FIAT 500L LIVING 2017 2.G Owners Manual

Manufacturer: FIAT, Model Year: 2017, Model line: 500L LIVING, Model: FIAT 500L LIVING 2017 2.GPages: 240, PDF Size: 5.26 MB

Page 111 of 240

HAZARD WARNING

LIGHTS

CONTROL

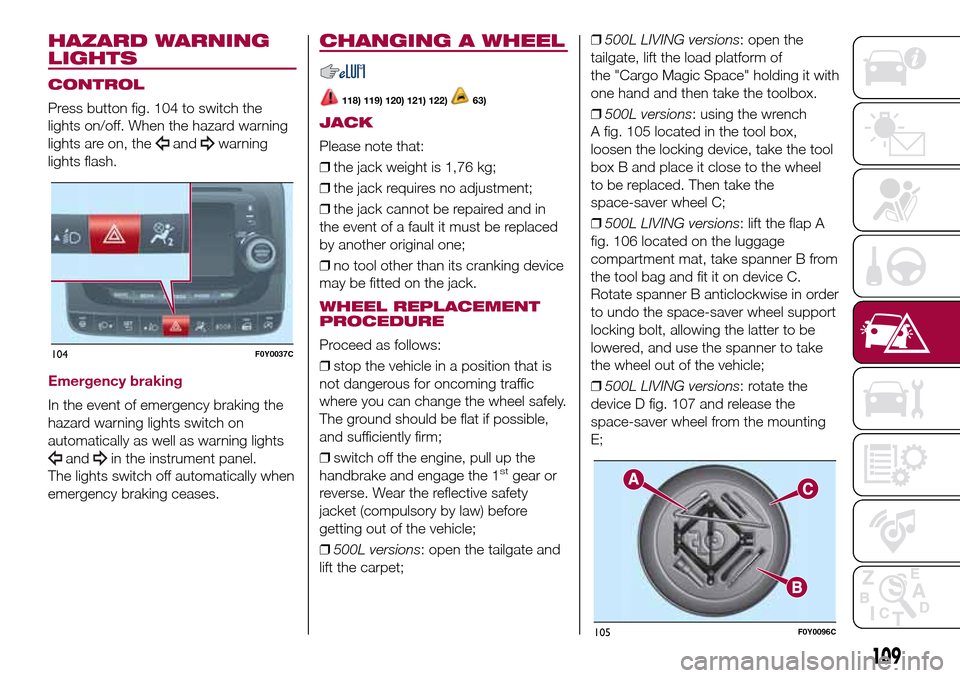

Press button fig. 104 to switch the

lights on/off. When the hazard warning

lights are on, the

andwarning

lights flash.

Emergency braking

In the event of emergency braking the

hazard warning lights switch on

automatically as well as warning lights

andin the instrument panel.

The lights switch off automatically when

emergency braking ceases.

CHANGING A WHEEL

118) 119) 120) 121) 122)63)

JACK

Please note that:

❒the jack weight is 1,76 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired and in

the event of a fault it must be replaced

by another original one;

❒no tool other than its cranking device

may be fitted on the jack.

WHEEL REPLACEMENT

PROCEDURE

Proceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground should be flat if possible,

and sufficiently firm;

❒switch off the engine, pull up the

handbrake and engage the 1

stgear or

reverse. Wear the reflective safety

jacket (compulsory by law) before

getting out of the vehicle;

❒500L versions: open the tailgate and

lift the carpet;❒500L LIVING versions: open the

tailgate, lift the load platform of

the "Cargo Magic Space" holding it with

one hand and then take the toolbox.

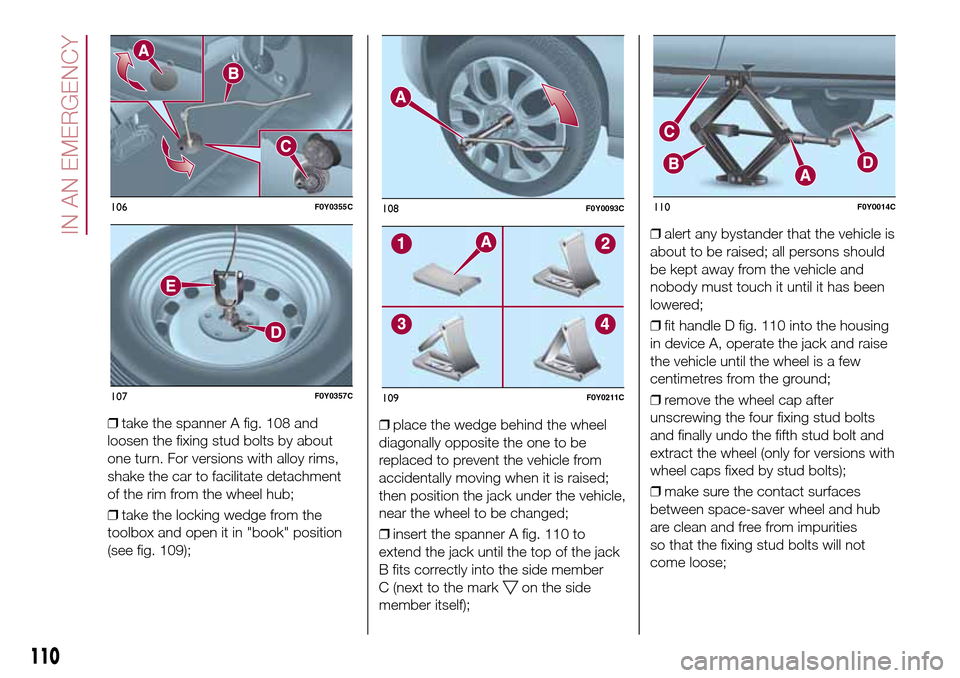

❒500L versions: using the wrench

A fig. 105 located in the tool box,

loosen the locking device, take the tool

box B and place it close to the wheel

to be replaced. Then take the

space-saver wheel C;

❒500L LIVING versions: lift the flap A

fig. 106 located on the luggage

compartment mat, take spanner B from

the tool bag and fit it on device C.

Rotate spanner B anticlockwise in order

to undo the space-saver wheel support

locking bolt, allowing the latter to be

lowered, and use the spanner to take

the wheel out of the vehicle;

❒500L LIVING versions: rotate the

device D fig. 107 and release the

space-saver wheel from the mounting

E;

104F0Y0037C

105F0Y0096C

109

Page 112 of 240

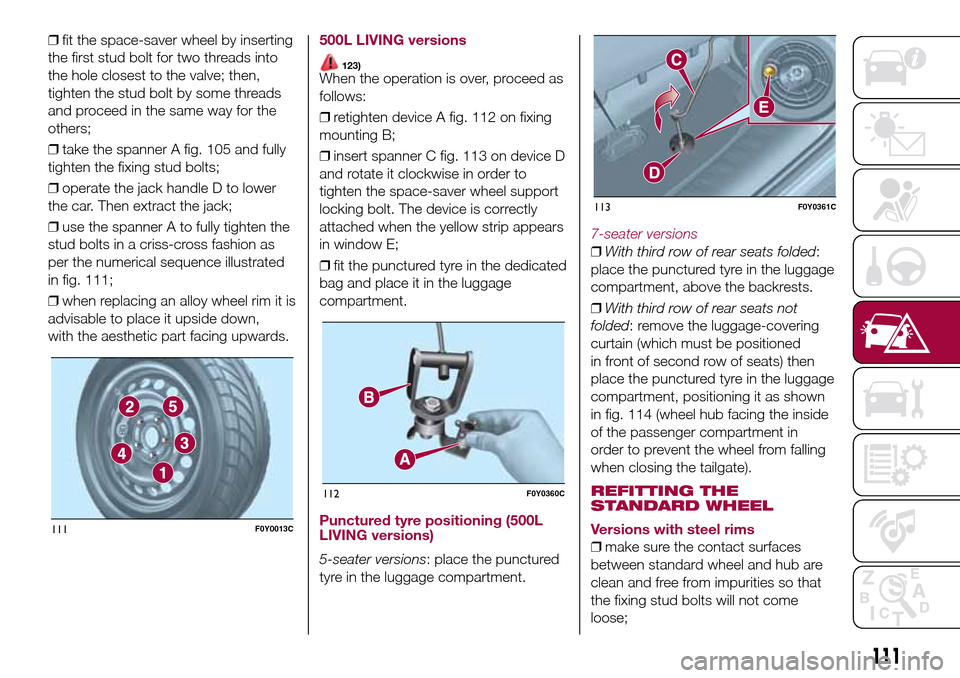

❒take the spanner A fig. 108 and

loosen the fixing stud bolts by about

one turn. For versions with alloy rims,

shake the car to facilitate detachment

of the rim from the wheel hub;

❒take the locking wedge from the

toolbox and open it in "book" position

(see fig. 109);❒place the wedge behind the wheel

diagonally opposite the one to be

replaced to prevent the vehicle from

accidentally moving when it is raised;

then position the jack under the vehicle,

near the wheel to be changed;

❒insert the spanner A fig. 110 to

extend the jack until the top of the jack

B fits correctly into the side member

C (next to the mark

on the side

member itself);❒alert any bystander that the vehicle is

about to be raised; all persons should

be kept away from the vehicle and

nobody must touch it until it has been

lowered;

❒fit handle D fig. 110 into the housing

in device A, operate the jack and raise

the vehicle until the wheel is a few

centimetres from the ground;

❒remove the wheel cap after

unscrewing the four fixing stud bolts

and finally undo the fifth stud bolt and

extract the wheel (only for versions with

wheel caps fixed by stud bolts);

❒make sure the contact surfaces

between space-saver wheel and hub

are clean and free from impurities

so that the fixing stud bolts will not

come loose;

106F0Y0355C

107F0Y0357C

108F0Y0093C

109F0Y0211C

110F0Y0014C

110

IN AN EMERGENCY

Page 113 of 240

❒fit the space-saver wheel by inserting

the first stud bolt for two threads into

the hole closest to the valve; then,

tighten the stud bolt by some threads

and proceed in the same way for the

others;

❒take the spanner A fig. 105 and fully

tighten the fixing stud bolts;

❒operate the jack handle D to lower

the car. Then extract the jack;

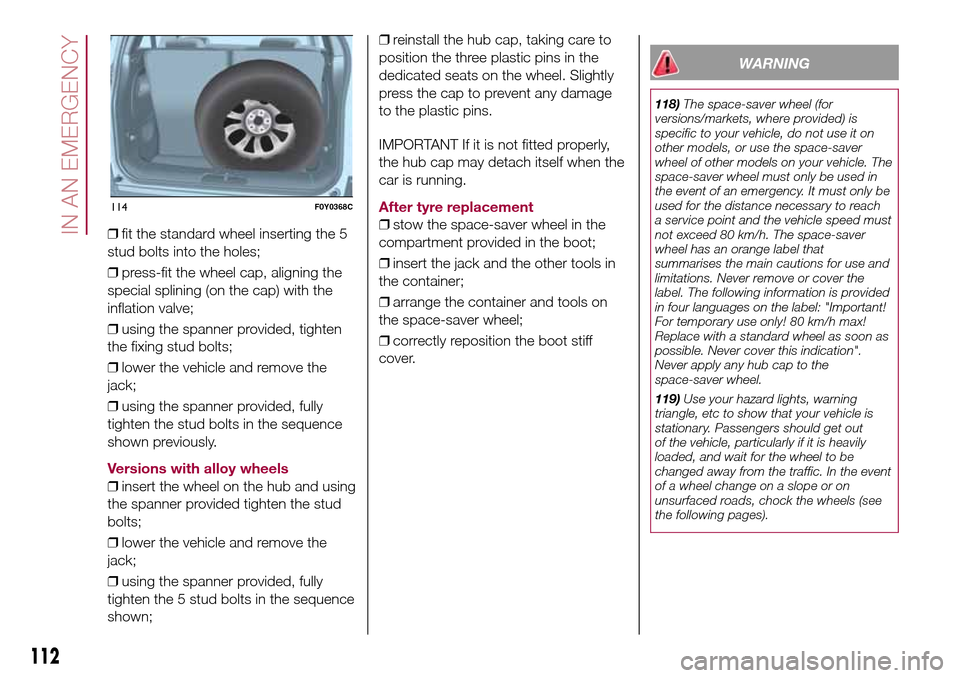

❒use the spanner A to fully tighten the

stud bolts in a criss-cross fashion as

per the numerical sequence illustrated

in fig. 111;

❒when replacing an alloy wheel rim it is

advisable to place it upside down,

with the aesthetic part facing upwards.500L LIVING versions

123)When the operation is over, proceed as

follows:

❒retighten device A fig. 112 on fixing

mounting B;

❒insert spanner C fig. 113 on device D

and rotate it clockwise in order to

tighten the space-saver wheel support

locking bolt. The device is correctly

attached when the yellow strip appears

in window E;

❒fit the punctured tyre in the dedicated

bag and place it in the luggage

compartment.

Punctured tyre positioning (500L

LIVING versions)

5-seater versions: place the punctured

tyre in the luggage compartment.

7-seater versions

❒With third row of rear seats folded:

place the punctured tyre in the luggage

compartment, above the backrests.

❒With third row of rear seats not

folded: remove the luggage-covering

curtain (which must be positioned

in front of second row of seats) then

place the punctured tyre in the luggage

compartment, positioning it as shown

in fig. 114 (wheel hub facing the inside

of the passenger compartment in

order to prevent the wheel from falling

when closing the tailgate).

REFITTING THE

STANDARD WHEEL

Versions with steel rims

❒make sure the contact surfaces

between standard wheel and hub are

clean and free from impurities so that

the fixing stud bolts will not come

loose;

111F0Y0013C

112F0Y0360C

113F0Y0361C

111

Page 114 of 240

❒fit the standard wheel inserting the 5

stud bolts into the holes;

❒press-fit the wheel cap, aligning the

special splining (on the cap) with the

inflation valve;

❒using the spanner provided, tighten

the fixing stud bolts;

❒lower the vehicle and remove the

jack;

❒using the spanner provided, fully

tighten the stud bolts in the sequence

shown previously.

Versions with alloy wheels

❒insert the wheel on the hub and using

the spanner provided tighten the stud

bolts;

❒lower the vehicle and remove the

jack;

❒using the spanner provided, fully

tighten the 5 stud bolts in the sequence

shown;❒reinstall the hub cap, taking care to

position the three plastic pins in the

dedicated seats on the wheel. Slightly

press the cap to prevent any damage

to the plastic pins.

IMPORTANT If it is not fitted properly,

the hub cap may detach itself when the

car is running.

After tyre replacement

❒stow the space-saver wheel in the

compartment provided in the boot;

❒insert the jack and the other tools in

the container;

❒arrange the container and tools on

the space-saver wheel;

❒correctly reposition the boot stiff

cover.

WARNING

118)The space-saver wheel (for

versions/markets, where provided) is

specific to your vehicle, do not use it on

other models, or use the space-saver

wheel of other models on your vehicle. The

space-saver wheel must only be used in

the event of an emergency. It must only be

used for the distance necessary to reach

a service point and the vehicle speed must

not exceed 80 km/h. The space-saver

wheel has an orange label that

summarises the main cautions for use and

limitations. Never remove or cover the

label. The following information is provided

in four languages on the label: "Important!

For temporary use only! 80 km/h max!

Replace with a standard wheel as soon as

possible. Never cover this indication".

Never apply any hub cap to the

space-saver wheel.

119)Use your hazard lights, warning

triangle, etc to show that your vehicle is

stationary. Passengers should get out

of the vehicle, particularly if it is heavily

loaded, and wait for the wheel to be

changed away from the traffic. In the event

of a wheel change on a slope or on

unsurfaced roads, chock the wheels (see

the following pages).

114F0Y0368C

112

IN AN EMERGENCY

Page 115 of 240

120)Vehicle handling is modified with the

space-saver wheel fitted. Avoid violent

acceleration and braking, abrupt steering

and fast cornering. The overall duration

of the space-saver wheel is about 3000

km, after which the relevant tyre must be

replaced with another one of the same

type. Never install a standard tyre on a rim

that is designed for use with a space-saver

wheel. Have the wheel repaired and refitted

as soon as possible. Using two or more

space-saver wheels at the same time

is forbidden. Do not grease the threads of

the stud bolts before fitting them: they

might slip out when driving.

121)The jack shall only be used for raising

the car model it has been supplied with.

Never use the jack for other purposes,

such as raising other car models. Never

use the jack for repair operations under the

vehicle. Incorrect positioning of the jack

may cause the vehicle to fall. Do not use

the jack for loads higher than the one

shown on its label. The space-saver wheel

cannot be fitted with snow chains. If a

front (drive) tyre is punctured and chains

are needed, use a standard wheel from the

rear axle and install the space-saver wheel

on the rear axle. This way, with two

standard front driving wheels, you can

install the snow chains on them.

122)Incorrect hub cap assembly may

cause it to come off when the vehicle is

moving. Never tamper with the inflation

valve. Never introduce tools of any kind

between rim and tyre. Check tyre and

space-saver wheel pressures regularly,

complying with the values given in the

"Technical specifications" chapter.123)At the end of the operation of

raising/locking the spare wheel, the ignition

key must be extracted, taking care not to

turn it in the wrong direction to facilitate the

extraction of the key itself, to prevent the

attachment device from being released and

the wheel assembly not being securely

retained.

WARNING

63)Contact a Fiat Dealership as soon as

possible to have the correct tightening

of the wheel stud bolts checked.

"Fix&Go Automatic"

kit

124) 125) 126) 127) 128) 129) 130) 131)

64)3)

DESCRIPTION

The "Fix&Go Automatic" kit is located in

the luggage compartment, inside a

dedicated container. Inside the

container there are also a screwdriver,

the tow ring and the funnel for

refuelling, in the event of an emergency.

To access the kit, open the tailgate,

remove the load platform and lift the

carpet.

LPG versions: a tool box secured to

the luggage compartment carpet with

dedicated fastenings contains the kit.

The kit includes:

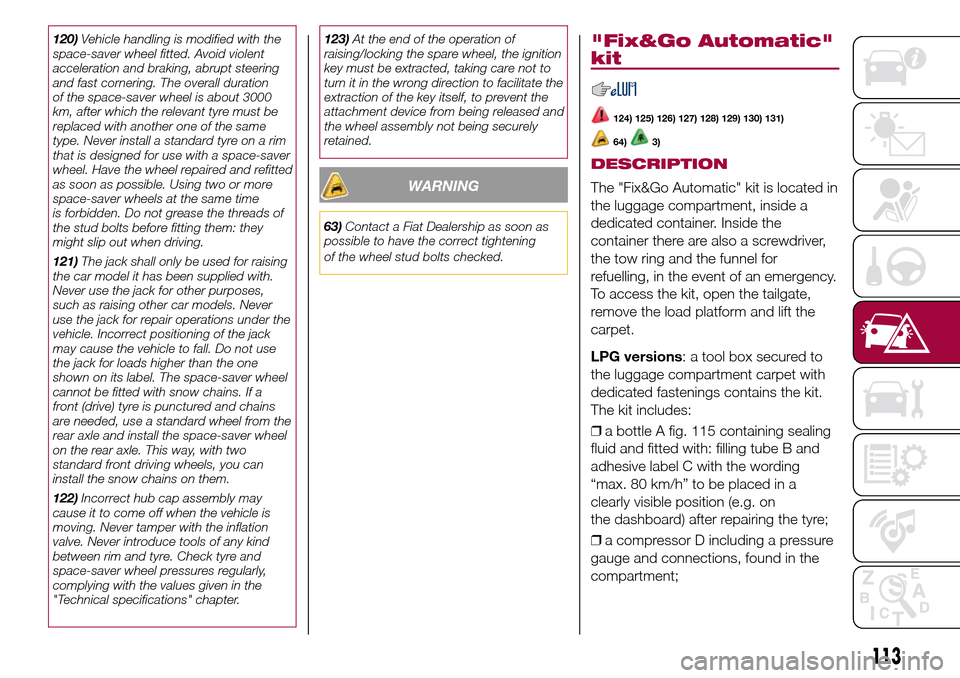

❒a bottle A fig. 115 containing sealing

fluid and fitted with: filling tube B and

adhesive label C with the wording

“max. 80 km/h” to be placed in a

clearly visible position (e.g. on

the dashboard) after repairing the tyre;

❒a compressor D including a pressure

gauge and connections, found in the

compartment;

113

Page 116 of 240

❒instruction booklet to be used for

prompt and correct use of the kit and

then to be handed to the personnel

charged with handling the treated tyre;

❒a pair of protective gloves located

in the side compartment of the

compressor;

❒adapters for inflating different

elements.

IMPORTANT The sealing fluid is

effective with external temperatures of

between –20°C and +50°C. The sealing

fluid has an expiry date.

INFLATION PROCEDURE

Proceed as follows:

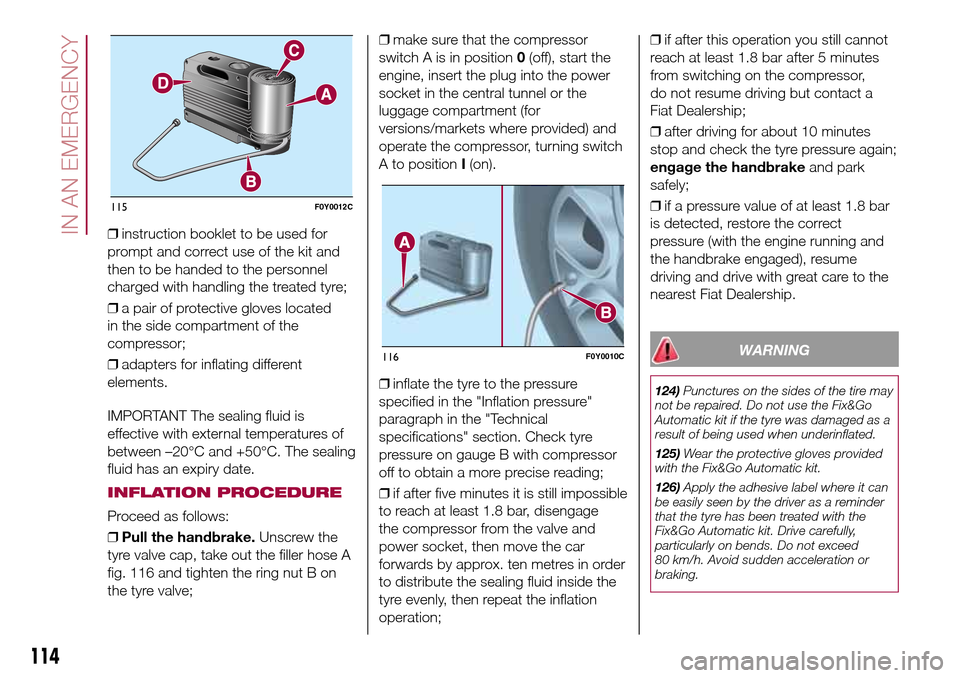

❒Pull the handbrake.Unscrew the

tyre valve cap, take out the filler hose A

fig. 116 and tighten the ring nut B on

the tyre valve;❒make sure that the compressor

switch A is in position0(off), start the

engine, insert the plug into the power

socket in the central tunnel or the

luggage compartment (for

versions/markets where provided) and

operate the compressor, turning switch

A to positionI(on).

❒inflate the tyre to the pressure

specified in the "Inflation pressure"

paragraph in the "Technical

specifications" section. Check tyre

pressure on gauge B with compressor

off to obtain a more precise reading;

❒if after five minutes it is still impossible

to reach at least 1.8 bar, disengage

the compressor from the valve and

power socket, then move the car

forwards by approx. ten metres in order

to distribute the sealing fluid inside the

tyre evenly, then repeat the inflation

operation;❒if after this operation you still cannot

reach at least 1.8 bar after 5 minutes

from switching on the compressor,

do not resume driving but contact a

Fiat Dealership;

❒after driving for about 10 minutes

stop and check the tyre pressure again;

engage the handbrakeand park

safely;

❒if a pressure value of at least 1.8 bar

is detected, restore the correct

pressure (with the engine running and

the handbrake engaged), resume

driving and drive with great care to the

nearest Fiat Dealership.

WARNING

124)Punctures on the sides of the tire may

not be repaired. Do not use the Fix&Go

Automatic kit if the tyre was damaged as a

result of being used when underinflated.

125)Wear the protective gloves provided

with the Fix&Go Automatic kit.

126)Apply the adhesive label where it can

be easily seen by the driver as a reminder

that the tyre has been treated with the

Fix&Go Automatic kit. Drive carefully,

particularly on bends. Do not exceed

80 km/h. Avoid sudden acceleration or

braking.

115F0Y0012C

116F0Y0010C

114

IN AN EMERGENCY

Page 117 of 240

127)If the pressure has fallen below 1.8

bar, do not drive any further: the Fix&Go

Automatic kit cannot guarantee proper

hold because the tyre is too damaged.

Contact a Fiat Dealership.

128)You must always indicate that the tyre

was repaired using the Fix&Go Automatic

kit. Give the booklet to the technicians who

will be handling the tyre that was treated

using the Fix&Go Automatic kit.

129)Repairs are not possible in the case of

damage to the wheel rim (bad groove

distortion causing air loss). Do not remove

foreign bodies (screws or nails) from the

tyre.

130)Never operate the compressor for

longer than 20 consecutive minutes. Risk

of overheating. The Fix&Go Automatic kit is

not suitable for definitive repairs, so the

repaired tyres may only be used

temporarily.

131)The information required by current

regulations, regarding the chemical

substances for the protection of human

health and the environment and on the safe

use of the sealing fluid, are on the

packaging label. Compliance with the

indications on the label is an essential

condition to ensure the safety and

the effectiveness of the product.

Remember to carefully read the label

before use; the user of the product

is responsible for any damages caused by

improper use. The sealing fluid has an

expiry date. Replace the bottle if the

sealant has expired.

WARNING

64)In the event of a puncture caused by

foreign bodies, the kit may be used to

repair tyres showing damage on the tread

or shoulder up to max. 4 mm diameter.

WARNING

3)Dispose of the bottle and the sealant

properly. Dispose of the components

in compliance with national and local

regulations.

REPLACING A BULB

132) 133)65) 66)

GENERAL

INSTRUCTIONS

❒Before changing a bulb check the

contacts for oxidation;

❒burnt bulbs must be replaced by

others of the same type and power;

❒after replacing a headlight bulb,

always check the correct alignment of

the light beam;

❒when a light is not working, check

that the corresponding fuse is intact

before changing a bulb. For the location

of fuses, refer to the paragraph “If a

fuse blows” in this section;

115

Page 118 of 240

IMPORTANT When the weather is cold

or damp or after heavy rain or washing,

the surface of headlights or rear lights,

may steam up and/or form drops of

condensation on the inside. This is

a natural phenomenon due to the

difference in temperature and humidity

between the inside and the outside

of the glass which does not indicate a

fault and does not compromise the

normal operation of lighting devices.

The mist disappears quickly when the

lights are turned on, starting from

the centre of the diffuser, extending

progressively towards the edges.

116

IN AN EMERGENCY

Page 119 of 240

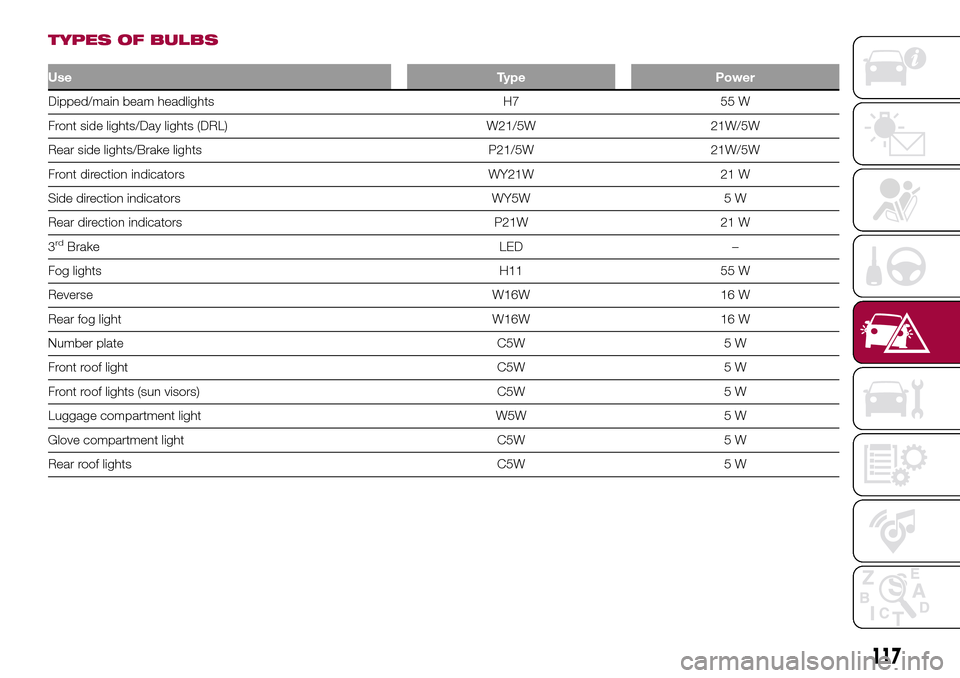

TYPES OF BULBS

UseType Power

Dipped/main beam headlights H7 55 W

Front side lights/Day lights (DRL) W21/5W 21W/5W

Rear side lights/Brake lights P21/5W 21W/5W

Front direction indicators WY21W 21 W

Side direction indicators WY5W 5 W

Rear direction indicators P21W 21 W

3

rdBrake LED –

Fog lights H11 55 W

Reverse W16W 16 W

Rear fog light W16W 16 W

Number plate C5W 5 W

Front roof light C5W 5 W

Front roof lights (sun visors) C5W 5 W

Luggage compartment light W5W 5 W

Glove compartment light C5W 5 W

Rear roof lights C5W 5 W

117

Page 120 of 240

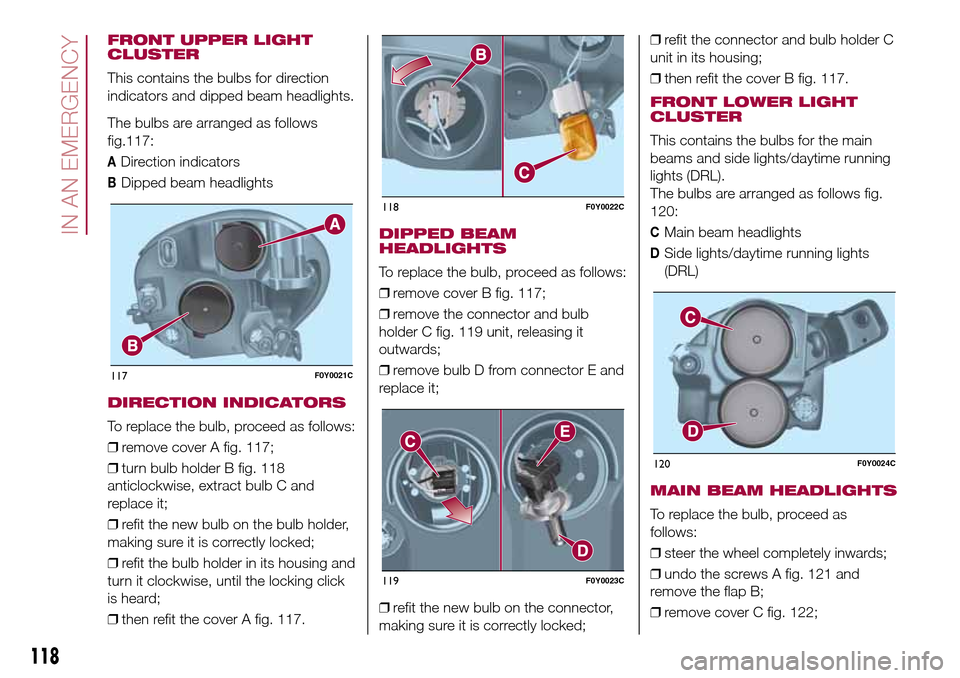

FRONT UPPER LIGHT

CLUSTER

This contains the bulbs for direction

indicators and dipped beam headlights.

The bulbs are arranged as follows

117:

ADirection indicators

BDipped beam headlights

DIRECTION INDICATORS

To replace the bulb, proceed as follows:

❒remove cover A fig. 117;

❒turn bulb holder B fig. 118

anticlockwise, extract bulb C and

replace it;

❒refit the new bulb on the bulb holder,

making sure it is correctly locked;

❒refit the bulb holder in its housing and

turn it clockwise, until the locking click

is heard;

❒then refit the cover A fig. 117.

DIPPED BEAM

HEADLIGHTS

To replace the bulb, proceed as follows:

❒remove cover B fig. 117;

❒remove the connector and bulb

holder C fig. 119 unit, releasing it

outwards;

❒remove bulb D from connector E and

replace it;

❒refit the new bulb on the connector,

making sure it is correctly locked;❒refit the connector and bulb holder C

unit in its housing;

❒then refit the cover B fig. 117.

FRONT LOWER LIGHT

CLUSTER

This contains the bulbs for the main

beams and side lights/daytime running

lights (DRL).

The bulbs are arranged as follows fig.

120:

CMain beam headlights

DSide lights/daytime running lights

(DRL)

MAIN BEAM HEADLIGHTS

To replace the bulb, proceed as

follows:

❒steer the wheel completely inwards;

❒undo the screws A fig. 121 and

remove the flap B;

❒remove cover C fig. 122;

117F0Y0021C

118F0Y0022C

119F0Y0023C

120F0Y0024C

118

IN AN EMERGENCY

fig.