fuel DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 4 of 1502

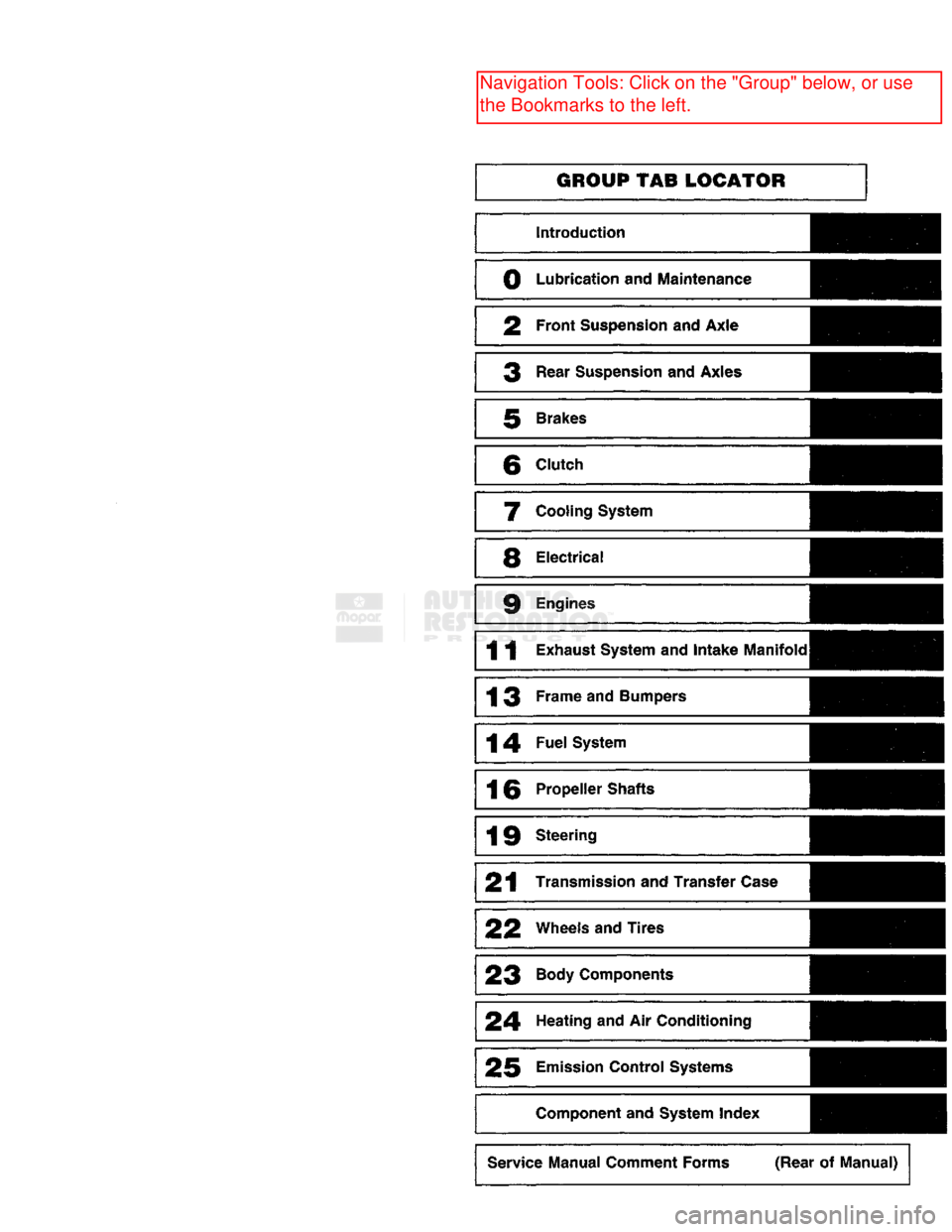

GROUP TAB LOCATOR

Introduction

0

Lubrication

and

Maintenance

2

Front Suspension

and

Axle

3

Rear Suspension

and

Axles

5

Brakes

6

Clutch

7

Cooling System

8

Electrical

9

Engines

11

Exhaust System

and

Intake

Manifold

13

Frame

and Bumpers

14

Fuel

System

16

Propeller Shafts

19

Steering

21

Transmission

and

Transfer Case

22

Wheels and Tires

23

Body Components

24

Heating

and Air

Conditioning

25

Emission Control Systems Component and System Index

Service Manual Comment Forms (Rear

of

Manual)

Page 15 of 1502

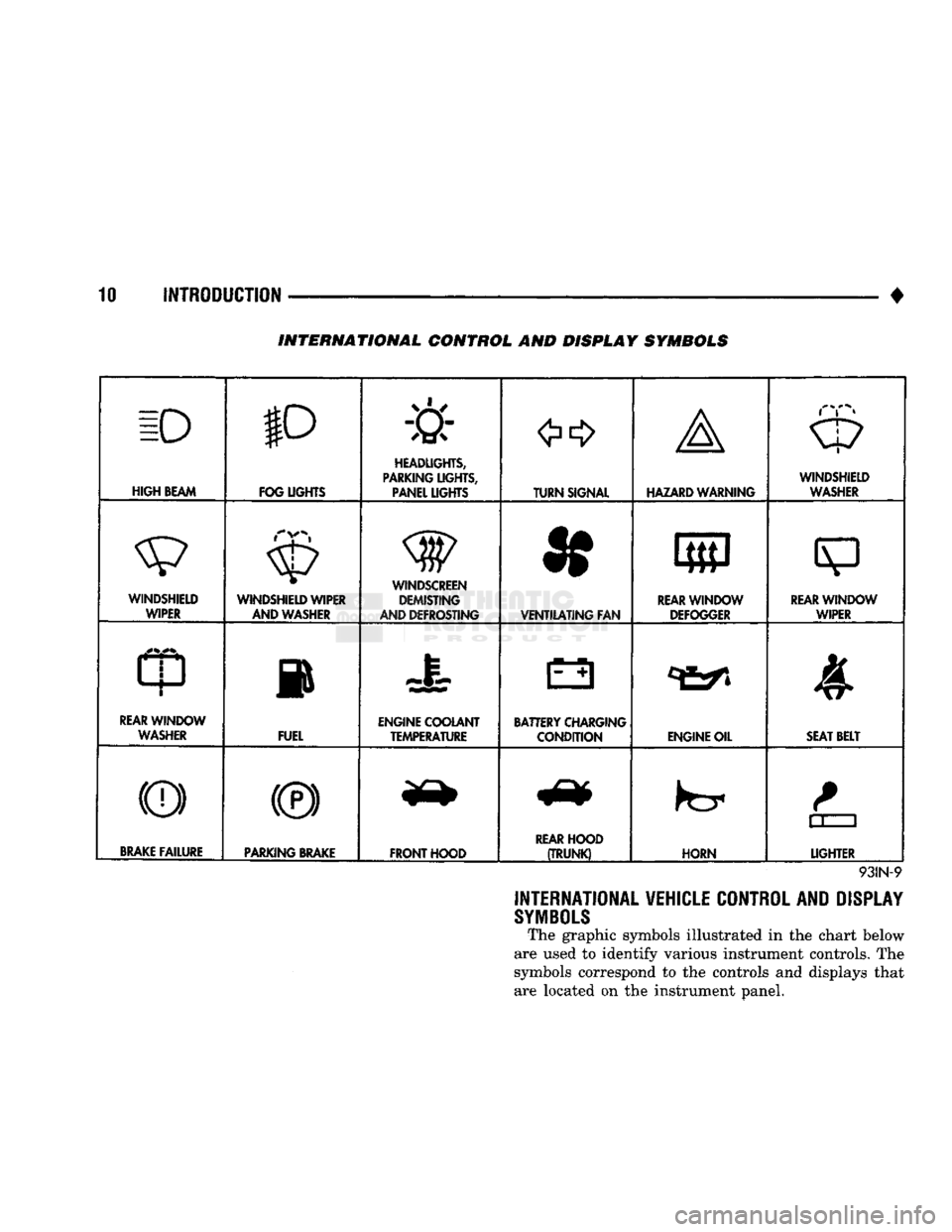

10 INTRODUCTION

•

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

ID

HIGH

BEAM P

FOG UGHTS -&

HEADLIGHTS,

PARKING UGHTS, PANEL UGHTS TURN SIGNAL A

HAZARD WARNING WINDSHIELD

WASHER

WINDSHIELD WIPER WINDSHIELD WIPER

AND WASHER

AND DEFROSTING *

VENTILATING

FAN 8

M f

REAR

WINDOW DEFOGGER

sp

REARWINLX)W WIPER

CD

l

m

REAR

WINDOW WASHER FUEL ENGINE COOLANT

TEMPERATURE BATTERY CHARGING

CONDITION ENGINE OIL

SEAT

BELT

(©) (®) ky

11 J

LIGHTER

BRAKE

FAILURE

PARKING

BRAKE

FRONT HOOD

REAR

HOOD

(TRUNK)

HORN

11 J

LIGHTER

93IN-9

INTERNATIONAL VEHICLE CONTROL AND DISPLAY

SYMBOLS

The graphic symbols illustrated in the chart below

are used to identify various instrument controls. The

symbols correspond to the controls and displays that are located on the instrument panel.

Page 20 of 1502

•

• —

LUiRICATlON

AND

MAINTENANCE

0 - 1

CONTENTS

page

page

CHASSIS

AND

BODY

28

ENGINE MAINTENANCE

14

DRIVETRAIN

.,,, 22

GENERAL INFORMATION

1

GENERAL

INFORMATION INDEl

page

Classification

of

Lubricants

. 3

Components

Requiring

No

Lubrication

4

Fuel Requirements

. 2

Introduction

1

Lubrication

and

Replacement Parts Recommendation

3

page

Routine Maintenance

2

Starting

Assistance (Jump Starting)

9

Vehicle

Lifting

Recommendations

............ 10

Vehicle Noise

Control

2

Vehicle Towing Recommendations

11

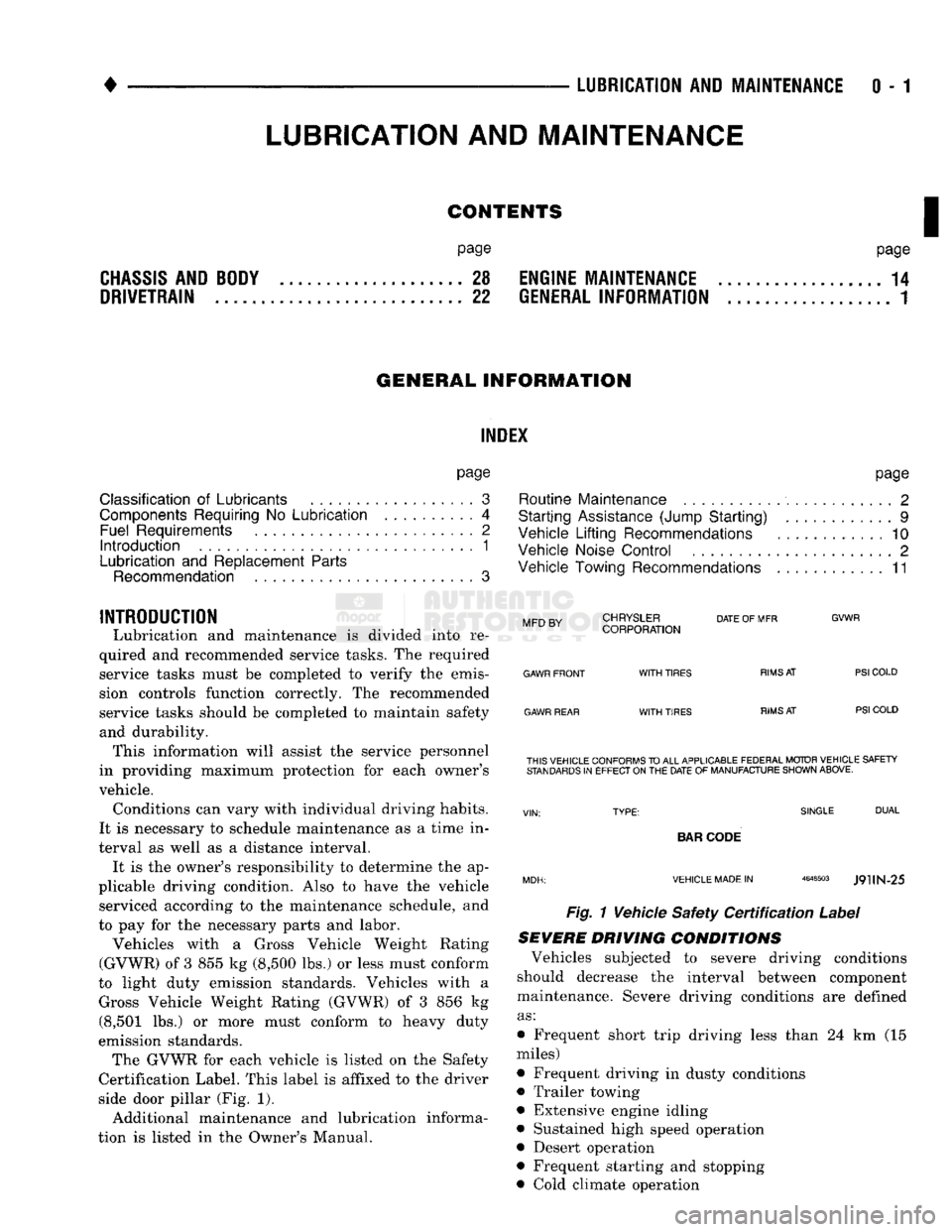

INTRODUCTION

Lubrication and maintenance is divided into re

quired and recommended service tasks. The required service tasks must be completed to verify the emis

sion controls function correctly. The recommended

service tasks should be completed to maintain safety

and durability. This information will assist the service personnel

in providing maximum protection for each owner's

vehicle. Conditions can vary with individual driving habits.

It is necessary to schedule maintenance as a time in

terval as well as a distance interval. It is the owner's responsibility to determine the ap

plicable driving condition. Also to have the vehicle serviced according to the maintenance schedule, and

to pay for the necessary parts and labor. Vehicles with a Gross Vehicle Weight Rating

(GVWR) of 3 855 kg (8,500 lbs.) or less must conform

to light duty emission standards. Vehicles with a Gross Vehicle Weight Rating (GVWR) of 3 856 kg

(8,501 lbs.) or more must conform to heavy duty

emission standards. The GVWR for each vehicle is listed on the Safety

Certification Label. This label is affixed to the driver

side door pillar (Fig. 1).

Additional maintenance and lubrication informa

tion is listed in the Owner's Manual.

Mm

rv

CHRYSLER

DATE

OF MFR

MFD BY CORPORATION

GVWR

GAWR FRONT

GAWR REAR

WITH

TIRES

WITH

TIRES

RIMS

AT

RIMS

AT

PSI

COLD

PSI

COLD THIS VEHICLE CONFORMS

TO

ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFETY

STANDARDS

IN

EFFECT ON

THE

DATE

OF

MANUFACTURE SHOWN ABOVE.

SINGLE

DUAL

BAR

CODE

VEHICLE MADE

IN

4648503

J9UN-25

Fig. 1 Vehicle Safety

Certification

Label

SEVERE DRIVING

CONDITIONS

Vehicles subjected to severe driving conditions

should decrease the interval between component

maintenance. Severe driving conditions are defined

as:

• Frequent short trip driving less than 24 km (15

miles)

• Frequent driving in dusty conditions

• Trailer towing

• Extensive engine idling

• Sustained high speed operation

• Desert operation

• Frequent starting and stopping

• Cold climate operation

LUBRICATION

AND

MAINTENANCE

Page 21 of 1502

0 - 2

LUBRICATION

AND

MAINTENANCE

• Commercial service

When a vehicle is continuously subjected to severe

driving conditions, lubricate:

• Body components

• All the driveline coupling joints

• Steering linkage More often than normal driving conditions

DUSTY

AREAS

With this type of severe driving condition, special

care should be given to the:

• Engine air cleaner filter

• PCV filter

• Crankcase ventilation system

• Brake booster control valve air filter. Verify that the filters and the associated compo

nents are clean. Also verify that they are functioning

effectively. This will minimize the amount of abra sive particles that enter the engine.

OFF-ROAD

(4WD)

OPERATION

After off-road (4WD) operation, inspect the under

side of the vehicle. Inspect the:

• Tires

• Body structure

• Steering components

• Suspension components • Exhaust system

• Threaded fasteners

HARSH

SURFACE ENVIRONMENTS

After extended operation in harsh environments,

the brake drums, brake linings, and rear wheel bear ings should be inspected and cleaned. This will pre

vent wear and erratic brake action.

ROUTINE MAINTENANCE

The following routine maintenance is recommended

on a monthly basis: TIRES—Inspect the tires for unusual wear/damage.

Determine if the inflation pressure is adequate for

the vehicle load. BATTERY—Inspect and clean the terminals.

Tighten the terminals if necessary. FLUIDS—Determine if the component fluid levels

are acceptable. Add fluid, if necessary. LIGHTS/ELECTRICAL—Test all the electrical sys

tems in the vehicle for proper operation. It is also recommended that the engine oil and the

washer fluid level be determined at each fuel fill-up.

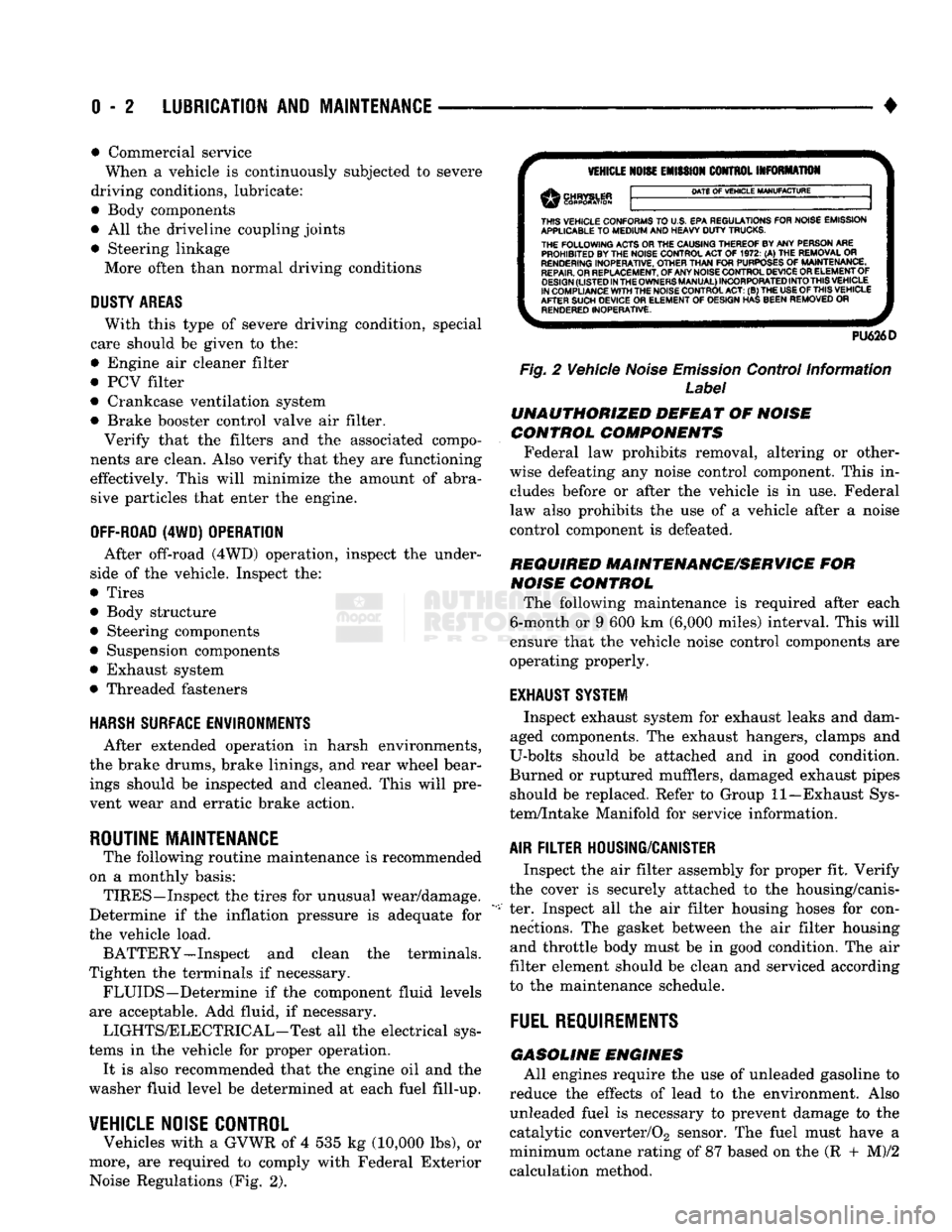

VEHICLE

NOISE CONTROL

Vehicles with a GVWR of 4 535 kg (10,000 lbs), or

more, are required to comply with Federal Exterior Noise Regulations (Fig. 2).

VEHICLE

NOISE

EMISSION

CONTROL INFORMATION

DATE

OF

VEHICLE

MANUFACTURE

THIS

VEHICLE CONFORMS

TO

U.S. EPA REGULATIONS FOR NOISE EMISSION

APPLICABLE

TO

MEDIUM

AND HEAVY

DUTY

TRUCKS. THE

FOLLOWING

ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE PROHIBITED BY THE NOISE CONTROL ACT

OF 1972. (A) THE

REMOVAL

OR

RENDERING

INOPERATIVE, OTHER

THAN

FOR

PURPOSES

OF

MAINTENANCE,

REPAIR.

OR REPLACEMENT, OF ANY NOISE CONTROL DEVICE OR ELEMENT OF

DESIGN

(LISTED

IN

THE

OWNERS

MANUAL)

INCORPORATED

INTO

THIS

VEHICLE

IN COMPLIANCE

WITH

THE NOISE CONTROL

ACT:

(B) THE

USE

OF

THIS

VEHICLE

AFTER SUCH DEVICE

OR

ELEMENT

OF

DESIGN HAS BEEN REMOVED

OR

RENDERED

INOPERATIVE.

PU626D

Fig.

2 Vehicle

Noise

Emission

Control Information

Label

UNAUTHORIZED

DEFEAT

OF

NOISE

CONTROL COMPONENTS

Federal law prohibits removal, altering or other

wise defeating any noise control component. This in

cludes before or after the vehicle is in use. Federal

law also prohibits the use of a vehicle after a noise

control component is defeated.

REQUIRED MAINTENANCE/SERVICE

FOR

NOISE

CONTROL

The following maintenance is required after each

6-month or 9 600 km (6,000 miles) interval. This will

ensure that the vehicle noise control components are

operating properly.

EXHAUST SYSTEM

Inspect exhaust system for exhaust leaks and dam

aged components. The exhaust hangers, clamps and

U-bolts should be attached and in good condition.

Burned or ruptured mufflers, damaged exhaust pipes should be replaced. Refer to Group 11—Exhaust Sys

tem/Intake Manifold for service information.

AIR

FILTER

HOUSING/CANISTER

Inspect the air filter assembly for proper fit. Verify

the cover is securely attached to the housing/canis

ter. Inspect all the air filter housing hoses for con nections. The gasket between the air filter housing and throttle body must be in good condition. The air

filter element should be clean and serviced according

to the maintenance schedule.

FUEL

REQUIREMENTS

GASOLINE

ENGINES

All engines require the use of unleaded gasoline to

reduce the effects of lead to the environment. Also unleaded fuel is necessary to prevent damage to the

catalytic converter/02 sensor. The fuel must have a

minimum octane rating of 87 based on the (R + M)/2

calculation method.

Page 22 of 1502

•

LUBRICATION AND MAINTENANCE

0 - 3

CAUTION: UNLEADED FUEL ONLY must

be

used

in

vehicles equipped

with

a

catalyst emission

control

system.

All

vehicles have reminders

printed

on the

instrument

panel below

the

fuel

gauge

and on the

fuel

filler

door.

The

vehicles also have

fuel

filler

tubes

that

are

specially designed

to

accept only

the

small-diameter nozzles.

It is

illegal

to

bypass

the

design

of an

unleaded

fuel

filler

tube.

DIESEL ENGINES All

Ram

Truck

and Ram

Cab/Chassis Diesel

en

gines normally

can use

number

2D

Diesel fuel

for

most year-round operations.

A

fuel conforming

to

ASTM Specification D-975

is

recommended.

For ex

treme cold-weather, number

ID

Diesel fuel

is

recom mended.

CLASSIFICATION

OF

LUBRICANTS

Lubricating fluids

and

chassis lubricants

are

clas

sified according

to

standards recommended

by the:

• Society

of

Automotive Engineers

(SAE)

• American Petroleum Institute

(API)

• National Lubricating Grease Institute (NLGI)

ENGINE

OIL

SAE

VISCOSITY

GRADE

An

SAE

viscosity grade

is

used

to

specify

the

vis

cosity

of

engine

oil. SAE 30

specifies

a

single viscos

ity engine

oil.

Engine oils also have multiple viscosities. These

are specified with

a

dual

SAE

viscosity grade which

indicates

the

cold-to-hot temperature viscosity range (Fig.

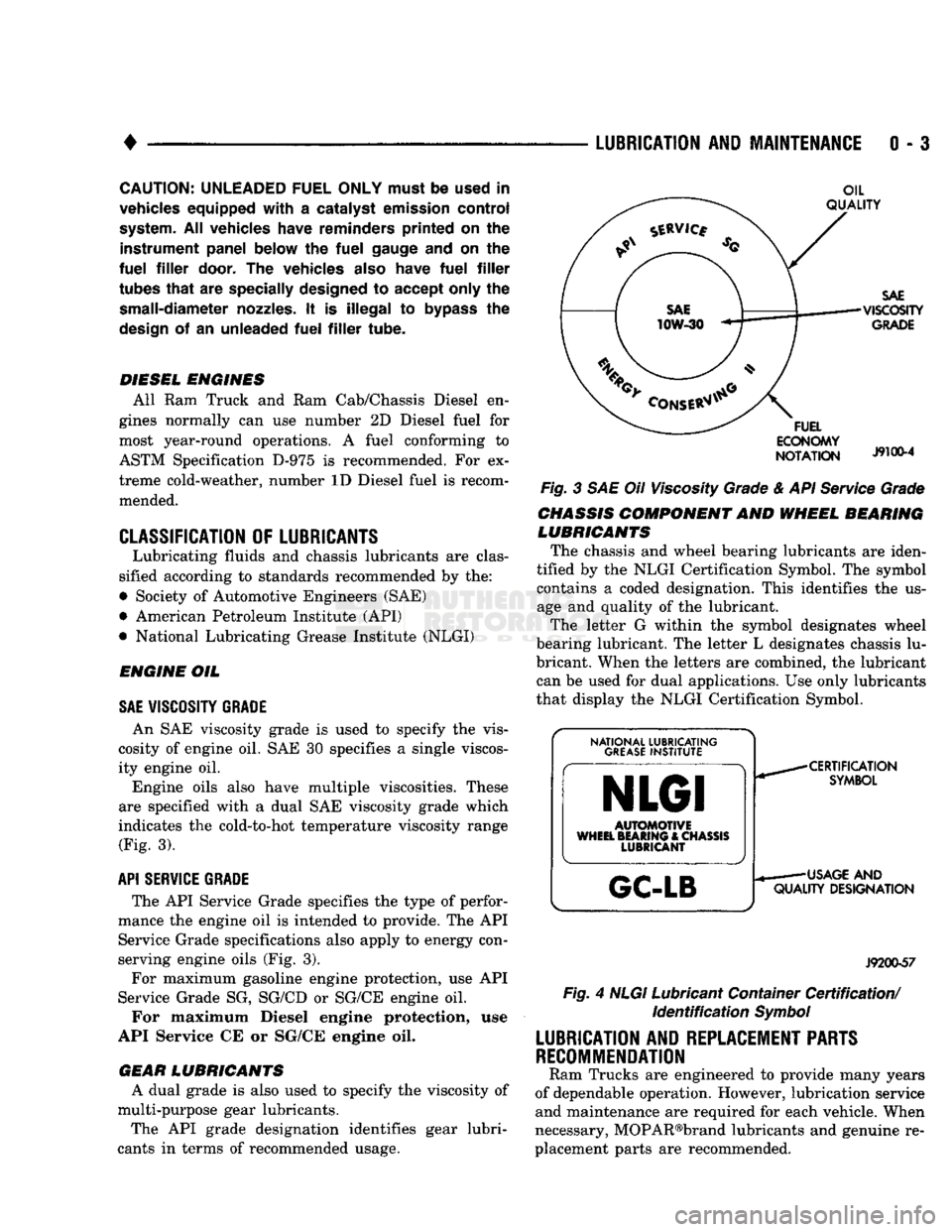

3).

API

SERVICE

GRADE

The

API

Service Grade specifies

the

type

of

perfor

mance

the

engine

oil is

intended

to

provide.

The API

Service Grade specifications also apply

to

energy con

serving engine oils

(Fig. 3).

For maximum gasoline engine protection,

use API

Service Grade

SG,

SG/CD

or

SG/CE engine

oil.

For maximum Diesel engine protection,

use

API Service

CE or

SG/CE engine

oil.

GEAR LUBRICANTS A dual grade

is

also used

to

specify

the

viscosity

of

multi-purpose gear lubricants.

The

API

grade designation identifies gear lubri

cants

in

terms

of

recommended usage.

OIL

QUALITY

SAE

VISCOSITY

GRADE

FUEL

ECONOMY

NOTATION

J91004

Fig.

3 SAE Oil

Viscosity Grade

& API

Service

Grade

CHASSIS COMPONENT

AND

WHEEL BEARING

LUBRICANTS The chassis

and

wheel bearing lubricants

are

iden

tified

by the

NLGI Certification Symbol.

The

symbol

contains

a

coded designation. This identifies

the us

age

and

quality

of the

lubricant.

The letter

G

within

the

symbol designates wheel

bearing lubricant.

The

letter

L

designates chassis

lu

bricant. When

the

letters

are

combined,

the

lubricant can

be

used

for

dual applications.

Use

only lubricants

that display

the

NLGI Certification Symbol.

NATIONAL LUBRICATING

GREASE

INSTITUTE

NLGI

AUTOMOTIVE

WHEEL BEARING

&

CHASSIS LUBRICANT

GC-LB

-CERTIFICATION

SYMBOL

—

USAGE

AND

QUALITY

DESIGNATION

J920W7

Fig.

4

NLGI

Lubricant Container

Certification/

Identification

Symbol

LUBRICATION

AND

REPLACEMENT

PARTS

RECOMMENDATION

Ram Trucks

are

engineered

to

provide many years

of dependable operation. However, lubrication service

and maintenance

are

required

for

each vehicle. When

necessary, MOPAR®brand lubricants

and

genuine

re

placement parts

are

recommended.

Page 25 of 1502

0 - 6

LUBRICATION

AND

MAINTENANCE

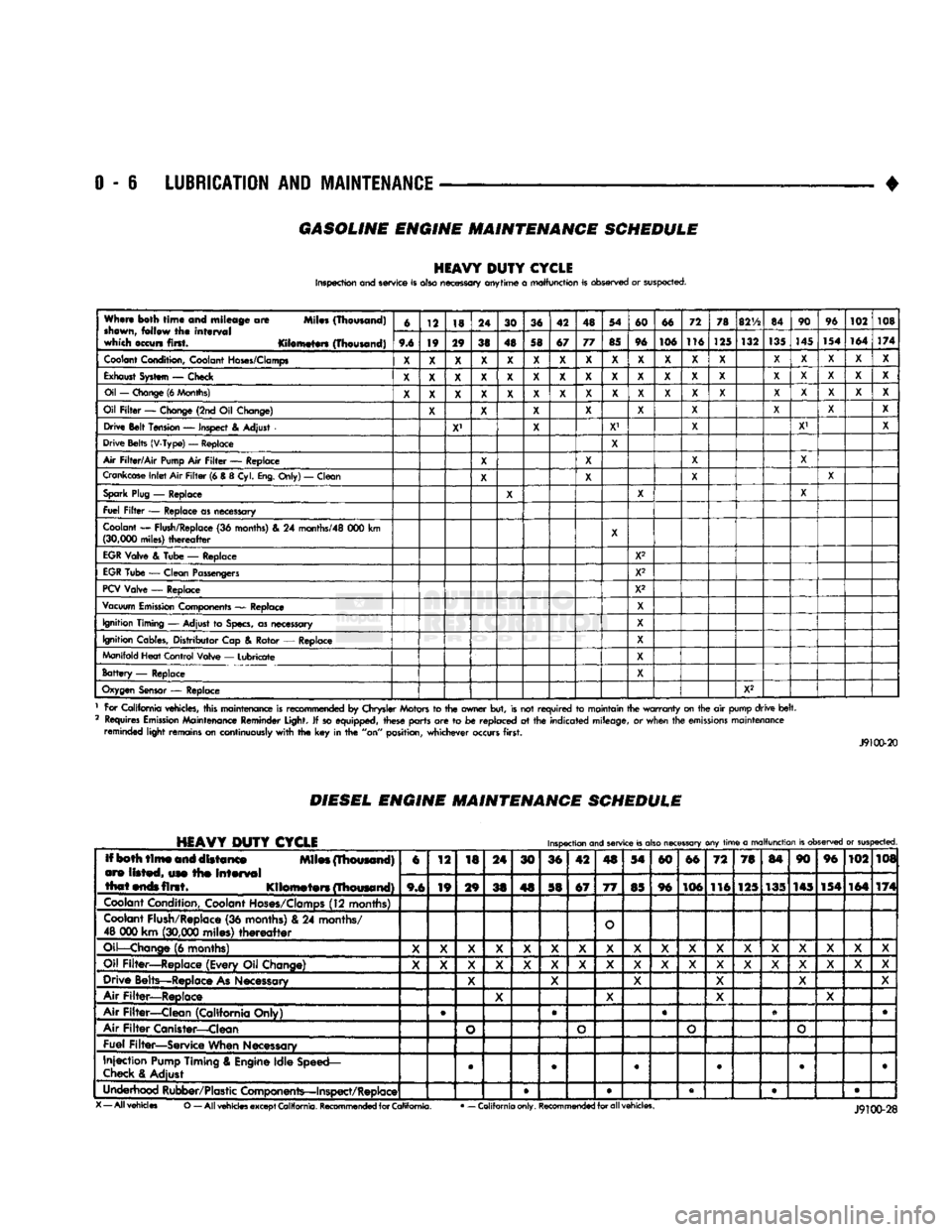

GASOLINE ENGINE MAINTENANCE SCHEDULE

HEAVY

DUTY

CYCLE

Inspection and service is also necessary anytime

a

malfunction is observed or suspected.

When both

time

and mileage

are

Miles (Thousand)

shewn,

follow

the

interval

which occurs first. Kilometers (Thousand) 6

12 18 24

30 36 42 48 54

60 66 72

78

82V2

84 90

96

102 108

When both

time

and mileage

are

Miles (Thousand)

shewn,

follow

the

interval

which occurs first. Kilometers (Thousand) 9.6 19 29

38 48 58 67 77

85 96 106 116

125 132

135

145

154 164

174

Coolant

Condition, Coolant

Hoses/Clamps

X

X X X

X X X X

X X X X

X X X

X X X

Exhaust

System

—

Check

X X X X X X X X X X X

X X X X X

X X

Oil

—

Change

(6

Months)

X X X X X X X

X X

X

X

X

X X X

X X

X

Oil

Filter

—

Change (2nd

Oil

Change)

X X X X

X X

X X

X

Drive Belt Tension

—

Inspect

&

Adjust

X' X

X1

X X' X

Drive Belts (V-Type)

—

Replace

X

Air

Filter/Air

Pump

Air

Filter

—

Replace

X X X

X

Crankcase

Inlet

Air

Filter

(6 &

8

Cyl.

Eng.

Only)

—

Clean

X X

X X

Spark

Plug

—

Replace

X X X

Fuel

Filter

—

Replace as necessary

Coolant

—

Flush/Replace

(36

months)

& 24

months/48

000 km

(30,000

miles)

thereafter

X

EGR

Valve

&

Tube

—

Replace X2

EGR

Tube

—

Clean Passengers

X2

PCV

Valve

—

Replace X2

Vacuum

Emission

Components

—

Replace

X

Ignition Timing

—

Adjust

to

Specs,

as necessary X

Ignition Cables, Distributor Cap

&

Rotor

—

Replace

X

Manifold Heat Control Valve

—

Lubricate

X

Battery

—

Replace X

Oxygen

Sensor

—

Replace

X2

1 For California vehicles, this maintenance is recommended

by

Chrysler Motors

to the

owner but, is not

required

to

maintain the

warranty

on the

air

pump drive

belt.

2 Requires

Emission

Maintenance Reminder Light.

If

so equipped, these parts

are to be

replaced

at the

indicated mileage,

or

when the

emissions

maintenance reminded light remains on continuously

with

the key in the

"on" position, whichever occurs first.

J9100-20

DIESEL

ENGINE

MAINTENANCE

SCHEDULE

HEAVY

DUTY

CYCLE

Inspection

and

service

is

also

necessary

any

time

a

malfunction

is

observed

or

suspected.

Iff both

time

and distance Miles (Thousand)

are listed, use the

interval

that

ends

first. Kilometers (Thousand) 6

12

18 24

30 36 42

4S

54

60 66

72 78

84 90 96

102 108

Iff both

time

and distance Miles (Thousand)

are listed, use the

interval

that

ends

first. Kilometers (Thousand) 9,6 19

29

38 48 58 67

77

85 96 106

116 125 135 145 154

164 174

Coolant

Condition, Coolant

Hoses/Clamps

(12 months)

Coolant

Flush/Replace (36 months) & 24 months/

48 000 km

(30,000

miles)

thereafter

O

Oil—Change

(6 months)

X X X

X X X

X X X X X

X X X X X X

X

Oil Filter—Replace (Every Oil Change)

X X X

X X X

X X

X X X

X

X X X X

X X

Drive Belts—Replace

As

Necessary

X X

X X X X

Air Filter—Replace

X X

X X

Air Filter—Clean (California Only) e

®

• •

Air

Filter

Canister—Clean

o o o

o

Fuel Filter—Service When Necessary

Injection

Pump

Timing & Engine Idle Speed—

Check

& Adjust

©

• 9 • • •

Underhood Rubber/Plastic Components—Inspect/Replace • • • • •

X

— All vehicles

O

— All

vehicles

except

California.

Recommended

for

California.

•

— California only.

Recommended

for all vehicles.

Page 28 of 1502

•

LUBRICATION AND MAINTENANCE

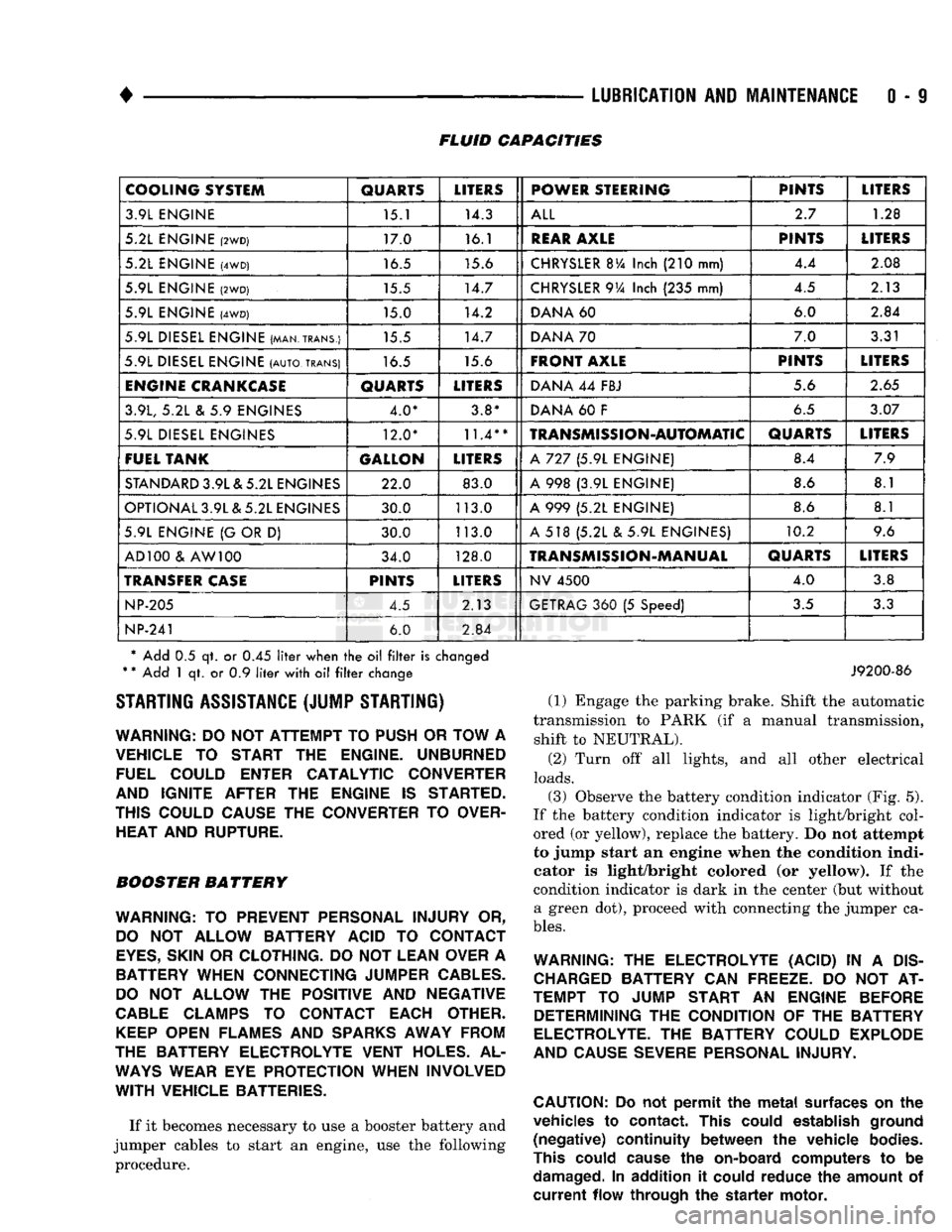

0 - 9 FLUID CAPACITIES

COOLING SYSTEM

QUARTS

LITERS

POWER STEERING PINTS

LITERS

3.9L ENGINE 15.1 14.3

ALL

2.7

1.28

5.2L ENGINE

(2WD)

17.0 16.1

REAR

AXLE

PINTS

LITERS

5.2L ENGINE

(4WD)

16.5 15.6

CHRYSLER

BVa

Inch

(210

mm) 4.4

2.08

5.9L ENGINE

(2WD)

15.5 14.7

CHRYSLER

9Va

Inch

(235

mm) 4.5

2.13

5.9L ENGINE

(4WD)

15.0 14.2

DANA

60 6.0

2.84

5.9L DIESEL ENGINE (MAN.TRANS.) 15.5 14.7

DANA

70 7.0

3.31

5.9L DIESEL ENGINE

(AUTO,

TRANS)

16.5 15.6

FRONT AXLE

PINTS

LITERS

ENGINE

CRANKCASE

QUARTS

LITERS

DANA

44

FBJ 5.6

2.65

3.9L,

5.2L & 5.9

ENGINES 4.0* 3.8*

DANA

60 F

6.5

3.07

5.9L DIESEL ENGINES 12.0*

11.4**

TRANSMISSION-AUTOMATIC

QUARTS

LITERS

FUEL TANK GALLON

LITERS

A

727 (5.9L

ENGINE) 8.4

7.9

STANDARD

3.9L & 5.2L ENGINES 22.0 83.0

A

998 (3.9L

ENGINE) 8.6

8.1

OPTIONAL 3.9L & 5.2L ENGINES 30.0 113.0

A

999 (5.2L

ENGINE) 8.6

8.1

5.9L ENGINE

{G

OR

D)

30.0 113.0

A

518 (5.2L & 5.9L

ENGINES) 10.2

9.6

AD 100

&

AW 100 34.0 128.0

TRANSMISSION-MANUAL

QUARTS

LITERS

TRANSFER

CASE

PINTS

LITERS

NV

4500

4.0

3.8

NP-205

4.5 2.13

GETRAG

360 (5

Speed)

3.5

3.3

NP-241

6.0

2.84

* Add

0.5 qt. or 0.45

liter

when

the oil filter

is

changed

*

*

Add

1 qt. or 0.9

liter

with

oil filter

change STARTING ASSISTANCE (JUMP STARTING)

WARNING:

DO NOT

ATTEMPT

TO

PUSH

OR

TOW

A

VEHICLE

TO

START

THE

ENGINE. UNBURNED FUEL COULD ENTER CATALYTIC CONVERTER

AND IGNITE AFTER

THE

ENGINE

IS

STARTED.

THIS COULD CAUSE

THE

CONVERTER

TO

OVER HEAT AND RUPTURE.

BOOSTER BATTERY

WARNING:

TO

PREVENT PERSONAL INJURY

OR,

DO

NOT

ALLOW BATTERY ACID

TO

CONTACT

EYES,

SKIN

OR

CLOTHING.

DO NOT

LEAN OVER

A

BATTERY WHEN CONNECTING JUMPER

CABLES.

DO

NOT

ALLOW

THE

POSITIVE

AND

NEGATIVE

CABLE

CLAMPS

TO

CONTACT EACH OTHER.

KEEP

OPEN FLAMES

AND

SPARKS

AWAY FROM

THE BATTERY ELECTROLYTE VENT HOLES.

AL

WAYS

WEAR

EYE

PROTECTION WHEN INVOLVED

WITH

VEHICLE BATTERIES.

If it becomes necessary to use a booster battery and

jumper cables to start an engine, use the following procedure.

J9200-86

(1) Engage the parking brake. Shift the automatic

transmission to PARK (if a manual transmission, shift to NEUTRAL).

(2) Turn off all lights, and all other electrical

loads.

(3)

Observe the battery condition indicator (Fig. 5).

If the battery condition indicator is light/bright col

ored (or yellow), replace the battery. Do not attempt

to jump start an engine when the condition indi

cator is light/bright colored (or yellow). If the

condition indicator is dark in the center (but without a green dot), proceed with connecting the jumper ca

bles.

WARNING:

THE

ELECTROLYTE (ACID)

IN A

DIS

CHARGED

BATTERY

CAN

FREEZE.

DO NOT AT

TEMPT

TO

JUMP START

AN

ENGINE BEFORE DETERMINING

THE

CONDITION

OF THE

BATTERY

ELECTROLYTE.

THE

BATTERY COULD EXPLODE

AND CAUSE SEVERE PERSONAL INJURY.

CAUTION:

Do not

permit

the

metal

surfaces

on the

vehicles

to

contact.

This

could

establish

ground

(negative)

continuity

between

the

vehicle

bodies.

This

could

cause

the

on-board

computers

to be

damaged.

In

addition

it

could

reduce

the

amount

of

current

flow

through

the

starter

motor.

Page 30 of 1502

LUBRICATION

AND

MAINTENANCE

0-11

J

DRIVE-ON

HOIST

I

FRAME

CONTACT

HOIST

TWIN

POST

CHASSIS

HOIST

FLOOR

JACK

RROOD30

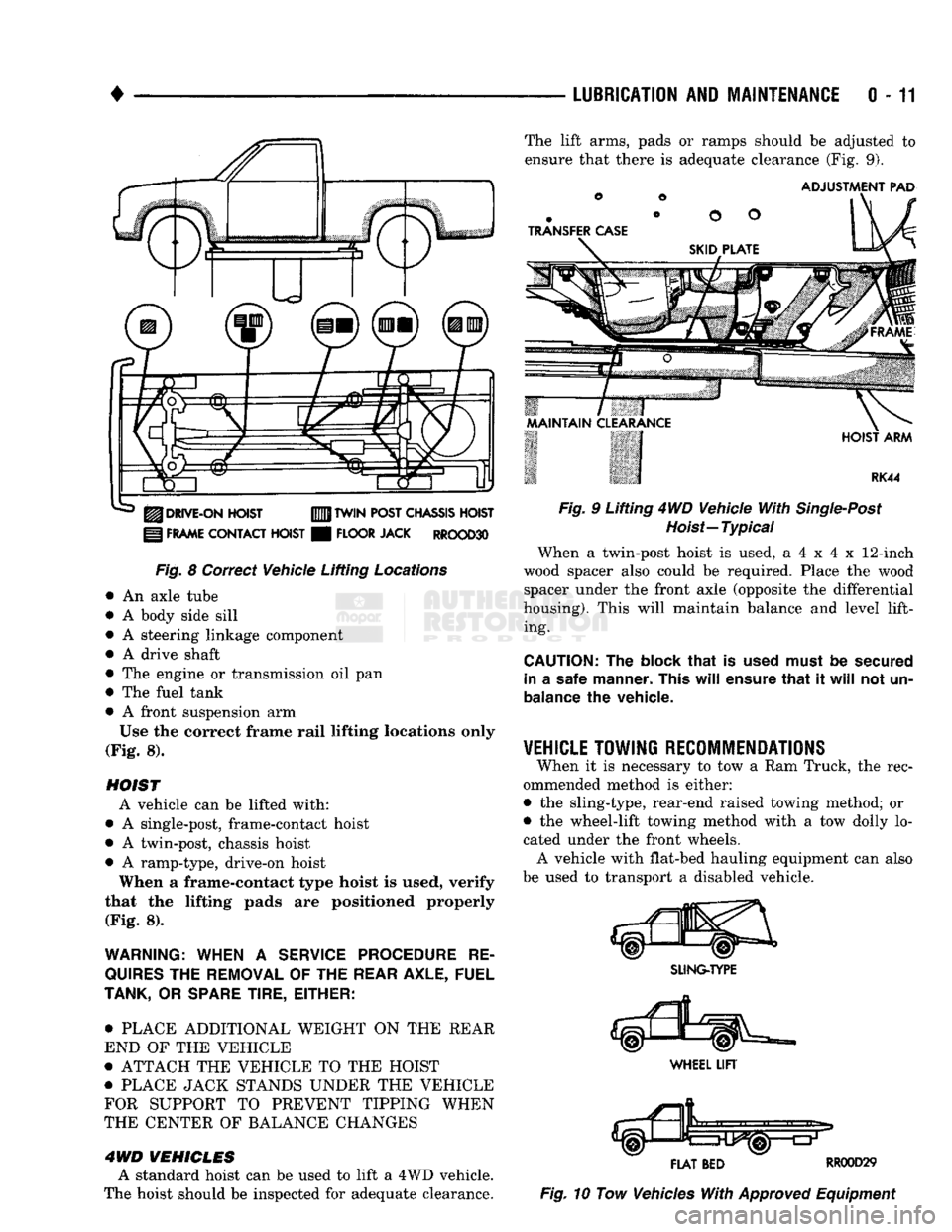

Fig.

8 Correct Vehicle Lifting

Locations

An axle tube

A body side sill

A steering linkage component

A drive shaft

The engine or transmission oil pan

The fuel tank

• A front suspension arm Use the correct frame rail lifting locations only

(Fig. 8).

HOIST A vehicle can be lifted with:

• A single-post, frame-contact hoist

• A twin-post, chassis hoist

• A ramp-type, drive-on hoist

When a frame-contact type hoist is used, verify

that the lifting pads are positioned properly (Fig. 8).

WARNING:

WHEN

A

SERVICE

PROCEDURE

RE

QUIRES

THE

REMOVAL

OF

THE

REAR

AXLE,

FUEL

TANK,

OR

SPARE

TIRE,

EITHER:

• PLACE ADDITIONAL WEIGHT ON THE REAR

END OF THE VEHICLE

« ATTACH THE VEHICLE TO THE HOIST

« PLACE JACK STANDS UNDER THE VEHICLE

FOR SUPPORT TO PREVENT TIPPING WHEN

THE CENTER OF BALANCE CHANGES

4WD VEHICLES A standard hoist can be used to lift a 4WD vehicle.

The hoist should be inspected for adequate clearance. The lift arms, pads or ramps should be adjusted to

ensure that there is adequate clearance (Fig. 9).

ADJUSTMENT

PAD

ii 7

MAINTAIN

CLEARANCE

HOIST

ARM

RK44

Fig.

9 Lifting 4WD Vehicle

With

Single-Post

Hoist—

Typical

When a twin-post hoist is used, a 4 x 4 x 12-inch

wood spacer also could be required. Place the wood spacer under the front axle (opposite the differential

housing). This will maintain balance and level lift ing.

CAUTION:

The

block

that

is

used must

be

secured in

a

safe manner. This

will

ensure

that

it

will

not un

balance

the

vehicle.

VEHICLE

TOWING

RECOMMENDATIONS

When it is necessary to tow a Ram Truck, the rec

ommended method is either:

• the sling-type, rear-end raised towing method; or

• the wheel-lift towing method with a tow dolly lo

cated under the front wheels. A vehicle with flat-bed hauling equipment can also

be used to transport a disabled vehicle.

SLING-TYPE

FLAT

BED

RR0OD29

Fig.

10 Tow Vehicles

With

Approved

Equipment

Page 31 of 1502

0 - 12

LUBRICATION

AND

MAINTENANCE

• A vehicle equipped with SAE approved sling-type

towing equipment can be used (Fig. 10). However,

many vehicles are equipped with air dams, spoilers, and/or ground effect panels. In this case a wheel-lift

towing vehicle or a flat-bed hauling vehicle is recom mended (Fig. 10). If a flat bed device is used, the ap

proach angle should not exceed 15 degrees.

GROUND CLEARANCE The lifted wheels of the disabled vehicle should be

a minimum of 10 cm (4 in.) off the ground. Make

sure there is enough clearance at the opposite end.

This is critical when towing over rough terrain. If necessary, the rear ground clearance can be increased by removing the wheels from the lifted end

and then towing with the lifted end closer to the

ground. If the rear wheels are removed, secure the

brake drums. A 20 cm (8 in.) ground clearance must

be maintained between brake drums or rotors and the ground.

SAFETY PRECAUTIONS The following safety precautions must be consid

ered when preparing for and during a vehicle towing operation:

• Remove exhaust pipe tips that interfere with the

tow sling and crossbar • Padding should be placed between the tow sling/

crossbar and any painted surfaces

• If the vehicle is damaged, secure the loose and pro

truding parts

• Always use a safety chain system that is indepen dent of the lifting and towing equipment

• When placing tow hooks on the rear axle, position them so they do not damage the brake tubing or

hoses

• Do not allow any of the towing equipment to con

tact the fuel tank

• Do not tow the vehicle by connecting to the front

or rear shock absorbers

• The operator should not go under a vehicle while

it is lifted by the towing equipment. The vehicle

should first be supported by safety stands

• Do not allow passengers in a vehicle being towed

• Observe all state and local laws involving warning signals, night illumination, speed, etc.

• Do not exceed a towing speed of 48 km/h (30 mph)

• Avoid towing distances of more than 24 km (15

miles) whenever possible • Do not attach tow chains or a tow sling to a

bumper, the steering linkage, the universal joints, or a drive shaft

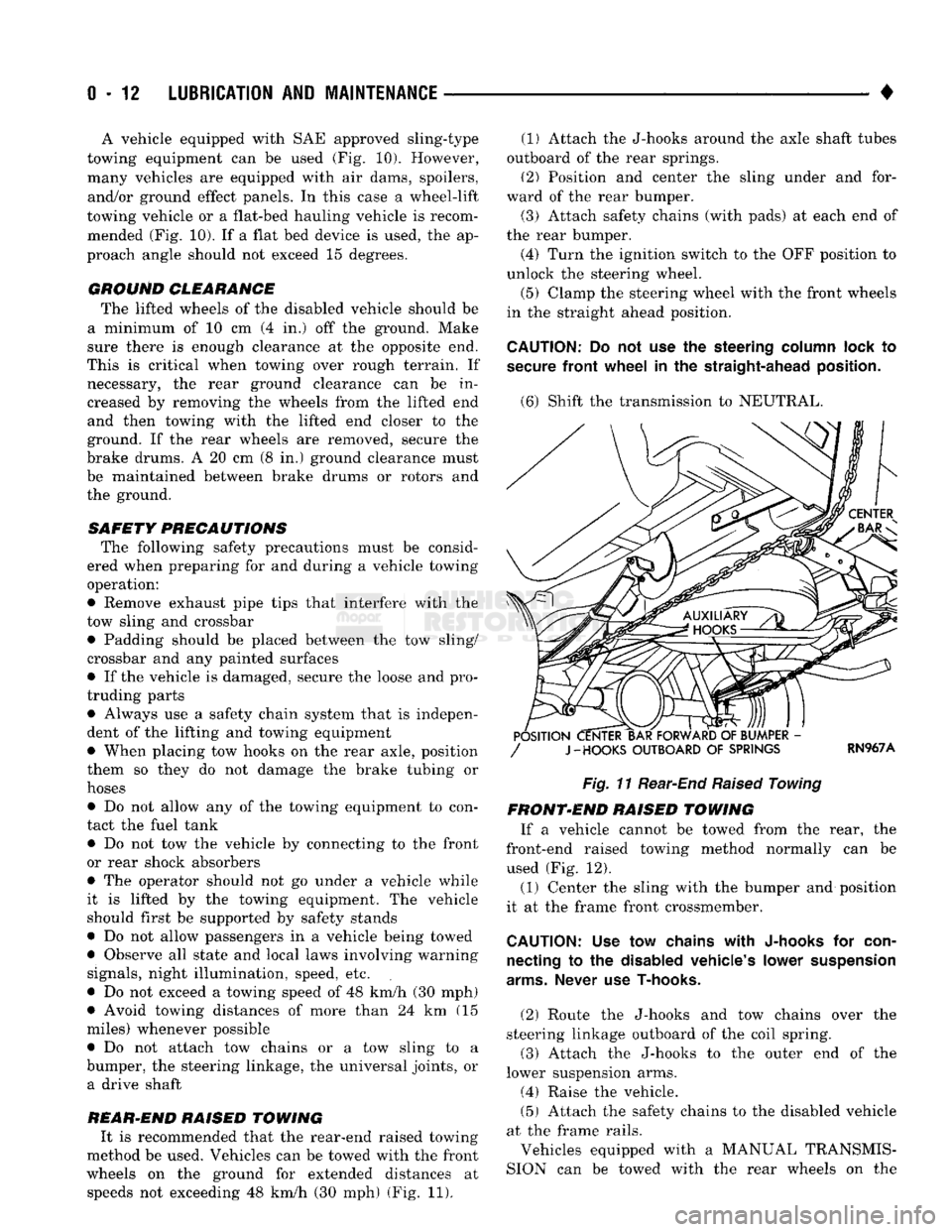

REAR-END RAISED TOWING It is recommended that the rear-end raised towing

method be used. Vehicles can be towed with the front

wheels on the ground for extended distances at speeds not exceeding 48 km/h (30 mph) (Fig. 11). (1) Attach the J-hooks around the axle shaft tubes

outboard of the rear springs. (2) Position and center the sling under and for

ward of the rear bumper. (3) Attach safety chains (with pads) at each end of

the rear bumper.

(4) Turn the ignition switch to the OFF position to

unlock the steering wheel. (5) Clamp the steering wheel with the front wheels

in the straight ahead position.

CAUTION:

Do not use the steering

column

lock

to

secure

front

wheel

in the straight-ahead

position.

(6) Shift the transmission to NEUTRAL.

POSITION CENTER BAR FORWARD

OF

BUMPER

-

/

J-HOOKS OUTBOARD

OF

SPRINGS

RN967A

Fig. 11 Rear-End

Raised

Towing

FRONT'END RAISED TOWING If a vehicle cannot be towed from the rear, the

front-end raised towing method normally can be

used (Fig. 12). (1) Center the sling with the bumper and position

it at the frame front crossmember.

CAUTION:

Use tow

chains

with

J-hooks

for

con

necting

to the

disabled

vehicle's

lower

suspension

arms.

Never use

T-hooks.

(2) Route the J-hooks and tow chains over the

steering linkage outboard of the coil spring.

(3) Attach the J-hooks to the outer end of the

lower suspension arms.

(4) Raise the vehicle.

(5.) Attach the safety chains to the disabled vehicle

at the frame rails.

Vehicles equipped with a MANUAL TRANSMIS

SION can be towed with the rear wheels on the

Page 33 of 1502

0 - 14

LUBRICATION

AND

MAINTENANCE

•

ENGINE

MAINTENANCE

INDEX

page

Air

Injection

Systems/Air Pump

. 17

Air-Conditioner

Compressor

21

Battery

19

Cooling System

15

Crankcase

Ventilation

System

17

Diesel Engine

Air Filter

Canister

17

Drive Belts

20

Engine

Air

Cleaner

Filter

Element

16

Engine Break-In

14

Engine

Oil 14

Engine

Oil

Change

and Filter

Replacement

15

Exhaust Gas

Recirculation

(EGR) System

...... 19

page

Exhaust

Manifold

Heat

Control

Valve

. 17

Exhaust System

, 21

Fuel System

18

Hoses

and

Fittings

16

Ignition

Cables,

Distributor

Cap and

Rotor

...... 19

Ignition

Timing

. 19

Oxygen

(02)

Sensor

19

Rubber/Plastic Components

20

Spark Plugs

. 19

Throttle

Control

Linkage

18

Vacuum Operated, Emission

Control

Components

19

ENGINE BREAK-IN

After first starting a new engine, allow it to idle

for 15 seconds before shifting into a drive gear. Also:

• Drive the vehicle at varying speeds less than 88

km/h (55 mph) for the first 480 km (300 miles).

• Avoid fast acceleration and sudden stops.

• Do not drive at full-throttle for extended periods of

time

• Do not drive at constant speeds

• Do not idle the engine excessively A special break-in engine oil is not required. The

original engine oil installed is a high quality lubri

cant. New engines tend to consume more fuel and oil un

til after the break-in period has ended.

ENGINE

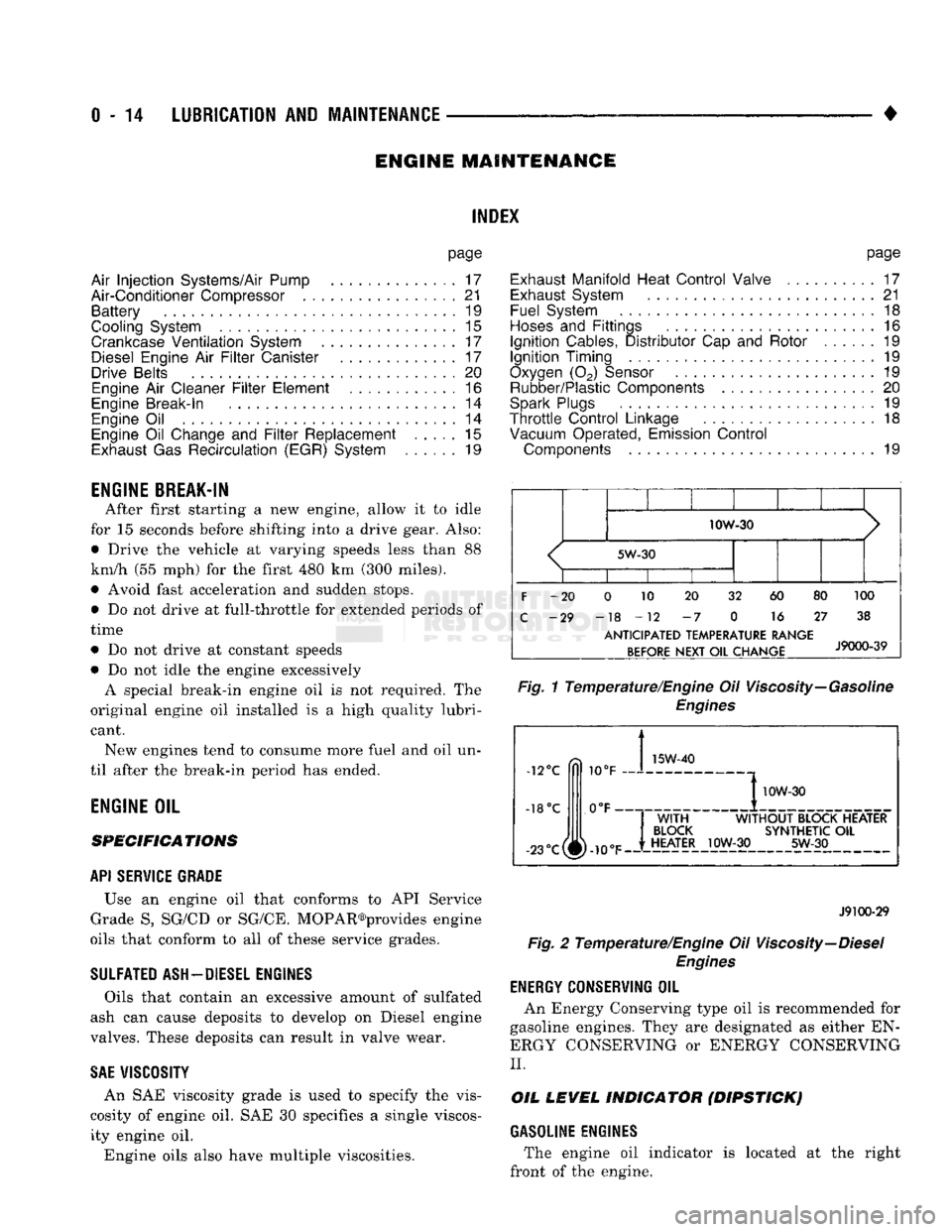

OIL SPECIFICATIONS

API SERWICE

GRADE

Use an engine oil that conforms to API Service

Grade S5 SG/CD or SG/CE. MOPAR®provides engine

oils that conform to all of these service grades.

SULFATED ASH—DIESEL ENGINES

Oils that contain an excessive amount of sulfated

ash can cause deposits to develop on Diesel engine

valves. These deposits can result in valve wear.

SAE

WISC0SITY

An SAE viscosity grade is used to specify the vis

cosity of engine oil. SAE 30 specifies a single viscos

ity engine oil.

Engine oils also have multiple viscosities. 10W-30

<

5W-30

1

1 1

F

-20 0 10 20 32 60 80 100

C

-29 -18 -12 -7 0 16 27 38

ANTICIPATED

TEMPERATURE RANGE BEFORE

NEXT

OIL

CHANGE

J9000-39

Fig.

1 Temperature/Engine Oil Viscosity—Gasoline

Engines

-12°C

-18°C 10°F

0°F- 15W-40

-23°c(^-10eF

I

10W-30

WITH

WITHOUT

BLOCK HEATER

BLOCK

SYNTHETIC

OIL

HEATER

10W-30 5W-30

J9100-29

Fig.

2 Temperature/Engine Oil Viscosity—Diesel

Engines

ENERGY

G0NSERWING

OIL

An Energy Conserving type oil is recommended for

gasoline engines. They are designated as either EN

ERGY CONSERVING or ENERGY CONSERVING

II.

OIL

LEVEL

INDICATOR (DIPSTICK)

GASOLINE ENGINES

The engine oil indicator is located at the right

front of the engine.