clock FIAT DUCATO 2006 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2006, Model line: DUCATO, Model: FIAT DUCATO 2006Pages: 238, PDF Size: 3.29 MB

Page 75 of 238

74

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

IMPORTANT

Do not use abrasive detergents or sol-

vents to clean the device. To clean its ex-

ternal surface, use a wet cloth or special

products for cleaning synthetic materials.

The multimeter is installed and sealed with

lead by authorised personnel: access to

the device and relevant power and record-

ing cables is forbidden.

The vehicle owner is responsible for gov-

erning the instrument use. The inspection

must be carried out at least every two

years and will include a test to confirm

correct operation.

After the inspection, check that the plate

is updated with specified data.DOORS

CENTRAL DOOR

LOCKING/UNLOCKING SYSTEM

Locking from the outside

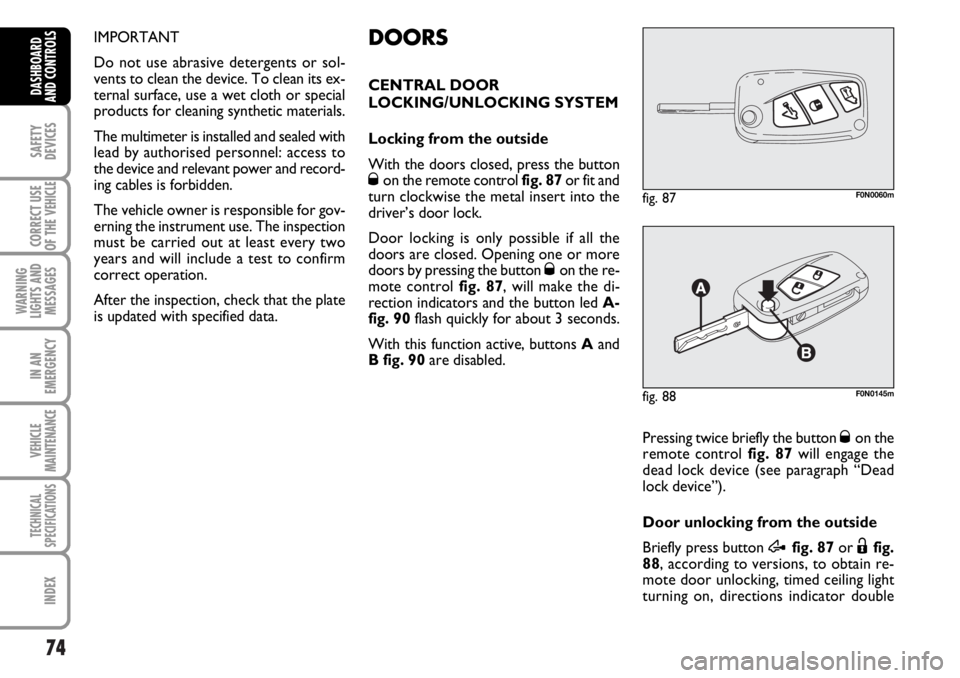

With the doors closed, press the button

Øon the remote control fig. 87or fit and

turn clockwise the metal insert into the

driver’s door lock.

Door locking is only possible if all the

doors are closed. Opening one or more

doors by pressing the button

Øon the re-

mote control fig. 87, will make the di-

rection indicators and the button led A-

fig. 90flash quickly for about 3 seconds.

With this function active, buttons Aand

B fig. 90are disabled.

fig. 87F0N0060m

Pressing twice briefly the button Øon the

remote control fig. 87will engage the

dead lock device (see paragraph “Dead

lock device”).

Door unlocking from the outside

Briefly press button

Æfig. 87or Ëfig.

88, according to versions, to obtain re-

mote door unlocking, timed ceiling light

turning on, directions indicator double

fig. 88F0N0145m

Page 76 of 238

75

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

flashing. Turn the metal insert counter-

clockwise into the driver’s door lock fig.

89to unlock all the doors.

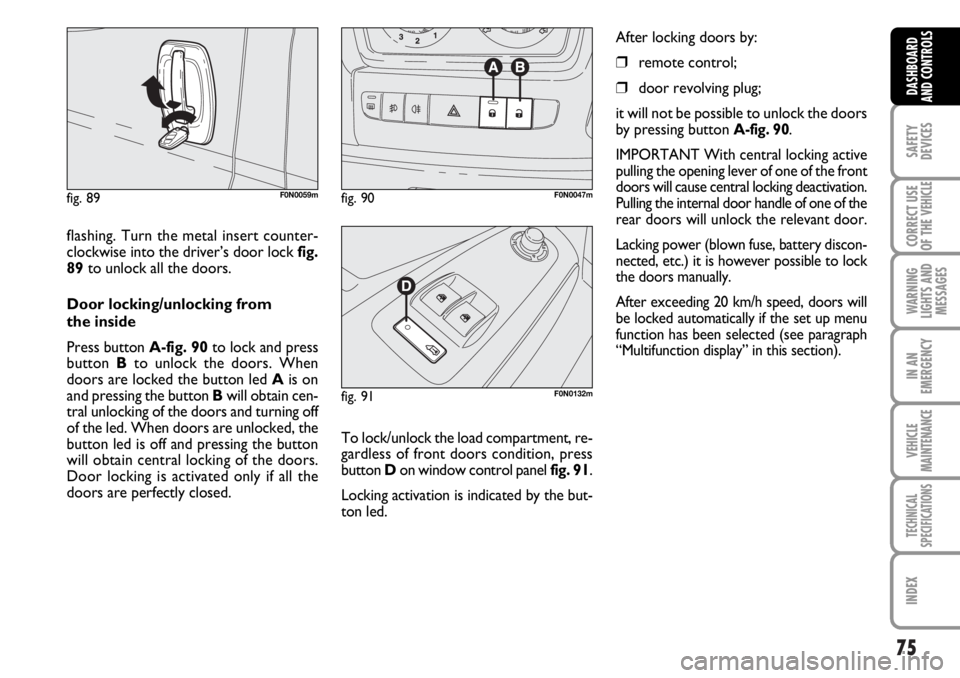

Door locking/unlocking from

the inside

Press button A-fig. 90to lock and press

button Bto unlock the doors. When

doors are locked the button led Ais on

and pressing the button Bwill obtain cen-

tral unlocking of the doors and turning off

of the led. When doors are unlocked, the

button led is off and pressing the button

will obtain central locking of the doors.

Door locking is activated only if all the

doors are perfectly closed.

fig. 89F0N0059mfig. 90F0N0047m

fig. 91F0N0132m

After locking doors by:

❒remote control;

❒door revolving plug;

it will not be possible to unlock the doors

by pressing button

A-fig. 90.

IMPORTANT With central locking active

pulling the opening lever of one of the front

doors will cause central locking deactivation.

Pulling the internal door handle of one of the

rear doors will unlock the relevant door.

Lacking power (blown fuse, battery discon-

nected, etc.) it is however possible to lock

the doors manually.

After exceeding 20 km/h speed, doors will

be locked automatically if the set up menu

function has been selected (see paragraph

“Multifunction display” in this section).

To lock/unlock the load compartment, re-

gardless of front doors condition, press

button Don window control panel fig. 91.

Locking activation is indicated by the but-

ton led.

Page 79 of 238

78

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

fig. 94F0N0129mfig. 95F0N0130mfig. 96F0N0131m

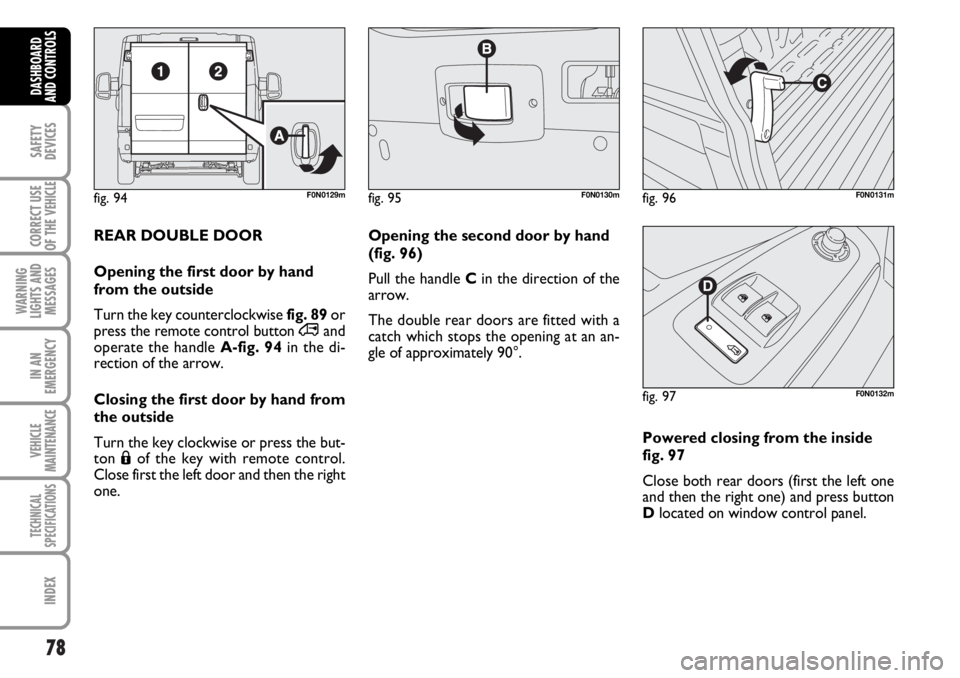

REAR DOUBLE DOOR

Opening the first door by hand

from the outside

Turn the key counterclockwise fig. 89or

press the remote control button ∞and

operate the handleA-fig. 94in the di-

rection of the arrow.

Closing the first door by hand from

the outside

Turn the key clockwise or press the but-

ton Áof the key with remote control.

Close first the left door and then the right

one. Opening the second door by hand

(fig. 96)

Pull the handle Cin the direction of the

arrow.

The double rear doors are fitted with a

catch which stops the opening at an an-

gle of approximately 90°.

Powered closing from the inside

fig. 97

Close both rear doors (first the left one

and then the right one) and press button

Dlocated on window control panel.

fig. 97F0N0132m

Page 145 of 238

144

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

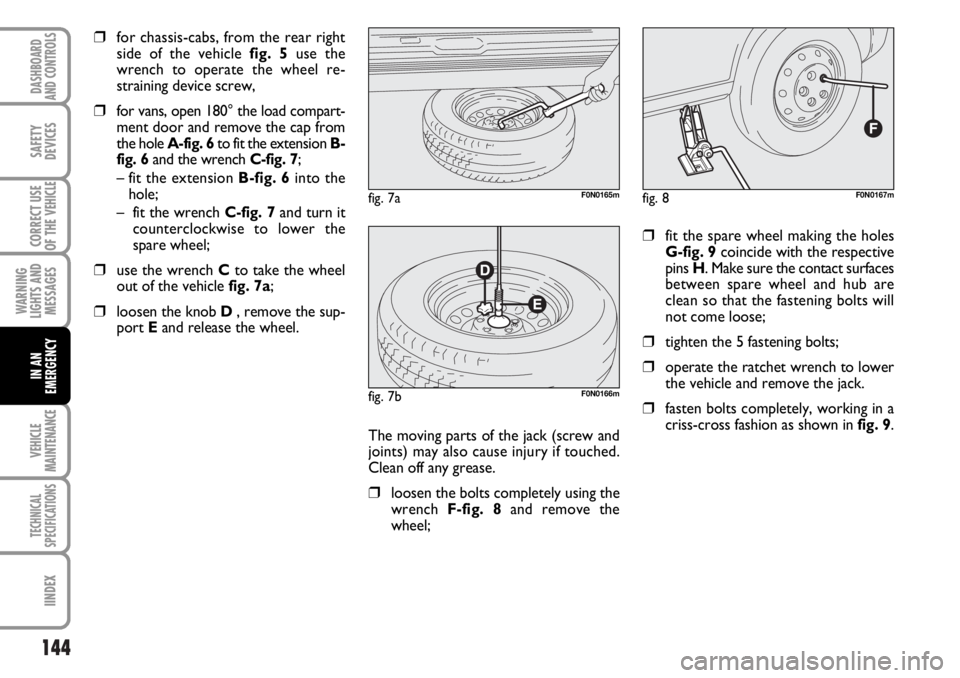

❒for chassis-cabs, from the rear right

side of the vehicle fig. 5use the

wrench to operate the wheel re-

straining device screw,

❒for vans, open 180° the load compart-

ment door and remove the cap from

the hole A-fig. 6to fit the extension B-

fig. 6and the wrench C-fig. 7;

– fit the extension B-fig. 6into the

hole;

– fit the wrench C-fig. 7and turn it

counterclockwise to lower the

spare wheel;

❒use the wrench Cto take the wheel

out of the vehicle fig. 7a;

❒loosen the knob D , remove the sup-

port Eand release the wheel.

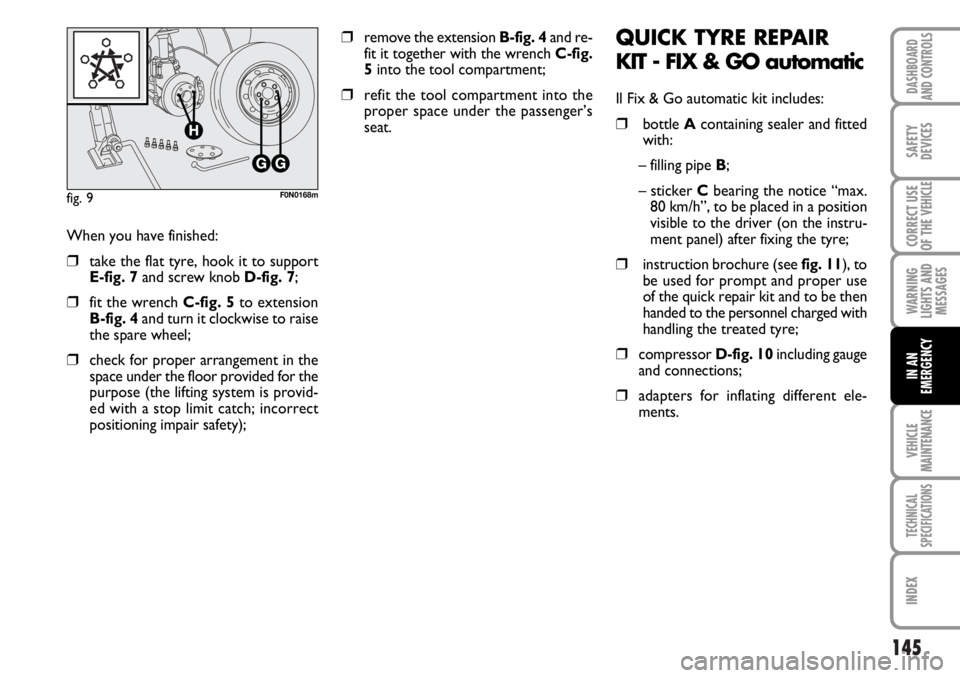

❒fit the spare wheel making the holes

G-fig. 9coincide with the respective

pins H. Make sure the contact surfaces

between spare wheel and hub are

clean so that the fastening bolts will

not come loose;

❒tighten the 5 fastening bolts;

❒operate the ratchet wrench to lower

the vehicle and remove the jack.

❒fasten bolts completely, working in a

criss-cross fashion as shown in fig. 9.

fig. 8F0N0167m

The moving parts of the jack (screw and

joints) may also cause injury if touched.

Clean off any grease.

❒loosen the bolts completely using the

wrench F-fig. 8and remove the

wheel;

fig. 7aF0N0165m

fig. 7bF0N0166m

Page 146 of 238

145

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

QUICK TYRE REPAIR

KIT - FIX & GO automatic

Il Fix & Go automatic kit includes:

❒bottle A containing sealer and fitted

with:

– filling pipe B;

– sticker Cbearing the notice “max.

80 km/h”, to be placed in a position

visible to the driver (on the instru-

ment panel) after fixing the tyre;

❒instruction brochure (see fig. 11), to

be used for prompt and proper use

of the quick repair kit and to be then

handed to the personnel charged with

handling the treated tyre;

❒compressor D-fig. 10including gauge

and connections;

❒adapters for inflating different ele-

ments. When you have finished:

❒take the flat tyre, hook it to support

E-fig. 7and screw knob D-fig. 7;

❒fit the wrench C-fig. 5to extension

B-fig. 4and turn it clockwise to raise

the spare wheel;

❒check for proper arrangement in the

space under the floor provided for the

purpose (the lifting system is provid-

ed with a stop limit catch; incorrect

positioning impair safety);

fig. 9F0N0168m

❒remove the extension B-fig. 4and re-

fit it together with the wrench C-fig.

5into the tool compartment;

❒refit the tool compartment into the

proper space under the passenger’s

seat.

Page 150 of 238

149

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

❒if at laest 3 bar pressure is read, re-

store proper pressure specified in

paragraph” Tyre pressure” in section

“Technical Specifications” (with engine

running and handbrake on) and

restart;

❒drive with the utmost care to the

nearest Fiat Dealership.

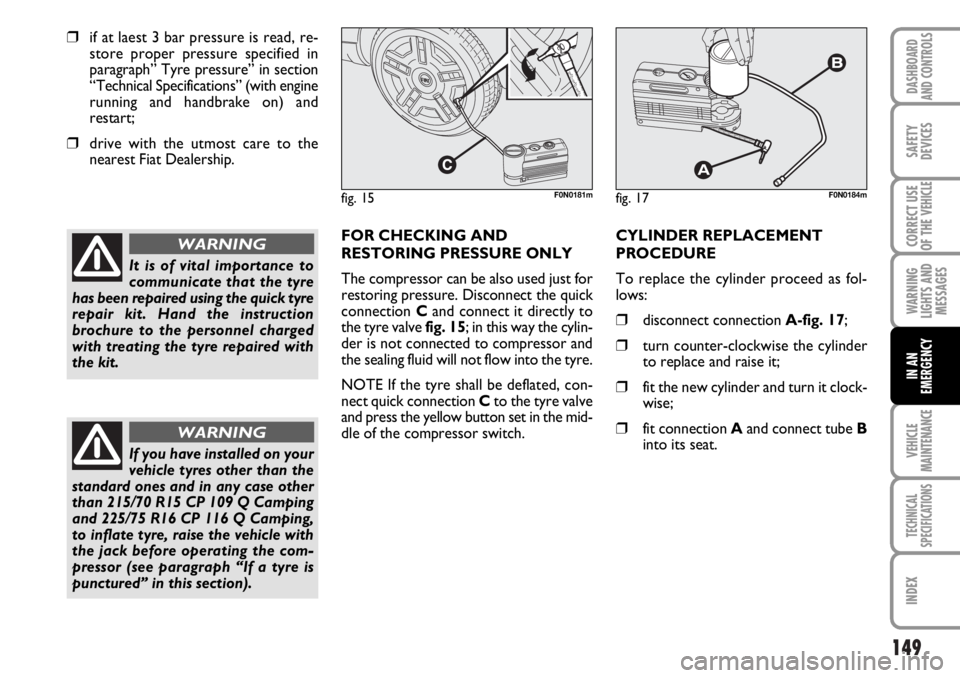

FOR CHECKING AND

RESTORING PRESSURE ONLY

The compressor can be also used just for

restoring pressure. Disconnect the quick

connection Cand connect it directly to

the tyre valve fig. 15; in this way the cylin-

der is not connected to compressor and

the sealing fluid will not flow into the tyre.

NOTE If the tyre shall be deflated, con-

nect quick connection Cto the tyre valve

and press the yellow button set in the mid-

dle of the compressor switch.CYLINDER REPLACEMENT

PROCEDURE

To replace the cylinder proceed as fol-

lows:

❒disconnect connection A-fig. 17;

❒turn counter-clockwise the cylinder

to replace and raise it;

❒fit the new cylinder and turn it clock-

wise;

❒fit connection Aand connect tube B

into its seat.

It is of vital importance to

communicate that the tyre

has been repaired using the quick tyre

repair kit. Hand the instruction

brochure to the personnel charged

with treating the tyre repaired with

the kit.

WARNING

fig. 17F0N0184mfig. 15F0N0181m

If you have installed on your

vehicle tyres other than the

standard ones and in any case other

than 215/70 R15 CP 109 Q Camping

and 225/75 R16 CP 116 Q Camping,

to inflate tyre, raise the vehicle with

the jack before operating the com-

pressor (see paragraph “If a tyre is

punctured” in this section).

WARNING

Page 151 of 238

150

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

WHEN NEEDING TO

CHANGE A BULB

GENERAL INSTRUCTIONS

❒When a light is not working, check

that the corresponding fuse is intact

before changing a bulb. For the loca-

tion of fuses, refer to the paragraph “If

a fuse blows” in this section;

❒Before changing a bulb check the con-

tacts for oxidation;

❒Burnt bulbs must be replaced by oth-

ers of the same type and power;

❒Always check the height of the head-

light beam after changing a bulb.

IMPORTANT The headlight inner surface

may be lightly misted over: this is not a

fault but a natural fact due to low tem-

perature and the level of air humidity. It

will disappear as soon the headlights are

turned on. The presence of drops inside

the headlights means water infiltration,

therefore contact Fiat Dealership.

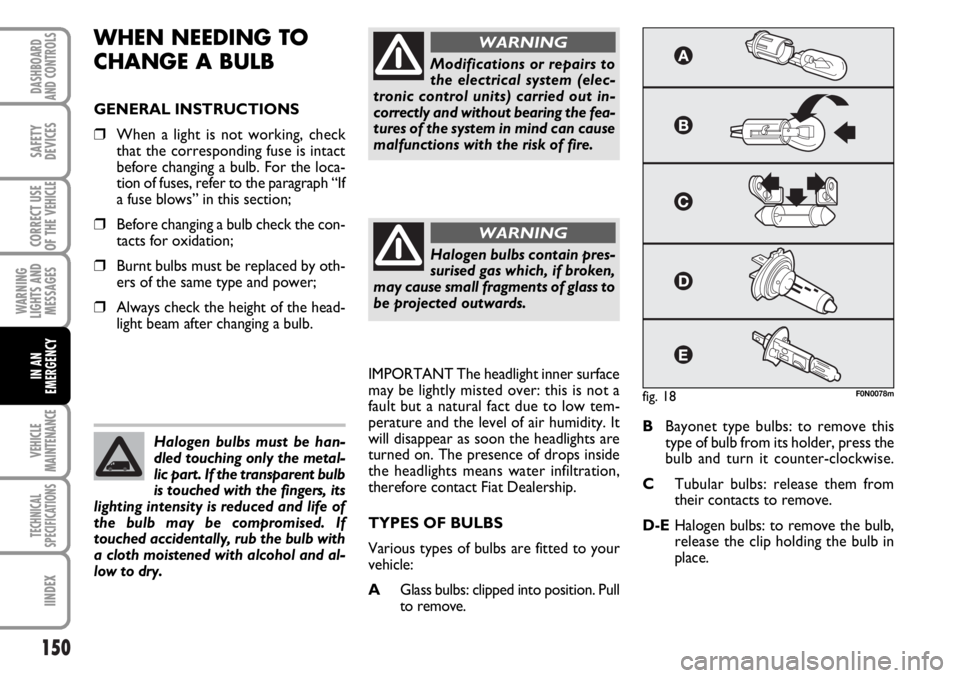

TYPES OF BULBS

Various types of bulbs are fitted to your

vehicle:

AGlass bulbs: clipped into position. Pull

to remove.BBayonet type bulbs: to remove this

type of bulb from its holder, press the

bulb and turn it counter-clockwise.

CTubular bulbs: release them from

their contacts to remove.

D-EHalogen bulbs: to remove the bulb,

release the clip holding the bulb in

place. Halogen bulbs must be han-

dled touching only the metal-

lic part. If the transparent bulb

is touched with the fingers, its

lighting intensity is reduced and life of

the bulb may be compromised. If

touched accidentally, rub the bulb with

a cloth moistened with alcohol and al-

low to dry.

Modifications or repairs to

the electrical system (elec-

tronic control units) carried out in-

correctly and without bearing the fea-

tures of the system in mind can cause

malfunctions with the risk of fire.

WARNING

Halogen bulbs contain pres-

surised gas which, if broken,

may cause small fragments of glass to

be projected outwards.

WARNING

fig. 18F0N0078m

Page 153 of 238

152

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

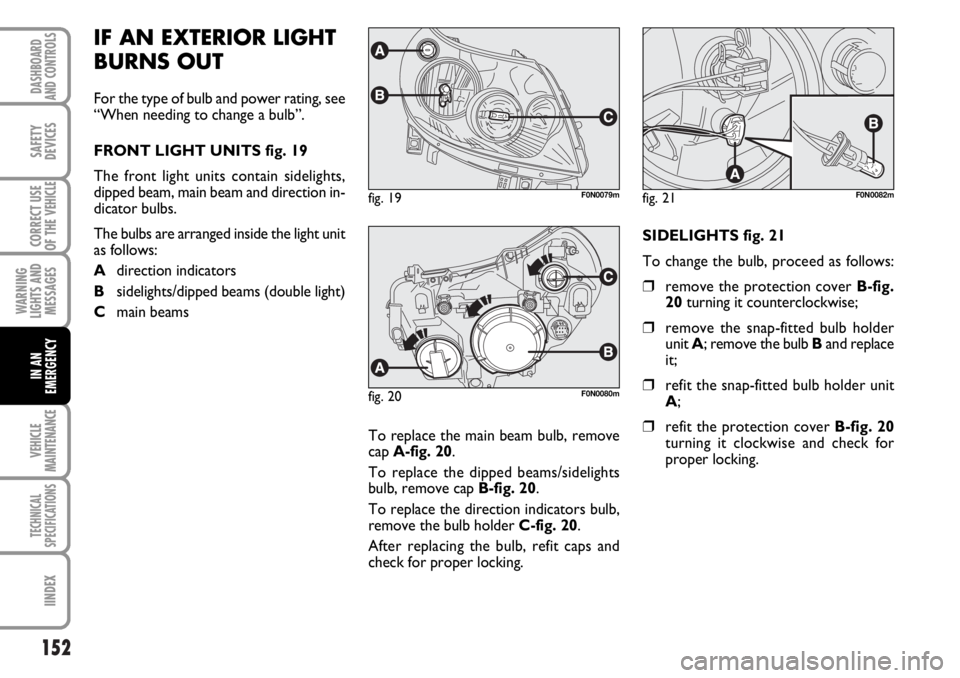

IF AN EXTERIOR LIGHT

BURNS OUT

For the type of bulb and power rating, see

“When needing to change a bulb”.

FRONT LIGHT UNITS fig. 19

The front light units contain sidelights,

dipped beam, main beam and direction in-

dicator bulbs.

The bulbs are arranged inside the light unit

as follows:

Adirection indicators

Bsidelights/dipped beams (double light)

Cmain beams

To replace the main beam bulb, remove

cap A-fig. 20.

To replace the dipped beams/sidelights

bulb, remove cap B-fig. 20.

To replace the direction indicators bulb,

remove the bulb holder C-fig. 20.

After replacing the bulb, refit caps and

check for proper locking.SIDELIGHTS fig. 21

To change the bulb, proceed as follows:

❒remove the protection cover B-fig.

20turning it counterclockwise;

❒remove the snap-fitted bulb holder

unit A; remove the bulb Band replace

it;

❒refit the snap-fitted bulb holder unit

A;

❒refit the protection cover B-fig. 20

turning it clockwise and check for

proper locking.

fig. 19F0N0079mfig. 21F0N0082m

fig. 20F0N0080m

Page 154 of 238

153

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

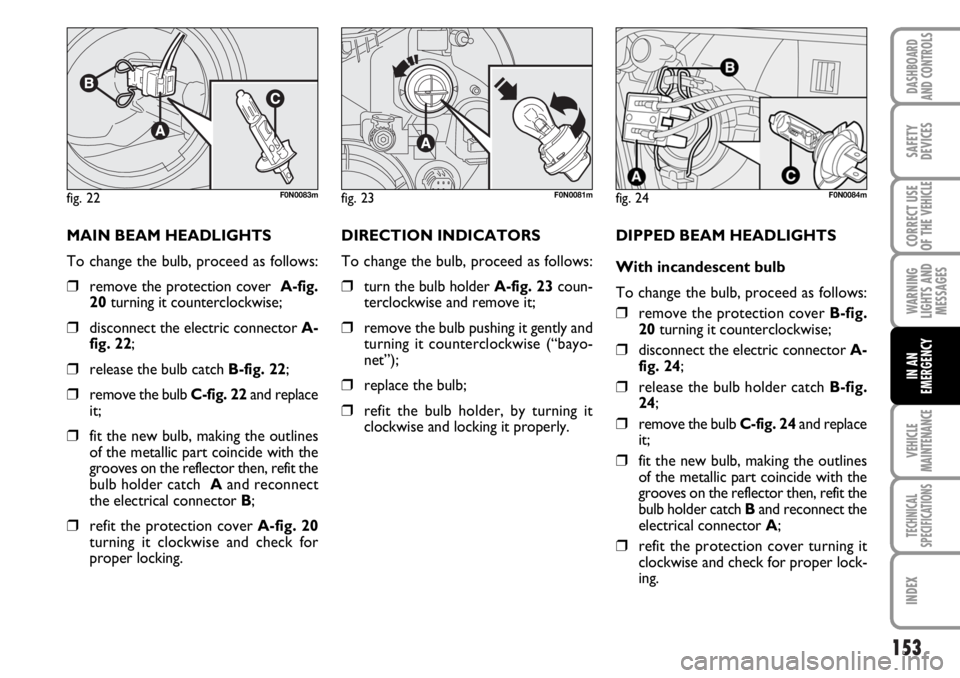

MAIN BEAM HEADLIGHTS

To change the bulb, proceed as follows:

❒remove the protection cover A-fig.

20 turning it counterclockwise;

❒disconnect the electric connector A-

fig. 22;

❒release the bulb catch B-fig. 22;

❒remove the bulb C-fig. 22 and replace

it;

❒fit the new bulb, making the outlines

of the metallic part coincide with the

grooves on the reflector then, refit the

bulb holder catch Aand reconnect

the electrical connector B;

❒refit the protection cover A-fig. 20

turning it clockwise and check for

proper locking.DIRECTION INDICATORS

To change the bulb, proceed as follows:

❒turn the bulb holder A-fig. 23coun-

terclockwise and remove it;

❒remove the bulb pushing it gently and

turning it counterclockwise (“bayo-

net”);

❒replace the bulb;

❒refit the bulb holder, by turning it

clockwise and locking it properly.DIPPED BEAM HEADLIGHTS

With incandescent bulb

To change the bulb, proceed as follows:

❒remove the protection cover B-fig.

20turning it counterclockwise;

❒disconnect the electric connector A-

fig. 24;

❒release the bulb holder catch B-fig.

24;

❒remove the bulb C-fig. 24and replace

it;

❒fit the new bulb, making the outlines

of the metallic part coincide with the

grooves on the reflector then, refit the

bulb holder catch Band reconnect the

electrical connector A;

❒refit the protection cover turning it

clockwise and check for proper lock-

ing.

fig. 22F0N0083mfig. 23F0N0081mfig. 24F0N0084m

Page 155 of 238

154

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

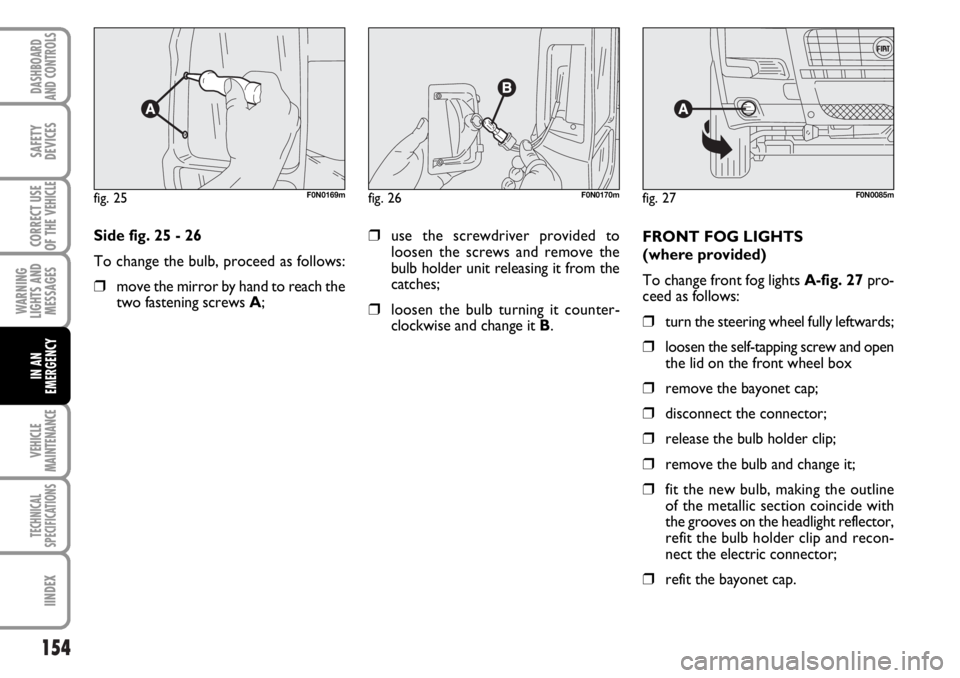

Side fig. 25 - 26

To change the bulb, proceed as follows:

❒move the mirror by hand to reach the

two fastening screws A;FRONT FOG LIGHTS

(where provided)

To change front fog lights A-fig. 27pro-

ceed as follows:

❒turn the steering wheel fully leftwards;

❒loosen the self-tapping screw and open

the lid on the front wheel box

❒remove the bayonet cap;

❒disconnect the connector;

❒release the bulb holder clip;

❒remove the bulb and change it;

❒fit the new bulb, making the outline

of the metallic section coincide with

the grooves on the headlight reflector,

refit the bulb holder clip and recon-

nect the electric connector;

❒refit the bayonet cap.

fig. 25F0N0169mfig. 27F0N0085mfig. 26F0N0170m

❒use the screwdriver provided to

loosen the screws and remove the

bulb holder unit releasing it from the

catches;

❒loosen the bulb turning it counter-

clockwise and change it B.