FIAT DOBLO 2009 2.G Owners Manual

Manufacturer: FIAT, Model Year: 2009, Model line: DOBLO, Model: FIAT DOBLO 2009 2.GPages: 274, PDF Size: 6.6 MB

Page 161 of 274

160

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0V0153mfig. 134bF0V0155mfig. 136

F0V0154mfig. 135

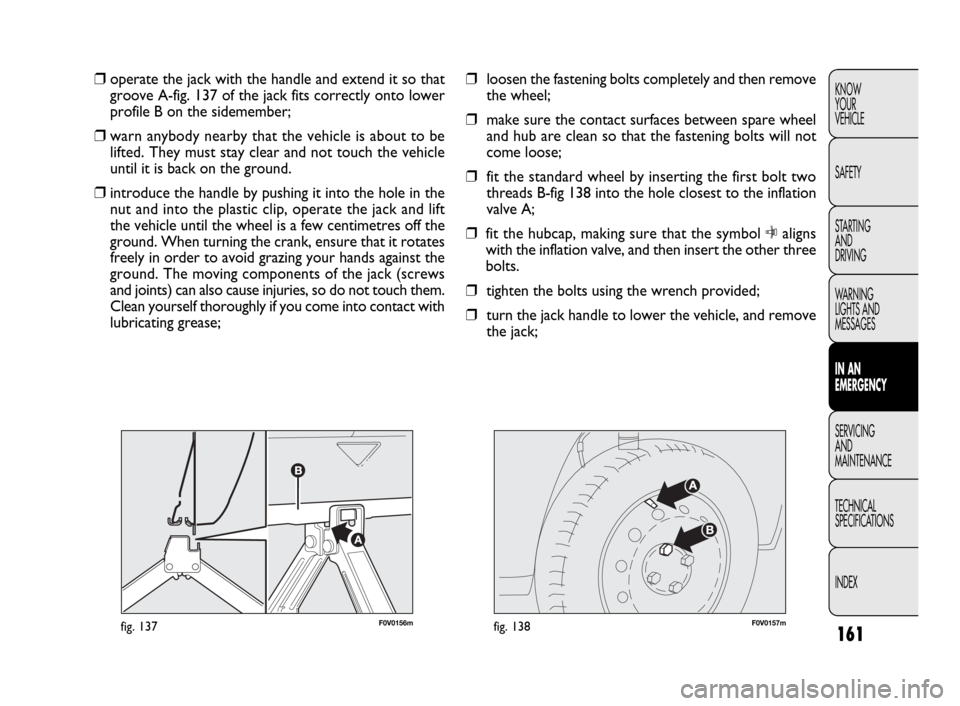

❒place the wedge D behind the wheel diagonally oppo-

site the one you want to replace fig. 134b to prevent

the vehicle from moving when it is raised.

❒

operate the jack using the handle (remove the crank from

the clip and from the hole in the nut) to partially extend it

fig. 135, then arrange it under the vehicle at references

A-fig. 136 near the tyre to be changed.

❒for versions with alloy wheels, remove the snap-fitted

hubcap;

❒loosen the fastening bolts of the wheel to be replaced by

about one turn, using the wrench provided;

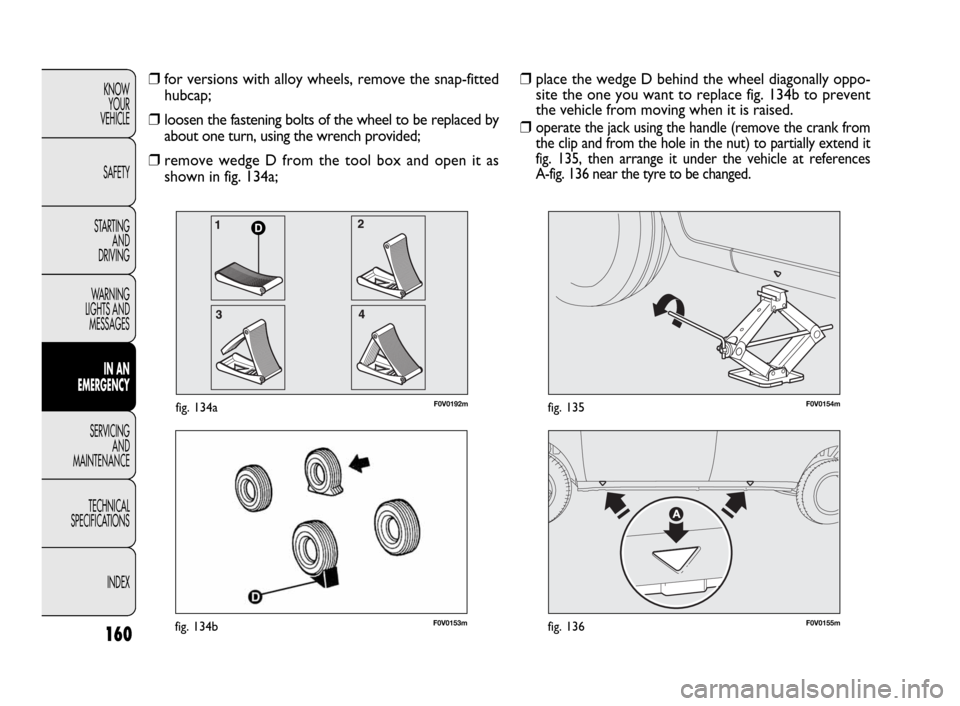

❒remove wedge D from the tool box and open it as

shown in fig. 134a;

D

F0V0192mfig. 134a

Page 162 of 274

161

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0V0156mfig. 137F0V0157mfig. 138

❒loosen the fastening bolts completely and then remove

the wheel;

❒make sure the contact surfaces between spare wheel

and hub are clean so that the fastening bolts will not

come loose;

❒fit the standard wheel by inserting the first bolt two

threads B-fig 138 into the hole closest to the inflation

valve A;

❒fit the hubcap, making sure that the symbol Caligns

with the inflation valve, and then insert the other three

bolts.

❒tighten the bolts using the wrench provided;

❒turn the jack handle to lower the vehicle, and remove

the jack; ❒operate the jack with the handle and extend it so that

groove A-fig. 137 of the jack fits correctly onto lower

profile B on the sidemember;

❒warn anybody nearby that the vehicle is about to be

lifted. They must stay clear and not touch the vehicle

until it is back on the ground.

❒introduce the handle by pushing it into the hole in the

nut and into the plastic clip, operate the jack and lift

the vehicle until the wheel is a few centimetres off the

ground. When turning the crank, ensure that it rotates

freely in order to avoid grazing your hands against the

ground. The moving components of the jack (screws

and joints) can also cause injuries, so do not touch them.

Clean yourself thoroughly if you come into contact with

lubricating grease;

Page 163 of 274

162

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0V0158mfig. 139F0V0194fig. 140

❒put the jack and the other implements back in the tool

box.

❒position the tool box behind the left seat (Cargo ver-

sions) or inside the compartment in the rear right side

panel by resting the base of the box on the side

(Doblò/Doblò Combi versions);

❒secure the tool box with the elastic strap and fasten

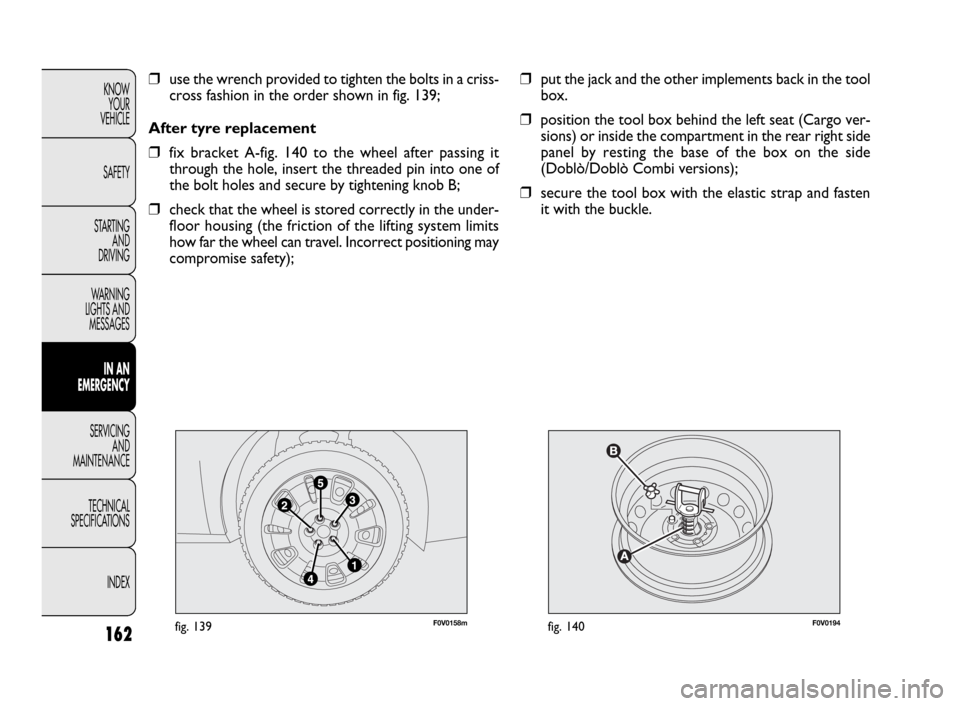

it with the buckle. ❒use the wrench provided to tighten the bolts in a criss-

cross fashion in the order shown in fig. 139;

After tyre replacement

❒fix bracket A-fig. 140 to the wheel after passing it

through the hole, insert the threaded pin into one of

the bolt holes and secure by tightening knob B;

❒check that the wheel is stored correctly in the under-

floor housing (the friction of the lifting system limits

how far the wheel can travel. Incorrect positioning may

compromise safety);

Page 164 of 274

163

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0V0093mfig. 141F0V0094mfig. 142

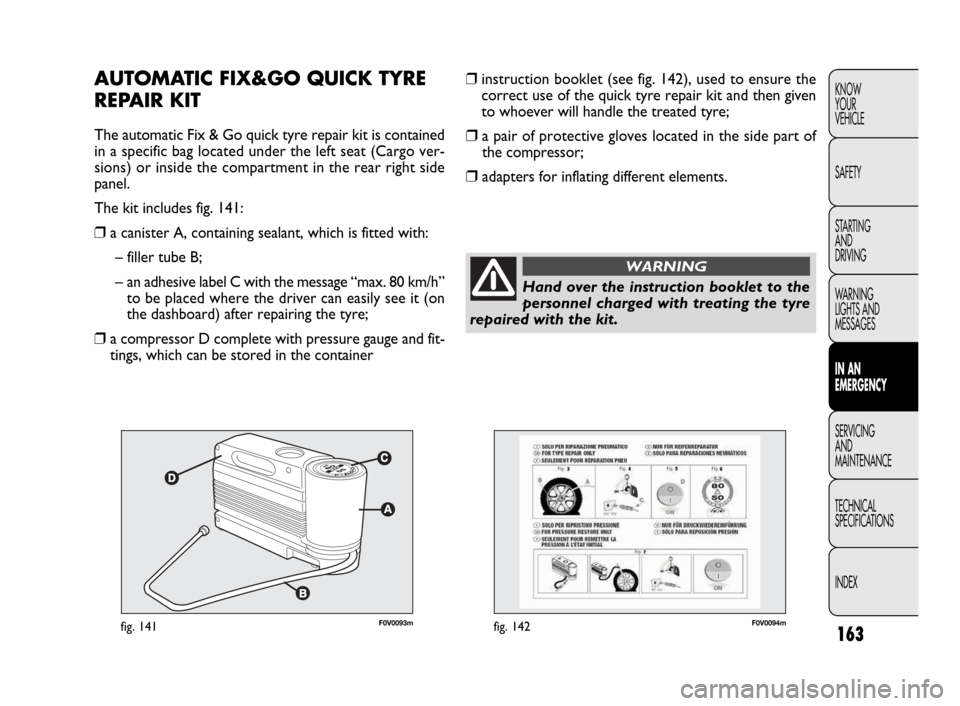

❒instruction booklet (see fig. 142), used to ensure the

correct use of the quick tyre repair kit and then given

to whoever will handle the treated tyre;

❒a pair of protective gloves located in the side part of

the compressor;

❒adapters for inflating different elements.

AUTOMATIC FIX&GO QUICK TYRE

REPAIR KIT

The automatic Fix & Go quick tyre repair kit is contained

in a specific bag located under the left seat (Cargo ver-

sions) or inside the compartment in the rear right side

panel.

The kit includes fig. 141:

❒a canister A, containing sealant, which is fitted with:

– filler tube B;

– an adhesive label C with the message “max. 80 km/h”

to be placed where the driver can easily see it (on

the dashboard) after repairing the tyre;

❒a compressor D complete with pressure gauge and fit-

tings, which can be stored in the container

Hand over the instruction booklet to the

personnel charged with treating the tyre

repaired with the kit.

WARNING

Page 165 of 274

164

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEXIn the event of a puncture caused by for-

eign bodies, it is possible to repair tyres

showing holes on the track or shoulder of

up to 4 mm in diameter.

It is not possible to repair damage to the

tyre sidewall. Do not use the quick repair

kit if the damage has been caused by travelling on

a flat tyre.

WARNING

If the wheel rim is damaged (the channel

is so deformed as to cause an air leakage)

it cannot be repaired. Do not remove foreign bod-

ies (screws or nails) from the tyre.

WARNING

IMPORTANT INFORMATION:

The sealing fluid of the quick tyre repair kit is effective at

external temperatures of between -20 °C and +50 °C.

Do not operate the compressor for longer

than 20 minutes at a time. Risk of over-

heating. The quick repair kit is not suitable for

permanent repairs. The tyres repaired must there-

fore be used only temporarily.

WARNING

Do not dispose of the cylinder and sealant

in the open environment. Dispose of them

according to the national and local laws in

force.

Page 166 of 274

165

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0V0095mfig. 143

INFLATION PROCEDURE

The cylinder contains ethylene glycol. It

contains latex, which may cause an aller-

gic reaction. Harmful if swallowed. Irritates the

eyes. There could be a reaction in case of inhala-

tion or contact. Avoid contact with your eyes, skin

and clothes. In the event of contact, wash imme-

diately with plenty of water. Do not induce vom-

iting if swallowed. Rinse your mouth out and drink

plenty of water. Call a doctor immediately. Keep

out of the reach of children. The product must

not be used by asthmatics. Do not breathe in the

vapours during insertion and suction. Call a doc-

tor immediately if allergic reactions are noted.

Store the canister in its proper compartment,

away from sources of heat. The sealant has an

expiry date. Replace the cylinder if its sealant is

out of date.

WARNING

Put on the protective gloves provided with

the quick tyre repair kit.

WARNING

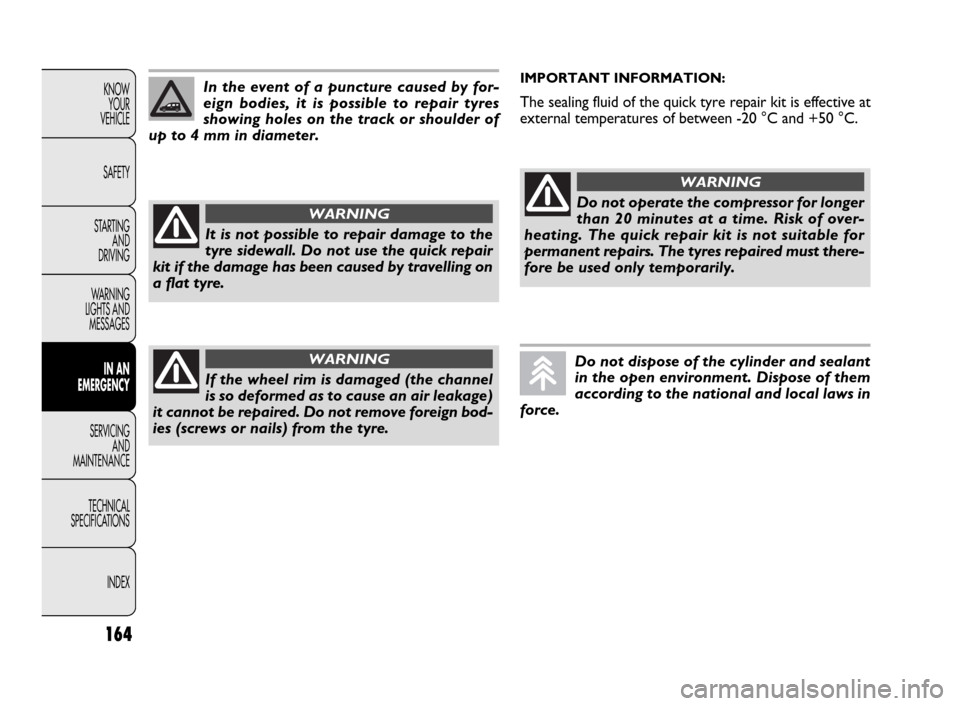

❒Make sure the handbrake is on. Unscrew the tyre valve

cap, remove the flexible filler tube A-fig. 143 and fas-

ten the nozzle B onto the tyre valve;

Page 167 of 274

166

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0V0096mfig. 144F0V0097mfig. 145

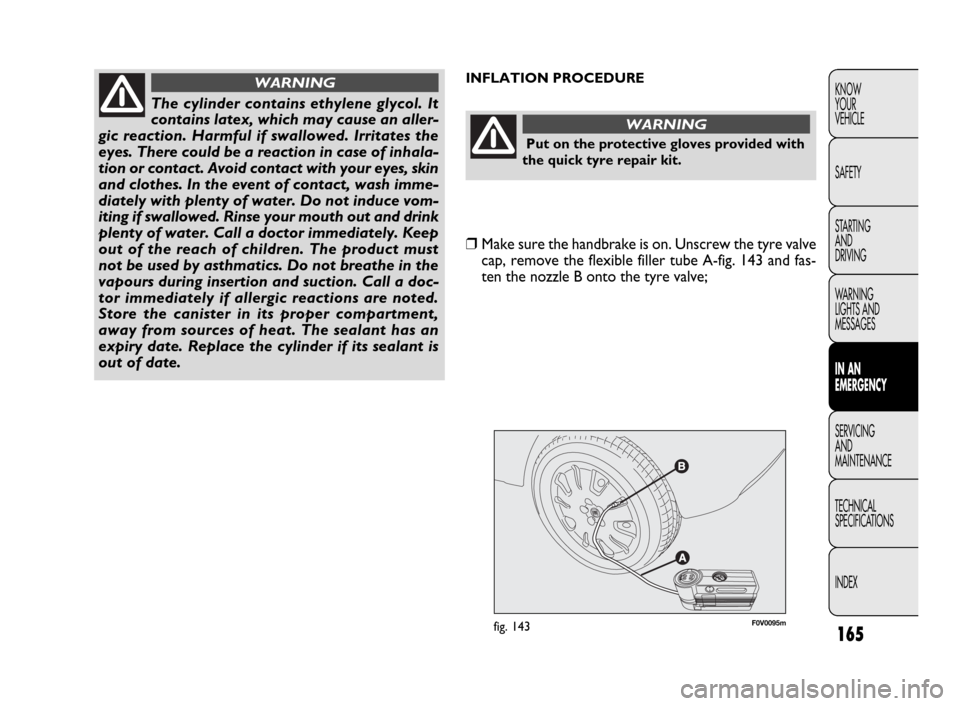

❒if in this case a pressure of at least 1.8 bar is not reached

within five minutes of switching on the compressor,

do not continue driving because the tyre is too dam-

aged and the hold cannot be guaranteed. Contact

a Fiat Dealership

❒if you do reach the tyre pressure specified in the “Cold

tyre pressures” paragraph of the “Technical specifica-

tions” section, continue your journey immediately; ❒make sure that switch E-fig. 145 of the compressor is

in position 0 (off), start the engine, insert plug D-fig.

144 into the socket and activate the compressor by

turning switch E-fig. 145 to position I (on). Inflate the

tyre to the pressure specified in the “Cold tyre pres-

sures” paragraph in the “Technical specifications” sec-

tion. For a more accurate reading, check pressure

gauge F-fig. 145 with the compressor off;

❒if a pressure value of a least 1.5 bar is not reached with-

in five minutes, disconnect the compressor from the

valve and socket, move the vehicle forwards by about

10 metres to distribute the sealant fluid within the tyre

and repeat the inflation procedure;

Page 168 of 274

167

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0V0098mfig. 146

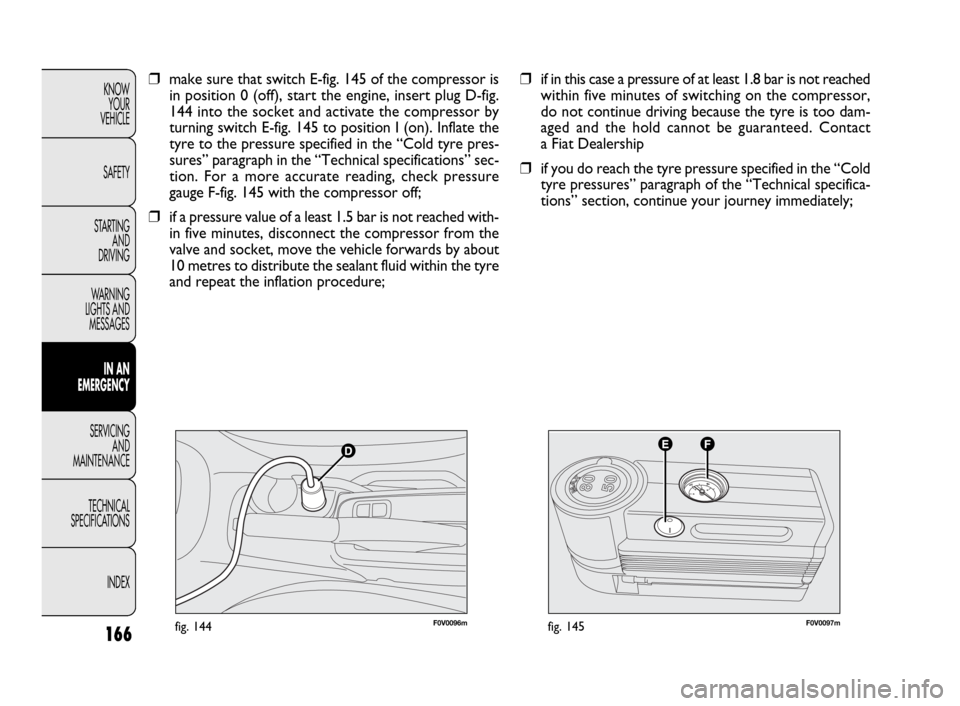

❒If you get a pressure reading of at least 1.8 bar, restore

the proper pressure (with engine running and hand-

brake on) and continue your journey.

❒drive with the utmost care to the nearest Fiat Dealer-

ship. ❒after driving for about 10 minutes, stop and check the

tyre pressure again; remember to put the handbrake

on;

Apply the adhesive label where it can be

easily seen by the driver as a reminder that

the tyre has been treated with the quick repair

kit. Drive carefully, particularly on bends. Do not

exceed 80 km/h. Do not accelerate or brake sud-

denly.

WARNING

If the pressure has fallen below 1.8 bar,

do not drive any further: the automatic

Fix & Go quick tyre repair kit cannot guarantee

proper hold because the tyre is too damaged.

Contact a Fiat Dealership.

WARNING

Remember to inform the workshop that

the tyre has been treated with a quick re-

pair kit. Give the instruction booklet to the per-

sonnel charged with handling the treated tyre.

WARNING

Page 169 of 274

168

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

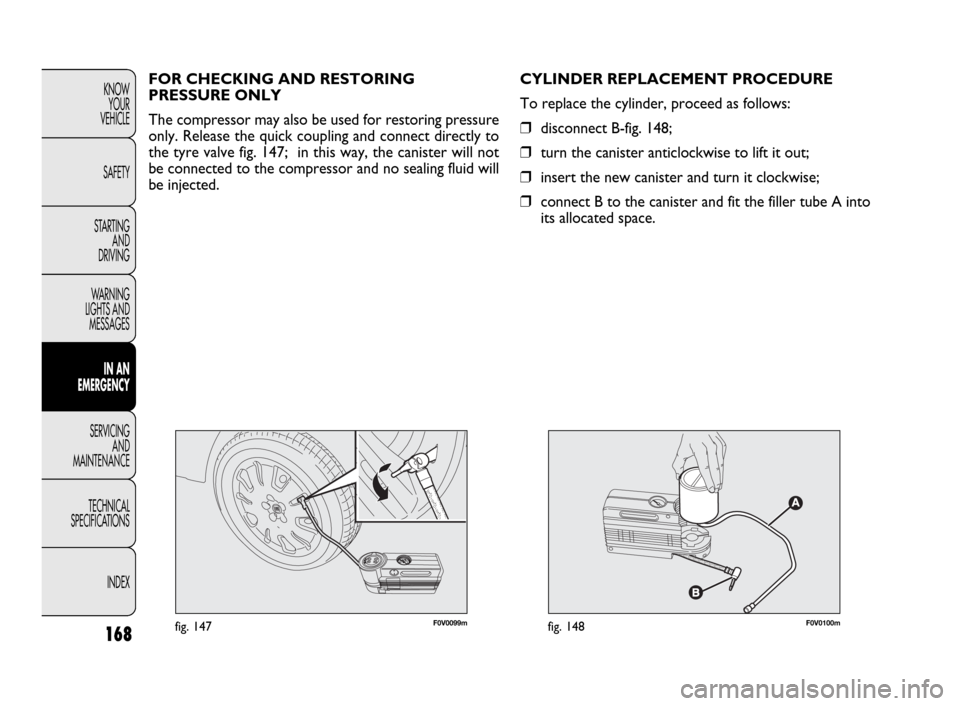

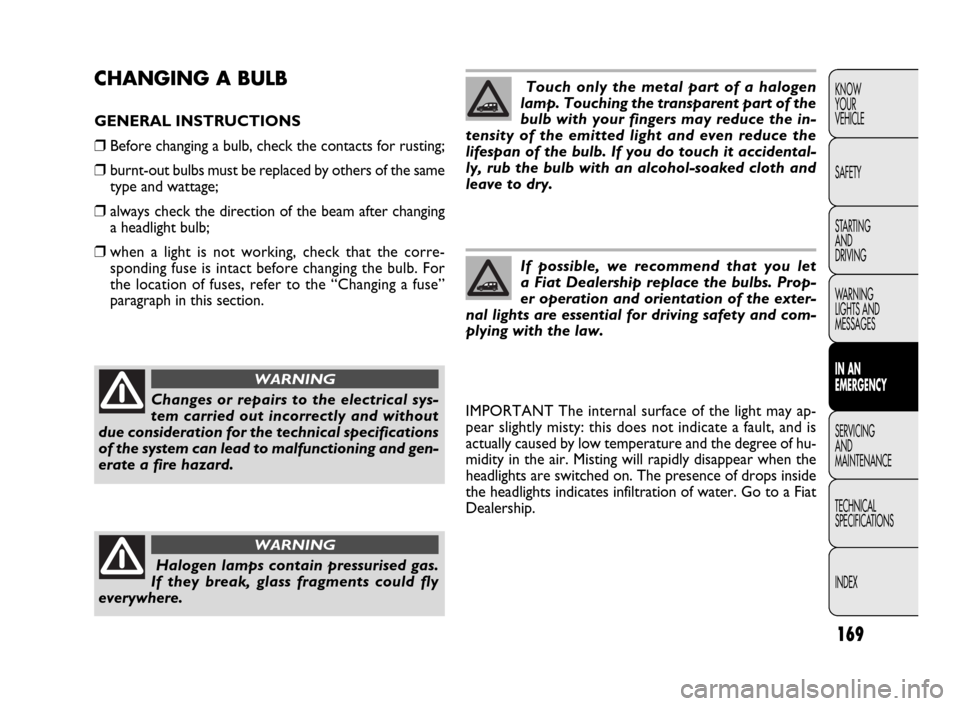

F0V0099mfig. 147F0V0100mfig. 148

CYLINDER REPLACEMENT PROCEDURE

To replace the cylinder, proceed as follows:

❒disconnect B-fig. 148;

❒turn the canister anticlockwise to lift it out;

❒insert the new canister and turn it clockwise;

❒connect B to the canister and fit the filler tube A into

its allocated space. FOR CHECKING AND RESTORING

PRESSURE ONLY

The compressor may also be used for restoring pressure

only. Release the quick coupling and connect directly to

the tyre valve fig. 147; in this way, the canister will not

be connected to the compressor and no sealing fluid will

be injected.

Page 170 of 274

169

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEXCHANGING A BULB

GENERAL INSTRUCTIONS

❒Before changing a bulb, check the contacts for rusting;

❒burnt-out bulbs must be replaced by others of the same

type and wattage;

❒always check the direction of the beam after changing

a headlight bulb;

❒when a light is not working, check that the corre-

sponding fuse is intact before changing the bulb. For

the location of fuses, refer to the “Changing a fuse”

paragraph in this section.

Changes or repairs to the electrical sys-

tem carried out incorrectly and without

due consideration for the technical specifications

of the system can lead to malfunctioning and gen-

erate a fire hazard.

WARNING

Halogen lamps contain pressurised gas.

If they break, glass fragments could fly

everywhere.

WARNING

Touch only the metal part of a halogen

lamp. Touching the transparent part of the

bulb with your fingers may reduce the in-

tensity of the emitted light and even reduce the

lifespan of the bulb. If you do touch it accidental-

ly, rub the bulb with an alcohol-soaked cloth and

leave to dry.

If possible, we recommend that you let

a Fiat Dealership replace the bulbs. Prop-

er operation and orientation of the exter-

nal lights are essential for driving safety and com-

plying with the law.

IMPORTANT The internal surface of the light may ap-

pear slightly misty: this does not indicate a fault, and is

actually caused by low temperature and the degree of hu-

midity in the air. Misting will rapidly disappear when the

headlights are switched on. The presence of drops inside

the headlights indicates infiltration of water. Go to a Fiat

Dealership.