handbrake FIAT DUCATO BASE CAMPER 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2018, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2018Pages: 304, PDF Size: 14.93 MB

Page 149 of 304

PROLONGED

VEHICLE INACTIVITY

If the vehicle needs to be off the road

for longer than one month, the following

precautions must be taken:

park the vehicle indoors in a dry

and, if possible, well-ventilated place;

engage a gear;

check that the handbrake is not

engaged;

disconnect the negative battery

terminal; if the vehicle is equipped with

a battery disconnection function

(disconnector), see the description of

the procedure in the "Controls"

paragraph in the "Dashboard and

controls" section;

clean and protect the painted parts

using protective wax;

clean and protect the shiny metal

parts using special compounds

available commercially;

sprinkle talcum powder on the

windscreen and rear window wiper

rubber blades and lift them off the

glass;

slightly open the windows;

cover the vehicle with a piece of

fabric or perforated plastic sheet. Do

not use compact plastic tarpaulins,

which prevent humidity from

evaporating from the surface of the

vehicle;

inflate tyres to +0.5 bar above the

standard specified pressure and check

it at intervals;

do not drain the engine cooling

system.

IMPORTANT If the vehicle is equipped

with an alarm system, switch off the

vehicle alarm with the remote control.

IMPORTANT After turning the ignition

key to STOP and having closed the

driver side door, wait at least one

minute before disconnecting the

electrical supply from the battery. When

reconnecting the electrical supply to

the battery, make sure that the ignition

key is in the STOP position and the

driver side door is closed.

147

Page 178 of 304

CHANGING A WHEEL

GENERAL

INSTRUCTIONS

Wheel replacement and correct use of

the jack and spare wheel (for

versions/markets, where provided) call

for some precautions, which are listed

below.

146) 147) 148) 149) 150)

Please note that:

the jack weight is 4.5 kg;

the jack requires no adjustment;

the jack cannot be repaired: in the

event of a fault it must be replaced

by another original one;

no tool other than its cranking

device may be fitted on the jack.

151)

To change a wheel, proceed as

follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground must be flat and sufficiently

compact;

switch off the engine and pull the

handbrake;

engage first gear or reverse;

put on the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;

indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

in the event of a wheel change on a

slope or on unsurfaced roads, put

any object as stop under the wheels;

take the tool bag from under the

passenger seat (see "Compartment

under the front passenger side seat" in

the "Internal equipment" chapter in

"Knowing the vehicle").

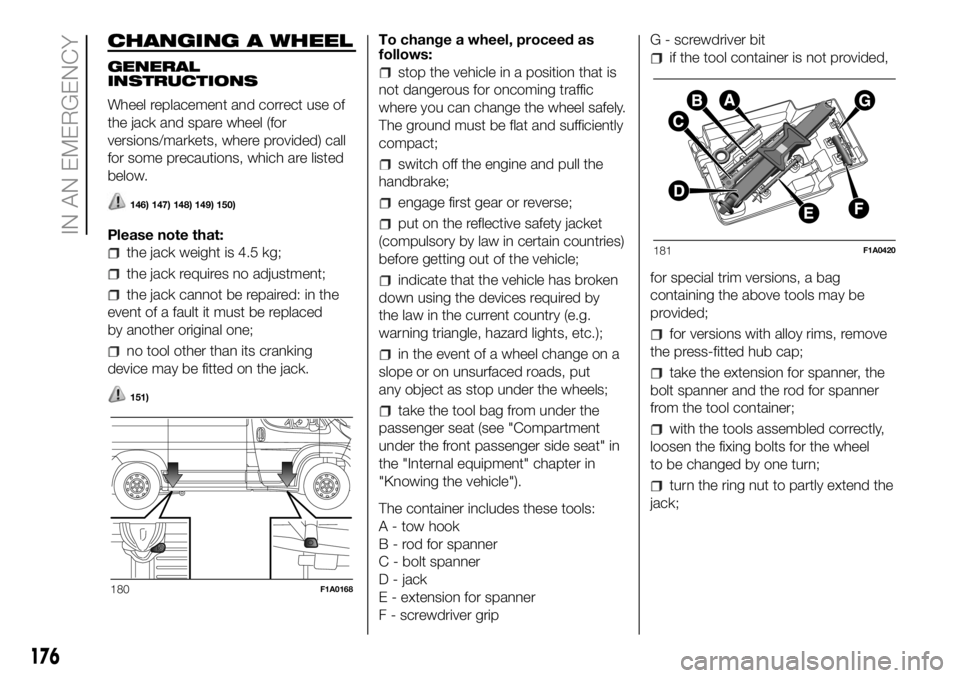

The container includes these tools:

A - tow hook

B - rod for spanner

C - bolt spanner

D - jack

E - extension for spanner

F - screwdriver gripG - screwdriver bit

if the tool container is not provided,

for special trim versions, a bag

containing the above tools may be

provided;

for versions with alloy rims, remove

the press-fitted hub cap;

take the extension for spanner, the

bolt spanner and the rod for spanner

from the tool container;

with the tools assembled correctly,

loosen the fixing bolts for the wheel

to be changed by one turn;

turn the ring nut to partly extend the

jack;

180F1A0168

181F1A0420

176

IN AN EMERGENCY

Page 181 of 304

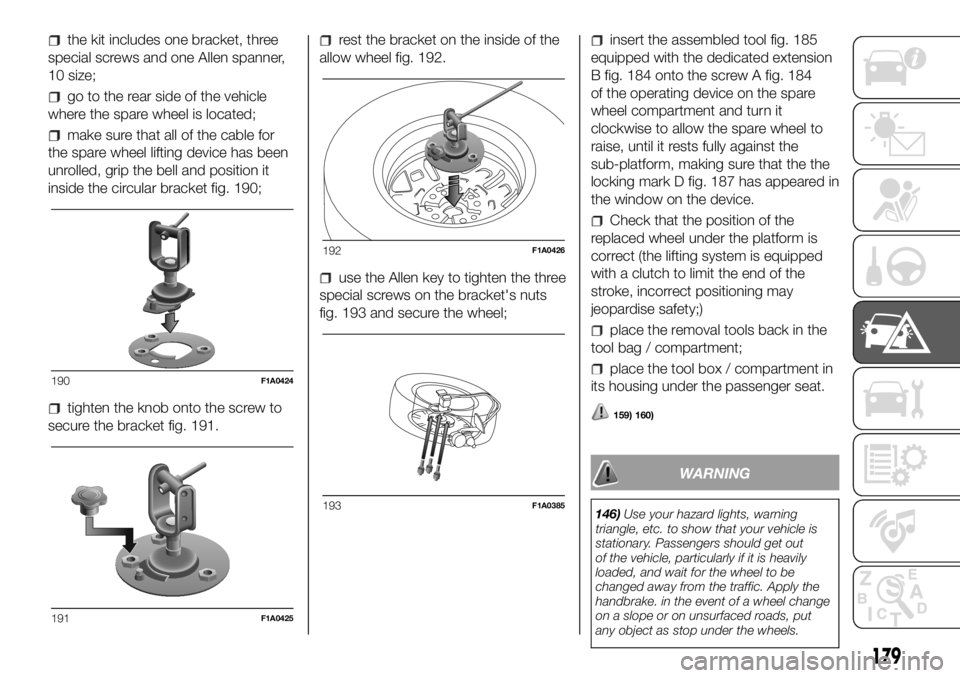

the kit includes one bracket, three

special screws and one Allen spanner,

10 size;

go to the rear side of the vehicle

where the spare wheel is located;

make sure that all of the cable for

the spare wheel lifting device has been

unrolled, grip the bell and position it

inside the circular bracket fig. 190;

tighten the knob onto the screw to

secure the bracket fig. 191.

rest the bracket on the inside of the

allow wheel fig. 192.

use the Allen key to tighten the three

special screws on the bracket's nuts

fig. 193 and secure the wheel;

insert the assembled tool fig. 185

equipped with the dedicated extension

B fig. 184 onto the screw A fig. 184

of the operating device on the spare

wheel compartment and turn it

clockwise to allow the spare wheel to

raise, until it rests fully against the

sub-platform, making sure that the the

locking mark D fig. 187 has appeared in

the window on the device.

Check that the position of the

replaced wheel under the platform is

correct (the lifting system is equipped

with a clutch to limit the end of the

stroke, incorrect positioning may

jeopardise safety;)

place the removal tools back in the

tool bag / compartment;

place the tool box / compartment in

its housing under the passenger seat.

159) 160)

WARNING

146)Use your hazard lights, warning

triangle, etc. to show that your vehicle is

stationary. Passengers should get out

of the vehicle, particularly if it is heavily

loaded, and wait for the wheel to be

changed away from the traffic. Apply the

handbrake. in the event of a wheel change

on a slope or on unsurfaced roads, put

any object as stop under the wheels.

190F1A0424

191F1A0425

192F1A0426

193F1A0385

179

Page 183 of 304

information leaflet (see fig. 195), to

be used for prompt and correct use

of the quick tyre repair kit and then to

be given to the personnel that must

handle the tyre treated with the tyre

repair kit;

compressor D complete with

pressure gauge and connectors;

a pair of protective gloves located in

the side compartment of the

compressor;

adaptors for inflating different

elements.

161) 162) 163)

49)

IMPORTANT

INFORMATION:

The sealing fluid of the quick repair kit is

effective at external temperatures of

between –20 °C and +50 °C.

The sealing fluid has an expiry date.

164) 165)

3)

INFLATION PROCEDURE

166) 167) 168) 169) 170)

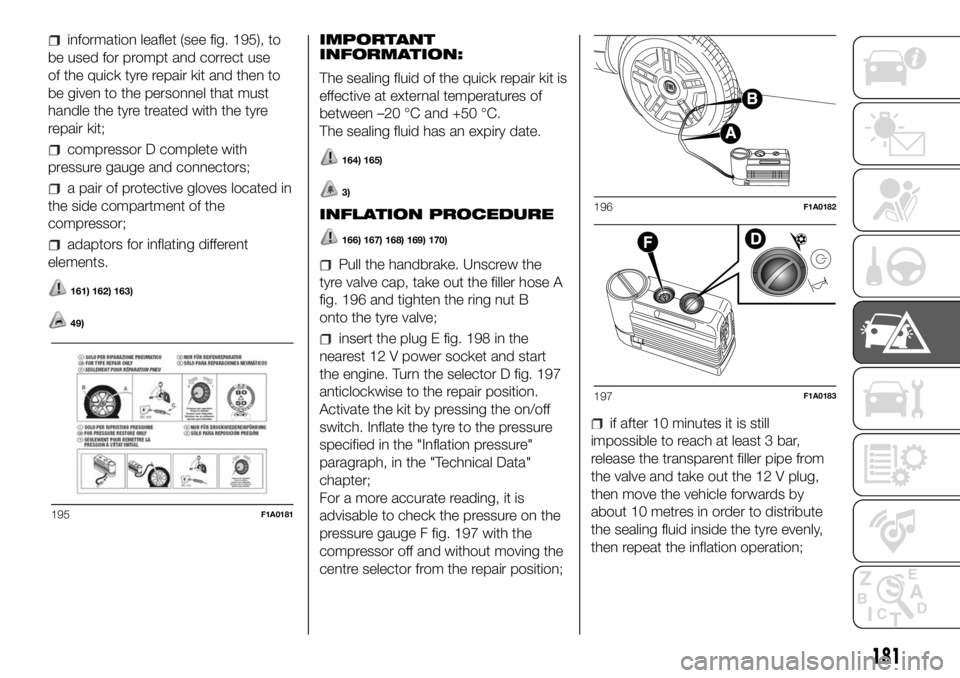

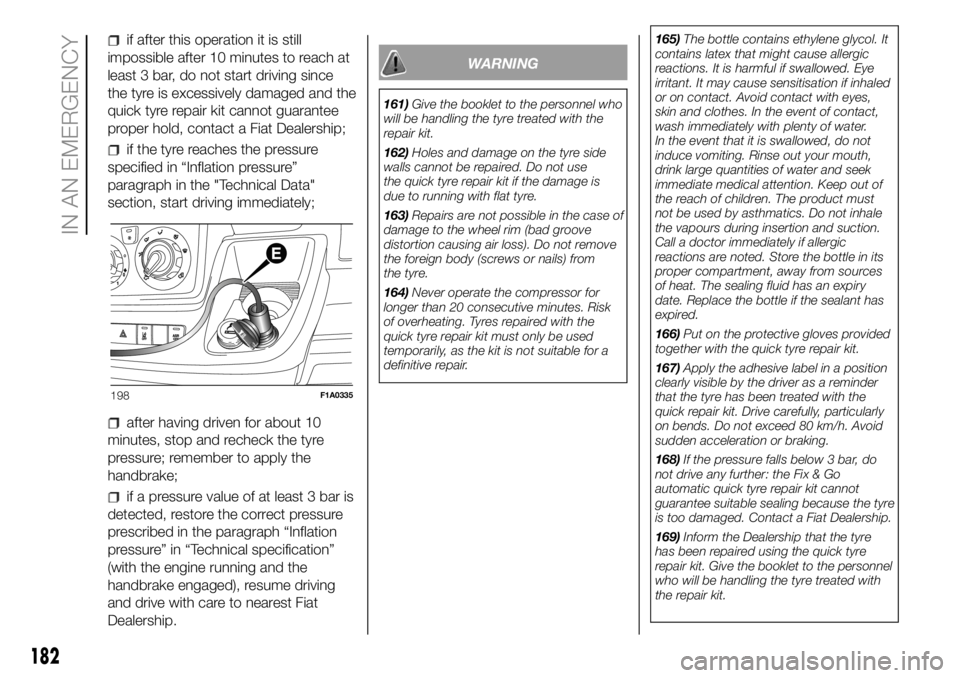

Pull the handbrake. Unscrew the

tyre valve cap, take out the filler hose A

fig. 196 and tighten the ring nut B

onto the tyre valve;

insert the plug E fig. 198 in the

nearest 12 V power socket and start

the engine. Turn the selector D fig. 197

anticlockwise to the repair position.

Activate the kit by pressing the on/off

switch. Inflate the tyre to the pressure

specified in the "Inflation pressure"

paragraph, in the "Technical Data"

chapter;

For a more accurate reading, it is

advisable to check the pressure on the

pressure gauge F fig. 197 with the

compressor off and without moving the

centre selector from the repair position;

if after 10 minutes it is still

impossible to reach at least 3 bar,

release the transparent filler pipe from

the valve and take out the 12 V plug,

then move the vehicle forwards by

about 10 metres in order to distribute

the sealing fluid inside the tyre evenly,

then repeat the inflation operation;

195F1A0181

196F1A0182

197F1A0183

181

Page 184 of 304

if after this operation it is still

impossible after 10 minutes to reach at

least 3 bar, do not start driving since

the tyre is excessively damaged and the

quick tyre repair kit cannot guarantee

proper hold, contact a Fiat Dealership;

if the tyre reaches the pressure

specified in “Inflation pressure”

paragraph in the "Technical Data"

section, start driving immediately;

after having driven for about 10

minutes, stop and recheck the tyre

pressure; remember to apply the

handbrake;

if a pressure value of at least 3 bar is

detected, restore the correct pressure

prescribed in the paragraph “Inflation

pressure” in “Technical specification”

(with the engine running and the

handbrake engaged), resume driving

and drive with care to nearest Fiat

Dealership.

WARNING

161)Give the booklet to the personnel who

will be handling the tyre treated with the

repair kit.

162)Holes and damage on the tyre side

walls cannot be repaired. Do not use

the quick tyre repair kit if the damage is

due to running with flat tyre.

163)Repairs are not possible in the case of

damage to the wheel rim (bad groove

distortion causing air loss). Do not remove

the foreign body (screws or nails) from

the tyre.

164)Never operate the compressor for

longer than 20 consecutive minutes. Risk

of overheating. Tyres repaired with the

quick tyre repair kit must only be used

temporarily, as the kit is not suitable for a

definitive repair.165)The bottle contains ethylene glycol. It

contains latex that might cause allergic

reactions. It is harmful if swallowed. Eye

irritant. It may cause sensitisation if inhaled

or on contact. Avoid contact with eyes,

skin and clothes. In the event of contact,

wash immediately with plenty of water.

In the event that it is swallowed, do not

induce vomiting. Rinse out your mouth,

drink large quantities of water and seek

immediate medical attention. Keep out of

the reach of children. The product must

not be used by asthmatics. Do not inhale

the vapours during insertion and suction.

Call a doctor immediately if allergic

reactions are noted. Store the bottle in its

proper compartment, away from sources

of heat. The sealing fluid has an expiry

date. Replace the bottle if the sealant has

expired.

166)Put on the protective gloves provided

together with the quick tyre repair kit.

167)Apply the adhesive label in a position

clearly visible by the driver as a reminder

that the tyre has been treated with the

quick repair kit. Drive carefully, particularly

on bends. Do not exceed 80 km/h. Avoid

sudden acceleration or braking.

168)If the pressure falls below 3 bar, do

not drive any further: the Fix & Go

automatic quick tyre repair kit cannot

guarantee suitable sealing because the tyre

is too damaged. Contact a Fiat Dealership.

169)Inform the Dealership that the tyre

has been repaired using the quick tyre

repair kit. Give the booklet to the personnel

who will be handling the tyre treated with

the repair kit.

198F1A0335

182

IN AN EMERGENCY

Page 196 of 304

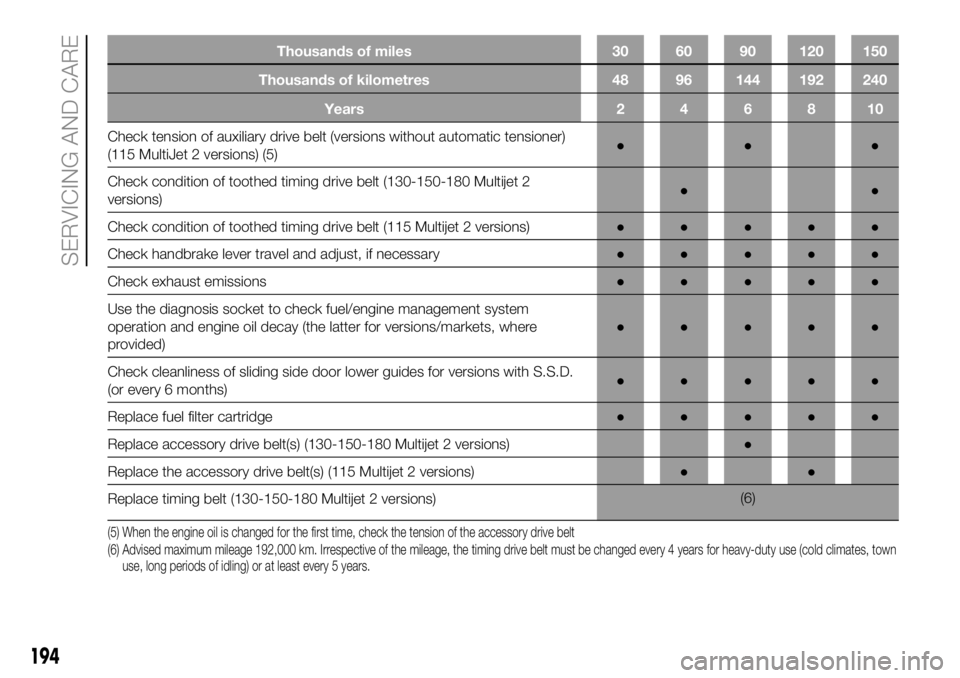

Thousands of miles 30 60 90 120 150

Thousands of kilometres 48 96 144 192 240

Years 2 4 6 8 10

Check tension of auxiliary drive belt (versions without automatic tensioner)

(115 MultiJet 2versions) (5)●●●

Check condition of toothed timing drive belt (130-150-180 Multijet 2

versions)●●

Check condition of toothed timing drive belt (115 Multijet 2 versions)●●●●●

Check handbrake lever travel and adjust, if necessary●●●●●

Check exhaust emissions●●●●●

Use the diagnosis socket to check fuel/engine management system

operation and engine oil decay (the latter for versions/markets, where

provided)●●●●●

Check cleanliness of sliding side door lower guides for versions with S.S.D.

(or every 6 months)●●●●●

Replace fuel filter cartridge●●●●●

Replace accessory drive belt(s) (130-150-180 Multijet 2 versions)●

Replace the accessory drive belt(s) (115 Multijet 2 versions)●●

Replace timing belt (130-150-180 Multijet 2 versions)(6)

(5) When the engine oil is changed for the first time, check the tension of the accessory drive belt

(6) Advised maximum mileage 192,000 km. Irrespective of the mileage, the timing drive belt must be changed every 4 years for heavy-duty use (cold climates, town

use, long periods of idling) or at least every 5 years.

194

SERVICING AND CARE

Page 199 of 304

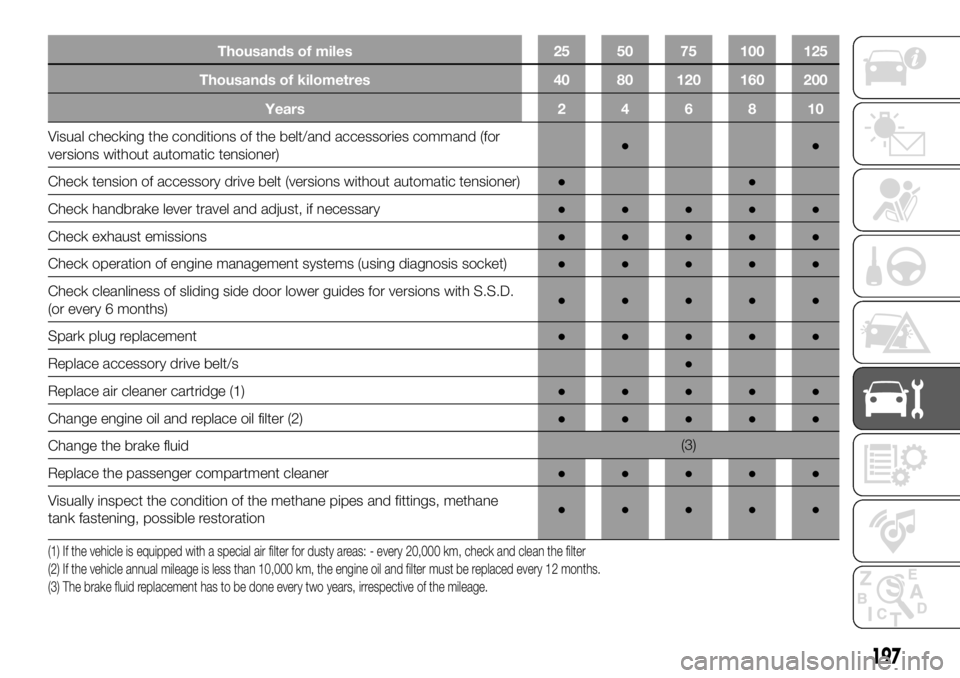

Thousands of miles 25 50 75 100 125

Thousands of kilometres 40 80 120 160 200

Years246810

Visual checking the conditions of the belt/and accessories command (for

versions without automatictensioner)●●

Check tension of accessory drive belt (versions without automatic tensioner)●●

Check handbrake lever travel and adjust, if necessary●●●●●

Check exhaust emissions●●●●●

Check operation of engine management systems (using diagnosis socket)●●●●●

Check cleanliness of sliding side door lower guides for versions with S.S.D.

(or every 6 months)●●●●●

Spark plug replacement●●●●●

Replace accessory drive belt/s●

Replace air cleaner cartridge (1)●●●●●

Change engine oil and replace oil filter (2)●●●●●

Change the brake fluid(3)

Replace the passenger compartment cleaner●●●●●

Visually inspect the condition of the methane pipes and fittings, methane

tank fastening, possible restoration●●●●●

(1) If the vehicle is equipped with a special air filter for dusty areas: - every 20,000 km, check and clean the filter

(2) If the vehicle annual mileage is less than 10,000 km, the engine oil and filter must be replaced every 12 months.

(3) The brake fluid replacement has to be done every two years, irrespective of the mileage.

197

Page 215 of 304

INTERIOR

Regularly check that water is not

trapped under the mats (due to water

dripping off shoes, umbrellas, etc.),

as this could cause oxidation of the

sheet metal.

205) 206)

SEATS AND FABRIC

PARTS

Remove dust with a soft brush or a

vacuum cleaner. It is advisable to use a

moist brush on velvet upholstery.

Rub the seats with a sponge moistened

with a solution of water and neutral

detergent.

PLASTIC PARTS

It is advisable to clean interior plastic

parts with a moist cloth and a solution

of water and non-abrasive mild soap.

Use specific products for cleaning

plastic, without solvents and specifically

designed to prevent damage to the

appearance and colour of the treated

parts, to remove grease and tough

stains.

IMPORTANT Do not use alcohol,

petrols or derivatives to clean

the instrument panel glass.LEATHER STEERING

WHEEL/GEAR LEVER

KNOB/HANDBRAKE

(for versions/markets, where provided)

These components must be cleaned

with mild soap and water only. Never

use alcohol or alcohol-based products.

WARNING

205)Never use flammable products, such

as petroleum ether or modified petrol, to

clean the inside of the car. The

electrostatic charges which are generated

by rubbing during the cleaning operation

may cause a fire.

206)Do not keep aerosol cans in the

vehicle: they might explode. Aerosol cans

must not be exposed to a temperature

exceeding 50°C. When the vehicle is

exposed to sunlight, the internal

temperature can greatly exceed this value.

RUBBER HOSES

As far as the brake system and fuel

supply system rubber hoses are

concerned, follow the "Scheduled

Servicing Plan" in this chapter carefully.

Ozone, high temperatures and

prolonged lack of fluid in the system

may cause hardening and cracking of

the hoses, with possible leaks. Careful

checking is therefore necessary.

213

Page 279 of 304

when prompted by the mobile

phone, use its keypad to enter the PIN

code shown on the system display

or confirm on the mobile phone the PIN

displayed;

from the "Settings" menu you can

always pair a mobile phone by selecting

"Phone menu/Add phone", then

proceed as described above;

during the pairing stage a screen is

displayed showing the progress of

the operation;

NOTE The priority for the automatic

reconnection is determined according

to the order of connection. The last

phone connected will have the highest

priority.

Making a phone call

The operations described below can

only be accessed if supported by

the mobile phone in use.

For all functions available, refer to the

mobile phone owner's handbook.

A call can be made by:

selecting "Contacts" (Phonebook

......);

selecting "Recent Calls list";

selecting "Keypad".Dialling the phone number using

the "keypad" on the display

Enter the phone number using the

graphic keypad displayed. Proceed as

follows:

press the PHONE button on the

front panel;

select "Keypad" on the display and

use the right "BROWSE/ENTER" knob

to enter the number

select the icon to make the call.

Dialling the phone number using

the mobile phone

It is possible to dial a phone number

with the mobile phone and continue

using the system (never allow yourself

to be distracted while driving).

When a phone number is dialled with

the keypad of the mobile phone, the

audio of the call is played over your

vehicle's sound system.

WARNING

277

209)When connecting a device (USB or

iPod) to the USB port, make sure that

it does not obstruct the operation of the

handbrake lever.

210)When connecting a device to the AUX

socket (for versions/markets where

provided), make sure that it does not

obstruct the operation of the handbrake

lever.