width DODGE TRUCK 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 708 of 1502

— 5.9L

ENGINE

9 - 103

SPECIFICATIONS—5.9L

ENGINE

EmmmE

SPECIFICATIONS

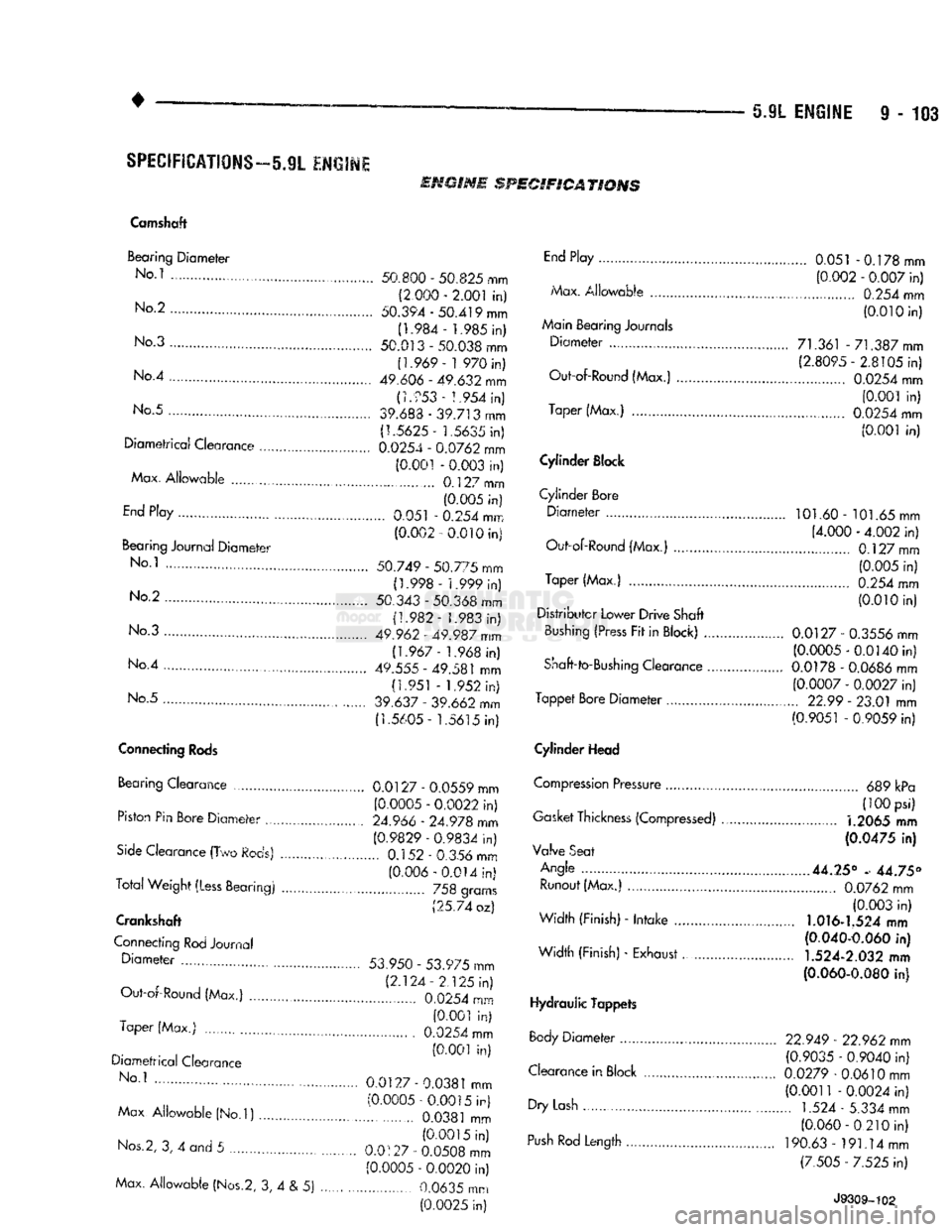

Camshaft

Bearing

Diameter

No i 50.800 - 50.825 mm "" (2.000 - 2.001 in)

No2

50.394-50.419 mm

' (1.984- 1.985 in)

No 3 50.013 - 50.038 mm

(1.969- 1 970 in)

No

4 49.606 - 49.632 mm

(1.953 - 1.954 in)

No

5 ................ 39.683 -39.713 mm

(1.5625-

1.5635 in)

Diametrical

Clearance 0.0254 - 0.0762 mm

(0.001 - 0.003 in)

Max.

Allowable

. 0.127 mm (0.005 in)

End

p|ay 0.051 - 0.254 mm

(0.002-0.010 in)

Bearinq

Journal

Diameter

No i 50.749 - 50.775 mm (1.998- 1.999 in)

No

2 50.343 - 50.368 mm

(1.982-

1.983 in)

No

3 . .............. 49.962 - 49.987 mm (1.967- 1.968 in)

No

4 . 49.555-49.581 mm

(1.951

- 1 952 in)

No

5 39.637 - 39.662 mm

(1.5605-

1.5615 in)

Connecting

Rods

Bearing Clearance 0.0127 - 0.0559 mm (0.0005 - 0.0022 in)

Piston Pin Bore

Diameter

24.966 - 24.978 mm

(0.9829 - 0.9834 in)

Side

Clearance (Two

Rods)

......................... 0.152 - 0.356 mm

(0.006-0.014 in)

Total

Weight

(Less

Bearing) . ... • 758 grams

(25.74 oz)

Crankshaft

Connecting

Rod

Journal

Diameter

. 53.950 - 53.975 mm (2.124 - 2.125 in)

Out-of-Round (Max.) 0.0254 mm

(0.001 in)

Taper (Max.) ... 0.0254 mm

(0.001 in)

Diametrical

Clearance

No

1

... ........ 0.0127 - 0.0381 mm (0.0005-0.0015 in)

Max

Allowable

(No.l)

- 0.0381 mm

(0.0015 in)

Nos.2,

3, 4 and 5 0.0127 - 0.0508 mm

(0.0005 - 0.0020 in)

Max.

Allowable

(Nos.2,

3, 4 & 5) ...... - 0.0635 mm (0.0025 in)

End

Play 0.051 -0.178 mm

(0.002 - 0.007 in)

Max.

Allowable

0.254 mm

(0.010 in)

Main Bearing Journals

Diameter

71.361 - 71.387 mm

(2.8095-

2.8105 in)

Out-of-Round (Max.) 0.0254 mm

(0.001 in)

Taper (Max.) .., 0.0254 mm

(0.001 in)

Cylinder Block

Cylinder

Bore

Diameter

, 101.60 - 101.65 mm (4.000 - 4.002 in)

Out-of-Round (Max.) ........... 0.127 mm

(0.005 in)

Taper (Max.) 0.254 mm

(0.010 in)

Distributor

Lower

Drive

Shaft

Bushing (Press Fit in Block) 0.0127 - 0.3556 mm (0.0005-0.0140 in)

Shaft-to-Bushing Clearance 0.0178 - 0.0686 mm (0.0007 - 0,0027 in)

Tappet

Bore

Diameter

.............. 22.99 - 23.01 mm (0.9051 - 0.9059 in)

Cylinder Head

Compression Pressure 689 kPa (100 psi)

Gasket Thickness (Compressed)

1.2065

mm

(0.0475 In)

Valve Seat

Angle .

44.25°

- 44.75° Runout (Max.) ....................... 0.0762 mm (0.003 in)

Width

(Finish) -

Intake

1.016-1.524

mm (0,040-0.060 in)

Width

(Finish) - Exhaust

1.524-2.032

mm

(0.060-0.080

in)

Hydraulic Tappets

Body

Diameter

22.949 - 22.962 mm (0.9035 - 0.9040 in)

Clearance in Block 0.0279 - 0.0610 mm

(0.0011 - 0.0024 in)

Dry

Lash

. 1.524 - 5.334 mm

(0.060-0210 in)

Push

Rod

Length

190.63 - 191.14mm

(7.505 - 7.525 in)

J9309-102

Page 709 of 1502

9 - 104 5.9L ENGINE

• ENGINE

SPECIFICATIONS

(CONT„)

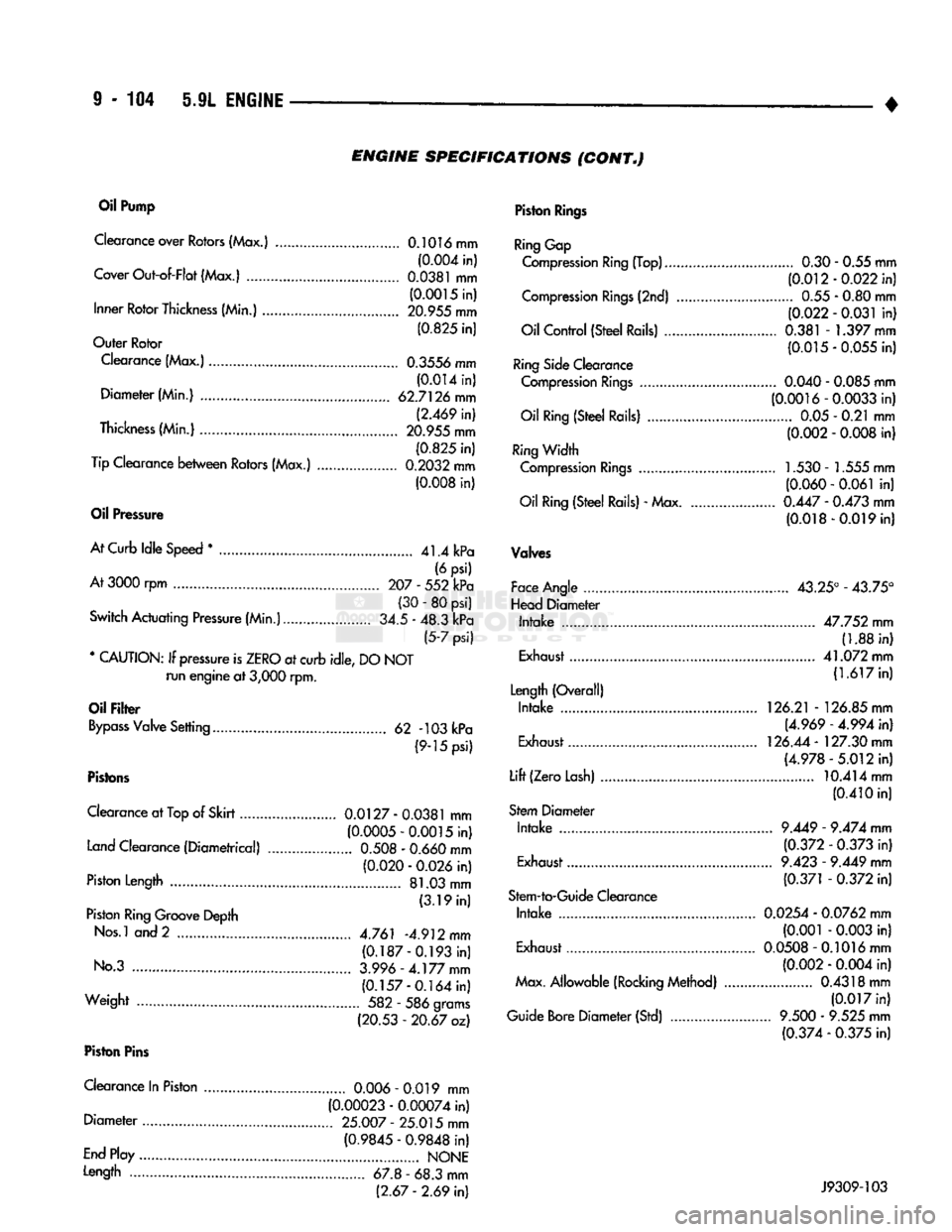

Oil

Pump

Clearance over Rotors (Max.) 0.1016 mm (0.004 in)

Cover Out-of-Flat (Max.)

0.0381

mm (0.0015 in)

Inner Rotor Thickness (Min.) 20.955 mm

(0.825 in)

Outer Rotor

Clearance (Max.) 0.3556 mm (0.014 in)

Diameter (Min.) 62.7126 mm (2.469 in)

Thickness (Min.) 20.955 mm (0.825 in)

Tip Clearance between Rotors (Max.) 0.2032 mm (0.008 in)

Oil

Pressure

At Curb Idle Speed

*

41.4 kPa (6 psi)

At

3000 rpm 207 - 552 kPa (30 - 80 psi)

Switch Actuating Pressure (Min.) 34.5 - 48.3 kPa (5-7 psi)

* CAUTION: If pressure is ZERO at curb idle, DO NOT run engine at

3,000

rpm.

Oil

Filter

Bypass Valve Setting 62 -103 kPa (9-15 psi)

Pistons

Clearance at

Top

of Skirt 0.0127

-

0.0381

mm (0.0005-0.0015 in)

Land Clearance (Diametrical)

0.508

-

0.660

mm (0.020 -

0.026

in)

Piston Length 81.03 mm (3.19 in)

Piston Ring Groove Depth

Nos.l and 2 4.761 -4.912 mm (0.187-0.193 in)

No.3 3.996-4.177

mm

(0.157-0.164 in)

Weight 582 - 586 grams (20.53 - 20.67 oz)

Piston

Pins

Clearance In Piston

0.006

- 0.019 mm (0.00023 - 0.00074 in)

Diameter 25.007

-

25.015 mm

(0.9845 - 0.9848 in)

End Play NONE

Length 67.8 - 68.3 mm (2.67

-

2.69 in)

Piston

Rings

Ring Gap

Compression Ring (Top) 0.30 - 0.55 mm (0.012-0.022 in)

Compression Rings (2nd) 0.55 - 0.80 mm (0.022 - 0.031 in)

Oil Control (Steel Rails) 0.381 - 1.397 mm (0.015-0.055 in)

Ring Side Clearance Compression Rings

0.040

-

0.085

mm (0.0016-0.0033 in)

Oil Ring (Steel Rails) 0.05 - 0.21 mm (0.002 -

0.008

in)

Ring Width Compression Rings 1.530 - 1.555 mm (0.060 - 0.061 in)

Oil Ring (Steel Rails) - Max

0.447

-

0.473

mm (0.018-0.019 in)

Valves

Face Angle 43.25° - 43.75°

Head Diameter Intake 47.752 mm (1.88 in)

Exhaust 41.072 mm

(1.617 in)

Length (Overall) Intake 126.21 - 126.85 mm

(4.969 - 4.994 in)

Exhaust 126.44 - 127.30 mm

(4.978-5.012 in)

Lift (Zero Lash) 10.414 mm

(0.410 in)

Stem Diameter Intake

9.449

-

9.474

mm

(0.372 -

0.373

in)

Exhaust

9.423

-

9.449

mm

(0.371 -

0.372

in)

Stem-to-Guide Clearance Intake 0.0254 - 0.0762 mm (0.001 -

0.003

in)

Exhaust 0.0508-0.1016 mm

(0.002 -

0.004

in)

Max. Allowable (Rocking Method) 0.4318 mm (0.017 in)

Guide Bore Diameter (Std)

9.500

-

9.525

mm (0.374 -

0.375

in) J9309-103

Page 724 of 1502

•

5.9L (DIESEL) ENGINE

9 - 119

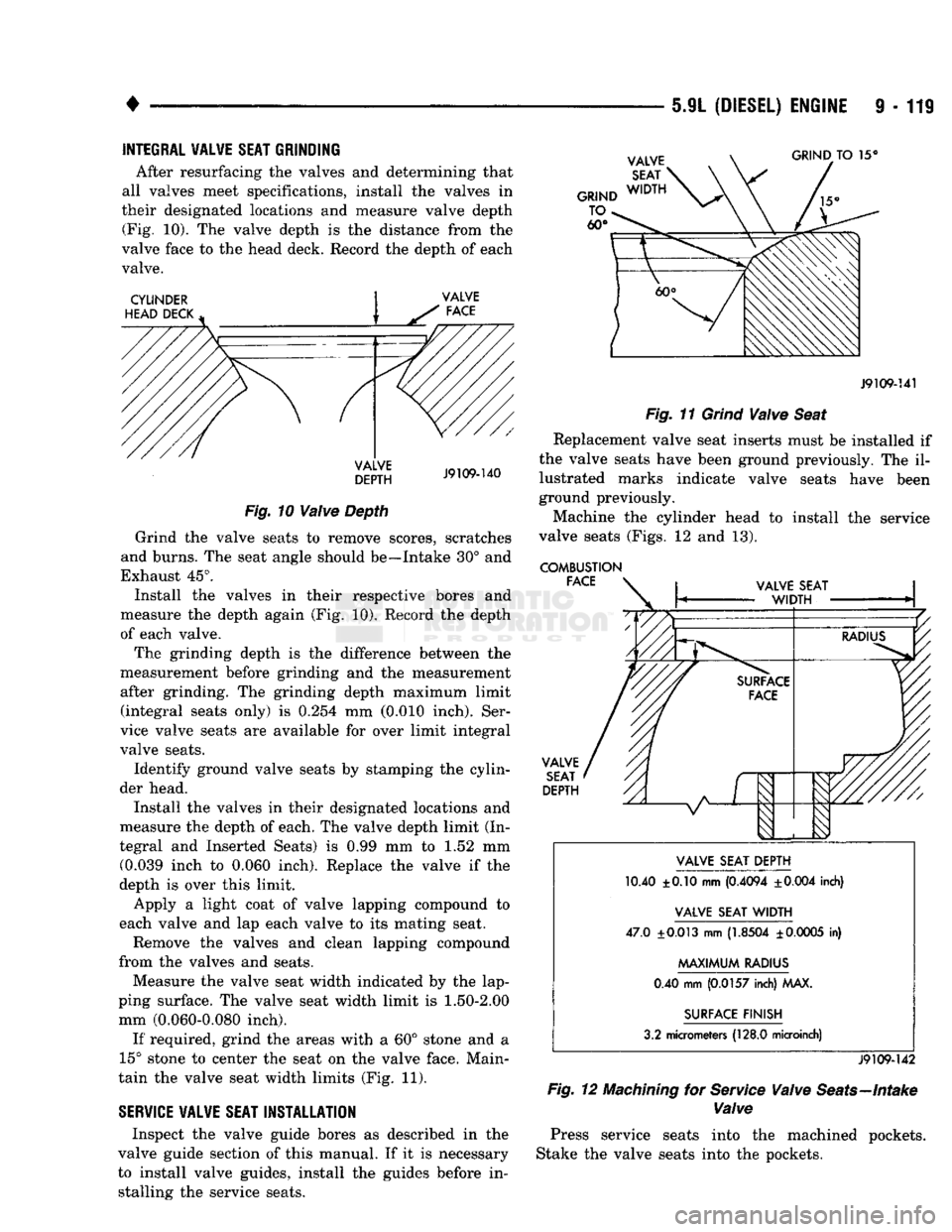

INTEGRAL VALWE SEAT GRINDING

After resurfacing the valves and determining that

all valves meet specifications, install the valves in

their designated locations and measure valve depth (Fig. 10). The valve depth is the distance from the

valve face to the head deck. Record the depth of each valve.

CYLINDER

HEAD DECK GRIND

TO 15°

VALVE

DEPTH

J9109-140

Fig.

10

Valve

Depth

Grind the valve seats to remove scores, scratches

and burns. The seat angle should be—Intake 30° and

Exhaust 45°. Install the valves in their respective bores and

measure the depth again (Fig. 10). Record the depth

of each valve.

The grinding depth is the difference between the

measurement before grinding and the measurement after grinding. The grinding depth maximum limit (integral seats only) is 0.254 mm (0.010 inch). Ser

vice valve seats are available for over limit integral

valve seats.

Identify ground valve seats by stamping the cylin

der head.

Install the valves in their designated locations and

measure the depth of each. The valve depth limit (In

tegral and Inserted Seats) is 0.99 mm to 1.52 mm (0.039 inch to 0.060 inch). Replace the valve if the

depth is over this limit.

Apply a light coat of valve lapping compound to

each valve and lap each valve to its mating seat.

Remove the valves and clean lapping compound

from the valves and seats.

Measure the valve seat width indicated by the lap

ping surface. The valve seat width limit is

1.50-2.00

mm (0.060-0.080 inch).

If required, grind the areas with a 60° stone and a

15° stone to center the seat on the valve face. Main

tain the valve seat width limits (Fig. 11).

SERVICE

VALVE

SEAT

INSTALLATION

Inspect the valve guide bores as described in the

valve guide section of this manual. If it is necessary

to install valve guides, install the guides before in stalling the service seats.

J9109-141

Fig.

11

Grind

Valve

Seat

Replacement valve seat inserts must be installed if

the valve seats have been ground previously. The il lustrated marks indicate valve seats have been

ground previously.

Machine the cylinder head to install the service

valve seats (Figs. 12 and 13).

COMBUSTION FACE VALVE

SEAT

DEPTH VALVE SEAT DEPTH

10.40 ±0.10 mm

(0.4094

±0.004

inch)

VALVE SEAT

WIDTH

47.0

±0.013

mm

(1.8504

±

0.0005

in)

MAXIMUM

RADIUS

0.40 mm

(0.0157

inch) MAX.

SURFACE FINISH

3.2 micrometers

(128.0

microinch)

J9109-142

Fig.

12

Machining

for

Service

Valve

Seats—Intake

Valve

Press service seats into the machined pockets.

Stake the valve seats into the pockets.

Page 725 of 1502

9

- 120 5.9L

(DIESEL)

ENGINE

•

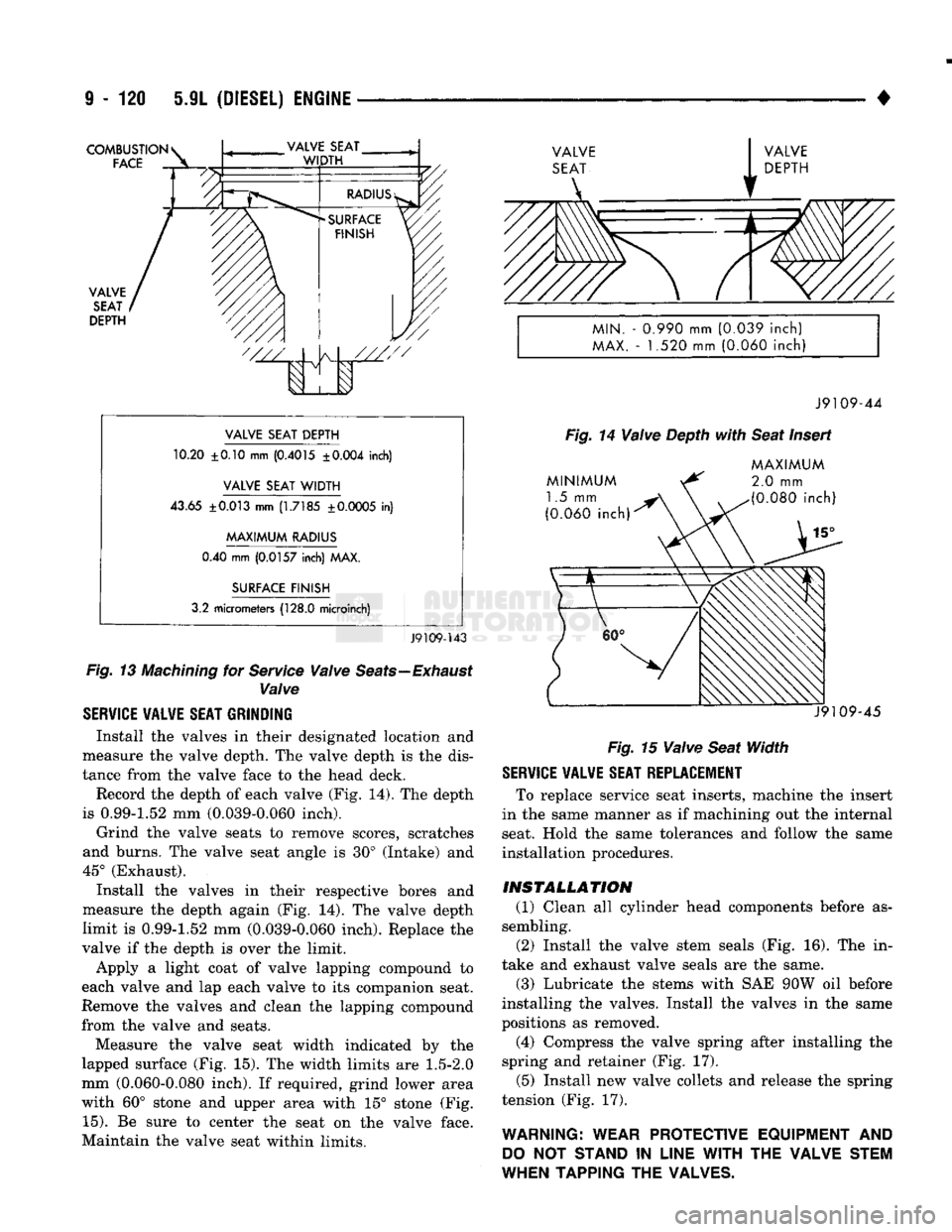

COMBUSTION

FACE

VALVE

SEAT

DEPTH

'///

A

I

V

1

VALVE

SEAT

DEPTH

10.20 ±0.10 mm

(0.4015

±0.004

inch)

VALVE

SEAT

WIDTH

43.65

±0.013

mm

(1.7185

±0.0005

in)

MAXIMUM

RADIUS

0.40 mm

(0.0157

inch) MAX.

SURFACE

FINISH

3.2 micrometers

(128.0

microinch)

J9109-143

Fig.

13

Machining

for

Service

Valve

Seats—Exhaust

Valve

SERVICE VALVE SEAT GRINDING

Install the valves in their designated location and

measure the valve depth. The valve depth is the dis

tance from the valve face to the head deck. Record the depth of each valve (Fig. 14). The depth

is 0.99-1.52 mm (0.039-0.060 inch).

Grind the valve seats to remove scores, scratches

and burns. The valve seat angle is 30° (Intake) and

45° (Exhaust). Install the valves in their respective bores and

measure the depth again (Fig. 14). The valve depth

limit is 0.99-1.52 mm (0.039-0.060 inch). Replace the

valve if the depth is over the limit.

Apply a light coat of valve lapping compound to

each valve and lap each valve to its companion seat.

Remove the valves and clean the lapping compound

from the valve and seats.

Measure the valve seat width indicated by the

lapped surface (Fig. 15). The width limits are

1.5-2.0

mm (0.060-0.080 inch). If required, grind lower area

with 60° stone and upper area with 15° stone (Fig.

15).

Be sure to center the seat on the valve face.

Maintain the valve seat within limits.

MIN.

-

0.990

mm

(0.039

inch)

MAX.

- 1.520 mm

(0.060

inch)

J9109-44

Fig.

14

Valve

Depth

with

Seat

Insert

MINIMUM

1.5 mm

(0.060

inch)

MAXIMUM

2.0

mm

(0.080

inch)

J9109-45

Fig.

15

Valve

Seat

Width

SERVICE VALVE SEAT REPLACEMENT

To replace service seat inserts, machine the insert

in the same manner as if machining out the internal

seat. Hold the same tolerances and follow the same

installation procedures.

INSTALLATION

(1) Clean all cylinder head components before as

sembling.

(2) Install the valve stem seals (Fig. 16). The in

take and exhaust valve seals are the same.

(3) Lubricate the stems with SAE 90W oil before

installing the valves. Install the valves in the same

positions as removed.

(4) Compress the valve spring after installing the

spring and retainer (Fig. 17).

(5) Install new valve collets and release the spring

tension (Fig. 17).

WARNING: WEAR PROTECTIVE EQUIPMENT

AND

DO

NOT

STAND

IN

LINE

WITH

THE VALVE STEM

WHEN TAPPING THE VALVES.

Page 744 of 1502

•

5.9L

(DIESEL) ENGINE 9 - 139

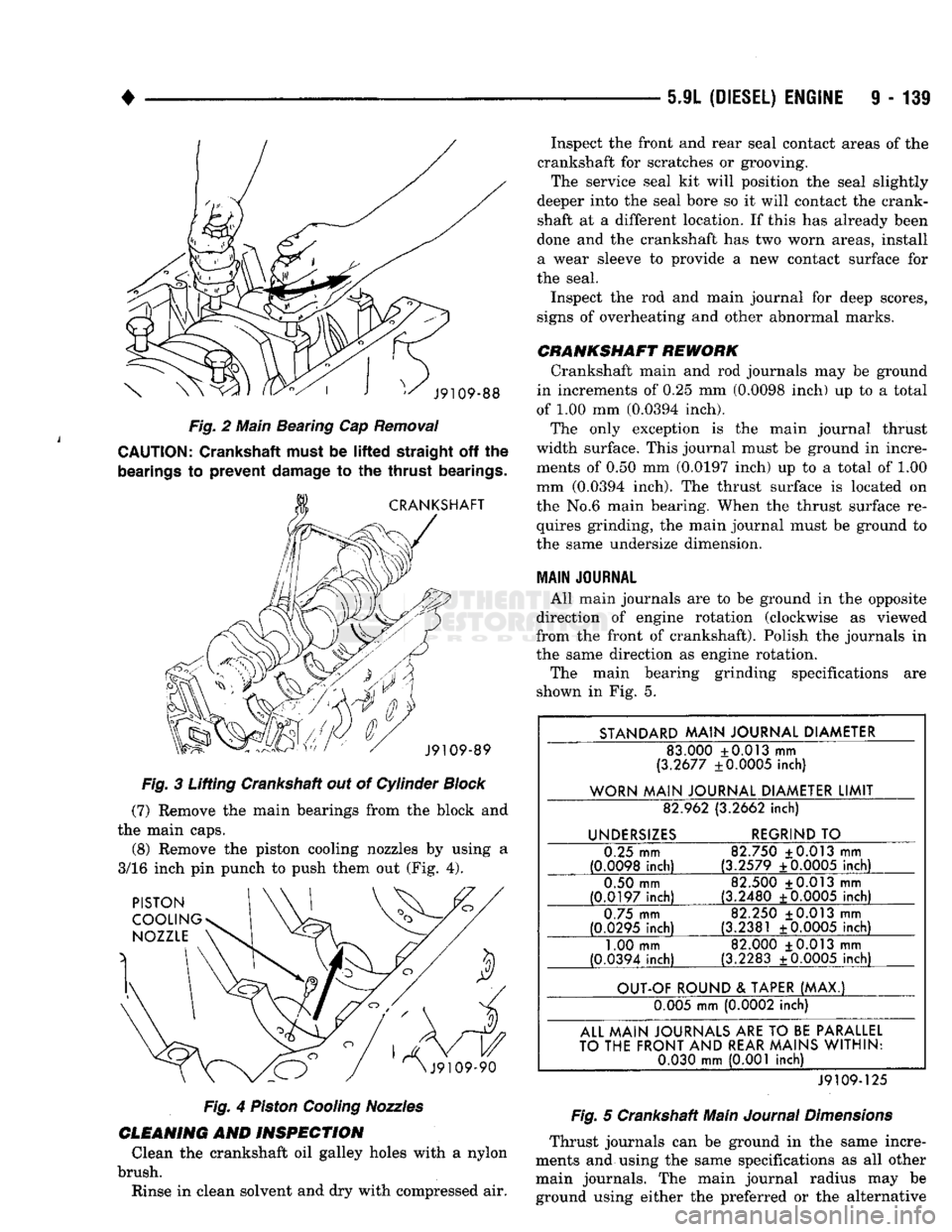

Fig.

2 Main Beating Cap

Removal

CAUTION:

Crankshaft must be

lifted

straight

off the

bearings

to

prevent

damage

to the

thrust

bearings.

Fig.

3 Lifting Crankshaft out of Cylinder

Block

(7)

Remove the main bearings from the block and

the main caps. (8) Remove the piston cooling nozzles by using a

3/16 inch pin punch to push them out (Fig. 4).

Fig.

4

Piston

Cooling

Nozzles

CLEANING

AND

INSPECTION

Clean the crankshaft oil galley holes with a nylon

brush. Rinse in clean solvent and dry with compressed air. Inspect the front and rear seal contact areas of the

crankshaft for scratches or grooving. The service seal kit will position the seal slightly

deeper into the seal bore so it will contact the crank

shaft at a different location. If this has already been

done and the crankshaft has two worn areas, install

a wear sleeve to provide a new contact surface for

the seal.

Inspect the rod and main journal for deep scores,

signs of overheating and other abnormal marks.

CRANKSHAFT

REWORK

Crankshaft main and rod journals may be ground

in increments of 0.25 mm (0.0098 inch) up to a total

of 1.00 mm (0.0394 inch). The only exception is the main journal thrust

width surface. This journal must be ground in incre ments of 0.50 mm (0.0197 inch) up to a total of 1.00

mm (0.0394 inch). The thrust surface is located on

the No.6 main bearing. When the thrust surface re quires grinding, the main journal must be ground to

the same undersize dimension.

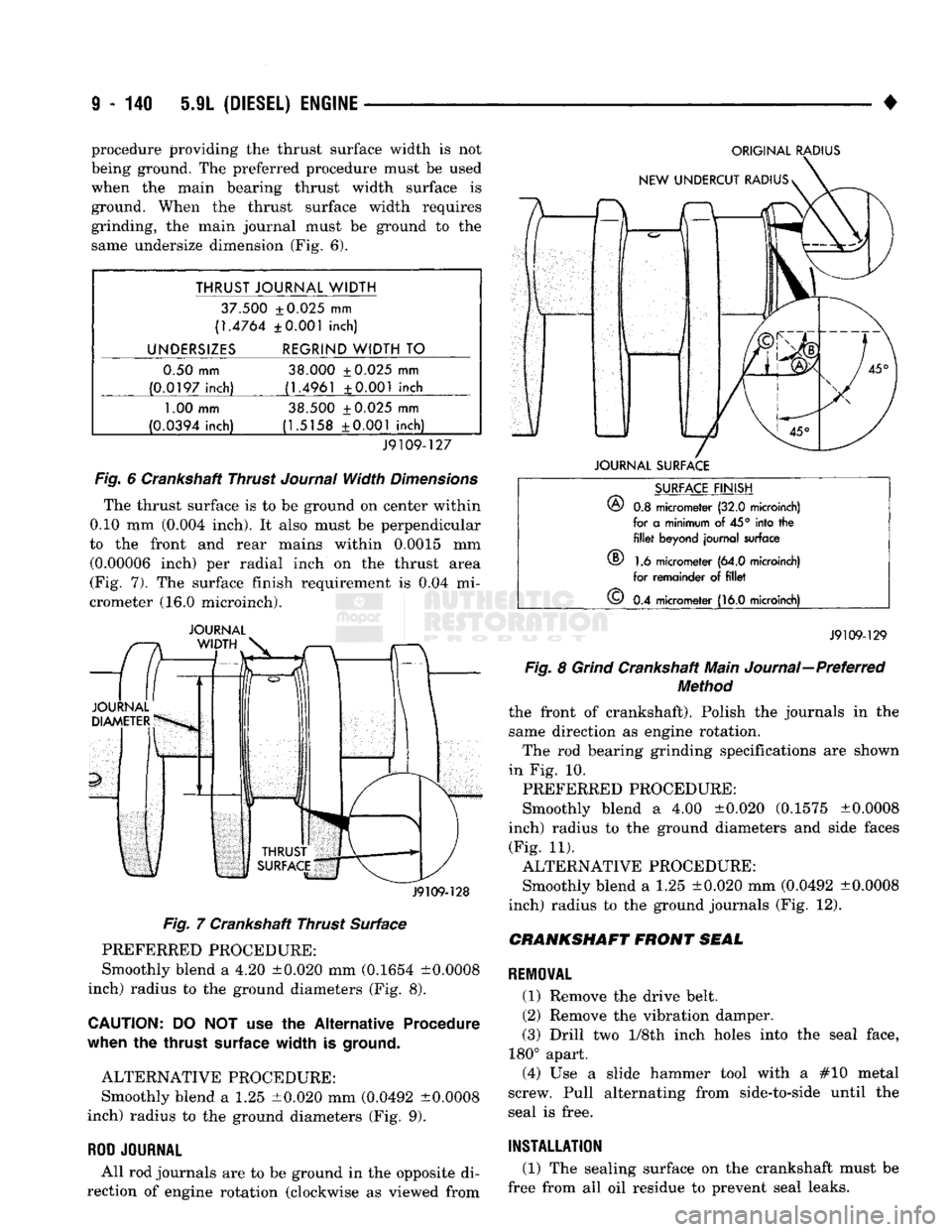

MAIN

JOURNAL

All main journals are to be ground in the opposite

direction of engine rotation (clockwise as viewed

from the front of crankshaft). Polish the journals in

the same direction as engine rotation.

The main bearing grinding specifications are

shown in Fig. 5.

STANDARD

MAIN

JOURNAL

DIAMETER

83.000 +0.013 mm

(3.2677 ±0.0005 inch)

WORN

MAIN

JOURNAL

DIAMETER

LIMIT

82.962 (3.2662

inch)

UNDERSIZES

REGRIND

TO

0.25 mm

(0.0098

inch)

82.750 ±0.013 mm

(3.2579 ±0.0005

inch)

0.50 mm

(0.0197

inch)

82.500 +0.013 mm

(3.2480 +0.0005

inch)

0.75 mm

(0.0295

inch)

82.250 +0.013 mm

(3.2381 ±0.0005

inch)

1.00 mm

(0.0394 inch) 82.000 +0.013 mm

(3.2283 ±0.0005 inch)

OUT-OF

ROUND

&

TAPER

(MAX.)

0.005 mm (0.0002 inch)

ALL

MAIN

JOURNALS

ARE

TO

BE

PARALLEL

TO

THE

FRONT

AND

REAR

MAINS

WITHIN:

0.030

mm

(0.001 inch)

J9109-125

Fig.

5 Crankshaft Main

Journal

Dimensions

Thrust journals can be ground in the same incre

ments and using the same specifications as all other main journals. The main journal radius may be ground using either the preferred or the alternative

Page 745 of 1502

9

- 140 5.9L

(DIESEL)

ENGINE

• procedure providing

the

thrust surface width

is not

being ground.

The

preferred procedure must

be

used

when

the

main bearing thrust width surface

is

ground. When

the

thrust surface width requires

grinding,

the

main journal must

be

ground

to the

same undersize dimension

(Fig. 6).

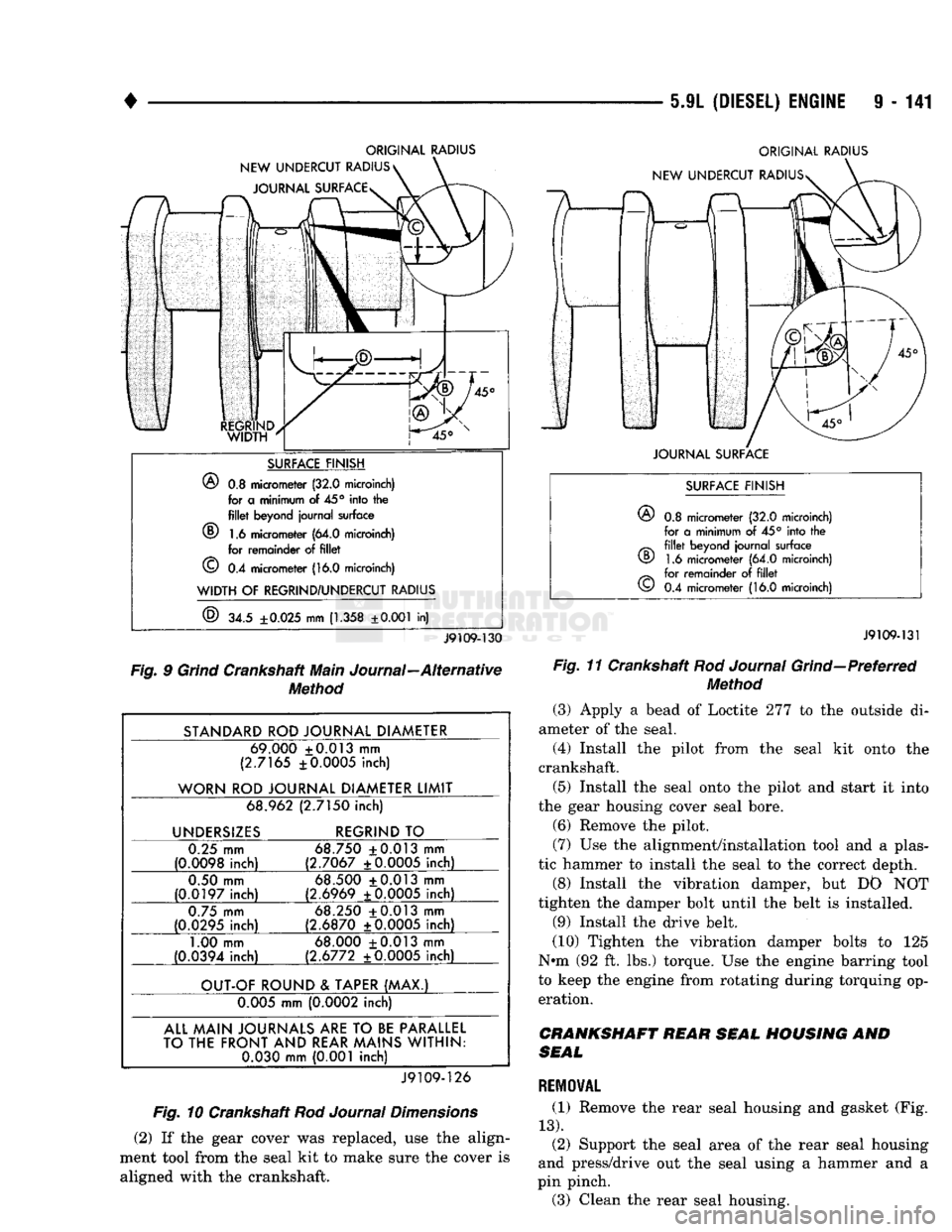

THRUST JOURNAL WIDTH

37.500 ±0.025

mm

(1.4764 ±0.001 inch)

UNDERSIZES REGRIND WIDTH

TO

0.50 mm 38.000 ±0.025

mm

(0.0197 inch) (1.4961 ±0.001 inch

1.00

mm 38.500 ±0.025

mm

(0.0394 inch) (1.5158 ±0.001 inch)

J9109-127

Fig.

6

Crankshaft Thrust

Journal

Width

Dimensions

The thrust surface

is to be

ground

on

center within

0.10

mm

(0.004 inch).

It

also must

be

perpendicular

to

the

front

and

rear mains within 0.0015

mm

(0.00006 inch)

per

radial inch

on the

thrust area

(Fig.

7). The

surface finish requirement

is 0.04 mi

crometer

(16.0

microinch).

JOURNAL

J9109-128

Fig.

7

Crankshaft Thrust Surface PREFERRED PROCEDURE:

Smoothly blend

a 4.20

±0.020

mm

(0.1654 ±0.0008

inch) radius

to the

ground diameters

(Fig. 8).

CAUTION:

DO NOT use the

Alternative Procedure

when

the

thrust

surface

width

is

ground.

ALTERNATIVE PROCEDURE: Smoothly blend

a 1.25

±0.020

mm

(0.0492 ±0.0008

inch) radius

to the

ground diameters

(Fig. 9).

ROD

JOURNAL

All

rod

journals

are to be

ground

in the

opposite

di

rection

of

engine rotation (clockwise

as

viewed from

ORIGINAL

RADIUS

JOURNAL

SURFACE

®

SURFACE

FINISH

®

0.8

micrometer

(32.0

microinch)

for

a

minimum

of 45°

into

the fillet

beyond journal surface

1.6

micrometer

(64.0

microinch)

for remainder

of fillet

©

0.4

micrometer

(16.0

microinch)

J9109-129

Fig.

8

Grind

Crankshaft Main Journal—Preferred

Method

the front

of

crankshaft). Polish

the

journals

in the

same direction

as

engine rotation. The

rod

bearing grinding specifications

are

shown

in

Fig. 10.

PREFERRED PROCEDURE:

Smoothly blend

a 4.00

±0.020 (0.1575 ±0.0008

inch) radius

to the

ground diameters

and

side faces (Fig.

11).

ALTERNATIVE PROCEDURE: Smoothly blend

a 1.25

±0.020

mm

(0.0492 ±0.0008

inch) radius

to the

ground journals

(Fig. 12).

CRANKSHAFT

FRONT

SEAL

REMOVAL

(1) Remove

the

drive belt.

(2) Remove

the

vibration damper.

(3) Drill

two 1/Sth

inch holes into

the

seal face,

180° apart. (4)

Use a

slide hammer tool with

a #10

metal

screw. Pull alternating from side-to-side until

the

seal

is

free.

INSTALLATION

(1)

The

sealing surface

on the

crankshaft must

be

free from

all oil

residue

to

prevent seal leaks.

Page 746 of 1502

5-9L

(DIESEL) ENGINE

9 - 141

ORIGINAL RADIUS

NEW UNDERCUT RADIUS JOURNAL SURFACE ORIGINAL RADIUS

NEW UNDERCUT RADIUSs

SURFACE FINISH

®

0.8 micrometer (32.0 microinch) for a minimum of

45°

into the

fillet

beyond journal surface

(D 1.6 micrometer (64.0 microinch) for remainder of

fillet

©

0.4 micrometer (16.0 microinch)

WIDTH

OF

REGRIND/UNDERCUT RADIUS

®

34.5

±0.025

mm

(1.358

±0.001

in)

JOURNAL SURFACE

J9109-130

Fig. 9 Grind Crankshaft Main Journal—Alternative Method

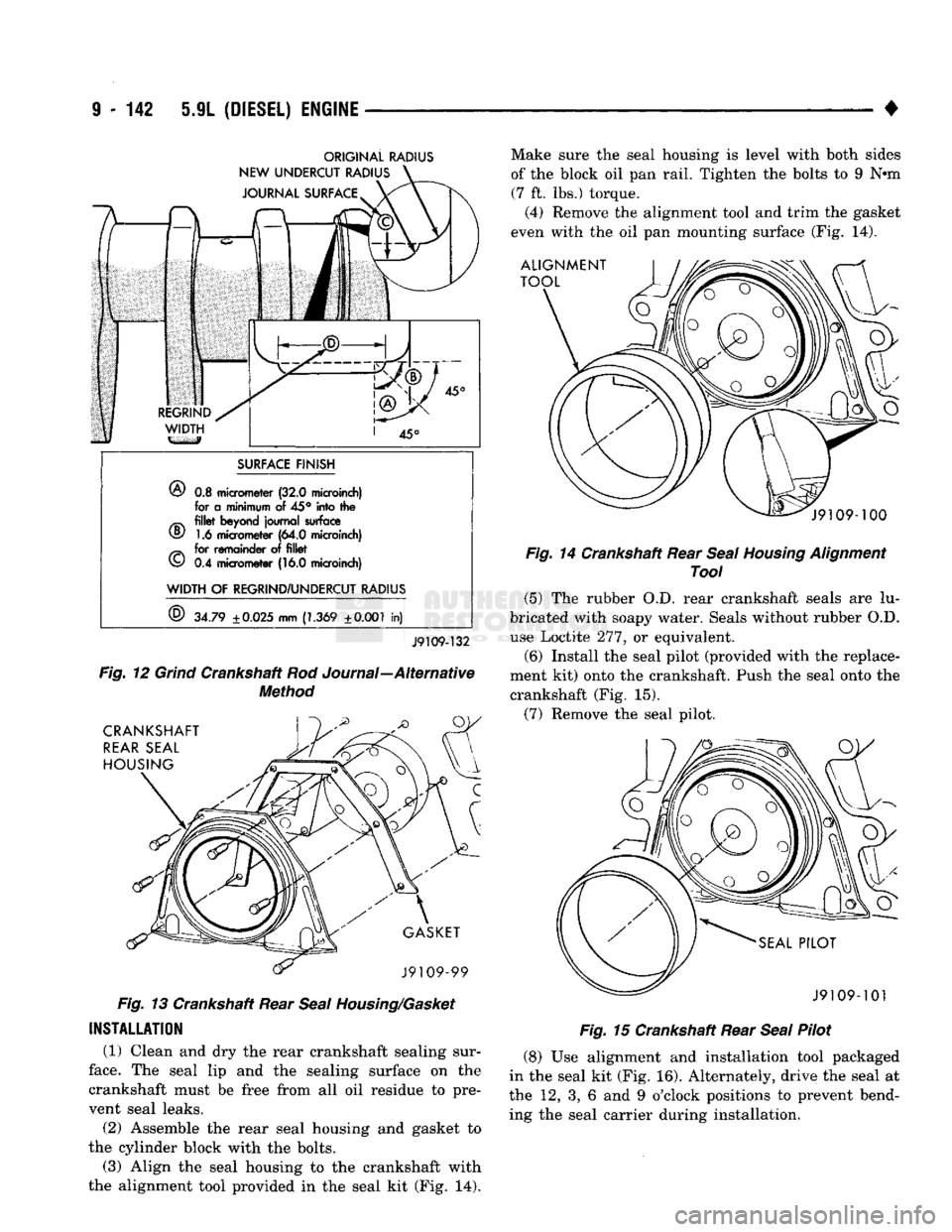

STANDARD ROD JOURNAL DIAMETER 69.000 +0.013 mm

(2.7165 ±0.0005 inch)

WORN ROD JOURNAL DIAMETER LIMIT 68.962 (2.7150 inch)

UNDERSIZES REGRIND TO

0.25 mm

(0.0098 inch) 68.750 +0.013 mm

(2.7067 ±0.0005 inch)

0.50 mm

(0.0197 inch) 68.500 +0.013 mm

(2.6969 ±0.0005 inch)

0.75 mm

(0.0295 inch) 68.250 +0.013 mm

(2.6870 ±0.0005 inch)

1.00 mm

(0.0394 inch) 68.000 +0.013 mm

(2.6772 ±0.0005 inch)

OUT-OF ROUND & TAPER (MAX.) 0.005 mm (0.0002 inch)

ALL MAIN JOURNALS

ARE

TO

BE

PARALLEL

TO THE FRONT AND REAR MAINS WITHIN: 0.030 mm (0.001 inch)

J9109-126

Fig. 10 Crankshaft Rod Journal Dimensions

(2) If the gear cover was replaced, use the align

ment tool from the seal kit to make sure the cover is aligned with the crankshaft.

SURFACE FINISH

©

0.8 micrometer (32.0 microinch)

for a minimum of 45° into the

fillet

beyond journal surface 1.6 micrometer (64.0 microinch)

for remainder of

fillet

0.4 micrometer (16.0 microinch)

CD

©

J9109-131

Fig. 11 Crankshaft Rod Journal Grind—Preferred Method

(3) Apply a bead of Loctite 277 to the outside di

ameter of the seal.

(4) Install the pilot from the seal kit onto the

crankshaft.

(5) Install the seal onto the pilot and start it into

the gear housing cover seal bore. (6) Remove the pilot.

(7) Use the alignment/installation tool and a plas

tic hammer to install the seal to the correct depth.

(8) Install the vibration damper, but DO NOT

tighten the damper bolt until the belt is installed.

(9) Install the drive belt.

(10) Tighten the vibration damper bolts to 125

Nun (92 ft. lbs.) torque. Use the engine barring tool

to keep the engine from rotating during torquing op eration.

CRANKSHAFT REAR SEAL HOUSING AND

SEAL

REMOVAL

(1) Remove the rear seal housing and gasket (Fig.

13).

(2) Support the seal area of the rear seal housing

and press/drive out the seal using a hammer and a

pin pinch.

(3) Clean the rear seal housing.

Page 747 of 1502

9

- 142 5.9L

(DIESEL)

ENGINE

•

ORIGINAL

RADIUS

SURFACE

FINISH

®

0.3

micrometer

(32.0

microinch)

for a

minimum

of

45° into the

^ fillet

beyond

journal

surface

v§/

1.6

micrometer

(64.0

microinch)

^ for

remainder

of

fillet

v£)

0.4

micrometer

(16.0

microinch)

WIDTH OF REGRIND/UNDERCUT RADIUS

©

34.79

±

0.025

mm

(1.369

±0.001 in)

J9109-132

Fig.

12

Grind

Crankshaft Rod Journal—Alternative

Method

Fig.

13 Crankshaft Rear

Seal

Housing/Gasket

INSTALLATION

(1) Clean and dry the rear crankshaft sealing sur

face.

The seal lip and the sealing surface on the

crankshaft must be free from all oil residue to pre vent seal leaks.

(2) Assemble the rear seal housing and gasket to

the cylinder block with the bolts.

(3) Align the seal housing to the crankshaft with

the alignment tool provided in the seal kit (Fig. 14). Make sure the seal housing is level with both sides

of the block oil pan rail. Tighten the bolts to 9 N*m

(7 ft. lbs.) torque.

(4) Remove the alignment tool and trim the gasket

even with the oil pan mounting surface (Fig. 14).

Fig.

14 Crankshaft Rear

Seal

Housing

Alignment

Tool

(5) The rubber O.D. rear crankshaft seals are lu

bricated with soapy water. Seals without rubber O.D. use Loctite 277, or equivalent.

(6) Install the seal pilot (provided with the replace

ment kit) onto the crankshaft. Push the seal onto the

crankshaft (Fig. 15).

(7) Remove the seal pilot.

Fig.

15 Crankshaft Rear

Seal

Pilot

(8) Use alignment and installation tool packaged

in the seal kit (Fig. 16). Alternately, drive the seal at

the 12, 3, 6 and 9 o'clock positions to prevent bend ing the seal carrier during installation.

Page 754 of 1502

• 5.9L

(DIESEL) ENGINE

9 - 151

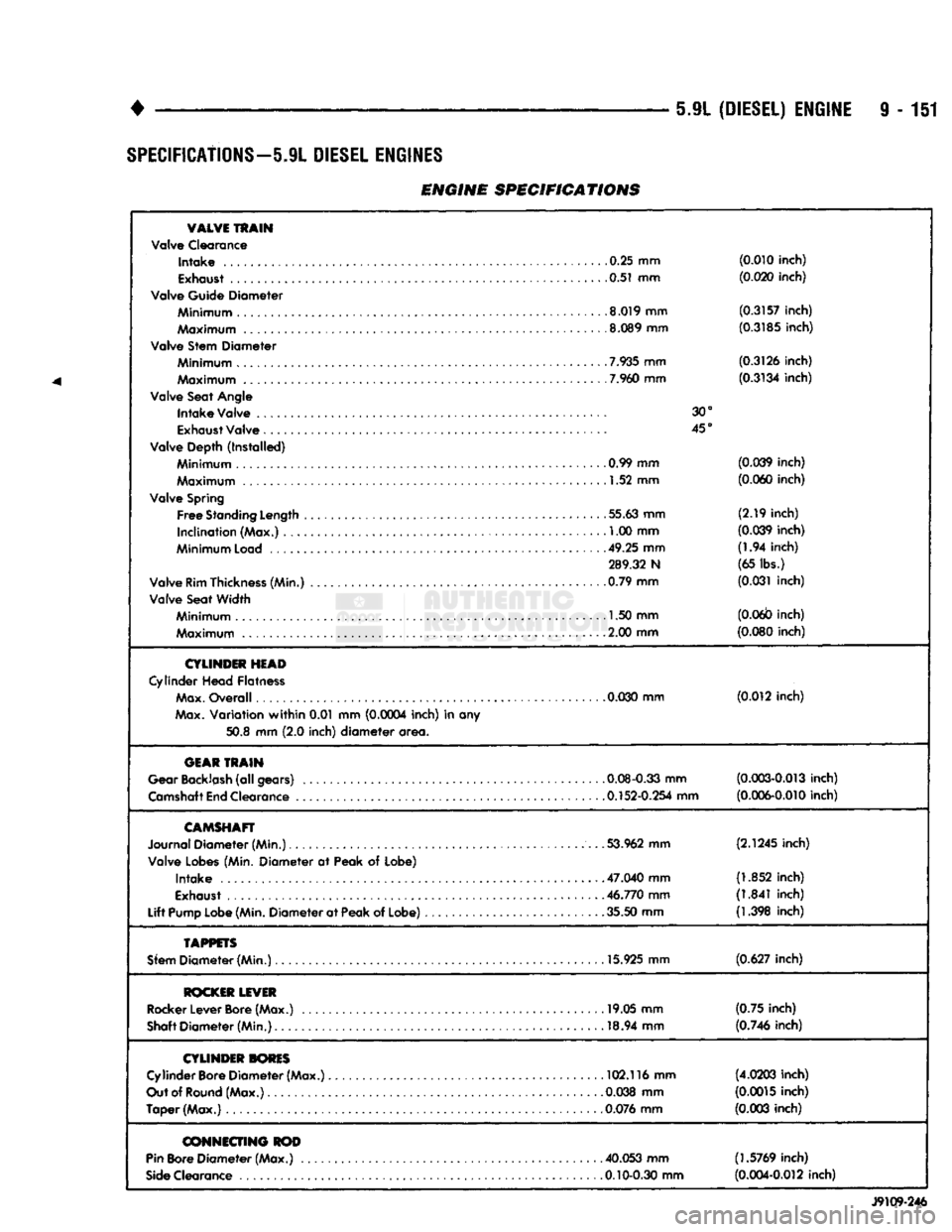

SPECIFICATIONS—5.9L DIESEL ENGINES

ENGINE SPECIFICATIONS

VALVE

TRAIN

Valve Clearance

Intake

.0.25 mm

(0.010 inch)

0.51 mm (0.020 inch)

Valve Guide Diameter

Minimum

8.019 mm

(0.3157 inch)

Maximum

.8.089 mm

(0.3185 inch)

Valve Stem Diameter

7.935

mm (0.3126 inch)

Maximum

7.960

mm

(0.3134 inch)

Valve Seat

Angle

Intake

Valve 30°

Exhaust

Valve 45°

Valve Depth (Installed)

Minimum

. .......... 0.99 mm (0.039 inch)

Maximum

1.52 mm

(0.060 inch)

Valve

Spring

Free

Standing

Length

55.63 mm

(2.19

inch)

Inclination (Max.) , 1.00 mm

(0.039 inch)

Minimum

Load

49.25 mm

(1.94

inch)

289.32 N (65 lbs.)

Valve

Rim

Thickness

(Min.) 0.79 mm

(0.031 inch)

Valve Seat Width

Minimum

1.50 mm

(0.06b inch)

Maximum

. 2.00 mm

(0.080 inch)

CYLINDER

HEAD

Cylinder

Head Flatness

Max.

Overall

0.030

mm (0.012 inch)

Max.

Variation

within

0.01 mm (0.0004 inch) in any

50.8

mm

(2.0

inch)

diameter

area.

GEAR

TRAIN

Gear

Backlash

(all gears) 0.08-0.33 mm

(0.003-0.013 inch)

Camshaft

End

Clearance 0.152-0.254 mm

(0.006-0.010 inch)

CAMSHAFT

Journal Diameter (Min.) 53.962 mm

(2.1245 inch)

Valve

Lobes

(Min. Diameter at Peak of Lobe)

Intake

.... 47.040 mm

(1.852 inch)

Exhaust

46.770 mm

(1.841 inch)

Lift

Pump

Lobe

(Min.

Diameter at

Peak

of Lobe) 35.50 mm

(1.398 inch)

TAPPETS

Sfem

Diameter (Min.) 15.925 mm

(0.627 inch)

ROCKER

LEVER

Rocker

Lever

Bore

(Max.) 19.05 mm

(0.75

inch)

Shaft

Diameter (Min.) 18.94 mm

(0.746 inch)

CYLINDER

TORES

Cylinder

Bore

Diameter (Max.) 102.116 mm

(4.0203 inch)

Out

of

Round

(Max.) . .0.038 mm

(0.0015 inch)

Taper (Max.)

0.076

mm

(0.003 inch)

CONNECTING

ROD

Pin

Bore

Diameter (Max.) . 40.053 mm (1.5769 inch)

Side

Clearance 0.10-0.30 mm

(0.004-0.012 inch)

J9109-246

Page 812 of 1502

FRAME

AND

BUMPERS

13 - 25

FUNCTION

The frame is the foundation and the structural cen

ter of the vehicle. The primary function of a frame is

to provide support and attachment locations: • For all the chassis/drivetrain components

• For the cab/body

• For the vehicle payload While limiting deflections and twisting of the

frame members. The frame maintains the correct relationship and

alignment of the powertrain. This relationship and

alignment ensures normal operation of the attached

units.

CONSTRUCTION MATERIAL High-strength, carbon steel with a minimum yield

strength of 32,000 psi is used to construct frame side

rails.

A frame made of 32,000 psi minimum yield

strength steel has, in reality, a range of 32,000 to

44,000 psi yield strength.

For 4WD vehicle applications, the frame side rails

reinforcements are constructed of the same high- strength, carbon steel as the side rails.

BENDING RESISTANCE A frame reacts to its load and the road surface de

viations by deflecting and twisting. The primary de

flecting frame members are the side rails. Resistance

to frame twist is provided by the crossmembers.

FRAME

INSPECTION/MEASUREMENTS

INSPECTION Inspect the frame members for visible damage and

metal deformations. Inspect all riveted, bolted and

welded connections for looseness and/or missing hardware. All damaged areas must be repaired and/or the

frame members replaced, as necessary.

MEASUREMENTS Measure the frame for mis-alignment with the cab/

body and cargo box attached to the frame. Figures 7, 8, 9 provide the frame alignment reference dimen

sions.

The following information applies to all measure

ments.

(1) Place the vehicle on a level surface.

(2) If the vehicle is loaded, verify the vehicle does

not exceed the gross vehicle weight rating (GVWR).

Verify the load is distributed in the vehicle as evenly as possible. For better measurement results, remove

the cargo/payload from the vehicle.

(3) Measure the tire inflation pressures. Adjust as

necessary.

HORIZONTAL/DIAGONAL

FRAME MEASUREMENTS

Determine the frame horizontal, according to the

following procedure.

(1) Select several reference points along one frame

side rail, preferably at the crossmember junctions.

(2) Transfer these reference points to the surface/

floor. Paper sheets can be attached to the surface be low the reference points.

(3) Locate the same reference points on the other

frame side rail. Transfer them to the surface/floor.

(4) Move the vehicle away. Measure between all

the reference points diagonally from and parallel to

the side rails (Fig. 10). The corresponding measure ments should not differ by more than 6 mm (1/4 in).

(5)

Measure the distance between the two front

reference points. Measure the distance between the

two rear reference points. Divide each distance in

half and indicate the two half-way points on the sur

face/floor. Designate the front point as 1 and the rear

point as 2 (Fig. 10).

(6) Place a chalk-line between points 1 and 2 (Fig.

10) and snap the string.

(7) Determine how close the center line is to the

diagonal intersection points in Figure 10.

(8) The marks on the floor will show the amount of

frame misalignment.

(9) The reference point transferred from one side

rail should be within 3 mm (1/8 in) of the opposite

reference point.

(10) Frame bow to the side should not exceed 3

mm per 2540 mm (1/8 inch per 100 inches) in frame

length.

(11) The overall width of the frame should not

vary more than 3 mm (1/8 in). (12) Repeat steps (1) through (11) after straighten

ing the frame.

Refer to Figures 7, 8, and 9 for frame horizon

tal alignment reference dimensions.

TWIST

AND PARALLEL FRAME MEASUREMENTS

Determine the amount of frame twist using the fol

lowing procedure.

(1) Mark the vertical reference points under the

frame side rails at 305-mm (12-in) intervals. Start at

the rear frame crossmember.

(2) Measure the distance up from a level surface/

floor to each corresponding reference point. (3) The distance to a reference point under one

side rail should be a maximum of 3 mm (1/8 in)

dif

ference than the opposite side rail.

Refer to Figures 7, 8 and 9 for frame vertical

alignment reference dimensions.