turn signal DODGE TRUCK 1993 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1993, Model line: TRUCK, Model: DODGE TRUCK 1993Pages: 1502, PDF Size: 80.97 MB

Page 15 of 1502

10 INTRODUCTION

•

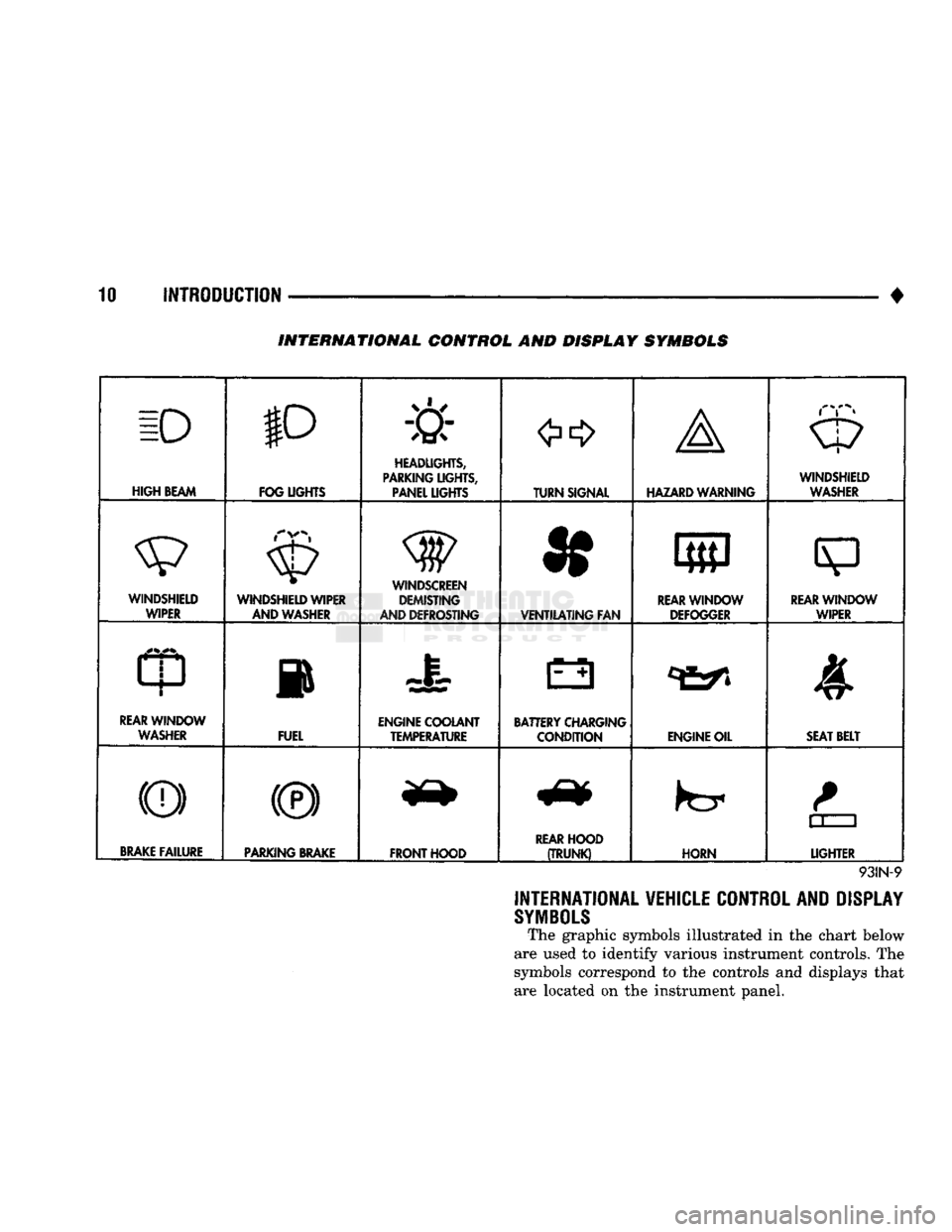

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

ID

HIGH

BEAM P

FOG UGHTS -&

HEADLIGHTS,

PARKING UGHTS, PANEL UGHTS TURN SIGNAL A

HAZARD WARNING WINDSHIELD

WASHER

WINDSHIELD WIPER WINDSHIELD WIPER

AND WASHER

AND DEFROSTING *

VENTILATING

FAN 8

M f

REAR

WINDOW DEFOGGER

sp

REARWINLX)W WIPER

CD

l

m

REAR

WINDOW WASHER FUEL ENGINE COOLANT

TEMPERATURE BATTERY CHARGING

CONDITION ENGINE OIL

SEAT

BELT

(©) (®) ky

11 J

LIGHTER

BRAKE

FAILURE

PARKING

BRAKE

FRONT HOOD

REAR

HOOD

(TRUNK)

HORN

11 J

LIGHTER

93IN-9

INTERNATIONAL VEHICLE CONTROL AND DISPLAY

SYMBOLS

The graphic symbols illustrated in the chart below

are used to identify various instrument controls. The

symbols correspond to the controls and displays that are located on the instrument panel.

Page 31 of 1502

0 - 12

LUBRICATION

AND

MAINTENANCE

• A vehicle equipped with SAE approved sling-type

towing equipment can be used (Fig. 10). However,

many vehicles are equipped with air dams, spoilers, and/or ground effect panels. In this case a wheel-lift

towing vehicle or a flat-bed hauling vehicle is recom mended (Fig. 10). If a flat bed device is used, the ap

proach angle should not exceed 15 degrees.

GROUND CLEARANCE The lifted wheels of the disabled vehicle should be

a minimum of 10 cm (4 in.) off the ground. Make

sure there is enough clearance at the opposite end.

This is critical when towing over rough terrain. If necessary, the rear ground clearance can be increased by removing the wheels from the lifted end

and then towing with the lifted end closer to the

ground. If the rear wheels are removed, secure the

brake drums. A 20 cm (8 in.) ground clearance must

be maintained between brake drums or rotors and the ground.

SAFETY PRECAUTIONS The following safety precautions must be consid

ered when preparing for and during a vehicle towing operation:

• Remove exhaust pipe tips that interfere with the

tow sling and crossbar • Padding should be placed between the tow sling/

crossbar and any painted surfaces

• If the vehicle is damaged, secure the loose and pro

truding parts

• Always use a safety chain system that is indepen dent of the lifting and towing equipment

• When placing tow hooks on the rear axle, position them so they do not damage the brake tubing or

hoses

• Do not allow any of the towing equipment to con

tact the fuel tank

• Do not tow the vehicle by connecting to the front

or rear shock absorbers

• The operator should not go under a vehicle while

it is lifted by the towing equipment. The vehicle

should first be supported by safety stands

• Do not allow passengers in a vehicle being towed

• Observe all state and local laws involving warning signals, night illumination, speed, etc.

• Do not exceed a towing speed of 48 km/h (30 mph)

• Avoid towing distances of more than 24 km (15

miles) whenever possible • Do not attach tow chains or a tow sling to a

bumper, the steering linkage, the universal joints, or a drive shaft

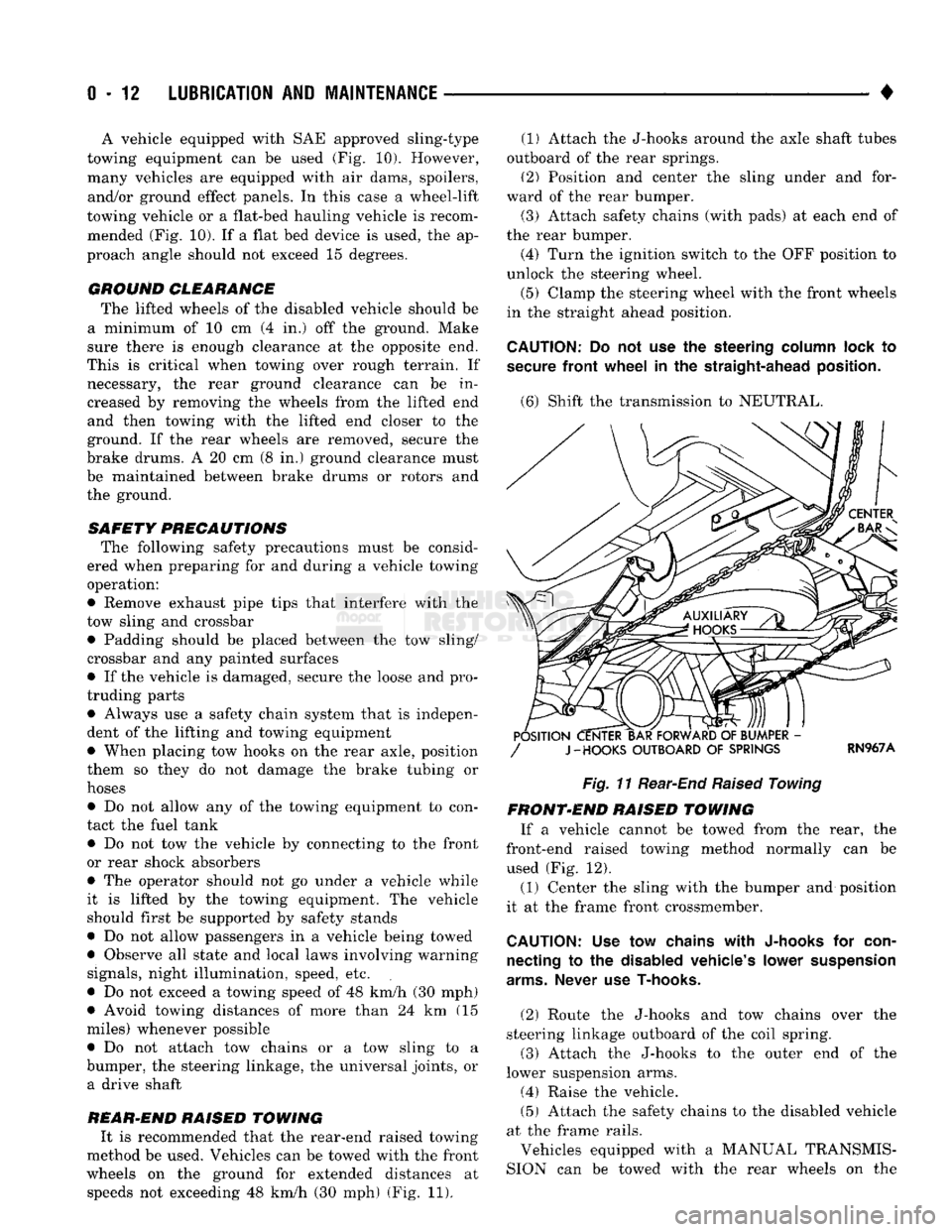

REAR-END RAISED TOWING It is recommended that the rear-end raised towing

method be used. Vehicles can be towed with the front

wheels on the ground for extended distances at speeds not exceeding 48 km/h (30 mph) (Fig. 11). (1) Attach the J-hooks around the axle shaft tubes

outboard of the rear springs. (2) Position and center the sling under and for

ward of the rear bumper. (3) Attach safety chains (with pads) at each end of

the rear bumper.

(4) Turn the ignition switch to the OFF position to

unlock the steering wheel. (5) Clamp the steering wheel with the front wheels

in the straight ahead position.

CAUTION:

Do not use the steering

column

lock

to

secure

front

wheel

in the straight-ahead

position.

(6) Shift the transmission to NEUTRAL.

POSITION CENTER BAR FORWARD

OF

BUMPER

-

/

J-HOOKS OUTBOARD

OF

SPRINGS

RN967A

Fig. 11 Rear-End

Raised

Towing

FRONT'END RAISED TOWING If a vehicle cannot be towed from the rear, the

front-end raised towing method normally can be

used (Fig. 12). (1) Center the sling with the bumper and position

it at the frame front crossmember.

CAUTION:

Use tow

chains

with

J-hooks

for

con

necting

to the

disabled

vehicle's

lower

suspension

arms.

Never use

T-hooks.

(2) Route the J-hooks and tow chains over the

steering linkage outboard of the coil spring.

(3) Attach the J-hooks to the outer end of the

lower suspension arms.

(4) Raise the vehicle.

(5.) Attach the safety chains to the disabled vehicle

at the frame rails.

Vehicles equipped with a MANUAL TRANSMIS

SION can be towed with the rear wheels on the

Page 247 of 1502

5

- 60

BRAKES

Fig.

2

Antilock

Electronic Control

Module

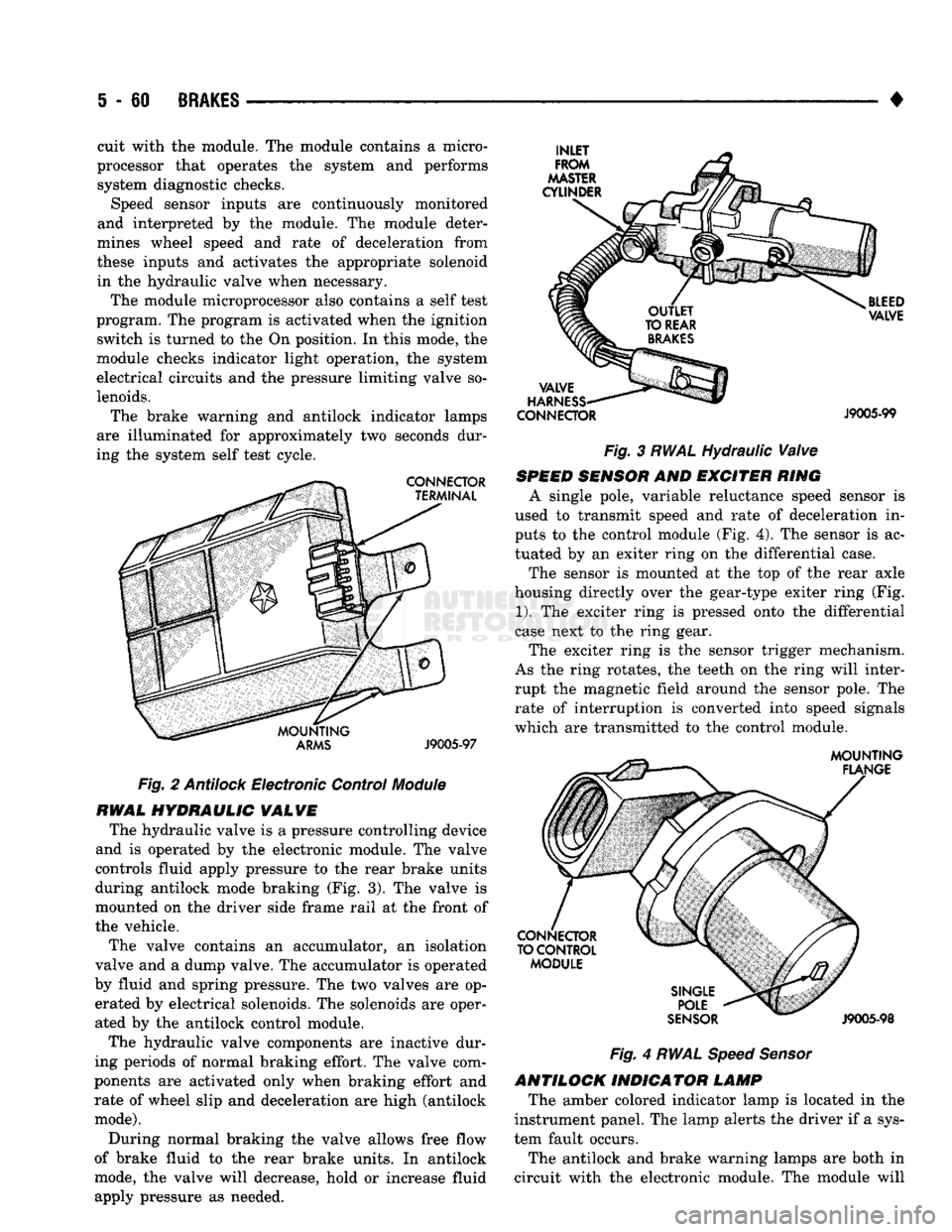

RWAL

HYDRAULIC

VALVE

The hydraulic valve is a pressure controlling device

and is operated by the electronic module. The valve

controls fluid apply pressure to the rear brake units

during antilock mode braking (Fig. 3). The valve is

mounted on the driver side frame rail at the front of

the vehicle.

The valve contains an accumulator, an isolation

valve and a dump valve. The accumulator is operated

by fluid and spring pressure. The two valves are op erated by electrical solenoids. The solenoids are oper

ated by the antilock control module.

The hydraulic valve components are inactive dur

ing periods of normal braking effort. The valve com

ponents are activated only when braking effort and rate of wheel slip and deceleration are high (antilock

mode).

During normal braking the valve allows free flow

of brake fluid to the rear brake units. In antilock

mode, the valve will decrease, hold or increase fluid

apply pressure as needed. •

CONNECTOR

J9005-99

Fig. 3 RWAL Hydraulic Valve

SPEED

SENSOR

AND EXCITER RING

A single pole, variable reluctance speed sensor is

used to transmit speed and rate of deceleration in

puts to the control module (Fig. 4). The sensor is ac

tuated by an exiter ring on the differential case.

The sensor is mounted at the top of the rear axle

housing directly over the gear-type exiter ring (Fig.

1).

The exciter ring is pressed onto the differential

case next to the ring gear.

The exciter ring is the sensor trigger mechanism.

As the ring rotates, the teeth on the ring will inter

rupt the magnetic field around the sensor pole. The rate of interruption is converted into speed signals

which are transmitted to the control module.

Fig.

4

RWAL Speed Sensor

ANTILOCK INDICATOR LAMP The amber colored indicator lamp is located in the

instrument panel. The lamp alerts the driver if a sys

tem fault occurs.

The antilock and brake warning lamps are both in

circuit with the electronic module. The module will

cuit with the module. The module contains a micro

processor that operates the system and performs system diagnostic checks. Speed sensor inputs are continuously monitored

and interpreted by the module. The module deter

mines wheel speed and rate of deceleration from

these inputs and activates the appropriate solenoid in the hydraulic valve when necessary.

The module microprocessor also contains a self test

program. The program is activated when the ignition switch is turned to the On position. In this mode, the

module checks indicator light operation, the system

electrical circuits and the pressure limiting valve so

lenoids.

The brake warning and antilock indicator lamps

are illuminated for approximately two seconds dur

ing the system self test cycle.

Page 248 of 1502

•

BRAKES

5 - 61 cause the two lamps to illuminate or flash to alert

the driver that system operation is either normal or

that a fault has occurred.

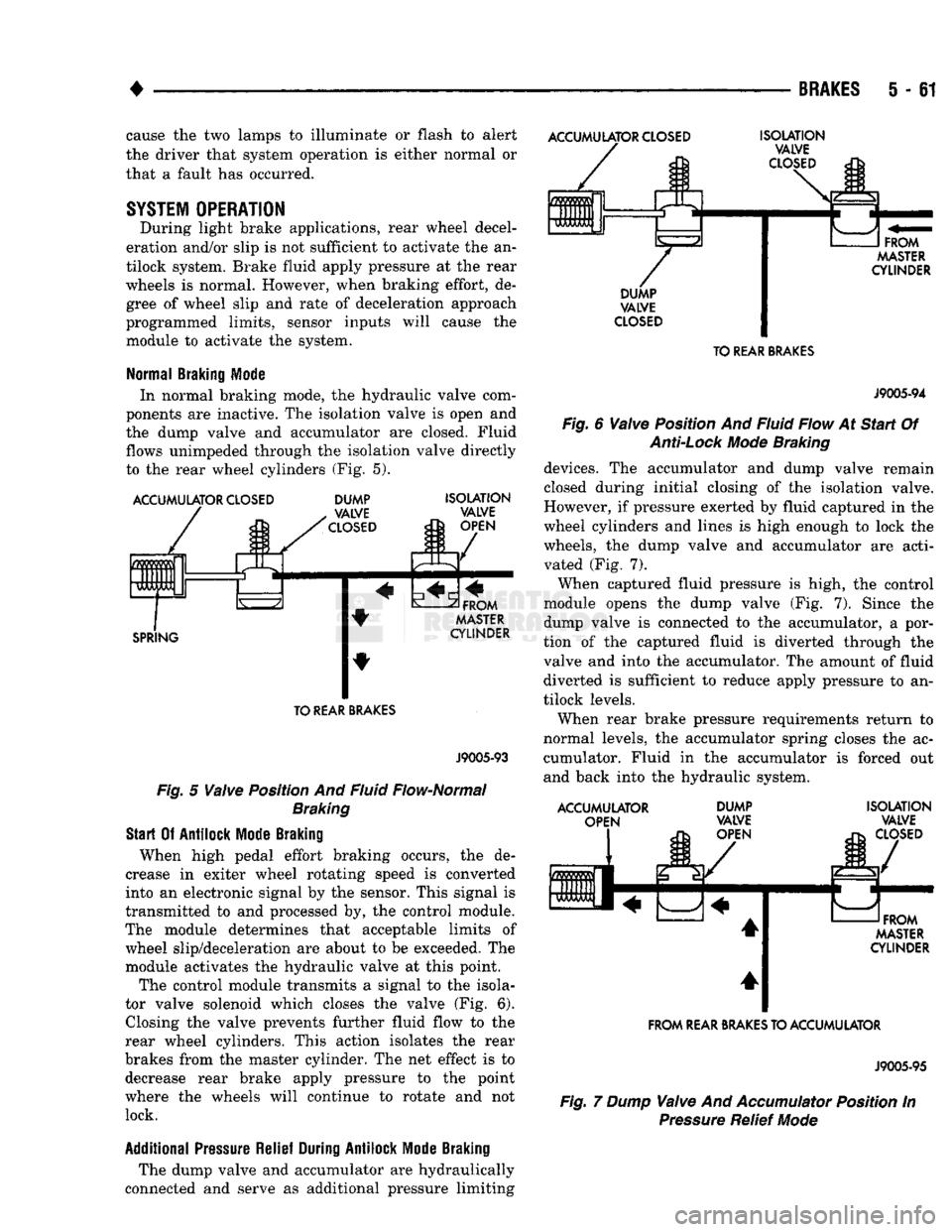

SYSTEM

OPERATION

During light brake applications, rear wheel decel

eration and/or slip is not sufficient to activate the an

tilock system. Brake fluid apply pressure at the rear

wheels is normal. However, when braking effort, de gree of wheel slip and rate of deceleration approach

programmed limits, sensor inputs will cause the module to activate the system.

Normal

Braking

Mode

In normal braking mode, the hydraulic valve com

ponents are inactive. The isolation valve is open and

the dump valve and accumulator are closed. Fluid

flows unimpeded through the isolation valve directly

to the rear wheel cylinders (Fig. 5).

ACCUMULATOR

CLOSED

ACCUMULATOR

CLOSED

0 m

m

0 UUb Ft

L DUMP

VALVE

CLOSED

SPRING

ISOLATION

VALVE

OPEN

FROM

MASTER

CYLINDER TO

REAR

BRAKES

J9005-93

Fig.

5

Valve

Position And Fluid Flow-Normal

Braking

Start

Of

Antilock

Mode

Braking

When high pedal effort braking occurs, the de

crease in exiter wheel rotating speed is converted

into an electronic signal by the sensor. This signal is

transmitted to and processed by, the control module.

The module determines that acceptable limits of wheel slip/deceleration are about to be exceeded. The

module activates the hydraulic valve at this point.

The control module transmits a signal to the isola

tor valve solenoid which closes the valve (Fig. 6). Closing the valve prevents further fluid flow to the

rear wheel cylinders. This action isolates the rear

brakes from the master cylinder. The net effect is to decrease rear brake apply pressure to the point

where the wheels will continue to rotate and not lock.

Additional

Pressure

Relief

During

Antilock

Mode

Braking

The dump valve and accumulator are hydraulically

connected and serve as additional pressure limiting

ISOLATION

VALVE

CLOSED

FROM

MASTER

CYLINDER

DUMP

VALVE

CLOSED

TO

REAR

BRAKES

J9005-94

Fig.

6

Valve

Position And Fluid Flow At

Start

Of

Anti-Lock

Mode

Braking

devices. The accumulator and dump valve remain

closed during initial closing of the isolation valve.

However, if pressure exerted by fluid captured in the

wheel cylinders and lines is high enough to lock the

wheels, the dump valve and accumulator are acti vated (Fig. 7).

When captured fluid pressure is high, the control

module opens the dump valve (Fig. 7). Since the

dump valve is connected to the accumulator, a por

tion of the captured fluid is diverted through the

valve and into the accumulator. The amount of fluid diverted is sufficient to reduce apply pressure to an

tilock levels.

When rear brake pressure requirements return to

normal levels, the accumulator spring closes the ac cumulator. Fluid in the accumulator is forced out

and back into the hydraulic system.

ACCUMULATOR OPEN DUMP

VALVE

OPEN ISOLATION

VALVE

CLOSED

FROM

MASTER

CYLINDER

FROM

REAR

BRAKES

TO ACCUMULATOR

J9005-95

Fig.

7 Dump

Valve

And

Accumulator

Position In

Pressure

Relief

Mode

Page 249 of 1502

i - 62

BRAKES

•

Isolation/Dump

Valve Cycle Times

Activation (opening/closing) of the isolation and

dump valves is continuous during antilock operation.

The valves cycle rapidly in response to speed sensor inputs and control module signal commands. Cycle

times are measured in milliseconds.

As the demand for antilock mode brake operation

is decreased, the module deactivates the hydraulic

valve components to restore normal brake operation.

ANTILOCK

SERVICE

DIAGNOSIS

GENERAL INFORMATION An antilock system malfunction will be indicated

by illumination of the amber antilock warning lamp.

The red brake warning lamp may also illuminate.

If a problem occurs, system diagnosis should begin

with a fluid level check followed by a visual exami

nation of the system electrical and hydraulic connec

tions.

If obvious defects (low fluid, leaks, loose connections, etc.) are not evident, road test the vehi

cle.

A road test should help determine if a malfunc

tion is actually related to an antilock component.

During the road test, note if other conditions are

evident such as a low pedal, pull, grab, or similar condition. Remember that brake malfunctions such as low fluid, system leaks, parking brakes partially

applied, will also affect the antilock system. The idea

is to determine if a malfunction is actually related to

an anti-lock component.

If a road test does reveal a problem, repeat the

road test with the owner driving. Make sure the owner is not riding the brake pedal, or has forgotten

to release the parking brakes. Either situation will

generate a fault and cause the antilock light to illu

minate.

SYSTEM FAULT

CODES

The antilock control module generates flash codes

to help identify the cause of an antilock system fault. Two different control modules are used with the

1992/1993 RWAL system. A type I module is used in

some early production models. All remaining produc

tion models are equipped with a type II module. The type I and II modules are identified by the way

fault codes 9 and 11 are processed. If the vehicle has a type I module, codes 9 and 11 are not erased when

the ignition switch is turned to Off position. If the vehicle has a type II module, codes 9 and 11 are

erased when the switch is turned to Off.

FAULT CODES WITH TYPE I CONTROL

MODULE

The microprocessor in the electronic control module

has a memory and a self test feature. The self test

feature is activated whenever the ignition switch is

turned to Accessory or Run position. If a system fault is detected, the control module il

luminates the antilock light and stores the fault code

in memory. Fault codes are retained in memory even after turning the ignition switch to Off position.

FAULT CODES WITH TYPE II CONTROL

MODULE The microprocessor in the electronic control module

has a memory and a self test feature. The self test

feature is activated whenever the ignition switch is

turned to Accessory or Run position.

If a system fault is detected, the control module

will illuminate the antilock indicator lamp and store

fault codes 1 through 8, 10 and 12 through 15 in the

microprocessor memory. When one of these fault

codes is generated, the control module will retain the code after the ignition switch is turned to the Off po

sition.

When fault code 9 is generated, the code only re

mains in microprocessor memory while the ignition switch is in Run position. Turning the ignition

switch to Off position erases fault code 9. However, if

the problem still exists when the switch is turned

back to Run position, code 9 will reappear in memory after 20 seconds and the antilock light will illumi

nate once again.

When fault code 11 is generated, the antilock light

will illuminate when vehicle speed exceeds approxi mately 60.35 km/h (37.5 mph). Code 11 only remains in memory while the ignition switch is in the Run

position and the fault is present.

When the cause of a fault code 11 is corrected, the

antilock light goes off. Code 11 is erased when the ig

nition switch is turned to Off position. However, if

the problem cause still exists when the ignition switch is turned to Run position, code 11 will reap

pear when vehicle speed exceeds approximately 60.35 km/h (37.5 mph).

FAULT

CODE

CAPACITY

The microprocessor memory will store and display

only one fault code at a time. The stored code can be

displayed by grounding the RWAL diagnostic connec

tor.

FAULT

CODE

IDENTIFICATION

To determine what the fault code is, momentarily

ground the RWAL diagnostic connector and count

the number of times the amber antilock lamp flashes. Fault codes and typical malfunctions are outlined in Figure 8. Note that when a fault code is gen

erated, the red brake warning lamp will also

illuminate. The initial flash will be a long flash followed by a

number of short flashes. The long flash indicates the

beginning of the fault number sequence and the short flashes are a continuation of that sequence.

Page 322 of 1502

•

ELECTRICAL

ELECTRICAL

8A - 1

Group

AUDIO

SYSTEMS

8F

BATTERY/STARTER/GENERATOR

SERVICE

.. 8B

BATTERY/STARTING/CHARGING

SYSTEMS

DIAGNOSTICS

8A

HORNS

8G

IGNITION

SYSTEMS

8D

INSTRUMENT PANEL AND

GAUGES

8E

LAMPS

8L

POWER

LOCKS

8P

INDEX

Group

POWER

MIRRORS

8T

POWER

WINDOWS 8S

REAR

WINDOW DEFOGGER 8N

TURN

SIGNALS

AND HAZARD WARNING

FLASHERS

8J

VEHICLE

SPEED

CONTROL SYSTEM 8H WARNING BUZZER SYSTEM 8U

WINDSHIELD WIPERS AND

WASHERS

8K

WIRING DIAGRAMS 8W

BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS

CONTENTS

page

page

BATTERY TEST

PROCEDURES

2 GENERATOR TEST

PROCEDURES

ON VEHICLE . 13

ENGINE

STARTER MOTOR TEST

PROCEDURES

..9 SPECIFICATIONS 18

GENERAL

INFORMATION 1

GENERAL INFORMATION

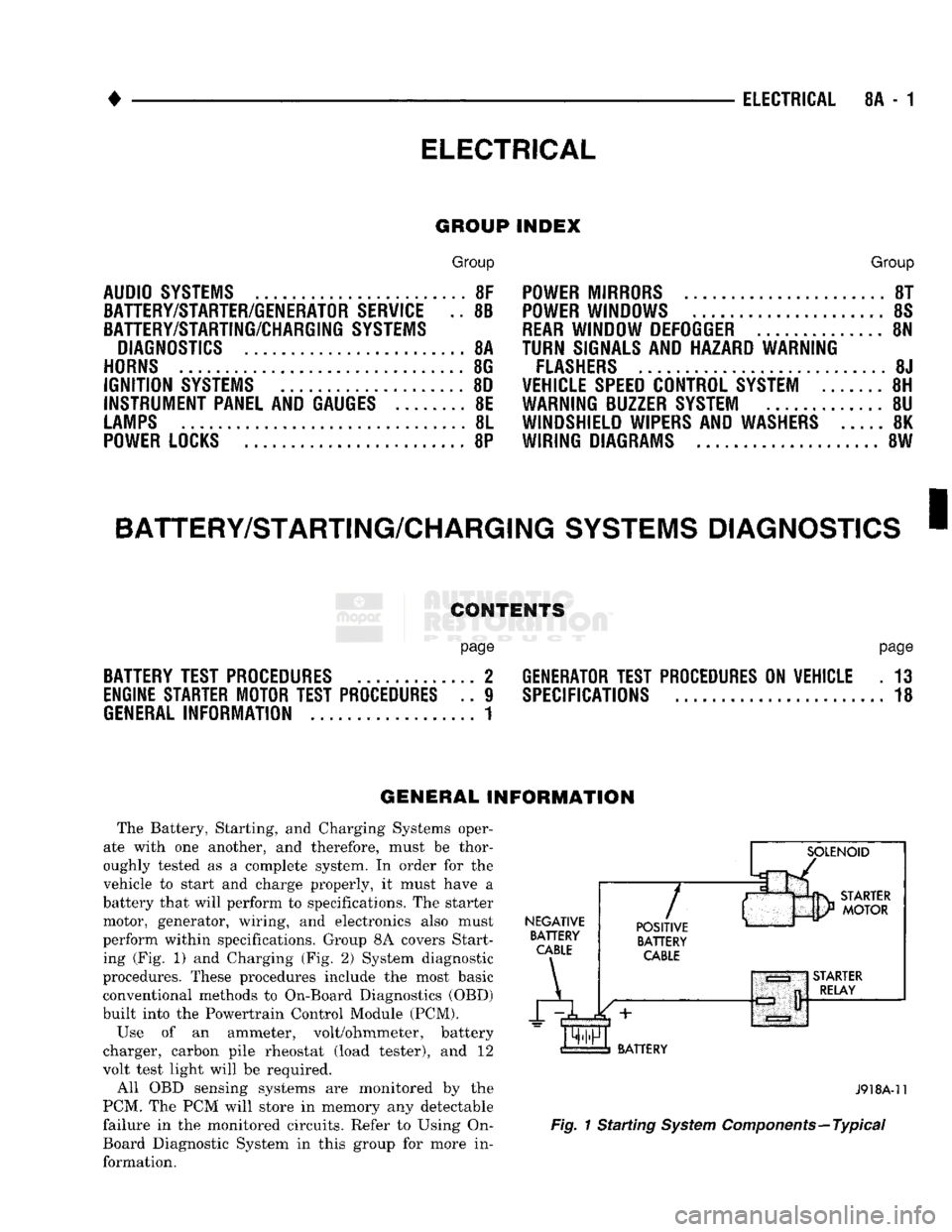

The Battery, Starting, and Charging Systems oper

ate with one another, and therefore, must be thor

oughly tested as a complete system. In order for the

vehicle to start and charge properly, it must have a

battery that will perform to specifications. The starter

motor, generator, wiring, and electronics also must

perform within specifications. Group 8A covers Start ing (Fig. 1) and Charging (Fig. 2) System diagnostic

procedures. These procedures include the most basic

conventional methods to On-Board Diagnostics (OBD)

built into the Powertrain Control Module (PCM).

Use of an ammeter, volt/ohmmeter, battery

charger, carbon pile rheostat (load tester), and 12

volt test light will be required.

All OBD sensing systems are monitored by the

PCM. The PCM will store in memory any detectable

failure in the monitored circuits. Refer to Using On-

Board Diagnostic System in this group for more in formation.

NEGATIVE

BATTERY

CABLE

A

7

POSITIVE

BATTERY

CABLE

BATTERY

J918A-11

Fig.

1 Starting

System

Components—Typical

Page 358 of 1502

•

IGNITION

SYSTEMS

80 - 7

DIAGNOSTICS/SERW1CE

PROCEDURES

INDEX

page

Automatic Shut Down (ASD) Relay

7

Camshaft Position

Sensor

Test

...............

7

Crankshaft Position

Sensor

Test

8

Distributor

Cap

8

Distributor

Rotor

8

Engine

Coolant Temperature

Sensor

Test

10

General

Information

7

Ignition

Coil

8

Ignition

Secondary

Circuit

Diagnosis

10

GENERAL

INFORMATION

This section

of the

group, Diagnostics/Service Pro

cedures, will discuss basic ignition system diagnos

tics

and

service adjustments. For system operation

and

component identification,

refer

to the

Component Identification/System Opera

tion section

of

this group. For removal

or

installation

of

ignition system com

ponents, refer

to the

Component Removal/Installa

tion section

of

this group. For other useful information, refer

to

On-Board

Di

agnostics

in the

General Diagnosis sections

of

Group

14,

Fuel System

in

this manual. For operation

of the DRB II

Diagnostic Scan Tool,

refer

to the

appropriate Powertrain Diagnostic Proce

dures service manual.

AUTOMATIC SHUT DOWN

(ASD)

RELAY

Refer

to

Relays—Operation/Testing

in the

Group

14,

Fuel System section

of

this service manual.

CAMSHAFT POSITION SENSOR TEST

The camshaft position sensor

is

located

in the

dis

tributor

on all

engines. To perform

a

complete test

of

this sensor

and its

circuitry, refer

to the DRB II

diagnostic scan tool.

Also refer

to the

appropriate Powertrain Diagnostics

Procedures manual.

To

test

the

sensor only, refer

to

the following: For this test,

an

analog (non-digital) voltmeter

is needed.

Do not

remove

the

distributor connector from

the

distributor. Using small paper clips, insert

them into

the

backside

of the

distributor wire har ness connector

to

make contact with

the

terminals.

Be sure that

the

connector

is not

damaged when

in

serting

the

paper clips. Attach voltmeter leads

to

these paper clips. (1) Connect

the

positive (

+

)

voltmeter lead into

the sensor output wire. This

is at

done

the

distribu tor wire harness connector.

For

wire identification,

refer

to

Group

8W,

Wiring Diagrams.

page

Ignition

Timing

12

Intake Manifold Charge

Air

Temperature

Sensor

Test

12

Manifold Absolute Pressure (MAP)

Sensor

Test

. 12

Oxygen

Sensor

Tests

17

Powertrain Control Module (PCM)

............

14

Spark

Plug Secondary Cables

16

Spark

Plugs

............................

14

Throttle

Position

Sensor

Test

17

(2) Connect

the

negative

(-)

voltmeter lead into

the

ground wire.

For

wire identification, refer

to

Group

8W, Wiring Diagrams.

(3)

Set the

voltmeter

to the 15

Volt

DC

scale. (4) Remove distributor

cap

from distributor

(two

screws). Rotate (crank)

the

engine until

the

distribu

tor rotor

is

pointed towards

the

rear

of

vehicle.

The

movable pulse ring should

now be

within

the

sensor

pickup.

(5) Turn ignition

key to ON

position. Voltmeter

should read approximately

5.0

volts.

(6)

If

voltage

is not

present, check

the

voltmeter

leads

for a

good connection.

(7)

If

voltage

is

still

not

present, check

for

voltage

at

the

supply wire.

For

wire identification, refer

to

Group

8W,

Wiring Diagrams.

(8)

If

voltage

is not

present

at

supply wire, check

for voltage

at

pin-7

of

powertrain control module (PCM) 60-way connector. Leave

the PCM

connector

connected

for

this test. (9)

If

voltage

is

still

not

present, perform vehicle

test using

the DRB II

diagnostic scan tool. (10)

If

voltage

is

present

at

pin-7,

but not at the

supply wire: (a) Check continuity between

the

supply wire.

This

is

checked between

the

distributor connector and pin-7

at the PCM. If

continuity

is not

present,

repair

the

harness

as

necessary. (b) Check

for

continuity between

the

camshaft

position sensor output wire

and

pin-44

at the PCM.

If continuity

is not

present, repair

the

harness

as

necessary. (c) Check

for

continuity between

the

ground cir

cuit wire

at the

distributor connector

and

ground.

If continuity

is not

present, repair

the

harness

as

necessary. (11) While observing

the

voltmeter, crank

the en

gine with ignition switch.

The

voltmeter needle should fluctuate between

0 and 5

volts while

the en

gine

is

cranking. This verifies that

the

camshaft

po

sition sensor

in the

distributor

is

operating properly

and

a

sync pulse signal

is

being generated.

Page 376 of 1502

IGNITION

SYSTEMS

80 - 25

IGNITION

SWITCH

INDEX

General

Information

page

. . 25

GENERAL

INFORMATION

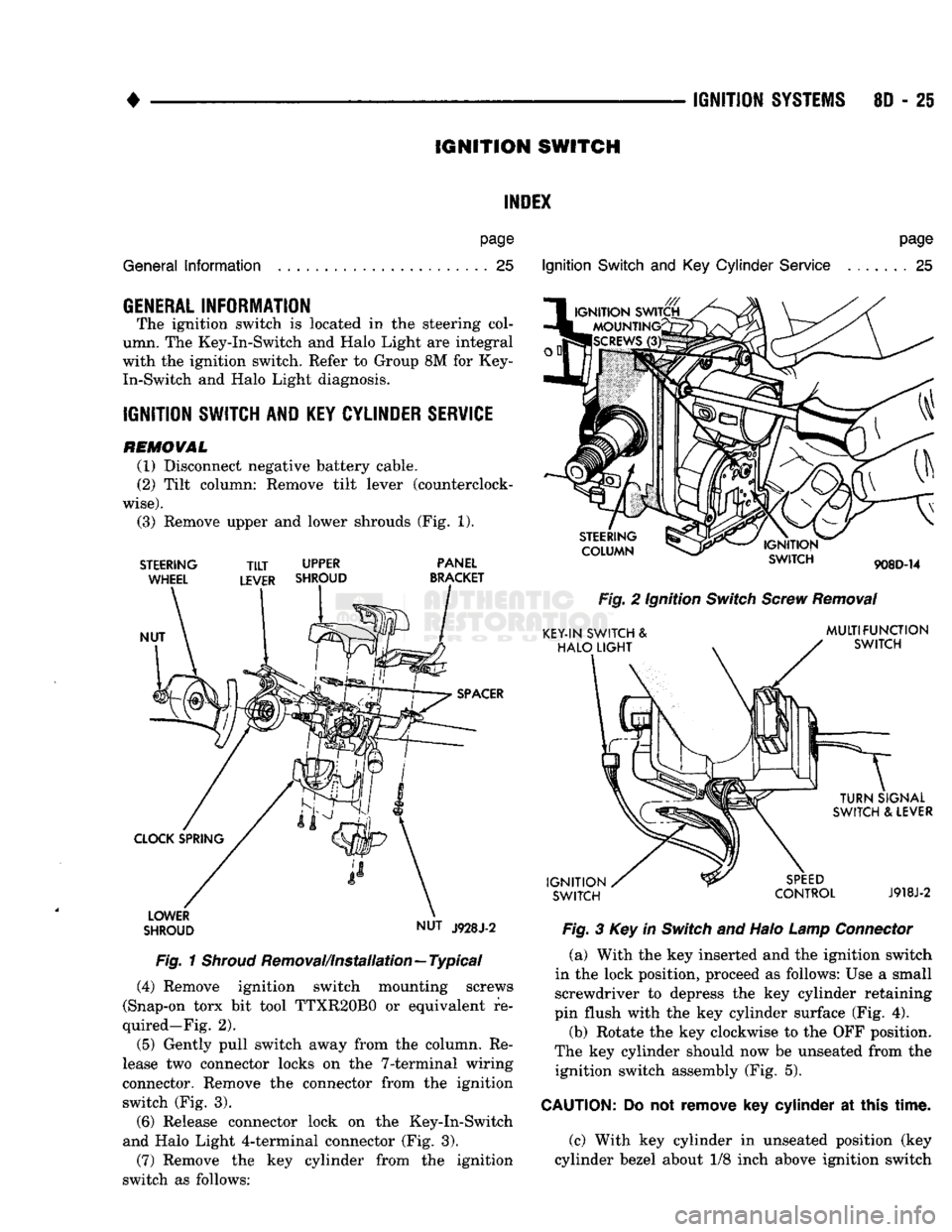

The ignition switch is located in the steering col

umn. The Key-In-Switch and Halo Light are integral

with the ignition switch. Refer to Group 8M for Key- In-Switch and Halo Light diagnosis.

IGNITION

SWITCH

AND

KEY

CYLINDER

SERVICE

REMOVAL

(1) Disconnect negative battery cable.

(2) Tilt column: Remove tilt lever (counterclock

wise).

(3) Remove upper and lower shrouds (Fig. 1).

STEERING

WHEEL

NUT

TILT

UPPER

LEVER SHROUD PANEL

BRACKET

SPACER

CLOCK SPRING LOWER

SHROUD NUT

J928J-2

Fig.

1

Shroud

Removal/Installation—Typical (4) Remove ignition switch mounting screws

(Snap-on torx bit tool TTXR20B0 or equivalent re

quired—Fig. 2).

(5) Gently pull switch away from the column. Re

lease two connector locks on the 7-terminal wiring

connector. Remove the connector from the ignition switch (Fig. 3).

(6) Release connector lock on the Key-In-Switch

and Halo Light 4-terminal connector (Fig. 3).

(7) Remove the key cylinder from the ignition

switch as follows:

Ignition

Switch

and Key

Cylinder

Service

page

. . 25

STEERING

COLUMN

IGNITION

SWITCH

908D-14

Fig.

2 Ignition

Switch

Screw

Removal

KEY-IN SWITCH &

HALO

LIGHT

MULTIFUNCTION

SWITCH

IGNITION

SWITCH

TURN

SIGNAL

SWITCH & LEVER

SPEED

CONTROL

J918J-2

Fig.

3 Key in

Switch

and Halo

Lamp

Connector

(a) With the key inserted and the ignition switch

in the lock position, proceed as follows: Use a small screwdriver to depress the key cylinder retaining

pin flush with the key cylinder surface (Fig. 4).

(b) Rotate the key clockwise to the OFF position.

The key cylinder should now be unseated from the ignition switch assembly (Fig. 5).

CAUTION:

Do not

remove

key

cylinder

at

this

time.

(c) With key cylinder in unseated position (key

cylinder bezel about 1/8 inch above ignition switch

Page 382 of 1502

• • ^ ^ ^ INSTRUMENT PANEL AND GAUGES 8E - 1

CONTENTS

page

CLUSTER AND GAUGE SERVICE PROCEDURES . 12

CLUSTER AND GAUGE TEST PROCEDURES .. i

GENERAL INFORMATION . 1

page

MESSAGE CENTER-DIESEL ENGINE ........ 4

MESSAGE CENTER-GAS ENGINE .......... 3

SWITCH

AND PANEL COMPONENT SERVICE . 16

GENERAL

INFORMATION

INDEX

page

Generator

Indicating

System

2

Distance

Sensor

2

Electronic

Digital

Clock

3

Fuel

Level

Indicating

System

1

page

Malfunction

Indicator

(Check

Engine)

3

Oil

Pressure

Warning

Lamp

................. 2

Speedometer/Odometer

System

2

Temperature

and Oil

Indicating

System

......... 2

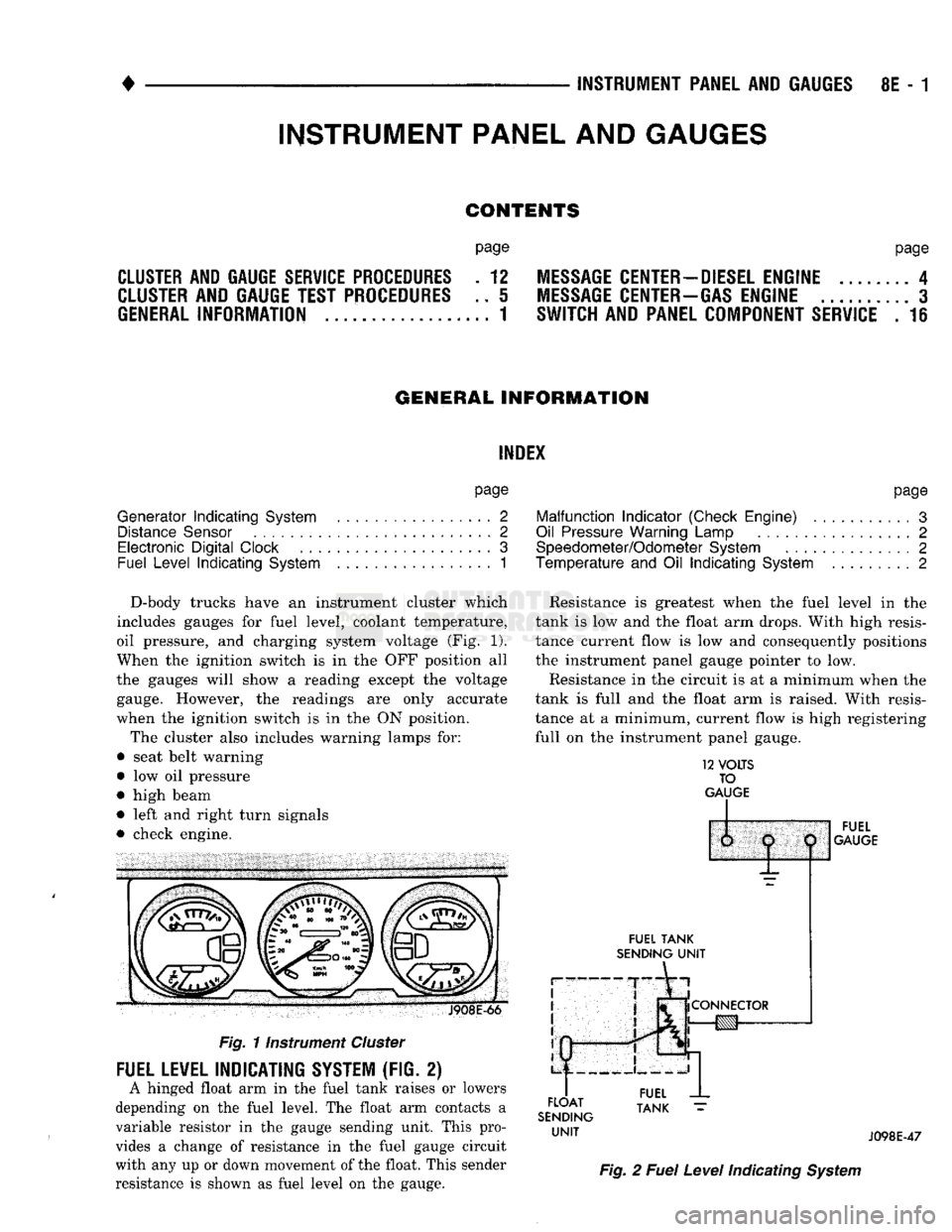

D-body trucks have an instrument cluster which

includes gauges for fuel level, coolant temperature,

oil pressure, and charging system voltage (Fig. 1).

When the ignition switch is in the OFF position all

the gauges will show a reading except the voltage gauge. However, the readings are only accurate

when the ignition switch is in the ON position.

The cluster also includes warning lamps for:

• seat belt warning

• low oil pressure

• high beam

• left and right turn signals

• check engine. J908E-66

Fig.

11nstrument

Cluster

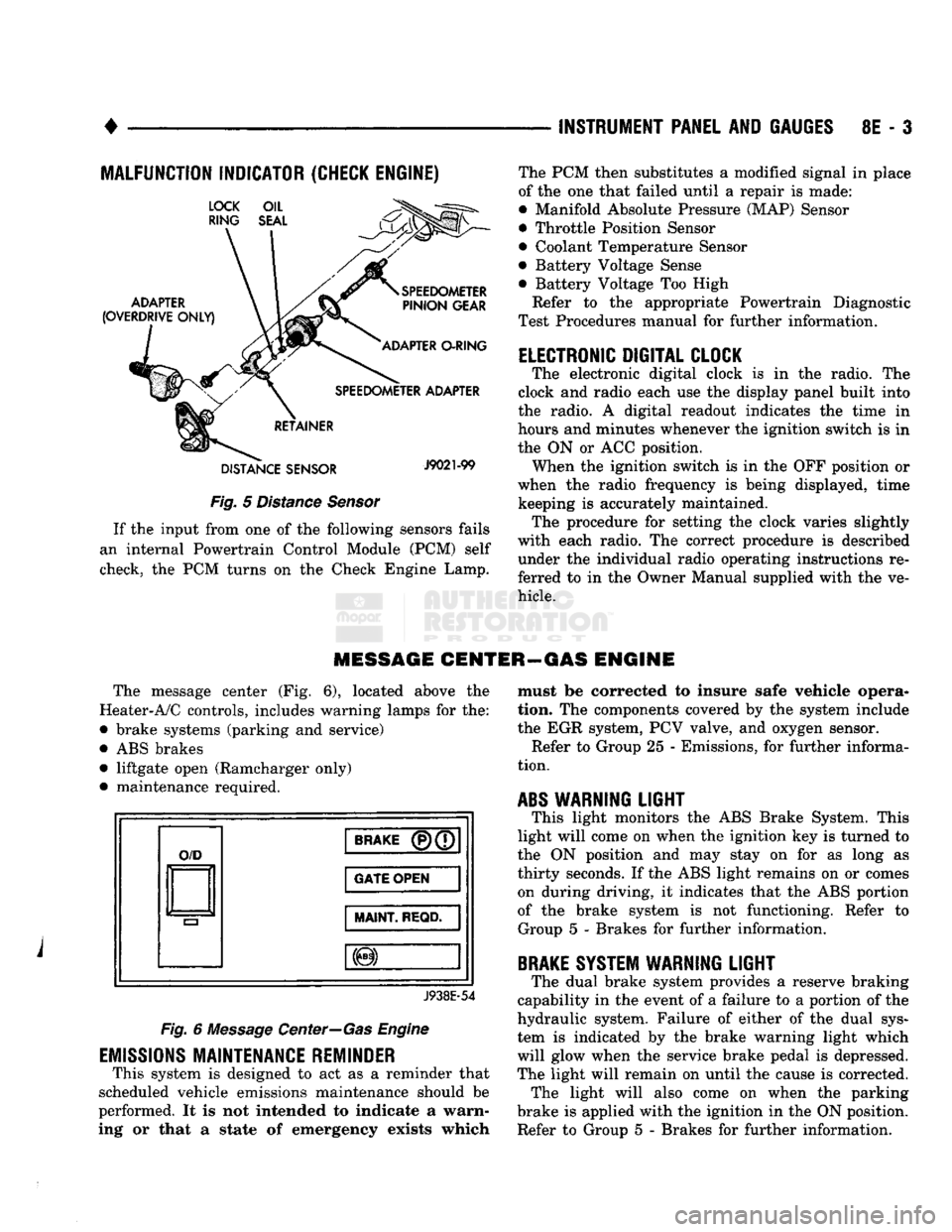

FUEL LEVEL INDICATING SYSTEM (FIG. 2)

A hinged float arm in the fuel tank raises or lowers

depending on the fuel level. The float arm contacts a

variable resistor in the gauge sending unit. This pro

vides a change of resistance in the fuel gauge circuit

with any up or down movement of the float. This sender

resistance is shown as fuel level on the gauge. Resistance is greatest when the fuel level in the

tank is low and the float arm drops. With high resis

tance current flow is low and consequently positions

the instrument panel gauge pointer to low.

Resistance in the circuit is at a minimum when the

tank is full and the float arm is raised. With resis

tance at a minimum, current flow is high registering

full on the instrument panel gauge.

12

VOLTS

TO

GAUGE

IP

FUEL

TANK

SENDING

UNIT

FLOAT

SENDING

UNIT

1:

1

j

^

fCONNECTOR

!g|yj-»—

FUEL

GAUGE

FUEL

TANK

J098E-47

Fig.

2

Fuel

Level

Indicating

System

INSTRUMENT PANEL AND GAUGES

Page 384 of 1502

•

INSTRUMENT PANEL

AND

GAUGES

8E - 3

MALFUNCTION INDICATOR (CHECK ENGINE)

Fig.

5

Distance Sensor

If

the

input from

one of the

following sensors fails

an internal Powertrain Control Module

(PCM)

self

check,

the PCM

turns

on the

Check Engine Lamp. The

PCM

then substitutes

a

modified signal

in

place

of

the one

that failed until

a

repair

is

made:

• Manifold Absolute Pressure (MAP) Sensor

• Throttle Position Sensor

• Coolant Temperature Sensor

• Battery Voltage Sense

• Battery Voltage

Too

High

Refer

to the

appropriate Powertrain Diagnostic

Test Procedures manual

for

further information.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock

is in the

radio.

The

clock

and

radio each

use the

display panel built into

the radio.

A

digital readout indicates

the

time

in

hours

and

minutes whenever

the

ignition switch

is in

the

ON or ACC

position. When

the

ignition switch

is in the OFF

position

or

when

the

radio frequency

is

being displayed, time keeping

is

accurately maintained. The procedure

for

setting

the

clock varies slightly

with each radio.

The

correct procedure

is

described under

the

individual radio operating instructions

re

ferred

to in the

Owner Manual supplied with

the ve

hicle.

MESSAGE CENTER—GAS ENGINE

The message center

(Fig. 6),

located above

the

Heater-A/C controls, includes warning lamps

for the:

• brake systems (parking

and

service)

•

ABS

brakes • liftgate open (Ramcharger only)

• maintenance required.

O/D

BRAKE

(P)(7

GATE OPEN

MAINT

REQD.

J938E-54

Fig.

6

Message Center—Gas Engine

EMISSIONS

MAINTENANCE REMINDER

This system

is

designed

to act as a

reminder that

scheduled vehicle emissions maintenance should

be

performed.

It is not

intended

to

indicate

a

warn

ing

or

that

a

state

of

emergency exists which must

be

corrected

to

insure safe vehicle opera

tion.

The

components covered

by the

system include

the

EGR

system,

PCV

valve,

and

oxygen sensor. Refer

to

Group

25 -

Emissions,

for

further informa

tion.

ABS

WARNING

LIGHT

This light monitors

the ABS

Brake System. This

light will come

on

when

the

ignition

key is

turned

to

the

ON

position

and may

stay

on for as

long

as

thirty seconds.

If the ABS

light remains

on or

comes on during driving,

it

indicates that

the ABS

portion

of

the

brake system

is not

functioning. Refer

to

Group

5 -

Brakes

for

further information.

BRAKE

SYSTEM WARNING

LIGHT

The dual brake system provides

a

reserve braking

capability

in the

event

of a

failure

to a

portion

of the

hydraulic system. Failure

of

either

of the

dual sys

tem

is

indicated

by the

brake warning light which

will glow when

the

service brake pedal

is

depressed.

The light will remain

on

until

the

cause

is

corrected. The light will also come

on

when

the

parking

brake

is

applied with

the

ignition

in the ON

position.

Refer

to

Group

5 -

Brakes

for

further information.