technical data FIAT DUCATO BASE CAMPER 2014 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2014, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2014Pages: 367, PDF Size: 20.39 MB

Page 1 of 367

The data contained in this publication is intended merely as a guide. FIAT reserves the right to modify the models and

versions described in this booklet at any time for technical and commercial reasons.

If you have any further questions please consult your FIAT dealer.

Printed in recycled paper without chlorine.

OWNER HANDBOOK

FIATDUCATO

ENGLISH

DUCATO LUM GB 17-12-2008 9:57 Pagina 1

Page 5 of 367

Dear Customer,We would like to congratulate and thank you for choosing a Fiat Ducato. We have written this handbook to help you get to know all the

features of your vehicle and use it in the best possible way. You should read it right through before taking to the road for the first time.

You will find information, tips and important warnings regarding the use of your vehicle to help you get the most from the technological features

of your Fiat Ducato. It also provides a description of special features and essential information for the care and maintenance of your vehicle

over time as well as for safe driving.

We urge you to read the warnings and indications found throughout the text with care, marked with the following symbols:

personal safety;vehicle integrity;environmental protection.

NOTE These symbols, when necessary, are reported at the end of each paragraph and are followed by a number. That number recalls the

corresponding warning at the end of the relevant section.

In the attached Warranty Booklet you will also find a description of the Services that Fiat offers to its customers, the Warranty Certificate and

the detail of the terms and conditions for maintaining its validity.

We are sure that these will help you to get in touch with and appreciate your new vehicle and the service provided by the people at Fiat.

Enjoy reading. Happy motoring!

This Owner Handbook describes all Fiat Ducato versions. As a consequence, you should only consider the information

which is related to the trim level, engine and version that you have purchased. All data contained in this publication is

purely indicative. Fiat Group Automobiles can modify the specifications of the vehicle model described in this publication

at any time, for technical or marketing purposes. For further information, contact a Fiat Dealership.

Page 9 of 367

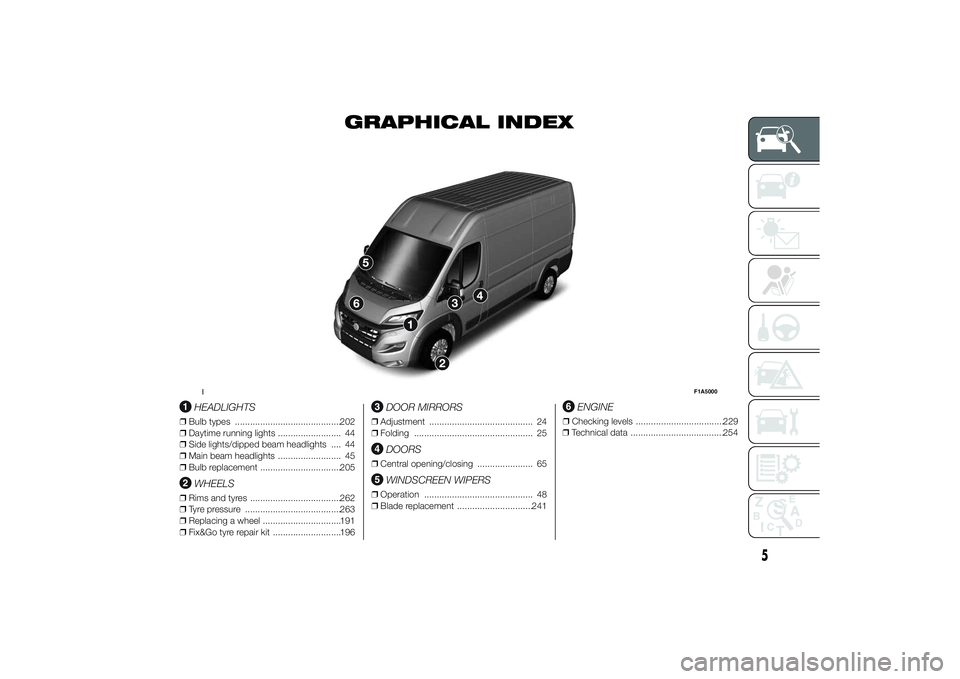

GRAPHICAL INDEX

.

HEADLIGHTS

❒Bulb types ..........................................202

❒Daytime running lights ......................... 44

❒Side lights/dipped beam headlights .... 44

❒Main beam headlights ......................... 45

❒Bulb replacement ................................205

WHEELS

❒Rims and tyres ....................................262

❒Tyre pressure ......................................263

❒Replacing a wheel ...............................191

❒Fix&Go tyre repair kit ...........................196

DOOR MIRRORS

❒Adjustment ......................................... 24

❒Folding ............................................... 25

DOORS

❒Central opening/closing ...................... 65

WINDSCREEN WIPERS

❒Operation ........................................... 48

❒Blade replacement ..............................241

ENGINE

❒Checking levels ...................................229

❒Technical data .....................................254

1

F1A5000

5

Page 179 of 367

LOADING ADVICEThe Fiat Ducato version used by you

has been designed and type approved

on the basis of certain maximum

weights (see "Weights" table in the

"Technical Data" chapter): kerb weight,

payload, total weight, maximum weight

on front axle, maximum weight on

rear axle, towable weight.

IMPORTANT The maximum permitted

load on the floor fastenings is 500

kg; the maximum permitted load on the

side panel is 150 kg.

IMPORTANT For versions with right and

left side flaps, it is advisable to

reposition the release lever in the closed

position before lowering the sides.

35)128) 129) 130)

In addition to these general

precautions, some simple precautions

can improve driving safety, travelling

comfort and vehicle durability:

❒distribute the load evenly over the

platform: if it is necessary to

concentrate it in a single area,

choose an area mid-way between

both axles;❒lastly, remember that the vehicle’s

dynamic behaviour is affected by

the weight transported: in particular,

the stopping distances are longer,

especially at high speed.

IMPORTANT

35) Each of these must be strictly

observed and MUST NEVER BE

EXCEEDED in any case. In

particular, ensure that you never

exceed the maximum permitted

weights on the front and rear

axles when arranging the load on

the vehicle (particularly if the

vehicle is equipped with a specific

trim level).

WARNING

128) Irregular trajectories and abrupt

braking may cause sudden

movements of the load with

consequent situations of hazard

for the driver and passengers:

before setting off, secure the load

tightly using the appropriate

hooks on the floor and use steel

cables, ropes or chains strong

enough to hold the items to be

secured.

129) If a vehicle is parked on a very

steep gradient or with a side

gradient, opening the rear door or

side door could cause any

unsecured items to emerge

suddenly.

130) If you wish to carry a reserve of

petrol in a can, observe the legal

restrictions and only use a can

that is type-approved and

properly secured to the load

anchorage eyebolts. Anyway, by

doing so, you increase the risk

of fire in the event of an accident

with your vehicle.

175

Page 183 of 367

IMPORTANT Electric brakes or other

devices must be used with engine

running.

In addition to the electrical branches,

the vehicle's electric system can only

be connected to the supply cable for an

electric brake and to the cable for an

internal light, though not above 15

W. For connections use the preset

control unit with battery cable no less

than 2.5 mm

2.

IMPORTANT The trailer tow hook

contributes to the length of the vehicle.

When installing on long wheelbase

versions, it is only possible to install

removable tow hooks because the total

vehicle length limit of 6 metres is

exceeded.

If no trailer is fitted, the hook must be

removed from the attachment base and

it must not exceed the vehicle's

original length.IMPORTANT If you wish to leave the

tow hook fitted without towing a trailer,

it is advisable to contact a Fiat

Dealership for the relevant system

update operations because the tow

hook could be detected as an obstacle

by the central sensors.Installation diagram for

Van versions fig. 172

The tow hook structure must be

fastened in the points shown by the

symbol Ø using a total of 6 M10x1.25

screws and 4 M12 screws.

The internal back plates must be at

least 5 mm thick. MAX LOAD ON

BALL: 100/120 kg according to the

payload (see “Weights” table in the

“Technical data” section).

133)

To install a tow hook, the bumpers

must be trimmed as described in the

supplier's installation kit.

Installation diagram for

Truck and Chassis Cab

versions fig. 173

Another tow hook specific to Truck and

Chassis Cab versions in shown in fig.

173.

The structure Ø must be fixed in the

points indicated using a total of 6

M10x1.25 screws and 4 M12 screws.

MAX LOAD ON BALL: 100/120 kg

according to the payload (see

“Weights” table in the “Technical data”

section).

134)

179

Page 200 of 367

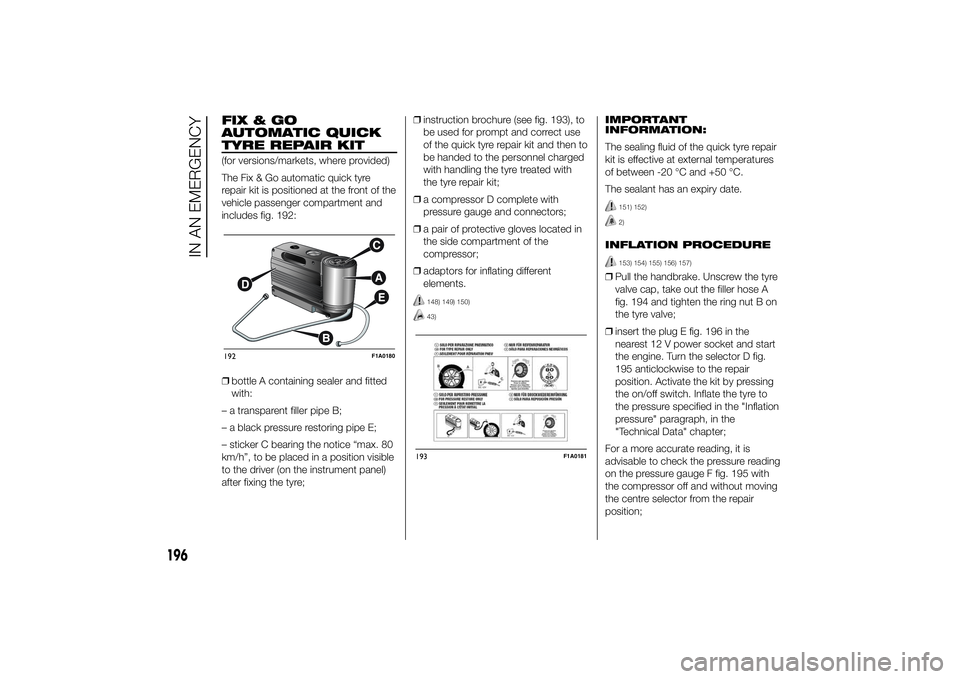

FIX&GO

AUTOMATIC QUICK

TYRE REPAIR KIT(for versions/markets, where provided)

The Fix & Go automatic quick tyre

repair kit is positioned at the front of the

vehicle passenger compartment and

includes fig. 192:

❒bottle A containing sealer and fitted

with:

– a transparent filler pipe B;

– a black pressure restoring pipe E;

– sticker C bearing the notice “max. 80

km/h”, to be placed in a position visible

to the driver (on the instrument panel)

after fixing the tyre;❒instruction brochure (see fig. 193), to

be used for prompt and correct use

of the quick tyre repair kit and then to

be handed to the personnel charged

with handling the tyre treated with

the tyre repair kit;

❒a compressor D complete with

pressure gauge and connectors;

❒a pair of protective gloves located in

the side compartment of the

compressor;

❒adaptors for inflating different

elements.

148) 149) 150)43)

IMPORTANT

INFORMATION:

The sealing fluid of the quick tyre repair

kit is effective at external temperatures

of between -20 °C and +50 °C.

The sealant has an expiry date.

151) 152)2)

INFLATION PROCEDURE

153) 154) 155) 156) 157)

❒Pull the handbrake. Unscrew the tyre

valve cap, take out the filler hose A

fig. 194 and tighten the ring nut B on

the tyre valve;

❒insert the plug E fig. 196 in the

nearest 12 V power socket and start

the engine. Turn the selector D fig.

195 anticlockwise to the repair

position. Activate the kit by pressing

the on/off switch. Inflate the tyre to

the pressure specified in the "Inflation

pressure" paragraph, in the

"Technical Data" chapter;

For a more accurate reading, it is

advisable to check the pressure reading

on the pressure gauge F fig. 195 with

the compressor off and without moving

the centre selector from the repair

position;

192

F1A0180

193

F1A0181

196

IN AN EMERGENCY

Page 201 of 367

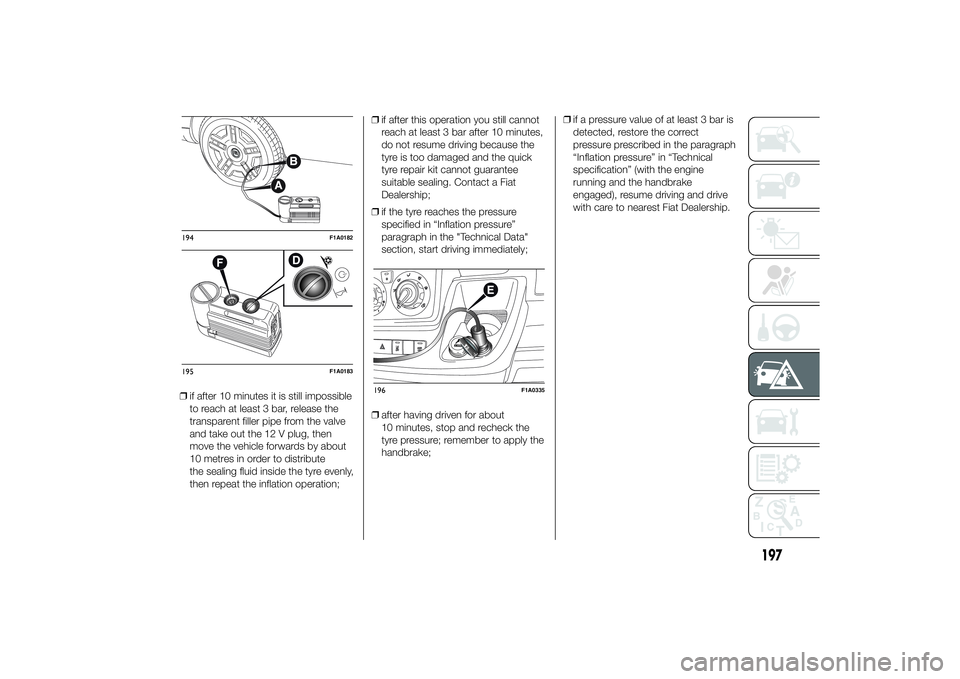

❒if after 10 minutes it is still impossible

to reach at least 3 bar, release the

transparent filler pipe from the valve

and take out the 12 V plug, then

move the vehicle forwards by about

10 metres in order to distribute

the sealing fluid inside the tyre evenly,

then repeat the inflation operation;❒if after this operation you still cannot

reach at least 3 bar after 10 minutes,

do not resume driving because the

tyre is too damaged and the quick

tyre repair kit cannot guarantee

suitable sealing. Contact a Fiat

Dealership;

❒if the tyre reaches the pressure

specified in “Inflation pressure”

paragraph in the "Technical Data"

section, start driving immediately;

❒after having driven for about

10 minutes, stop and recheck the

tyre pressure; remember to apply the

handbrake;❒if a pressure value of at least 3 bar is

detected, restore the correct

pressure prescribed in the paragraph

“Inflation pressure” in “Technical

specification” (with the engine

running and the handbrake

engaged), resume driving and drive

with care to nearest Fiat Dealership.194

F1A0182

195

F1A0183

196

F1A0335

197

Page 202 of 367

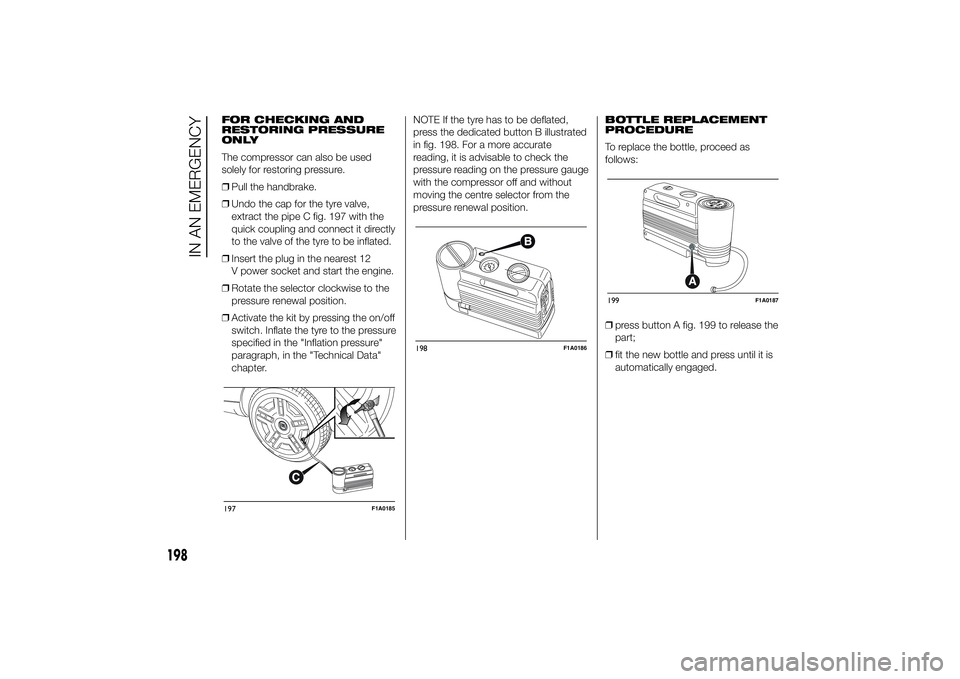

FOR CHECKING AND

RESTORING PRESSURE

ONLY

The compressor can also be used

solely for restoring pressure.

❒Pull the handbrake.

❒Undo the cap for the tyre valve,

extract the pipe C fig. 197 with the

quick coupling and connect it directly

to the valve of the tyre to be inflated.

❒Insert the plug in the nearest 12

V power socket and start the engine.

❒Rotate the selector clockwise to the

pressure renewal position.

❒Activate the kit by pressing the on/off

switch. Inflate the tyre to the pressure

specified in the "Inflation pressure"

paragraph, in the "Technical Data"

chapter.NOTE If the tyre has to be deflated,

press the dedicated button B illustrated

in fig. 198. For a more accurate

reading, it is advisable to check the

pressure reading on the pressure gauge

with the compressor off and without

moving the centre selector from the

pressure renewal position.BOTTLE REPLACEMENT

PROCEDURE

To replace the bottle, proceed as

follows:

❒press button A fig. 199 to release the

part;

❒fit the new bottle and press until it is

automatically engaged.197

F1A0185

198

F1A0186

199

F1A0187

198

IN AN EMERGENCY

Page 253 of 367

TECHNICAL SPECIFICATIONS

Everything you may find useful for

understanding how your vehicle

is made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

vehicle.IDENTIFICATION DATA....................250

ENGINE CODES - BODYWORK

VERSION ........................................252

ENGINE ..........................................254

POWER SUPPLY ............................255

TRANSMISSION .............................256

SUSPENSION .................................257

BRAKES .........................................258

STEERING ......................................259

WHEELS .........................................260

DIMENSIONS ..................................264

PERFORMANCE .............................274

WEIGHTS........................................276

SUPPLIES .......................................316

FLUIDS AND LUBRICANTS ............318

FUEL CONSUMPTION ....................321

CO2 EMISSIONS ............................332

OFFICIAL TYPE APPROVALS .........342

PRESCRIPTIONS FOR HANDLING

THE VEHICLE AT THE END OF ITS

LIFE ................................................346

249

Page 254 of 367

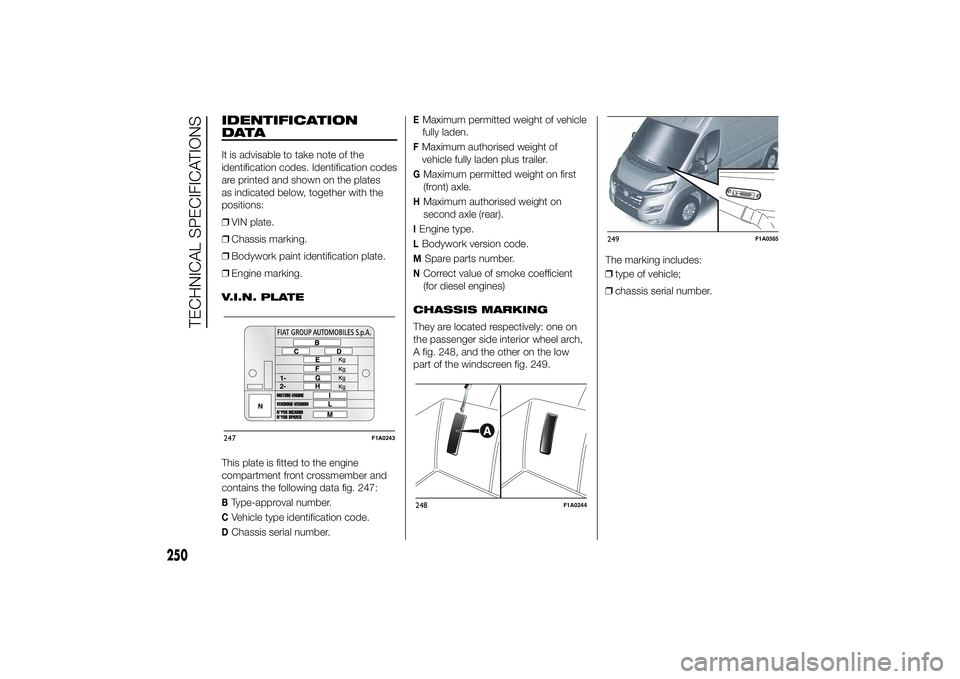

IDENTIFICATION

DATAIt is advisable to take note of the

identification codes. Identification codes

are printed and shown on the plates

as indicated below, together with the

positions:

❒VIN plate.

❒Chassis marking.

❒Bodywork paint identification plate.

❒Engine marking.

V.I.N. PLATE

This plate is fitted to the engine

compartment front crossmember and

contains the following data fig. 247:BType-approval number.CVehicle type identification code.DChassis serial number.

EMaximum permitted weight of vehicle

fully laden.FMaximum authorised weight of

vehicle fully laden plus trailer.GMaximum permitted weight on first

(front) axle.HMaximum authorised weight on

second axle (rear).IEngine type.LBodywork version code.M

Spare parts number.

NCorrect value of smoke coefficient

(for diesel engines)

CHASSIS MARKING

They are located respectively: one on

the passenger side interior wheel arch,

A fig. 248, and the other on the low

part of the windscreen fig. 249.The marking includes:

❒type of vehicle;

❒chassis serial number.

247

F1A0243

248

F1A0244

249

F1A0365

250

TECHNICAL SPECIFICATIONS