DODGE TRUCK 1993 Service Repair Manual

Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 631 of 1502

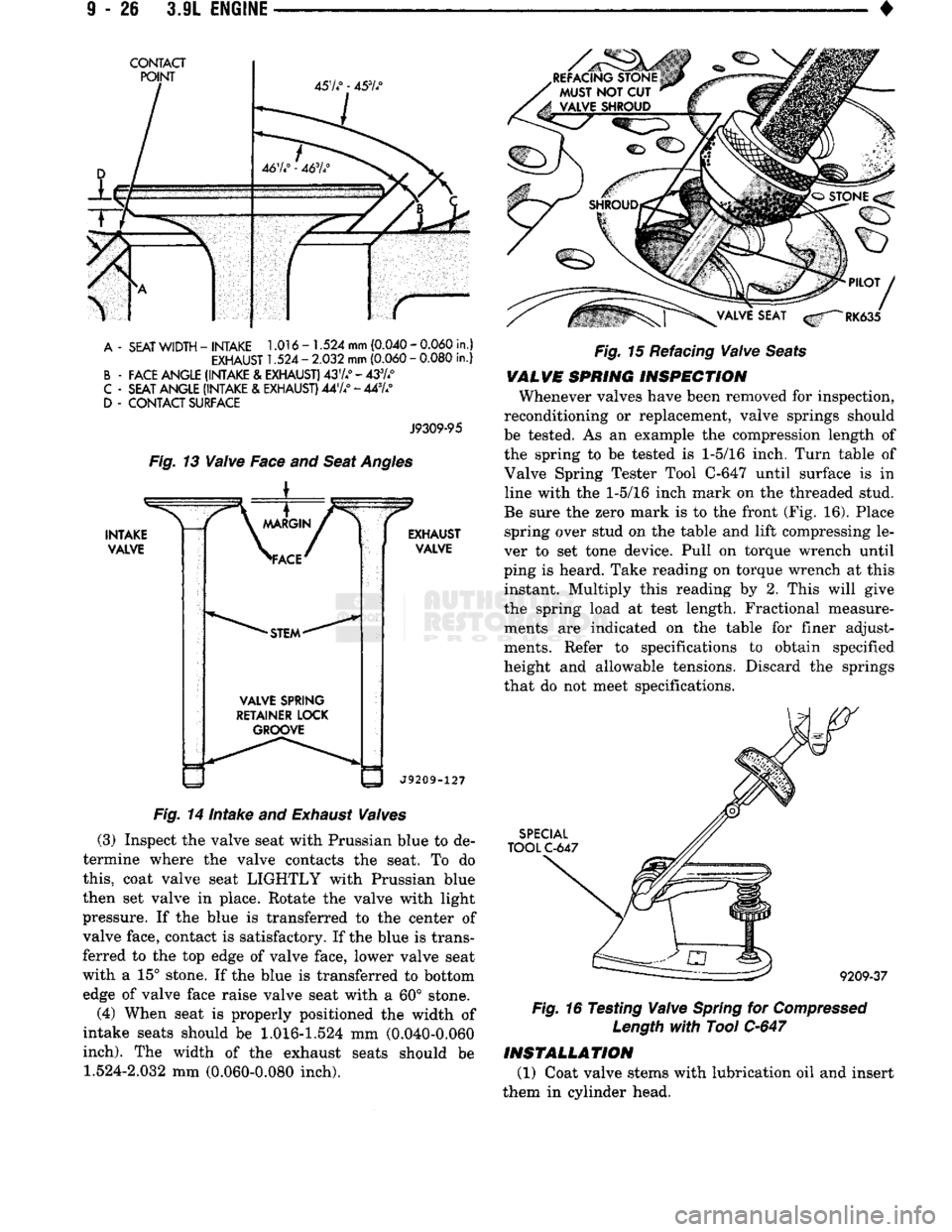

A

-

SEAT

WIDTH

-

INTAKE

1.016

-

1.524

mm

(0.040

-

0.060

in.)

EXHAUST

1.524

-

2.032

mm

(0.060

-

0.080

in.)

B

-

FACE

ANGLE

(INTAKE

& EXHAUST)

4374°

-

433A°

C

-

SEAT

ANGLE

(INTAKE

& EXHAUST)

4474°

-

44%°

D

-

CONTACT SURFACE

J9309-95

Fig.

13

Valve

Face and

Seat

Angles

i

INTAKE

VALVE

\

MARGIN

/ "

>FACE'

•STEM"

VALVE SPRING

RETAINER LOCK GROOVE EXHAUST

VALVE

J9209-127

Fig.

14 Intake and

Exhaust

Valves

(3) Inspect

the

valve seat with Prussian blue

to de

termine where

the

valve contacts

the

seat.

To do

this,

coat valve seat LIGHTLY with Prussian blue

then

set

valve

in

place. Rotate

the

valve with light

pressure.

If the

blue

is

transferred

to the

center

of

valve face, contact

is

satisfactory.

If

the blue

is

trans

ferred

to the top

edge

of

valve face, lower valve seat

with

a 15°

stone.

If

the blue

is

transferred

to

bottom edge

of

valve face raise valve seat with

a 60°

stone.

(4)

When seat

is

properly positioned

the

width

of

intake seats should

be 1.016-1.524 mm (0.040-0.060

inch).

The

width

of the

exhaust seats should

be 1.524-2.032 mm (0.060-0.080

inch).

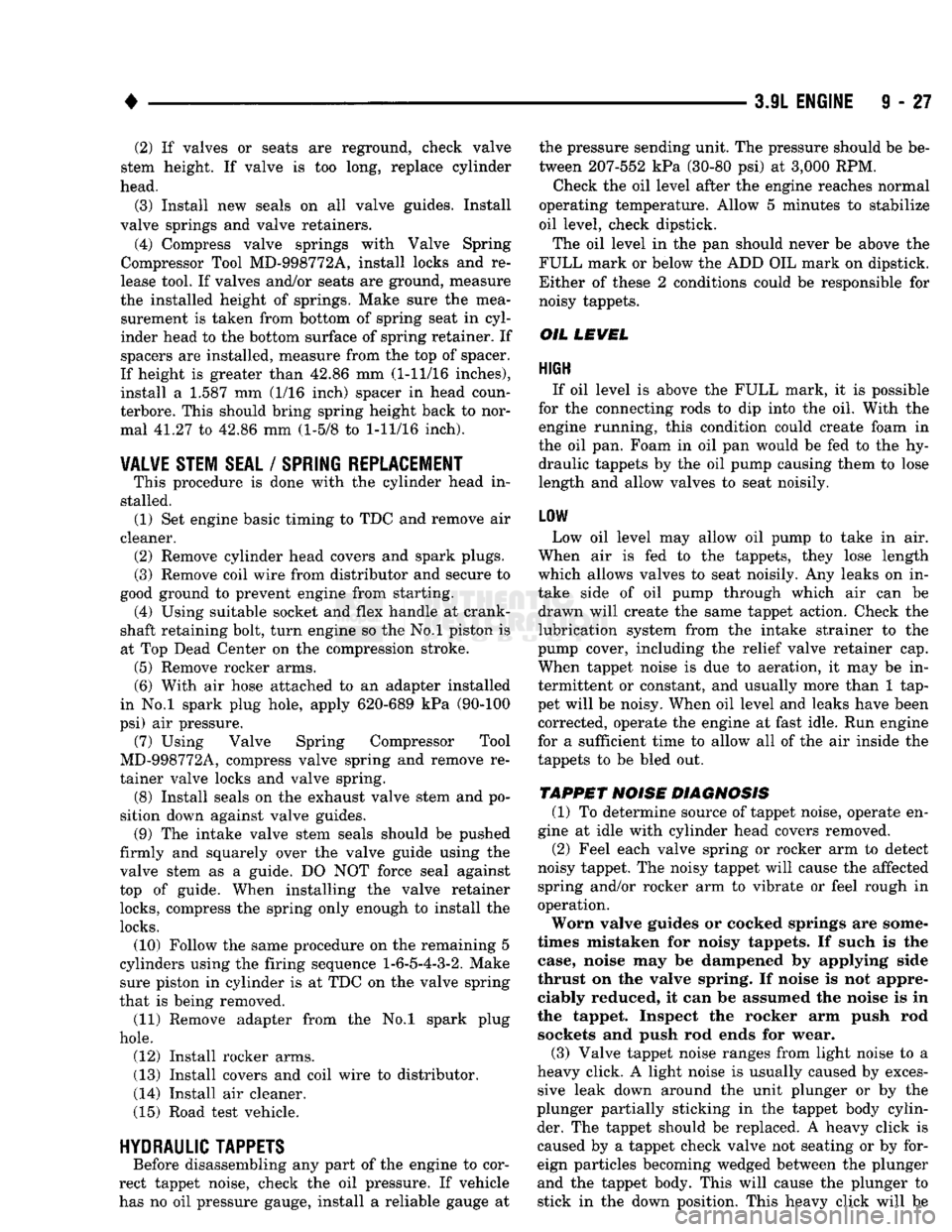

Fig.

15 Refacing

Valve

Seats

VALVE

SPRING

INSPECTION

Whenever valves have been removed

for

inspection,

reconditioning

or

replacement, valve springs should

be tested.

As an

example

the

compression length

of

the spring

to be

tested

is 1-5/16

inch. Turn table

of

Valve Spring Tester Tool

C-647

until surface

is in

line with

the 1-5/16

inch mark

on the

threaded stud.

Be sure

the

zero mark

is to the

front (Fig.

16).

Place spring over stud

on the

table

and

lift compressing

le

ver

to set

tone device. Pull

on

torque wrench until

ping

is

heard. Take reading

on

torque wrench

at

this instant. Multiply this reading

by 2.

This will give

the spring load

at

test length. Fractional measure ments

are

indicated

on the

table

for

finer adjustments. Refer

to

specifications

to

obtain specified

height

and

allowable tensions. Discard

the

springs

that

do not

meet specifications.

SPECIAL

TOOL

C-647

9209-37

Fig.

16 Testing

Valve

Spring

for

Compressed

Length

with

Tool

C-647

INSTALLATION

(1)

Coat valve stems with lubrication

oil and

insert

them

in

cylinder head.

Page 632 of 1502

•

3.9L

ENGINE

9 - 27 (2) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(3) Install new seals on all valve guides. Install

valve springs and valve retainers.

(4) Compress valve springs with Valve Spring

Compressor Tool MD-998772A, install locks and re

lease tool. If valves and/or seats are ground, measure

the installed height of springs. Make sure the mea surement is taken from bottom of spring seat in cyl

inder head to the bottom surface of spring retainer. If

spacers are installed, measure from the top of spacer.

If height is greater than 42.86 mm (1-11/16 inches), install a 1.587 mm (1/16 inch) spacer in head coun-

terbore. This should bring spring height back to nor

mal 41.27 to 42.86 mm (1-5/8 to

1-11/16

inch).

VALVE STEM SEAL

/

SPRING REPLACEMENT

This procedure is done with the cylinder head in

stalled. (1) Set engine basic timing to TDC and remove air

cleaner. (2) Remove cylinder head covers and spark plugs.

(3) Remove coil wire from distributor and secure to

good ground to prevent engine from starting. (4) Using suitable socket and flex handle at crank

shaft retaining bolt, turn engine so the No.l piston is

at Top Dead Center on the compression stroke. (5) Remove rocker arms.

(6) With air hose attached to an adapter installed

in No.l spark plug hole, apply 620-689 kPa (90-100

psi) air pressure. (7) Using Valve Spring Compressor Tool

MD-998772A, compress valve spring and remove re

tainer valve locks and valve spring. (8) Install seals on the exhaust valve stem and po

sition down against valve guides. (9) The intake valve stem seals should be pushed

firmly and squarely over the valve guide using the valve stem as a guide. DO NOT force seal against

top of guide. When installing the valve retainer

locks,

compress the spring only enough to install the

locks.

(10) Follow the same procedure on the remaining 5

cylinders using the firing sequence

1-6-5-4-3-2.

Make sure piston in cylinder is at TDC on the valve spring

that is being removed. (11) Remove adapter from the No.l spark plug

hole.

(12) Install rocker arms.

(13) Install covers and coil wire to distributor.

(14) Install air cleaner.

(15) Road test vehicle.

HYDRAULIC

TAPPETS

Before disassembling any part of the engine to cor

rect tappet noise, check the oil pressure. If vehicle

has no oil pressure gauge, install a reliable gauge at the pressure sending unit. The pressure should be be

tween 207-552 kPa (30-80 psi) at 3,000 RPM.

Check the oil level after the engine reaches normal

operating temperature. Allow 5 minutes to stabilize

oil level, check dipstick.

The oil level in the pan should never be above the

FULL mark or below the ADD OIL mark on dipstick.

Either of these 2 conditions could be responsible for

noisy tappets.

OIL

LEWEL

HIGH

If oil level is above the FULL mark, it is possible

for the connecting rods to dip into the oil. With the engine running, this condition could create foam in

the oil pan. Foam in oil pan would be fed to the hy draulic tappets by the oil pump causing them to lose

length and allow valves to seat noisily.

LOW

Low oil level may allow oil pump to take in air.

When air is fed to the tappets, they lose length

which allows valves to seat noisily. Any leaks on in

take side of oil pump through which air can be drawn will create the same tappet action. Check the

lubrication system from the intake strainer to the

pump cover, including the relief valve retainer cap.

When tappet noise is due to aeration, it may be in

termittent or constant, and usually more than 1 tap

pet will be noisy. When oil level and leaks have been corrected, operate the engine at fast idle. Run engine

for a sufficient time to allow all of the air inside the

tappets to be bled out.

TAPPET

NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate en

gine at idle with cylinder head covers removed. (2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

Worn valve guides or cocked springs are some

times mistaken for noisy tappets. If such is the

case, noise may be dampened by applying side

thrust on the valve spring. If noise is not appre ciably reduced, it can be assumed the noise is in

the tappet. Inspect the rocker arm push rod sockets and push rod ends for wear.

(3) Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces sive leak down around the unit plunger or by the

plunger partially sticking in the tappet body cylin der. The tappet should be replaced. A heavy click is

caused by a tappet check valve not seating or by for

eign particles becoming wedged between the plunger

and the tappet body. This will cause the plunger to

stick in the down position. This heavy click will be

Page 633 of 1502

9

- 28 3.9L

ENGINE

•

accompanied by excessive clearance between the

valve stem and rocker arm as valve closes. In either

case,

tappet assembly should be removed for inspec

tion and cleaning.

The valve train generates a noise very much like a

light tappet noise during normal operation. Care

must be taken to ensure that tappets are making the

noise. In general, if more than one tappet seems to

be noisy, its probably not the tappets.

REMOVAL

(1) Remove the air cleaner.

(2) Remove cylinder head cover.

(3) Remove rocker assembly and push rods. Iden

tify push rods to ensure installation in original loca

tion.

(4) Remove intake manifold.

(5) Remove yoke retainer and aligning yokes.

(6) Slide Hydraulic Tappet Remover/Installer Tool

C-4129-A

through opening in cylinder head and seat

tool firmly in the head of tappet.

(7) Pull tappet out of bore with a twisting motion.

If all tappets are to be removed, identify tappets to

ensure installation in original location. (8) If the tappet or bore in cylinder block is scored,

scuffed, or shows signs of sticking, ream the bore to

next oversize. Replace with oversize tappet.

CAUTION:

The

plunger

and

tappet bodies

are not

interchangeable.

The

plunger

and

valve must

al

ways

be fitted to the

original body.

It is

advisable

to

work

on one

tappet

at a

time

to

avoid mixing

of

parts.

Mixed parts

are not

compatible.

DO NOT

dis

assemble

a

tappet

on a

dirty

work bench.

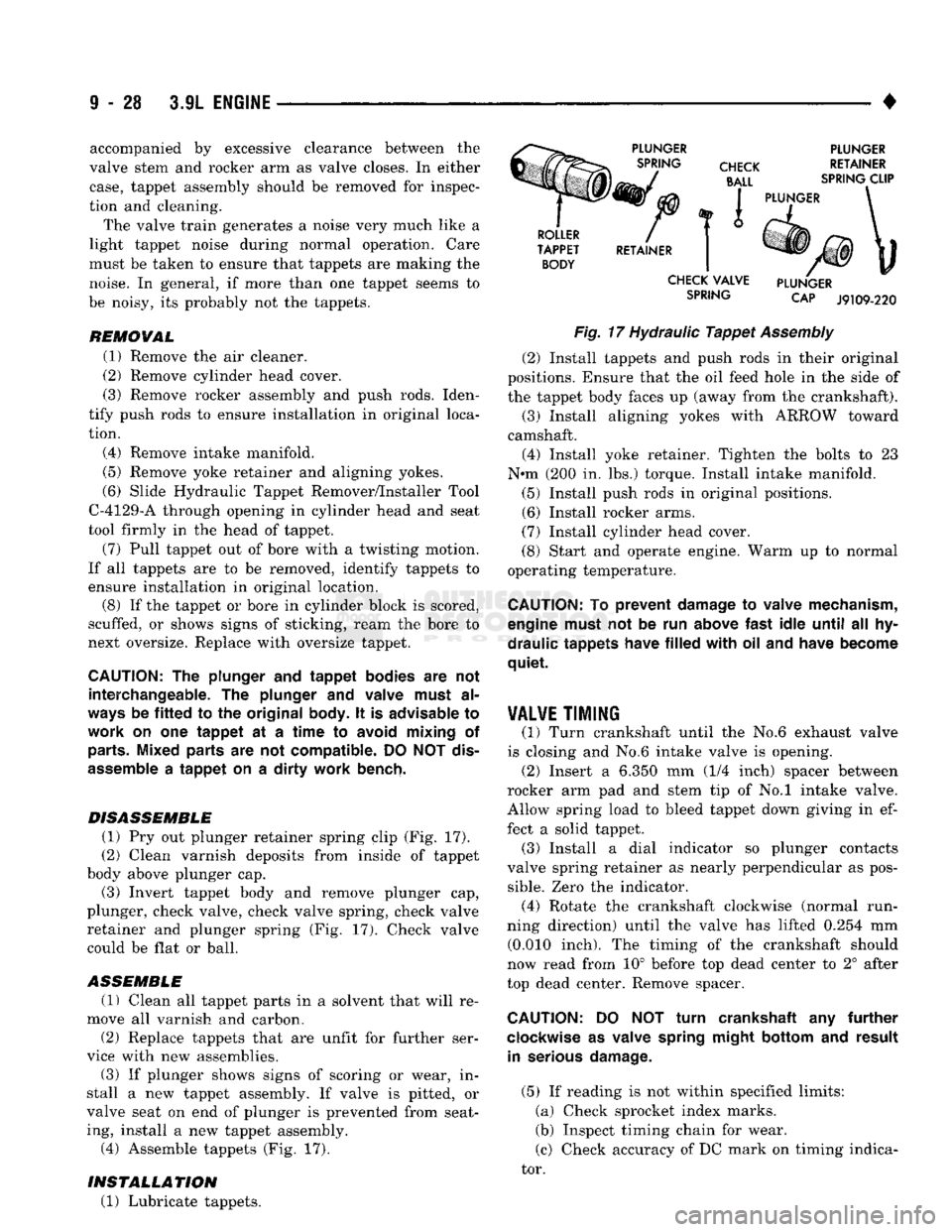

DISASSEMBLE (1) Pry out plunger retainer spring clip (Fig. 17).

(2) Clean varnish deposits from inside of tappet

body above plunger cap.

(3) Invert tappet body and remove plunger cap,

plunger, check valve, check valve spring, check valve retainer and plunger spring (Fig. 17). Check valve

could be flat or ball.

ASSEMBLE (1) Clean all tappet parts in a solvent that will re

move all varnish and carbon.

(2) Replace tappets that are unfit for further ser

vice with new assemblies. (3) If plunger shows signs of scoring or wear, in

stall a new tappet assembly. If valve is pitted, or

valve seat on end of plunger is prevented from seat ing, install a new tappet assembly.

(4) Assemble tappets (Fig. 17).

INSTALLATION

(1) Lubricate tappets.

PLUNGER

SPRING CHECK

BALL PLUNGER

RETAINER

SPRING CLIP

ROLLER

TAPPET

BODY RETAINER

I

PLUNGER

CHECK VALVE

SPRING PLUNGER

CAP

J9109-220

Fig.

17 Hydraulic

Tappet

Assembly

(2) Install tappets and push rods in their original

positions. Ensure that the oil feed hole in the side of

the tappet body faces up (away from the crankshaft).

(3) Install aligning yokes with ARROW toward

camshaft.

(4) Install yoke retainer. Tighten the bolts to 23

N*m (200 in. lbs.) torque. Install intake manifold.

(5) Install push rods in original positions. (6) Install rocker arms.

(7) Install cylinder head cover.

(8) Start and operate engine. Warm up to normal

operating temperature.

CAUTION:

To

prevent damage

to

valve mechanism,

engine must

not be run

above fast idle

until

all hy

draulic tappets have

filled

with

oil and

have become

quiet.

VALVE

TIMING

(1) Turn crankshaft until the No.6 exhaust valve

is closing and No.6 intake valve is opening. (2) Insert a 6.350 mm (1/4 inch) spacer between

rocker arm pad and stem tip of No.l intake valve.

Allow spring load to bleed tappet down giving in ef fect a solid tappet. (3) Install a dial indicator so plunger contacts

valve spring retainer as nearly perpendicular as pos sible. Zero the indicator. (4) Rotate the crankshaft clockwise (normal run

ning direction) until the valve has lifted 0.254 mm (0.010 inch). The timing of the crankshaft should

now read from 10° before top dead center to 2° after

top dead center. Remove spacer.

CAUTION:

DO NOT

turn

crankshaft

any

further

clockwise

as

valve spring might bottom

and

result in serious damage.

(5) If reading is not within specified limits: (a) Check sprocket index marks.

(b) Inspect timing chain for wear. (c) Check accuracy of DC mark on timing indica

tor.

Page 634 of 1502

•

3.9L

ENGINE

I - 21

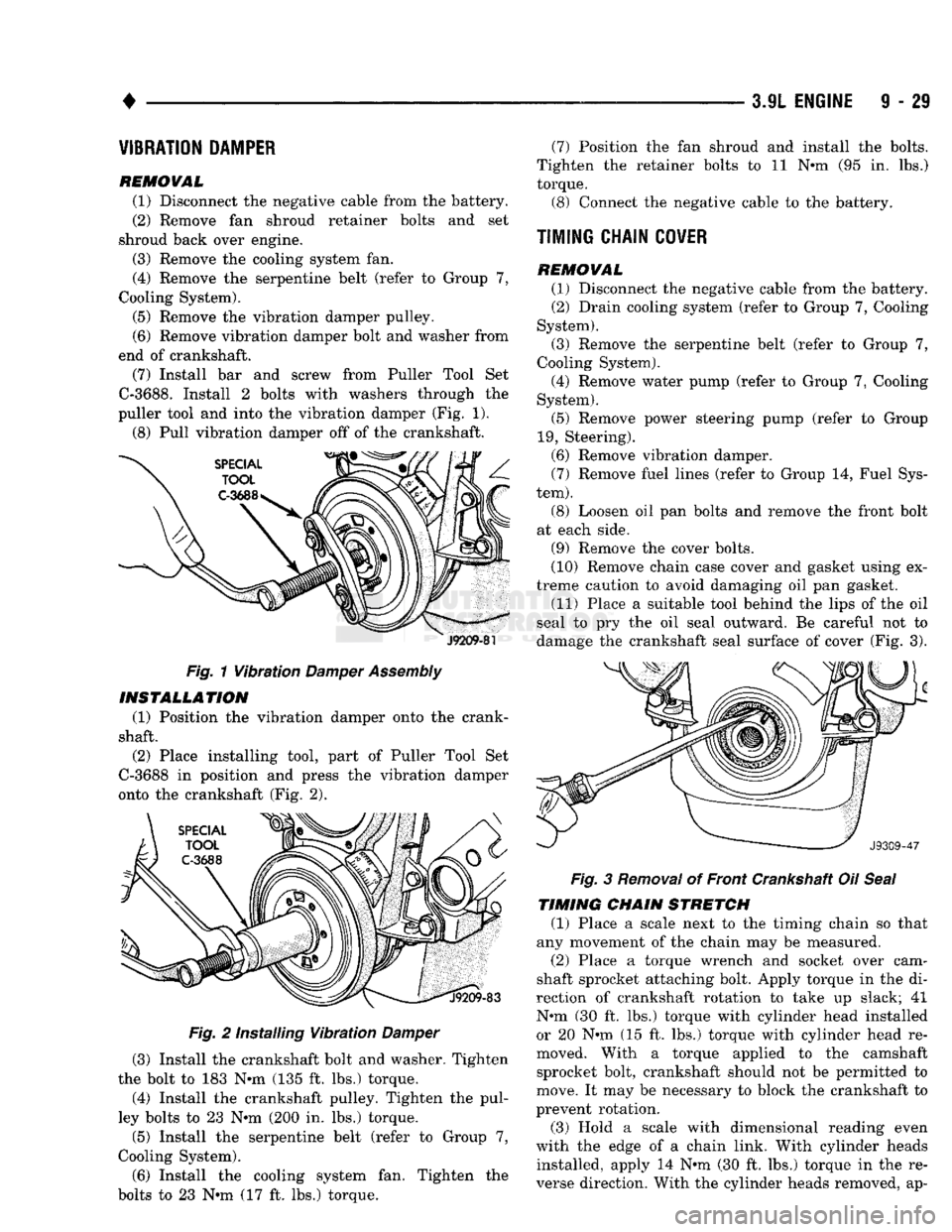

VIBRATION

DAMPER

REMOVAL

(1) Disconnect the negative cable from the battery,

(2) Remove fan shroud retainer bolts and set

shroud back over engine.

(3) Remove the cooling system fan.

(4) Remove the serpentine belt (refer to Group 7,

Cooling System).

(5) Remove the vibration damper pulley.

(6) Remove vibration damper bolt and washer from

end of crankshaft.

(7) Install bar and screw from Puller Tool Set

C-3688.

Install 2 bolts with washers through the

puller tool and into the vibration damper (Fig. 1).

(8) Pull vibration damper off of the crankshaft.

J9209-81

Fig. 1 Vibration

Damper

Assembly INSTALLATION

(1) Position the vibration damper onto the crank

shaft.

(2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 2).

Fig. 2 Installing Vibration Damper

(3) Install the crankshaft bolt and washer. Tighten

the bolt to 183 N*m (135 ft. lbs.) torque.

(4) Install the crankshaft pulley. Tighten the pul

ley bolts to 23 N*m (200 in. lbs.) torque.

(5) Install the serpentine belt (refer to Group 7,

Cooling System).

(6) Install the cooling system fan. Tighten the

bolts to 23 N*m (17 ft. lbs.) torque. (7) Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N*m (95 in. lbs.)

torque.

(3)

Connect the negative cable to the battery.

TIMING CHAIN

COVER

REMOVAL (1)

Disconnect the negative cable from the battery.

(2)

Drain cooling system (refer to Group 7, Cooling

System).

(3)

Remove the serpentine belt (refer to Group 7,

Cooling System).

(4)

Remove water pump (refer to Group 7, Cooling

System).

(5)

Remove power steering pump (refer to Group

19,

Steering).

(6)

Remove vibration damper. (7) Remove fuel lines (refer to Group 14, Fuel Sys

tem).

(8) Loosen oil pan bolts and remove the front bolt

at each side.

(9)

Remove the cover bolts.

(10)

Remove chain case cover and gasket using ex

treme caution to avoid damaging oil pan gasket.

(11)

Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover (Fig. 3). Fig. 3 Removal of Front Crankshaft Oil Seal

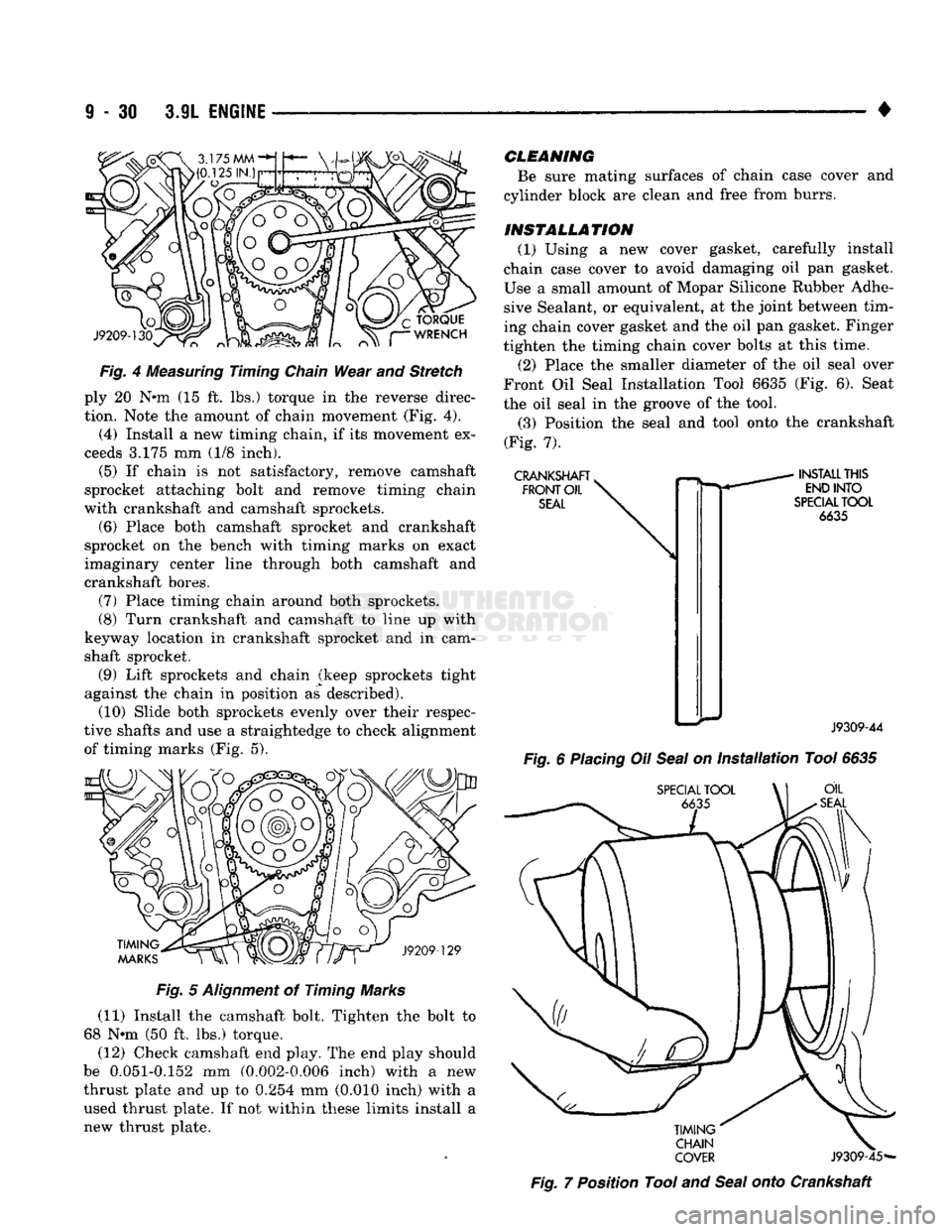

TIMING CHAIN STRETCH

(1) Place a scale next to the timing chain so that

any movement of the chain may be measured.

(2)

Place a torque wrench and socket over cam

shaft sprocket attaching bolt. Apply torque in the di

rection of crankshaft rotation to take up slack; 41

N#m (30 ft. lbs.) torque with cylinder head installed or 20 N»m (15 ft. lbs.) torque with cylinder head re

moved. With a torque applied to the camshaft sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block the crankshaft to

prevent rotation.

(3)

Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads installed, apply 14 N*m (30 ft. lbs.) torque in the re

verse direction. With the cylinder heads removed, ap-

Page 635 of 1502

i - 30

3.9L

ENGINE

J9209-130

Fig.

4

Measuring

Timing

Chain

Wear and Stretch ply 20 N*m (15 ft. lbs.) torque in the reverse direc

tion. Note the amount of chain movement (Fig. 4).

(4) Install a new timing chain, if its movement ex

ceeds 3.175 mm (1/8 inch).

(5) If chain is not satisfactory, remove camshaft

sprocket attaching bolt and remove timing chain

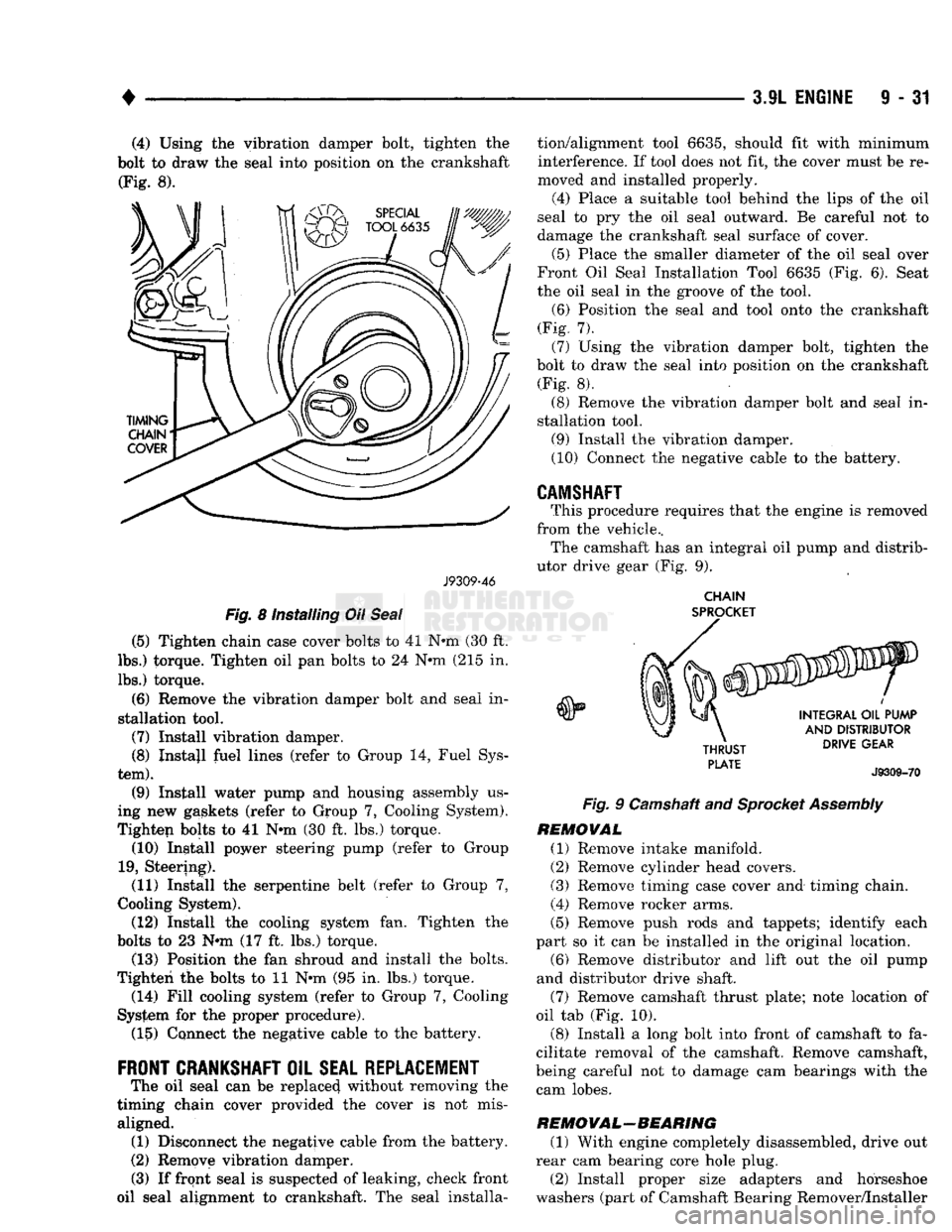

with crankshaft and camshaft sprockets. (6) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(7) Place timing chain around both sprockets. (8) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam

shaft sprocket.

(9) Lift sprockets and chain (keep sprockets tight

against the chain in position as described). (10) Slide both sprockets evenly over their respec

tive shafts and use a straightedge to check alignment of timing marks (Fig. 5).

TIMING

MARKS

J9209-129

Fig.

5

Alignment

of Timing Marks

(11) Install the camshaft bolt. Tighten the bolt to

68 Nnn (50 ft. lbs.) torque. (12) Check camshaft end play. The end play should

be 0.051-0.152 mm (0.002-0.006 inch) with a new

thrust plate and up to 0.254 mm (0.010 inch) with a used thrust plate. If not within these limits install a

new thrust plate.

CLEANING

Be sure mating surfaces of chain case cover and

cylinder block are clean and free from burrs.

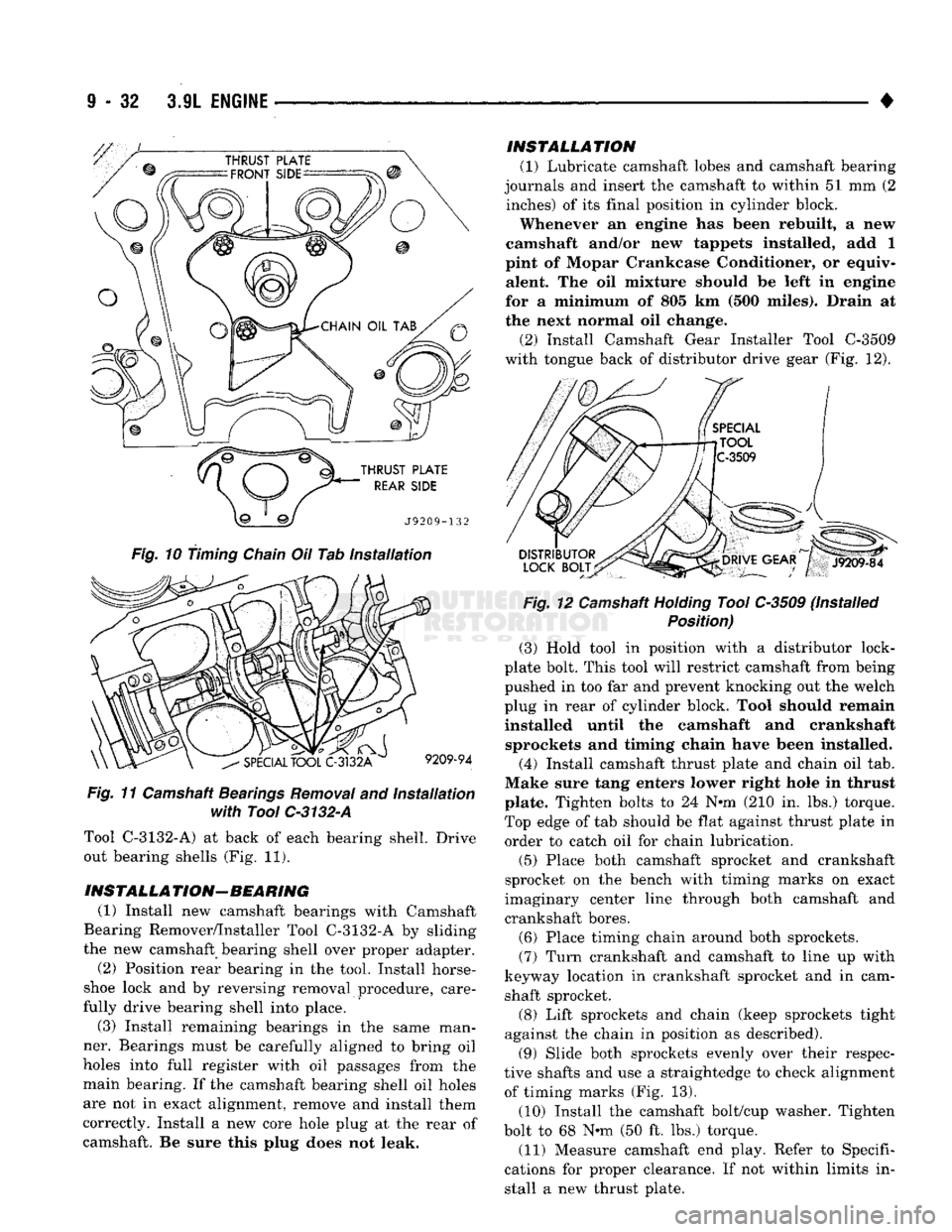

INSTALLATION

(1) Using a new cover gasket, carefully install

chain case cover to avoid damaging oil pan gasket.

Use a small amount of Mopar Silicone Rubber Adhe

sive Sealant, or equivalent, at the joint between tim ing chain cover gasket and the oil pan gasket. Finger

tighten the timing chain cover bolts at this time.

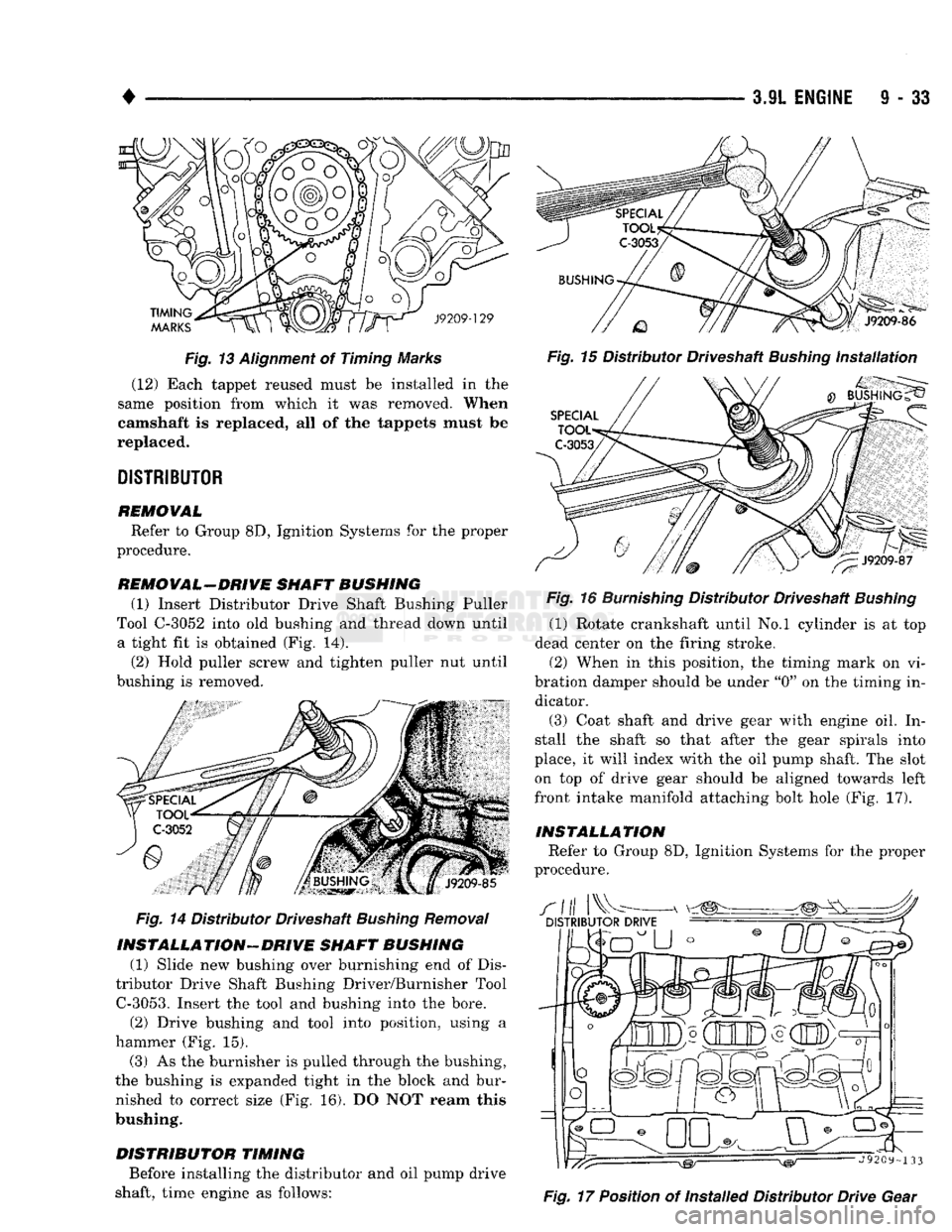

(2) Place the smaller diameter of the oil seal over

Front Oil Seal Installation Tool 6635 (Fig. 6). Seat

the oil seal in the groove of the tool.

(3) Position the seal and tool onto the crankshaft

(Fig. 7).

CRANKSHAFT

>

FRONT

OIL

SEAL

INSTALL

THIS

END

INTO

SPECIAL

TOOL

6635

J9309-44

Fig.

6

Placing

Oil

Seal

on

Installation

Tool

6635

SPECIAL

TOOL

\\ OIL

SEAL

TIMING'

CHAIN

COVER

J9309-45-

Fig.

7 Position Tool and

Seal

onto Crankshaft

Page 636 of 1502

•

3.9L

ENGINE

9 - 31 (4) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft (Fig. 8).

J9309-46

Fig.

8 installing Oil

Seal

(5) Tighten chain case cover bolts to 41 N-m (30 ft.

lbs.) torque. Tighten oil pan bolts to 24 N*m (215 in.

lbs.) torque.

(6) Remove the vibration damper bolt and seal in

stallation tool.

(7) Install vibration damper. (8) Instajl fuel lines (refer to Group 14, Fuel Sys

tem).

(9) Install water pump and housing assembly us

ing new gaskets (refer to Group 7, Cooling System).

Tighten bolts to 41 N-m (30 ft. lbs.) torque. (10) Install power steering pump (refer to Group

19,

Steering). (11) Install the serpentine belt (refer to Group 7,

Cooling System). (12) Install the cooling system fan. Tighten the

bolts to 23 N-m (17 ft. lbs.) torque. (13) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N-m (95 in. lbs.) torque. (14) Fill cooling system (refer to Group 7, Cooling

System for the proper procedure). (15) Connect the negative cable to the battery.

FRONT

CRANKSHAFT

OIL

SEAL REPLACEMENT

The oil seal can be replaced without removing the

timing chain cover provided the cover is not mis aligned. (1) Disconnect the negative cable from the battery.

(2) Remove vibration damper.

(3) If front seal is suspected of leaking, check front

oil seal alignment to crankshaft. The seal installa tion/alignment tool 6635, should fit with minimum

interference. If tool does not fit, the cover must be re

moved and installed properly.

(4)

Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of cover.

(5) Place the smaller diameter of the oil seal over

Front Oil Seal Installation Tool 6635 (Fig. 6). Seat

the oil seal in the groove of the tool.

(6) Position the seal and tool onto the crankshaft

(Fig. 7). (7) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft (Fig. 8).

(8) Remove the vibration damper bolt and seal in

stallation tool. (9) Install the vibration damper.

(10) Connect the negative cable to the battery.

CAMSHAFT

This procedure requires that the engine is removed

from the vehicle.. The camshaft has an integral oil pump and distrib

utor drive gear (Fig. 9).

CHAIN

SPROCKET

Fig.

9 Camshaft and

Sprocket

Assembly

REMOVAL

(1) Remove intake manifold.

(2) Remove cylinder head covers. (3) Remove timing case cover and timing chain.

(4) Remove rocker arms.

(5) Remove push rods and tappets; identify each

part so it can be installed in the original location. (6) Remove distributor and lift out the oil pump

and distributor drive shaft.

(7) Remove camshaft thrust plate; note location of

oil tab (Fig. 10).

(8) Install a long bolt into front of camshaft to fa

cilitate removal of the camshaft. Remove camshaft,

being careful not to damage cam bearings with the cam lobes.

RE

MO

VAL-BEA RING

(1) With engine completely disassembled, drive out

rear cam bearing core hole plug.

(2) Install proper size adapters and horseshoe

washers (part of Camshaft Bearing Remover/Installer

Page 637 of 1502

9

- 32 3.9L

ENGINE

•

Fig,

10 timing

Chain

Oil Tab installation

Fig,

11 Camshaft Bearings Removal and Installation

with

Tool

C-3132-A

Tool C-3132-A) at back of each bearing shell. Drive out bearing shells (Fig. 11).

INSTALLA

TION— BEARING (1) Install new camshaft bearings with Camshaft

Bearing Remover/Installer Tool C-3132-A by sliding

the new camshaft bearing shell over proper adapter.

(2) Position rear bearing in the tool. Install horse

shoe lock and by reversing removal procedure, care

fully drive bearing shell into place.

(3) Install remaining bearings in the same man

ner. Bearings must be carefully aligned to bring oil

holes into full register with oil passages from the main bearing. If the camshaft bearing shell oil holes

are not in exact alignment, remove and install them

correctly. Install a new core hole plug at the rear of

camshaft. Be sure this plug does not leak. INSTALLATION

(1) Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft to within 51 mm (2 inches) of its final position in cylinder block.

Whenever an engine has been rebuilt, a new

camshaft and/or new tappets installed, add 1

pint of Mopar Crankcase Conditioner, or equiv alent. The oil mixture should be left in engine

for a minimum of 805 km (500 miles). Drain at

the next normal oil change.

(2) Install Camshaft Gear Installer Tool C-3509

with tongue back of distributor drive gear (Fig. 12).

Fig.

12 Camshaft

Holding

Tool C-3509 (Installed

Position)

(3) Hold tool in position with a distributor lock-

plate bolt. This tool will restrict camshaft from being

pushed in too far and prevent knocking out the welch

plug in rear of cylinder block. Tool should remain

installed until the camshaft and crankshaft sprockets and timing chain have been installed.

(4) Install camshaft thrust plate and chain oil tab.

Make sure tang enters lower right hole in thrust plate. Tighten bolts to 24 N*m (210 in. lbs.) torque.

Top edge of tab should be flat against thrust plate in order to catch oil for chain lubrication.

(5) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(6) Place timing chain around both sprockets.

(7)

Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam shaft sprocket.

(8) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

(9) Slide both sprockets evenly over their respec

tive shafts and use a straightedge to check alignment of timing marks (Fig. 13).

(10) Install the camshaft bolt/cup washer. Tighten

bolt to 68 N*m (50 ft. lbs.) torque.

(11) Measure camshaft end play. Refer to Specifi

cations for proper clearance. If not within limits in stall a new thrust plate.

Page 638 of 1502

•

3.9L

ENGINE

9 - 33

Fig. 13 Alignment of Timing Marks (12) Each tappet reused must be installed in the

same position from which it was removed.

When

camshaft

Is replaced, all of the tappets must be

replaced.

DISTRIBUTOR

REMOVAL

Refer to Group 8D, Ignition Systems for the proper

procedure.

REMOVAL-DRIVE SHAFT BUSHING (1)

Insert Distributor Drive Shaft Bushing Puller

Tool C-3052 into old bushing and thread down until a tight fit is obtained (Fig. 14).

(2)

Hold puller screw and tighten puller nut until

bushing is removed.

Fig.

14 Distributor Driveshaft Bushing Removal

INSTALLATION-DRIVE

SHAFT BUSHING (1) Slide new bushing over burnishing end of Dis

tributor Drive Shaft Bushing Driver/Burnisher Tool

C-3053.

Insert the tool and bushing into the bore. (2) Drive bushing and tool into position, using a

hammer (Fig. 15).

(3) As the burnisher is pulled through the bushing,

the bushing is expanded tight in the block and bur nished to correct size (Fig. 16). DO NOT ream this

bushing.

DISTRIBUTOR

TIMING

Before installing the distributor and oil pump drive

shaft, time engine as follows:

Fig.

16

Burnishing

Distributor Driveshaft

Bushing

(1) Rotate crankshaft until No.l cylinder is at top

dead center on the firing stroke. (2) When in this position, the timing mark on vi

bration damper should be under "0" on the timing in dicator.

(3) Coat shaft and drive gear with engine oil. In

stall the shaft so that after the gear spirals into

place, it will index with the oil pump shaft. The slot on top of drive gear should be aligned towards left

front intake manifold attaching bolt hole (Fig. 17).

INSTALLATION

Refer to Group 8D, Ignition Systems for the proper

procedure.

Fig.

17 Position of Installed Distributor Drive Gear

Page 639 of 1502

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove engine oil dipstick.

(3) Raise vehicle.

(4) Drain engine oil.

(5)

Remove exhaust pipe.

(6) Remove left engine to transmission strut.

(7) Remove oil pan and one-piece gasket.

CLEANING Clean the block and pan gasket surfaces.

Trim or remove excess sealant film in the rear

main cap oil pan gasket groove. DO NOT remove

the sealant inside the rear main cap slots.

If present, trim excess sealant from inside the en

gine.

Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol

vent. Inspect condition of screen.

INSPECTION Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary. Inspect oil pan mounting flange for bends or distor

tion. Straighten flange, if necessary.

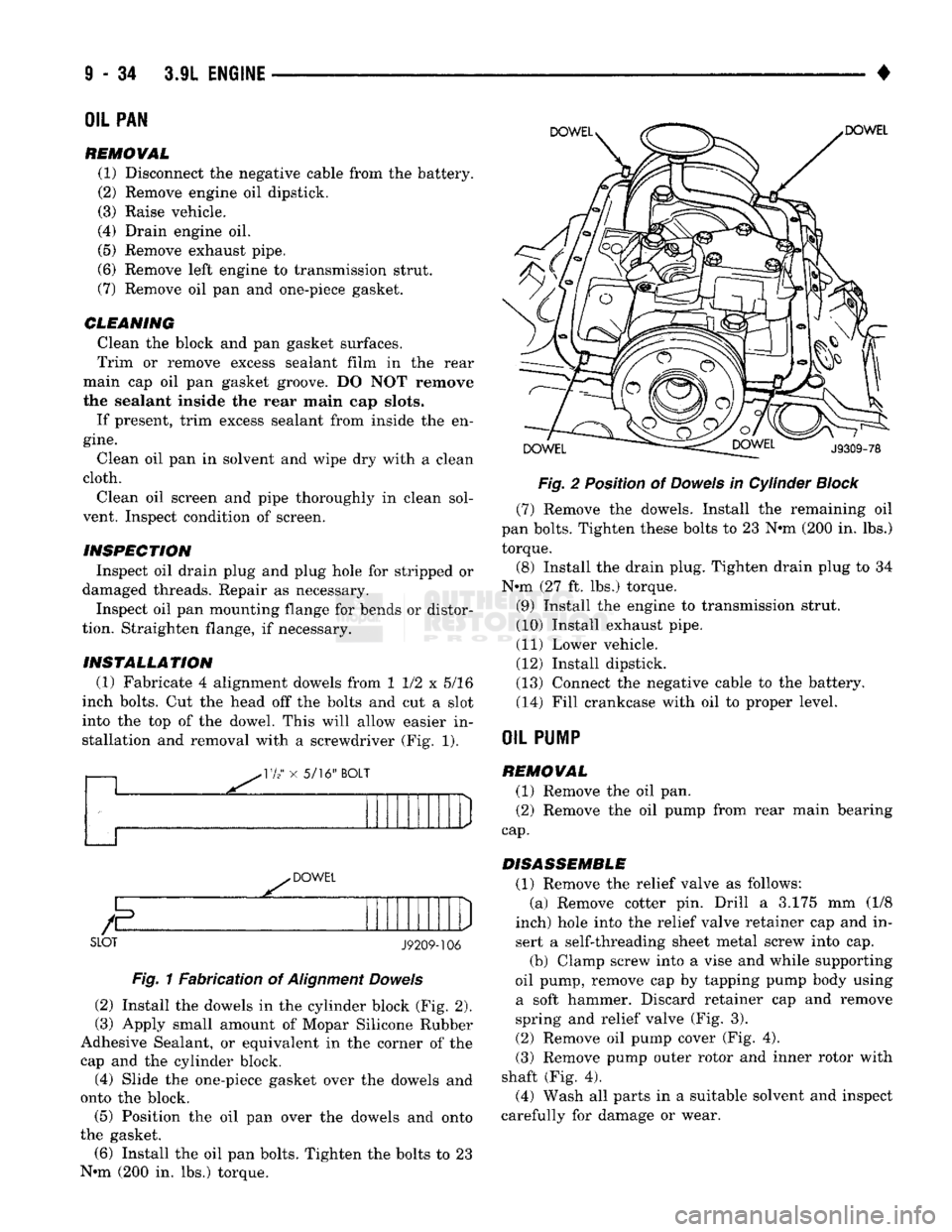

INSTALLATION (1) Fabricate 4 alignment dowels from 1 1/2 x 5/16

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier in stallation and removal with a screwdriver (Fig. 1).

11/2"

x 5/16" BOLT

,

DOWEL

SLOT

J9209-106

Fig. 1 Fabrication of Alignment Dowels

(2) Install the dowels in the cylinder block (Fig. 2).

(3) Apply small amount of Mopar Silicone Rubber

Adhesive Sealant, or equivalent in the corner of the cap and the cylinder block.

(4) Slide the one-piece gasket over the dowels and

onto the block. (5) Position the oil pan over the dowels and onto

the gasket. (6) Install the oil pan bolts. Tighten the bolts to 23

N-m (200 in. lbs.) torque. Fig. 2 Position of Dowels in Cylinder

Block

(7) Remove the dowels. Install the remaining oil

pan bolts. Tighten these bolts to 23 N-m (200 in. lbs.) torque.

(8) Install the drain plug. Tighten drain plug to 34

N-m (27 ft. lbs.) torque.

(9) Install the engine to transmission strut.

(10) Install exhaust pipe.

(11) Lower vehicle.

(12) Install dipstick.

(13) Connect the negative cable to the battery. (14) Fill crankcase with oil to proper level.

OIL

PU1P

REMOVAL (1) Remove the oil pan. (2) Remove the oil pump from rear main bearing

cap.

DISASSEMBLE (1) Remove the relief valve as follows: (a) Remove cotter pin. Drill a 3.175 mm (1/8

inch) hole into the relief valve retainer cap and in

sert a self-threading sheet metal screw into cap. (b) Clamp screw into a vise and while supporting

oil pump, remove cap by tapping pump body using a soft hammer. Discard retainer cap and remove

spring and relief valve (Fig. 3).

(2) Remove oil pump cover (Fig. 4).

(3) Remove pump outer rotor and inner rotor with

shaft (Fig. 4). (4) Wash all parts in a suitable solvent and inspect

carefully for damage or wear.

Page 640 of 1502

OIL PUMP

ASSEMBLY

SPRING

RELIEF VALVE

• RETAINER

CAP

COTTER

PIN

RH174

Fig.

3 Oil

Pressure

Relief

Valve

INNER ROTOR AND SHAFT DISTRIBUTOR DRIVESHAFT

mm

(REFERENCE)

COTTER

PIN

RELIEF VALVE

LARGE

CHAMFERED

EDGE

SPRING

RETAINER

CAP

RY10B

Fig.

4 Oil

Pump

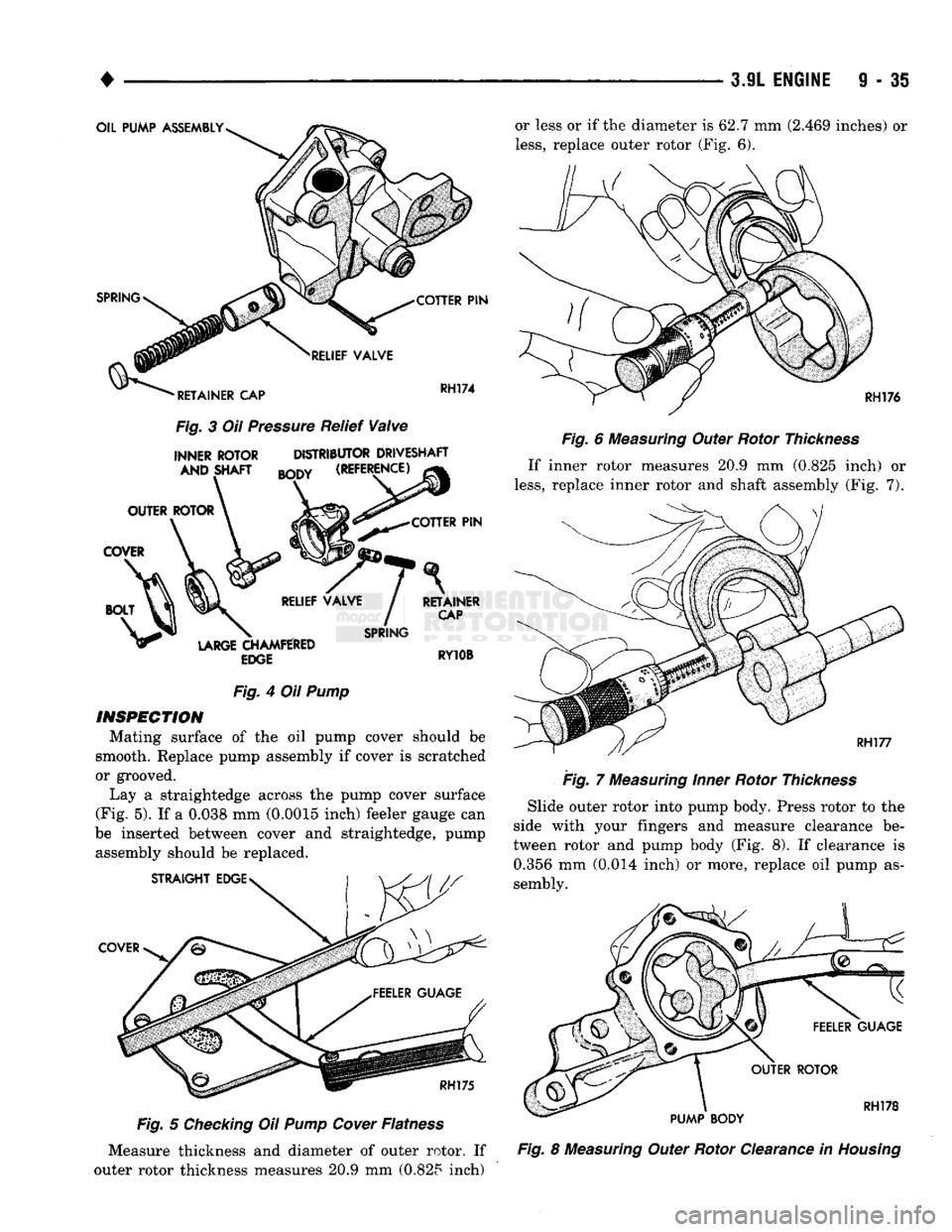

INSPECTION

Mating surface of the oil pump cover should be

smooth. Replace pump assembly if cover is scratched

or grooved.

Lay a straightedge across the pump cover surface

(Fig. 5). If a 0.038 mm (0.0015 inch) feeler gauge can

be inserted between cover and straightedge, pump assembly should be replaced.

STRAIGHT EDGE>

COVER

RH175

Fig.

5

Checking

Oil

Pump

Cover

Flatness Measure thickness and diameter of outer rotor. If

outer rotor thickness measures 20.9 mm (0.825 inch) or less or if the diameter is 62.7 mm (2.469 inches) or

less,

replace outer rotor (Fig. 6).

RH176

Fig.

6

Measuring

Outer Rotor

Thickness

If inner rotor measures 20.9 mm (0.825 inch) or

less,

replace inner rotor and shaft assembly (Fig. 7).

RH177

. Fig. 7

Measuring

Inner

Rotor

Thickness

Slide outer rotor into pump body. Press rotor to the

side with your fingers and measure clearance be

tween rotor and pump body (Fig. 8). If clearance is 0.356 mm (0.014 inch) or more, replace oil pump as

sembly.

FEELER

GUAGE

OUTER ROTOR

RH178

PUMP BODY

Fig.

8

Measuring

Outer Rotor Clearance in

Housing