DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 651 of 1502

9

- 46 3.9L

ENGINE

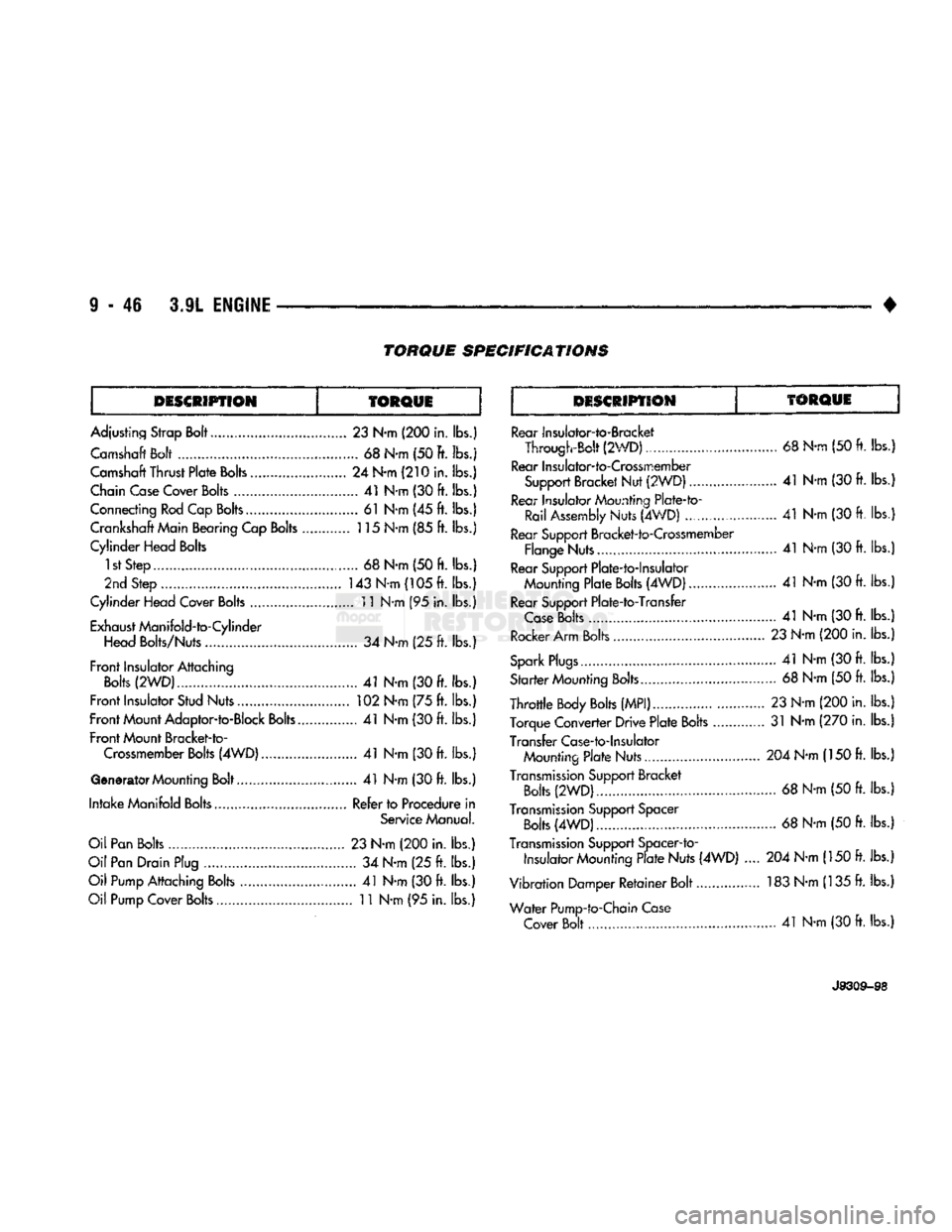

TORQUE

SPECIFICATIONS

DESCRIPTION

TORQUE

DESCRIPTION

TORQUE

Adjusting Strap Bolt.....

23

N-m

(200

in. lbs.) Camshaft Bolt

68

N-m (50 ft. lbs.j

Camshaft Thrust

Plate

Bolts

24

N-m

(210

in. lbs.)

Chain Case Cover

Bolts

41

N-m

(30 ft.

lbs.)

Connecting Rod Cap Bolts

61

N*m

(45 ft.

lbs.) Crankshaft Main Bearing Cap

Bolts

115 N-m

(85 ft.

lbs.}

Cylinder Head Bolts

1st Step

. 68

N-m

(50 ft.

lbs.)

2nd Step

.............................................

143 N-m (105 ft. lbs.)

Cylinder Head Cover

Bolts

11 N-m

(95

in. lbs.)

Exhaust ManifoId-to-Cylinder Head Bolts/Nuts

34

N-m

(25 ft.

lbs.)

Front

Insulator Attaching

Bolts

(2WD)...

41

N-m

(30 ft.

lbs.)

Front

Insulator Stud Nuts

102

N-m

(75 ft.

lbs.)

Front

Mount Adaptor-to-Block

Bolts..

41

N-m

(30 ft.

lbs.)

Front

Mount Bracket-to- Crossmember

Bolts

(4WD).

41

N-m

(30 ft.

lbs.)

Generator Mounting Bolt

41

N-m

(30 ft.

lbs.)

Intake

Manifold Bolts Refer to Procedure

in

Service Manual.

Oil Pan Bolts

23

N-m

(200

in.

lbs.)

Oil Pan Drain Plug

34

N-m

(25 ft.

lbs.)

Oil Pump Attaching Bolts

41

N-m

(30 ft. lbs.)

Oil Pump Cover

Bolts

11

N-m

(95

in. lbs.) Rear Insulalor-to-Bracket

Through-Bolt (2WD)

68

N-rn

(50 ft. lbs.)

Rear Insuiator-to-Crossmember Support Bracket Nut (2WDJ

.. 41

N-m

(30 ft.

lbs.

Rear Insulator Mounting Plate-to- Rail Assembly

Nuts (4WD)

......................

41

N-m

(30 ft. lbs.

Rear Support Bracket-to-Crossmember Flange Nuts....

41

N-m

(30 ft.

lbs.

Rear Support Plate-to-lnsulator Mounting

Plate

Bolts

(4WD) 41

N-m

(30

ft. lbs.

Rear Support Plate-to-Transfer

Case

Bolts

41

N-m

(30 ft.

lbs.

Rocker Arm Bolts

23

N-m

(200

in. lbs.

Spark

Plugs.......

41

N-m

(30 ft. lbs.

Sfarfer Counting

Bolts.

68

N-m

(50 ft.

lbs.

Throttle

Body

Bolts

(MPI)

23

N-m

(200

in. lbs.

Torque Converter Drive

Plate

Bolts

31

N-m

(270

in. lbs.

Transfer Case-to-Insulator Mounting

Plate

Nuts..............

204

N-m

(150

ft. lbs.

Transmission

Support Bracket

Bolts

(2WD)

68

N-m

(50 ft.

lbs.

Transmission

Support Spacer

Bolts

(4WD).

68

N-m

(50 ft.

lbs.

Transmission

Support Spacer-to-

Insulator Mounting

Plate

Nuts (4WD)

.... 204

N-m

(150 ft.

lbs.

Vibration Damper

Retainer

Bolt................ 183 N-m (135

ft.

lbs.

Water

Pump-to-Chain Case Cover Bolt...

41

N-m

(30

ft. lbs.)

J9309-S8

Page 652 of 1502

5.2L

ENGINE

9 - 47

S.2L ENGINE

SERVICE

PROCEDURES

INDEX

page

Camshaft

. , . 61

Crankshaft

68

Crankshaft Main Bearings

69

Crankshaft Rear

Oil

Seals

...... ........

70

Cylinder Block ...........................

71

Cylinder Head Cover

. . . . 51

Cylinder Heads

52

Distributor

62

Engine

Assembly

. 50

Engine

Front Mounts

47

Engine

Rear Mount ...............

48

Front Crankshaft

Oil

Seal Replacement

. . 61

GENERAL

INFORMATION

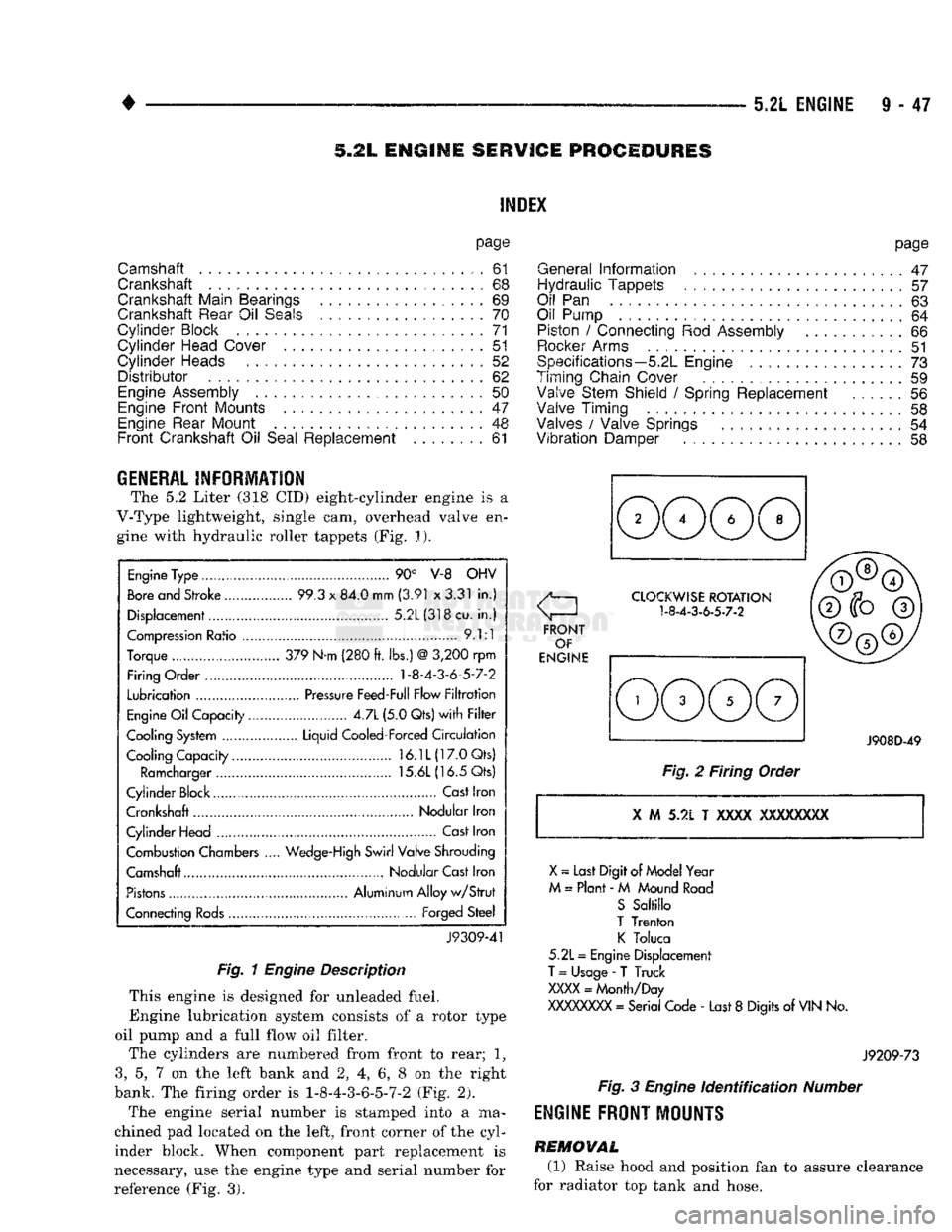

The 5.2 Liter (318 CID) eight-cylinder engine is a

V-Type lightweight, single cam, overhead valve en gine with hydraulic roller tappets (Fig. J).

Engine

Type ....

90° V-8 OHV

Bore

and Stroke .....

99.3

x

84.0 mm

(3.91

x

3.31

in.)

Displacement................

5.2L(318cu.

in.)

Compression

Ratio ....... .

9.1:1

Torque .. 379 N-m (280

ft.

lbs.)

@

3,200

rpm

Firing Order .... 1-8-4-3-6-5-7-2

Lubrication

.......

Pressure

Feed-Full Flow

Filtration

Engine

Oil

Capacity......

4.7L

(5.0 Qts)

with Filter

Cooling System ...... Liquid Cooled-Forced

Circulation

Cooling Capacity..........

16.1L(17.0Qts)

Ramcharger

15.6L

(16.5 Qts)

Cylinder Block

,

Cast

Iron

Crankshaft Nodular Iron

Cylinder Head ..............

Cast

Iron

Combustion Chambers

..

Wedge-High

Swirl Valve Shrouding

Camshaft Nodular Cast Iron

Pistons

Aluminum Alloy

w/Strut

Connecting

Rods...........

Forged

Steel

J9309-41

Fig. 1

Engine

Description

This engine is designed for unleaded fuel.

Engine lubrication system consists of a rotor type

oil pump and a full flow oil filter.

The cylinders are numbered from front to rear; 1?

3,

5, 7 on the left bank and 2, 4, 6, 8 on the right

bank. The firing order is 1-8-4-3-6-5-7-2 (Fig. 2).

The engine serial number is stamped into a ma

chined pad located on the left, front corner of the cyl

inder block. When component part replacement is

necessary, use the engine type and serial number for

reference (Fig. 3).

page

General

Information

.......................

47

Hydraulic Tappets

57

Oil

Pan . 63

Oil Pump

. 64

Piston

/

Connecting

Rod

Assembly

66

Rocker

Arms

51

Specifications—5.2L Engine

73

Timing Chain Cover ................

59

Valve Stem Shield

/

Spring Replacement

56

Valve Timing

. 58

Valves

/

Valve Springs

54

Vibration

Damper

. . 58

J908D-49

Fig.

2 Firing Order

X

M 5.2L T

XXXX

XXXXXXXX

X

~

Last Digit of

Model

Year

M

=

Plant

- M

Mound

Road

S

Saltillo

T

Trenton

K

Toluca

5.2L

=

Engine Displacement

T

=

Usage

-

T Truck

XXXX

=

Month/Day

XXXXXXXX

=

Serial Code

-

Last

8

Digits

of

VIN

No.

J9209-73

Fig.

3

Engine

Identification

Number

ENGINE

FRONT

MOUNTS

REMOVAL

(1) Raise hood and position fan to assure clearance

for radiator top tank and hose.

Page 653 of 1502

9

• 48 5.2L

ENGINE

•

CAUTION;

DO NOT lift the

engine

by the

intake

manifold.

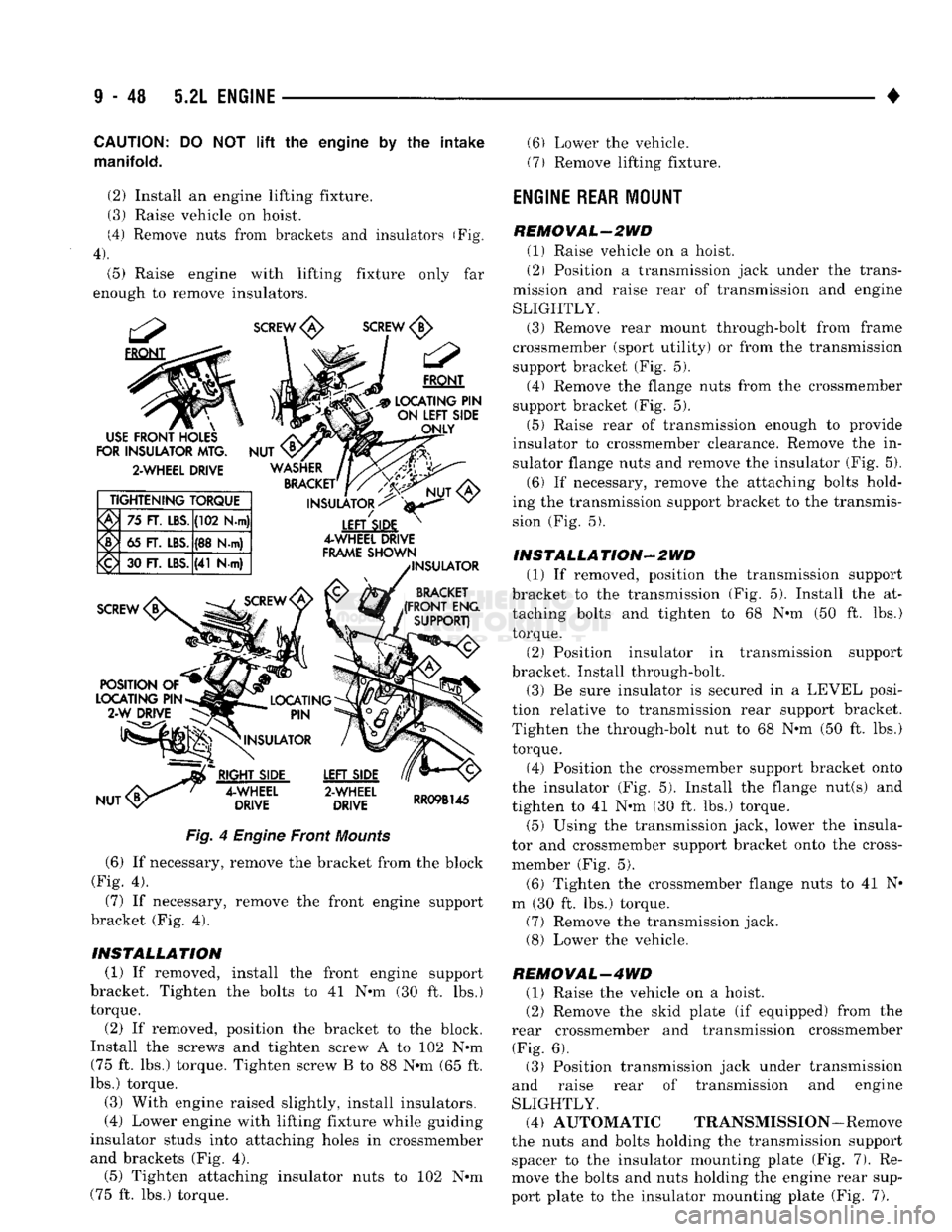

(2) Install an engine lifting fixture.

(3) Raise vehicle on hoist.

(4) Remove nuts from brackets and insulators (Fig.

4).

(5) Raise engine with lifting fixture only far

enough to remove insulators.

SCREW

<£>

SCREW

<1j>

FRONT

LOCATING PIN

" ON LEFT

SIDE

ONLY

USE

FRONT HOLES

FOR

INSULATOR MTG,

2-WHEEL DRIVE TIGHTENING TORQUE

75

FT. LBS. (102 N-m)

65 FT. LBS. (88 N.m)

<£>

30 FT. LBS.

(41

N-m)

NUT

WASHER

BRACKET'

INSULATOR

<

LEFTSIDE

4-WHEEL DRIVE

FRAME SHOWN INSULATOR

BRACKET

(FRONT ENG SUPPORT)

Fig.

4

Engine

Front

Mounts

(6) If necessary, remove the bracket from the block

(Fig. 4).

(7) If necessary, remove the front engine support

bracket (Fig. 4).

INSTALLATION (1) If removed, install the front engine support

bracket. Tighten the bolts to 41 N-m (30 ft. lbs.)

torque.

(2) If removed, position the bracket to the block.

Install the screws and tighten screw A to 102 N-m (75 ft. lbs.) torque. Tighten screw B to 88 N-m (65 ft.

lbs.) torque.

(3) With engine raised slightly, install insulators.

(4) Lower engine with lifting fixture while guiding

insulator studs into attaching holes in crossmember

and brackets (Fig. 4). (5) Tighten attaching insulator nuts to 102 N-m

(75 ft. lbs.) torque. (6) Lower the vehicle.

(7) Remove lifting fixture.

ENGINE REAR

MOUNT

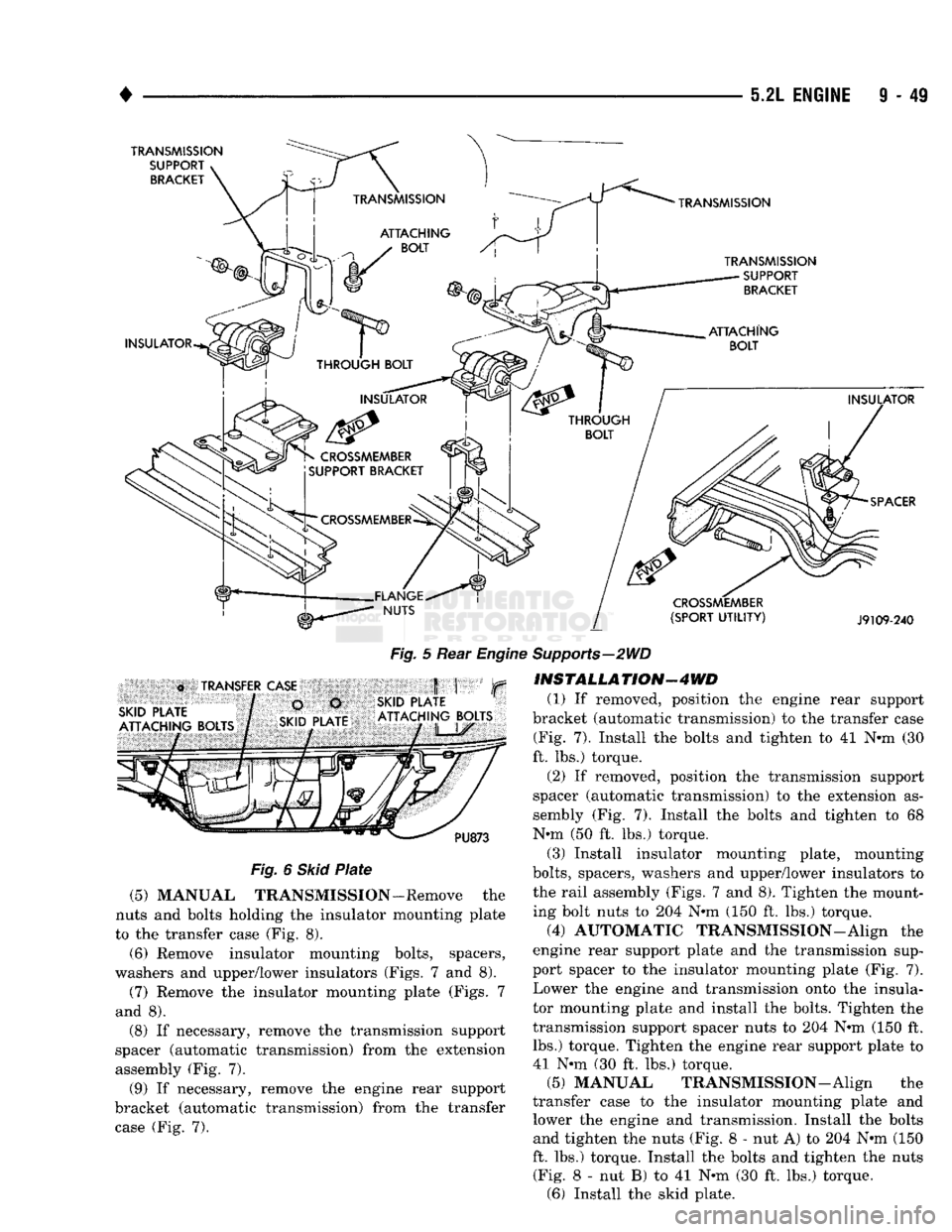

REMOVAL-2WD (1) Raise vehicle on a hoist.

(2) Position a transmission jack under the trans

mission and raise rear of transmission and engine

SLIGHTLY. (3) Remove rear mount through-bolt from frame

crossmember (sport utility) or from the transmission support bracket (Fig. 5). (4) Remove the flange nuts from the crossmember

support bracket (Fig. 5).

(5) Raise rear of transmission enough to provide

insulator to crossmember clearance. Remove the in

sulator flange nuts and remove the insulator (Fig. 5). (6) If necessary, remove the attaching bolts hold

ing the transmission support bracket to the transmis

sion (Fig. 5).

INSTALLATION-2WD (1) If removed, position the transmission support

bracket to the transmission (Fig. 5). Install the at taching bolts and tighten to 68 N-m (50 ft. lbs.)

torque.

(2) Position insulator in transmission support

bracket. Install through-bolt.

(3) Be sure insulator is secured in a LEVEL posi

tion relative to transmission rear support bracket.

Tighten the through-bolt nut to 68 N-m (50 ft. lbs.) torque.

(4) Position the crossmember support bracket onto

the insulator (Fig. 5). Install the flange nut(s) and

tighten to 41 N-m (30 ft. lbs.) torque.

(5) Using the transmission jack, lower the insula

tor and crossmember support bracket onto the cross-

member (Fig. 5).

(6) Tighten the crossmember flange nuts to 41 N-

m (30 ft. lbs.) torque. (7) Remove the transmission jack. (8) Lower the vehicle.

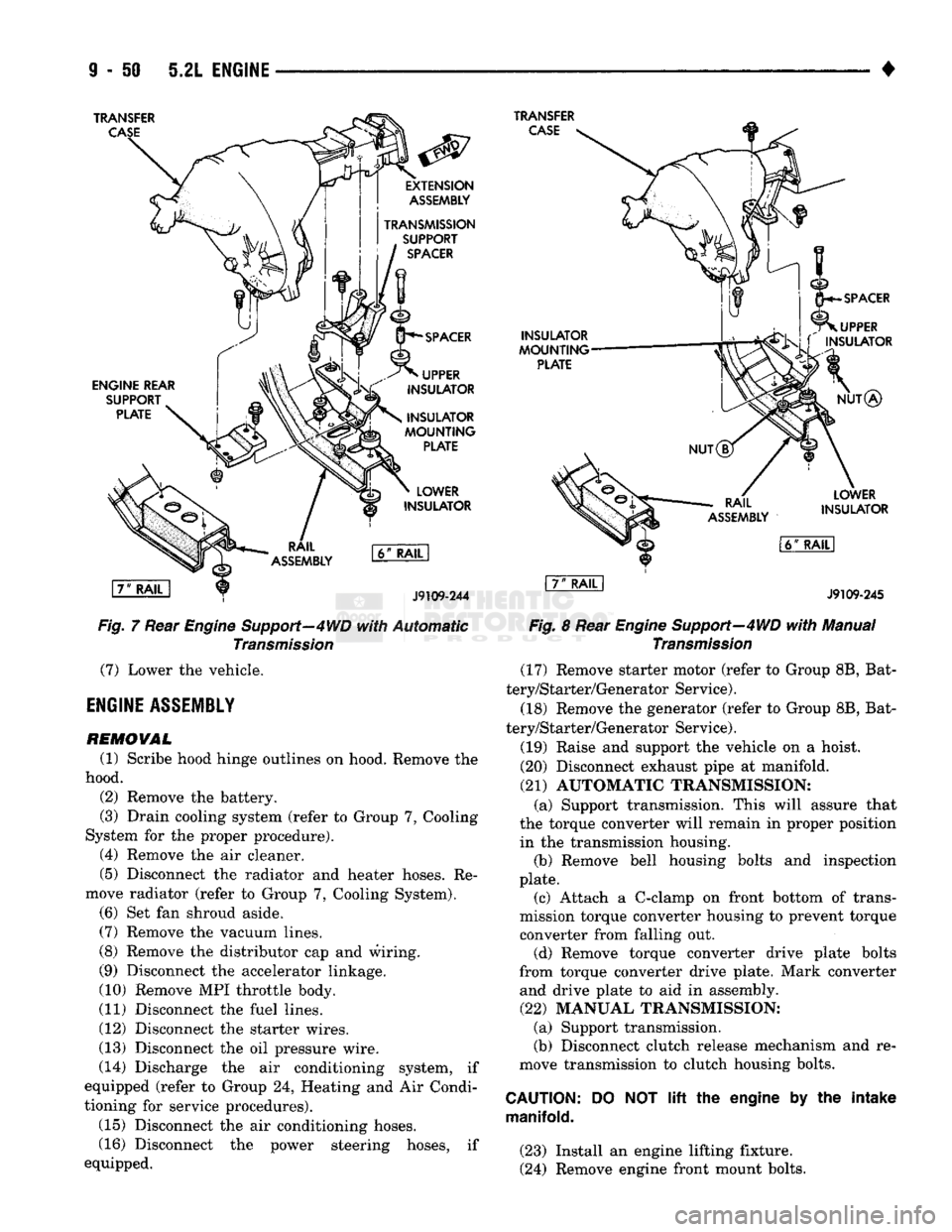

REMOVAL-4WD (1) Raise the vehicle on a hoist.

(2) Remove the skid plate (if equipped) from the

rear crossmember and transmission crossmember (Fig. 6). (3) Position transmission jack under transmission

and raise rear of transmission and engine

SLIGHTLY. (4) AUTOMATIC TRANSMISSION-Remove

the nuts and bolts holding the transmission support spacer to the insulator mounting plate (Fig. 7). Re

move the bolts and nuts holding the engine rear sup

port plate to the insulator mounting plate (Fig. 7).

Page 654 of 1502

•

5.21 ENGINE 9 - 49

TRANSMISSION

SUPPORT

BRACKET

TRANSMISSION

TRANSMISSION SUPPORT BRACKET

INSULATOR

CROSSMEMBER

(SPORT

UTILITY)

J9109-240

l^^^U.TRANSFERJCASE

.

SKIDRATlf

~—l!pW;;^

ni ®p

ATTACHING

BOLTS

1|BS^ID

PLATE|

Fig.

5 Rear

Engine

iSKID PLATE

I

ATTACHING

BOLTS

PU873

Fig.

6

Skid

Plate

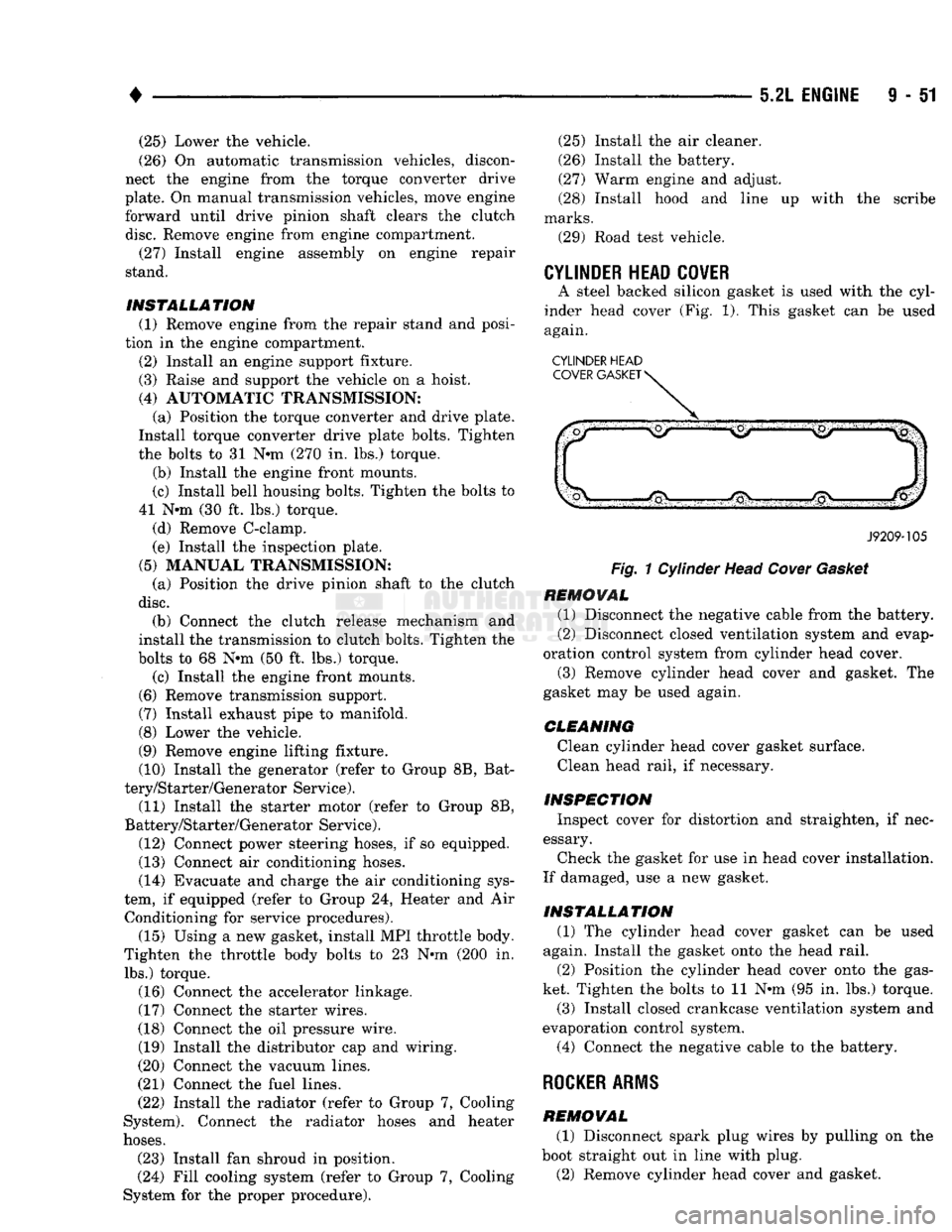

(5) MANUAL TRANSMISSION-Remove the

nuts and bolts holding the insulator mounting plate

to the transfer case (Fig. 8).

(6) Remove insulator mounting bolts, spacers,

washers and upper/lower insulators (Figs. 7 and 8).

(7) Remove the insulator mounting plate (Figs. 7

and 8). (8) If necessary, remove the transmission support

spacer (automatic transmission) from the extension

assembly (Fig. 7).

(9) If necessary, remove the engine rear support

bracket (automatic transmission) from the transfer case (Fig. 7).

Supports—2WD

mSYALLATION-4WD

(1) If removed, position the engine rear support

bracket (automatic transmission) to the transfer case (Fig. 7). Install the bolts and tighten to 41 N-m (30

ft. lbs.) torque.

(2) If removed, position the transmission support

spacer (automatic transmission) to the extension as

sembly (Fig. 7). Install the bolts and tighten to 68

Nnn (50 ft. lbs.) torque.

(3) Install insulator mounting plate, mounting

bolts,

spacers, washers and upper/lower insulators to the rail assembly (Figs. 7 and 8). Tighten the mounting bolt nuts to 204 N-m (150 ft. lbs.) torque.

(4) AUTOMATIC TRANSMISSION—Align the

engine rear support plate and the transmission sup

port spacer to the insulator mounting plate (Fig. 7). Lower the engine and transmission onto the insula

tor mounting plate and install the bolts. Tighten the

transmission support spacer nuts to 204 N-m (150 ft. lbs.) torque. Tighten the engine rear support plate to

41 N-m (30 ft. lbs.) torque. (5) MANUAL TRANSMISSION—Align the

transfer case to the insulator mounting plate and lower the engine and transmission. Install the bolts and tighten the nuts (Fig. 8 - nut A) to 204 N-m (150

ft. lbs.) torque. Install the bolts and tighten the nuts (Fig. 8 - nut B) to 41 N-m (30 ft. lbs.) torque. (6) Install the skid plate.

Page 655 of 1502

TRANSFER

CASE

TRANSFER

CASE

ENGINE

REAR

SUPPORT PLATE

EXTENSION

ASSEMBLY

TRANSMISSION

SUPPORT

SPACER

SPACER

UPPER

INSULATOR

INSULATOR

MOUNTING

PLATE

LOWER

INSULATOR

fT^RAIL

J9109-244

Fig,

7 Rear Engine Support—4WD

with

Automatic

Transmission

(7)

Lower the vehicle.

ENGINE

ASSEMBLY

REMOVAL

(1) Scribe hood hinge outlines on hood. Remove the

hood. (2) Remove the battery.

(3) Drain cooling system (refer to Group 7, Cooling

System for the proper procedure). (4) Remove the air cleaner.

(5) Disconnect the radiator and heater hoses. Re

move radiator (refer to Group 7, Cooling System). (6) Set fan shroud aside.

(7)

Remove the vacuum lines.

(8) Remove the distributor cap and wiring.

(9) Disconnect the accelerator linkage.

(10) Remove MPI throttle body.

(11) Disconnect the fuel lines.

(12) Disconnect the starter wires.

(13) Disconnect the oil pressure wire.

(14) Discharge the air conditioning system, if

equipped (refer to Group 24, Heating and Air Condi

tioning for service procedures).

(15) Disconnect the air conditioning hoses.

(16) Disconnect the power steering hoses, if

equipped.

INSULATOR

MOUNTING

PLATE

SPACER

UPPER

L\ f

INSULATOR

NUT®

RAIL

ASSEMBLY

LOWER

INSULATOR

l6ff

RAIL

I

J9109-245

Fig.

8 Rear

Engine

Support—4WD

with

Manual

Transmission

(17) Remove starter motor (refer to Group 8B, Bat

tery/Starter/Generator Service).

(18) Remove the generator (refer to Group 8B, Bat

tery/Starter/Generator Service).

(19) Raise and support the vehicle on a hoist.

(20) Disconnect exhaust pipe at manifold.

(21)

AUTOMATIC TRANSMISSION: (a) Support transmission. This will assure that

the torque converter will remain in proper position in the transmission housing. (b) Remove bell housing bolts and inspection

plate. (c) Attach a C-clamp on front bottom of trans

mission torque converter housing to prevent torque

converter from falling out. (d) Remove torque converter drive plate bolts

from torque converter drive plate. Mark converter and drive plate to aid in assembly.

(22)

MANUAL TRANSMISSION; (a) Support transmission.

(b) Disconnect clutch release mechanism and re

move transmission to clutch housing bolts.

CAUTION:

manifold.

DO

NOT lift the

engine

by the

intake

(23) Install an engine lifting fixture.

(24) Remove engine front mount bolts.

Page 656 of 1502

•

5.2L

ENGINE

9 - 51 (25) Lower the vehicle.

(26) On automatic transmission vehicles, discon

nect the engine from the torque converter drive

plate. On manual transmission vehicles, move engine forward until drive pinion shaft clears the clutch

disc.

Remove engine from engine compartment.

(27) Install engine assembly on engine repair

stand.

INSTALLATION

(1) Remove engine from the repair stand and posi

tion in the engine compartment.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) AUTOMATIC TRANSMISSION: (a) Position the torque converter and drive plate.

Install torque converter drive plate bolts. Tighten

the bolts to 31 N-m (270 in. lbs.) torque.

(b) Install the engine front mounts.

(c) Install bell housing bolts. Tighten the bolts to

41 N-m (30 ft. lbs.) torque.

(d) Remove C-clamp.

(e) Install the inspection plate.

(5) MANUAL TRANSMISSION: (a) Position the drive pinion shaft to the clutch

disc.

(b) Connect the clutch release mechanism and

install the transmission to clutch bolts. Tighten the

bolts to 68 N-m (50 ft. lbs.) torque.

(c) Install the engine front mounts.

(6) Remove transmission support.

(7) Install exhaust pipe to manifold. (8) Lower the vehicle.

(9) Remove engine lifting fixture. (10) Install the generator (refer to Group 8B, Bat

tery/Starter/ Generator Service). (11) Install the starter motor (refer to Group 8B,

Battery/Starter/Generator Service). (12) Connect power steering hoses, if so equipped.

(13) Connect air conditioning hoses.

(14) Evacuate and charge the air conditioning sys

tem, if equipped (refer to Group 24, Heater and Air Conditioning for service procedures).

(15) Using a new gasket, install MPI throttle body.

Tighten the throttle body bolts to 23 N-m (200 in. lbs.) torque. (16) Connect the accelerator linkage.

(17) Connect the starter wires.

(18) Connect the oil pressure wire. (19) Install the distributor cap and wiring.

(20) Connect the vacuum lines.

(21) Connect the fuel lines,

(22) Install the radiator (refer to Group 7, Cooling

System). Connect the radiator hoses and heater

hoses.

(23) Install fan shroud in position.

(24) Fill cooling system (refer to Group 7, Cooling

System for the proper procedure). (25) Install the air cleaner.

(26) Install the battery. (27) Warm engine and adjust.

(28) Install hood and line up with the scribe

marks. (29) Road test vehicle.

CYLIiiER

HEAD

COVER

A steel backed silicon gasket is used with the cyl

inder head cover (Fig. 1). This gasket can be used

again.

CYLINDER HEAD

J9209-105

Fig.

1 Cylinder Head

Cover

Gasket

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Disconnect closed ventilation system and evap

oration control system from cylinder head cover.

(3) Remove cylinder head cover and gasket. The

gasket may be used again.

CLEANING

Clean cylinder head cover gasket surface. Clean head rail, if necessary.

INSPECTION

Inspect cover for distortion and straighten, if nec

essary.

Check the gasket for use in head cover installation.

If damaged, use a new gasket.

INSTALLATION

(1) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.

(2) Position the cylinder head cover onto the gas

ket. Tighten the bolts to 11 N-m (95 in. lbs.) torque.

(3) Install closed crankcase ventilation system and

evaporation control system.

(4) Connect the negative cable to the battery.

ROCKER ARMS

REMOVAL

(1) Disconnect spark plug wires by pulling on the

boot straight out in line with plug. (2) Remove cylinder head cover and gasket.

Page 657 of 1502

9

- 52 5.2L

ENGINE

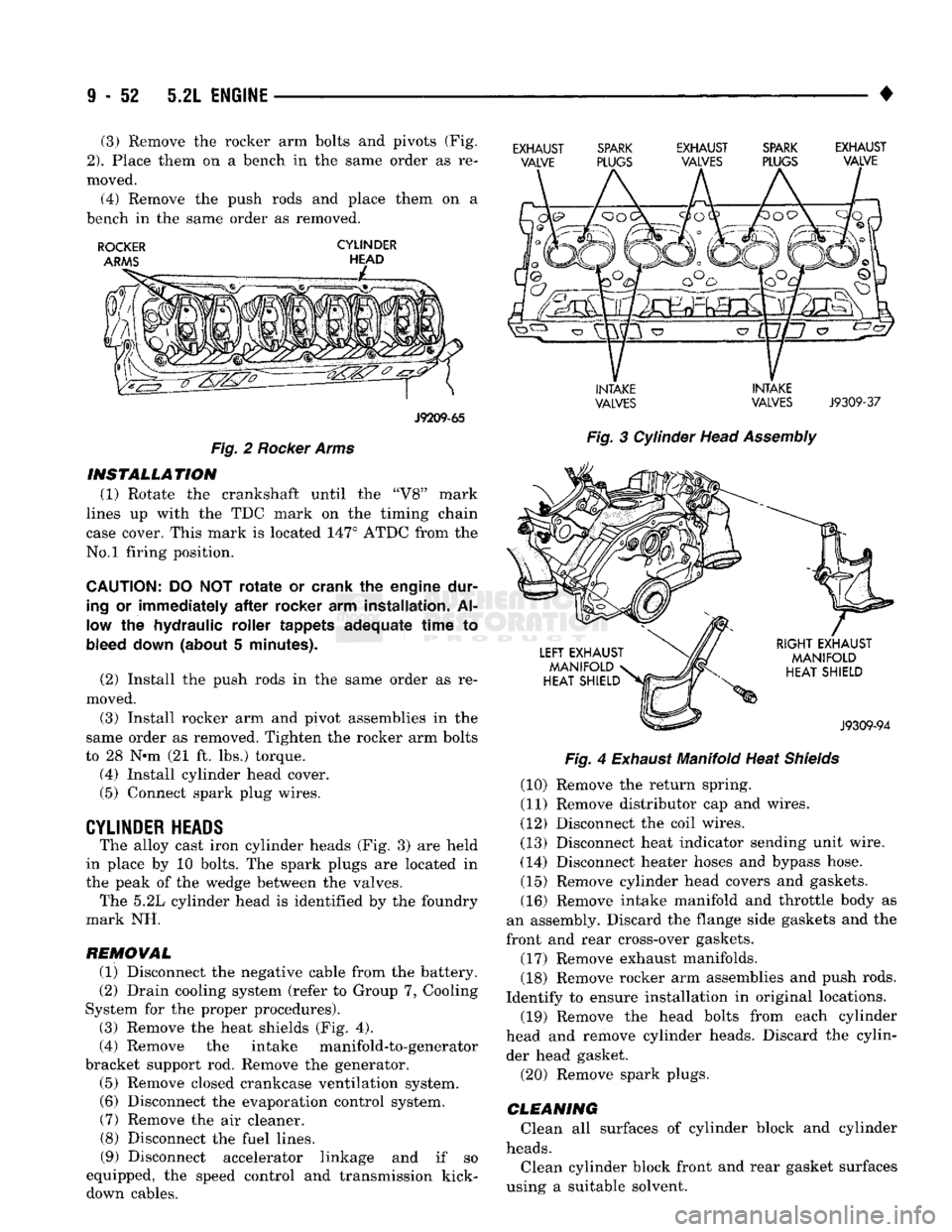

• (3) Remove the rocker arm bolts and pivots (Fig,

2).

Place them on a bench in the same order as re

moved.

(4) Remove the push rods and place them on a

bench in the same order as removed.

ROCKER

CYLINDER

J9209-65

Fig.

2

Rocker

Arms INSTALLATION

(1) Rotate the crankshaft until the "V8" mark

lines up with the TDC mark on the timing chain

case cover. This mark is located 147° ATDC from the

No.l firing position.

CAUTION:

DO NOT

rotate

or crank the engine dur

ing

or immediately

after

rocker arm installation. Al

low

the hydraulic roller tappets adequate

time

to

bleed

down

(about 5 minutes).

(2) Install the push rods in the same order as re

moved.

(3) Install rocker arm and pivot assemblies in the

same order as removed. Tighten the rocker arm bolts

to 28 N-m (21 ft. lbs.) torque. (4) Install cylinder head cover.

(5) Connect spark plug wires.

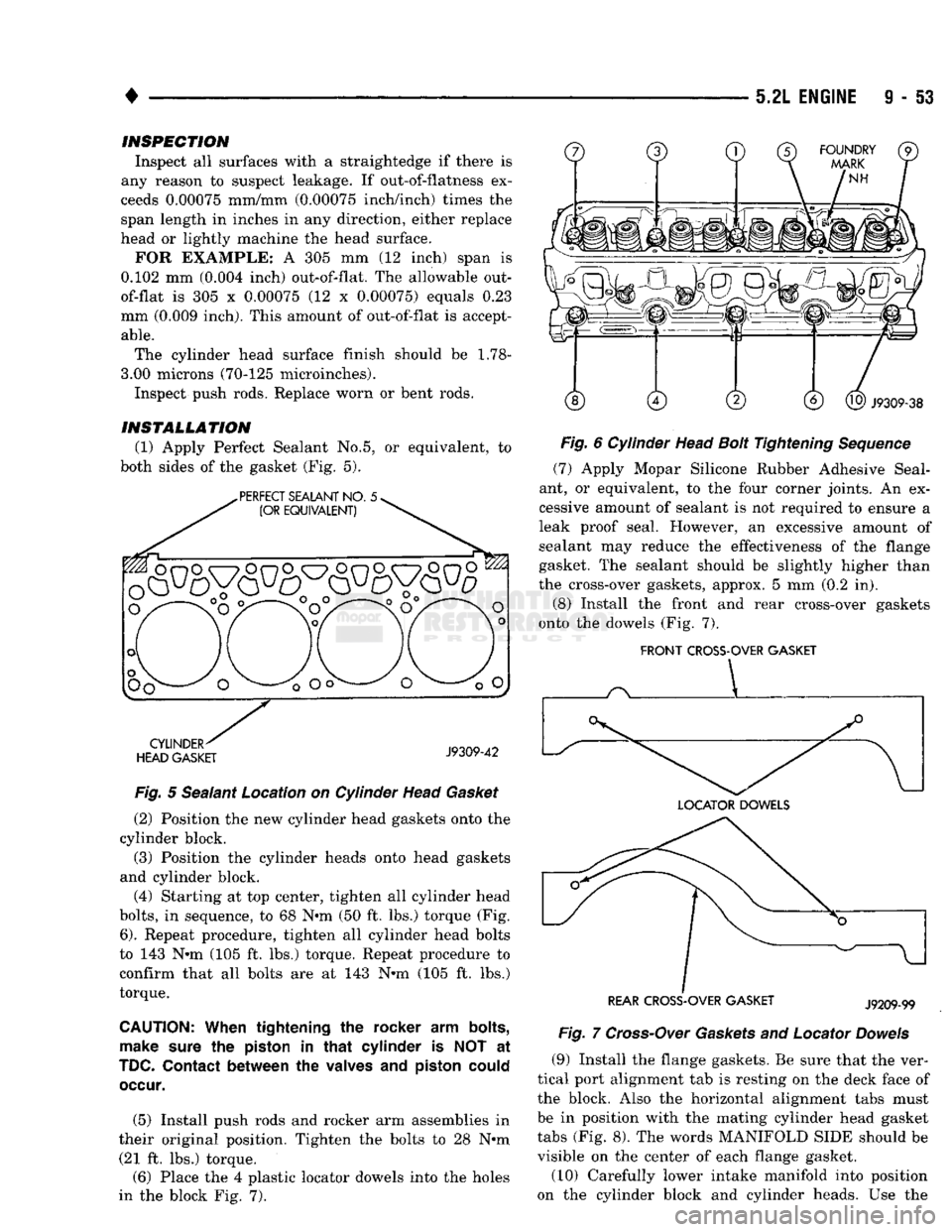

CYLINDER HEADS

The alloy cast iron cylinder heads (Fig. 3) are held

in place by 10 bolts. The spark plugs are located in

the peak of the wedge between the valves. The 5.2L cylinder head is identified by the foundry

mark NH.

REMOVAL (1) Disconnect the negative cable from the battery.

(2) Drain cooling system (refer to Group 7, Cooling

System for the proper procedures).

(3) Remove the heat shields (Fig. 4).

(4) Remove the intake manifold-to-generator

bracket support rod. Remove the generator. (5) Remove closed crankcase ventilation system. (6) Disconnect the evaporation control system. (7) Remove the air cleaner.

(8) Disconnect the fuel lines. (9) Disconnect accelerator linkage and if so

equipped, the speed control and transmission kick- down cables.

EXHAUST SPARK EXHAUST SPARK EXHAUST

VALVE PLUGS VALVES PLUGS VALVE

INTAKE INTAKE

VALVES VALVES

J9309-37

Fig.

3 Cylinder Head

Assembly

Fig.

4

Exhaust

Manifold Heat

Shields

(10) Remove the return spring.

(11) Remove distributor cap and wires.

(12) Disconnect the coil wires.

(13) Disconnect heat indicator sending unit wire.

(14) Disconnect heater hoses and bypass hose. (15) Remove cylinder head covers and gaskets. (16) Remove intake manifold and throttle body as

an assembly. Discard the flange side gaskets and the

front and rear cross-over gaskets.

(17) Remove exhaust manifolds.

(18) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(19) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin der head gasket.

(20) Remove spark plugs.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

Page 658 of 1502

•

5.2L ENGINE

9 - 53

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness ex

ceeds 0.00075 mm/mm (0.00075 inch/inch) times the span length in inches in any direction, either replace

head or lightly machine the head surface.

FOR EXAMPLE: A 305 mm (12 inch) span is

0.102 mm (0.004 inch) out-of-flat. The allowable out-

of-flat is 305 x 0.00075 (12 x 0.00075) equals 0.23

mm (0.009 inch). This amount of out-of-flat is accept

able.

The cylinder head surface finish should be 1.78-

3.00 microns (70-125 microinches). Inspect push rods. Replace worn or bent rods.

INSTALLATION

(1) Apply Perfect Sealant No.5, or equivalent, to

both sides of the gasket (Fig. 5).

Fig.

5 Sealant Location on Cylinder Head

Gasket

(2) Position the new cylinder head gaskets onto the

cylinder block. (3) Position the cylinder heads onto head gaskets

and cylinder block. (4) Starting at top center, tighten all cylinder head

bolts,

in sequence, to 68 N»m (50 ft. lbs.) torque (Fig.

6).

Repeat procedure, tighten all cylinder head bolts

to 143 N®m (105 ft. lbs.) torque. Repeat procedure to confirm that all bolts are at 143 N-m (105 ft. lbs.)

torque.

CAUTION:

When

tightening the rocker arm

bolts,

make

sure

the

piston

in

that

cylinder is NOT at

TDC.

Contact

between the

valves

and

piston

could

occur.

(5) Install push rods and rocker arm assemblies in

their original position. Tighten the bolts to 28 N»m (21 ft. lbs.) torque. (6) Place the 4 plastic locator dowels into the holes

in the block Fig. 7).

Fig.

6 Cylinder Head

Bolt

Tightening

Sequence

(7) Apply Mopar Silicone Rubber Adhesive Seal

ant, or equivalent, to the four corner joints. An ex

cessive amount of sealant is not required to ensure a

leak proof seal. However, an excessive amount of sealant may reduce the effectiveness of the flange

gasket. The sealant should be slightly higher than

the cross-over gaskets, approx. 5 mm (0.2 in).

(8) Install the front and rear cross-over gaskets

onto the dowels (Fig. 7).

FRONT

CROSS-OVER GASKET

REAR CROSS-OVER GASKET

J9209-99

Fig.

7

Cross-Over

Gaskets

and Locator

Dowels

(9) Install the flange gaskets. Be sure that the ver

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must

be in position with the mating cylinder head gasket

tabs (Fig. 8). The words MANIFOLD SIDE should be visible on the center of each flange gasket.

(10) Carefully lower intake manifold into position

on the cylinder block and cylinder heads. Use the

Page 659 of 1502

FLANGE GASKET

X

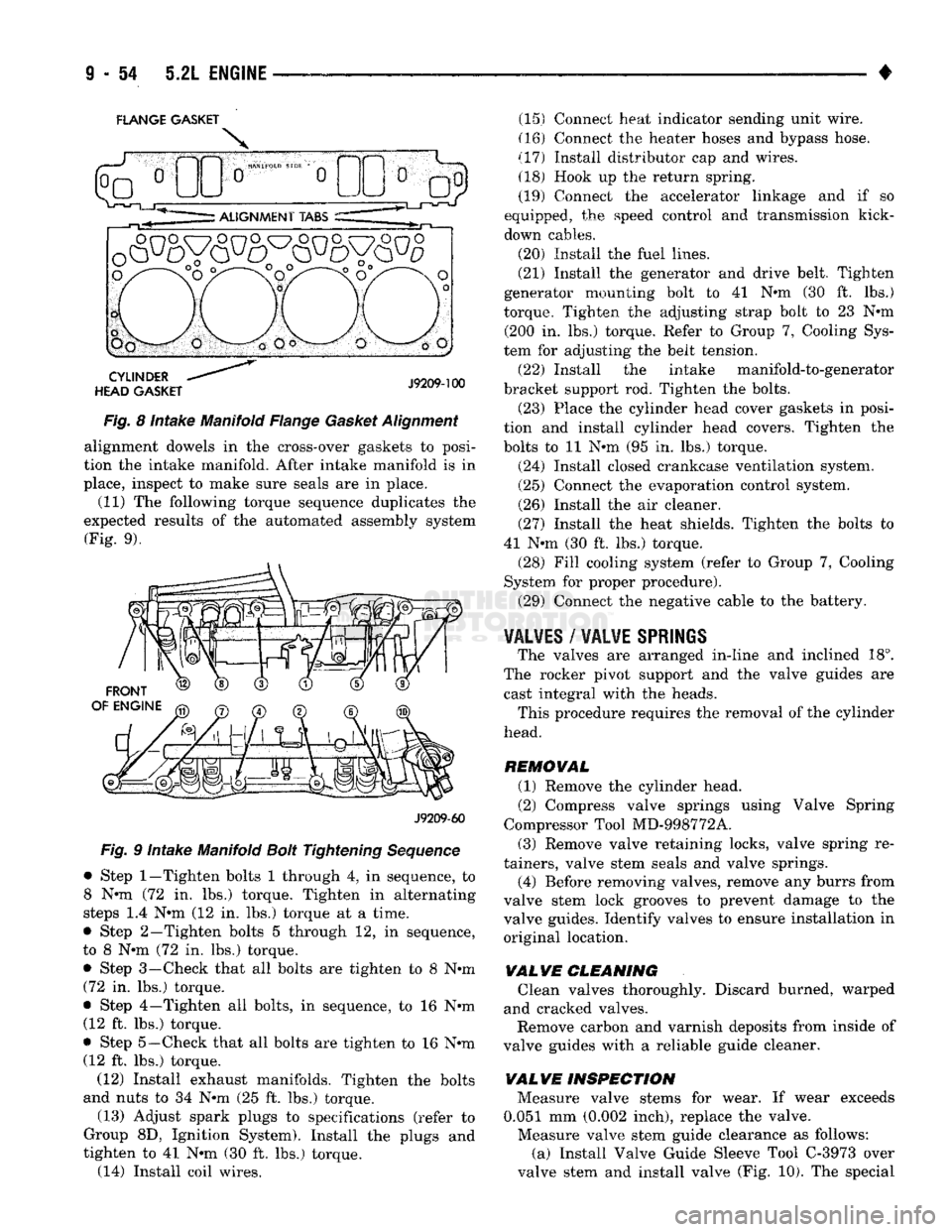

Fig. 8 intake Manifold Flange Gasket Alignment alignment dowels in the cross-over gaskets to posi

tion the intake manifold. After intake manifold is in

place, inspect to make sure seals are in place. (11) The following torque sequence duplicates the

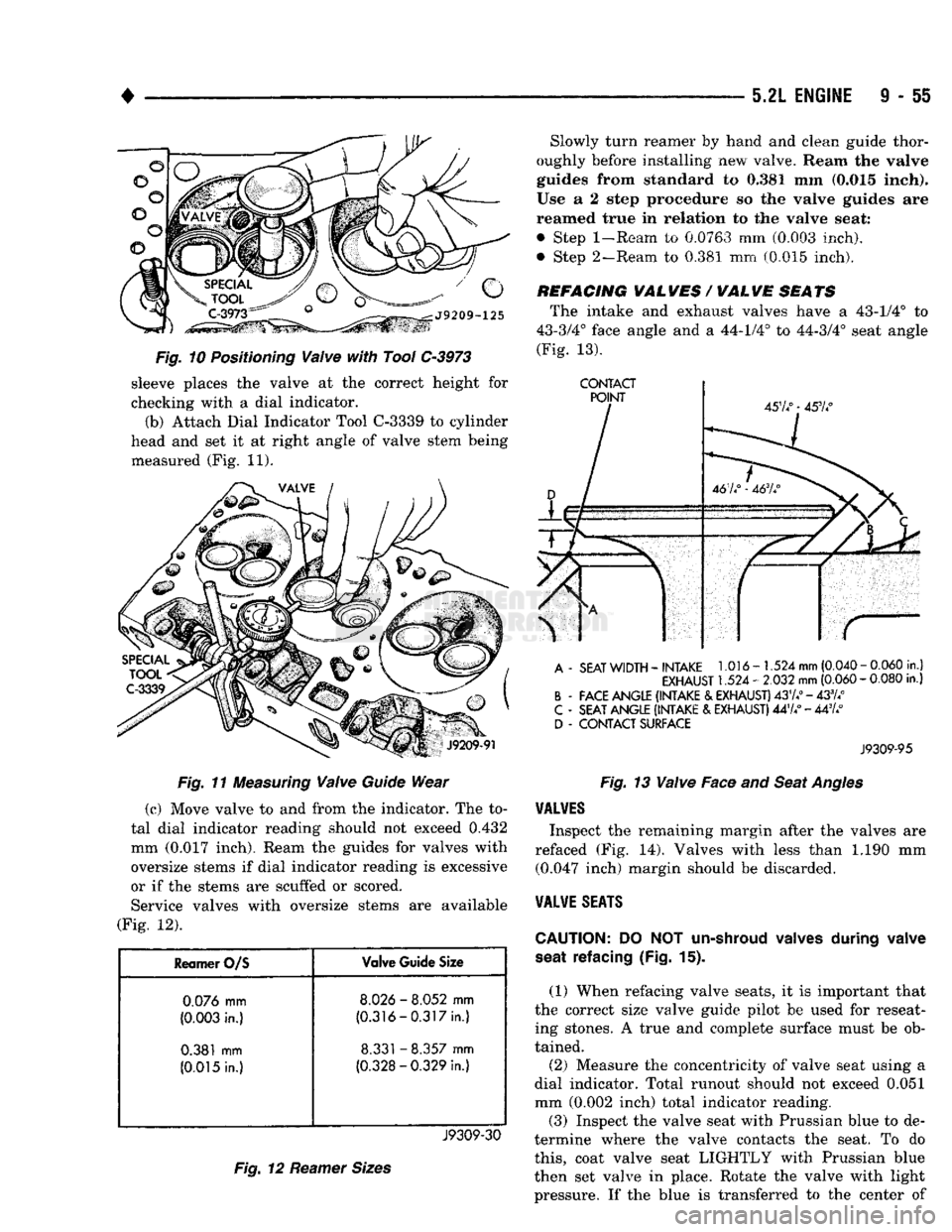

expected results of the automated assembly system (Fig. 9).

J9209-60

Fig. 9 Intake Manifold Bolt Tightening Sequence

• Step

1—Tighten

bolts 1 through 4, in sequence, to

8 N-m (72 in. lbs.) torque. Tighten in alternating

steps 1.4 N-m (12 in. lbs.) torque at a time.

• Step 2—Tighten bolts 5 through 12, in sequence,

to 8 N-m (72 in. lbs.) torque.

• Step 3—Check that all bolts are tighten to 8 N-m (72 in. lbs.) torque.

• Step 4—Tighten all bolts, in sequence, to 16 N-m (12 ft. lbs.) torque.

• Step

5—Check

that all bolts are tighten to 16 N-m (12 ft. lbs.) torque.

(12) Install exhaust manifolds. Tighten the bolts

and nuts to 34 N-m (25 ft. lbs.) torque.

(13) Adjust spark plugs to specifications (refer to

Group 8D, Ignition System). Install the plugs and

tighten to 41 N-m (30 ft. lbs.) torque. (14) Install coil wires. (15) Connect heat indicator sending unit wire.

(16) Connect the heater hoses and bypass hose.

(17) Install distributor cap and wires. (18) Hook up the return spring.

(19) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(20) Install the fuel lines.

(21) Install the generator and drive belt. Tighten

generator mounting bolt to 41 N-m (30 ft. lbs.)

torque. Tighten the adjusting strap bolt to 23 N-m (200 in. lbs.) torque. Refer to Group 7, Cooling Sys

tem for adjusting the belt tension.

(22) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts. (23) Place the cylinder head cover gaskets in posi

tion and install cylinder head covers. Tighten the

bolts to 11 N-m (95 in. lbs.) torque.

(24) Install closed crankcase ventilation system.

(25) Connect the evaporation control system.

(26) Install the air cleaner.

(27) Install the heat shields. Tighten the bolts to

41 N-m (30 ft. lbs.) torque. (28) Fill cooling system (refer to Group 7, Cooling

System for proper procedure).

(29) Connect the negative cable to the battery.

VALVES

/

VALVE

SPRINGS

The valves are arranged in-line and inclined 18°.

The rocker pivot support and the valve guides are cast integral with the heads. This procedure requires the removal of the cylinder

head.

REMOVAL (1) Remove the cylinder head.

(2) Compress valve springs using Valve Spring

Compressor Tool MD-998772A.

(3) Remove valve retaining locks, valve spring re

tainers, valve stem seals and valve springs.

(4) Before removing valves, remove any burrs from

valve stem lock grooves to prevent damage to the

valve guides. Identify valves to ensure installation in

original location.

VALVE CLEANING Clean valves thoroughly. Discard burned, warped

and cracked valves. Remove carbon and varnish deposits from inside of

valve guides with a reliable guide cleaner.

VAL VE INSPECTION Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 inch), replace the valve. Measure valve stem guide clearance as follows:

(a) Install Valve Guide Sleeve Tool C-3973 over

valve stem and install valve (Fig. 10). The special

Page 660 of 1502

•

5.2L

ENGINE

I - 55

Fig. 10 Positioning Valve with Tool C-3973 sleeve places the valve at the correct height for

checking with a dial indicator.

(b) Attach Dial Indicator Tool C-3339 to cylinder

head and set it at right angle of valve stem being measured (Fig. 11).

Fig. 11 Measuring Valve Guide Wear

(c) Move valve to and from the indicator. The to

tal dial indicator reading should not exceed

0.432

mm

(0.017

inch). Ream the guides for valves with

oversize stems if dial indicator reading is excessive

or if the stems are scuffed or scored. Service valves with oversize stems are available

(Fig. 12).

Reamer

O/S

Valve

Guide

Size

0.076

mm

8.026

-

8.052

mm

(0.003

in.)

(0.316-0.317in.)

0.381

mm

8.331

-

8.357

mm

(0.015

In.)

(0.328-0.329

In.)

J9309-30

Fig. 12 Reamer Sizes

Slowly turn reamer

by

hand

and

clean guide thor

oughly before installing

new

valve. Ream

the valve

guides from standard

to 0,381 mm

(0.015 Inch).

Use

a 2

step procedure

so the

valve guides

are

reamed true

in

relation

to the

valve seat:

• Step

1-Ream

to 0.0763 mm (0.003 inch),

• Step 2—Ream, to 0.381 mm (0.015 inch).

REFACING

VAL

WES

/

WAL

WE

SEATS

The intake and exhaust valves have a 43-1/4° to

43-3/4° face angle and a 44-1/4° to 44-3/4° seat angle

(Fig.

13).

CONTACT

A

-

SEAT

WIDTH

-

INTAKE

1.016-1.524

mm

(0.040

-

0.060

in.)

EXHAUST

1.524 -

2.032

mm

(0.060

-

0.080

in.)

B

-

FACE ANGLE (INTAKE

&

EXHAUST)

437.°

-433//

C

-

SEAT ANGLE (INTAKE

&

EXHAUST)

447/ - 447/

D

-

CONTACT SURFACE

J9309-95

Fig. 13 Valve Face and Seat Angles

VALVES

Inspect the remaining margin after the valves are

refaced (Fig. 14). Valves with less than 1.190 mm (0.047 inch) margin should be discarded.

VALVE

SEATS

CAUTION:

DO NOT

un-shroud valves

during

valve

seat

refacing (Fig.

15).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat ing stones. A true and complete surface must be ob

tained.

(2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.051

mm (0.002 inch) total indicator reading. (3) Inspect the valve seat with Prussian blue to de

termine where the valve contacts the seat. To do

this,

coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of