FIAT DOBLO COMBI 2018 Owner handbook (in English)

Manufacturer: FIAT, Model Year: 2018, Model line: DOBLO COMBI, Model: FIAT DOBLO COMBI 2018Pages: 272, PDF Size: 23.75 MB

Page 131 of 272

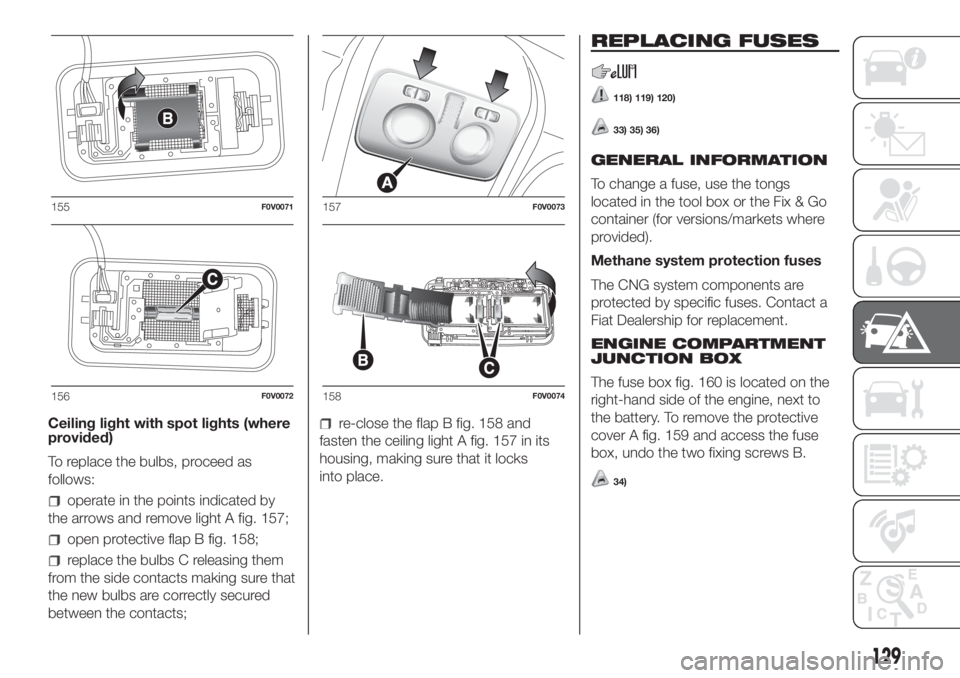

Ceiling light with spot lights (where

provided)

To replace the bulbs, proceed as

follows:

operate in the points indicated by

the arrows and remove light A fig. 157;

open protective flap B fig. 158;

replace the bulbs C releasing them

from the side contacts making sure that

the new bulbs are correctly secured

between the contacts;

re-close the flap B fig. 158 and

fasten the ceiling light A fig. 157 in its

housing, making sure that it locks

into place.

REPLACING FUSES

118) 119) 120)

33) 35) 36)

GENERAL INFORMATION

To change a fuse, use the tongs

located in the tool box or the Fix & Go

container (for versions/markets where

provided).

Methane system protection fuses

The CNG system components are

protected by specific fuses. Contact a

Fiat Dealership for replacement.

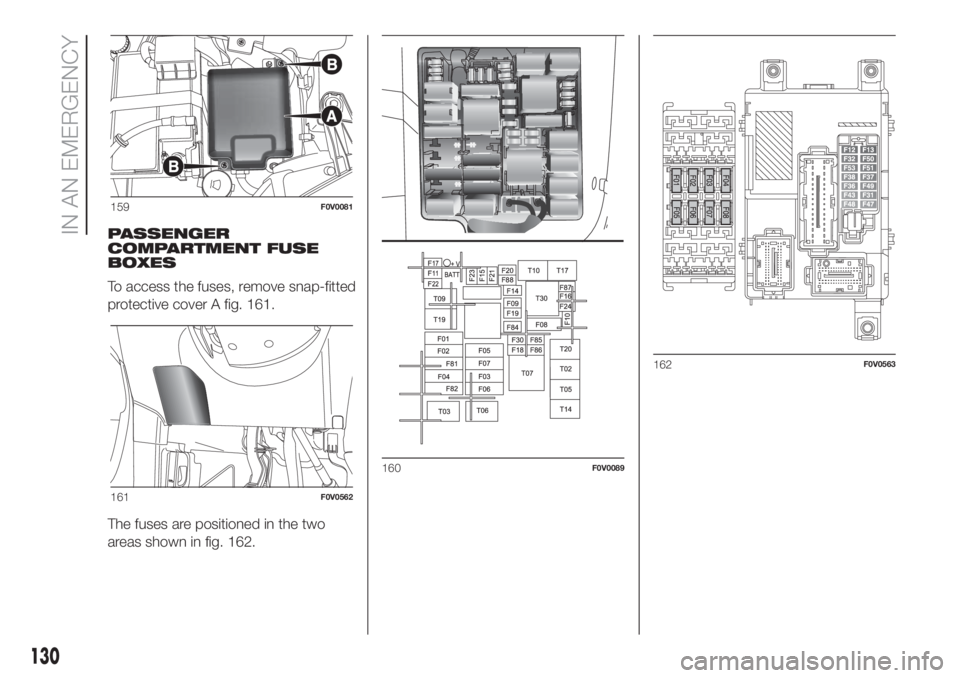

ENGINE COMPARTMENT

JUNCTION BOX

The fuse box fig. 160 is located on the

right-hand side of the engine, next to

the battery. To remove the protective

cover A fig. 159 and access the fuse

box, undo the two fixing screws B.

34)

155F0V0071

156F0V0072

157F0V0073

158F0V0074

129

Page 132 of 272

PASSENGER

COMPARTMENT FUSE

BOXES

To access the fuses, remove snap-fitted

protective cover A fig. 161.

The fuses are positioned in the two

areas shown in fig. 162.

159F0V0081

161F0V0562

160F0V0089

162F0V0563

130

IN AN EMERGENCY

Page 133 of 272

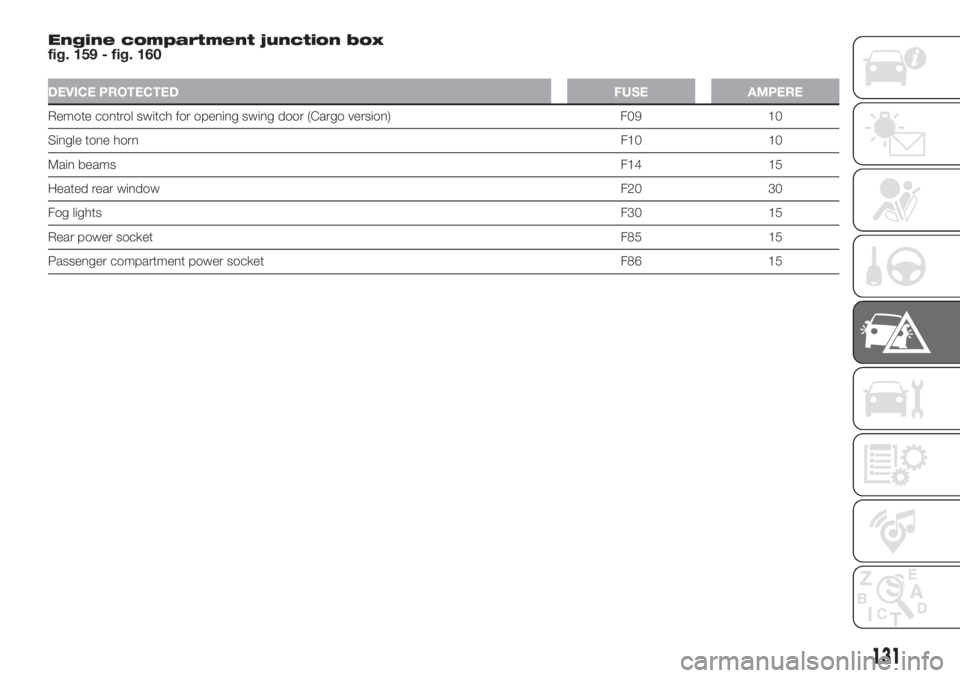

Engine compartment junction box

fig. 159 - fig. 160

DEVICE PROTECTEDFUSE AMPERE

Remote control switch for opening swing door (Cargo version) F09 10

Single tone hornF10 10

Main beamsF14 15

Heated rear windowF20 30

Fog lightsF30 15

Rear power socketF85 15

Passenger compartment power socket F86 15

131

Page 134 of 272

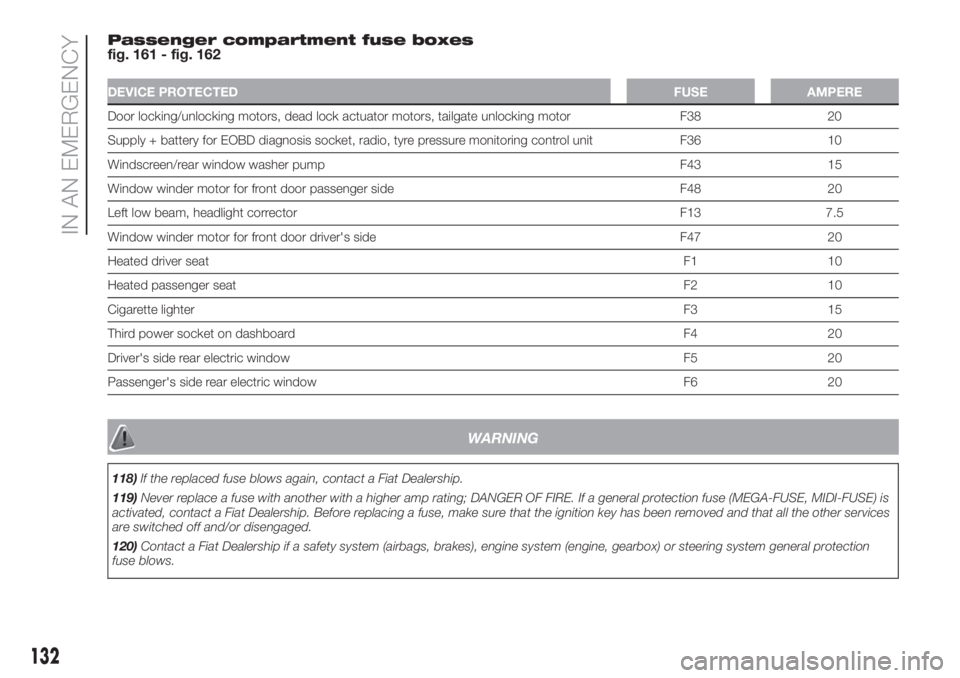

Passenger compartment fuse boxes

fig. 161 - fig. 162

DEVICE PROTECTEDFUSE AMPERE

Door locking/unlocking motors, dead lock actuator motors, tailgate unlocking motor F38 20

Supply + battery for EOBD diagnosis socket, radio, tyre pressure monitoring control unit F36 10

Windscreen/rear window washer pump F43 15

Window winder motor for front door passenger side F48 20

Left low beam, headlight corrector F13 7.5

Window winder motor for front door driver's side F47 20

Heated driver seatF1 10

Heated passenger seatF2 10

Cigarette lighterF3 15

Third power socket on dashboard F4 20

Driver's side rear electric window F5 20

Passenger's side rear electric window F6 20

WARNING

118)If the replaced fuse blows again, contact a Fiat Dealership.

119)Never replace a fuse with another with a higher amp rating; DANGER OF FIRE. If a general protection fuse (MEGA-FUSE, MIDI-FUSE) is

activated, contact a Fiat Dealership. Before replacing a fuse, make sure that the ignition key has been removed and that all the other services

are switched off and/or disengaged.

120)Contact a Fiat Dealership if a safety system (airbags, brakes), engine system (engine, gearbox) or steering system general protection

fuse blows.

132

IN AN EMERGENCY

Page 135 of 272

WARNING

33)Never replace a fuse with metal wires or other material.

34)If you need to wash the engine compartment, take care not to directly hit the fuse box and the window wiper motors with the water jet.

35)The Comfort-Matic/Dualogic system components are protected by specific fuses. Contact a Fiat Dealership for replacement.

36)The Natural Power system components are protected by specific fuses. Contact a Fiat Dealership for replacement.

133

Page 136 of 272

REPLACING A

WHEEL

The vehicle is originally equipped with

the Fix&Go automatic quick tyre repair

kit (see instructions in the next section).

As an alternative, the vehicle may

have a normal-sized spare wheel.

Wheel changing and correct use of the

jack and spare wheel call for some

precautions, as listed below.

121) 122) 123) 124)

Note for one-way tyres

One-way tyres have a few arrows on

the side indicating the rotation direction.

If a wheel is changed (when punctured,

for example) the direction of the arrows

on the spare wheel tyre may not

coincide with the rotation direction of

the wheel to be replaced.

In these conditions, too, the tyre still

maintains its safety features.

Anyway, it is recommended to have the

wheel repaired and refitted as soon as

possible, as the best performance is

achieved when the rotation direction of

all tyres coincides with the one

indicated by the arrows.JACK

Please note that:

the jack weight is 4 kg;

the jack requires no adjustment;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another genuine one;

no tool other than its cranking

device may be fitted on the jack.

WHEEL REPLACEMENT

PROCEDURE

To change a wheel, proceed as follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground must be flat and sufficiently

compact;

switch off the engine and pull the

handbrake;

engage first gear or reverse;

wear the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;

indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

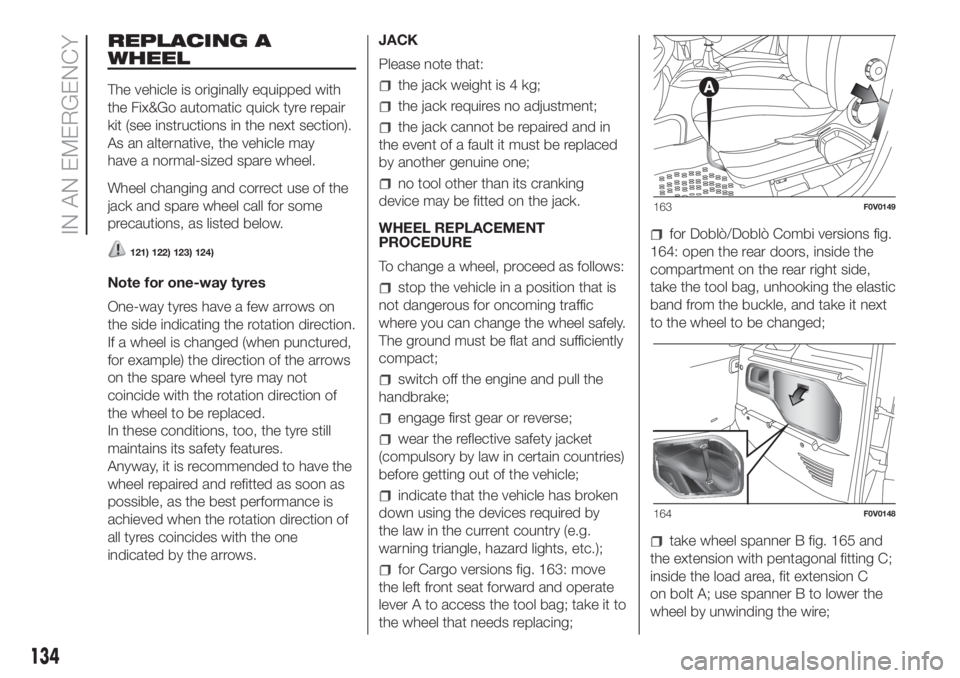

for Cargo versions fig. 163: move

the left front seat forward and operate

lever A to access the tool bag; take it to

the wheel that needs replacing;

for Doblò/Doblò Combi versions fig.

164: open the rear doors, inside the

compartment on the rear right side,

take the tool bag, unhooking the elastic

band from the buckle, and take it next

to the wheel to be changed;

take wheel spanner B fig. 165 and

the extension with pentagonal fitting C;

inside the load area, fit extension C

on bolt A; use spanner B to lower the

wheel by unwinding the wire;

163F0V0149

164F0V0148

134

IN AN EMERGENCY

Page 137 of 272

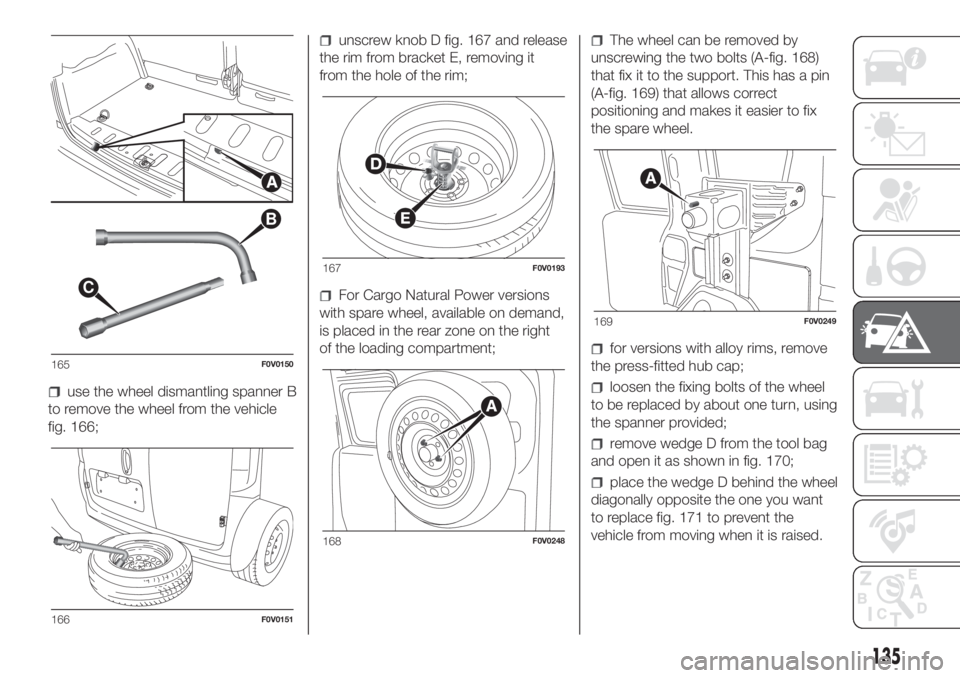

use the wheel dismantling spanner B

to remove the wheel from the vehicle

fig. 166;

unscrew knob D fig. 167 and release

the rim from bracket E, removing it

from the hole of the rim;

For Cargo Natural Power versions

with spare wheel, available on demand,

is placed in the rear zone on the right

of the loading compartment;

The wheel can be removed by

unscrewing the two bolts (A-fig. 168)

that fix it to the support. This has a pin

(A-fig. 169) that allows correct

positioning and makes it easier to fix

the spare wheel.

for versions with alloy rims, remove

the press-fitted hub cap;

loosen the fixing bolts of the wheel

to be replaced by about one turn, using

the spanner provided;

remove wedge D from the tool bag

and open it as shown in fig. 170;

place the wedge D behind the wheel

diagonally opposite the one you want

to replace fig. 171 to prevent the

vehicle from moving when it is raised.

B

C

165F0V0150

166F0V0151

167F0V0193

168F0V0248

169F0V0249

135

Page 138 of 272

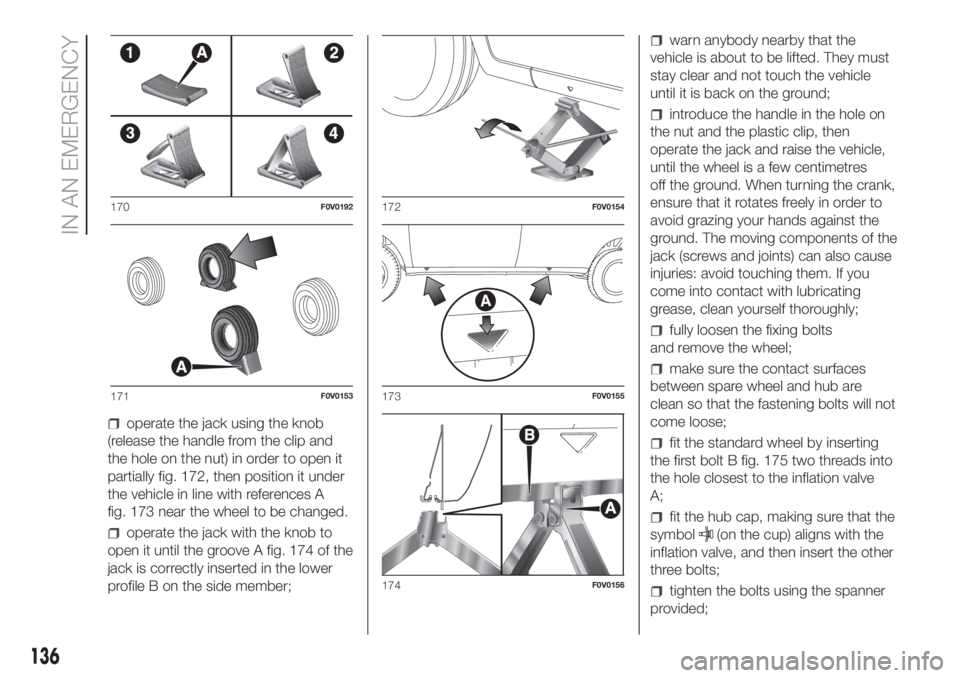

operate the jack using the knob

(release the handle from the clip and

the hole on the nut) in order to open it

partially fig. 172, then position it under

the vehicle in line with references A

fig. 173 near the wheel to be changed.

operate the jack with the knob to

open it until the groove A fig. 174 of the

jack is correctly inserted in the lower

profile B on the side member;

warn anybody nearby that the

vehicle is about to be lifted. They must

stay clear and not touch the vehicle

until it is back on the ground;

introduce the handle in the hole on

the nut and the plastic clip, then

operate the jack and raise the vehicle,

until the wheel is a few centimetres

off the ground. When turning the crank,

ensure that it rotates freely in order to

avoid grazing your hands against the

ground. The moving components of the

jack (screws and joints) can also cause

injuries: avoid touching them. If you

come into contact with lubricating

grease, clean yourself thoroughly;

fully loosen the fixing bolts

and remove the wheel;

make sure the contact surfaces

between spare wheel and hub are

clean so that the fastening bolts will not

come loose;

fit the standard wheel by inserting

the first bolt B fig. 175 two threads into

the hole closest to the inflation valve

A;

fit the hub cap, making sure that the

symbol

(on the cup) aligns with the

inflation valve, and then insert the other

three bolts;

tighten the bolts using the spanner

provided;

170F0V0192

171F0V0153

172F0V0154

173F0V0155

174F0V0156

136

IN AN EMERGENCY

Page 139 of 272

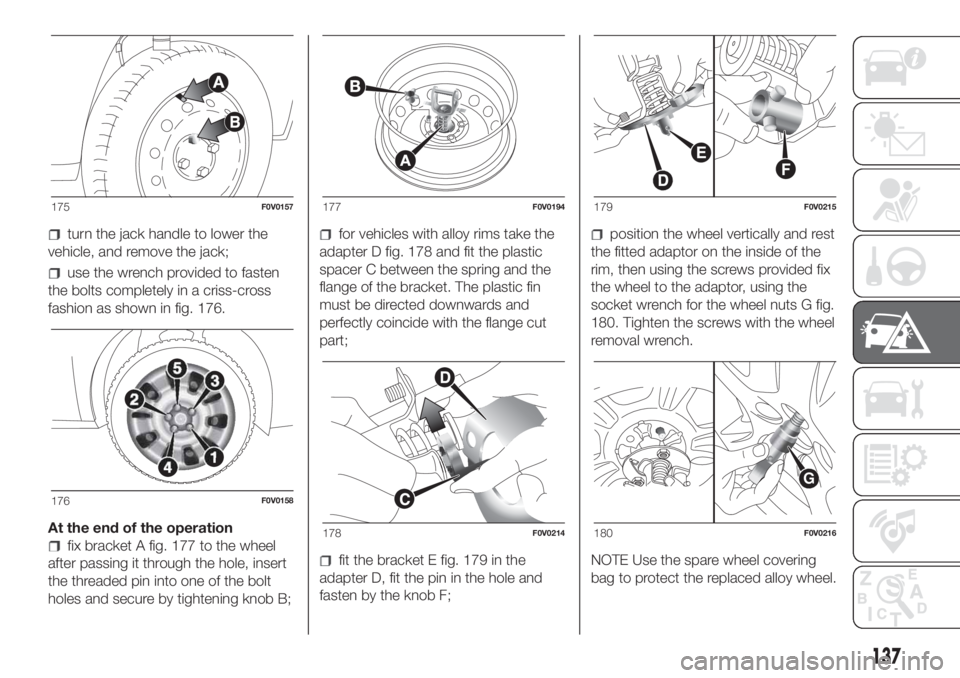

turn the jack handle to lower the

vehicle, and remove the jack;

use the wrench provided to fasten

the bolts completely in a criss-cross

fashion as shown in fig. 176.

At the end of the operation

fix bracket A fig. 177 to the wheel

after passing it through the hole, insert

the threaded pin into one of the bolt

holes and secure by tightening knob B;

for vehicles with alloy rims take the

adapter D fig. 178 and fit the plastic

spacer C between the spring and the

flange of the bracket. The plastic fin

must be directed downwards and

perfectly coincide with the flange cut

part;

fit the bracket E fig. 179 in the

adapter D, fit the pin in the hole and

fasten by the knob F;

position the wheel vertically and rest

the fitted adaptor on the inside of the

rim, then using the screws provided fix

the wheel to the adaptor, using the

socket wrench for the wheel nuts G fig.

180. Tighten the screws with the wheel

removal wrench.

NOTE Use the spare wheel covering

bag to protect the replaced alloy wheel.

175F0V0157

176F0V0158

177F0V0194

178F0V0214

179F0V0215

G

180F0V0216

137

Page 140 of 272

check that the position of the

replaced wheel under the platform is

correct (the lifting system is equipped

with a clutch to limit the end of the

stroke, incorrect positioning may

jeopardise safety;)

put the jack and the tools back in

the dedicated tool bag;

reposition the tool bag behind the

left side seat (Cargo versions) or, resting

the bottom of the bag against the side

panel, in the compartment inside the

rear right side (Doblò/Doblò Combi

versions).

WARNING

121)The spare wheel (where provided) is

specifically for your vehicle. Therefore, it

must not be used on other models. Do not

use spare wheels of other models on

your vehicle. The spare wheel must be

used only in an emergency. Use of the

spare wheel must kept to the minimum

necessary.122)Use your hazard lights, warning

triangle, etc to show that your vehicle is

stationary. Passengers should get out

of the vehicle, particularly if it is heavily

loaded, and wait for the wheel to be

changed away from the traffic. If you are on

a slope or uneven surface, place wedges

or other suitable objects under the wheels

to secure the vehicle. Have the wheel

repaired and refitted as soon as possible.

Do not apply grease to the bolt threads

before fitting: they could come unscrewed.

123)Use the jack only to replace wheels

on the vehicle with which it is supplied

or on other vehicles of the same model.

Never use the jack for other purposes,

such as lifting other models. Never use the

jack to carry out repairs under the vehicle.

Incorrect positioning of the jack may cause

the lifted vehicle to fall. Do not use the

jack for loads higher than the one shown

on its label.

124)Incorrect hub cap assembly may

cause it to come off when the vehicle is

moving. Never tamper with the inflation

valve. Never introduce tools of any kind

between rim and tyre. Check tyre and

space-saver wheel pressures regularly,

complying with the values given in the

"Technical specifications" chapter.

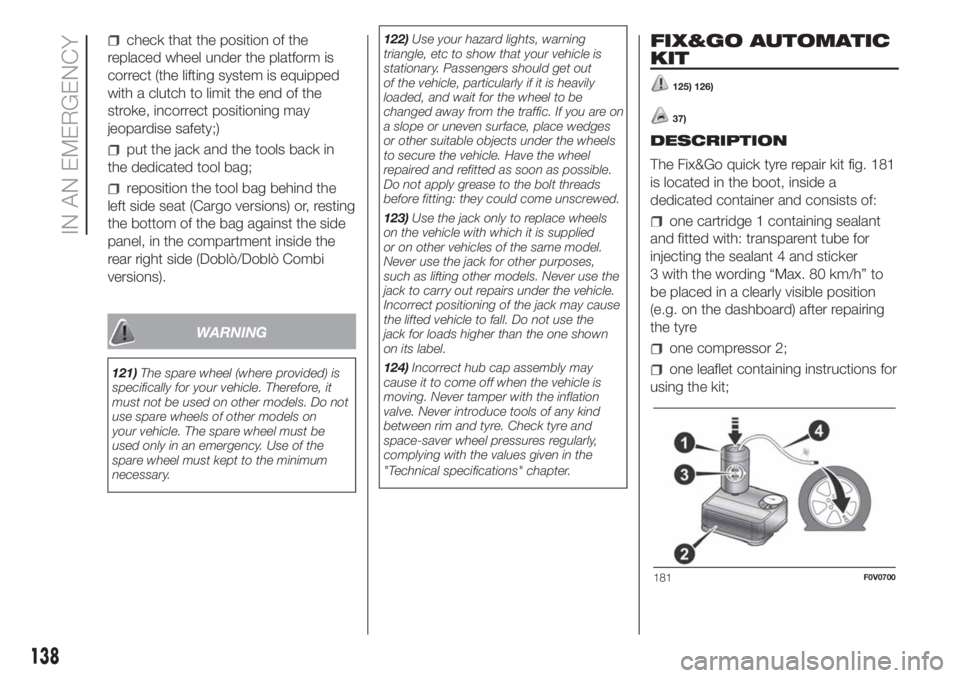

FIX&GO AUTOMATIC

KIT

125) 126)

37)

DESCRIPTION

The Fix&Go quick tyre repair kit fig. 181

is located in the boot, inside a

dedicated container and consists of:

one cartridge 1 containing sealant

and fitted with: transparent tube for

injecting the sealant 4 and sticker

3 with the wording “Max. 80 km/h” to

be placed in a clearly visible position

(e.g. on the dashboard) after repairing

the tyre

one compressor 2;

one leaflet containing instructions for

using the kit;

181F0V0700

138

IN AN EMERGENCY