ESC FIAT DUCATO BASE CAMPER 2016 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2016Pages: 387, PDF Size: 20.76 MB

Page 195 of 387

For the electric connection a standard

connector should be used which is

generally placed on a special bracket

normally fastened to the towing device,

and a special ECU for external trailer

light control must be installed on the

vehicle. For the electrical connection, 7

or 13 pin 12 V DC connections are to

be used (CUNA/UNI and ISO/DIN

Standards). Follow the instructions

provided by the vehicle manufacturer

and/or the tow hitch manufacturer.

An electric brake (or electric winch)

should be supplied directly by the

battery through a cable with a cross

section of no less than 2.5 mm

2.

IMPORTANT Electric brakes or other

devices must be used with engine

running.

In addition to the electrical branches,

the vehicle's electric system can only

be connected to the supply cable for an

electric brake and to the cable for an

internal light, though not above 15

W. For connections use the preset

control unit with battery cable no less

than 2.5 mm

2.IMPORTANT The trailer tow hook

contributes to the length of the vehicle.

When installing on long wheelbase

versions, it is only possible to install

removable tow hooks because the total

vehicle length limit of 6 metres is

exceeded.

If no trailer is fitted, the hook must be

removed from the attachment base and

it must not exceed the vehicle's

original length.

IMPORTANT If you wish to leave the

tow hook fitted without towing a trailer,

it is advisable to contact a Fiat

Dealership for the relevant system

update operations because the tow

hook could be detected as an obstacle

by the central sensors.Installation diagram for

Van versions fig. 174

The tow hook structure must be

fastened in the points shown by the

symbol Ø using a total of 6 M10x1.25

screws and 4 M12 screws.

The internal back plates must be at

least 5 mm thick. MAX LOAD ON

BALL: 100/120 kg according to the

payload (see “Weights” table in the

“Technical data” section).

142)

To install a tow hook, the bumpers

must be trimmed as described in the

supplier's installation kit.

191

Page 203 of 387

IMPORTANT

43) Keep your speed down when

snow chains are fitted; do not

exceed 50 km/h. Avoid potholes,

steps and pavements and avoid

driving for long distances on

roads not covered with snow to

prevent damaging the vehicle and

the roadbed.

PROLONGED

VEHICLE INACTIVITY

If the vehicle needs to be off the road

for longer than one month, the following

precautions must be taken:

❒park the vehicle indoors in a dry and,

if possible, well-ventilated place;

❒engage a gear;

❒check that the handbrake is not

engaged;

❒disconnect the negative battery

terminal; if the vehicle is equipped

with a battery disconnection function

(disconnector), see the description

of the procedure in the "Controls"

paragraph in the "Dashboard and

controls" section;

❒clean and protect the painted parts

using protective wax;

❒clean and protect the shiny metal

parts using special compounds

available commercially;

❒sprinkle talcum powder on the

windscreen and rear window wiper

rubber blades and lift them off the

glass;

❒slightly open the windows;❒cover the vehicle with a piece of

fabric or perforated plastic sheet. Do

not use compact plastic tarpaulins,

which prevent humidity from

evaporating from the surface of the

vehicle;

❒inflate tyres to +0.5 bar above the

standard specified pressure and

check it at intervals;

❒do not drain the engine cooling

system.

IMPORTANT If the vehicle is equipped

with an alarm system, switch off the

vehicle alarm with the remote control.

IMPORTANT After turning the ignition

key to STOP and having closed the

driver side door, wait at least one

minute before disconnecting the

electrical supply from the battery. When

reconnecting the electrical supply to

the battery, make sure that the ignition

key is in the STOP position and the

driver side door is closed.

199

Page 210 of 387

At the end of the operation:

❒take the removed wheel, re-attach it

to the mount E fig. 187 and tighten

the knob D;

❒introduce the assembled tool fig. 186

with the suitable extension B fig. 185

on the screw A fig. 185 of the spare

wheel housing manoeuvring device

and turn clockwise to lift the spare

wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 186

appears in the window on the device;

155)

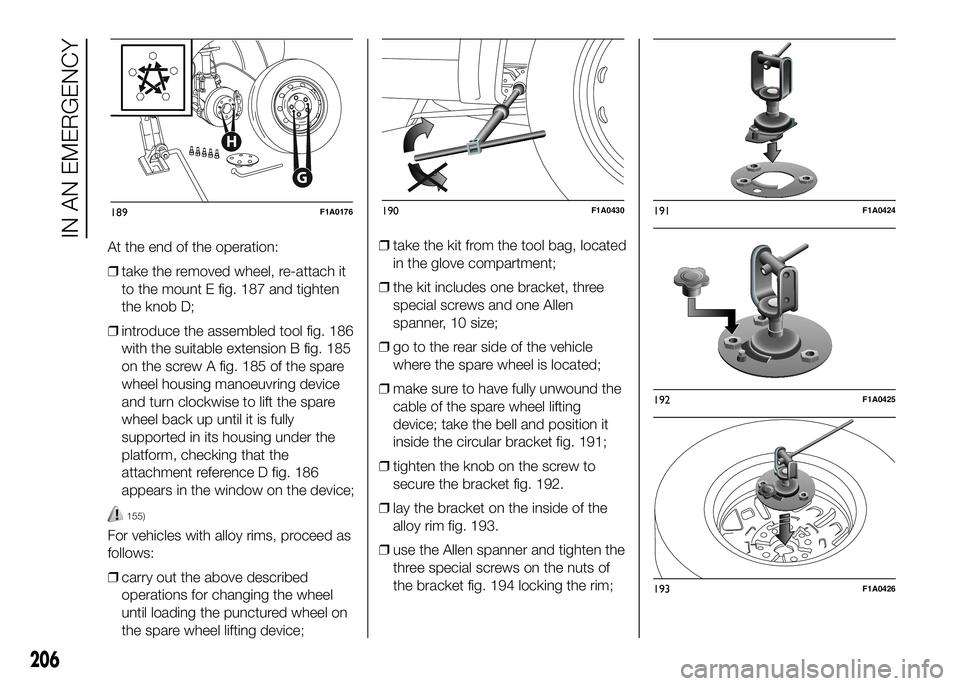

For vehicles with alloy rims, proceed as

follows:

❒carry out the above described

operations for changing the wheel

until loading the punctured wheel on

the spare wheel lifting device;❒take the kit from the tool bag, located

in the glove compartment;

❒the kit includes one bracket, three

special screws and one Allen

spanner, 10 size;

❒go to the rear side of the vehicle

where the spare wheel is located;

❒make sure to have fully unwound the

cable of the spare wheel lifting

device; take the bell and position it

inside the circular bracket fig. 191;

❒tighten the knob on the screw to

secure the bracket fig. 192.

❒lay the bracket on the inside of the

alloy rim fig. 193.

❒use the Allen spanner and tighten the

three special screws on the nuts of

the bracket fig. 194 locking the rim;

G

H

189F1A0176190F1A0430191F1A0424

192F1A0425

193F1A0426

206

IN AN EMERGENCY

Page 214 of 387

❒if after this operation you still cannot

reach at least 3 bar after 10 minutes,

do not resume driving because the

tyre is too damaged and the quick

tyre repair kit cannot guarantee

suitable sealing. Contact a Fiat

Dealership;

❒if the tyre reaches the pressure

specified in “Inflation pressure”

paragraph in the "Technical Data"

section, start driving immediately;

❒after having driven for about

10 minutes, stop and recheck the

tyre pressure; remember to apply the

handbrake;❒if a pressure value of at least 3 bar is

detected, restore the correct

pressure prescribed in the paragraph

“Inflation pressure” in “Technical

specification” (with the engine

running and the handbrake

engaged), resume driving and drive

with care to nearest Fiat Dealership.

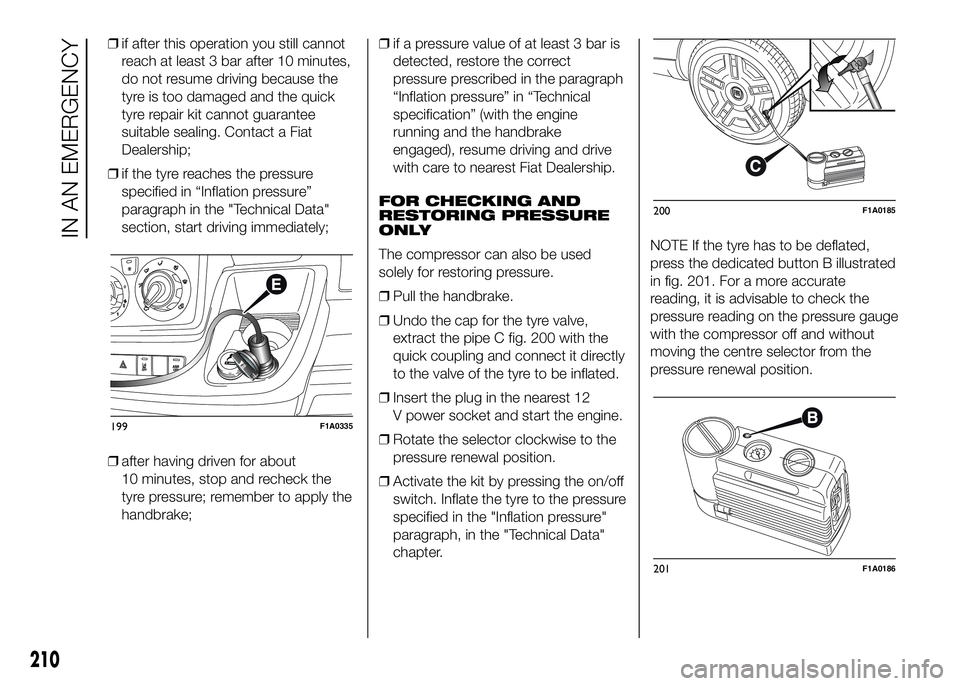

FOR CHECKING AND

RESTORING PRESSURE

ONLY

The compressor can also be used

solely for restoring pressure.

❒Pull the handbrake.

❒Undo the cap for the tyre valve,

extract the pipe C fig. 200 with the

quick coupling and connect it directly

to the valve of the tyre to be inflated.

❒Insert the plug in the nearest 12

V power socket and start the engine.

❒Rotate the selector clockwise to the

pressure renewal position.

❒Activate the kit by pressing the on/off

switch. Inflate the tyre to the pressure

specified in the "Inflation pressure"

paragraph, in the "Technical Data"

chapter.NOTE If the tyre has to be deflated,

press the dedicated button B illustrated

in fig. 201. For a more accurate

reading, it is advisable to check the

pressure reading on the pressure gauge

with the compressor off and without

moving the centre selector from the

pressure renewal position.

199F1A0335

200F1A0185

201F1A0186

210

IN AN EMERGENCY

Page 220 of 387

REPLACING AN

EXTERIOR BULB

For the type of bulb and power rating,

see “Replacing a bulb”.

FRONT LIGHT CLUSTERS

The front light clusters contain the side

lights and DRLs (where the LED

solution is not provided), dipped beam,

main beam and direction indicator

bulbs.

Bulbs must be replaced with the

headlight removed and placed on a

work surface.

To remove the headlight, operate as

follows:

❒open the bonnet following the

procedure in the "Bonnet/Luggage

Compartment" paragraph in the

"Knowing your car" chapter;

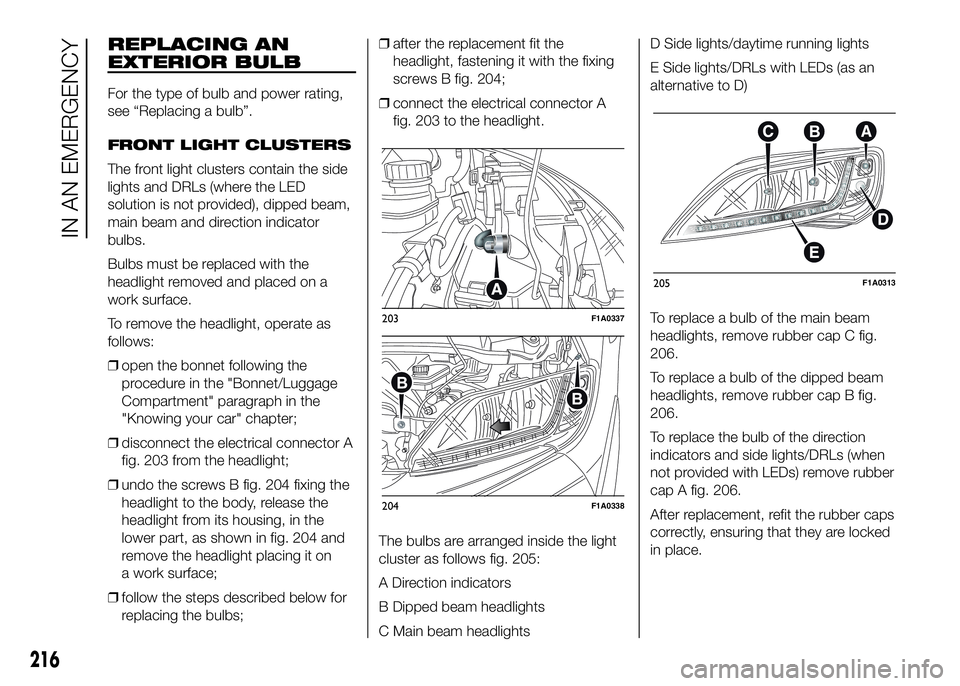

❒disconnect the electrical connector A

fig. 203 from the headlight;

❒undo the screws B fig. 204 fixing the

headlight to the body, release the

headlight from its housing, in the

lower part, as shown in fig. 204 and

remove the headlight placing it on

a work surface;

❒follow the steps described below for

replacing the bulbs;❒after the replacement fit the

headlight, fastening it with the fixing

screws B fig. 204;

❒connect the electrical connector A

fig. 203 to the headlight.

The bulbs are arranged inside the light

cluster as follows fig. 205:

A Direction indicators

B Dipped beam headlights

C Main beam headlightsD Side lights/daytime running lights

E Side lights/DRLs with LEDs (as an

alternative to D)

To replace a bulb of the main beam

headlights, remove rubber cap C fig.

206.

To replace a bulb of the dipped beam

headlights, remove rubber cap B fig.

206.

To replace the bulb of the direction

indicators and side lights/DRLs (when

not provided with LEDs) remove rubber

cap A fig. 206.

After replacement, refit the rubber caps

correctly, ensuring that they are locked

in place.

203F1A0337

204F1A0338

205F1A0313

216

IN AN EMERGENCY

Page 221 of 387

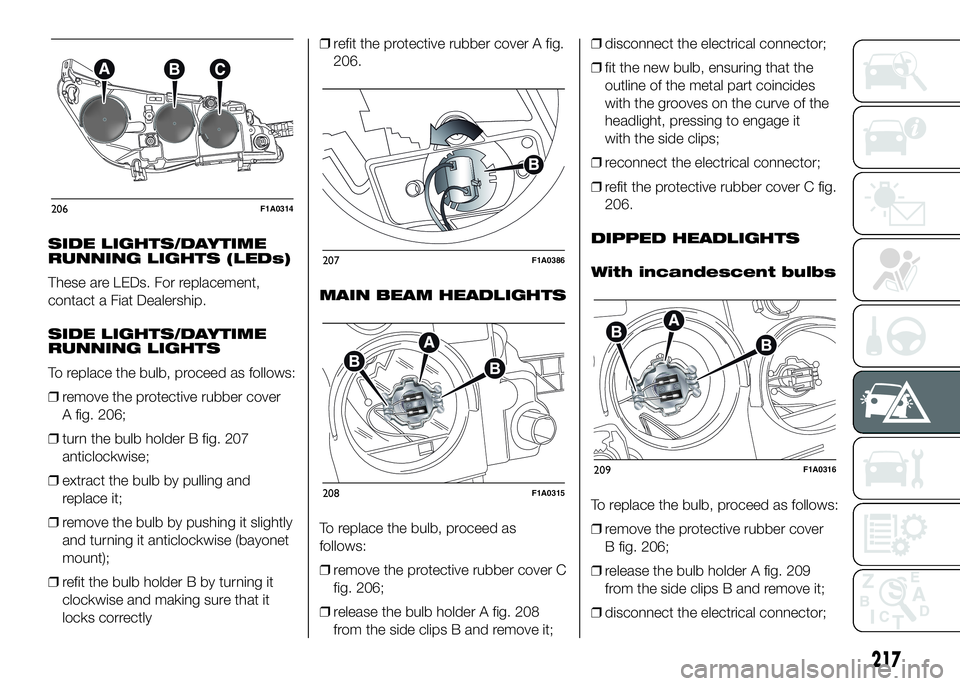

SIDE LIGHTS/DAYTIME

RUNNING LIGHTS (LEDs)

These are LEDs. For replacement,

contact a Fiat Dealership.

SIDE LIGHTS/DAYTIME

RUNNING LIGHTS

To replace the bulb, proceed as follows:

❒remove the protective rubber cover

A fig. 206;

❒turn the bulb holder B fig. 207

anticlockwise;

❒extract the bulb by pulling and

replace it;

❒remove the bulb by pushing it slightly

and turning it anticlockwise (bayonet

mount);

❒refit the bulb holder B by turning it

clockwise and making sure that it

locks correctly❒refit the protective rubber cover A fig.

206.

MAIN BEAM HEADLIGHTS

To replace the bulb, proceed as

follows:

❒remove the protective rubber cover C

fig. 206;

❒release the bulb holder A fig. 208

from the side clips B and remove it;❒disconnect the electrical connector;

❒fit the new bulb, ensuring that the

outline of the metal part coincides

with the grooves on the curve of the

headlight, pressing to engage it

with the side clips;

❒reconnect the electrical connector;

❒refit the protective rubber cover C fig.

206.

DIPPED HEADLIGHTS

With incandescent bulbs

To replace the bulb, proceed as follows:

❒remove the protective rubber cover

B fig. 206;

❒release the bulb holder A fig. 209

from the side clips B and remove it;

❒disconnect the electrical connector;

206F1A0314

207F1A0386

208F1A0315

209F1A0316

217

Page 222 of 387

❒fit the new bulb, ensuring that the

outline of the metal part coincides

with the grooves on the curve of the

headlight, pressing to engage it

with the side clips;

❒reconnect the electrical connector;

❒refit the protective rubber cover B fig.

206.

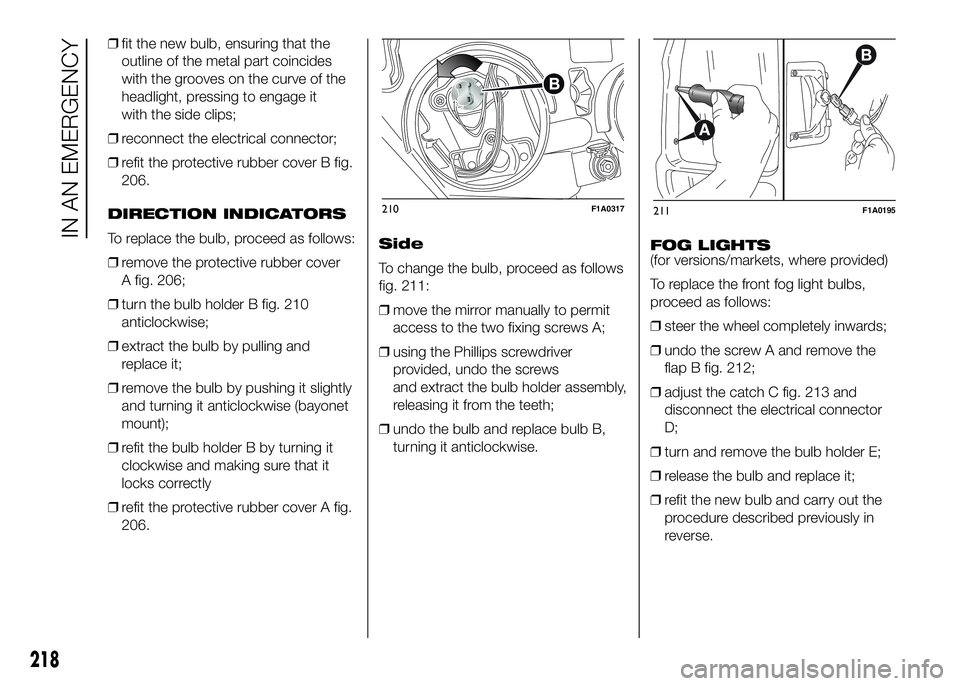

DIRECTION INDICATORS

To replace the bulb, proceed as follows:

❒remove the protective rubber cover

A fig. 206;

❒turn the bulb holder B fig. 210

anticlockwise;

❒extract the bulb by pulling and

replace it;

❒remove the bulb by pushing it slightly

and turning it anticlockwise (bayonet

mount);

❒refit the bulb holder B by turning it

clockwise and making sure that it

locks correctly

❒refit the protective rubber cover A fig.

206.Side

To change the bulb, proceed as follows

fig. 211:

❒move the mirror manually to permit

access to the two fixing screws A;

❒using the Phillips screwdriver

provided, undo the screws

and extract the bulb holder assembly,

releasing it from the teeth;

❒undo the bulb and replace bulb B,

turning it anticlockwise.FOG LIGHTS

(for versions/markets, where provided)

To replace the front fog light bulbs,

proceed as follows:

❒steer the wheel completely inwards;

❒undo the screw A and remove the

flap B fig. 212;

❒adjust the catch C fig. 213 and

disconnect the electrical connector

D;

❒turn and remove the bulb holder E;

❒release the bulb and replace it;

❒refit the new bulb and carry out the

procedure described previously in

reverse.

210F1A0317211F1A0195

218

IN AN EMERGENCY

Page 252 of 387

❒check that the fluid level is up to the

MAX mark on the dipstick attached

to the reservoir cap F fig. 241 -

fig. 242 - fig. 243 - fig. 244 (use the

level shown on the 20°C side of

the dipstick to check when cold).

If the level of the fluid in the tank is

lower than the specified level, top up

using only one of the products

indicated in the "Fluid and lubricants"

table in the "Technical specifications"

section, proceeding as follows:

❒Start the engine and wait for the fluid

level in the tank to stabilise.

❒With the engine running, turn the

steering wheel from right to left

fully several times.

❒Top up the fuel to the MAX level and

then retighten the cap.

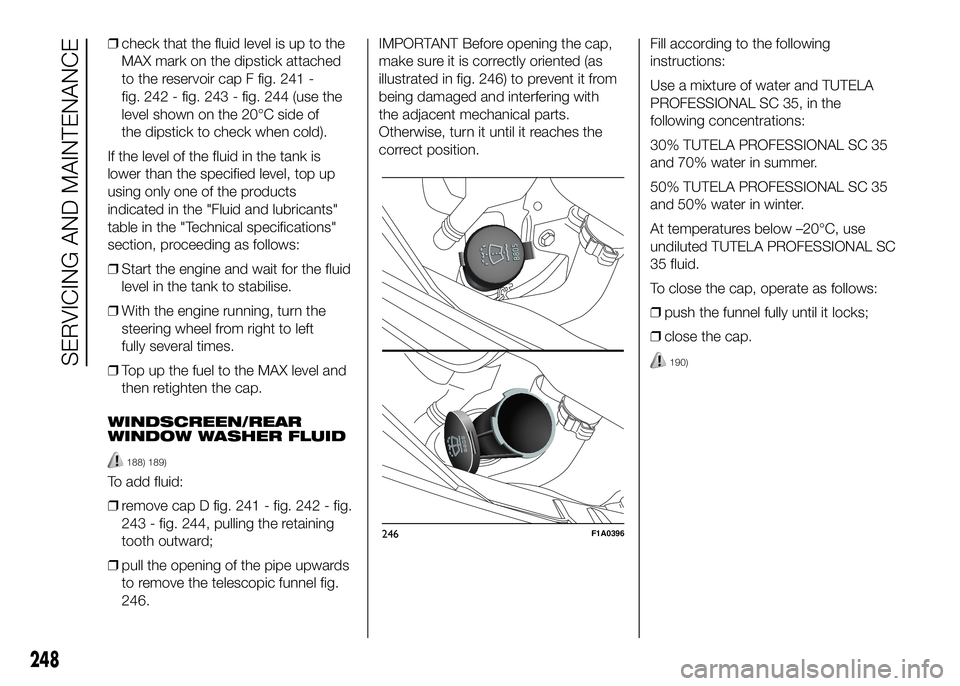

WINDSCREEN/REAR

WINDOW WASHER FLUID

188) 189)

To add fluid:

❒remove cap D fig. 241 - fig. 242 - fig.

243 - fig. 244, pulling the retaining

tooth outward;

❒pull the opening of the pipe upwards

to remove the telescopic funnel fig.

246.IMPORTANT Before opening the cap,

make sure it is correctly oriented (as

illustrated in fig. 246) to prevent it from

being damaged and interfering with

the adjacent mechanical parts.

Otherwise, turn it until it reaches the

correct position.Fill according to the following

instructions:

Use a mixture of water and TUTELA

PROFESSIONAL SC 35, in the

following concentrations:

30% TUTELA PROFESSIONAL SC 35

and 70% water in summer.

50% TUTELA PROFESSIONAL SC 35

and 50% water in winter.

At temperatures below –20°C, use

undiluted TUTELA PROFESSIONAL SC

35 fluid.

To close the cap, operate as follows:

❒push the funnel fully until it locks;

❒close the cap.

190)

246F1A0396

248

SERVICING AND MAINTENANCE

Page 256 of 387

USEFUL ADVICE FOR

EXTENDING THE LIFE OF

YOUR BATTERY

To avoid draining your battery and

make it last longer, observe the

following instructions:

❒when you park the vehicle, ensure

that the doors, tailgate and bonnet

are closed properly, to prevent any

roof lights from remaining on inside

the passenger's compartment;

❒switch off all roof lights inside the

vehicle: the vehicle is however

equipped with a system which

switches all internal lights off

automatically;

❒do not keep accessories (e.g. sound

system, hazard lights, etc.) switched

on for a long time when the engine

is not running;

❒before carrying out any operation on

the electrical system, disconnect the

negative battery cable through the

suitable terminal;

❒Completely tighten the battery

terminals.IMPORTANT After turning the ignition

key to STOP and having closed the

driver side door, wait at least one

minute before disconnecting the

electrical supply from the battery. When

reconnecting the electrical supply to

the battery, make sure that the ignition

key is in the STOP position and the

driver side door is closed.

IMPORTANT If the charge level remains

under 50% for a long time, the battery

is damaged by sulphation, reducing

its capacity and efficiency at start-up.

The battery is also more prone to the

risk of freezing (at temperatures as high

as -10°C).

Refer to the paragraph "Car inactivity"

in "Starting and driving" if the car is

left parked for a long time.If, after buying the vehicle, you want to

install electrical accessories which

require permanent electric supply

(alarm, etc.) or accessories that in any

case burden the electrical supply,

contact a Fiat Dealership, whose

qualified personnel, in addition

to suggesting the most suitable devices

from Lineaccessori Fiat, will evaluate

the overall electrical consumption,

checking whether the vehicle’s electrical

system is capable of withstanding the

load required, or whether it should

be integrated with a more powerful

battery.

Since some of these devices continue

to consume electricity even when

the engine is off, they gradually run

down the battery.

IMPORTANT If a tachograph is fitted, if

the vehicle is parked for a long period

of 5 days, it is advisable to disconnect

the negative battery terminal to

maintain its charge.

If the vehicle is equipped with a battery

disconnection function (disconnector),

see the description of the procedure

in the "Controls" paragraph in the

"Dashboard and controls" section.

252

SERVICING AND MAINTENANCE

Page 265 of 387

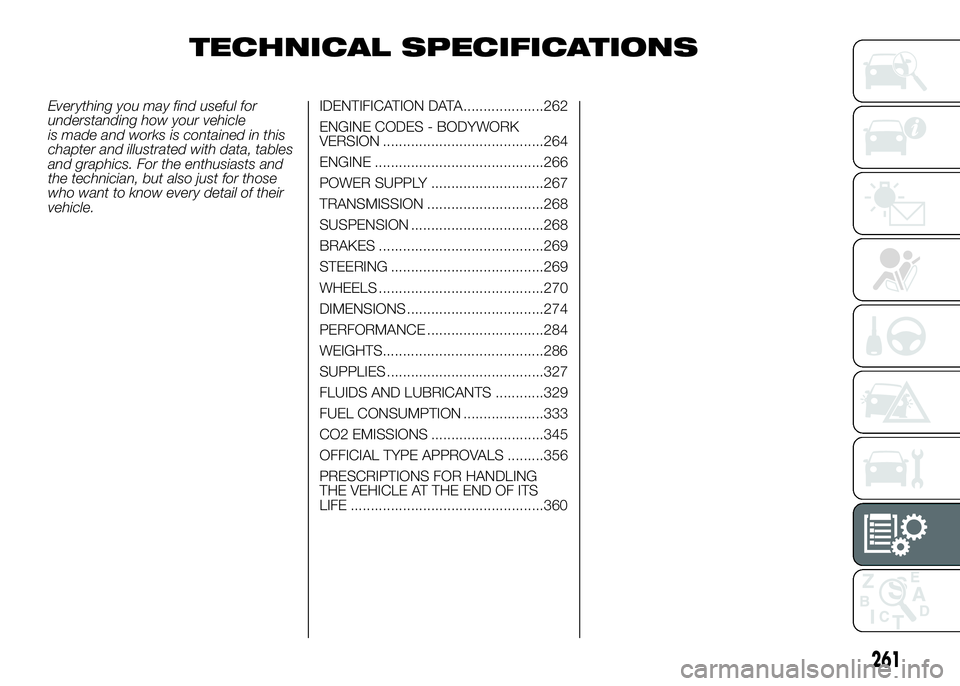

TECHNICAL SPECIFICATIONS

Everything you may find useful for

understanding how your vehicle

is made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

vehicle.IDENTIFICATION DATA....................262

ENGINE CODES - BODYWORK

VERSION ........................................264

ENGINE ..........................................266

POWER SUPPLY ............................267

TRANSMISSION .............................268

SUSPENSION .................................268

BRAKES .........................................269

STEERING ......................................269

WHEELS .........................................270

DIMENSIONS ..................................274

PERFORMANCE .............................284

WEIGHTS........................................286

SUPPLIES .......................................327

FLUIDS AND LUBRICANTS ............329

FUEL CONSUMPTION ....................333

CO2 EMISSIONS ............................345

OFFICIAL TYPE APPROVALS .........356

PRESCRIPTIONS FOR HANDLING

THE VEHICLE AT THE END OF ITS

LIFE ................................................360

261