fuel pressure FIAT BARCHETTA 2003 1.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2003, Model line: BARCHETTA, Model: FIAT BARCHETTA 2003 1.GPages: 170, PDF Size: 3.55 MB

Page 31 of 170

ENGINE CONTROL

SYSTEM FAILURE

(EOBD) (amber)

In normal conditions, the warning

light will come on when the ignition

key is turned to MARand should go

out as soon as the engine is started.

The initial lighting up shows that the

warning light is working properly.

If the warning light either stays on or

comes on while travelling:

1.Fixed light - warning of a fuel

feed/ignition system failure which may

increase emissions in exhaust or cause

possible drops in performance, poor

handling and high consumption. In such

conditions, you can continue driving

but you should not tax the engine and

you should moderate the speed. Pro-

longed use with the warning light on

can cause damage. Contact aFiat

Dealershipas soon as possible.

The warning light will go out when

the failure disappears. In any case, the

system will store the error. ENGINE OIL

PRESSURE TOO

LOW (red)

When the pressure of the oil in the

engine falls below the normal level.

The light comes on when you turn

the ignition key to MARbut it should

go out when the engine starts.

A delay in the light going out is ac-

ceptable only when the engine is idling.

If the engine has been taxed heavily,

the light might flash when idling but

should go out on accelerating slightly.

30

v

U

INDICATOR AND

WARNING LIGHTS

These light up in the following cas-

es:2.Flashing light - warning that the

catalyser may be damaged (see

“EOBD system” in this chapter). If the

warning light starts flashing, release the

accelerator pedal and slow the engine

until the warning light stops flashing.

Continue driving at moderate speed,

preventing the warning light from

coming on again. Contact a Fiat Deal-

ership as soon as possible.

Contact a Fiat Dealer-

ship as soon as possible if

the

Uwarning light ei-

ther does not come on when the

key is turned to MAR or comes

on, with fixed or flashing light,

when travelling.

If the warning light comes

on when the vehicle is mov-

ing, switch off the engine and con-

tact a Fiat Dealership.

WARNING

Page 66 of 170

65

A catalytic converter

that does not work prop-

erly leads to the emission

of harmful gases and the conse-

quent pollution of the atmos-

phere.

Never put even the tini-

est amount of leaded

petrol into the fuel tank,

even in an emergency. You would

damage the catalytic converter

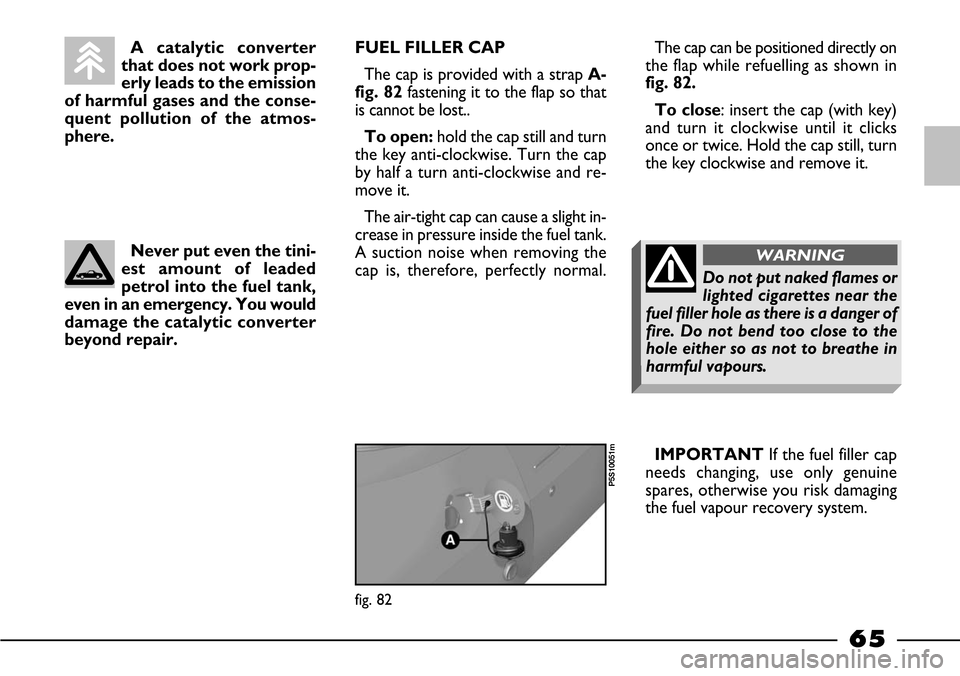

beyond repair.FUEL FILLER CAP

The cap is provided with a strap A-

fig. 82fastening it to the flap so that

is cannot be lost..

To open:hold the cap still and turn

the key anti-clockwise. Turn the cap

by half a turn anti-clockwise and re-

move it.

The air-tight cap can cause a slight in-

crease in pressure inside the fuel tank.

A suction noise when removing the

cap is, therefore, perfectly normal.The cap can be positioned directly on

the flap while refuelling as shown in

fig. 82.

To close: insert the cap (with key)

and turn it clockwise until it clicks

once or twice. Hold the cap still, turn

the key clockwise and remove it.

IMPORTANT If the fuel filler cap

needs changing, use only genuine

spares, otherwise you risk damaging

the fuel vapour recovery system.

fig. 82

P5S10051m

Do not put naked flames or

lighted cigarettes near the

fuel filler hole as there is a danger of

fire. Do not bend too close to the

hole either so as not to breathe in

harmful vapours.

WARNING

Page 77 of 170

76

Here are some suggestions which

may help you to keep the running

costs of your vehicle down and low-

er the amount of toxic emissions re-

leased into the atmosphere.

GENERAL

CONSIDERATIONS

Car maintenance

The overall state of the car is an im-

portant factor which has a marked in-

fluence over fuel consumption and dri-

ving comfort and on the life span of

your car. For this reason care should

be taken to maintain your car by car-

rying out the necessary checks and

regulations in accordance with the

specifications given in the Scheduled

Maintenance Programme (see sec-

tions... spark plugs, idle, air filter, tim-

ing).

CONTAINING RUNNING COSTS

AND POLLUTION

Tyres

Tyres should be checked at least

every four weeks: if the pressure is

too low fuel consumption increases as

the resistance to the rolling movement

of the tyre is greater. In this state, tyre

wear is increased and car handling suf-

fers which will affect safety.

Unnecessary loads

Do not travel with too much luggage

stowed in the boot. The weight of the

vehicle (especially when driving in

town) and its trim greatly affects con-

sumption and stability. To get the most out of ABS:

– During emergency stops or when

grip conditions are poor, you will feel

a slight pulsation on the brake pedal.

This is the sign that the ABS is in ac-

tion. Do not release the brake pedal

but continue to press so as not to in-

terrupt the braking action.

– ABS prevents the wheels from

locking but it does not increase actu-

al grip conditions between tyre and

road. Therefore, even if your car is fit-

ted with ABS, respect the safety dis-

tance from the car in front of you and

keep your speed down when driving

into bends.

– ABS serves to increase the con-

trollability of the car, not to enable you

to go faster.

Page 114 of 170

113

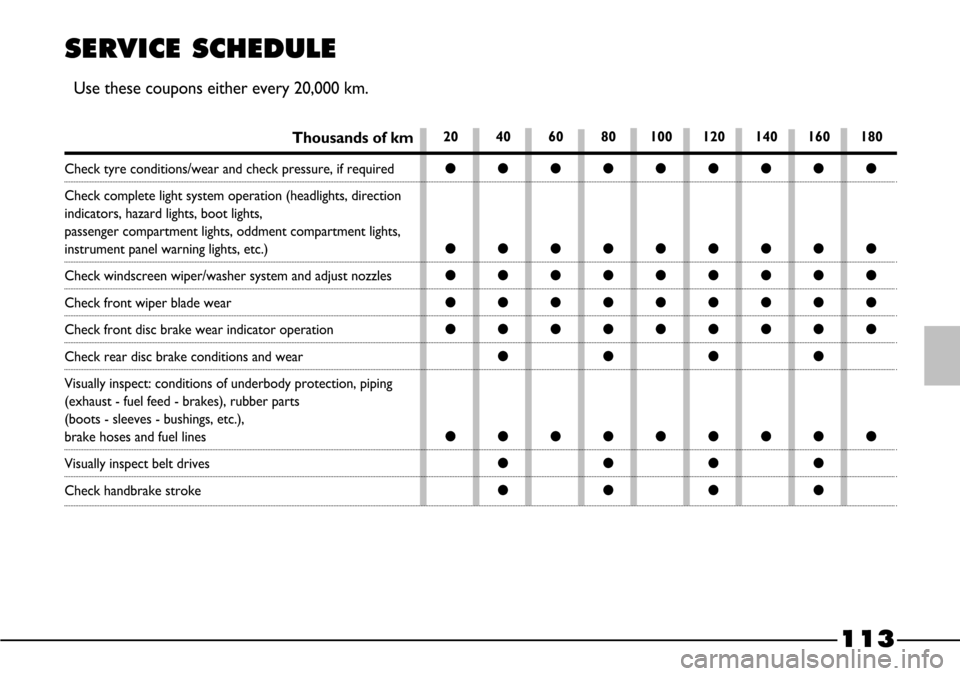

SERVICE SCHEDULE

Use these coupons either every 20,000 km.

Thousands of km20 40 60 80 100 120 140 160 180

Check tyre conditions/wear and check pressure, if required

Check complete light system operation (headlights, direction

indicators, hazard lights, boot lights,

passenger compartment lights, oddment compartment lights,

instrument panel warning lights, etc.)

Check windscreen wiper/washer system and adjust nozzles

Check front wiper blade wear

Check front disc brake wear indicator operation

Check rear disc brake conditions and wear

Visually inspect: conditions of underbody protection, piping

(exhaust - fuel feed - brakes), rubber parts

(boots - sleeves - bushings, etc.),

brake hoses and fuel lines

Visually inspect belt drives

Check handbrake stroke

ççççççççç

ççççççççç

ççççççççç

ççççççççç

ççççççççç

çççç

ççççççççç

çççç

çççç

Page 116 of 170

115

ANNUAL

INSPECTION

SCHEDULE

The following annual inspection

schedule is required for cars travelling

less than 20,000 km a year (e.g. ap-

proximately 10,000 km). The schedule

includes the following operations:

– Check tyre condition and wear and

adjust pressure, if required (including

spare-saver spare wheel).

– Check operation of lights (head-

lights, direction indicators, hazard

lights, boot light, passenger compart-

ment ceiling light, glove compartment

light, instrument panel lights, etc.).

– Check windscreen wiper/washer

and adjust nozzles.

– Check position wear of windscreen

window wiper blades.

ADDITIONAL

OPERATIONS

Every 1,000 kmor before long

trips, check and top up as necessary:

– coolant level

– brake fluid level

– power steering fluid level

– electrolyte level

– windscreen washer liquid level

– tyre condition and pressure.

We advise you to use FL Selenia

products, which have been designed

and produced expressly for the Fiat

vehicles (see the table “Capacities” giv-

en in the “Technical specifications”

section).

Every 3,000 km check and top up

as necessary: engine oil level. – Check rear brake pad conditions

and wear.

– Inspect conditions of. engine, gear-

box, transmission, piping (exhaust - fu-

el feed - brakes), rubber parts (boots

- sleeves - bushings - etc.), brake and

fuel line hoses.

– Check battery charge status.

– Check conditions of various con-

trol belts.

– Check and top up fluid levels (en-

gine coolant, brakes, windscreen

washer, battery, etc.).

– Change engine oil.

– Replace engine oil filter.

– Replace pollen filter (where fitted).

Page 136 of 170

135

TECHNICAL SPECIFICATIONS

Motor and engineering enthusiasts as well as those

“in the trade” will probably start reading from this point

in the manual. This, in fact, is where a section jam-

packed with facts, figures, formulae, measurements and

tables begins. In a sense it is the Fiat barchetta’s iden-

tity card. A document that introduces the car and ex-

plains in technical jargon all the features that go together

to make the Fiat barchetta a model designed to give you

superlative driving satisfaction.IDENTIFICATION DATA ................................................ 136

ENGINE CODE - BODY VERSION .............................. 137

ENGINE ................................................................................. 137

TRANSMISSION ................................................................. 139

BRAKES ................................................................................. 139

SUSPENSIONS .................................................................... 140

STEERING ............................................................................. 140

WHEEL GEOMETRY ......................................................... 140

PERFORMANCE ................................................................. 140

WHEELS ................................................................................ 141

DIMENSIONS ...................................................................... 142

WEIGHTS ............................................................................. 143

CAPACITIES ........................................................................ 144

FLUIDS AND LUBRICANTS ........................................... 145

FUEL CONSUMPTION .................................................... 147

CO

2EMISSIONS ................................................................. 147

TYRES PRESSURE ............................................................... 148

Page 139 of 170

138

FUEL SUPPLY/IGNITION

Integrated electronic injection and ig-

nition system: a single electronic con-

trol unit controls both functions. It

processes both the time the injection

lasts (for fuel metering) and the igni-

tion’s advance angle.

Type: Sequential in phase Multipoint

Air cleaner: dry-type with paper fil-

ter element; thermostatically con-

trolled intake.

Petrol pump: in-tank.

Injection pressure: 3 bar

Method of measuring the amount of

aspirated air by directly measuring the

maximum rate of flow with a hot wire

air flow meter.

“Closed loop” petrol metering (in-

formation about combustion provid-

ed by the Lambda sensor).Firing order: 1-3-4-2

Spark plugs:

– Champion RC10YCC

– NGK BKR6EZLUBRICATION

Forced-fed with gear pump with

pressure relief valve incorporated.

Oil purification by means of full-flow-

cartridge filter.

COOLING

Cooling system with radiator, cen-

trifugal pump and expansion tank.

“Controlled” by-pass type thermo-

stat on the secondary circuit for the

recirculation of water from the engine

to the radiator.

Electric fan for radiator cooling with

thermostatically-controlled on/off

switch on the radiator.

Modifications or repairs to

the fuel feed system that

are not carried out properly or do

not take the system’s technical

specifications into account can

cause malfunctions with the risk of

fire.

WARNING