technical specifications FIAT DUCATO 2007 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2007, Model line: DUCATO, Model: FIAT DUCATO 2007Pages: 282, PDF Size: 4.49 MB

Page 155 of 282

154

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

FRONT FOG LIGHTS

(green)

The warning light turns on

when the front fog lights are turned on.

5

LEFT-HAND

DIRECTION

INDICATOR

(green - intermittent)

The warning light turns on when the di-

rection indicator control lever is moved

downwards or, together with the right in-

dicator, when the hazard warning light

button is pressed.

F

PARKING SENSOR

FAILURE

(where provided)

(amber)

The warning light turns on when failure

is detected in parking sensors.

On certain versions warning light èturns

on as an alternative.

Contact Fiat Dealership.

On certain versions the dedicated mes-

sage is displayed.

t

SIDE/TAILLIGHTS

AND LOW BEAMS

(green)

FOLLOW ME HOME

(green)

Side/taillights and low beams

The warning light turns on when side/tail-

lights or low beams are turned on.

Follow me home

The warning light will turn when this de-

vice is active (see “Follow me home” in

section “Dashboard and controls”).

The display will show the dedicated mes-

sage.

3

Page 156 of 282

155

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

CRUISE CONTROL

(where provided) (green)

Turning the ignition key to

MARthe warning light will turn on but

it should go off after a few seconds.

The instrument panel warning light turns

on when turning the knurled ring of the

Cruise Control to ON.

On certain versions the dedicated mes-

sage is displayed.

Ü

MAIN BEAMS (blue)

The warning light turns on

when the main beams are

turned on.

1

RIGHT-HAND

DIRECTION

INDICATOR (green -

intermittent)

The warning light turns on when the di-

rection indicator control lever is moved

upwards or, together with the left indica-

tor, when the hazard warning light button

is pressed.

D

ASR SYSTEM

(where provided)

(amber)

Turning the ignition key to

MAR, the warning light turns on but it

should go off after few seconds. The led

on the ASR button turns on when the sys-

tem is switched off. The warning light

flashes when the ASR system cuts in to

alert the driver that the system is adapt-

ing to the road surface grip conditions.

The turning on of the warning light to-

gether with the message on the display

and the buzzer, also indicates a failure of

the ASR system. In this case contact Fiat

Dealership as soon as possible.

Messages are displayed when the ASR

function is activated/deactivated manual-

ly (see “ASR system” in section “Dash-

board and controls”).

In versions fitted with ASR system only, at

deactivation (ASR OFF) the warning light

will always stay on.

V

POWER STEERING

FAILURE (red)

Turning the ignition key to

MARthe warning light on the di-

al turns on, but it should go off after few

seconds.

If the warning light stays on together with

the message on the display and the buzzer,

you will not have steering assistance and

the effort on the steering wheel will be in-

creased, steering is however possible.

Contact Fiat Dealership.

g

Page 157 of 282

156

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

WARNING

LIGHTS AND

MESSAGES

AUTOMATIC

TRANSMISSION

FAILURE/MAX.

GEARBOX OIL

TEMPERATURE

(where provided) (red)

Turning the ignition key to MAR, the

warning light shall turn on but it should

turn off a few seconds later.

The warning light turns on flashing (to-

gether with the message on the display and

the buzzer) when the gearbox is failing.

The warning light turns on glowing steadi-

ly (together with the message on the dis-

play and the buzzer) when the automatic

transmission oil is too hot. SCHEDULED

SERVICING

(where provided)

This warning light turns on to in-

dicate servicing and it will stay on glowing

steadily until reaching the deadline. The

warning light will turn off after carrying out

servicing at Fiat Dealership or after 1000

km at servicing deadline.SELF-LEVELLING

SUSPENSIONS

FAILURE

(where provided) (red)

Turning the ignition key to MARthe

warning light shall turn on but it should

turn off a few seconds later.

The warning light will turn on to indicate a

failure at self-levelling suspension system.POSSIBLE PRESENCE OF ICE

ON THE ROAD

This indication starts flashing when the

outside temperature reaches or falls be-

low 3°C to warn the driver of the possi-

ble presence of ice on the road.

The display will show the dedicated mes-

sage (only for versions with a multifunc-

tional display).

LIMITED RANGE

(versions with multifunction

display)

The display will show the dedicated mes-

sage to warn the driver that the cruising

range is less than 50 km.

SPEED LIMIT EXCEEDED

The display will show the dedicated mes-

sage when the vehicle exceeds the set

speed limit (see “Multifunction Display” in

section “Dashboard and controls”). ENGINE COOLANT

LEVEL (red)

(where provided)

The warning light turns on when

the coolant level in radiator falls below the

min. level.

n

õ

Œ

t

Page 158 of 282

157

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

ENGINE STARTING ............................................................ 158

IF A TYRE IS PUNCTURED ................................................ 159

QUICK TYRE REPAIR KIT

FIX & GO automatic ............................................................. 163

WHEN NEEDING TO CHANGE A BULB .................... 168

IF AN EXTERIOR LIGHT BURNS OUT .......................... 170

IF AN INTERIOR LIGHT BURNS OUT ........................... 176

IF A FUSE BLOWS ................................................................. 177

IF THE BATTERY IS FLAT ................................................... 185

JACKING THE VEHICLE ..................................................... 186

TOWING THE VEHICLE .................................................... 186

I I

N N

A A

N N

E E

M M

E E

R R

G G

E E

N N

C C

Y Y

Page 159 of 282

158

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

ENGINE

STARTING

EMERGENCY START-UP

If the instrument panel warning light

Yturns on glowing steadily, contact im-

mediately Fiat Dealership.

JUMP STARTING fig. 1-2

If the battery is flat, it is possible to start

the engine using an auxiliary battery with

the same capacity or a little higher than

the flat one.

Contact Fiat Dealership to have the bat-

tery checked/replaced.Proceed as follows:

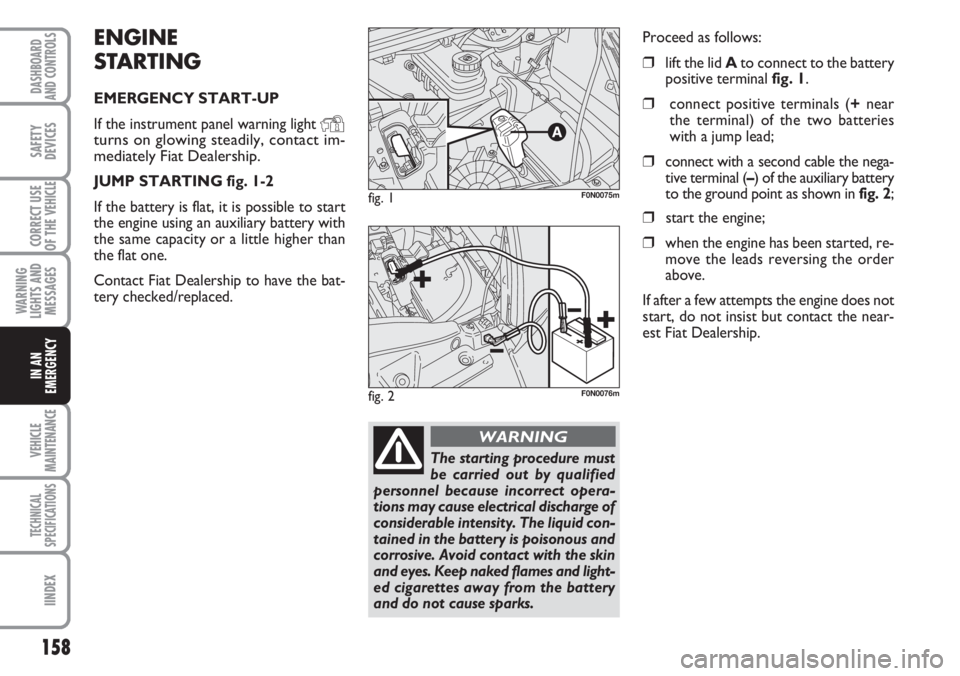

❒lift the lid Ato connect to the battery

positive terminal fig. 1.

❒connect positive terminals (+near

the terminal) of the two batteries

with a jump lead;

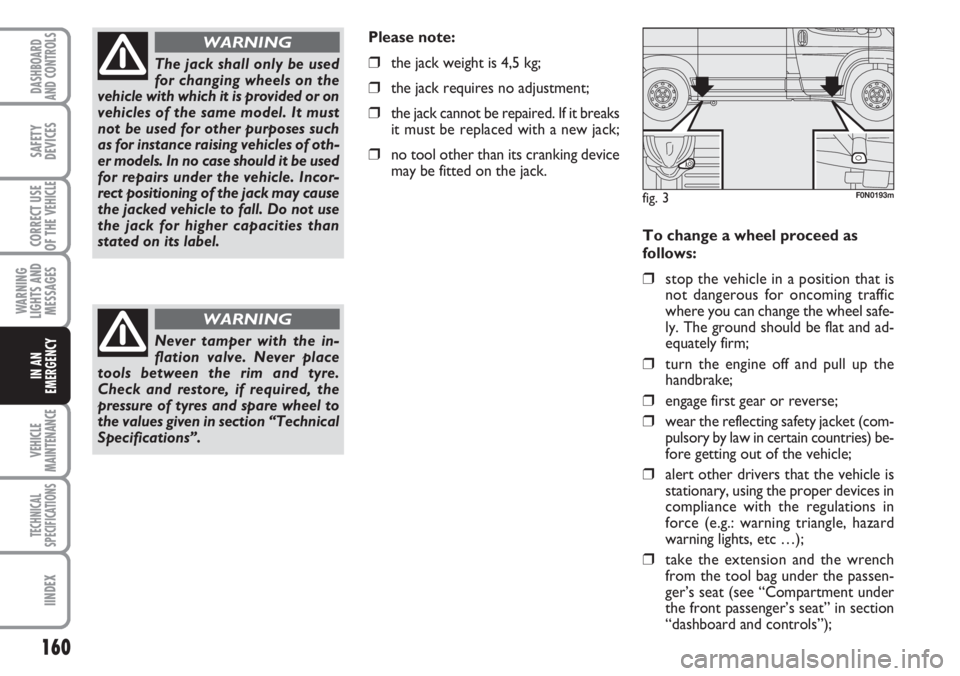

❒connect with a second cable the nega-

tive terminal (–) of the auxiliary battery

to the ground point as shown in fig. 2;

❒start the engine;

❒when the engine has been started, re-

move the leads reversing the order

above.

If after a few attempts the engine does not

start, do not insist but contact the near-

est Fiat Dealership.

fig. 1F0N0075m

The starting procedure must

be carried out by qualified

personnel because incorrect opera-

tions may cause electrical discharge of

considerable intensity. The liquid con-

tained in the battery is poisonous and

corrosive. Avoid contact with the skin

and eyes. Keep naked flames and light-

ed cigarettes away from the battery

and do not cause sparks.

WARNING

fig. 2F0N0076m

Page 160 of 282

159

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

IMPORTANT Do not directly connect the

negative terminals of the two batteries:

sparks could ignite the flammable gas from

the battery. If the other battery is fitted in

another vehicle, prevent accidental con-

tacts between the metal parts of the two

vehicles.

BUMP STARTING

Never bump start the engine (by pushing,

towing, or coasting downhill) as this could

cause fuel to flow into the catalytic ex-

haust system and damage it beyond repair.

IMPORTANT Remember that the brake

booster and the power steering system

are not operating until the engine is start-

ed, a greater effort will therefore be re-

quired to press the brake pedal or turn

the steering wheel.IF A TYRE

IS PUNCTURED

GENERAL INSTRUCTIONS

Wheel changing and correct use of the

jack and spare wheel call for some pre-

cautions as listed below.

Alert other drivers that the

vehicle is stationary in com-

pliance with the regulations in force:

hazard warning lights, warning trian-

gle etc. Any passengers on board

should leave the vehicle, especially if

it is heavily laden. Passengers should

stay away from oncoming traffic

while the wheel is being changed on.

Pull the handbrake.

WARNING

The spare wheel is specific to

your vehicle, do not use it on

other models, or use the spare wheel

of other models on your vehicle.

Wheel bolts are specific to your vehi-

cle: do not use them on other models

and do not use bolts of other models.

WARNING

Have the punctured wheel

repaired and refitted as soon

as possible. Do not grease the threads

of bolts before installing them: they

might slip out.

WARNING

Page 161 of 282

160

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

To change a wheel proceed as

follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safe-

ly. The ground should be flat and ad-

equately firm;

❒turn the engine off and pull up the

handbrake;

❒engage first gear or reverse;

❒wear the reflecting safety jacket (com-

pulsory by law in certain countries) be-

fore getting out of the vehicle;

❒alert other drivers that the vehicle is

stationary, using the proper devices in

compliance with the regulations in

force (e.g.: warning triangle, hazard

warning lights, etc …);

❒take the extension and the wrench

from the tool bag under the passen-

ger’s seat (see “Compartment under

the front passenger’s seat” in section

“dashboard and controls”);

The jack shall only be used

for changing wheels on the

vehicle with which it is provided or on

vehicles of the same model. It must

not be used for other purposes such

as for instance raising vehicles of oth-

er models. In no case should it be used

for repairs under the vehicle. Incor-

rect positioning of the jack may cause

the jacked vehicle to fall. Do not use

the jack for higher capacities than

stated on its label.

WARNING

Never tamper with the in-

flation valve. Never place

tools between the rim and tyre.

Check and restore, if required, the

pressure of tyres and spare wheel to

the values given in section “Technical

Specifications”.

WARNING

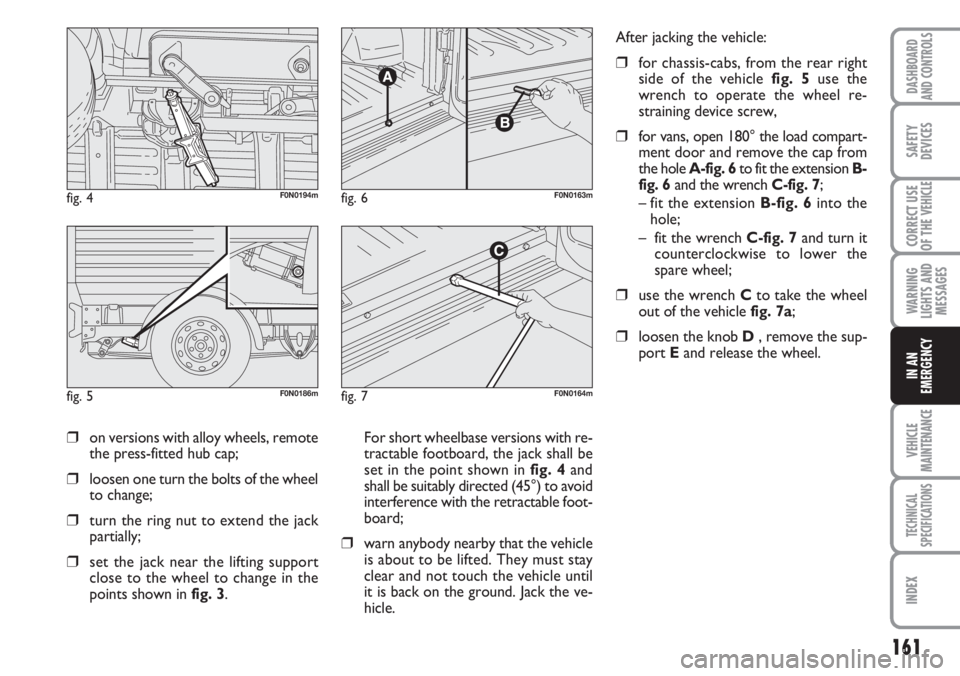

Please note:

❒the jack weight is 4,5 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired. If it breaks

it must be replaced with a new jack;

❒no tool other than its cranking device

may be fitted on the jack.

fig. 3F0N0193m

Page 162 of 282

161

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

❒on versions with alloy wheels, remote

the press-fitted hub cap;

❒loosen one turn the bolts of the wheel

to change;

❒turn the ring nut to extend the jack

partially;

❒set the jack near the lifting support

close to the wheel to change in the

points shown in fig. 3. For short wheelbase versions with re-

tractable footboard, the jack shall be

set in the point shown in fig. 4and

shall be suitably directed (45°) to avoid

interference with the retractable foot-

board;

❒warn anybody nearby that the vehicle

is about to be lifted. They must stay

clear and not touch the vehicle until

it is back on the ground. Jack the ve-

hicle.

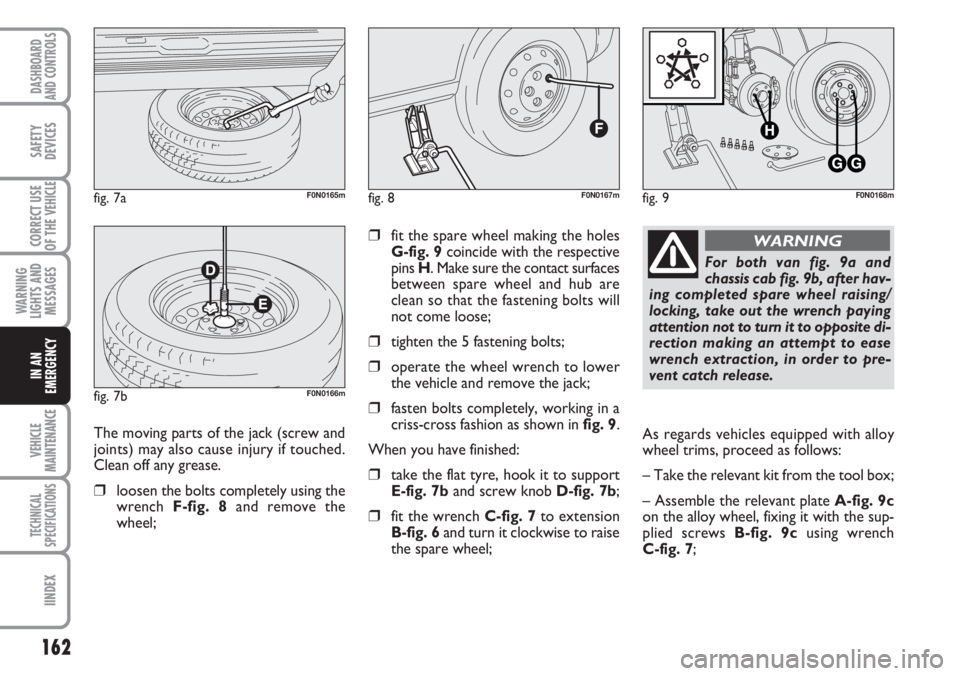

fig. 4F0N0194m

fig. 5F0N0186m

fig. 6F0N0163m

fig. 7F0N0164m

After jacking the vehicle:

❒for chassis-cabs, from the rear right

side of the vehicle fig. 5use the

wrench to operate the wheel re-

straining device screw,

❒for vans, open 180° the load compart-

ment door and remove the cap from

the hole A-fig. 6to fit the extension B-

fig. 6and the wrench C-fig. 7;

– fit the extension B-fig. 6into the

hole;

– fit the wrench C-fig. 7and turn it

counterclockwise to lower the

spare wheel;

❒use the wrench Cto take the wheel

out of the vehicle fig. 7a;

❒loosen the knob D , remove the sup-

port Eand release the wheel.

Page 163 of 282

162

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

❒fit the spare wheel making the holes

G-fig. 9coincide with the respective

pins H. Make sure the contact surfaces

between spare wheel and hub are

clean so that the fastening bolts will

not come loose;

❒tighten the 5 fastening bolts;

❒operate the wheel wrench to lower

the vehicle and remove the jack;

❒fasten bolts completely, working in a

criss-cross fashion as shown in fig. 9.

When you have finished:

❒take the flat tyre, hook it to support

E-fig. 7band screw knob D-fig. 7b;

❒fit the wrench C-fig. 7to extension

B-fig. 6and turn it clockwise to raise

the spare wheel;

fig. 8F0N0167mfig. 9F0N0168m

The moving parts of the jack (screw and

joints) may also cause injury if touched.

Clean off any grease.

❒loosen the bolts completely using the

wrench F-fig. 8and remove the

wheel;

fig. 7aF0N0165m

fig. 7bF0N0166m

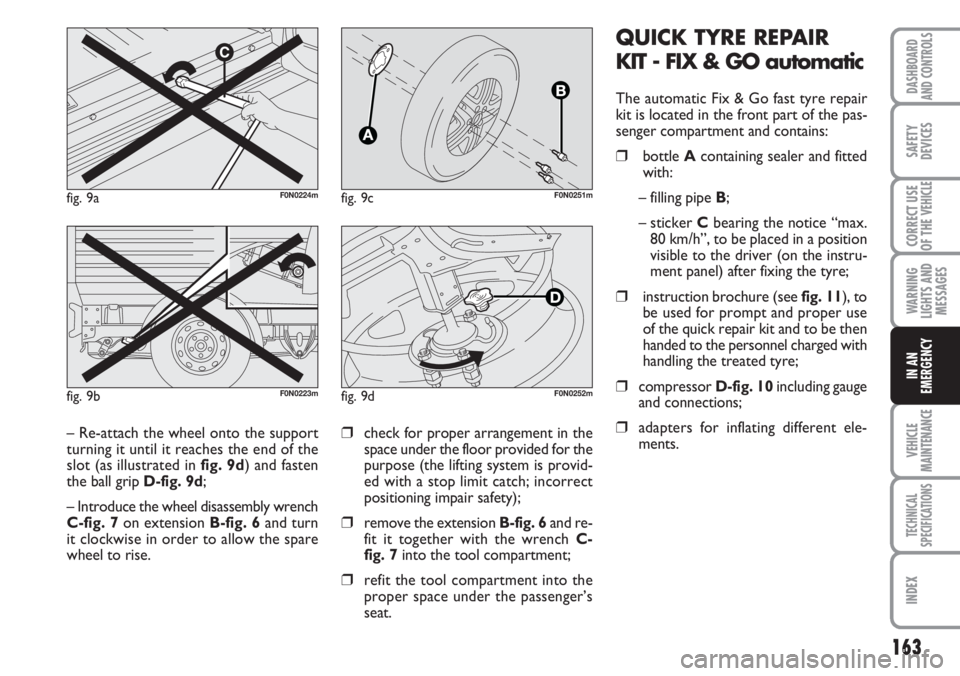

For both van fig. 9a and

chassis cab fig. 9b, after hav-

ing completed spare wheel raising/

locking, take out the wrench paying

attention not to turn it to opposite di-

rection making an attempt to ease

wrench extraction, in order to pre-

vent catch release.

WARNING

As regards vehicles equipped with alloy

wheel trims, proceed as follows:

– Take the relevant kit from the tool box;

– Assemble the relevant plate A-fig. 9c

on the alloy wheel, fixing it with the sup-

plied screws B-fig. 9cusing wrench

C-fig. 7;

Page 164 of 282

163

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

QUICK TYRE REPAIR

KIT - FIX & GO automatic

The automatic Fix & Go fast tyre repair

kit is located in the front part of the pas-

senger compartment and contains:

❒bottle A containing sealer and fitted

with:

– filling pipe B;

– sticker Cbearing the notice “max.

80 km/h”, to be placed in a position

visible to the driver (on the instru-

ment panel) after fixing the tyre;

❒instruction brochure (see fig. 11), to

be used for prompt and proper use

of the quick repair kit and to be then

handed to the personnel charged with

handling the treated tyre;

❒compressor D-fig. 10including gauge

and connections;

❒adapters for inflating different ele-

ments.❒check for proper arrangement in the

space under the floor provided for the

purpose (the lifting system is provid-

ed with a stop limit catch; incorrect

positioning impair safety);

❒remove the extension B-fig. 6and re-

fit it together with the wrench C-

fig. 7into the tool compartment;

❒refit the tool compartment into the

proper space under the passenger’s

seat.

fig. 9aF0N0224m

fig. 9bF0N0223m

– Re-attach the wheel onto the support

turning it until it reaches the end of the

slot (as illustrated in fig. 9d) and fasten

the ball grip D-fig. 9d;

– Introduce the wheel disassembly wrench

C-fig. 7on extension B-fig. 6and turn

it clockwise in order to allow the spare

wheel to rise.

fig. 9cF0N0251m

fig. 9dF0N0252m