key DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 25 of 1502

0 - 6

LUBRICATION

AND

MAINTENANCE

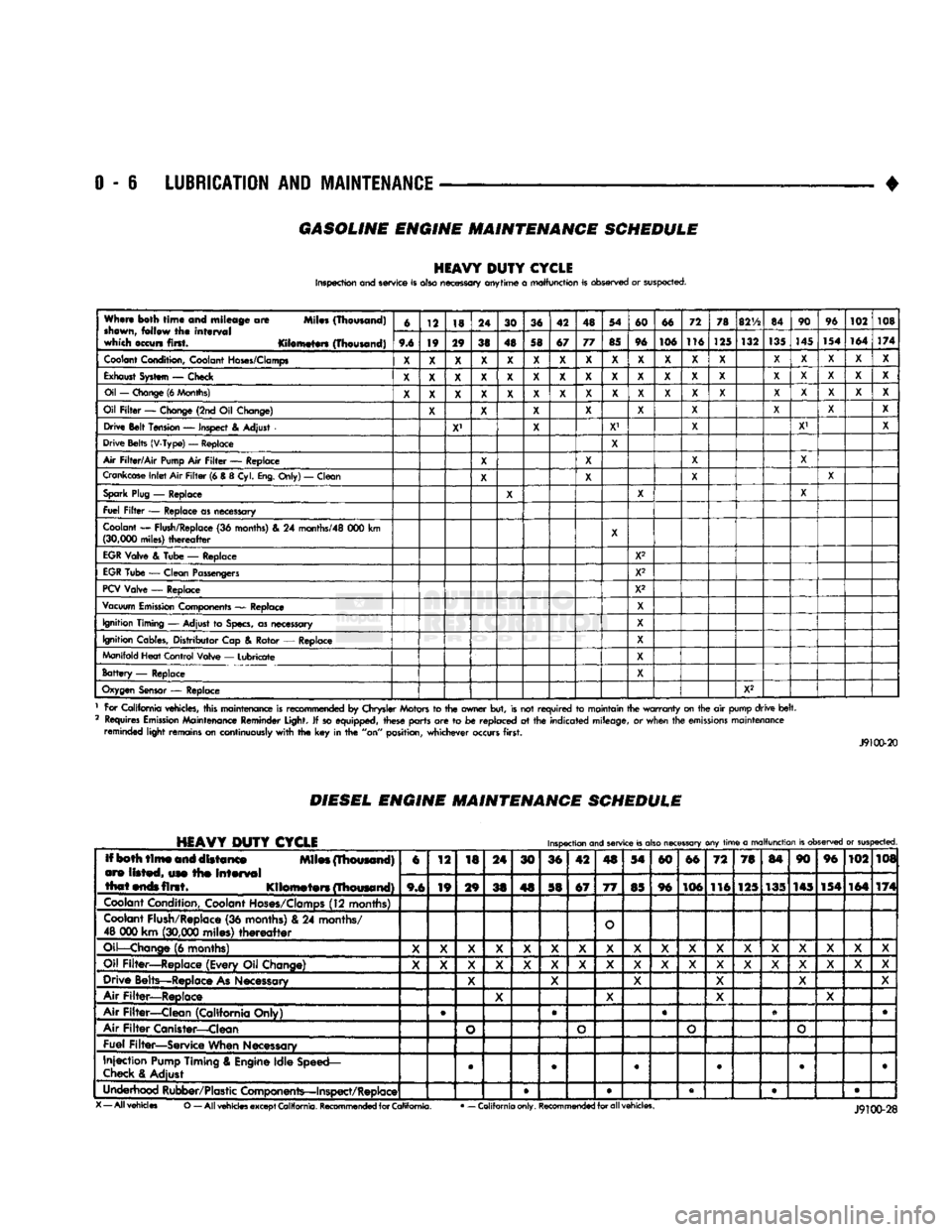

GASOLINE ENGINE MAINTENANCE SCHEDULE

HEAVY

DUTY

CYCLE

Inspection and service is also necessary anytime

a

malfunction is observed or suspected.

When both

time

and mileage

are

Miles (Thousand)

shewn,

follow

the

interval

which occurs first. Kilometers (Thousand) 6

12 18 24

30 36 42 48 54

60 66 72

78

82V2

84 90

96

102 108

When both

time

and mileage

are

Miles (Thousand)

shewn,

follow

the

interval

which occurs first. Kilometers (Thousand) 9.6 19 29

38 48 58 67 77

85 96 106 116

125 132

135

145

154 164

174

Coolant

Condition, Coolant

Hoses/Clamps

X

X X X

X X X X

X X X X

X X X

X X X

Exhaust

System

—

Check

X X X X X X X X X X X

X X X X X

X X

Oil

—

Change

(6

Months)

X X X X X X X

X X

X

X

X

X X X

X X

X

Oil

Filter

—

Change (2nd

Oil

Change)

X X X X

X X

X X

X

Drive Belt Tension

—

Inspect

&

Adjust

X' X

X1

X X' X

Drive Belts (V-Type)

—

Replace

X

Air

Filter/Air

Pump

Air

Filter

—

Replace

X X X

X

Crankcase

Inlet

Air

Filter

(6 &

8

Cyl.

Eng.

Only)

—

Clean

X X

X X

Spark

Plug

—

Replace

X X X

Fuel

Filter

—

Replace as necessary

Coolant

—

Flush/Replace

(36

months)

& 24

months/48

000 km

(30,000

miles)

thereafter

X

EGR

Valve

&

Tube

—

Replace X2

EGR

Tube

—

Clean Passengers

X2

PCV

Valve

—

Replace X2

Vacuum

Emission

Components

—

Replace

X

Ignition Timing

—

Adjust

to

Specs,

as necessary X

Ignition Cables, Distributor Cap

&

Rotor

—

Replace

X

Manifold Heat Control Valve

—

Lubricate

X

Battery

—

Replace X

Oxygen

Sensor

—

Replace

X2

1 For California vehicles, this maintenance is recommended

by

Chrysler Motors

to the

owner but, is not

required

to

maintain the

warranty

on the

air

pump drive

belt.

2 Requires

Emission

Maintenance Reminder Light.

If

so equipped, these parts

are to be

replaced

at the

indicated mileage,

or

when the

emissions

maintenance reminded light remains on continuously

with

the key in the

"on" position, whichever occurs first.

J9100-20

DIESEL

ENGINE

MAINTENANCE

SCHEDULE

HEAVY

DUTY

CYCLE

Inspection

and

service

is

also

necessary

any

time

a

malfunction

is

observed

or

suspected.

Iff both

time

and distance Miles (Thousand)

are listed, use the

interval

that

ends

first. Kilometers (Thousand) 6

12

18 24

30 36 42

4S

54

60 66

72 78

84 90 96

102 108

Iff both

time

and distance Miles (Thousand)

are listed, use the

interval

that

ends

first. Kilometers (Thousand) 9,6 19

29

38 48 58 67

77

85 96 106

116 125 135 145 154

164 174

Coolant

Condition, Coolant

Hoses/Clamps

(12 months)

Coolant

Flush/Replace (36 months) & 24 months/

48 000 km

(30,000

miles)

thereafter

O

Oil—Change

(6 months)

X X X

X X X

X X X X X

X X X X X X

X

Oil Filter—Replace (Every Oil Change)

X X X

X X X

X X

X X X

X

X X X X

X X

Drive Belts—Replace

As

Necessary

X X

X X X X

Air Filter—Replace

X X

X X

Air Filter—Clean (California Only) e

®

• •

Air

Filter

Canister—Clean

o o o

o

Fuel Filter—Service When Necessary

Injection

Pump

Timing & Engine Idle Speed—

Check

& Adjust

©

• 9 • • •

Underhood Rubber/Plastic Components—Inspect/Replace • • • • •

X

— All vehicles

O

— All

vehicles

except

California.

Recommended

for

California.

•

— California only.

Recommended

for all vehicles.

Page 51 of 1502

0

- 32

LUBRICATION

AND

MAINTENANCE

•

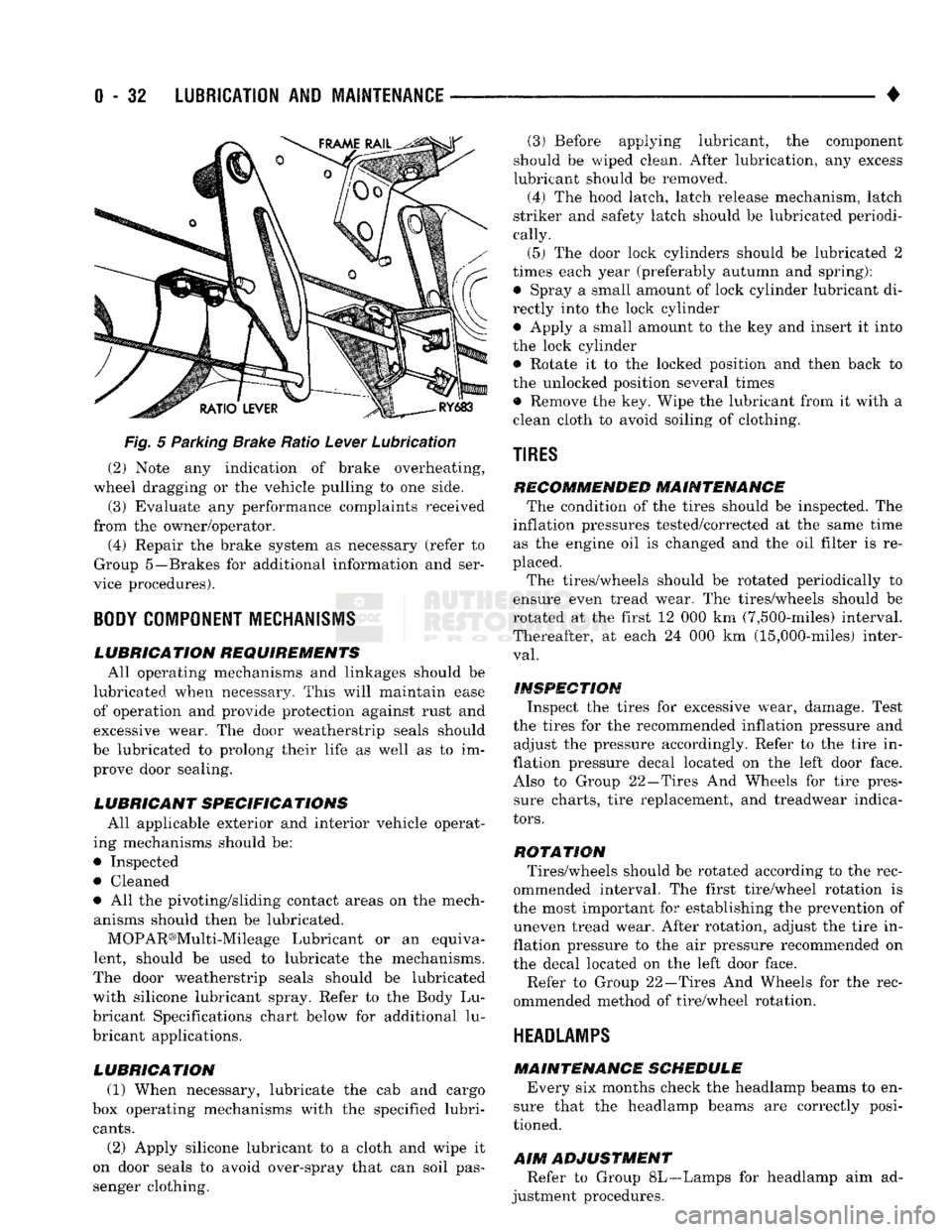

Fig.

5 Parking Brake Ratio Lever Lubrication (2) Note any indication of brake overheating,

wheel dragging or the vehicle pulling to one side.

(3) Evaluate any performance complaints received

from the owner/operator. (4) Repair the brake system as necessary (refer to

Group 5—Brakes for additional information and ser

vice procedures).

BODY

COMPONENT

MECHANISMS

LUBRICATION REQUIREMENTS

All operating mechanisms and linkages should be

lubricated when necessary. This will maintain ease of operation and provide protection against rust and

excessive wear. The door weatherstrip seals should

be lubricated to prolong their life as well as to im prove door sealing.

LUBRICANT SPECIFICATIONS

All applicable exterior and interior vehicle operat

ing mechanisms should be:

• Inspected • Cleaned

• All the pivoting/sliding contact areas on the mech anisms should then be lubricated.

MOPAR®Multi-Mileage Lubricant or an equiva

lent, should be used to lubricate the mechanisms.

The door weatherstrip seals should be lubricated

with silicone lubricant spray. Refer to the Body Lu

bricant Specifications chart below for additional lu

bricant applications.

LUBRICATION

(1) When necessary, lubricate the cab and cargo

box operating mechanisms with the specified lubri

cants.

(2) Apply silicone lubricant to a cloth and wipe it

on door seals to avoid over-spray that can soil pas

senger clothing. (3) Before applying lubricant, the component

should be wiped clean. After lubrication, any excess

lubricant should be removed.

(4) The hood latch, latch release mechanism, latch

striker and safety latch should be lubricated periodi

cally.

(5) The door lock cylinders should be lubricated 2

times each year (preferably autumn and spring): • Spray a small amount of lock cylinder lubricant di

rectly into the lock cylinder

• Apply a small amount to the key and insert it into

the lock cylinder • Rotate it to the locked position and then back to

the unlocked position several times

• Remove the key. Wipe the lubricant from it with a

clean cloth to avoid soiling of clothing.

TIRES

RECOMMENDED MAINTENANCE

The condition of the tires should be inspected. The

inflation pressures tested/corrected at the same time as the engine oil is changed and the oil filter is re

placed.

The tires/wheels should be rotated periodically to

ensure even tread wear. The tires/wheels should be

rotated at the first 12 000 km (7,500-miles) interval.

Thereafter, at each 24 000 km (15,000-miles) inter

val.

INSPECTION

Inspect the tires for excessive wear, damage. Test

the tires for the recommended inflation pressure and adjust the pressure accordingly. Refer to the tire in

flation pressure decal located on the left door face. Also to Group 22—Tires And Wheels for tire pressure charts, tire replacement, and treadwear indica

tors.

ROTATION

Tires/wheels should be rotated according to the rec

ommended interval. The first tire/wheel rotation is

the most important for establishing the prevention of uneven tread wear. After rotation, adjust the tire in

flation pressure to the air pressure recommended on

the decal located on the left door face.

Refer to Group 22—Tires And Wheels for the rec

ommended method of tire/wheel rotation.

HEADLAMPS

MAINTENANCE SCHEDULE

Every six months check the headlamp beams to en

sure that the headlamp beams are correctly posi

tioned.

AIM

ADJUSTMENT

Refer to Group 8L—Lamps for headlamp aim ad

justment procedures.

Page 160 of 1502

•

REAR

SUSPENSION

AND

AXLE

3 - 33

WHEEL BEARING SERVICE

REMOVAL (1) Remove the axle shaft, refer to the removal

procedure. (2) Remove the nut lock and adjustment nut.

(3) Remove the hub and drum assembly. The outer

wheel bearing will slide out as the hub is being re

moved. (4) Place hub on bench and remove inner grease

seal. Discard seal. (5) Remove inner wheel bearing. Inspect wheel

bearings for wear. Replace as necessary.

CLEANING AND INSPECTION (1) Thoroughly clean both wheel bearings and in

terior of the hub. Remove all of the residual lubri cant. (2) To clean the bearings:

• Soak them in an appropriate cleaning solvent

• Strike the flat of each bearing against a hardwood

block several times • Flush bearing between strikes

• Repeat the procedure above until each bearing is clean

• Dry the bearings with compressed air but do not

spin them (3) After cleaning, apply engine oil to each bear

ing. (4) Rotate each bearing slowly while applying

downward force. Examine the rollers for pitting and

roughness. Replace worn or otherwise defective bear

ings.

If a bearing has pitted and/or rough surfaced

rollers, replace both the bearing and bearing cup. (5) If reusable, remove the engine oil from each

bearing. Pack each bearing with multi-purpose

NLGI, grade 2, EP-type lubricant. Ensure that lubricant is forced into all the cav

ities between the bearing cage and rollers.

INSTALLATION (1) If a bearing and cup must be replaced, remove

the cup from the hub bore. Use a brass drift or an appropriate removal tool to tap out the cup. (2) Install the replacement bearing cup(s) with an

appropriate installation tool.

(3) Apply lubricant to surface area of the hub bore.

Install the inner wheel bearing in the hub. Install a

replacement bearing seal with an appropriate seal installation tool. (4) Inspect the bearing and seal contact surfaces on

the axle for burrs and/or roughness.

(5) Remove all the rough contact surfaces from the

axle.

Apply a coating of multi-purpose NLGI, grade

2,

EP-type lubricant to the axle.

CAUTION:

Use care to prevent the inner

wheel

bear

ing

and bearing

seal

from contacting the axle

threads

during installation. Otherwise, the

threads,

bearing,

and

seal

could

be

damaged.

(6) Carefully slide the hub onto the axle. Install

the outer wheel bearing, the locktab and outer wheel

bearing locknut.

(7) Tighten the adjustment nut to 163-190 Nnn

(120-140 ft. lbs.) torque while rotating the wheel. (8) Loosen the adjustment nut 1/3 of-a-turn (120

degrees) to provide 0.001-inch to 0.008-inch wheel

bearing end play.

(9) Tap the nut lock into the spindle keyway and

adjustment nut.

(10) Install the axle shaft, refer to the installation

procedure.

COMPLETE AXLE REMOVAL/INSTALLATION

REMOVAL It is not necessary to remove the complete axle

from the vehicle for routine or differential service. If

the differential housing or axle shaft tubes are dam aged, the complete axle can be removed and in

stalled.

(1) Raise the rear of the vehicle until the rear

wheels are not contacting the surface. Support the

vehicle body at the front of the rear springs.

(2) Use a wooden block to retain the brake pedal

in the up position.

(3) Remove the axle shafts, wheels, hubs and

brake drums. If necessary, refer to the applicable re moval procedures.

(4) Disconnect the brake line and cap the fittings

to prevent loss of brake fluid. (5) Disconnect the parking brake cables.

Scribe installation alignment reference marks

on drive shaft U-joint and on pinion yoke. (6) Disconnect the drive shaft U-joint from the pin

ion yoke. Secure it in an upright position to prevent

damage to the U-joint.

(7) Remove the rear shock absorbers and the rear

spring U-bolts from the axle. (8) Remove the rear axle from the vehicle.

INSTALLATION (1) If the differential housing cover was removed,

ensure differential housing and cover mating sur

faces are clean.

(2) If cover was removed, apply a bead of MOPAR

Silicone Rubber Sealant around the cover bolt circle.

Install the differential housing cover. Tighten the

cover bolts to 47 N»m (35 ft. lbs.) torque. Install the axle gear ratio identification tag under one of

the cover bolts.

(3) With the vehicle body supported at the front of

the rear springs, position the axle under the rear springs.

Page 224 of 1502

•

BRAKES

5 - 37

BENDIX

DISC

BRAKE

INDEX

page

Caliper Overhaul

41

Disc

Brake Inspection

39

Disc

Brakeshoe

Installation

40

Disc

Brakeshoe Removal

. 39

GENERAL

SERVICE

INFORMATION

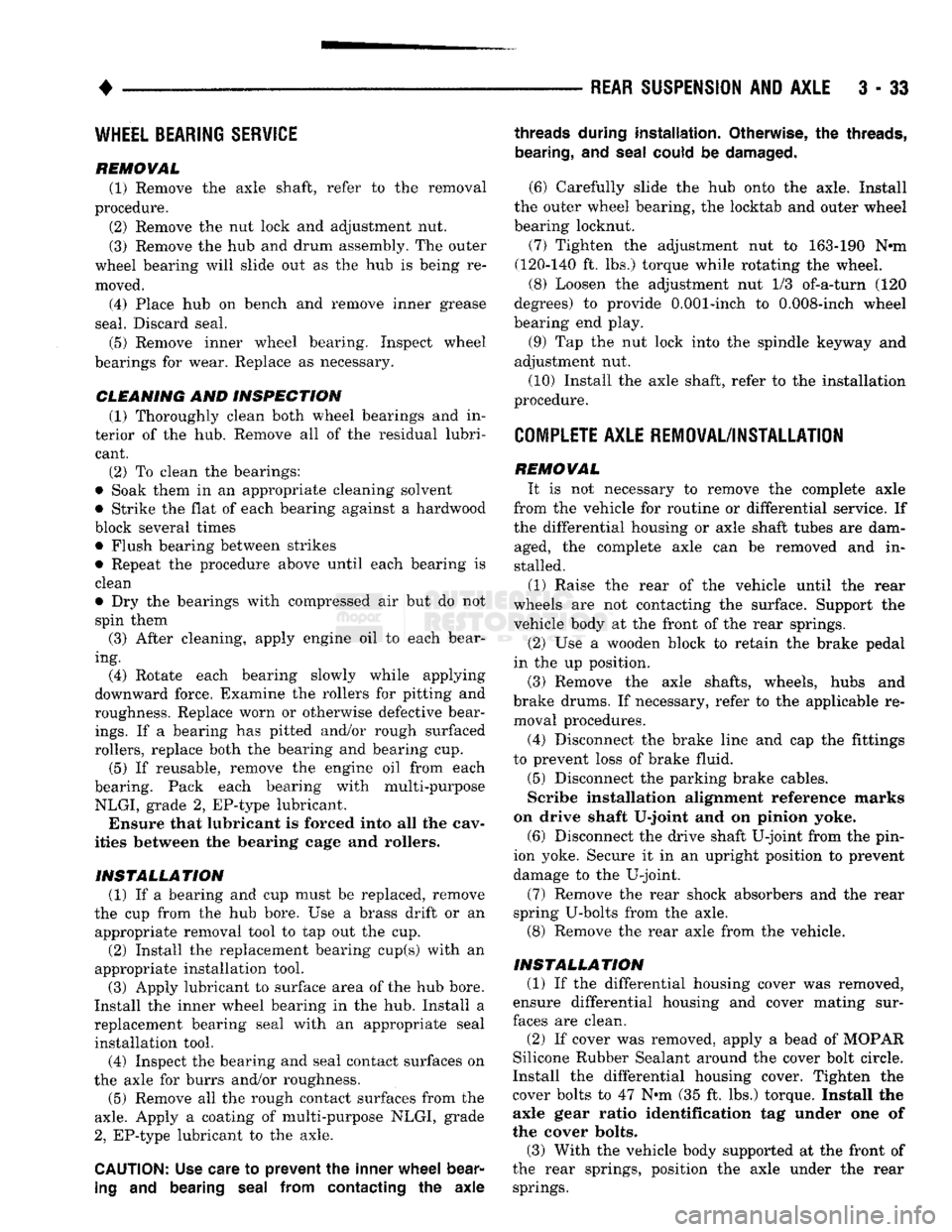

The Bendix disc brake assembly consists of a single

piston, sliding type caliper and ventilated rotor (Fig. 1). A splash shield is used to protect the rotor. The

shield is bolted to the adapter and protects the bear

ings and inboard surface of the rotor from road splash. The wheel protects the outboard surface of

the rotor and brake assembly. The caliper slides laterally on surfaces machined

into the caliper and mounting adapter. The adapter

is bolted to the steering knuckle (Fig. 2). The caliper

is positioned in the adapter with a support key and spring (Fig. 1). A retaining screw is used to secure

the support key. The inboard brakeshoe is mounted in the caliper

adapter. The outboard brakeshoe is mounted in the

caliper. The linings are riveted to the shoes, and the

inner and outer shoes are not interchangeable.

DISC

BRAKE OPERATION

The significant feature of caliper operation is that

the caliper is free to move laterally on the adapter slide surfaces (Fig. 3).

Fig.

1

Bendix

Disc

Brake Caliper

page

General Service

Information

37

Rotor Inspection

and

Service

................ 43

Rotor

Installation

45

Rotor Removal

45

Fig.

2 Caliper

Mounting

Adapter Attachment

At brake application, fluid pressure is exerted

equally against the caliper piston and all surfaces of

the caliper piston bore.

Pressure applied to the piston is transmitted di

rectly to the inboard brakeshoe pressing the shoe lin ing against the rotor. At the same time, pressure applied to the caliper bore surfaces, causes the cali

per to slide inward laterally. The inward movement

presses the lining of the outboard shoe against the

opposite side of the rotor to complete braking action (Fig. 3).

Any application or release of brake fluid pressure

causes only a very modest movement of the caliper and piston. At brake release, the piston and caliper

return to the non-applied position.

The brakeshoes do not retract an appreciable dis

tance from the rotor. The minimal running clearance

provides the improved response and reduced pedal

travel; It also helps in preventing dirt and foreign

material from lodging between the shoe and rotor surfaces.

Page 226 of 1502

BRAKES

5 - 39

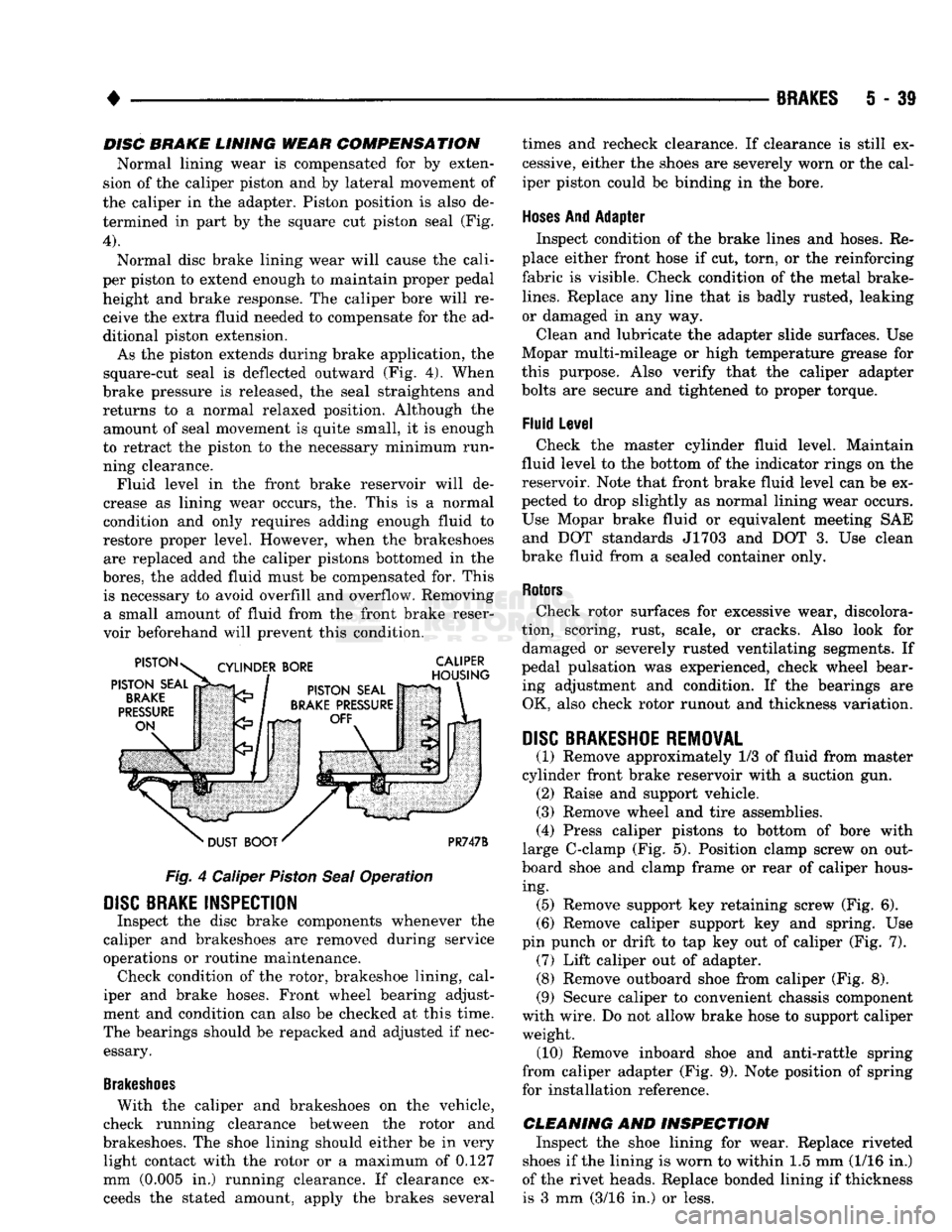

DISC BRAKE LINING WEAR COMPENSATION

Normal lining wear is compensated for by exten

sion of the caliper piston and by lateral movement of

the caliper in the adapter. Piston position is also de termined in part by the square cut piston seal (Fig.

4).

Normal disc brake lining wear will cause the cali

per piston to extend enough to maintain proper pedal height and brake response. The caliper bore will receive the extra fluid needed to compensate for the ad

ditional piston extension.

As the piston extends during brake application, the

square-cut seal is deflected outward (Fig. 4). When

brake pressure is released, the seal straightens and returns to a normal relaxed position. Although the amount of seal movement is quite small, it is enough

to retract the piston to the necessary minimum run ning clearance. Fluid level in the front brake reservoir will de

crease as lining wear occurs, the. This is a normal

condition and only requires adding enough fluid to

restore proper level. However, when the brakeshoes are replaced and the caliper pistons bottomed in the

bores,

the added fluid must be compensated for. This is necessary to avoid overfill and overflow. Removing a small amount of fluid from the front brake reser

voir beforehand will prevent this condition.

Fig.

4 Caliper

Piston

Seal

Operation

DISC

BRAKE INSPECTION

Inspect the disc brake components whenever the

caliper and brakeshoes are removed during service

operations or routine maintenance. Check condition of the rotor, brakeshoe lining, cal

iper and brake hoses. Front wheel bearing adjust

ment and condition can also be checked at this time.

The bearings should be repacked and adjusted if nec essary.

Brakeshoes

With the caliper and brakeshoes on the vehicle,

check running clearance between the rotor and

brakeshoes. The shoe lining should either be in very light contact with the rotor or a maximum of 0.127

mm (0.005 in.) running clearance. If clearance exceeds the stated amount, apply the brakes several times and recheck clearance. If clearance is still ex

cessive, either the shoes are severely worn or the cal

iper piston could be binding in the bore.

Hoses

And Adapter Inspect condition of the brake lines and hoses. Re

place either front hose if cut, torn, or the reinforcing

fabric is visible. Check condition of the metal brake-

lines.

Replace any line that is badly rusted, leaking

or damaged in any way.

Clean and lubricate the adapter slide surfaces. Use

Mopar multi-mileage or high temperature grease for

this purpose. Also verify that the caliper adapter

bolts are secure and tightened to proper torque.

Fluid Level Check the master cylinder fluid level. Maintain

fluid level to the bottom of the indicator rings on the

reservoir. Note that front brake fluid level can be ex

pected to drop slightly as normal lining wear occurs.

Use Mopar brake fluid or equivalent meeting SAE and DOT standards J1703 and DOT 3. Use clean

brake fluid from a sealed container only.

Rotors

Check rotor surfaces for excessive wear, discolora

tion, scoring, rust, scale, or cracks. Also look for damaged or severely rusted ventilating segments. If

pedal pulsation was experienced, check wheel bear ing adjustment and condition. If the bearings are OK, also check rotor runout and thickness variation.

DISC

BRAKESHOE REMOVAL

(1) Remove approximately 1/3 of fluid from master

cylinder front brake reservoir with a suction gun. (2) Raise and support vehicle.

(3) Remove wheel and tire assemblies.

(4) Press caliper pistons to bottom of bore with

large C-clamp (Fig. 5). Position clamp screw on out

board shoe and clamp frame or rear of caliper hous ing. (5) Remove support key retaining screw (Fig. 6).

(6) Remove caliper support key and spring. Use

pin punch or drift to tap key out of caliper (Fig. 7). (7) Lift caliper out of adapter. (8) Remove outboard shoe from caliper (Fig. 8).

(9) Secure caliper to convenient chassis component

with wire. Do not allow brake hose to support caliper weight. (10) Remove inboard shoe and anti-rattle spring

from caliper adapter (Fig. 9). Note position of spring

for installation reference.

CLEANING AND INSPECTION Inspect the shoe lining for wear. Replace riveted

shoes if the lining is worn to within 1.5 mm (1/16 in.)

of the rivet heads. Replace bonded lining if thickness is 3 mm (3/16 in.) or less.

Page 227 of 1502

5

- 40

BRAKES

•

Fig.

6 Removing/Installing

Support

Key Retaining

Screw

If the shoe lining will be reused, do not intermix

the shoes. Keep them with the caliper they were re moved from.

Examine the caliper piston area for evidence of

leaks.

Also check condition of the piston boot. Over

haul the caliper if leakage is evident or the boot is

cut or torn.

Clean rust and corrosion from the support key and

the caliper and adapter slide surfaces (machined

ways) with a wire brush. Then lubricate the slide surfaces with Mopar multi-mileage grease, or equiv

alent.

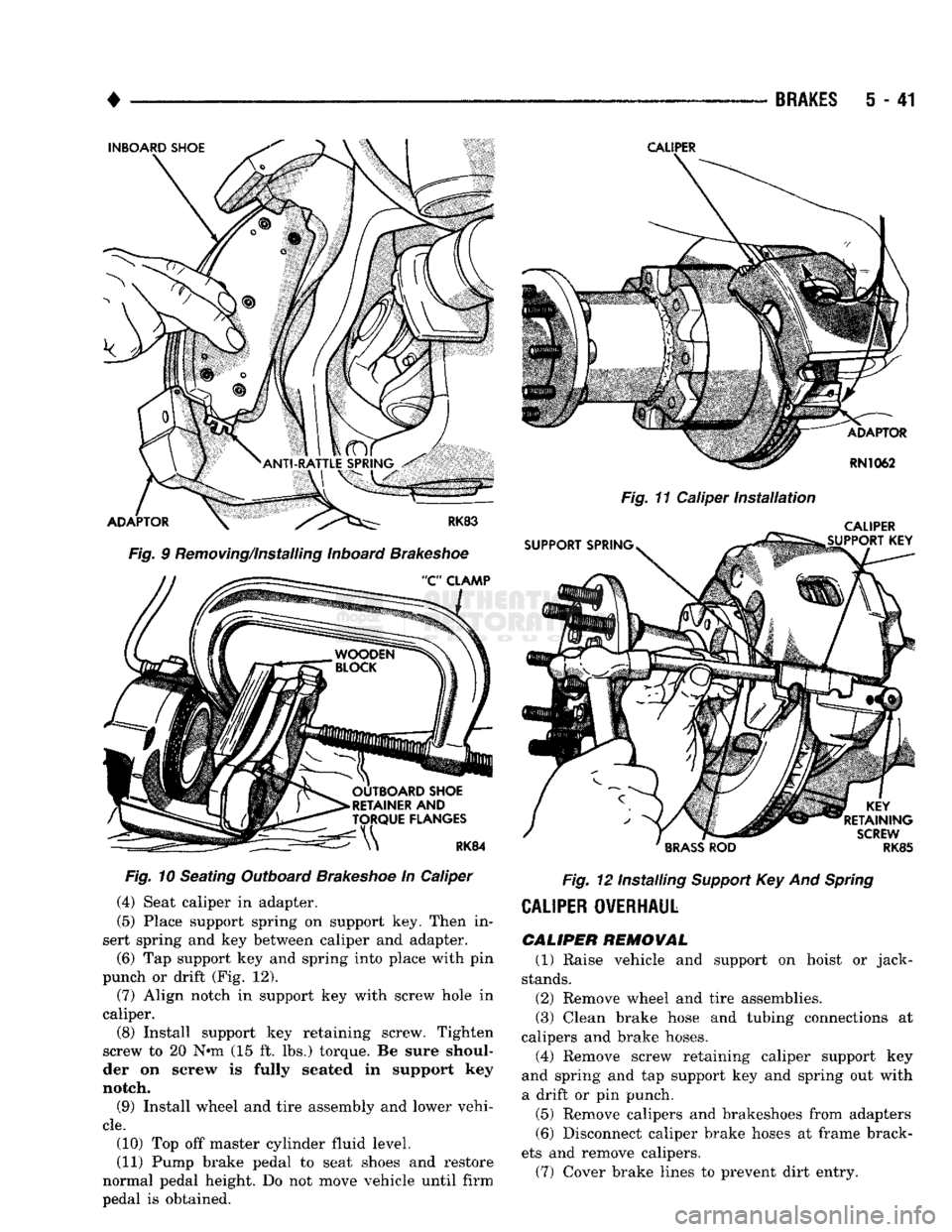

DISC

BRAKESHOE

INSTALLATION

(1) Install anti-rattle spring on inboard brakeshoe

and install shoe in adapter. Be sure spring remains

in place and is positioned as shown (Fig. 9). Loop

portion of spring should face away from the rotor.

BRASS

ROD

Fig.

7

Removing

Caliper

Support

Key And

Spring

Fig.

8 Removing/Installing Outboard

Brakeshoe

(2) Install outboard shoe in caliper. Free play

should not exist between shoe retaining flanges and

machined surfaces on caliper. If shoe cannot be

pressed into place by hand, use a C-Clamp. If a C-Clamp is used, protect shoe with wood block (Fig.

10).

(3) Position caliper over rotor and in adapter (Fig.

11).

Be careful to avoid damaging piston dust boot

during installation.

CAUTION:

Verify

that

the brake

hose

is straight

and

not twisted, kinked, or

touching

any

chassis

components.

Page 228 of 1502

•

BRAKES

5 - 41

Fig.

9 Removing/Installing Inboard

Brakeshoe

Fig.

10 Seating Outboard

Brakeshoe

In Caliper (4) Seat caliper in adapter.

(5) Place support spring on support key. Then in

sert spring and key between caliper and adapter.

(6) Tap support key and spring into place with pin

punch or drift (Fig. 12). (7) Align notch in support key with screw hole in

caliper.

(8) Install support key retaining screw. Tighten

screw to 20 N»m (15 ft. lbs.) torque. Be sure shoul

der on screw is fully seated in support key

notch.

(9) Install wheel and tire assembly and lower vehi

cle.

(10) Top off master cylinder fluid level.

(11) Pump brake pedal to seat shoes and restore

normal pedal height. Do not move vehicle until firm

pedal is obtained.

CALIPER

Fig.

11 Caliper

Installation

CALIPER

Fig.

12 Installing

Support

Key And

Spring

CALIPER

OVERHAUL

CALIPER REMOVAL

(1) Raise vehicle and support on hoist or jack-

stands.

(2) Remove wheel and tire assemblies.

(3) Clean brake hose and tubing connections at

calipers and brake hoses.

(4) Remove screw retaining caliper support key

and spring and tap support key and spring out with

a drift or pin punch.

(5) Remove calipers and brakeshoes from adapters (6) Disconnect caliper brake hoses at frame brack

ets and remove calipers. (7) Cover brake lines to prevent dirt entry.

Page 229 of 1502

5

- 42

BRAKES

•

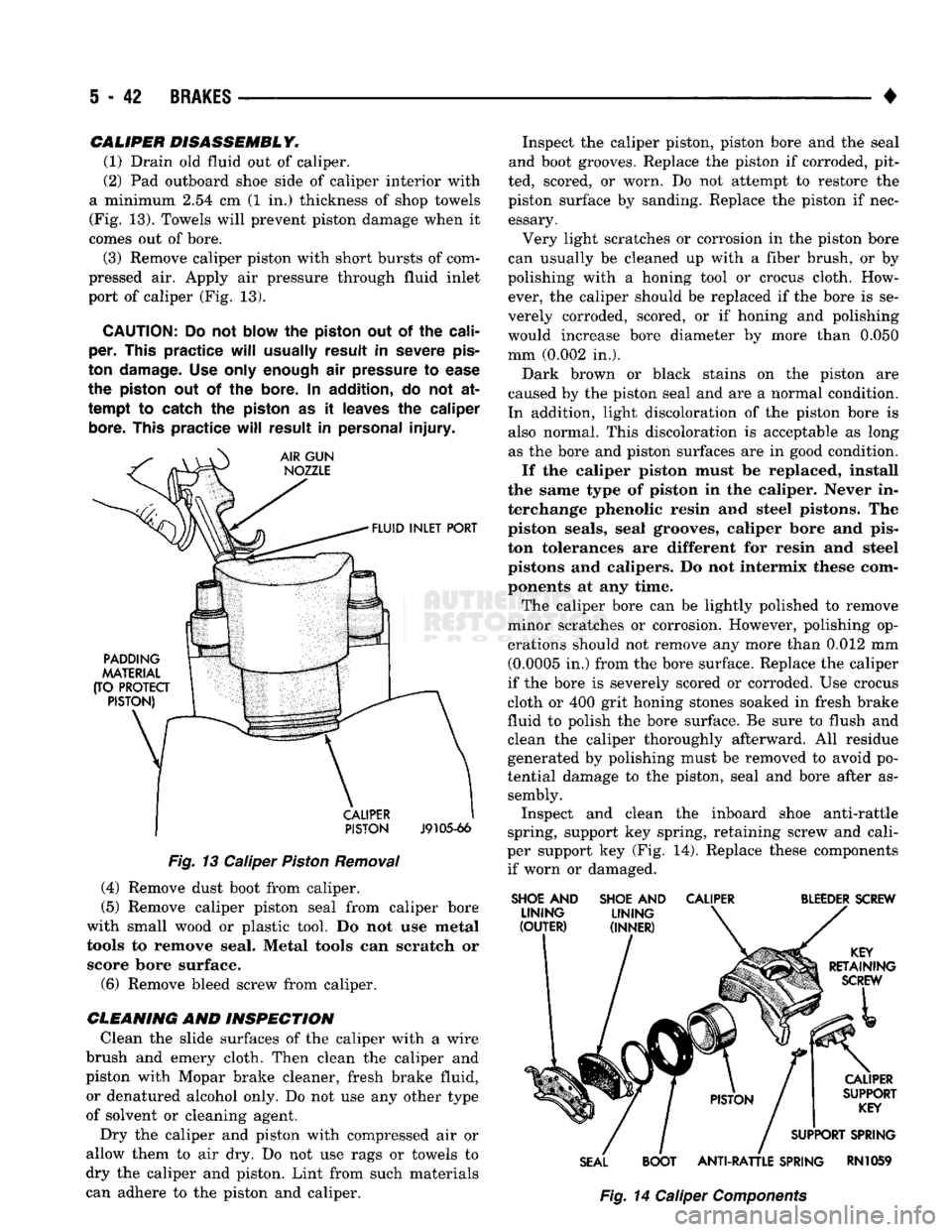

CALIPER

DISASSEMBLY.

(1) Drain old fluid out of caliper.

(2) Pad outboard shoe side of caliper interior with

a minimum 2.54 cm (1 in.) thickness of shop towels

(Fig. 13). Towels will prevent piston damage when it

comes out of bore.

(3) Remove caliper piston with short bursts of com

pressed air. Apply air pressure through fluid inlet

port of caliper (Fig. 13).

CAUTION:

Do not

blow

the

piston

out of the

cali

per.

This

practice

will

usually

result

in

severe

pis

ton

damage.

Use only

enough

air

pressure

to

ease

the

piston

out of the

bore.

In

addition,

do not at

tempt

to catch the

piston

as it

leaves

the

caliper

bore.

This

practice

will

result

in

personal

injury.

PISTON

J9105-66

Fig.

13 Caliper

Piston

Removal (4) Remove dust boot from caliper.

(5) Remove caliper piston seal from caliper bore

with small wood or plastic tool. Do not use metal tools to remove seal. Metal tools can scratch or score bore surface. (6) Remove bleed screw from caliper.

CLEANING

AND INSPECTION Clean the slide surfaces of the caliper with a wire

brush and emery cloth. Then clean the caliper and

piston with Mopar brake cleaner, fresh brake fluid, or denatured alcohol only. Do not use any other type

of solvent or cleaning agent.

Dry the caliper and piston with compressed air or

allow them to air dry. Do not use rags or towels to

dry the caliper and piston. Lint from such materials

can adhere to the piston and caliper. Inspect the caliper piston, piston bore and the seal

and boot grooves. Replace the piston if corroded, pit

ted, scored, or worn. Do not attempt to restore the

piston surface by sanding. Replace the piston if nec essary.

Very light scratches or corrosion in the piston bore

can usually be cleaned up with a fiber brush, or by

polishing with a honing tool or crocus cloth. How ever, the caliper should be replaced if the bore is se

verely corroded, scored, or if honing and polishing

would increase bore diameter by more than 0.050

mm (0.002 in.).

Dark brown or black stains on the piston are

caused by the piston seal and are a normal condition.

In addition, light discoloration of the piston bore is also normal. This discoloration is acceptable as long as the bore and piston surfaces are in good condition.

If the caliper piston must be replaced, install

the same type of piston in the caliper. Never in

terchange phenolic resin and steel pistons. The piston seals, seal grooves, caliper bore and pis

ton tolerances are different for resin and steel

pistons and calipers. Do not intermix these com ponents at any time.

The caliper bore can be lightly polished to remove

minor scratches or corrosion. However, polishing op

erations should not remove any more than 0.012 mm (0.0005 in.) from the bore surface. Replace the caliper

if the bore is severely scored or corroded. Use crocus

cloth or 400 grit honing stones soaked in fresh brake

fluid to polish the bore surface. Be sure to flush and

clean the caliper thoroughly afterward. All residue generated by polishing must be removed to avoid po

tential damage to the piston, seal and bore after as sembly. Inspect and clean the inboard shoe anti-rattle

spring, support key spring, retaining screw and cali

per support key (Fig. 14). Replace these components if worn or damaged.

SHOE

AND

SHOE

AND

CALIPER

BLEEDER

SCREW

SEAL

BOOT

ANTI-RATTLE

SPRING

RN1059

Fig.

14 Caliper

Components

Page 232 of 1502

•

BRAKES

5 - 45 multaneously with dual cutter heads. Equipment ca

pable of machining only one side at a time will

produce a tapered rotor. The lathe should also be equipped with a grinder

attachment or dual sanding discs for final cleanup or

light refinishing.

If the rotor surfaces only need minor cleanup of

rust, scale, or scoring, use abrasive discs to clean up

the rotor surfaces. However, when a rotor is scored or

worn, machining with cutting tools will be required.

CAUTION:

Do not refinish a rotor if

machining

would

cause

the rotor to

fall

below minimum allow

able

thickness.

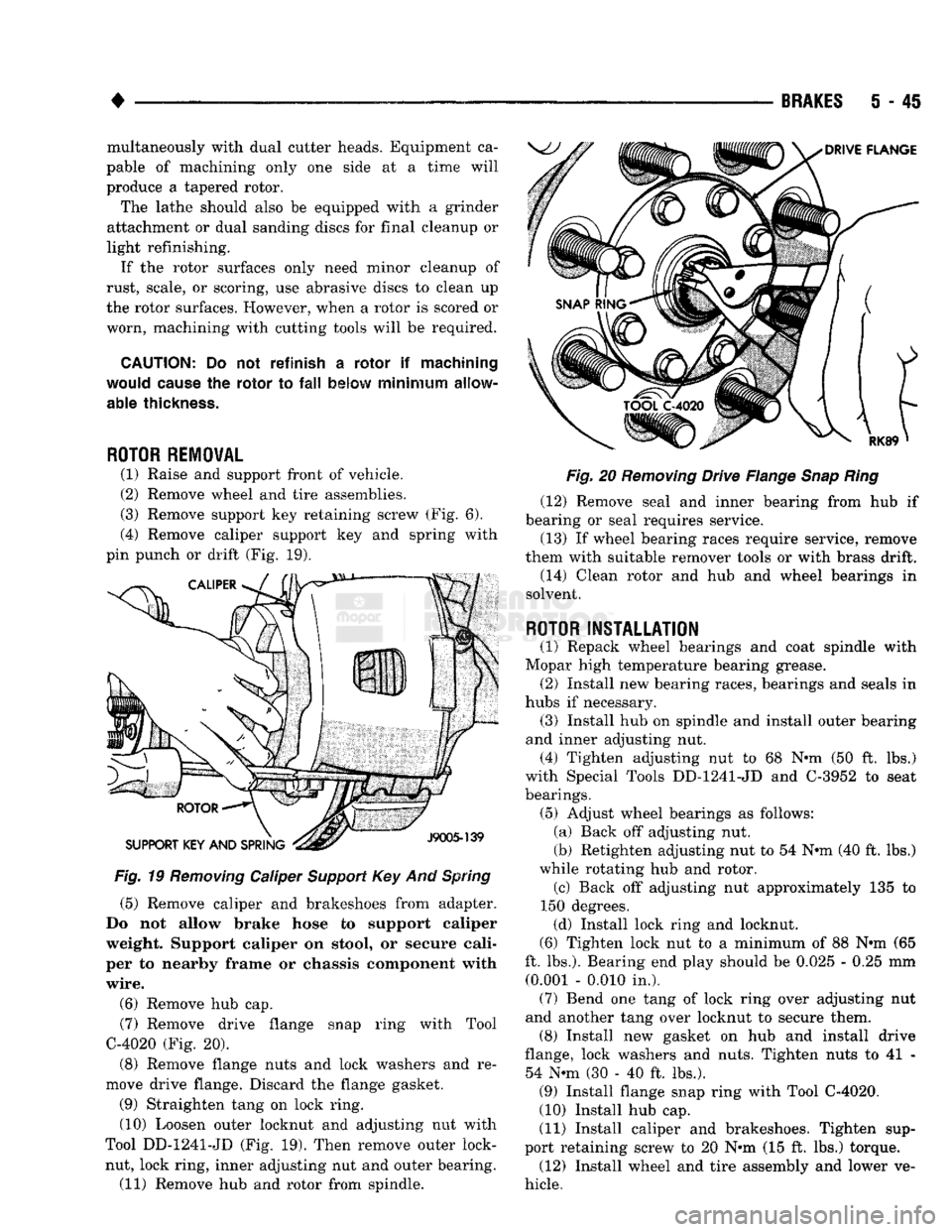

ROTOR REMOVAL

(1) Raise and support front of vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove support key retaining screw (Fig. 6).

(4) Remove caliper support key and spring with

pin punch or drift (Fig. 19).

Fig.

19

Removing

Caliper

Support

Key And

Spring

(5) Remove caliper and brakeshoes from adapter.

Do not allow brake hose to support caliper

weight. Support caliper on stool, or secure cali

per to nearby frame or chassis component with

wire.

(6) Remove hub cap. (7) Remove drive flange snap ring with Tool

C-4020 (Fig. 20).

(8) Remove flange nuts and lock washers and re

move drive flange. Discard the flange gasket.

(9) Straighten tang on lock ring. (10) Loosen outer locknut and adjusting nut with

Tool DD-1241-JD (Fig. 19). Then remove outer lock- nut, lock ring, inner adjusting nut and outer bearing. (11) Remove hub and rotor from spindle.

Fig.

20

Removing

Drive Flange

Snap

Ring

(12) Remove seal and inner bearing from hub if

bearing or seal requires service.

(13) If wheel bearing races require service, remove

them with suitable remover tools or with brass drift. (14) Clean rotor and hub and wheel bearings in

solvent.

ROTOR

INSTALLATION

(1) Repack wheel bearings and coat spindle with

Mopar high temperature bearing grease. (2) Install new bearing races, bearings and seals in

hubs if necessary. (3) Install hub on spindle and install outer bearing

and inner adjusting nut. (4) Tighten adjusting nut to 68 Nrni (50 ft. lbs.)

with Special Tools DD-1241-JD and C-3952 to seat

bearings. (5) Adjust wheel bearings as follows: (a) Back off adjusting nut.

(b) Retighten adjusting nut to 54 N*m (40 ft. lbs.)

while rotating hub and rotor. (c) Back off adjusting nut approximately 135 to

150 degrees. (d) Install lock ring and locknut.

(6) Tighten lock nut to a minimum of 88 N»m (65

ft. lbs.). Bearing end play should be 0.025 - 0.25 mm (0.001 - 0.010 in.). (7) Bend one tang of lock ring over adjusting nut

and another tang over locknut to secure them. (8) Install new gasket on hub and install drive

flange, lock washers and nuts. Tighten nuts to 41 - 54 N«m (30 - 40 ft. lbs.). (9) Install flange snap ring with Tool C-4020.

(10) Install hub cap.

(11) Install caliper and brakeshoes. Tighten sup

port retaining screw to 20 Nnn (15 ft. lbs.) torque. (12) Install wheel and tire assembly and lower ve

hicle.

Page 252 of 1502

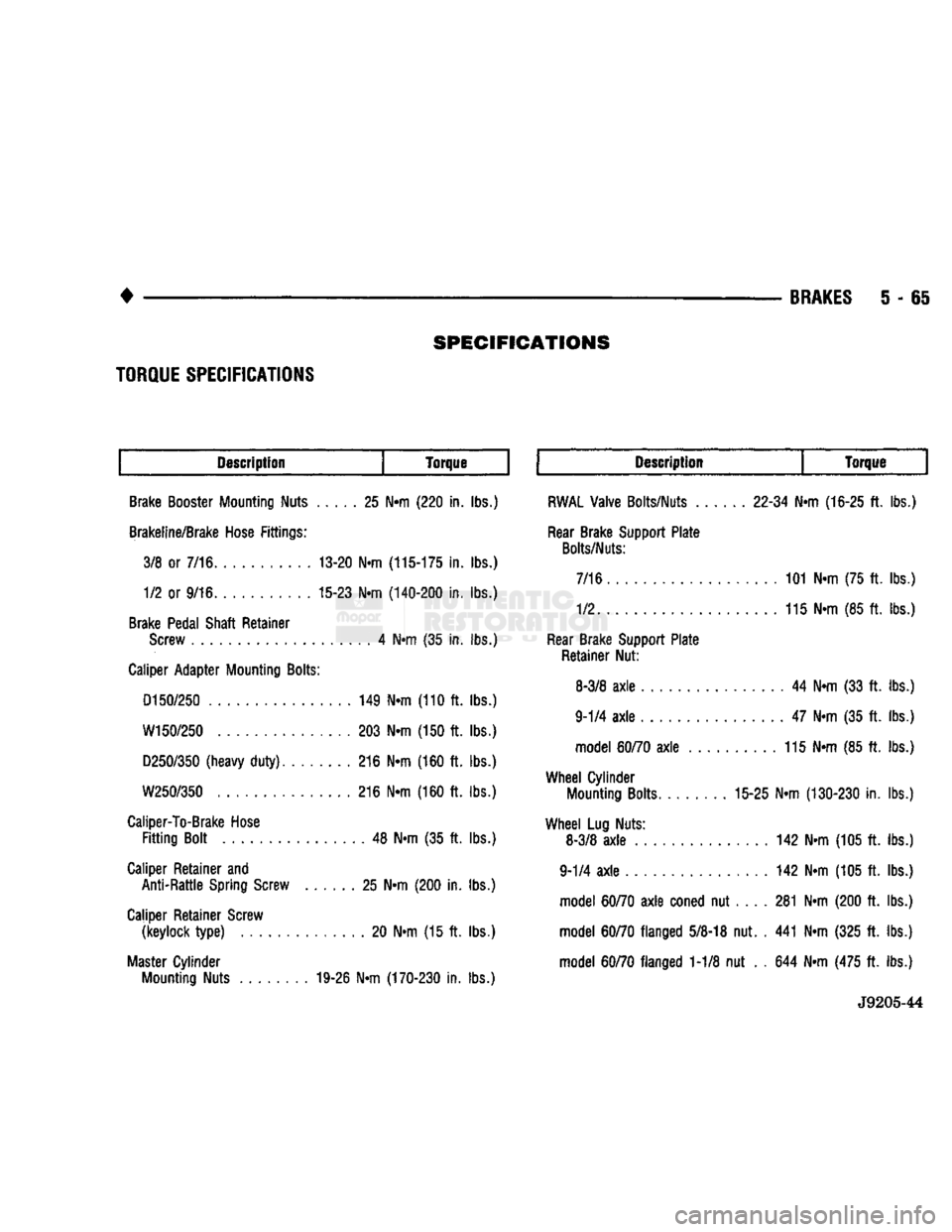

•

SPECIFICATIONS

BRAKES

5 - 65

Description

Torque Description

Torque

Brake Booster Mounting Nuts 25 N«m (220 in. lbs.)

Brakeline/Brake Hose Fittings: 3/8 or 7/16 13-20 Nrn

(115-175

in. lbs.) 1/2 or 9/16 15-23 N«m

(140-200

in. lbs.)

Brake Pedal Shaft Retainer Screw 4 Ntn (35 in. lbs.)

Caliper Adapter Mounting

Bolts:

D150/250

149 N«m (110 ft. lbs.)

W150/250

203 N«m (150 ft. lbs.)

D250/350

(heavy

duty)

216 Nrn (160 ft. lbs.)

W250/350

216 N»m (160 ft. lbs.)

Caliper-To-Brake Hose

Fitting

Bolt 48 N«m (35 ft. lbs.)

Caliper Retainer and Anti-Rattle Spring Screw 25 N«m (200 in. lbs.)

Caliper Retainer Screw (keylock

type)

20 N«m (15 ft. lbs.)

Master Cylinder Mounting Nuts 19-26 N«m

(170-230

in. lbs.)

RWAL

Valve Bolts/Nuts

22-34

Nrn

(16-25

ft. lbs.)

Rear Brake Support Plate

Bolts/Nuts:

7/16 101 N»m (75 ft. lbs.)

1/2 115 N«m (85 ft. lbs.)

Rear Brake Support Plate Retainer Nut:

8-3/8

axle

44 N«m (33 ft. lbs.)

9-1/4

axle

47 N-m (35 ft. lbs.) model

60/70

axle

115 N-m (85 ft. lbs.)

Wheel

Cylinder Mounting Bolts 15-25 N«m

(130-230

in. lbs.)

Wheel

Lug Nuts: 8-3/8

axle

142 N»m (105 ft. lbs.)

9-1/4

axle

142 Nrn (105 ft. lbs.) model

60/70

axle

coned nut 281 N«m (200 ft. lbs.)

model

60/70

flanged

5/8-18

nut. . 441 Nrn (325 ft. lbs.)

model

60/70

flanged 1-1/8 nut . . 644 Nrn (475 ft. lbs.)

J9205-44

TORQUE

SPECIFICATIONS