FIAT DUCATO BASE CAMPER 2016 Owner handbook (in English)

Manufacturer: FIAT, Model Year: 2016, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2016Pages: 387, PDF Size: 20.76 MB

Page 201 of 387

IMPORTANT

37) The removable ball head bar can

be repaired and disassembled by

the manufacturer only.

38) The supplied plate must be

applied in a visible point on the

vehicle, close to the mounting

pipe or inside the luggage

compartment.

39) Regularly remove all dirt

deposits from the ball head bar

and from the mounting pipe to

ensure a correct system

operation. The mechanical

components must be serviced at

the specified intervals. The lock

must be treated with graphite

only.

40) Periodically lubricate the joints,

the sliding surfaces and the balls

with grease without resin or oil.

Lubrication is also a further

corrosion protection.

41) When the vehicle is cleaned with

high-pressure jets, previously

remove the ball head bar and

insert the suitable plug. The ball

head plug must never be treated

with high-pressure jets.42) Two keys are supplied together

with the removable ball tow bar.

Note down the key number on the

pawl for any following order and

keep it.

197

Removing the tow bar

1. Remove the protection cap from the

lock and press it on the key grip. Open

the lock with the key.

2. Hold the tow bar firmly, remove the

flywheel following the direction of the

arrow and rotate according to the

direction of the arrow b until stopping,

so as to remove till the extracted

position. Then remove the tow bar from

the housing pipe. The flywheel can

then be released; it autonomously

stops in the released position.

3. Arrange the tow bar in the luggage

compartment so that it cannot be

dirtied or damaged by other

transported objects.

4. Insert the suitable plug in the

mounting pipe.

Page 202 of 387

SNOW TYRES

A Fiat Dealership will be happy to

provide advice concerning the most

suitable type of tyre for the customer's

requirements.

The performance of these tyres is

considerably reduced when the tread

depth is less than 4 mm. Replace them

in this case.

Due to the specific characteristics of

snow tyres, in normal weather

conditions or on long motorway

journeys, the performance of these

tyres is lower than that of standard

tyres. Their usage should therefore be

restricted in accordance with their

type approval.

IMPORTANT When using snow tyres

with a maximum speed index below the

one that can be reached by the vehicle

(increased by 5%), place a notice in

the passenger compartment, plainly in

view, which states the maximum speed

allowed by the snow tyres (as per EC

Directive).

All four tyres should be the same (brand

and track) to ensure greater safety

when driving and braking as well as a

good manoeuvrability.

Remember that you should not change

the rotation direction of the tyres.

144)

WARNING

144) The maximum speed for snow

tyres marked "Q" is 160 km/h,

while it is 190 km/h for "T" tyres

and 210 km/h for "H" tyres. You

should, however, always comply

with the speed limits of the

highway code.

SNOW CHAINS

The use of snow chains should be in

compliance with local regulations of

each country.

Snow chains can be fitted to the tyres

of the front wheels (drive wheels) only.

Use of Lineaccessori Fiat snow chains

is recommended. Check the tension

of the snow chains after the first few

metres have been driven.

43)

IMPORTANT With snow chains, use the

accelerator with extreme care to

prevent, or to limit as much as possible,

slipping of the drive wheels that could

cause chain breakage, resulting in

damage to the car body or mechanical

components.

IMPORTANT For versions fitted with

225/75 R16 tyre, use snow chains with

max. thickness 16 mm.

When travelling on snowy roads with

snow chains, it may be helpful to turn

the ASR off: in fact, in these conditions,

the driving wheels skidding when

moving off gives you better traction.

198

STARTING AND DRIVING

Page 203 of 387

IMPORTANT

43) Keep your speed down when

snow chains are fitted; do not

exceed 50 km/h. Avoid potholes,

steps and pavements and avoid

driving for long distances on

roads not covered with snow to

prevent damaging the vehicle and

the roadbed.

PROLONGED

VEHICLE INACTIVITY

If the vehicle needs to be off the road

for longer than one month, the following

precautions must be taken:

❒park the vehicle indoors in a dry and,

if possible, well-ventilated place;

❒engage a gear;

❒check that the handbrake is not

engaged;

❒disconnect the negative battery

terminal; if the vehicle is equipped

with a battery disconnection function

(disconnector), see the description

of the procedure in the "Controls"

paragraph in the "Dashboard and

controls" section;

❒clean and protect the painted parts

using protective wax;

❒clean and protect the shiny metal

parts using special compounds

available commercially;

❒sprinkle talcum powder on the

windscreen and rear window wiper

rubber blades and lift them off the

glass;

❒slightly open the windows;❒cover the vehicle with a piece of

fabric or perforated plastic sheet. Do

not use compact plastic tarpaulins,

which prevent humidity from

evaporating from the surface of the

vehicle;

❒inflate tyres to +0.5 bar above the

standard specified pressure and

check it at intervals;

❒do not drain the engine cooling

system.

IMPORTANT If the vehicle is equipped

with an alarm system, switch off the

vehicle alarm with the remote control.

IMPORTANT After turning the ignition

key to STOP and having closed the

driver side door, wait at least one

minute before disconnecting the

electrical supply from the battery. When

reconnecting the electrical supply to

the battery, make sure that the ignition

key is in the STOP position and the

driver side door is closed.

199

Page 204 of 387

200

This page is intentionally left blank

Page 205 of 387

IN AN EMERGENCY

A punctured tyre or a burnt-out bulb?

At times, a problem may interfere

with our journey.

The pages on emergencies can help

you to deal with critical situations

independently and with calm.

In an emergency we recommend that

you call the freephone number found in

the Warranty Booklet.

It is also possible to call the 00 800

3428 0000 freephone number to

search the nearest Fiat Dealership.STARTING THE ENGINE .................202

REPLACING A WHEEL ...................203

FIX & GO AUTOMATIC QUICK

TYRE REPAIR KIT ...........................208

CHANGING A BULB .......................212

REPLACING AN EXTERIOR BULB ..216

CHANGING AN INTERIOR BULB ....221

REPLACING FUSES........................222

BATTERY RECHARGING ................232

LIFTING THE VEHICLE....................233

TOWING THE VEHICLE ..................233

201

Page 206 of 387

STARTING THE

ENGINE

Go to a Fiat Dealership immediately if

warning light

stays on constantly on

the instrument panel.

JUMP STARTING

If the battery is flat, it is possible to start

the engine using an auxiliary battery

with the same capacity or a little higher

than the flat one.

It is advisable to contact a Fiat

Dealership to check/replace the battery.

145)

Proceed as follows to start the vehicle:

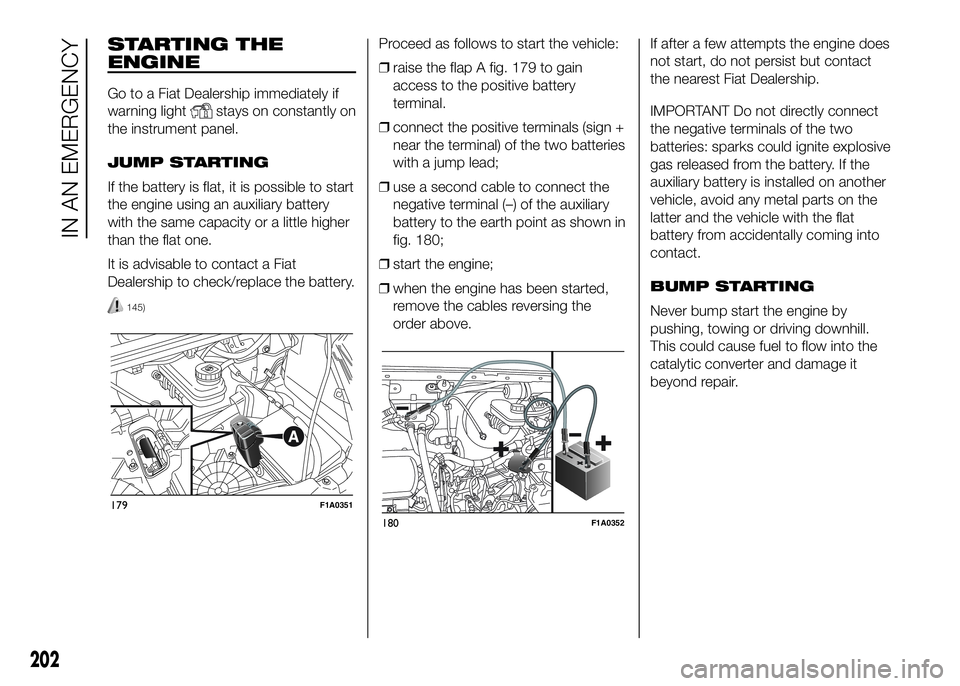

❒raise the flap A fig. 179 to gain

access to the positive battery

terminal.

❒connect the positive terminals (sign +

near the terminal) of the two batteries

with a jump lead;

❒use a second cable to connect the

negative terminal (–) of the auxiliary

battery to the earth point as shown in

fig. 180;

❒start the engine;

❒when the engine has been started,

remove the cables reversing the

order above.If after a few attempts the engine does

not start, do not persist but contact

the nearest Fiat Dealership.

IMPORTANT Do not directly connect

the negative terminals of the two

batteries: sparks could ignite explosive

gas released from the battery. If the

auxiliary battery is installed on another

vehicle, avoid any metal parts on the

latter and the vehicle with the flat

battery from accidentally coming into

contact.

BUMP STARTING

Never bump start the engine by

pushing, towing or driving downhill.

This could cause fuel to flow into the

catalytic converter and damage it

beyond repair.

179F1A0351

180F1A0352

202

IN AN EMERGENCY

Page 207 of 387

WARNING

145) This procedure must be

performed by qualified personnel

as incorrect actions may cause

high-intensity electrical discharge.

Furthermore, battery fluid is

poisonous and corrosive: avoid

contact with skin and eyes. Keep

naked flames and lighted

cigarettes away from the battery

and do not cause sparks.

REPLACING A

WHEEL

GENERAL

INSTRUCTIONS

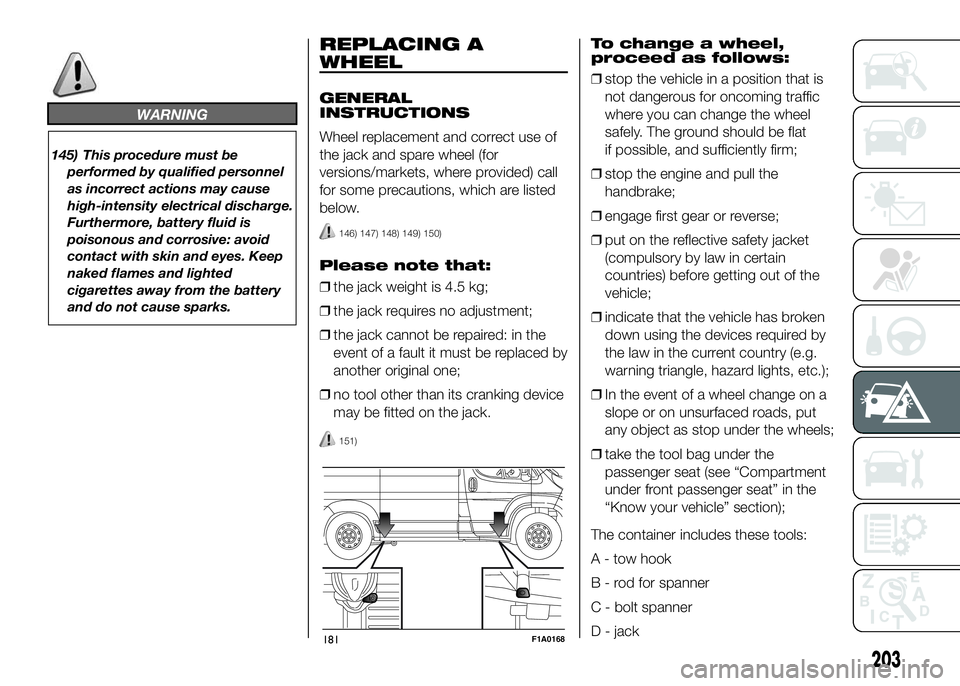

Wheel replacement and correct use of

the jack and spare wheel (for

versions/markets, where provided) call

for some precautions, which are listed

below.

146) 147) 148) 149) 150)

Please note that:

❒the jack weight is 4.5 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired: in the

event of a fault it must be replaced by

another original one;

❒no tool other than its cranking device

may be fitted on the jack.

151)

To change a wheel,

proceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel

safely. The ground should be flat

if possible, and sufficiently firm;

❒stop the engine and pull the

handbrake;

❒engage first gear or reverse;

❒put on the reflective safety jacket

(compulsory by law in certain

countries) before getting out of the

vehicle;

❒indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

❒In the event of a wheel change on a

slope or on unsurfaced roads, put

any object as stop under the wheels;

❒take the tool bag under the

passenger seat (see “Compartment

under front passenger seat” in the

“Know your vehicle” section);

The container includes these tools:

A - tow hook

B - rod for spanner

C - bolt spanner

D - jack

181F1A0168

203

Page 208 of 387

E - extension for spanner

F - screwdriver grip

G - screwdriver bit

❒if the tool container is not provided,

for special trim versions, a bag

containing the above tools may be

provided;

❒for versions with alloy rims, remove

the press-fitted hub cap;

❒take the extension for spanner, the

bolt spanner and the rod for spanner

from the tool container;

❒with the tools assembled correctly,

loosen the fixing bolts for the wheel

to be changed by one turn;

❒turn the ring nut to partly extend the

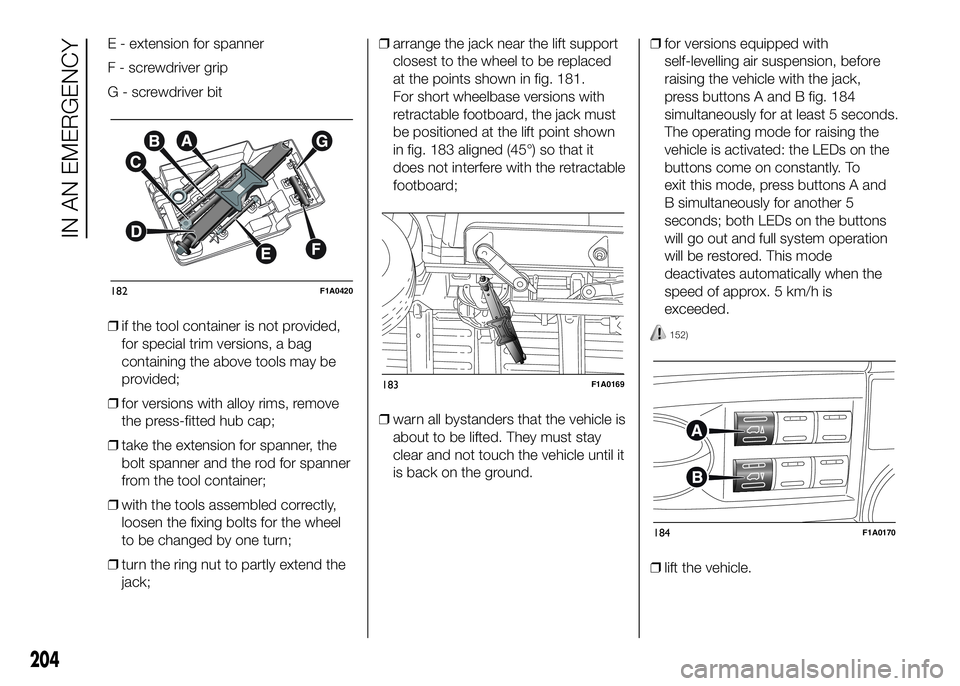

jack;❒arrange the jack near the lift support

closest to the wheel to be replaced

at the points shown in fig. 181.

For short wheelbase versions with

retractable footboard, the jack must

be positioned at the lift point shown

in fig. 183 aligned (45°) so that it

does not interfere with the retractable

footboard;

❒warn all bystanders that the vehicle is

about to be lifted. They must stay

clear and not touch the vehicle until it

is back on the ground.❒for versions equipped with

self-levelling air suspension, before

raising the vehicle with the jack,

press buttons A and B fig. 184

simultaneously for at least 5 seconds.

The operating mode for raising the

vehicle is activated: the LEDs on the

buttons come on constantly. To

exit this mode, press buttons A and

B simultaneously for another 5

seconds; both LEDs on the buttons

will go out and full system operation

will be restored. This mode

deactivates automatically when the

speed of approx. 5 km/h is

exceeded.

152)

❒lift the vehicle.

182F1A0420

183F1A0169

184F1A0170

204

IN AN EMERGENCY

Page 209 of 387

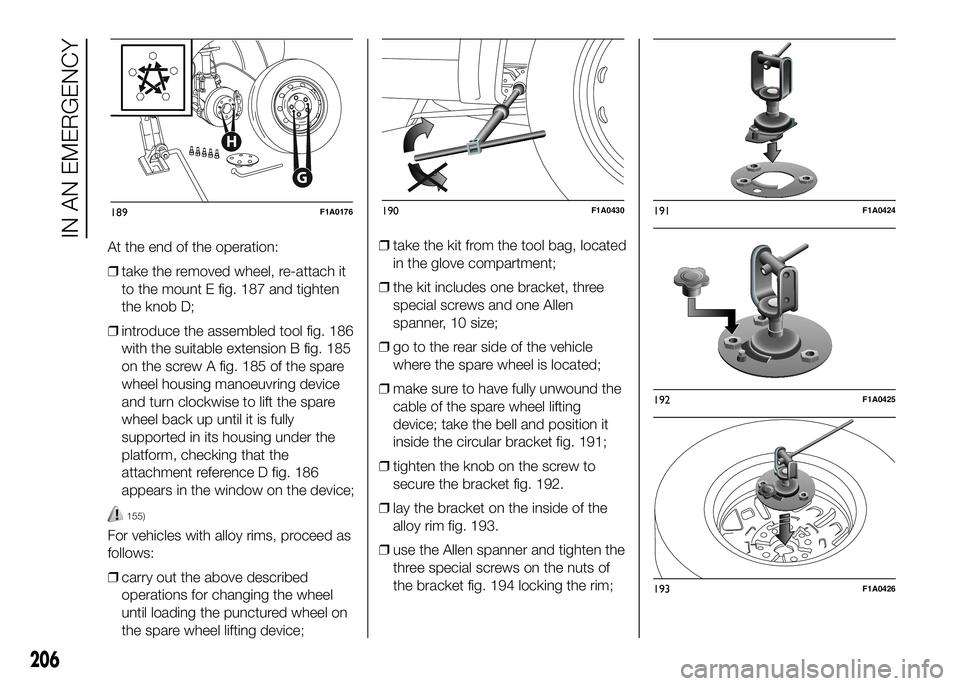

After lifting the vehicle:

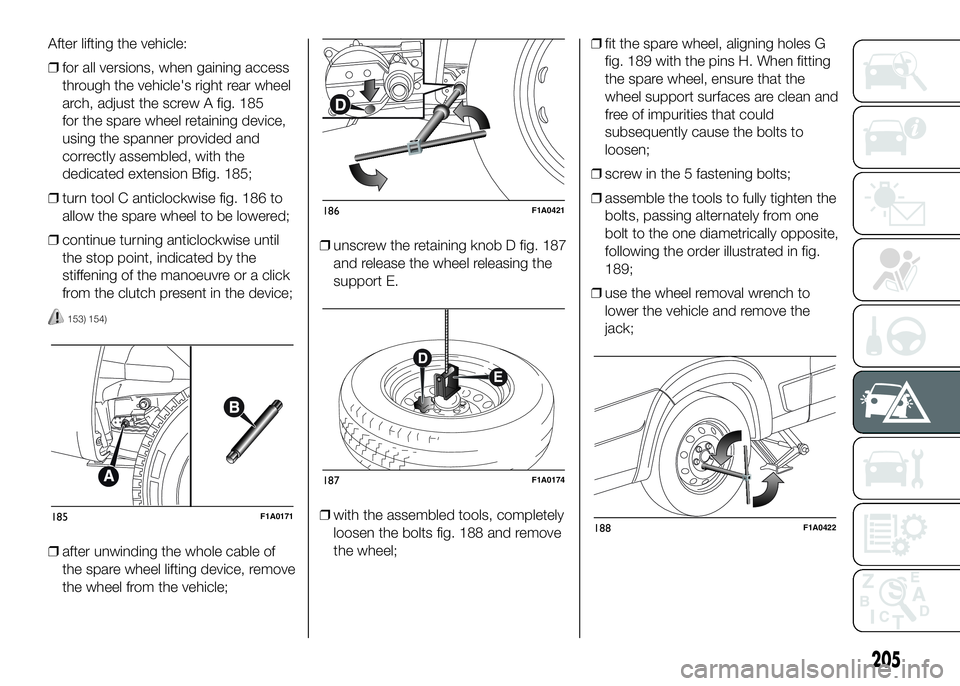

❒for all versions, when gaining access

through the vehicle's right rear wheel

arch, adjust the screw A fig. 185

for the spare wheel retaining device,

using the spanner provided and

correctly assembled, with the

dedicated extension Bfig. 185;

❒turn tool C anticlockwise fig. 186 to

allow the spare wheel to be lowered;

❒continue turning anticlockwise until

the stop point, indicated by the

stiffening of the manoeuvre or a click

from the clutch present in the device;

153) 154)

❒after unwinding the whole cable of

the spare wheel lifting device, remove

the wheel from the vehicle;❒unscrew the retaining knob D fig. 187

and release the wheel releasing the

support E.

❒with the assembled tools, completely

loosen the bolts fig. 188 and remove

the wheel;❒fit the spare wheel, aligning holes G

fig. 189 with the pins H. When fitting

the spare wheel, ensure that the

wheel support surfaces are clean and

free of impurities that could

subsequently cause the bolts to

loosen;

❒screw in the 5 fastening bolts;

❒assemble the tools to fully tighten the

bolts, passing alternately from one

bolt to the one diametrically opposite,

following the order illustrated in fig.

189;

❒use the wheel removal wrench to

lower the vehicle and remove the

jack;

185F1A0171

186F1A0421

187F1A0174

188F1A0422

205

Page 210 of 387

At the end of the operation:

❒take the removed wheel, re-attach it

to the mount E fig. 187 and tighten

the knob D;

❒introduce the assembled tool fig. 186

with the suitable extension B fig. 185

on the screw A fig. 185 of the spare

wheel housing manoeuvring device

and turn clockwise to lift the spare

wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 186

appears in the window on the device;

155)

For vehicles with alloy rims, proceed as

follows:

❒carry out the above described

operations for changing the wheel

until loading the punctured wheel on

the spare wheel lifting device;❒take the kit from the tool bag, located

in the glove compartment;

❒the kit includes one bracket, three

special screws and one Allen

spanner, 10 size;

❒go to the rear side of the vehicle

where the spare wheel is located;

❒make sure to have fully unwound the

cable of the spare wheel lifting

device; take the bell and position it

inside the circular bracket fig. 191;

❒tighten the knob on the screw to

secure the bracket fig. 192.

❒lay the bracket on the inside of the

alloy rim fig. 193.

❒use the Allen spanner and tighten the

three special screws on the nuts of

the bracket fig. 194 locking the rim;

G

H

189F1A0176190F1A0430191F1A0424

192F1A0425

193F1A0426

206

IN AN EMERGENCY