technical specifications FIAT DUCATO 2007 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2007, Model line: DUCATO, Model: FIAT DUCATO 2007Pages: 282, PDF Size: 4.49 MB

Page 165 of 282

164

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

IT SHOULD BE NOTICED THAT:

The sealing fluid of the quick tyre repair

kit is effective with external temperatures

between –20 °C and +50 °C.

The sealing fluid has limited life.

The compressor shall not be

operated for more than 20

minutes. Risk of overheating!. Tyres

repaired with the quick tyre repair kit

shall be used temporarily only.

WARNING

In the event of a puncture

caused by foreign bodies, it is

possible to repair tyres show-

ing damages on the track or

shoulder up to max 4 mm diameter.

Holes and damages on the

tyre side walls cannot be re-

paired. Do not use the quick tyre re-

pair kit if damaging is due to running

with flat tyre.

WARNING

Repairs are not possible in

case of damages on the

wheel rim (bad groove distortion

causing air loss). Do not remove for-

eign bodies (screws or nails) from the

tyre.

WARNINGIf the compressor stops due to excessive

overheating, wait a few minutes to allow

for compressor cooling, press the RESET

button set aside the compressor, then re-

activate the compressor.

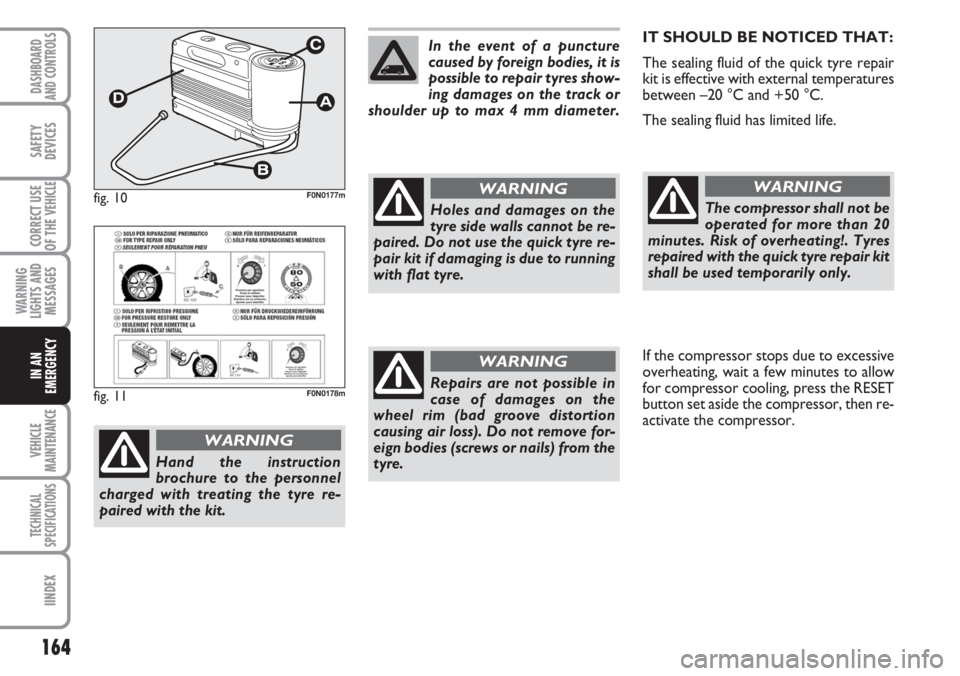

fig. 11F0N0178m

Hand the instruction

brochure to the personnel

charged with treating the tyre re-

paired with the kit.

WARNING

fig. 10F0N0177m

Page 166 of 282

165

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

The cylinder contains ethyl-

ene glycol. The cylinder con-

tains latex: it can cause allergic reac-

tions. It is harmful if ingested or in-

haled and irritant for the eyes and in

case of contact. In case of contact

rinse immediately with water and take

off contaminated clothes. If swal-

lowed, do not induce vomit, rinse out

the mouth, drink a lot of water and

call the doctor immediately. Keep

away from children. This product must

not be used by asthmatics. Do not in-

hale vapours. Call the doctor imme-

diately in case of allergic reactions.

Keep the cylinder in the space provid-

ed for the purpose and far from heat.

The sealing fluid has limited life.

WARNINGReplace the cylinder if sealer

has run out. Do not throw

away the cylinder and the

sealing fluid. Have the sealing

fluid and the cylinder disposed of in

compliance with national and local

regulations.

Put on the protection gloves

provided together with quick

tyre repair kit.

WARNING

❒Pull up the handbrake. Loosen tyre

inflation valve cap, take out the filler

hose A-fig. 12and screw the ring nut

Bon the tyre valve;

fig. 12F0N0179m

INFLATING PROCEDURE

Page 167 of 282

166

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

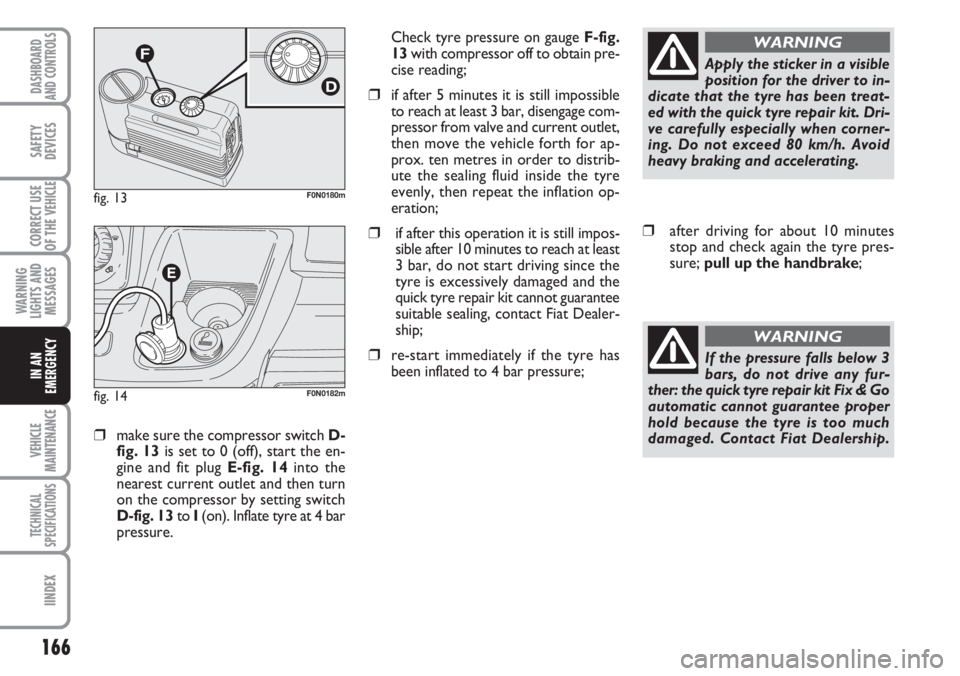

❒make sure the compressor switch D-

fig. 13is set to 0 (off), start the en-

gine and fit plug E-fig. 14into the

nearest current outlet and then turn

on the compressor by setting switch

D-fig. 13to I(on). Inflate tyre at 4 bar

pressure. Check tyre pressure on gauge F-fig.

13with compressor off to obtain pre-

cise reading;

❒if after 5 minutes it is still impossible

to reach at least 3 bar, disengage com-

pressor from valve and current outlet,

then move the vehicle forth for ap-

prox. ten metres in order to distrib-

ute the sealing fluid inside the tyre

evenly, then repeat the inflation op-

eration;

❒if after this operation it is still impos-

sible after 10 minutes to reach at least

3 bar, do not start driving since the

tyre is excessively damaged and the

quick tyre repair kit cannot guarantee

suitable sealing, contact Fiat Dealer-

ship;

❒re-start immediately if the tyre has

been inflated to 4 bar pressure;

fig. 13F0N0180m

fig. 14F0N0182m

Apply the sticker in a visible

position for the driver to in-

dicate that the tyre has been treat-

ed with the quick tyre repair kit. Dri-

ve carefully especially when corner-

ing. Do not exceed 80 km/h. Avoid

heavy braking and accelerating.

WARNING

❒after driving for about 10 minutes

stop and check again the tyre pres-

sure; pull up the handbrake;

If the pressure falls below 3

bars, do not drive any fur-

ther: the quick tyre repair kit Fix & Go

automatic cannot guarantee proper

hold because the tyre is too much

damaged. Contact Fiat Dealership.

WARNING

Page 168 of 282

167

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

❒if at laest 3 bar pressure is read, re-

store proper pressure specified in

paragraph” Tyre pressure” in section

“Technical Specifications” (with engine

running and handbrake on) and

restart;

❒drive with the utmost care to the

nearest Fiat Dealership.

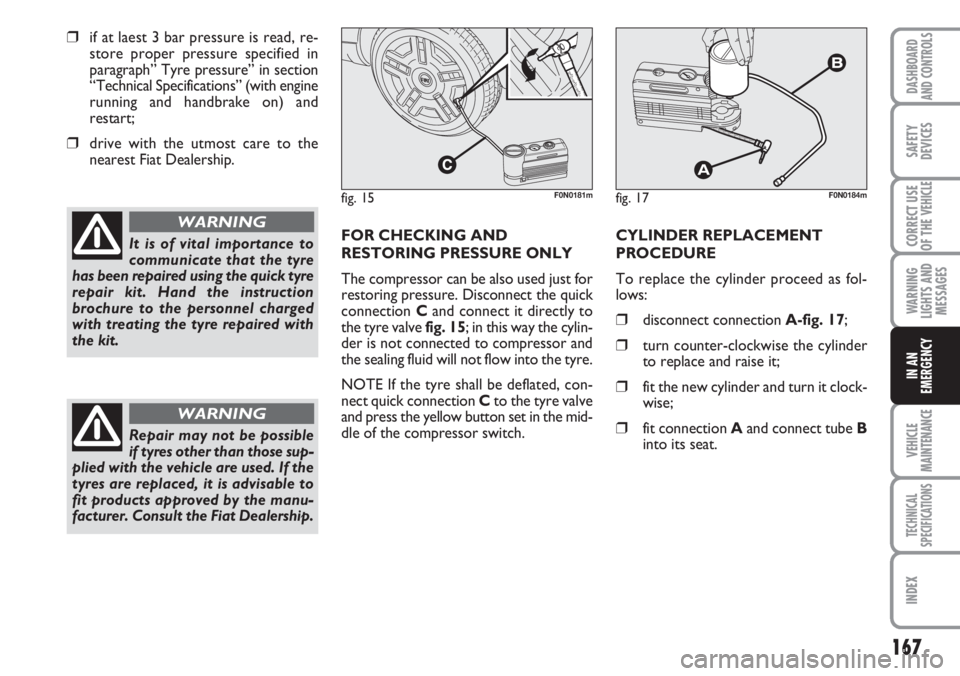

FOR CHECKING AND

RESTORING PRESSURE ONLY

The compressor can be also used just for

restoring pressure. Disconnect the quick

connection Cand connect it directly to

the tyre valve fig. 15; in this way the cylin-

der is not connected to compressor and

the sealing fluid will not flow into the tyre.

NOTE If the tyre shall be deflated, con-

nect quick connection Cto the tyre valve

and press the yellow button set in the mid-

dle of the compressor switch.CYLINDER REPLACEMENT

PROCEDURE

To replace the cylinder proceed as fol-

lows:

❒disconnect connection A-fig. 17;

❒turn counter-clockwise the cylinder

to replace and raise it;

❒fit the new cylinder and turn it clock-

wise;

❒fit connection Aand connect tube B

into its seat.

It is of vital importance to

communicate that the tyre

has been repaired using the quick tyre

repair kit. Hand the instruction

brochure to the personnel charged

with treating the tyre repaired with

the kit.

WARNING

fig. 17F0N0184mfig. 15F0N0181m

Repair may not be possible

if tyres other than those sup-

plied with the vehicle are used. If the

tyres are replaced, it is advisable to

fit products approved by the manu-

facturer. Consult the Fiat Dealership.

WARNING

Page 169 of 282

168

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

WHEN NEEDING TO

CHANGE A BULB

GENERAL INSTRUCTIONS

❒When a light is not working, check

that the corresponding fuse is intact

before changing a bulb. For the loca-

tion of fuses, refer to the paragraph “If

a fuse blows” in this section;

❒Before changing a bulb check the con-

tacts for oxidation;

❒Burnt bulbs must be replaced by oth-

ers of the same type and power;

❒Always check the height of the head-

light beam after changing a bulb.

IMPORTANT The headlight inner surface

may be lightly misted over: this is not a

fault but a natural fact due to low tem-

perature and the level of air humidity. It

will disappear as soon the headlights are

turned on. The presence of drops inside

the headlights means water infiltration,

therefore contact Fiat Dealership.

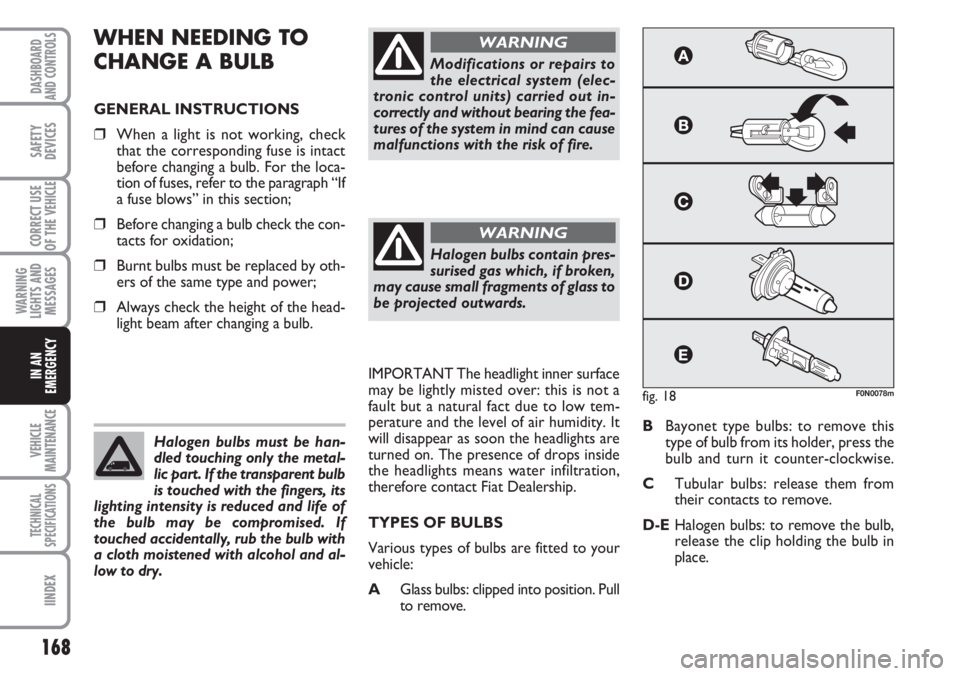

TYPES OF BULBS

Various types of bulbs are fitted to your

vehicle:

AGlass bulbs: clipped into position. Pull

to remove.BBayonet type bulbs: to remove this

type of bulb from its holder, press the

bulb and turn it counter-clockwise.

CTubular bulbs: release them from

their contacts to remove.

D-EHalogen bulbs: to remove the bulb,

release the clip holding the bulb in

place. Halogen bulbs must be han-

dled touching only the metal-

lic part. If the transparent bulb

is touched with the fingers, its

lighting intensity is reduced and life of

the bulb may be compromised. If

touched accidentally, rub the bulb with

a cloth moistened with alcohol and al-

low to dry.

Modifications or repairs to

the electrical system (elec-

tronic control units) carried out in-

correctly and without bearing the fea-

tures of the system in mind can cause

malfunctions with the risk of fire.

WARNING

Halogen bulbs contain pres-

surised gas which, if broken,

may cause small fragments of glass to

be projected outwards.

WARNING

fig. 18F0N0078m

Page 170 of 282

169

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

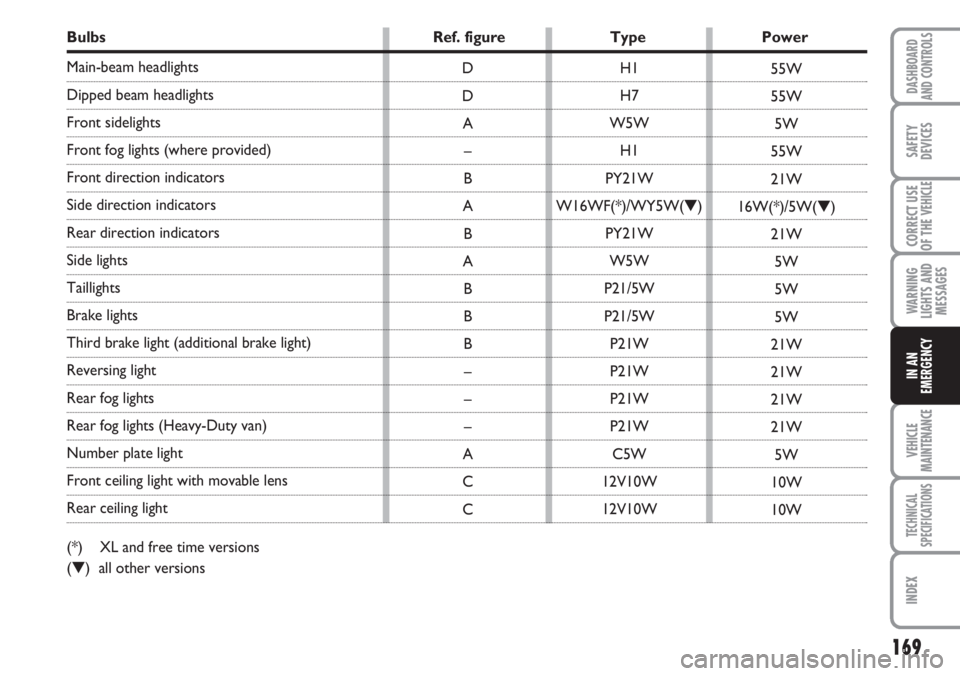

Bulbs Ref. figure Type Power

Main-beam headlights

Dipped beam headlights

Front sidelights

Front fog lights (where provided)

Front direction indicators

Side direction indicators

Rear direction indicators

Side lights

Taillights

Brake lights

Third brake light (additional brake light)

Reversing light

Rear fog lights

Rear fog lights (Heavy-Duty van)

Number plate light

Front ceiling light with movable lens

Rear ceiling light

(*) XL and free time versions

(▼) all other versionsH1

H7

W5W

H1

PY21W

W16WF(*)/WY5W(▼)

PY21W

W5W

P21/5W

P21/5W

P21W

P21W

P21W

P21W

C5W

12V10W

12V10W D

D

A

–

B

A

B

A

B

B

B

–

–

–

A

C

C55W

55W

5W

55W

21W

16W(*)/5W(▼)

21W

5W

5W

5W

21W

21W

21W

21W

5W

10W

10W

Page 171 of 282

170

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

IF AN EXTERIOR LIGHT

BURNS OUT

For the type of bulb and power rating, see

“When needing to change a bulb”.

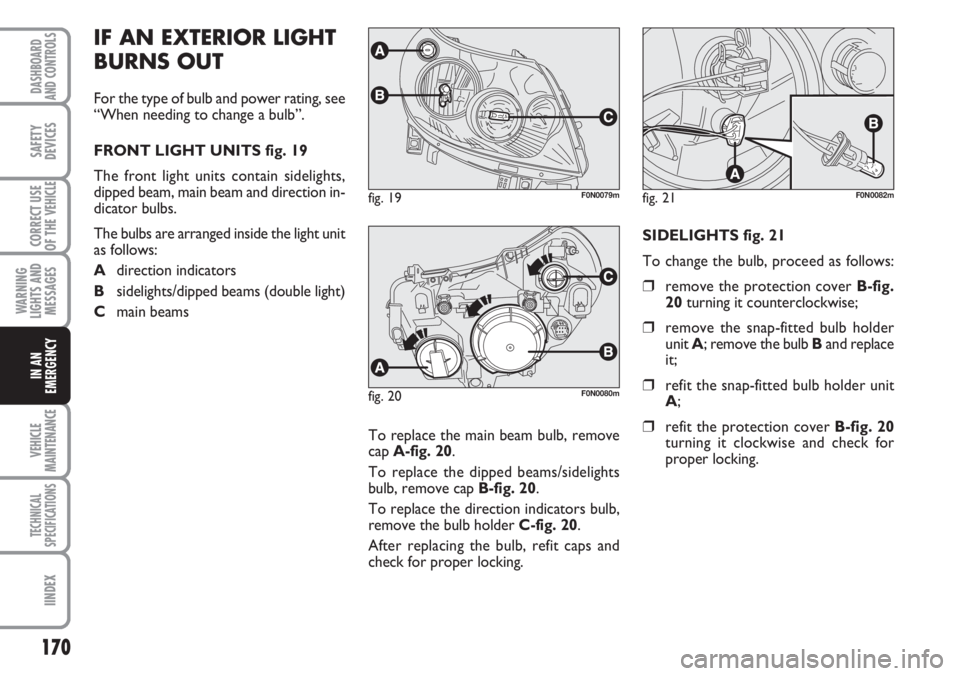

FRONT LIGHT UNITS fig. 19

The front light units contain sidelights,

dipped beam, main beam and direction in-

dicator bulbs.

The bulbs are arranged inside the light unit

as follows:

Adirection indicators

Bsidelights/dipped beams (double light)

Cmain beams

To replace the main beam bulb, remove

cap A-fig. 20.

To replace the dipped beams/sidelights

bulb, remove cap B-fig. 20.

To replace the direction indicators bulb,

remove the bulb holder C-fig. 20.

After replacing the bulb, refit caps and

check for proper locking.SIDELIGHTS fig. 21

To change the bulb, proceed as follows:

❒remove the protection cover B-fig.

20turning it counterclockwise;

❒remove the snap-fitted bulb holder

unit A; remove the bulb Band replace

it;

❒refit the snap-fitted bulb holder unit

A;

❒refit the protection cover B-fig. 20

turning it clockwise and check for

proper locking.

fig. 19F0N0079mfig. 21F0N0082m

fig. 20F0N0080m

Page 172 of 282

171

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

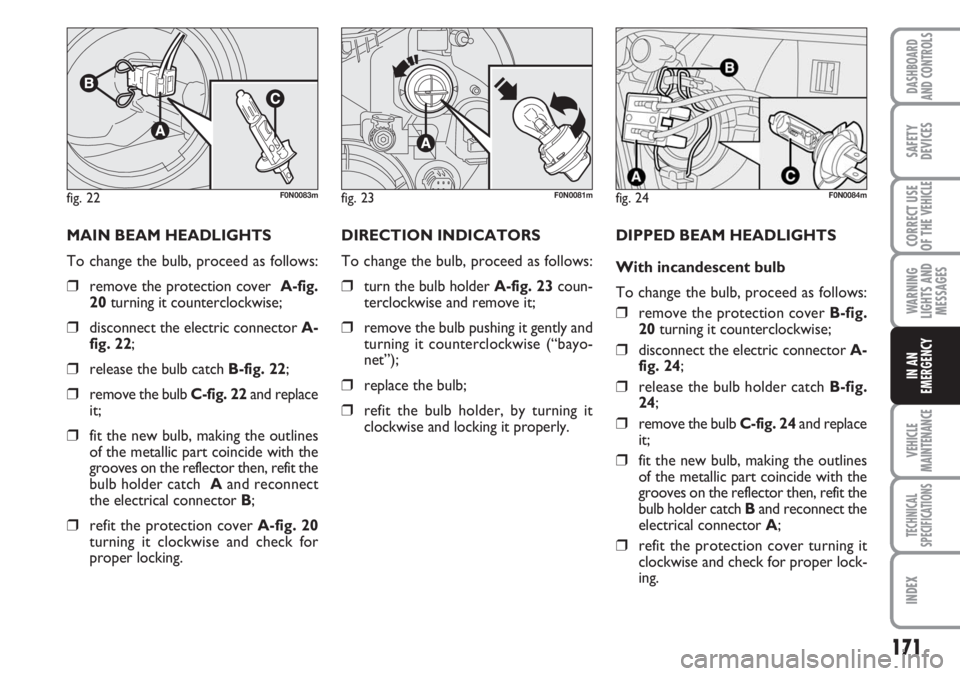

MAIN BEAM HEADLIGHTS

To change the bulb, proceed as follows:

❒remove the protection cover A-fig.

20 turning it counterclockwise;

❒disconnect the electric connector A-

fig. 22;

❒release the bulb catch B-fig. 22;

❒remove the bulb C-fig. 22 and replace

it;

❒fit the new bulb, making the outlines

of the metallic part coincide with the

grooves on the reflector then, refit the

bulb holder catch Aand reconnect

the electrical connector B;

❒refit the protection cover A-fig. 20

turning it clockwise and check for

proper locking.DIRECTION INDICATORS

To change the bulb, proceed as follows:

❒turn the bulb holder A-fig. 23coun-

terclockwise and remove it;

❒remove the bulb pushing it gently and

turning it counterclockwise (“bayo-

net”);

❒replace the bulb;

❒refit the bulb holder, by turning it

clockwise and locking it properly.DIPPED BEAM HEADLIGHTS

With incandescent bulb

To change the bulb, proceed as follows:

❒remove the protection cover B-fig.

20turning it counterclockwise;

❒disconnect the electric connector A-

fig. 24;

❒release the bulb holder catch B-fig.

24;

❒remove the bulb C-fig. 24and replace

it;

❒fit the new bulb, making the outlines

of the metallic part coincide with the

grooves on the reflector then, refit the

bulb holder catch Band reconnect the

electrical connector A;

❒refit the protection cover turning it

clockwise and check for proper lock-

ing.

fig. 22F0N0083mfig. 23F0N0081mfig. 24F0N0084m

Page 173 of 282

172

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

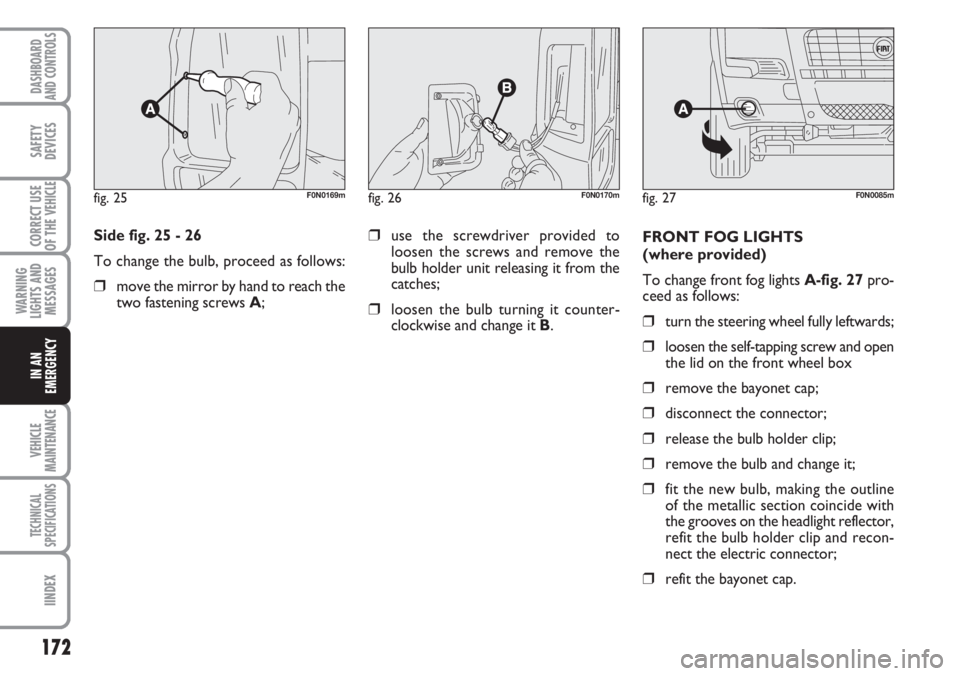

Side fig. 25 - 26

To change the bulb, proceed as follows:

❒move the mirror by hand to reach the

two fastening screws A;FRONT FOG LIGHTS

(where provided)

To change front fog lights A-fig. 27pro-

ceed as follows:

❒turn the steering wheel fully leftwards;

❒loosen the self-tapping screw and open

the lid on the front wheel box

❒remove the bayonet cap;

❒disconnect the connector;

❒release the bulb holder clip;

❒remove the bulb and change it;

❒fit the new bulb, making the outline

of the metallic section coincide with

the grooves on the headlight reflector,

refit the bulb holder clip and recon-

nect the electric connector;

❒refit the bayonet cap.

fig. 25F0N0169mfig. 27F0N0085mfig. 26F0N0170m

❒use the screwdriver provided to

loosen the screws and remove the

bulb holder unit releasing it from the

catches;

❒loosen the bulb turning it counter-

clockwise and change it B.

Page 174 of 282

173

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

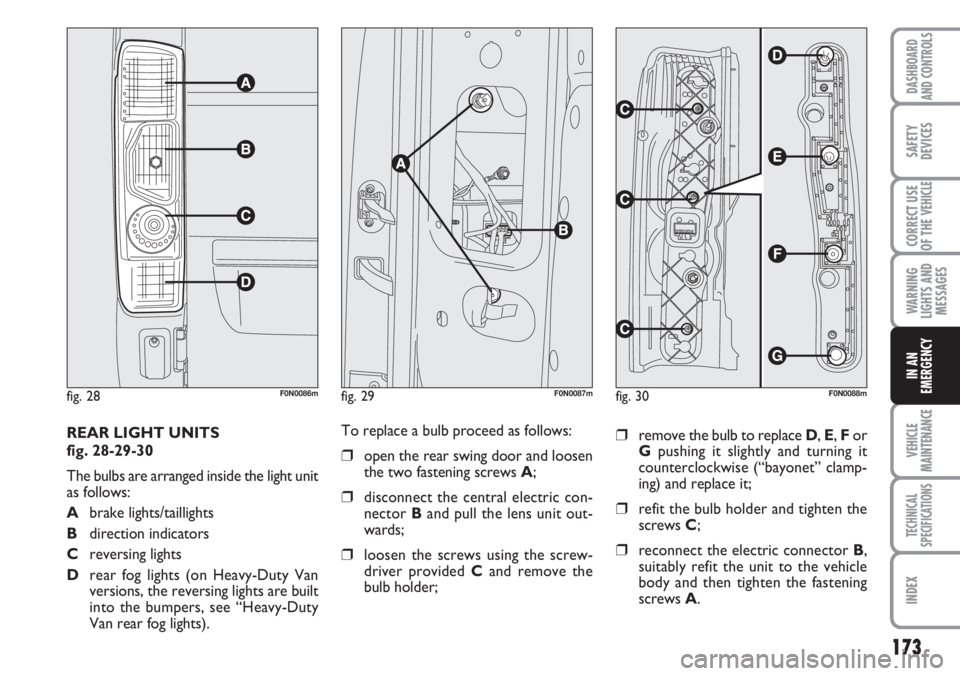

REAR LIGHT UNITS

fig. 28-29-30

The bulbs are arranged inside the light unit

as follows:

Abrake lights/taillights

Bdirection indicators

Creversing lights

Drear fog lights (on Heavy-Duty Van

versions, the reversing lights are built

into the bumpers, see “Heavy-Duty

Van rear fog lights).

fig. 28F0N0086m

To replace a bulb proceed as follows:

❒open the rear swing door and loosen

the two fastening screws A;

❒disconnect the central electric con-

nector B and pull the lens unit out-

wards;

❒loosen the screws using the screw-

driver provided Cand remove the

bulb holder;

❒remove the bulb to replace D, E, For

Gpushing it slightly and turning it

counterclockwise (“bayonet” clamp-

ing) and replace it;

❒refit the bulb holder and tighten the

screws C;

❒reconnect the electric connector B,

suitably refit the unit to the vehicle

body and then tighten the fastening

screws A.

fig. 30F0N0088mfig. 29F0N0087m