, broken

or

porous

metal

part.

1. Replace the gasket.

2. Tighten,

repair

or replace the

part.

OIL

PUMPING

AT

RINGS;

SPARK

PLUGS

FOULING

1.

Worn, scuffed

or broken

rings.

2. Carbon in oil ring

slot.

3.

Rings

fitted

too

tightly

in grooves.

4. Worn valve guides.

5. Leaking

intake

gasket.

6. Leaking valve guide

seals.

7. Dislodged valve guide

seals.

1.

Hone cylinder bores and install new rings.

2. Install new rings.

3. Remove the rings. Check

grooves.

If

grooves

are not proper width, replace piston.

4. Ream guides and replace valves

with

oversize valves and

seals.

5. Replace gasket and tighten

intake

manifold

to

proper torque.

6. Replace

seals.

7. Seat

valve guide

seals

or

replace, as needed.

J9209-58

Page 631 of 1502

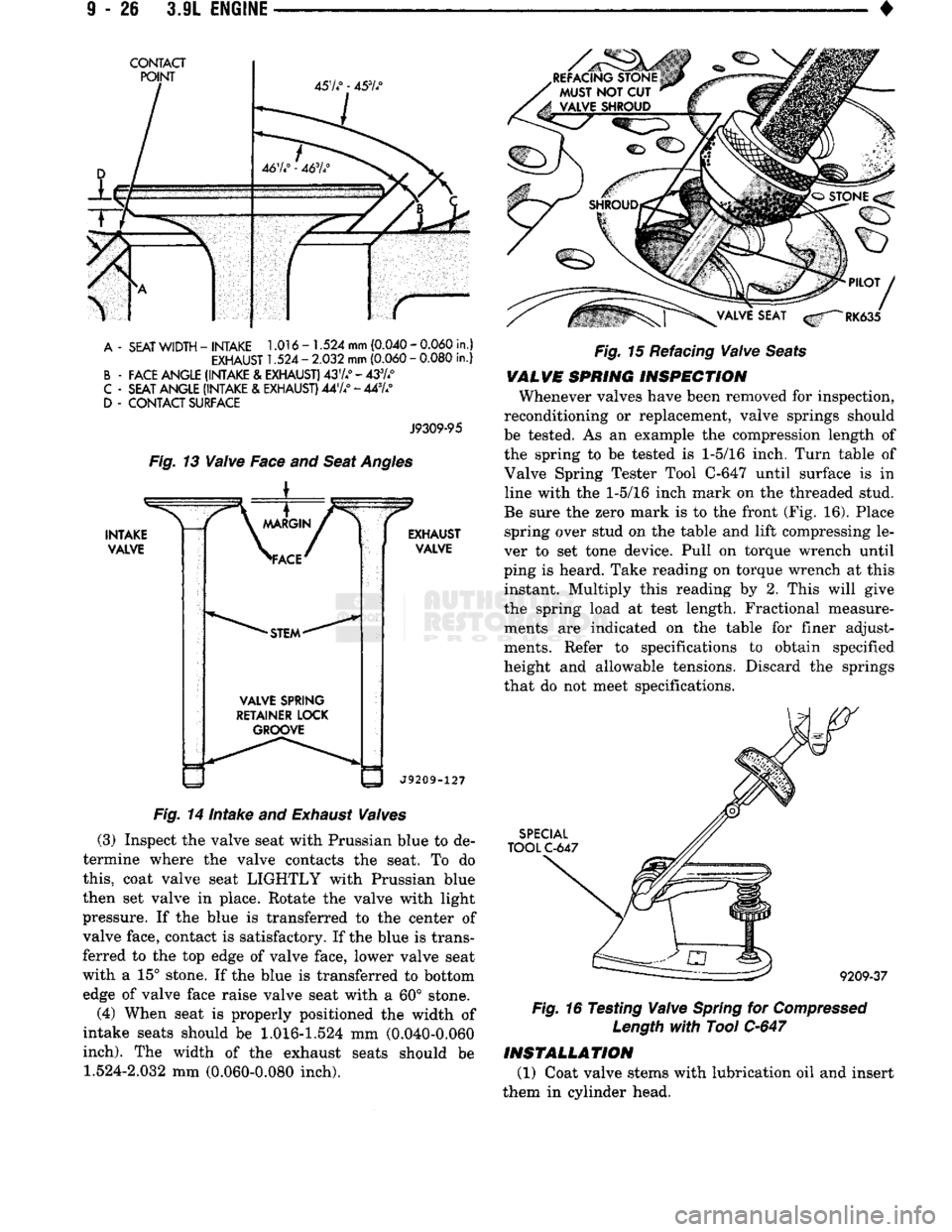

A

-

SEAT

WIDTH

-

INTAKE

1.016

-

1.524

mm

(0.040

-

0.060

in.)

EXHAUST

1.524

-

2.032

mm

(0.060

-

0.080

in.)

B

-

FACE

ANGLE

(INTAKE

& EXHAUST)

4374°

-

433A°

C

-

SEAT

ANGLE

(INTAKE

& EXHAUST)

4474°

-

44%°

D

-

CONTACT SURFACE

J9309-95

Fig.

13

Valve

Face and

Seat

Angles

i

INTAKE

VALVE

\

MARGIN

/ "

>FACE'

•STEM"

VALVE SPRING

RETAINER LOCK GROOVE EXHAUST

VALVE

J9209-127

Fig.

14 Intake and

Exhaust

Valves

(3) Inspect

the

valve seat with Prussian blue

to de

termine where

the

valve contacts

the

seat.

To do

this,

coat valve seat LIGHTLY with Prussian blue

then

set

valve

in

place. Rotate

the

valve with light

pressure.

If the

blue

is

transferred

to the

center

of

valve face, contact

is

satisfactory.

If

the blue

is

trans

ferred

to the top

edge

of

valve face, lower valve seat

with

a 15°

stone.

If

the blue

is

transferred

to

bottom edge

of

valve face raise valve seat with

a 60°

stone.

(4)

When seat

is

properly positioned

the

width

of

intake seats should

be 1.016-1.524 mm (0.040-0.060

inch).

The

width

of the

exhaust seats should

be 1.524-2.032 mm (0.060-0.080

inch).

Fig.

15 Refacing

Valve

Seats

VALVE

SPRING

INSPECTION

Whenever valves have been removed

for

inspection,

reconditioning

or

replacement, valve springs should

be tested.

As an

example

the

compression length

of

the spring

to be

tested

is 1-5/16

inch. Turn table

of

Valve Spring Tester Tool

C-647

until surface

is in

line with

the 1-5/16

inch mark

on the

threaded stud.

Be sure

the

zero mark

is to the

front (Fig.

16).

Place spring over stud

on the

table

and

lift compressing

le

ver

to set

tone device. Pull

on

torque wrench until

ping

is

heard. Take reading

on

torque wrench

at

this instant. Multiply this reading

by 2.

This will give

the spring load

at

test length. Fractional measure ments

are

indicated

on the

table

for

finer adjustments. Refer

to

specifications

to

obtain specified

height

and

allowable tensions. Discard

the

springs

that

do not

meet specifications.

SPECIAL

TOOL

C-647

9209-37

Fig.

16 Testing

Valve

Spring

for

Compressed

Length

with

Tool

C-647

INSTALLATION

(1)

Coat valve stems with lubrication

oil and

insert

them

in

cylinder head.

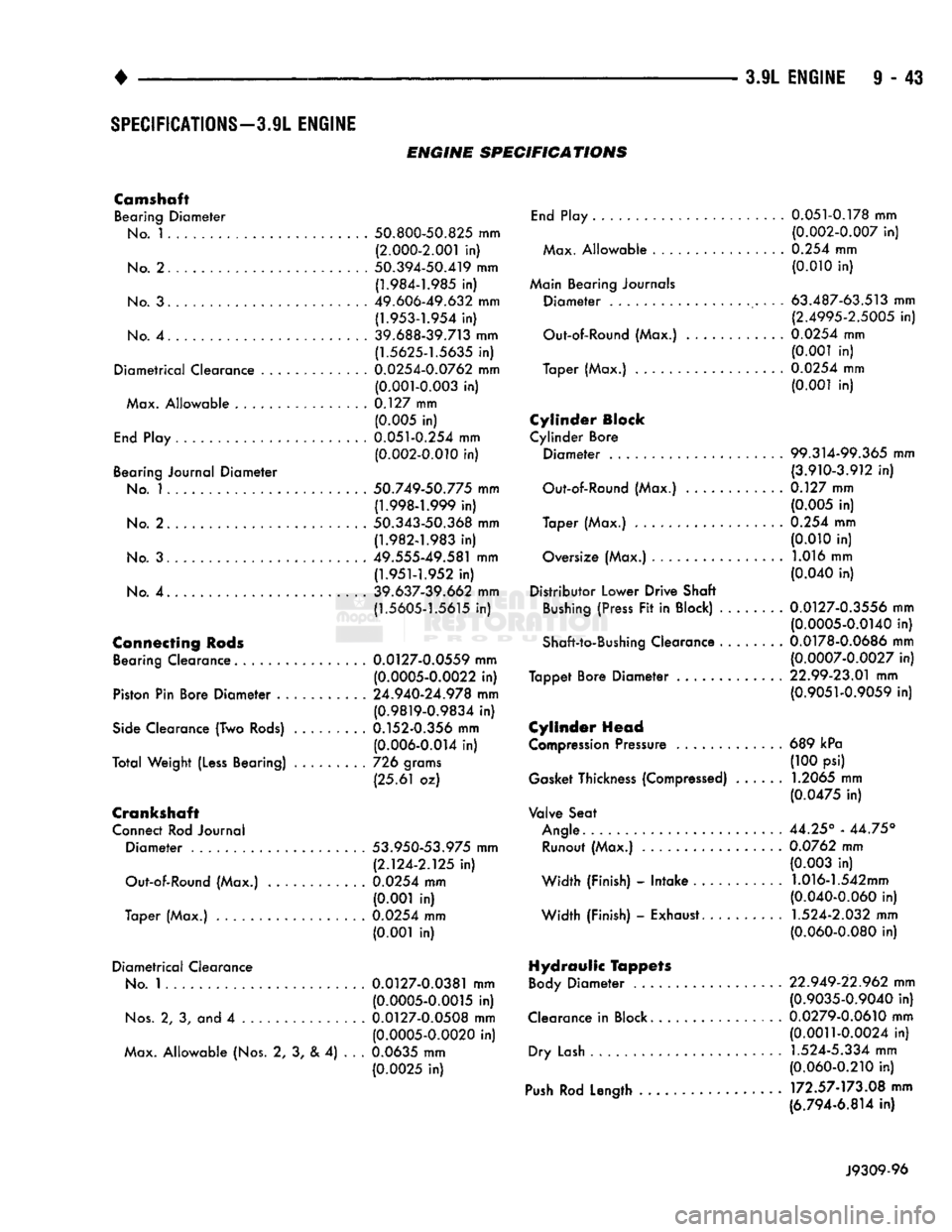

Page 648 of 1502

SPECIFICATIONS—3.9L

ENGINE

ENGINE

SPECIFICATIONS

Camshaft Bearing

Diameter

No.

1 50.800-50.825 mm

(2.000-2.001

in)

No.

2... 50.394-50.419 mm (1.984-1.985 in)

No.

3 49.606-49.632 mm (1.953-1.954 in)

No.

4 39.688-39.713 mm (1.5625-1.5635 in)

Diametrical

Clearance 0.0254-0.0762 mm (0.001-0.003 in)

Max. Allowable 0.127 mm (0.005 in)

End

Play 0.051-0.254 mm (0.002-0.010 in)

Bearing Journal

Diameter

No.

1.... 50.749-50.775 mm (1.998-1.999 in)

No.

2 50.343-50.368 mm

(1.982-1.983

in)

No.

3 49.555-49.581 mm

(1.951-1.952

in)

No.

4 .... 39.637-39.662 mm (1.5605-1.5615 in)

Connecting

Rods

Bearing Clearance 0.0127-0.0559 mm (0.0005-0.0022 in)

Piston Pin Bore

Diameter

24.940-24.978 mm (0.9819-0.9834 in)

Side

Clearance (Two

Rods)

0.152-0.356 mm (0.006-0.014 in)

Total

Weight

(Less

Bearing) 726 grams

(25.61 oz)

Crankshaft

Connect Rod Journal

Diameter

53.950-53.975 mm

(2.124-2.125 in)

Out-of-Round (Max.) . 0.0254 mm (0.001 in)

Taper (Max.) 0.0254 mm (0.001 in)

Diametrical

Clearance

No.

1 0.0127-0.0381 mm (0.0005-0.0015 in)

Nos.

2, 3, and 4 0.0127-0.0508 mm (0.0005-0.0020 in)

Max. Allowable (Nos. 2, 3, & 4) . . . 0.0635 mm

(0.0025 in)

End

Play 0.051-0.178 mm

(0.002-0.007 in)

Max. Allowable . 0.254 mm (0.010 in)

Main Bearing Journals

Diameter

63.487-63.513 mm (2.4995-2.5005 in)

Out-of-Round (Max.) . 0.0254 mm (0.001 in)

Taper (Max.) 0.0254 mm (0.001 in)

Cylinder Block

Cylinder Bore

Diameter

. 99.314-99.365 mm (3.910-3.912 in)

Out-of-Round (Max.) 0.127 mm (0.005 in)

Taper (Max.) . 0.254 mm (0.010 in)

Oversize (Max.) . 1.016 mm (0.040 in)

Distributor Lower Drive Shaft

Bushing

(Press Fit in Block) .... 0.0127-0.3556 mm (0.0005-0.0140 in)

Shaft-to-Bushing Clearance 0.0178-0.0686 mm (0.0007-0.0027 in)

Tappet Bore

Diameter

22.99-23.01 mm (0.9051-0.9059 in)

Cylinder Head

Compression

Pressure 689 kPa (100 psi)

Gasket Thickness (Compressed) 1.2065 mm (0.0475 in)

Valve Seat

Angle

44.25° - 44.75° Runout (Max.) 0.0762 mm (0.003 in)

Width (Finish) -

Intake

1.016-1.542mm (0.040-0.060 in)

Width (Finish) - Exhaust. 1.524-2.032 mm (0.060-0.080 in)

Hydraulic Tappets

Body

Diameter

. . 22.949-22.962 mm

(0.9035-0.9040 in)

Clearance in Block. . 0.0279-0.0610 mm (0.0011-0.0024 in)

Dry

Lash

1.524-5.334 mm (0.060-0.210 in)

Push

Rod Length 172.57-173.08 mm (6.794-6.814 in)

J9309-96

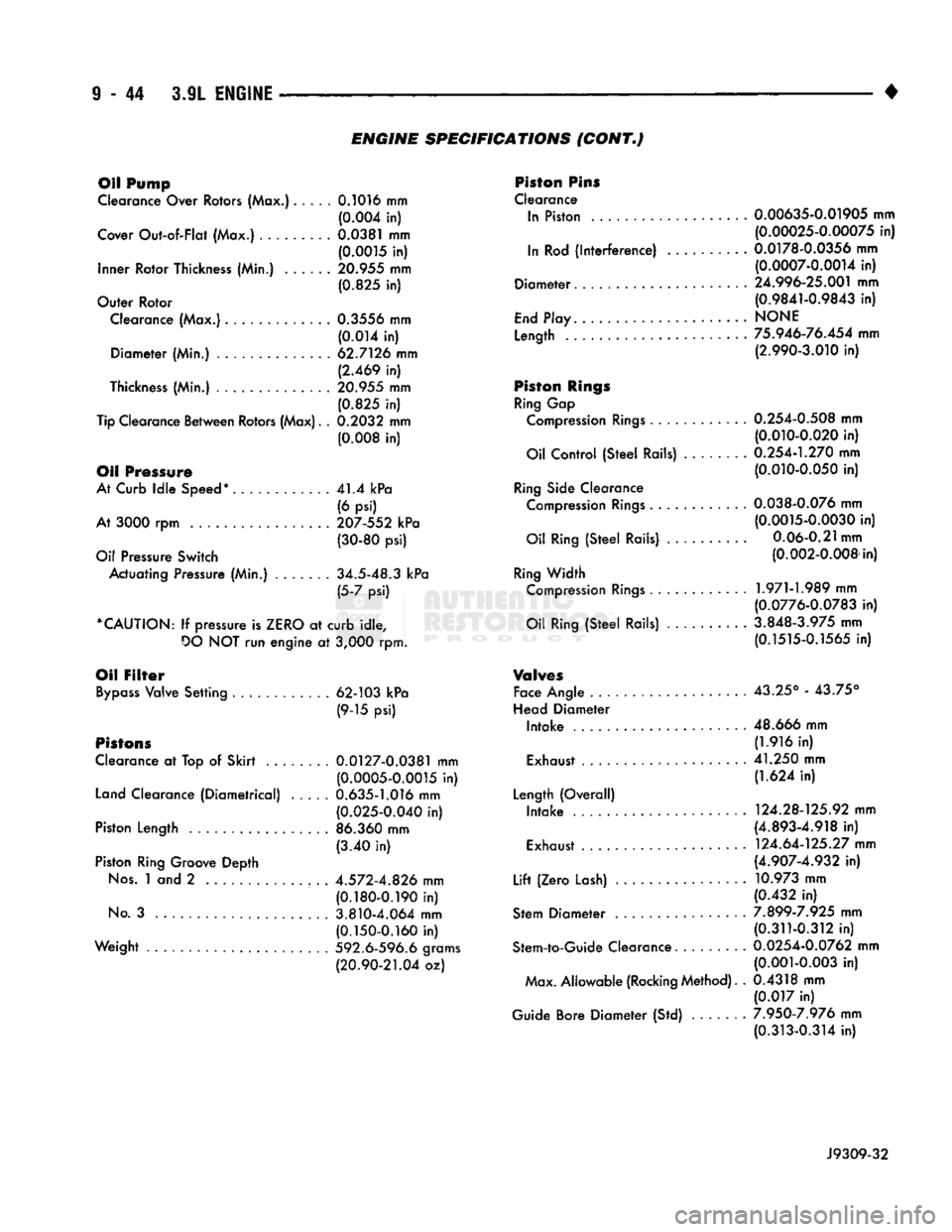

Page 649 of 1502

ENGINE SPECIFICATIONS (CONT.f

Oil

Pump

Clearance

Over

Rotors

(Max.).....

0.1016

mm (0.004 in)

Cover

Out-of-Flat

(Max.)

0.0381 mm (0.0015 in)

Inner

Rotor

Thickness

(Min.) ...... 20.955 mm (0.825 in)

Outer

Rotor

Clearance

(Max.)

0.3556 mm (0.014 in)

Diameter

(Min.) 62.7126 mm (2.469 in)

Thickness

(Min.) . . ........ 20.955 mm

(0.825 in)

Tip

Clearance

Between

Rotors

(Max).

. 0.2032 mm

(0.008 in)

Oil

Pressure

At

Curb

Idle

Speed*

41.4 kPa

(6 psi)

At

3000 rpm 207-552 kPa

(30-80 psi)

Oil

Pressure

Switch

Actuating

Pressure

(Min.) ... 34.5-48.3 kPa (5-7 psi)

*CAUTION:

If

pressure

is

ZERO

at

curb

idle,

DO

NOT run

engine

at

3,000

rpm.

Oil

Filter

Bypass

Valve

Setting

. 62-103 kPa (9-15 psi)

Pistons

Clearance

at

Top

of

Skirt

0.0127-0.0381 mm

(0.0005-0.0015 in)

Land

Clearance

(Diametrical) 0.635-1.016 mm (0.025-0.040 in)

Piston

Length

86.360 mm (3.40 in)

Piston

Ring

Groove

Depth

Nos.

1 and 2 4.572-4.826 mm (0.180-0.190 in)

No.

3 3.810-4.064 mm (0.150-0.160 in)

Weight

592.6-596.6

grams

(20.90-21.04

oz)

Piston

Pins

Clearance

In

Piston

0.00635-0.01905 mm (0.00025-0.00075 in)

In

Rod

(Interference) 0.0178-0.0356 mm (0.0007-0.0014 in)

Diameter.

24.996-25.001 mm (0.9841-0.9843 in)

End

Play..

NONE

Length

75.946-76.454 mm (2.990-3.010 in)

Piston

Rings

Ring

Gap

Compression

Rings

0.254-0.508 mm (0.010-0.020 in)

Oil

Control

(Steel

Rails)

0.254-1.270 mm (0.010-0.050 in)

Ring

Side

Clearance

Compression

Rings

0.038-0.076 mm

(0.0015-0.0030 in)

Oil

Ring

(Steel

Rails)

0.06-0.21

mm

(0.002-0.008 in)

Ring

Width

Compression

Rings

1.971-1.989 mm

(0.0776-0.0783 in)

Oil

Ring

(Steel

Rails)

3.848-3.975 mm (0.1515-0.1565 in)

Valves

Face

Angle

43.25° - 43.75°

Head

Diameter

Intake

48.666 mm (1.916 in)

Exhaust

41.250 mm (1.624 in)

Length

(Overall)

Intake

124.28-125.92 mm (4.893-4.918 in)

Exhaust

124.64-125.27 mm (4.907-4.932 in)

Lift

(Zero

Lash)

10.973 mm (0.432 in)

Stem

Diameter 7.899-7.925 mm (0.311-0.312 in)

Stem-to-Guide

Clearance

0.0254-0.0762 mm

(0.001-0.003 in)

Max.

Allowable

(Rocking

Method).

. 0.4318 mm (0.017 in)

Guide

Bore

Diameter (Std) 7.950-7.976 mm (0.313-0.314 in)

J9309-32

Page 660 of 1502

•

5.2L

ENGINE

I - 55

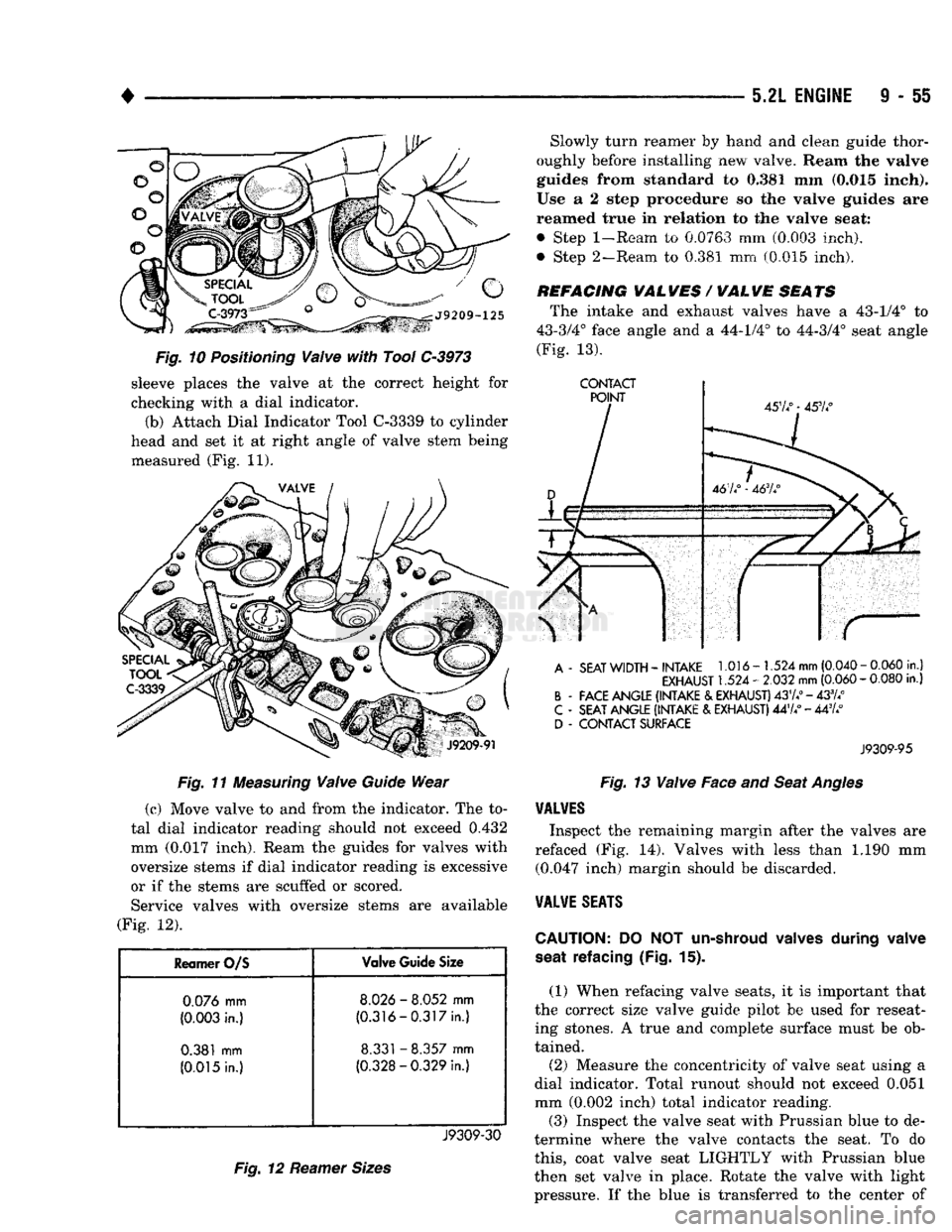

Fig. 10 Positioning Valve with Tool C-3973 sleeve places the valve at the correct height for

checking with a dial indicator.

(b) Attach Dial Indicator Tool C-3339 to cylinder

head and set it at right angle of valve stem being measured (Fig. 11).

Fig. 11 Measuring Valve Guide Wear

(c) Move valve to and from the indicator. The to

tal dial indicator reading should not exceed

0.432

mm

(0.017

inch). Ream the guides for valves with

oversize stems if dial indicator reading is excessive

or if the stems are scuffed or scored. Service valves with oversize stems are available

(Fig. 12).

Reamer

O/S

Valve

Guide

Size

0.076

mm

8.026

-

8.052

mm

(0.003

in.)

(0.316-0.317in.)

0.381

mm

8.331

-

8.357

mm

(0.015

In.)

(0.328-0.329

In.)

J9309-30

Fig. 12 Reamer Sizes

Slowly turn reamer

by

hand

and

clean guide thor

oughly before installing

new

valve. Ream

the valve

guides from standard

to 0,381 mm

(0.015 Inch).

Use

a 2

step procedure

so the

valve guides

are

reamed true

in

relation

to the

valve seat:

• Step

1-Ream

to 0.0763 mm (0.003 inch),

• Step 2—Ream, to 0.381 mm (0.015 inch).

REFACING

VAL

WES

/

WAL

WE

SEATS

The intake and exhaust valves have a 43-1/4° to

43-3/4° face angle and a 44-1/4° to 44-3/4° seat angle

(Fig.

13).

CONTACT

A

-

SEAT

WIDTH

-

INTAKE

1.016-1.524

mm

(0.040

-

0.060

in.)

EXHAUST

1.524 -

2.032

mm

(0.060

-

0.080

in.)

B

-

FACE ANGLE (INTAKE

&

EXHAUST)

437.°

-433//

C

-

SEAT ANGLE (INTAKE

&

EXHAUST)

447/ - 447/

D

-

CONTACT SURFACE

J9309-95

Fig. 13 Valve Face and Seat Angles

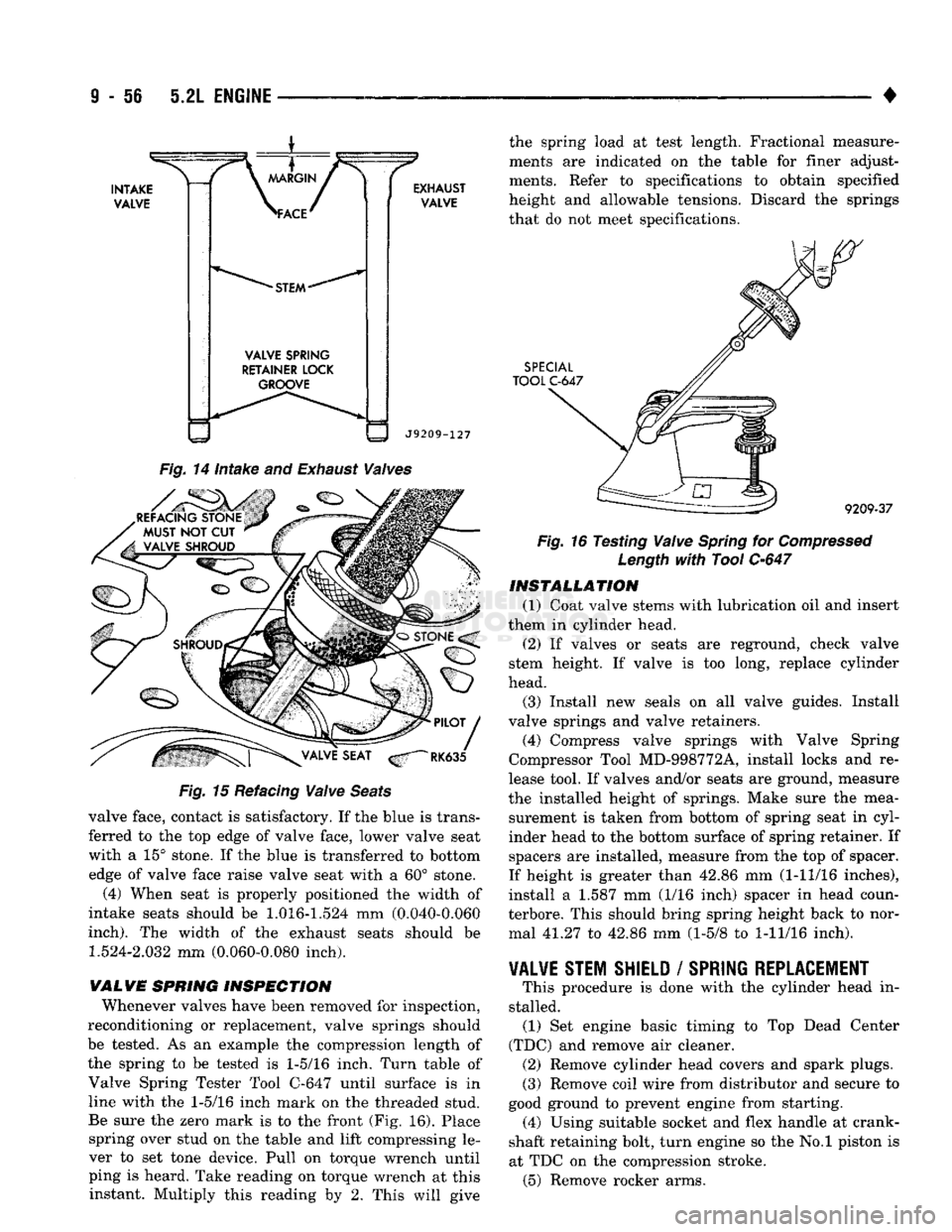

VALVES

Inspect the remaining margin after the valves are

refaced (Fig. 14). Valves with less than 1.190 mm (0.047 inch) margin should be discarded.

VALVE

SEATS

CAUTION:

DO NOT

un-shroud valves

during

valve

seat

refacing (Fig.

15).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat ing stones. A true and complete surface must be ob

tained.

(2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.051

mm (0.002 inch) total indicator reading. (3) Inspect the valve seat with Prussian blue to de

termine where the valve contacts the seat. To do

this,

coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

Page 661 of 1502

9

- 56 5.2L

ENGINE

•

VALVE

SPRING

RETAINER LOCK GROOVE

EXHAUST

VALVE

J9209-127 the spring load at test length. Fractional measure

ments are indicated on the table for finer adjust

ments. Refer to specifications to obtain specified

height and allowable tensions. Discard the springs

that do not meet specifications.

SPECIAL

TOOL

C-647

Fig.

14 Intake and

Exhaust

Valves

Fig.

15 Refacing

Valve

Seats

valve face, contact is satisfactory. If the blue is trans

ferred to the top edge of valve face, lower valve seat

with a 15° stone. If the blue is transferred to bottom edge of valve face raise valve seat with a 60° stone.

(4) When seat is properly positioned the width of

intake seats should be

1.016-1.524

mm (0.040-0.060

inch).

The width of the exhaust seats should be

1.524-2.032

mm (0.060-0.080 inch).

WALVE SPRING INSPECTION Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested. As an example the compression length of

the spring to be tested is

1-5/16

inch. Turn table of Valve Spring Tester Tool C-647 until surface is in line with the

1-5/16

inch mark on the threaded stud.

Be sure the zero mark is to the front (Fig. 16). Place spring over stud on the table and lift compressing le

ver to set tone device. Pull on torque wrench until ping is heard. Take reading on torque wrench at this instant. Multiply this reading by 2. This will give ^

9209-37

Fig.

16 Testing

Valve

Spring

for

Compressed

Length

with

Tool

C-647

INSTALLATION

(1) Coat valve stems with lubrication oil and insert

them in cylinder head.

(2) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(3) Install new seals on all valve guides. Install

valve springs and valve retainers.

(4) Compress valve springs with Valve Spring

Compressor Tool MD-998772A, install locks and re

lease tool. If valves and/or seats are ground, measure

the installed height of springs. Make sure the mea surement is taken from bottom of spring seat in cyl

inder head to the bottom surface of spring retainer. If spacers are installed, measure from the top of spacer.

If height is greater than 42.86 mm (1-11/16 inches),

install a 1.587 mm (1/16 inch) spacer in head coun-

terbore. This should bring spring height back to nor mal 41.27 to 42.86 mm (1-5/8 to

1-11/16

inch).

VALVE STEM SHIELD

/

SPRING REPLACEMENT

# This procedure is done with the cylinder head in

stalled. (1) Set engine basic timing to Top Dead Center

(TDC) and remove air cleaner. (2) Remove cylinder head covers and spark plugs.

(3) Remove coil wire from distributor and secure to

good ground to prevent engine from starting. (4) Using suitable socket and flex handle at crank

shaft retaining bolt, turn engine so the No.l piston is

at TDC on the compression stroke. (5) Remove rocker arms.

Page 678 of 1502

SPECIFICATIONS—5.2L

ENGINE

ENGINE SPECIFICATIONS

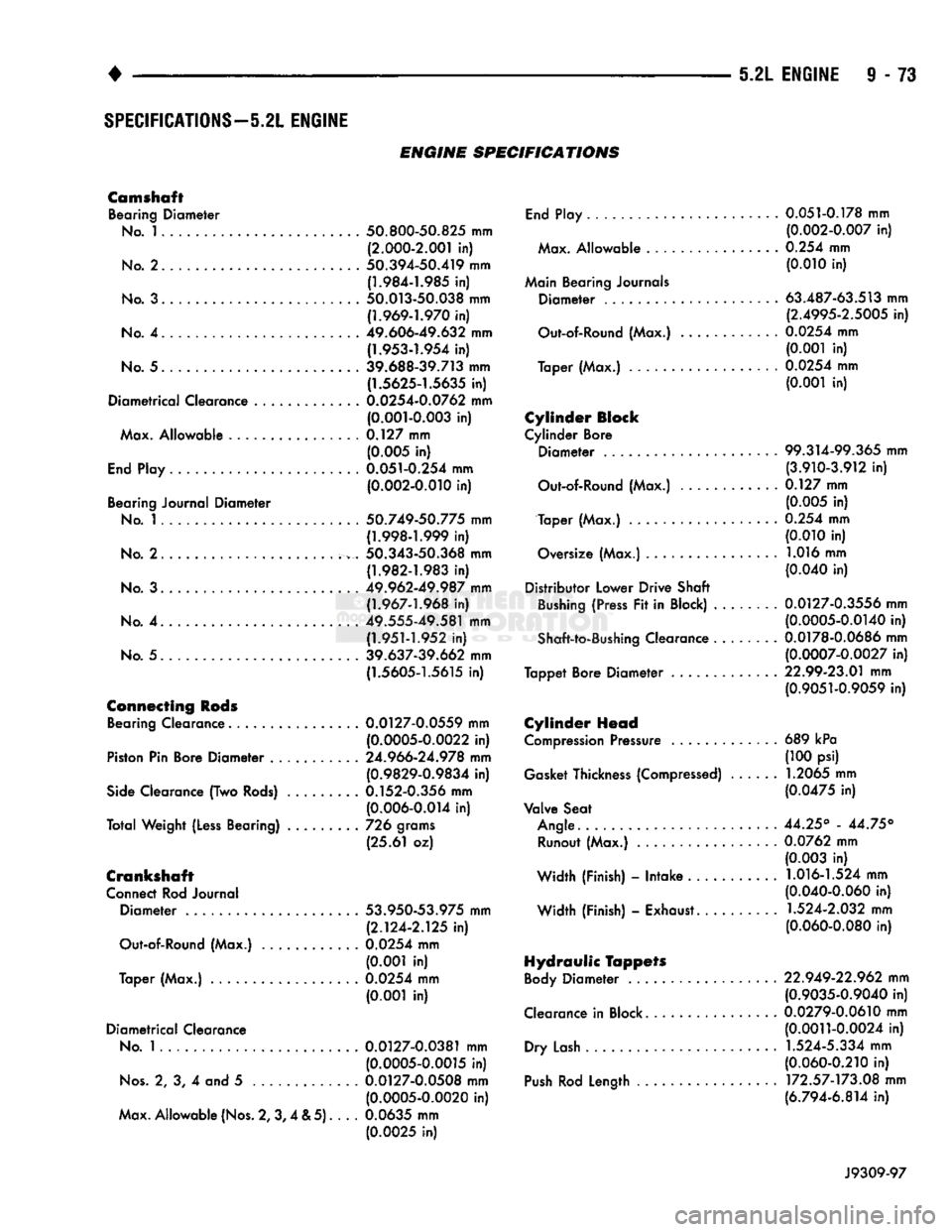

Camshaft

Bearing Diameter

No.

1....................... . 50.800-50.825 mm (2.000-2.001 in)

No.

2... 50.394-50.419 mm (1.984-1.985 in)

No.

3. . 50.013-50.038 mm

(1.969-1.970

in)

No.

4...........

......... 49.606-49.632 mm (1.953-1.954 in)

No.

5 39.688-39.713 mm

(1.5625-1.5635 in)

Diametrical Clearance 0.0254-0.0762 mm (0.001-0.003 in)

Max. Allowable 0.127 mm (0.005 in)

End Play. . .... 0.051-0.254 mm (0.002-0.010 in)

Bearing Journal Diameter

No.

1....................... . 50.749-50.775 mm (1.998-1.999 in)

No.

2 50.343-50.368 mm

(1.982-1.983

in)

No.

3... 49.962-49.987 mm (1.967-1.968 in)

No.

4. ......... .......... 49.555-49.581 mm (1.951-1.952 in)

No.

5 39.637-39.662 mm

(1.5605-1.5615 in)

Connecting

Rods

Bearing Clearance 0.0127-0.0559 mm (0.0005-0.0022 in)

Piston Pin Bore Diameter . 24.966-24.978 mm (0.9829-0.9834 in)

Side Clearance (Two Rods) ......... 0.152-0.356 mm (0.006-0.014 in)

Total Weight (Less Bearing) ......... 726 grams (25.61 oz)

Crankshaft

Connect Rod Journal Diameter ....... 53.950-53.975 mm (2.124-2.125 in)

Out-of-Round (Max.) ............ 0.0254 mm (0.001 in)

Taper (Max.) .... ...... 0.0254 mm (0.001 in)

Diametrical Clearance

No.

1 0.0127-0.0381 mm (0.0005-0.0015 in)

Nos.

2, 3, 4 and 5 ............. 0.0127-0.0508 mm (0.0005-0.0020 in)

Max. Allowable (Nos. 2, 3,4&5) 0.0635 mm (0.0025 in) End Play 0.051-0.178 mm

(0.002-0.007 in)

Max. Allowable 0.254 mm (0.010 in)

Main Bearing Journals Diameter ..................... 63.487-63.513 mm (2.4995-2.5005 in)

Out-of-Round (Max.) 0.0254 mm (0.001 in)

Taper (Max.) 0.0254 mm (0.001 in)

Cylinder

Block

Cylinder Bore Diameter 99.314-99.365 mm (3.910-3.912 in)

Out-of-Round (Max.) ............ 0.127 mm (0.005 in)

Taper (Max.) 0.254 mm (0.010 in)

Oversize (Max.) ................ 1.016 mm (0.040 in)

Distributor Lower Drive Shaft Bushing (Press Fit in Block) 0.0127-0.3556 mm (0.0005-0.0140 in)

Shaft-to-Bushing Clearance ........ 0.0178-0.0686 mm (0.0007-0.0027 in)

Tappet Bore Diameter ......... 22.99-23.01 mm (0.9051-0.9059 in)

Cylinder

Head

Compression Pressure 689 kPa (100 psi)

Gasket Thickness (Compressed) ......

1.2065

mm (0.0475 in)

Valve Seat Angle. .... 44.25° - 44.75° Runout (Max.) .......... ... 0.0762 mm (0.003 in)

Width (Finish) - Intake

1.016-1.524

mm

(0.040-0.060 in)

Width (Finish) - Exhaust. .........

1.524-2.032

mm (0.060-0.080 in)

Hydraulic

Tappets Body Diameter 22.949-22.962 mm (0.9035-0.9040 in)

Clearance in Block . 0.0279-0.0610 mm (0.0011-0.0024 in)

Dry

Lash

1.524-5.334

mm (0.060-0.210 in)

Push Rod Length ............. 172.57-173.08 mm (6.794-6.814 in)

J9309-97

Page 679 of 1502

ENGINE

SPECIFICATIONS

(CONT*)

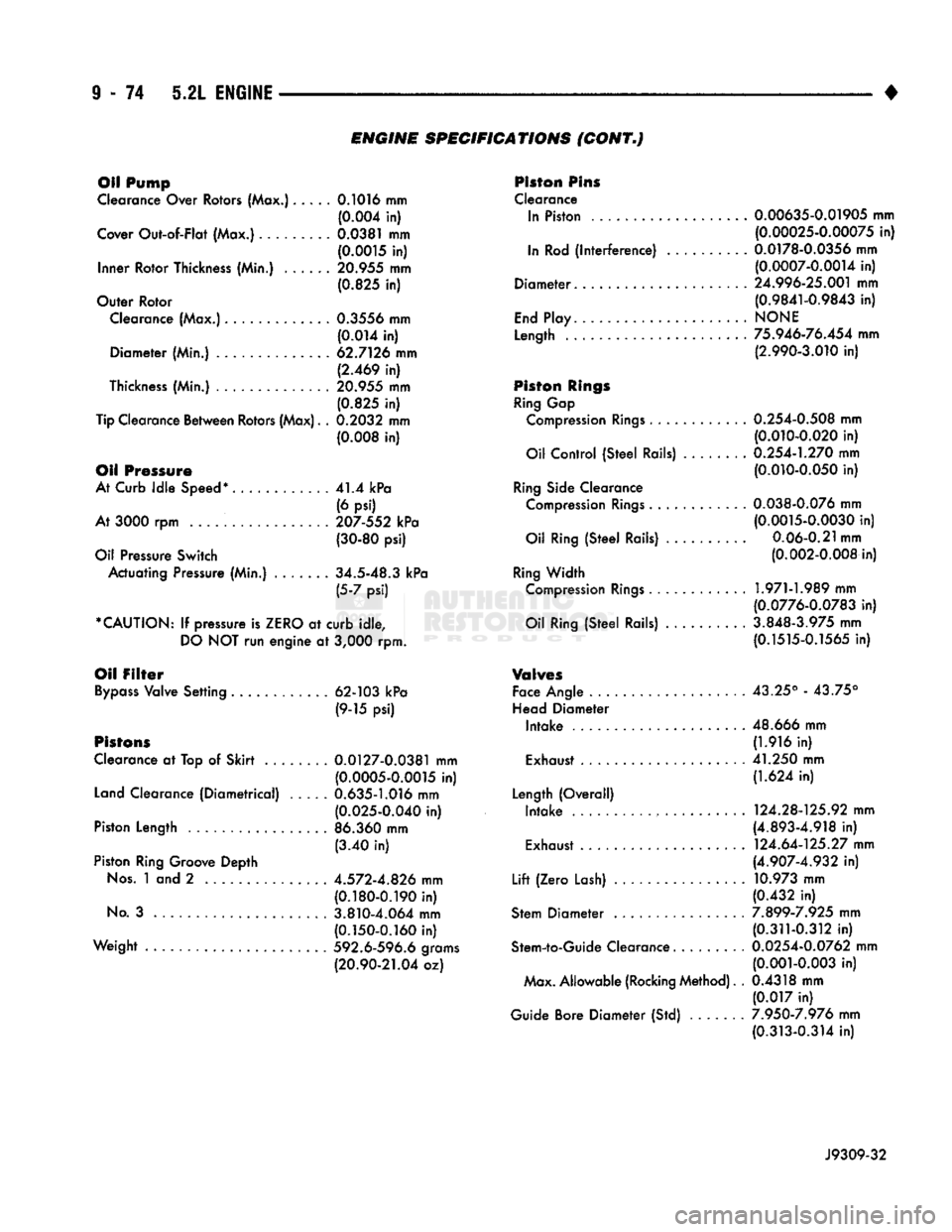

Oil Pump

Clearance Over Rotors (Max.)..... 0.1016 mm (0.004 in)

Cover

Out-of-Flat

(Max.).. ... 0.0381 mm (0.0015 in)

Inner

Rotor

Thickness (Min.) 20.955 mm (0.825 in)

Outer

Rotor

Clearance (Max.)............. 0.3556 mm

(0.014 in)

Diameter

(Min.) 62.7126 mm (2.469 in)

Thickness (Min.) 20.955 mm

(0.825 in)

Tip Clearance

Between

Rotors (Max). . 0.2032 mm

(0.008 in)

Oil Pressure

At Curb

Idle

Speed*

41.4 kPa

(6 psi)

At 3000 rpm 207-552 kPa (30-80 psi)

Oil Pressure

Switch

Actuating

Pressure (Min.) . 34.5-48.3 kPa (5-7 psi)

*CAUTION:

If pressure is

ZERO

at

curb

idle,

DO

NOT run

engine

at 3,000 rpm.

Oil

Filter

Bypass

Valve

Setting

............

62-103 kPa

(9-15 psi)

Pistons

Clearance at Top of

Skirt

.... 0.0127-0.0381 mm (0.0005-0.0015 in)

Land Clearance

(Diametrical)

..... 0.635-1.016 mm (0.025-0.040 in)

Piston

Length

.................

86.360 mm

(3.40 in)

Piston Ring Groove

Depth

Nos.

1 and 2 4.572-4.826 mm (0.180-0.190 in)

No.

3 3.810-4.064 mm (0.150-0.160 in)

Weight

592.6-596.6 grams

(20.90-21.04 oz) Piston Pins

Clearance In Piston . 0.00635-0.01905 mm (0.00025-0.00075 in)

In Rod

(interference)

..........

0.0178-0.0356 mm (0.0007-0.0014 in)

Diameter.

24.996-25.001 mm (0.9841-0.9843 in)

End

Play

NONE

Length

75.946-76.454 mm (2.990-3.010 in)

Piston

Rings

Ring Gap Compression

Rings

. 0.254-0.508 mm (0.010-0.020 in)

Oil

Control

(Steel

Rails) . 0.254-1.270 mm (0.010-0.050 in)

Ring Side Clearance Compression

Rings

0.038-0.076 mm (0.0015-0.0030 in)

Oil Ring

(Steel

Rails)

..........

0.06-0.21 mm (0.002-0.008 in)

Ring

Width

Compression

Rings

1.971-1.989 mm (0.0776-0.0783 in)

Oil Ring

(Steel

Rails) 3.848-3.975 mm (0.1515-0.1565 in)

V®hr©s

Face Angle 43.25° - 43.75°

Head

Diameter

Intake

.....................

48.666 mm (1.916 in)

Exhaust 41.250 mm (1.624 in)

Length

(Overall)

Intake

. 124.28-125.92 mm (4.893-4.918 in)

Exhaust . 124.64-125.27 mm (4.907-4.932 in)

Lift

(Zero

Lash) 10.973 mm (0.432 in)

Stem

Diameter

7.899-7.925 mm (0.311-0.312 in)

Stem-to-Guide

Clearance......... 0.0254-0.0762 mm (0.001-0.003 in)

Max.

Allowable

(Rocking Method). . 0.4318 mm

(0.017 in)

Guide Bore

Diameter

(Std) 7.950-7.976 mm (0.313-0.314 in)

J9309-32

Page 690 of 1502

•

5.9L

ENGINE

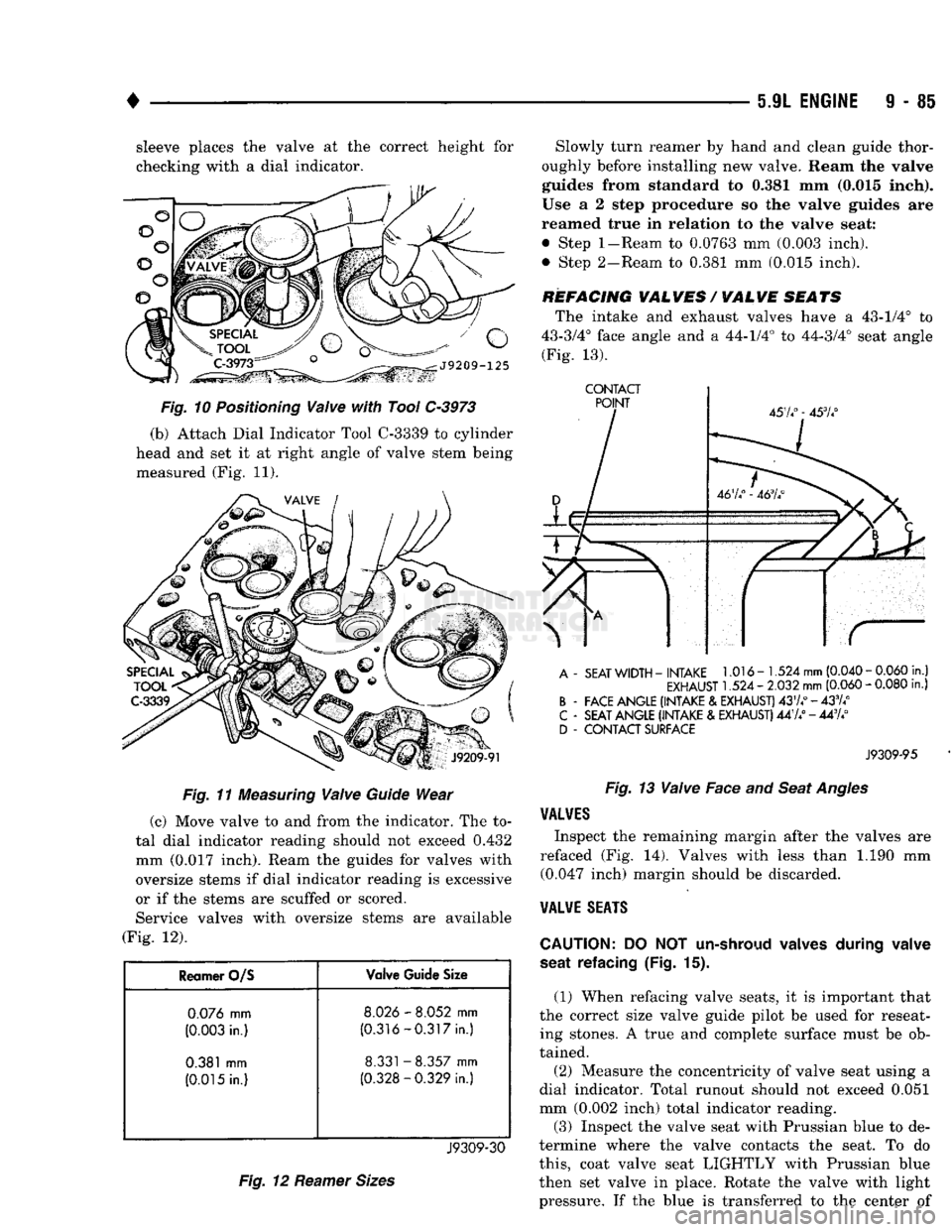

9 - 85 sleeve places the valve at the correct height for

checking with a dial indicator.

Fig.

11

Measuring

Valve

Guide

Wear

(c) Move valve to and from the indicator. The to

tal dial indicator reading should not exceed 0.432

mm (0.017 inch). Ream the guides for valves with

oversize stems if dial indicator reading is excessive

or if the stems are scuffed or scored. Service valves with oversize stems are available

(Fig. 12).

Reamer O/S Valve Guide Size

0.076

mm

8.026

-

8.052

mm

(0.003

in.)

(0.316-0.317

in.)

0.381

mm

8.331

-

8.357

mm

(0.015

in.)

(0.328-0.329

in.)

J9309-30

Fig.

12

Reamer

Sizes

Slowly turn reamer by hand and clean guide thor

oughly before installing new valve. Ream the valve

guides from standard to 0.381 mm (0.015 inch).

Use a 2 step procedure so the valve guides are

reamed true in relation to the valve seat:

• Step

1-Ream

to 0.0763 mm (0.003 inch).

• Step 2-Ream to 0.381 mm (0.015 inch).

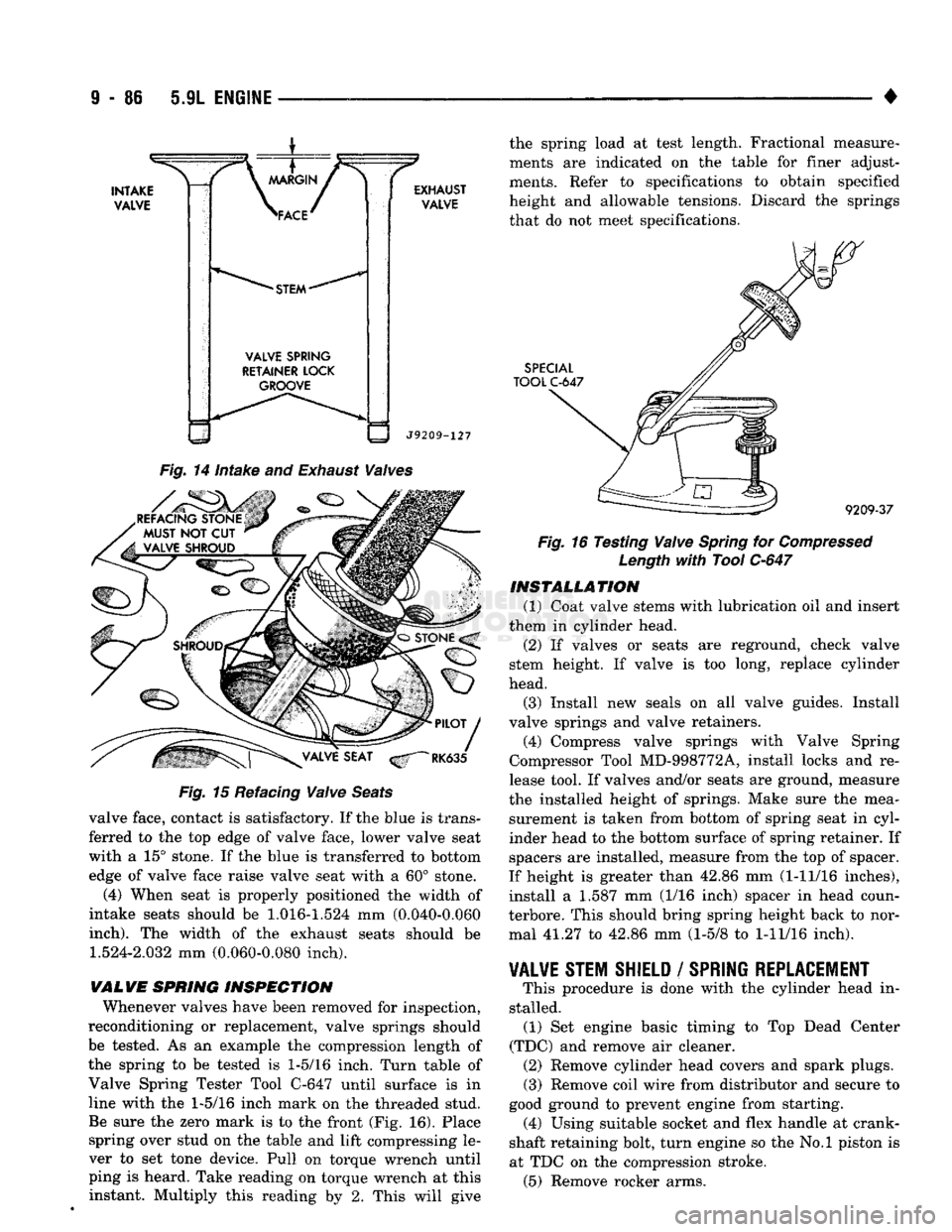

REFACING VALVES / VALVE SEATS The intake and exhaust valves have a 43-1/4° to

43-3/4° face angle and a 44-1/4° to 44-3/4° seat angle (Fig. 13).

CONTACT

A

-

SEAT

WIDTH

-

INTAKE

1.016-1.524

mm

(0.040

-

0.060

in.)

EXHAUST

1.524 -

2.032

mm

(0.060

-

0.080

in.)

B

-

FACE ANGLE (INTAKE

&

EXHAUST)

4374°-433/4°

C

-

SEAT ANGLE (INTAKE

&

EXHAUST)

447/ - 443A°

D

-

CONTACT SURFACE

J9309-95

Fig.

13

Valve

Face and

Seat

Angles

VALVES

Inspect the remaining margin after the valves are

refaced (Fig. 14). Valves with less than 1.190 mm (0.047 inch) margin should be discarded.

VALVE

SEATS

CAUTION:

DO NOT

un-shroud valves during valve

seat refacing

(Fig. 15).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat ing stones. A true and complete surface must be ob

tained.

(2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.051

mm (0.002 inch) total indicator reading.

(3)

Inspect the valve seat with Prussian blue to de

termine where the valve contacts the seat. To do

this,

coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light pressure. If the blue is transferred to the center of

Page 691 of 1502

9

• 86 5.9L

ENGINE

•

INTAKE

VALVE

\

MARGIN

/ >

\ACE^

*

STEM

*

VALVE

SPRING

RETAINER

LOCK

GROOVE EXHAUST

VALVE

J9209-127

Fig.

14

intake

and

Exhaust

Waives

REFACING STONE MUST

NOT CUT

VALVE SHROUD Fig.

15 Refacing

Waive

Seats

valve face, contact is satisfactory. If the blue is trans ferred to the top edge of valve face, lower valve seat

with a 15° stone. If the blue is transferred to bottom edge of valve face raise valve seat with a 60° stone.

(4) When seat is properly positioned the width of

intake seats should be

1.016-1.524

mm (0.040-0.060

inch).

The width of the exhaust seats should be

1.524-2.032

mm (0.060-0.080 inch).

VALVE

SPRING

INSPECTION

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should be tested. As an example the compression length of

the spring to be tested is

1-5/16

inch. Turn table of

Valve Spring Tester Tool C-647 until surface is in

line with the

1-5/16

inch mark on the threaded stud. Be sure the zero mark is to the front (Fig. 16). Place spring over stud on the table and lift compressing le

ver to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this instant. Multiply this reading by 2. This will give the spring load at test length. Fractional measure

ments are indicated on the table for finer adjust

ments. Refer to specifications to obtain specified

height and allowable tensions. Discard the springs that do not meet specifications.

SPECIAL

TOOL

C-647

9209-37

Fig.

16 Testing

Waive

Spring

for

Compressed

Length

with

Tool

C-647

INSTALLATION

(1) Coat valve stems with lubrication oil and insert

them in cylinder head.

(2) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(3) Install new seals on all valve guides. Install

valve springs and valve retainers.

(4) Compress valve springs with Valve Spring

Compressor Tool MD-998772A, install locks and re

lease tool. If valves and/or seats are ground, measure

the installed height of springs. Make sure the mea surement is taken from bottom of spring seat in cyl

inder head to the bottom surface of spring retainer. If

spacers are installed, measure from the top of spacer.

If height is greater than 42.86 mm (1-11/16 inches),

install a 1.587 mm (1/16 inch) spacer in head coun-

terbore. This should bring spring height back to nor mal 41.27 to 42.86 mm (1-5/8 to

1-11/16

inch).

¥AL¥E

STEM SHIELD

/

SPRING REPLACEMENT

This procedure is done with the cylinder head in

stalled. (1) Set engine basic timing to Top Dead Center

(TDC) and remove air cleaner. (2) Remove cylinder head covers and spark plugs. (3) Remove coil wire from distributor and secure to

good ground to prevent engine from starting. (4) Using suitable socket and flex handle at crank

shaft retaining bolt, turn engine so the No.l piston is

at TDC on the compression stroke. (5) Remove rocker arms.