DODGE VIPER 2010 ZB II / 2.G Owner's Guide

Manufacturer: DODGE, Model Year: 2010, Model line: VIPER, Model: DODGE VIPER 2010 ZB II / 2.GPages: 80, PDF Size: 8.08 MB

Page 31 of 80

AERODYNAMICS

• The Viper ACR aerodynamics are capable of high levels of downforce which willnoticeably affect the grip and handling of the vehicle at speeds as low as 50 mph.

• Regularly inspect all of the aerodynamic components and attachments for damage or wear.

29

PERFORMANCE/ACR

Page 32 of 80

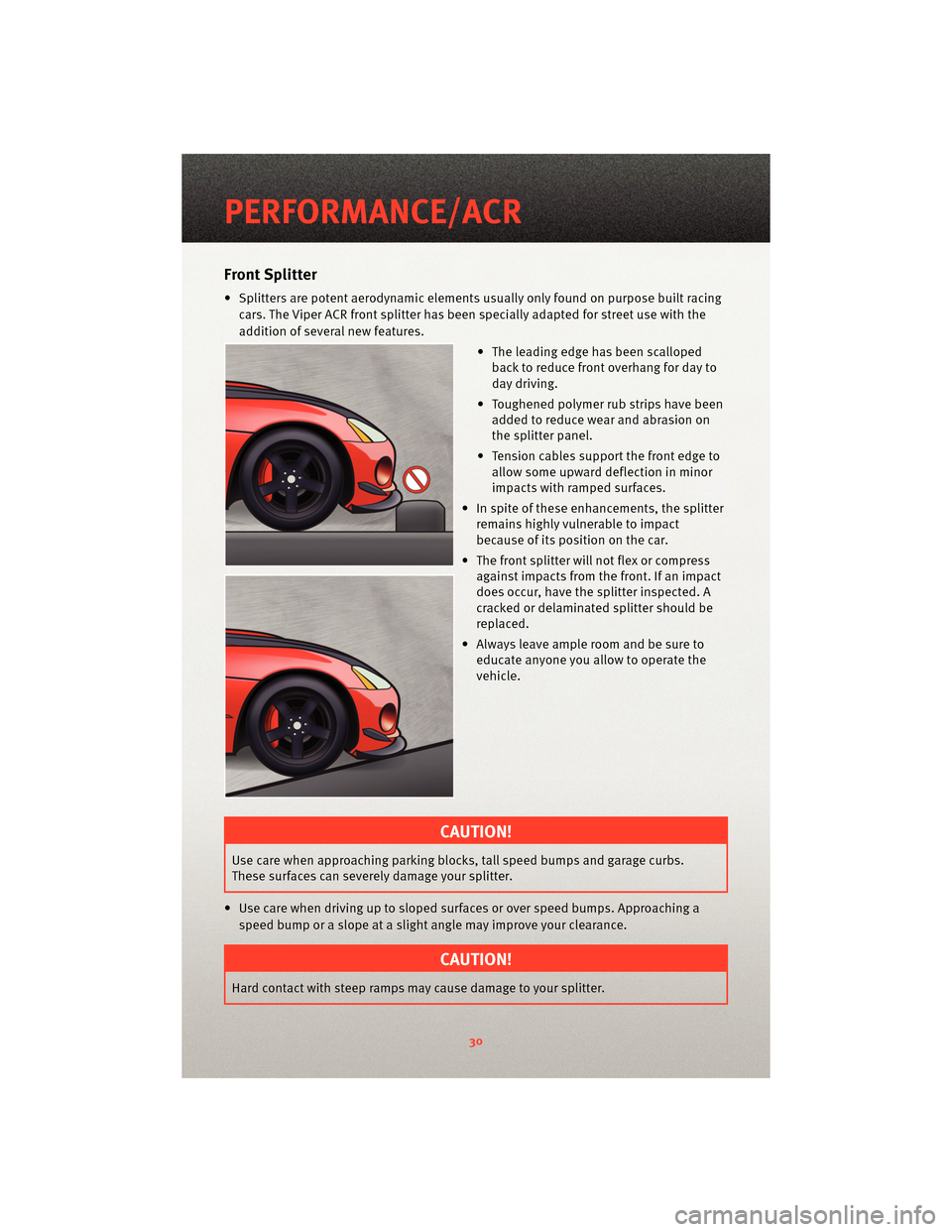

Front Splitter

• Splitters are potent aerodynamic elements usually only found on purpose built racing

cars. The Viper ACR front splitter has been specially adapted for street use with the

addition of several new features.

• The leading edge has been scallopedback to reduce front overhang for day to

day driving.

• Toughened polymer rub strips have been added to reduce wea r and abrasion on

the splitter panel.

• Tension cables support the front edge to allow some upward deflection in minor

impacts with ramped surfaces.

• In spite of these enhancements, the splitter remains highly vulnerable to impact

because of its position on the car.

• The front splitter will not flex or compress against impacts from the front. If an impact

does occur, have the splitter inspected. A

cracked or delaminated splitter should be

replaced.

• Always leave ample room and be sure to educate anyone you allow to operate the

vehicle.

CAUTION!

Use care when approaching parking bloc ks, tall speed bumps and garage curbs.

These surfaces can severely damage your splitter.

• Use care when driving up to sloped surfaces or over speed bumps. Approaching a speed bump or a slope at a slight angle may improve your clearance.

CAUTION!

Hard contact with steep ramps may cause damage to your splitter.

PERFORMANCE/ACR

30

Page 33 of 80

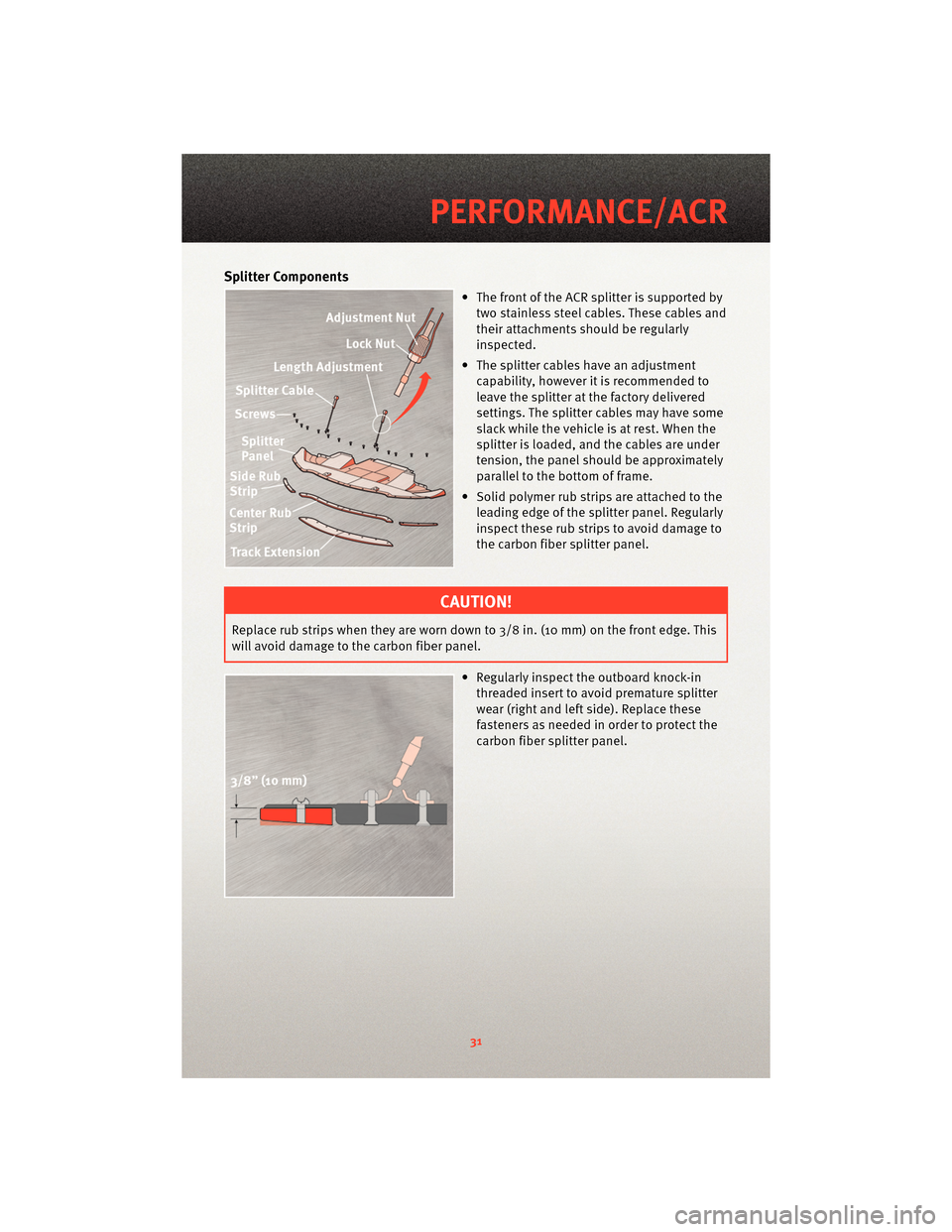

Splitter Components

• The front of the ACR splitter is supported bytwo stainless steel cables. These cables and

their attachments should be regularly

inspected.

• The splitter cables have an adjustment capability, however it is recommended to

leave the splitter at the factory delivered

settings. The splitter cables may have some

slack while the vehicle is at rest. When the

splitter is loaded, and the cables are under

tension, the panel should be approximately

parallel to the bottom of frame.

• Solid polymer rub strips are attached to the leading edge of the splitter panel. Regularly

inspect these rub strips to avoid damage to

the carbon fiber splitter panel.

CAUTION!

Replace rub strips when they are worn down to 3/8 in. (10 mm) on the front edge. This

will avoid damage to the carbon fiber panel.

• Regularly inspect the outboard knock-inthreaded insert to avoid premature splitter

wear (right and left side). Replace these

fasteners as needed in order to protect the

carbon fiber splitter panel.

31

PERFORMANCE/ACR

Page 34 of 80

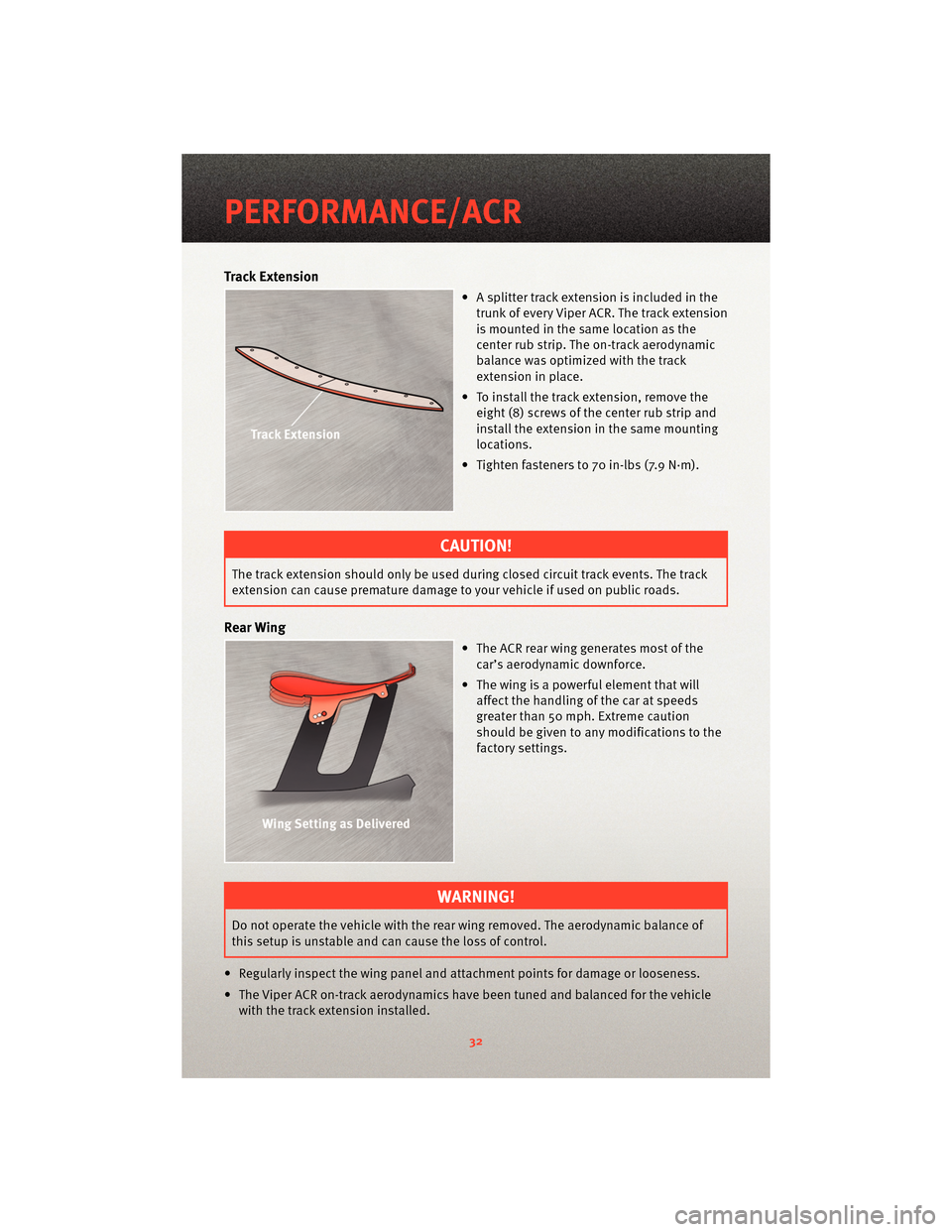

Track Extension

• A splitter track extension is included in thetrunk of every Viper ACR. The track extension

is mounted in the same location as the

center rub strip. The on-track aerodynamic

balance was optimized with the track

extension in place.

• To install the track extension, remove the eight (8) screws of the center rub strip and

install the extension in the same mounting

locations.

• Tighten fasteners to 70 in-lbs (7.9 N·m).

CAUTION!

The track extension should only be used during closed circuit track events. The track

extension can cause prem ature damage to your vehicle if used on public roads.

Rear Wing

• The ACR rear wing generates most of the

car’s aerodynamic downforce.

• The wing is a powerful element that will affect the handling of the car at speeds

greater than 50 mph. Extreme caution

should be given to any modifications to the

factory settings.

WARNING!

Do not operate the vehicle with the rear wing removed. The aerodynamic balance of

this setup is unstable and can cause the loss of control.

• Regularly inspect the wing panel and attachment points for damage or looseness.

• The Viper ACR on-track aerodynamics have been tuned and balanced for the vehicle with the track extension installed.

PERFORMANCE/ACR

32

Page 35 of 80

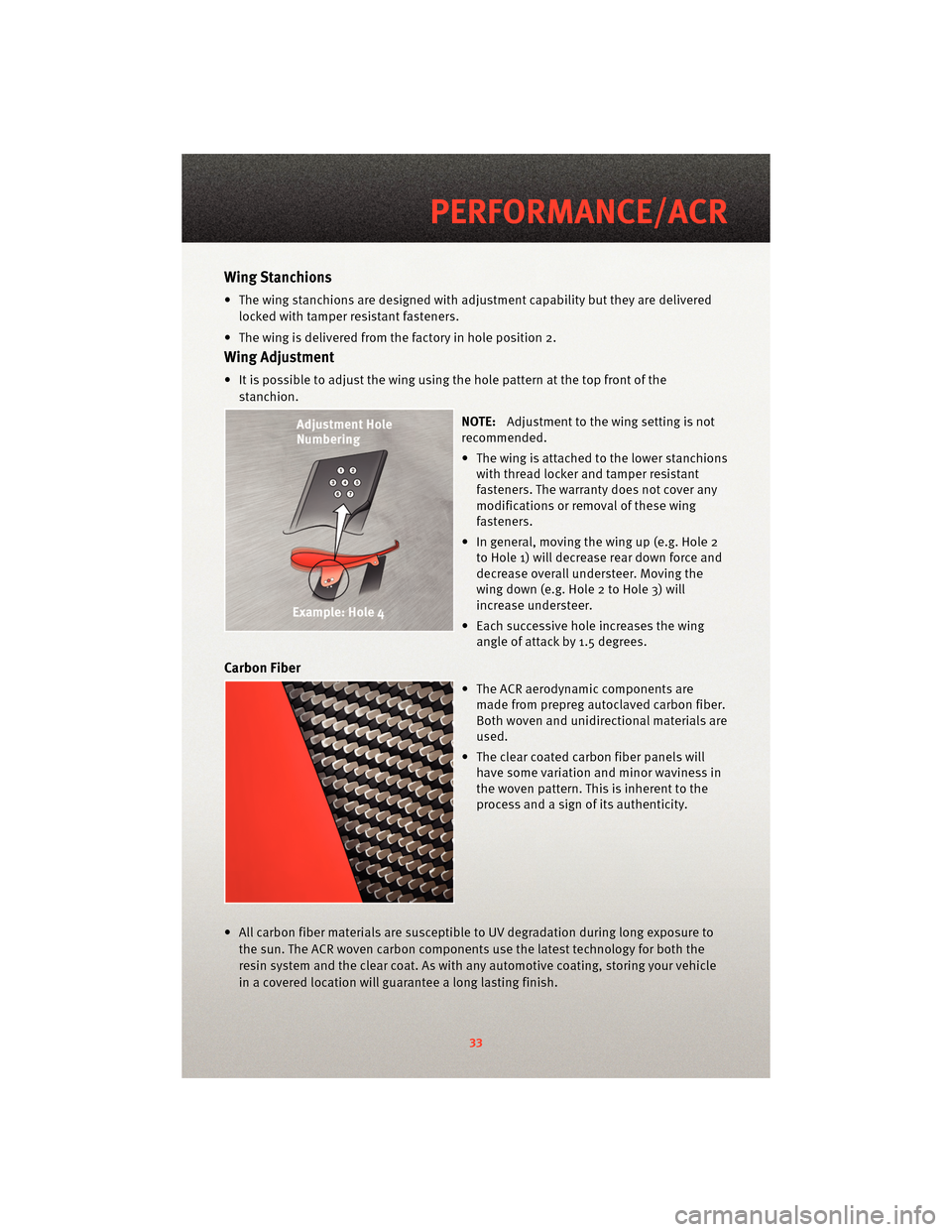

Wing Stanchions

• The wing stanchions are designed with adjustment capability but they are delivered

locked with tamper resistant fasteners.

• The wing is delivered from the factory in hole position 2.

Wing Adjustment

• It is possible to adjust the wing using the hole pattern at the top front of the stanchion.

NOTE:Adjustment to the wing setting is not

recommended.

• The wing is attached to the lower stanchions with thread locker and tamper resistant

fasteners. The warranty does not cover any

modifications or removal of these wing

fasteners.

• In general, moving the wing up (e.g. Hole 2 to Hole 1) will decrease rear down force and

decrease overall understeer. Moving the

wing down (e.g. Hole 2 to Hole 3) will

increase understeer.

• Each successive h ole increases the wing

angle of attack by 1.5 degrees.

Carbon Fiber

• The ACR aerodynamic components are made from prepreg autoclaved carbon fiber.

Both woven and unidirectional materials are

used.

• The clear coated carbon fiber panels will have some variation and minor waviness in

the woven pattern. This is inherent to the

process and a sign of its authenticity.

• All carbon fiber materials are susceptible to UV degradation during long exposure to

the sun. The ACR woven carbon components use the latest technology for both the

resin system and the clear coat. As with any automotive coating, storing your vehicle

in a covered location will guarantee a long lasting finish.

33

PERFORMANCE/ACR

Page 36 of 80

• The rear wing on the non two-tone ACR is molded completely with unidirectionalcarbon fiber and painted in body color. Some patterned or linear conditions may be

visible in the p ainted carbon fiber surfaces. This i s also a normal result of the carbon

fiber process.

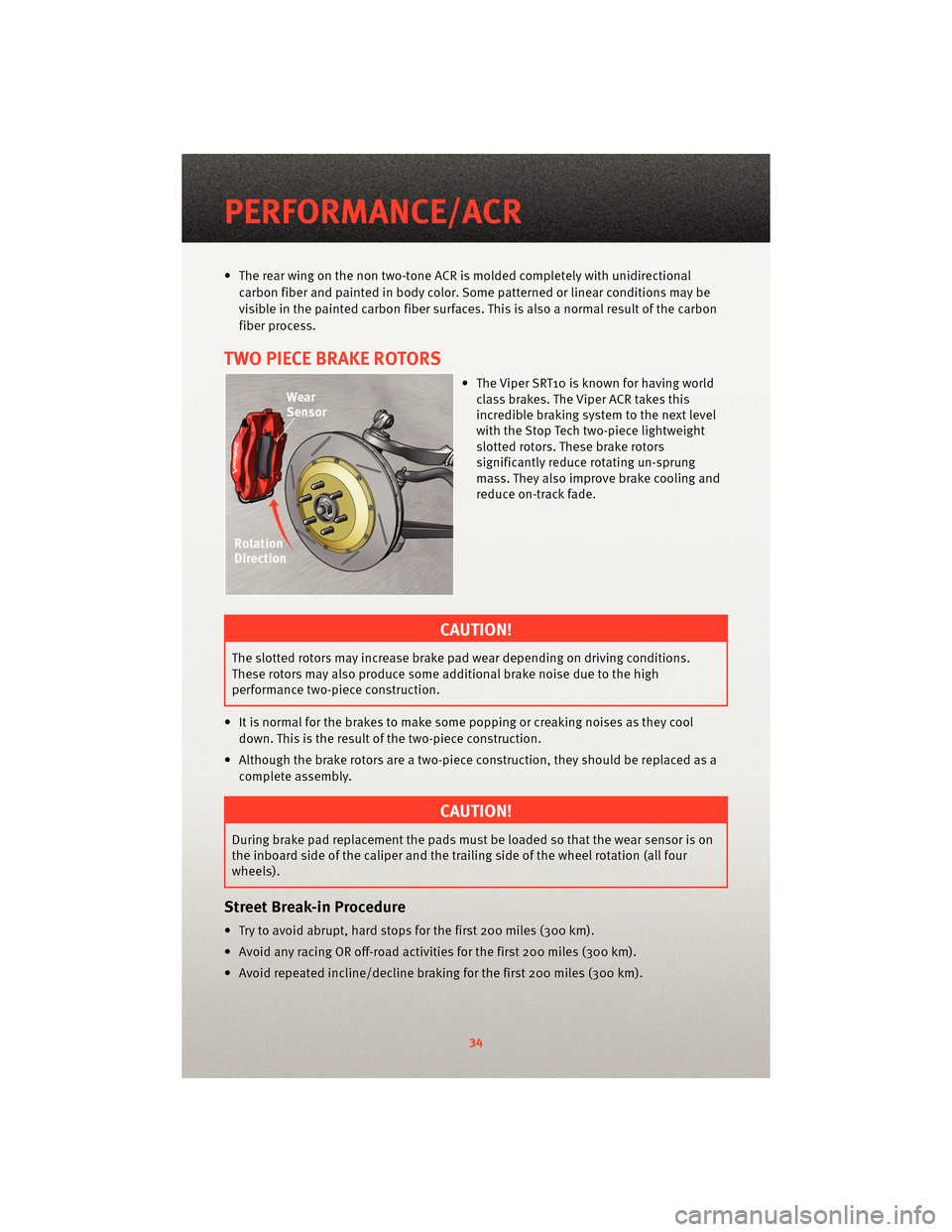

TWO PIECE BRAKE ROTORS

• The Viper SRT10 is known for having world class brakes . The Viper ACR takes this

incredible braking system to the next level

with the Stop Tech two-piece lightweight

slotted rotors. These brake rotors

significantly reduce rotating un-sprung

mass. They also improve brake cooling and

reduce on-track fade.

CAUTION!

The slotted rotors may increase brake pad wear depending on driving conditions.

These rotors may also produce some additional brake noise due to the high

performance two-piece construction.

• It is normal for the brakes to make some popping or creaking noises as they cool down. This is the result of the two-piece construction.

• Although the brake rotors are a two-piece construction, they should be replaced as a complete assembly.

CAUTION!

During brake pad replacement the pads must be loaded so that the wear sensor is on

the inboard side of the caliper and the trailing side of the wheel rotation (all four

wheels).

Street Break-in Procedure

• Try to avoid abrupt, hard stops for the first 200 miles (300 km).

• Avoid any racing OR off-road activities for the first 200 miles (300 km).

• Avoid repeated incline/decline braking for the first 200 miles (300 km).

PERFORMANCE/ACR

34

Page 37 of 80

Alternate Break in Procedure

CAUTION!

Chrysler does not endorse speeding on public roads; therefore, if a safe area cannot

be used for break-in, you must perform the street break-in procedure. Regardless of

completing the “street brea k-in procedure,” this alternative break-in procedure is

recommended before any track use of the vehicle.

• In the event that the street break-in procedure can’t be performed before the pads and

rotors are thermally stressed, use the following procedure:

• Read through the procedure and find a suitab le, safe and legal area to perform the

necessary stops.

• BEFORE starting the break-in procedure, drive with gentle braking. Do not use

brakes aggressively until performing brake-in procedure.

• Make a series of 10 stops from 60 to 5-10 MPH. At the end of each stop, immediately accelerate to 60 again for the next stop. Run all stops continuously in

one cycle.

NOTE: A moderate braking effort is needed to properly break in the rotors and pads. A

stopping force of approxim ately 0.8G’s, just short of ABS intervention, is the level of

pedal effort you are trying to attain.

• During the 60 to 5-10 MPH series of stops, the exact speed is not critical. Accelerateto approximately 60 and begin the brak ing cycle. As you approach 5-10 MPH, it is

not necessary to watch the speedometer. Keep your eyes on the road and

approximate your speed at the end of each cycle.

CAUTION!

Do not come to a complete stop! This will imprint pad material onto the rotor, causing

a vibration during future use.

• Watch for the following:

• On the 8th or 9th stop, there should be a distinct smell from the brakes. Smoke may be evident during earlier stops as well.

• Also on the 8th or 9th stop, some friction materials will experience “green fade”. This is a slight fading of the brakes. The fade will

stabilize, but not completely go away until the brakes have cooled.

• After the break-in cycle is finished there will be a light gray film on the rotor face. The gray film is pad material starting to transfer onto the

rotor face.

35

PERFORMANCE/ACR

Page 38 of 80

CAUTION!

Do not come to a complete stop when the system is hot and leave your foot on the

pedal. Pad material will immediately transfer to the rotor causing a vibration during

future use.

• After the final stop, drive as much as possible without using the brakes to cool off the system. Ideally, the brakes should be allowed to cool to ambient temperature

before using them again.

• After the first break in cycle, the brakes will still not be operating at optimum capacity. A second or third heat cycle is typically necessary before the brakes start

to work optimally. This will occur during everyday use.

Care and Maintenance

• Your brake calipers have a painted finish. Immedi ately clean off any spilled brake

fluid, wiping it off with a soft, clean terry-cloth towel.

• Do not use any harsh chemicals when cleaning your calipers. Wash your calipers with soap and rinse with water.

• Do not use any harsh chemicals when cleaning your rotor hats (the anodized center part of the rotor assembly). Wash your rotor hats with soap and rinse with water.

• Breaking-in rotors and pads is critical to the optimum performance of your new brakes. When breaking-in new parts, you are not only heat-cycling the pads, you are

also depositing a layer of pad material onto the rotor face. If not broken-in properly, an

uneven layer of pad material will be deposited onto the rotor, causing vibration.

• If you experience brake pedal pulsation, steering vibration, or repeatable brake noise, perform the break-in procedure again as soon as possible. This will re-condition the

rotor surface and remove irregular brake pad deposits. If concerns continue, please

visit y our local dealer fo r further diagnosis.

PILOT SPORT CUP TIRES

• Your Viper ACR comes equipped with Michelin Pilot Sport Cup competition oriented

tires that are DOT approved for street use. The Pilot Sport Cup tire uses a special tread

and compound which provides considerably more dry grip than normal street tires.

• Due to the special tread and compound of your Pilot Sport Cup Tires, the minimum tread depth can be reached earlier dependin g on your driving style, resulting in

reduced tire life. The special Pilot S port Cup tread and compound may lead to

performance degradation in cold climates, heavy rain or in conditions with standing

water.

WARNING!

Use extreme caution and drive slowly in wet situations to reduce the risk of

hydroplaning. Avoid driving in any conditions of heavy rain or standing water. These

conditions can cause loss of control or accident.

PERFORMANCE/ACR

36

Page 39 of 80

WARNING!

The Pilot Sport Cup tires were NOT intended to be driven on snow or ice. The Pilot

Sport Cup is a summer season tire and has diminished capability on cold road

surfaces (below 50°F). DO NOT OPERATE THE VEHICLE DURING THESE CONDITIONS.

Snow, ice and cold road surfaces can cause a loss of control or accident.

ADJUSTABLE DAMPERS

• The Viper ACR suspension includes a set of adjustable coil-over racing dampers built

by KW Suspensions. These dampers hav e been tuned by SRT handling engineers to

provide the maximum handling performance without sacrificing reasonable road

manners.

• The two-way adjustable dampers inc lude adjustments for compression (bump) and

rebound damping.

NOTE: Keep your damper settings at the street positions when operating your vehicle on

the street.

WARNING!

Only experienced track drivers should ma ke adjustments to the suspension settings.

Improper suspension adjustment can disrupt the balance of the vehicle and lead to a

loss of control or accident.

CAUTION!

Do not make any adjustments or modifications to the nitrogen pressure of the damper

canisters. This will void the warranty.

• The ACR suspension was designed and tuned with an uncompromising focus on handling. The ride response to road conditions m ay be harsher than expected from a

typical sports car.

37

PERFORMANCE/ACR

Page 40 of 80

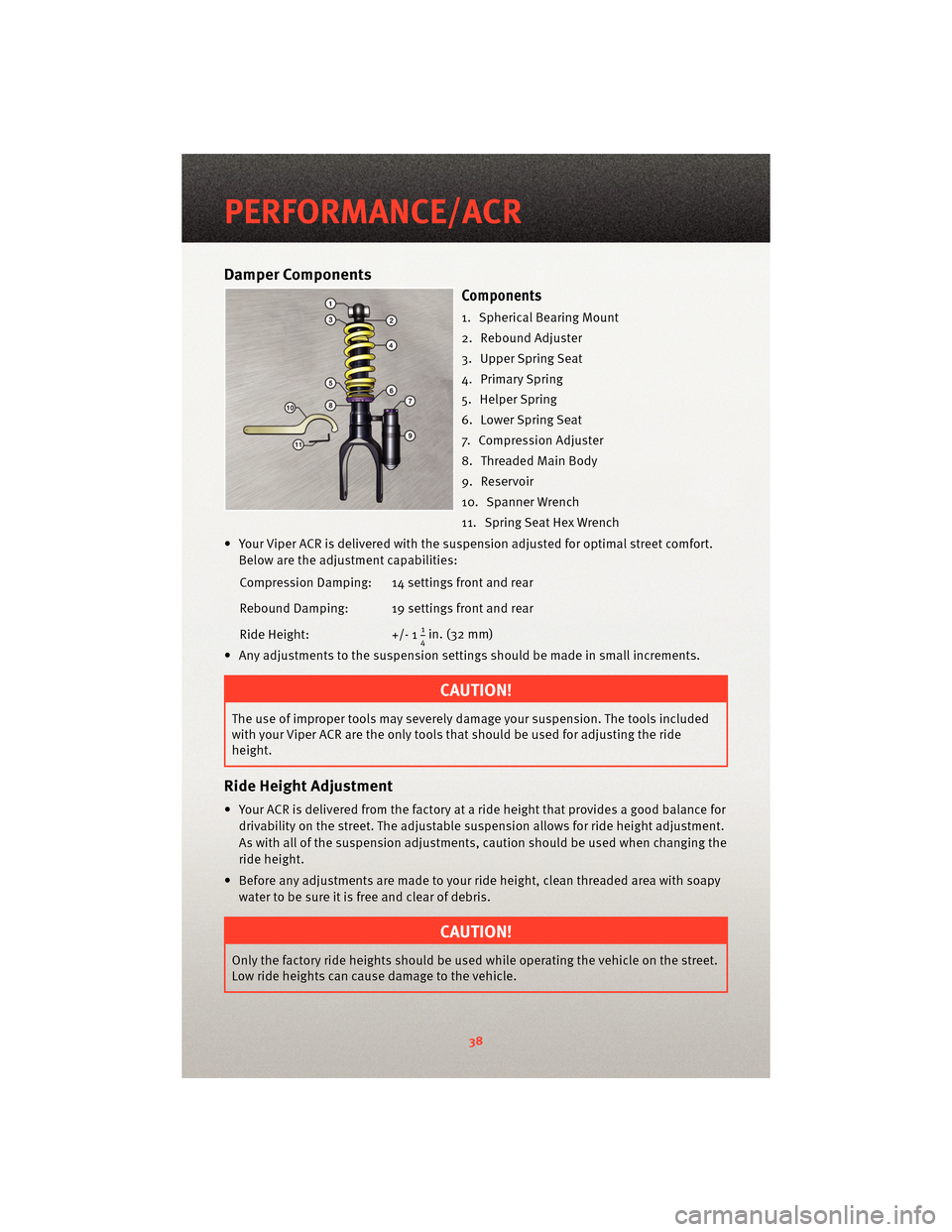

Damper Components

Components

1. Spherical Bearing Mount

2. Rebound Adjuster

3. Upper Spring Seat

4. Primary Spring

5. Helper Spring

6. Lower Spring Seat

7. Compression Adjuster

8. Threaded Main Body

9. Reservoir

10. Spanner Wrench

11. Spring Seat Hex Wrench

• Your Viper ACR is delivered with the suspension adjusted for optimal street comfort. Below are the adjustment capabilities:

Compression Damping: 14 settings front and rear

Rebound Damping: 19 settings front and rear

Ride Height: +/- 1

14in. (32 mm)

• Any adjustments to the suspension settings should be made in small increments.

CAUTION!

The use of improper tools may severely damage your suspension. The tools included

with your Viper ACR are the only tools that should be used for adjusting the ride

height.

Ride Height Adjustment

• Your ACR is delivered from the factory at a ride height that provides a good balance for

drivability on the street. The adjustable suspension allows for ride height adjustment.

As with all of the suspension adjus tments, caution should be used when changing the

ride height.

• Before any adjustments are made to your ride height, clean threaded area with soapy

water to be sure it is free and clear of debris.

CAUTION!

Only the factory ride heights should be used while operating the vehicle on the street.

Low ride heights can cause damage to the vehicle.

PERFORMANCE/ACR

38