bulb DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 190 of 1502

•

BRAKES

i - 3 BRAKE DIAGNOSIS

INDEX

page

Brake

Warning Lights

3

Diagnosing

Brake Problems .................

4

Diagnosis

Procedures

3

Low

Vacuum

Switch—Diesel

Models

3

page

Master

Cylinder/Power Booster Test

5

Power

Booster

Check

Valve Test .............

6

Power

Booster

Vacuum

Test .................

6

Testing Diesel

Engine

Vacuum

Pump

Output

.... 6

DIAGNOSIS

PROCEDURES

Brake diagnosis involves determining

if the

prob

lem

is

related

to a

mechanical, hydraulic

or

vacuum

operated component.

A

preliminary check, road test

ing

and

component inspection

can all be

used

to de

termine

a

problem cause. Road testing will either verify proper brake opera

tion

or

confirm

the

existence

of a

problem. Compo nent inspection will,

in

most cases, identify

the

actual part causing

a

problem. The first diagnosis step

is the

preliminary check. This

involves inspecting fluid level, parking brake action,

wheel

and

tire condition, checking

for

obvious leaks

or

component damage

and

testing brake pedal response. A road test will confirm

the

existence

of a

problem.

Final diagnosis procedure involves road test analysis and

a

visual inspection

of

brake components.

BRAKE

WARNING LIGHTS

The

red

brake warning light

is

connected

to the

parking brake switch

and to the

pressure differential switch

in the

combination valve. The

red

light will illuminate when

the

parking

brakes

are

applied

or

when

a

fluid pressure drop

oc

curs

in the

front

or

rear brake circuit.

The

light will

also illuminate

for

approximately

2-4

seconds

at en

gine start

up.

This

is a

self test feature designed

to

check bulb

and

circuit operation each time

the en

gine

is

started. The amber antilock light

is

connected

to the

anti-

lock rear brake hydraulic valve.

The

light will illu

minate

if a

fault occurs within

the

antilock system.

LOW VACUUM SWITCH-DIESEL MODELS

On diesel models,

the red

brake warning light

is

also

used

to

alert

the

driver

of a low

brake booster vacuum

condition.

The

warning light

is in

circuit with

a

vacuum

warning switch mounted

on the

driver side fender

panel.

The

vacuum side

of the

switch

is

connected

to the

power brake booster.

The

electrical side

of the

switch

is

connected

to the

brake warning light. The

low

vacuum switch monitors booster vacuum

level whenever

the

engine

is

running.

If

booster vac

uum falls below

8.5

inches vacuum

for a

minimum

of

10 seconds,

the

switch completes

the

circuit

to the

warning light causing

it to

illuminate.

The

warning light

is

designed

to

differentiate between

a low

vac

uum condition

and a

hydraulic circuit fault.

PRELIMINARY

BRAKE CHECK

(1) Check condition

of

tires

and

wheels. Damaged

wheels

and

worn, damaged,

or

underinflated tires

can

cause pull, shudder, tramp,

and a

condition similar

to

grab.

(2)

If

complaint

was

based

on

noise when braking,

check suspension components. Jounce front

and

rear

of

vehicle

and

listen

for

noise that might

be

caused

by

loose, worn

or

damaged suspension

or

steering compo

nents.

(3) Inspect brake fluid level

and

condition. Note

that

the

front disc brake reservoir fluid level will drop

in

proportion

to

normal lining wear. Also note

that brake fluid tends

to

darken over time. This

is normal

and

should

not be

mistaken

for

con

tamination.

If the

fluid

is

still clear

and

free

of

foreign material,

it is OK.

(a)

If

fluid level

is

abnormally

low,

look

for

evi

dence

of

leaks

at

calipers, wheel cylinders, brake-

lines

and

master cylinder.

(b)

If

fluid appears contaminated, drain

out a

sample.

If

fluid

is

separated into layers,

or

obvi

ously contains

oil or a

substance other than brake

fluid,

the

system seals

and

cups will have

to be re

placed

and the

hydraulic system flushed.

(4) Check parking brake operation. Verify free

movement

and

full release

of

cables

and

pedal. Also

note

if

vehicle

was

being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does

not

bind

and has

adequate free play.

If

pedal

lacks free play, check pedal

and

power booster

for be

ing loose

or for

bind condition.

Do not

road test until

condition

is

corrected.

(6)

If

components checked appear

OK,

road test

the

vehicle.

ROAD

TESTING (1)

If

complaint involved

low

brake pedal, pump

the pedal

and

note

if the

pedal comes back

up to

nor mal height.

(2) Check brake pedal response with transmission

in Neutral

and

engine running. Pedal should remain

firm under steady foot pressure.

Page 200 of 1502

•

BRAKES

5 - 13

COMBINATION VALVE OPERATION

METERING (HOLD-OFF) VALVE The metering valve is used to balance brake action

between the front disc and rear drum brakes. The

valve meters (holds-off) full apply pressure to the front disc brakes until the rear brakeshoes are in full

contact with the drums.

The valve is designed to maintain front brake fluid

pressure at 3-30 psi until the hold-off limit of 117 psi is reached. At this point, the metering valve opens completely permitting full fluid apply pressure to the

front disc brakes.

PRESSURE DIFFERENTIAL SWITCH AND VALVE The pressure differential switch is connected to the

brake warning light. The switch is triggered by movement of the switch valve. The purpose of the switch is to monitor fluid pressure in the separate

front/rear brake hydraulic circuits.

A decrease or loss of fluid pressure in either hy

draulic circuit will cause the switch valve to shuttle

forward or rearward in response to a pressure differ ential.

Movement of the switch valve will push the switch

plunger upward. This closes the switch internal con tacts completing the electrical circuit to the warning light. The switch valve will remain in an actuated

position until repair restores system pressures to nor mal levels.

COMBINATION VALVE TESTING

TESTING METERING VALVE Metering valve operation can be checked visually

and with the aid of a helper.

Observe the metering valve stem while a helper

applies and releases the brakes. If the valve is oper

ating correctly, the stem will extend slightly when

the brakes are applied and retract when the brakes are released.

If the valve is faulty, replace the entire combina

tion valve as an assembly.

TESTING PRESSURE DIFFERENTIAL SWITCH (1) Have helper sit in drivers seat to observe brake

warning light and to operate brake pedal.

(2) Raise vehicle on hoist.

(3) Connect bleed hose to left or right rear wheel

cylinder. Then immerse hose end in glass jar par

tially filled with brake fluid.

(4) Have helper press and hold brake pedal all the

way down and observe warning light.

(a) If warning light illuminates, switch is operat

ing correctly. (b) If light fails to illuminate, check circuit fuse,

bulb and wiring. Repair as necessary and repeat test steps (3) and (4). (5) If warning light still fails to illuminate, check

brakelight and park brake switches (and wiring) with test lamp. Repair or replace parts as necessary and test differential pressure switch operation again.

(6) If warning light still does not illuminate,

switch is faulty. Replace combination valve, bleed

brakes and verify proper switch and valve operation.

COMBINATION VALVE REMOVAL/INSTALLATION

VALVE REMOVAL (1) Raise vehicle on hoist.

(2) Mark or tag brake lines connected to valve for

assembly reference.

(3) Disconnect lines at valve (Fig. 8).

(4) Disconnect wires from differential pressure

switch.

(5) Remove bolts attaching valve to frame bracket

and remove valve.

VALVE INSTALLATION (1) Mount new valve on bracket and tighten valve

and bracket screws/nuts securely.

(2) Connect brakelines to valve. Tighten fittings to

16 N*m (145 in. lbs.)

(3) Connect wires to pressure differential switch

terminal. (4) Bleed brakes.

(5) Lower vehicle and verify proper brake opera

tion.

BRAKE

LINES AND

HOSES

BRAKE LINE AND HOSE INSPECTION Flexible rubber hose is used at both front brakes

and at the rear axle junction block. Inspect the hoses

whenever the brake system is serviced, at every en gine oil change, or whenever the vehicle is in for ser

vice.

Inspect the hoses for surface cracking, scuffing, or

worn spots. Replace any brake hose immediately if

the fabric casing of the hose is exposed by cracks or abrasion.

Also check brake hose installation. Faulty installa

tion can result in kinked, twisted hoses, or contact with the wheels and tires or other chassis compo

nents.

All of these conditions can lead to scuffing,

cracking and eventual failure.

The steel brake lines should be inspected periodi

cally for evidence of corrosion, twists, kinks, leaks, or

other damage. Heavily corroded lines will eventually

rust through causing leaks. In any case, corroded or damaged brake lines should be replaced.

Page 325 of 1502

8A

- 4

ELECTRICAL

•

IGNITION

OFF

DRAW

(IOD)

Ignition off draw refers to power being drained

from the battery with the ignition turned off. A nor

mal vehicle electrical system will draw from 5 to 20

milliamps. A vehicle that has not been operated for

an extended period of time (approximately 20 days)

may discharge the battery to an inadequate level.

Battery drain should not exceed approximately 20

MA (20 milliamps = 0.020 amps). The 20 MA are needed to supply PCM memory,

digital clock memory, and ETR (electronically tuned

radio) memory. Excessive battery drain is caused by items left

turned on, internally shorted generator, or intermit

tent short in wiring.

If the IOD is excessive (over 20 milliamperes), the

defect must be found and corrected before replacing a

battery. In most cases the battery can be charged and returned to service.

TEST PROCEDURE Testing for higher amperage IOD must be per

formed first to prevent damage to most milliamp

meters.

Verify that all electrical accessories are OFF. Turn

off all lights, remove ignition key, and close all

doors.

If the vehicle is equipped with electronic acces

sories (illuminated entry, high line radio), allow the

systems to automatically shut off (time out), up to 3

minutes.

(1) After determining that the underhood lamp is

operating properly then disconnect bulb. (2) Disconnect negative cable from battery.

(3) Connect a typical 12 volt test light (low watt

age bulb) between the negative cable clamp and the

battery negative terminal. The test light may light brightly for up to 3 min

utes or may not light at all (depending on the elec

trical equipment). The term brightly being used

throughout the following tests, implies the bright ness of the test light will be the same as if it were

connected across the battery.

The test light must be securely clamped to the neg

ative cable and battery terminal. If the test light be

comes disconnected during any of the IOD test, the electronic timer function will be activated and all

tests must be repeated.

(4) After 3 minutes, the test light should turn OFF

or be DIMLY lit (depending on the electrical equip

ment).

If the test light remains brightly lit do not

disconnect it. Remove each fuse or circuit breaker (refer to Group 8 - Wiring Diagrams) until test light

is either OFF or DIMLY lit. This will eliminate the

higher amperage draw.

If test light is still bright after disconnecting each

fuse and circuit breaker, disconnect the wiring har ness from the generator. Refer to Generator Testing

in this group. Do not disconnect the test light. After higher amperage IOD has been corrected, low

amperage IOD may be checked.

It is now safe to install milliamp meter to check for

low amperage IOD.

(5) With test light still connected, securely clamp

an ammeter between battery negative terminal and

negative battery cable.

If the test light or the milliamp meter circuit is

broken the various timer circuits will start. Do

not open any doors or turn on any electrical ac cessories with the test light disconnected or the

meter may be damaged.

(6) Disconnect test light. The current draw should

not exceed 0.020 amp. If it exceeds 20 milliamps iso

late each circuit by removing circuit breakers and

fuses.

The meter reading drops once the high current

problem is found. Repair this section of the circuit,

whether it is a wiring short or component failure.

BATTERY

OPEN CIRCUIT VOLTAGE TEST

A battery voltage (no load) test will indicate the

state of charge of a battery that will pass the Battery

Load Test described in this section. Before proceed

ing with this test or the Battery Load Test the

battery must be completely charged as de scribed in Battery Charging in this section. If a battery has a no load voltage reading of 12.4

volts or greater but will not endure a load test, it is

defective and should be replaced. Refer to Group 8B,

Battery/Starter Service for instructions. To test bat

tery no load voltage, perform the following operation: (1) Before measuring open circuit voltage, the sur

face charge must be removed from plates. Turn head lights on for 15 seconds then allow up to 5 minutes

for voltage to stabilize. (2) Remove both battery cables, negative first.

(3) Using a voltmeter connected to the battery

posts,

see instructions provided with voltmeter, mea sure open circuit voltage (Fig. 6). This voltage reading will indicate state of charge,

but will not reveal cranking capacity. Refer to Bat

tery Open Circuit Voltage chart.

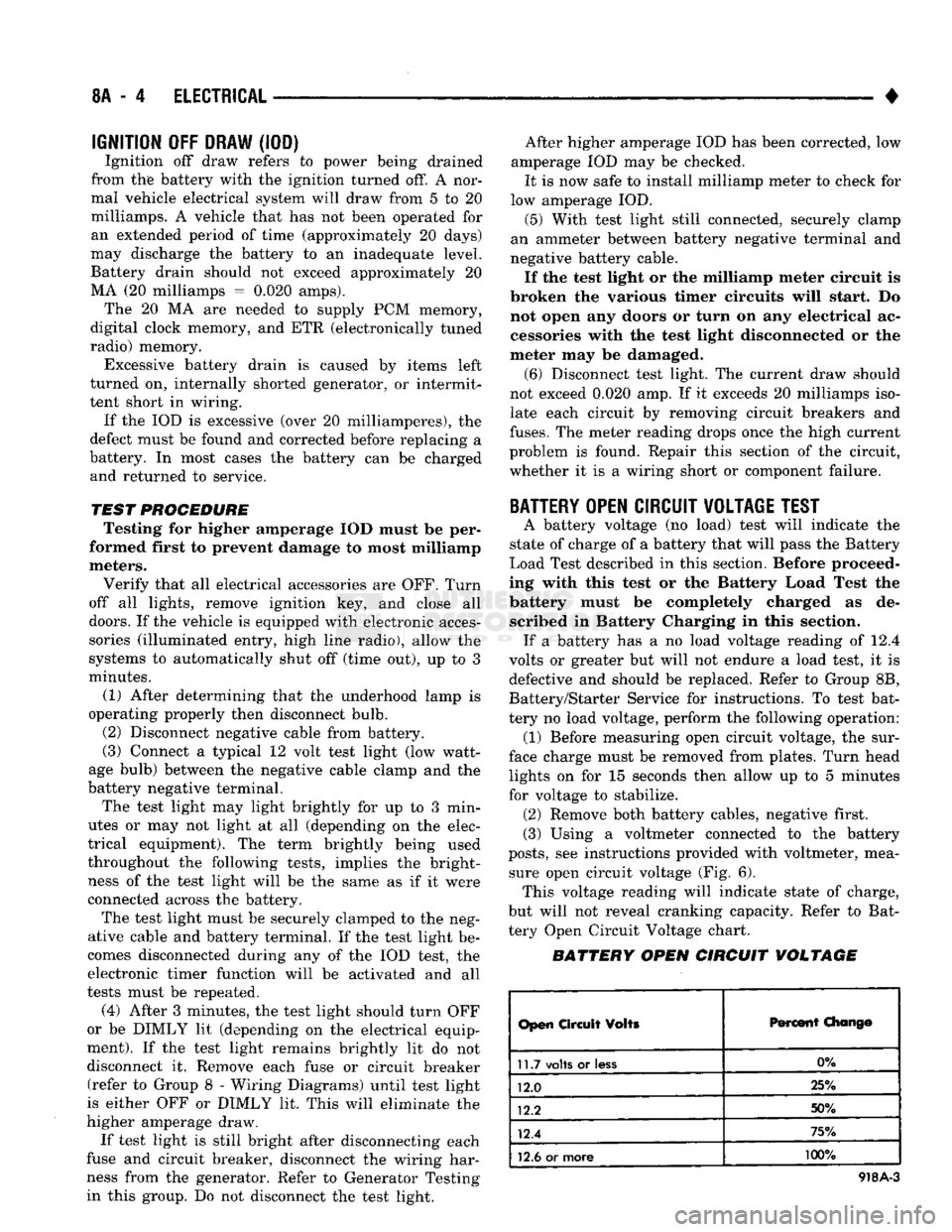

BATTERY OPEN CIRCUIT VOLTAGE

Open

Circuit

Volts

Percent

Chang©

11.7

volts

or

less

0%

12.0 25%

12.2 50%

12.4 75%

12.6

or more 100%

918A-3

Page 334 of 1502

•

ELECTRICAL

8A - 13 GENERATOR TEST PROCEDURES ON

VEHICLE

INDEX

page

Current

Output

Test

......................

14

Diagnostic Procedures

13

General

Information

13

Generator

Output

Wire Resistance Test

.......

13

page

How

to

Use

Malfunction

Indicator

(Check Engine) Lamp

for

Fault

Codes

17

Operational Check

with

Voltmeter

............

13

Using

On-Board Diagnostic System

15

GENERAL

INFORMATION

The generator

is

belt-driven

by the

engine.

All en

gines

use

serpentine drive. The amount

of DC

current produced

by the

gener

ator

is

controlled

by the

Powertrain Control Module (PCM).

All vehicles

are

equipped with

On

Board Diagnos

tics (OBD).

All OBD

sensing systems

are

monitored

by

the PCM. The PCM

will store

in

electronic mem ory

any

detectable failure within

the

monitored cir

cuits.

Refer

to

USING ON-BOARD DIAGNOSTIC SYSTEM

in

this group

for

more information.

OPERATIONAL CHECK

WITH

VOLTMETER

When

the

ignition switch

is

turned

to the RUN po

sition, battery potential will register

on the

voltme

ter. During engine cranking

a

lower voltage will appear

on the

meter. With

the

engine running,

a

voltage reading higher than

the

first reading (igni

tion

in RUN)

should register.

DIAGNOSTIC PROCEDURES

If

the

indicator does

not

operate properly,

or if an

undercharged

or

overcharged battery condition

oc

curs,

the

following procedures

may be

used

to

diag

nose

the

charging system. Remember that

an

undercharged battery

is

often

caused

by:

• accessories being left

on

overnight

•

or by a

defective switch which allows

a

bulb, such

as a

trunk

or

glove

box

light,

to

stay

on

(refer

to

Ignition

Off

Draw).

WISUAL

INSPECTION

• Inspect condition

of

battery cable terminals, bat

tery posts, connections

at

engine block, starter motor solenoid

and

relay. They should

be

clean

and

tight.

Repair

as

required.

• Inspect

all

fuses

in the

fuse block

for

tightness

in

receptacles. They should

be

properly installed

and

tight. Repair

or

replace

as

required.

• Inspect generator mounting bolts

for

tightness.

Re

place

or

torque bolt

as

required (refer

to

Torque Specifications).

• Inspect generator drive belt condition

and

tension.

Tension

or

replace belt

as

required. Refer

to

Belt

Tension Specifications. • Inspect connection

at

generator

B+

output.

It

should

be

clean

and

tight. Repair

as

required.

GENERATOR

OUTPUT

WIRE RESISTANCE TEST

(FIG.

1)

Generator output wire resistance test will show

amount

of

voltage drop across generator output wire

between generator

BAT

terminal

and

battery posi tive post.

PREPARATION

(1) Before starting test make sure vehicle

has a

fully charged battery. Test

and

procedures

on how to

check

for a

fully charged battery

are

shown

in

Bat

tery section

of

this Group.

(2) Turn

OFF

ignition switch.

(3)

Disconnect negative cable from battery.

(4)

Disconnect generator output wire from genera

tor output Battery terminal. (5) Connect

a 0-150

ampere scale

D.C.

ammeter

in

series between generator

BAT

terminal

and

discon

nected generator output wire. Connect Positive lead

to generator

BAT

terminal

and

Negative lead

to

dis connected generator output wire. (6) Connect Positive lead

of a

test voltmeter

(Range

0-18

volts minimum)

to

disconnected genera

tor output wire. Connect negative lead

of

test voltme

ter

to

battery positive cable

at

positive post. (7) Connect

one end of a

Jumper Wire

to

ground

and with other

end

probe green

K20

lead wire

at

back

of

generator

(Fig. 1).

(This will generate

a

fault

code).

CAUTION:

Do not

connect blue

A142

lead

of

wiring

to ground. Refer

to

Group

8W

-

Wiring Diagrams

for

more information.

(8) Connect

an

engine tachometer

and

connect neg

ative cable

to

battery.

(9) Connect

a

variable carbon pile rheostat

be

tween battery terminals.

Be

sure carbon pile

is in

"Open"

or "Off

position before connecting leads.

See

Battery Section, Load Testing

for

instructions.

TEST

(1) Start engine. Immediately after starting,

re

duce engine speed

to

idle.

Page 387 of 1502

8E

- 6

INSTRUMENT PANEL

AND

GAUGES

•

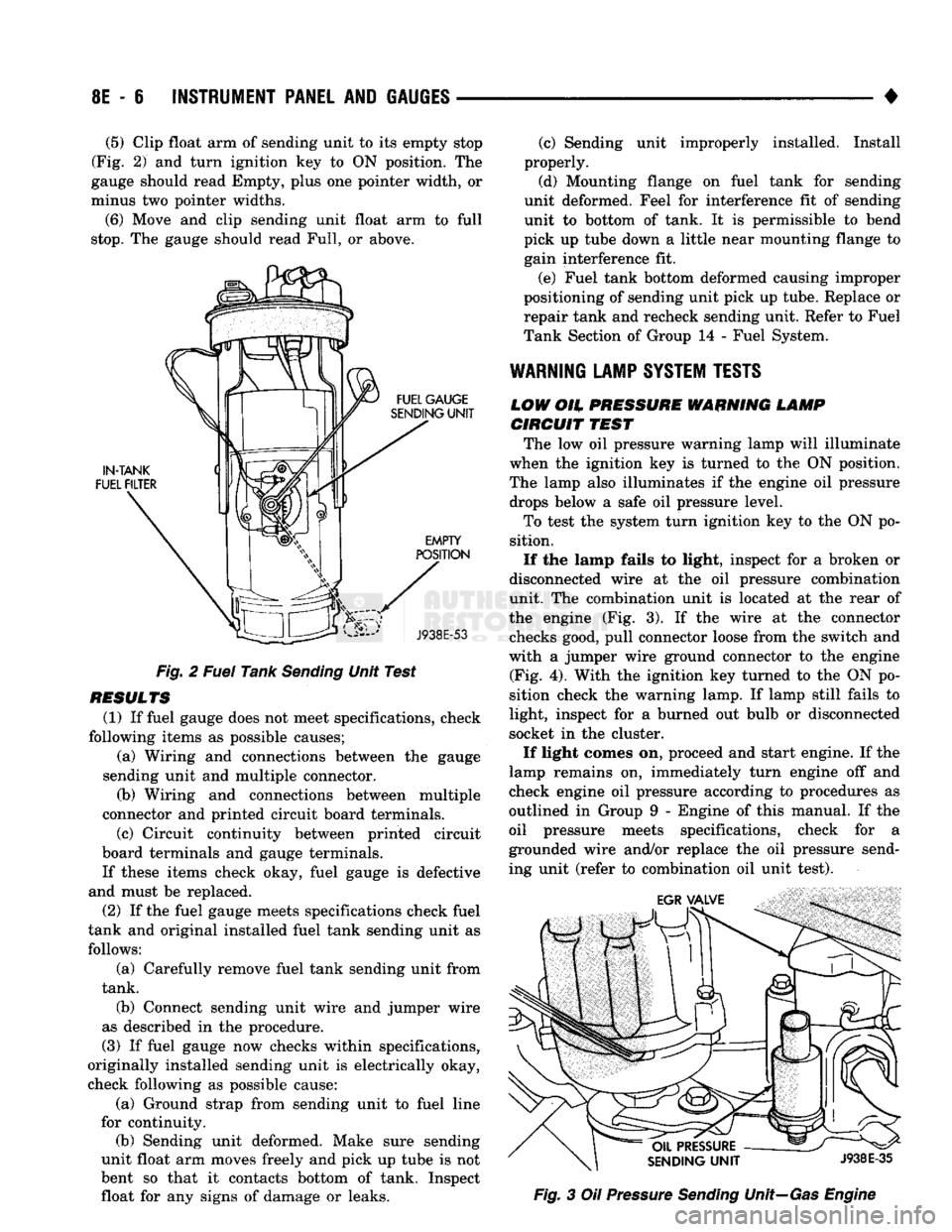

(5)

Clip float arm of sending unit to its empty stop

(Fig. 2) and turn ignition key to ON position. The

gauge should read Empty, plus one pointer width, or

minus two pointer widths.

(6) Move and clip sending unit float arm to full

stop.

The gauge should read Full, or above.

Fig. 2 Fuel Tank Sending Unit Test

RESULTS (1) If fuel gauge does not meet specifications, check

following items as possible causes; (a) Wiring and connections between the gauge

sending unit and multiple connector. (b) Wiring and connections between multiple

connector and printed circuit board terminals.

(c) Circuit continuity between printed circuit

board terminals and gauge terminals.

If these items check okay, fuel gauge is defective

and must be replaced.

(2) If the fuel gauge meets specifications check fuel

tank and original installed fuel tank sending unit as follows:

(a) Carefully remove fuel tank sending unit from

tank.

(b) Connect sending unit wire and jumper wire

as described in the procedure.

(3) If fuel gauge now checks within specifications,

originally installed sending unit is electrically okay,

check following as possible cause:

(a) Ground strap from sending unit to fuel line

for continuity. (b) Sending unit deformed. Make sure sending

unit float arm moves freely and pick up tube is not

bent so that it contacts bottom of tank. Inspect float for any signs of damage or leaks. (c) Sending unit improperly installed. Install

properly.

(d) Mounting flange on fuel tank for sending

unit deformed. Feel for interference fit of sending

unit to bottom of tank. It is permissible to bend

pick up tube down a little near mounting flange to gain interference fit.

(e) Fuel tank bottom deformed causing improper

positioning of sending unit pick up tube. Replace or

repair tank and recheck sending unit. Refer to Fuel

Tank Section of Group 14 - Fuel System.

WARNING

LAMP

SYSTEM

TESTS

LOW

OH.

PRESSURE WARNING LAMP CIRCUIT

TEST

The low oil pressure warning lamp will illuminate

when the ignition key is turned to the ON position.

The lamp also illuminates if the engine oil pressure drops below a safe oil pressure level.

To test the system turn ignition key to the ON po

sition.

If the lamp fails to light, inspect for a broken or

disconnected wire at the oil pressure combination

unit. The combination unit is located at the rear of

the engine (Fig. 3). If the wire at the connector checks good, pull connector loose from the switch and

with a jumper wire ground connector to the engine (Fig. 4). With the ignition key turned to the ON po

sition check the warning lamp. If lamp still fails to

light, inspect for a burned out bulb or disconnected

socket in the cluster.

If light comes on, proceed and start engine. If the

lamp remains on, immediately turn engine off and

check engine oil pressure according to procedures as

outlined in Group 9 - Engine of this manual. If the

oil pressure meets specifications, check for a

grounded wire and/or replace the oil pressure send

ing unit (refer to combination oil unit test). Fig. 3 Oil Pressure Sending Unit—Gas Engine

Page 388 of 1502

•

INSTRUMENT

PANEL

AND

GAUGES

8E - 7

STEERING PUMP

ENGINE

BLOCK

J9U9-74

Fig.

4 Oil

Pressure

Sending

Unit—Diesel

Engine

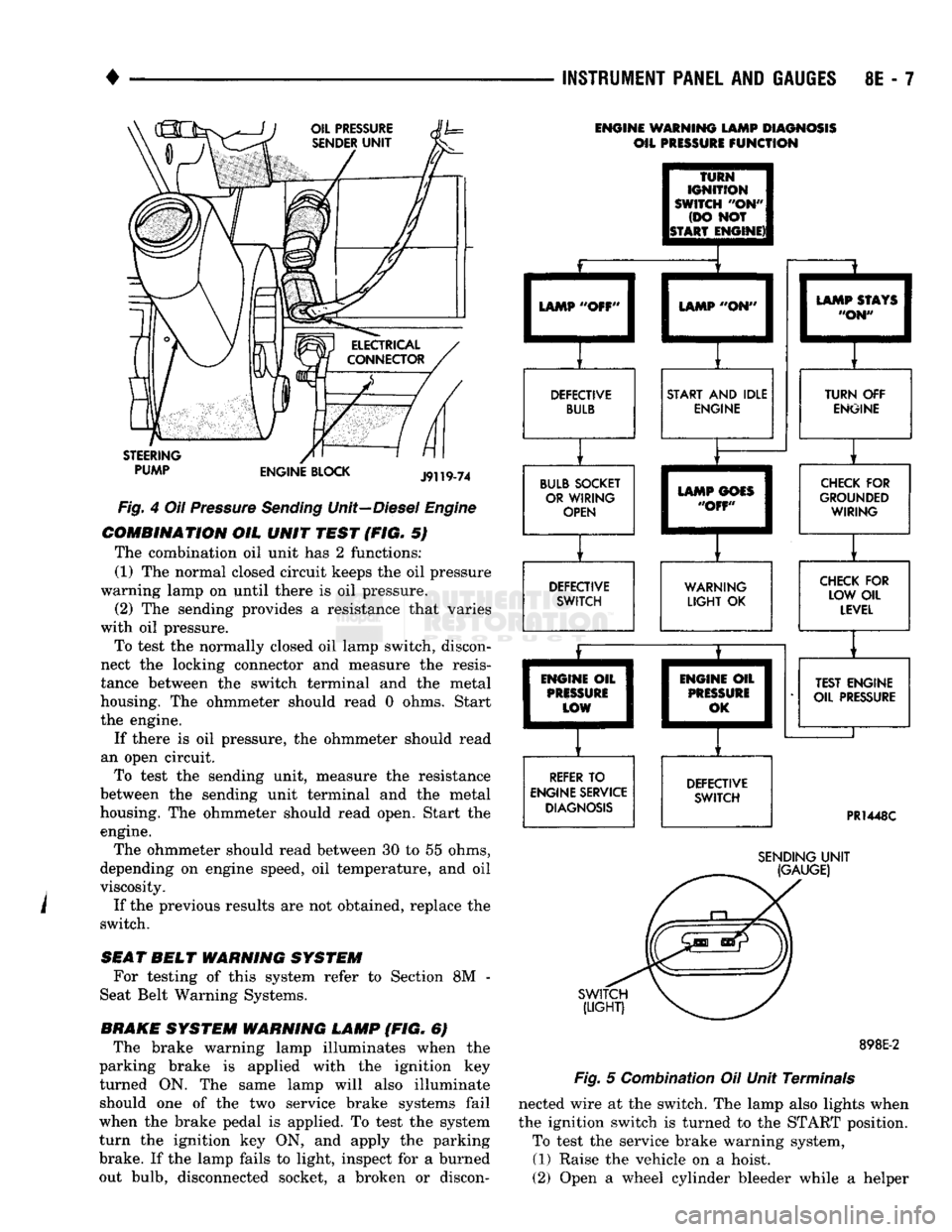

COMBINATION

OIL

UNIT

TEST

(FIG. 5)

The combination oil unit has 2 functions:

(1) The normal closed circuit keeps the oil pressure

warning lamp on until there is oil pressure. (2) The sending provides a resistance that varies

with oil pressure.

To test the normally closed oil lamp switch, discon

nect the locking connector and measure the resis

tance between the switch terminal and the metal

housing. The ohmmeter should read 0 ohms. Start

the engine.

If there is oil pressure, the ohmmeter should read

an open circuit. To test the sending unit, measure the resistance

between the sending unit terminal and the metal

housing. The ohmmeter should read open, Start the engine.

The ohmmeter should read between 30 to 55 ohms,

depending on engine speed, oil temperature, and oil

viscosity.

If the previous results are not obtained, replace the

switch.

SEAT

BELT

WARNING

SYSTEM

For testing of this system refer to Section 8M -

Seat Belt Warning Systems.

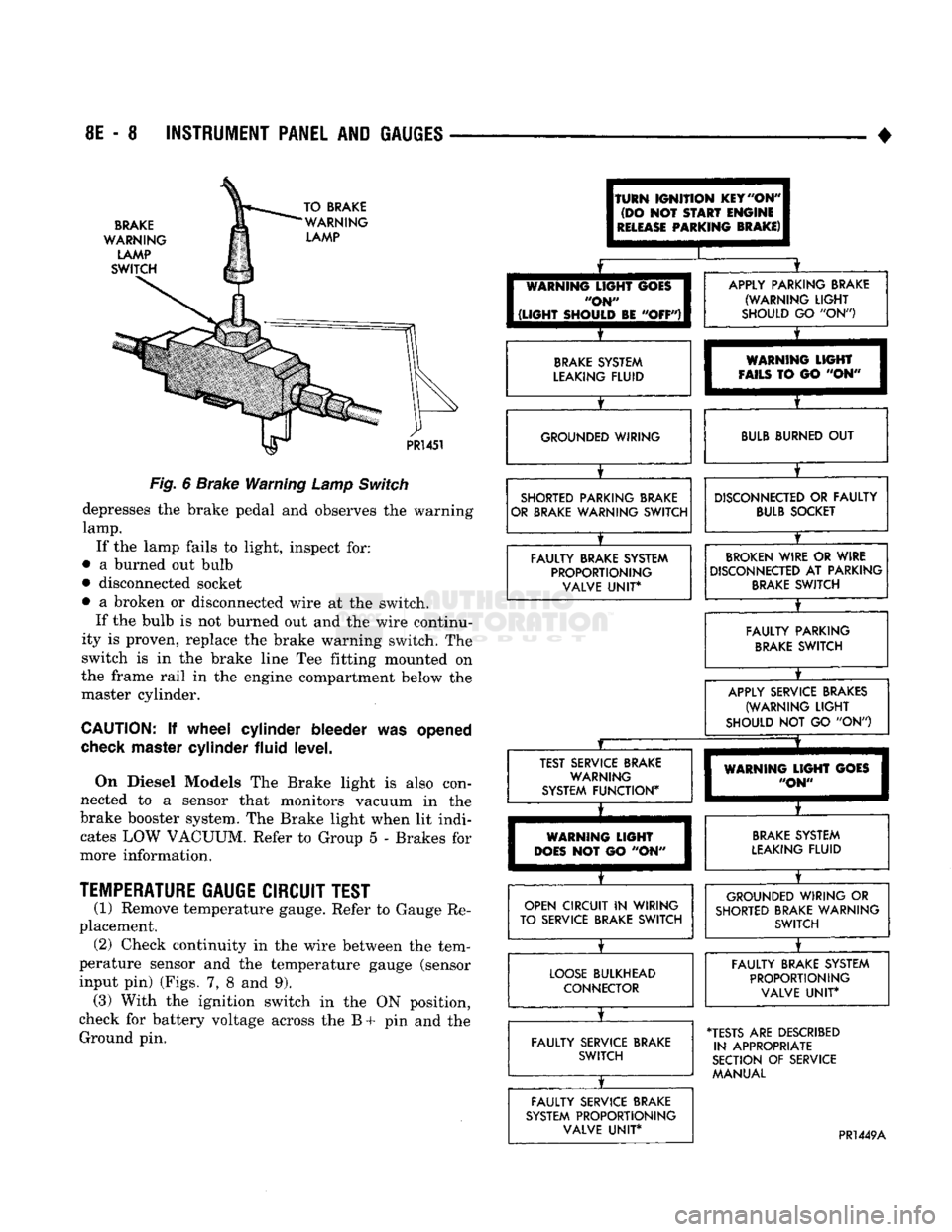

BRAKE

SYSTEM

WARNING

LAMP

(FIG. 6) The brake warning lamp illuminates when the

parking brake is applied with the ignition key

turned ON. The same lamp will also illuminate should one of the two service brake systems fail

when the brake pedal is applied. To test the system

turn the ignition key ON, and apply the parking

brake. If the lamp fails to light, inspect for a burned

out bulb, disconnected socket, a broken or discon-

ENGINE WARNING LAMP DIAGNOSIS

OIL PRESSURE

FUNCTION

TURN

IGNITION

SWITCH

"OH"

(DO NOT

ISTART ENGINE)! LAMP "OFF'

LAMP "ON"

DEFECTIVE BULB START AND IDLE

ENGINE

BULB SOCKET OR WIRING OPEN LAMP STAYS

"ON" TURN OFF

ENGINE LAMP GOES

"OFF" DEFECTIVE

SWITCH CHECK FOR

GROUNDED WIRING

WARNING

LIGHT

OK CHECK FOR

LOW OIL LEVEL

ENGINE OIL

PRISSURi

LOW

REFER TO

ENGINE SERVICE DIAGNOSIS ENGIM

PRES

0

IE OIL

1

SURE

1

,K I

DEFECTIVE SWITCH TEST ENGINE

OIL PRESSURE

PR1448C

SWITCH

(LIGHT)

SENDING

UNIT

(GAUGE)

898E-2

Fig.

5 Combination Oil Unit Terminals

nected wire at the switch. The lamp also lights when

the ignition switch is turned to the START position. To test the service brake warning system,

(1) Raise the vehicle on a hoist.

(2) Open a wheel cylinder bleeder while a helper

Page 389 of 1502

8E

- 8 INSTRUMENT PANEL AND GAUGES

•

BRAKE

WARNING

LAMP

SWITCH TO BRAKE

WARNING LAMP

PR!

451

Fig.

6

Brake Warning

Lamp

Switch

depresses

the

brake pedal

and

observes

the

warning

lamp.

If

the

lamp fails

to

light, inspect

for:

•

a

burned

out

bulb

• disconnected socket

•

a

broken

or

disconnected wire

at the

switch. If

the

bulb

is not

burned

out and the

wire continu

ity

is

proven, replace

the

brake warning switch.

The

switch

is in the

brake line

Tee

fitting mounted

on

the frame rail

in the

engine compartment below

the

master cylinder.

CAUTION:

If

wheel cylinder bleeder

was

opened

check

master cylinder fluid level.

On Diesel Models

The

Brake light

is

also con

nected

to a

sensor that monitors vacuum

in the

brake booster system.

The

Brake light when

lit

indi cates

LOW

VACUUM. Refer

to

Group

5 -

Brakes

for

more information.

TEMPERATURE

GAUGE CIRCUIT TEST

(1) Remove temperature gauge. Refer

to

Gauge

Re

placement. (2) Check continuity

in the

wire between

the

tem

perature sensor

and the

temperature gauge (sensor

input

pin)

(Figs.

7, 8 and 9).

(3) With

the

ignition switch

in the ON

position,

check

for

battery voltage across

the B + pin and the

Ground

pin.

(TURN

IGNITION

KEY

"ON"

(DO

NOT

START

ENGINE

I

RELEASE

PARKING

BRAKE)

I

I

[

WARNING

LIGHT

GOES

I

"ON"

I

1

(LIGHT

SHOULD

BE

"OFF")!

X

APPLY PARKING BRAKE (WARNING

LIGHT

SHOULD

GO "ON")

BRAKE

SYSTEM

LEAKING FLUID

X

WARNING

LIGHT

FAILS

TO GO "ON" GROUNDED WIRING

BULB

BURNED

OUT

SHORTED PARKING BRAKE

OR BRAKE WARNING SWITCH

X

DISCONNECTED

OR

FAULTY

BULB

SOCKET

FAULTY BRAKE SYSTEM PROPORTIONING VALVE

UNIT*

BROKEN

WIRE

OR

WIRE

DISCONNECTED

AT

PARKING

BRAKE

SWITCH

X

FAULTY PARKING

BRAKE

SWITCH

X

APPLY SERVICE BRAKES

(WARNING

LIGHT

SHOULD

NOT GO "ON")

JZ

X

TEST SERVICE BRAKE WARNING

SYSTEM FUNCTION*

X

WARNING

LIGHT

GOES

"ON"

WARNING

LIGHT

DOES

NOT GO "ON"

BRAKE

SYSTEM

LEAKING FLUID

OPEN CIRCUIT

IN

WIRING

TO SERVICE BRAKE SWITCH

X

GROUNDED WIRING

OR

SHORTED BRAKE WARNING SWITCH

LOOSE

BULKHEAD CONNECTOR

X

FAULTY BRAKE SYSTEM

PROPORTIONING VALVE

UNIT*

FAULTY SERVICE BRAKE SWITCH

X

•TESTS

ARE

DESCRIBED

IN APPROPRIATE

SECTION

OF

SERVICE MANUAL

FAULTY SERVICE BRAKE

SYSTEM PROPORTIONING VALVE

UNIT*

PR1449A

Page 393 of 1502

8E

- 12

INSTRUMENT PANEL

AND

GAUGES

•

CLUSTER AND GAUGE

SERVICE

PROCEDURES

INDEX

page

Cluster Bezel

12

Cluster

Mask

and

Lens

12

Fuel Gauge

13

Instrument

Cluster Assembly

12

Lamp Bulb Replacement—Message Center

..... 15

CLUSTER

BEZEL

REMOVAL

(1) Disconnect negative cable from battery.

(2) Tape

or

cover steering column

to

prevent dam

age

to

paint.

(3) Remove

2

screws and remove map lamp.

CAUTION:

Map

lamp must

be

removed

to

prevent

damage

to

instrument panel.

(4) Remove

6

screws which attach cluster bezel

to

base panel (Fig.

1).

Make sure

the

screw below

the

Heater-A/C control

is

removed.

(5)

Place column shift lever

in

Position

"1".

(6) Remove bezel

by

pulling

top

edge rearward

to

clear brow. Disengage attaching clips around bottom

of bezel

and

complete removal

of

bezel.

(7)

If

bezel

is

equipped with

a

four wheel drive

in

dicator, remove bulb socket

as

bezel

is

removed.

(8) Disconnect message center wires.

INSTRUMENT

CLUSTER BEZEL

J938E-51

Fig.

1 instrument

Cluster

Bezel

INSTALLATION

(1) Connect bulb socket

for

four wheel drive indi

cator

if

equipped.

(2)

Connect message center wires.

(3) Engage attaching clips around bottom

of

bezel,

roll bezel into position.

(4) Install

6

mounting screws. page

Lamp Bulbs

. . 15

Printed

Circuit

Board

13

PRND21

Indicator

. 15

Specifications

15

Speedometer/Odometer

14

(5)

Install map lamp.

(6) Remove tape from steering column.

(7) Connect negative cable

to

battery.

CLUSTER

MASK AND LENS REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove cluster bezel.

(3) Remove

8

screws holding mask

and

lens.

(4) Remove mask

and

lens.

INSTALLATION

(1) Position mask

and

lens.

(2) Install

8

screws.

(3) Install cluster bezel.

(4) Connect negative cable

to

battery.

INSTRUMENT CLUSTER ASSEMBLY

(Fig.

2)

REMOVAL

(1) Disconnect negative cable from battery.

(2) Tape

or

cover steering column

to

prevent dam

age

to

paint.

(3) Remove bezel.

(4) Remove lower steering column cover

4

screws.

(5)

Spread upper steering column cover

out of

the

locking tangs

and

slide downward. (6) Disconnect PRND21 actuator cable from steer

ing column

if

equipped.

(7) Loosen heater

and

A/C control. Pull rearward

to clear forward mount

on

cluster housing.

(8) Remove

6

screws that retain cluster. Pull clus

ter rearward

and

disconnect

2

large connectors.

(9) Remove cluster.

INSTALLATION

(1) Connect

2

large connectors

to

cluster.

(2) Position cluster

to

instrument panel and install

6 retaining screws.

(3) Install heater A/C control.

(4) Connect PRND21 actuator

to

steering column

if

equipped.

(5)

Position upper steering column cover

and

slide

upward until tangs snap into place.

Page 396 of 1502

•

INSTRUMENT PANEL

AND

GAUGES

8E - 15

PRND21 INDICATOR

REMOVAL

(1) Remove bezel. Refer to Cluster Bezel Removal.

(2)

Remove cluster mask and lens. Refer to Cluster

Mask and Lens Removal. (3) Remove cluster assembly. Refer to Instrument

Cluster Removal. (4) Remove screws attaching PRND21 mechanism

to cluster housing.

(5)

Remove PRND21 mechanism.

INSTALLATION (1) Position PRND21 mechanism to cluster hous

ing. (2) Install mounting screws.

(3)

Install cluster assembly. (4) Install mask-lens.

(5)

Install bezel.

LAMP BULBS

CLUSTER ILLUMINATION LAMPS TURN SIGNAL INDICATOR LAMPS

LOW OIL PRESSURE INDICATOR LAMP

HIGH BEAM INDICATOR LAMP CHECK ENGINE LAMP

SEAT BELT WARNING LAMP

REMOVAL (1) Disconnect negative cable from battery.

(2) Remove instrument cluster. See cluster re

moval.

(3)

Twist lamp socket assembly and remove from

printed circuit board. (4) Remove bulb from socket.

INSTALLATION (1) Install bulb into socket.

(2) Install socket assembly into printed circuit

board.

(3)

Position cluster into place in panel. See cluster

installation. (4) Connect battery negative cable.

LAMP BULB REPLACEMENT—MESSAGE CENTER

REMOVAL (1) Disconnect battery negative cable.

(2) Remove instrument cluster bezel assembly. Re

fer to Instrument Cluster removal.

(3)

Twist lamp socket assembly and remove from

printed circuit board. (4) Remove bulb from socket.

INSTALLATION (1) Install bulb into socket assembly. (2) Install lamp socket assembly into printed cir

cuit board.

(3)

Install Instrument Cluster bezel assembly to

instrument panel. Refer to Instrument Cluster instal

lation.

(4) Connect negative cable from battery.

FOUR WHEEL DRIVE INDICATOR LAMP (1) Pull bulb and socket assembly from rear of

housing. (2) Remove bulb from socket.

(3)

Reverse removal procedures to install.

SPECIFICATIONS

Fuel

Gauge Calibration

Mntar Position Resistance

Empty Graduation 90

ohms

± 3

ohms

Empty Stop

Greater

than

96.5 ohms

Full

Graduation 12 ohm

± 3

ohms

Full

Stop

Less

than

8

ohms

1/2

45.3 ohms

± 3

ohms

Temperature

Gauge

Calibration

Pointer

Position Resistance

Cold Graduation 655 ohms

Hot Graduation 64 ohms

Oil Pressure Gauge Calibration

Pointer

Position Resistance

Low Graduation 100 ohms

High Graduation 12 ohms

J908E-58

Page 397 of 1502

8E - 16 INSTRUMENT PANEL AND GAUGES

• SWITCH AND

PANEL

COMPONENT

SERVICE

INDEX

page

Ash

Tray

20

Cigar

Lighter

........................ 20

Four

Wheel Drive

Indicator

19

Fuse

Block

and

Flashers

................... 19

Glove

Box 21

Heater A/C Control

17

page

Heater Control

16

Hood

Release

19

Illumination

Bulb Replacement

22

Message

Center Module

................... 18

Steering Column Lowering

and

Raising

16

Switches

17

DISCONNECT NEGATIVE CABLE FEOM

BATTERY IN ENGINE COMPAETMENT BE FORE SERVICING INSTRUMENT PANEL.

STEERING COLUMN LOWERING AND RAISING When servicing the instrument panel and the Low

ering and Raising of the steering column is required,

the following is the procedure for doing so: This procedure is not for removing and replac

ing the steering column. Refer to Group - 19 Steering of this manual for the removal and re

placement procedures.

LOWERING STEERING COLUMN

(1) Disconnect negative cable from battery.

(2)

Remove 3 toe plate nuts and washers (Fig. 1).

(3) Remove 1 toe plate screw.

(4) Remove 4 screws attaching lower steering col

umn cover and remove cover. The fuse block is at

tached to this cover and should be supported when cover is removed.

(5) Spread upper steering column cover out of lock

ing tangs and slide downward.

(6)

Disconnect cable from shift indicator bracket.

(7)

Remove 2 nuts and washers attaching steering

column bracket to instrument panel steering column support bracket.

(8)

Allow column to lower and rest on seat.

STEERING

COLUMN SUPPORT

WASHER

AND NUT

Fig.

1 Steering

Column

Mounting

RAISING STEERING COLUMN

(1) Raise steering column assembly against the in

strument panel support bracket. (2) Install 2 steering column bracket washers and

nuts (Finger Tighten Only).

CAUTION:

Check that

all

wiring

is

clear

and not

pinched.

(3) Tighten the 2 bracket nuts to 12 Nnn-(110 in.

lbs.) torque. (4) Slide toe plate into position, install attaching

screw, tighten to 4 N®m (35 in. lbs.).

(5) Install toe plate nuts and washers and tighten

to 23 N*m (200 in. lbs.).

(6)

Connect cable to shift indicator bracket.

(7)

Position upper steering column cover and slide

upward until tangs snap into place.

(8) Install fuse block to cover.

(9)

Position lower steering column cover and in

stall 4 attaching screws.

HEATER CONTROL

REMOVAL

(1) Remove map lamp.

(2) Remove cluster bezel (refer to Cluster Bezel Re

moval). (3) Remove 2 control attaching screws. (4) Pull control rearward.

(5) Disconnect illumination lamp, and wire connec

tions.

(6)

Disconnect control cables.

(7)

Remove control.

INSTALLATION

(1) Position control near panel.

(2) Connect control cables to control (see Heater

A/C Section). (3) Connect illumination lamp, and wire connec

tors.

(4) Push control into panel.

(5) Install 2 control mounting screws.

(6)

Install bezel.

(7)

Install map lamp.