ESP FIAT DUCATO BASE CAMPER 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2018, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2018Pages: 304, PDF Size: 14.93 MB

Page 132 of 304

REAR CAMERA

(PARKVIEW® REAR

BACK UP CAMERA)

(for versions/markets, where provided)

124)

27)

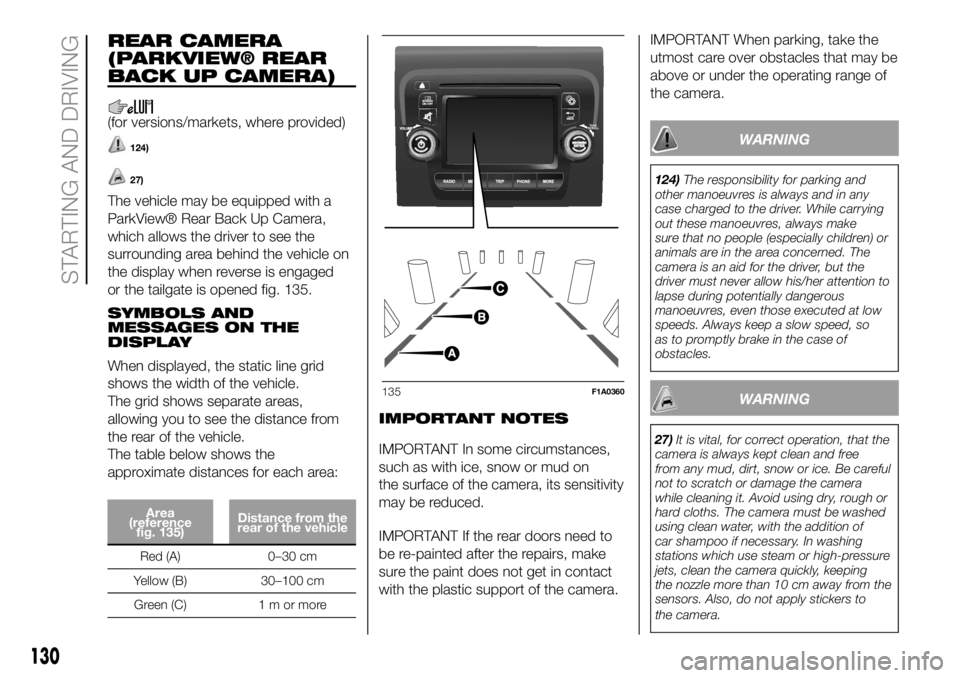

The vehicle may be equipped with a

ParkView® Rear Back Up Camera,

which allows the driver to see the

surrounding area behind the vehicle on

the display when reverse is engaged

or the tailgate is opened fig. 135.

SYMBOLS AND

MESSAGES ON THE

DISPLAY

When displayed, the static line grid

shows the width of the vehicle.

The grid shows separate areas,

allowing you to see the distance from

the rear of the vehicle.

The table below shows the

approximate distances for each area:

Area

(reference

fig. 135)Distance from the

rear of the vehicle

Red (A) 0–30 cm

Yellow (B) 30–100 cm

Green (C) 1 m or more

IMPORTANT NOTES

IMPORTANT In some circumstances,

such as with ice, snow or mud on

the surface of the camera, its sensitivity

may be reduced.

IMPORTANT If the rear doors need to

be re-painted after the repairs, make

sure the paint does not get in contact

with the plastic support of the camera.IMPORTANT When parking, take the

utmost care over obstacles that may be

above or under the operating range of

the camera.

WARNING

124)The responsibility for parking and

other manoeuvres is always and in any

case charged to the driver. While carrying

out these manoeuvres, always make

sure that no people (especially children) or

animals are in the area concerned. The

camera is an aid for the driver, but the

driver must never allow his/her attention to

lapse during potentially dangerous

manoeuvres, even those executed at low

speeds. Always keep a slow speed, so

as to promptly brake in the case of

obstacles.

WARNING

27)It is vital, for correct operation, that the

camera is always kept clean and free

from any mud, dirt, snow or ice. Be careful

not to scratch or damage the camera

while cleaning it. Avoid using dry, rough or

hard cloths. The camera must be washed

using clean water, with the addition of

car shampoo if necessary. In washing

stations which use steam or high-pressure

jets, clean the camera quickly, keeping

the nozzle more than 10 cm away from the

sensors. Also, do not apply stickers to

the camera.

135F1A0360

130

STARTING AND DRIVING

Page 133 of 304

TRAFFIC SIGN

RECOGNITION

(for versions/markets, where provided)

125) 126) 127) 128)

28) 29) 30) 31) 32) 33) 34)

The system automatically detects the

recognisable traffic signs: speed limits,

no overtaking signs and signs indicating

the end of such prohibitions.

The camera is fitted behind the internal

rear view mirror. The sensor always

checks the traffic signs indicating the

current speed limit and possible no

overtaking signs.

IMPORTANT The system is designed to

read signs complying with the

specifications of the Vienna convention.

USE OF THE TRAFFIC

SIGN RECOGNITION

System switching on and off

The system can be activated/

deactivated using the display menu.

Refer to the "Display" paragraph in the

"Knowing the instrument panel"

chapter.

Note: The system state and settings do

not change throughout the various

on-off cycles.

WARNING

125)If the camera loses its position due to

a load variation, the system may not work

temporarily to allow the camera to perform

an auto-calibration.

126)The system only detects the preset

traffic signs. If the minimum visibility

conditions and distance from the sign are

met it can detect all traffic signs.

127)The system is a driving assistance

system but it does not relieve the driver of

the responsibility of driving with due

attention and diligence in compliance with

the laws in force.

128)When the system is active, the driver

is responsible for controlling the vehicle

and monitoring the system, and must

intervene as appropriate if necessary.

WARNING

28)In the event of errors the system may

not work.

29)At low temperatures and in particularly

adverse weather conditions, the system

may not work.

30)Rain, snow, splashes and strong light

contrast may influence the sensor.

31)Do not repair the area of the

windscreen directly surrounding the sensor.

32)If the vehicle is equipped with a

non-genuine suspension kit, the system

may not work correctly.

33)Always use genuine spare parts when

replacing the bulbs of the headlights. Other

bulbs may reduce the system

performance.

34)Clean the windscreen from foreign

matters such as bird droppings, insects,

snow or ice.

100

136F1A0373

131

Page 137 of 304

turn the key in the pawl starter in the

ON position (no need to start the

engine);

wait for the warning on the

instrument panel to switch off before

moving the vehicle, the warning light

may stay on for a few seconds to half a

minute. In case of motor start-up and

movement of the vehicle, the warning

light will remain on for a longer period of

time, but there are no problems on the

engine functionality;

if topping up is done with the UREA

tank empty, you have to wait two

minutes before starting the vehicle;

NOTE The driving conditions (altitude,

vehicle speed, load, etc.) determine the

quantity of UREA used by the vehicle.

In order to use the additive for Diesel

Emissions (UREA) correctly, see "Fluids

and lubricants" in the "Technical data".

132)

IMPORTANT

Exceeding the maximum filling level

of the tank UREA, it can cause damage

to the tank and spilling UREA. Please

avoid topping up after filling the tank.

DO NOT EXCEED THE MAXIMUM

LEVEL. The UREA freezes at under -11

° C. Although the system is designed

to operate below the freezing point

of the UREA, it is advisable not to fill the

tank beyond the maximum level

because if the UREA freezes the

system can be damaged.

If the UREA is spilled on painted

surfaces or aluminium, immediately

clean the area with water and use

absorbent material to collect the fluid

that has been spilled on the ground.

Do not try to start the engine if

UREA was accidentally added to the

Diesel fuel tank, this can result in

serious engine damage, contact

Dealership.

Use AdBlue only according to DIN

70 070 and ISO 22241-1. Other fluids

may cause damage to the system: also

exhaust emissions would no longer

comply with the law. The distribution

companies are responsible for the

compliance of their product. Observe

the precautions of storage and

servicing, in order to preserve the initial

qualities. The manufacturer of the

vehicle does not recognise any

guarantee in case of malfunctions and

damage caused to the vehicle due

to the use of urea (AdBlue) not in

accordance with regulations.

Any introduction of diesel fuel inside

the tank AdBlue, causes irreversible

damage to the pumping unit circuit

AdBlue.

Do not add additives to AdBlue. Do

not dilute AdBlue with tap water as

this may damage the system of

purification of exhaust gases.

In case of damage to the sewage

system of exhaust gas resulting from

the use of additives / tap water, the

introduction of diesel fuel, or at least by

not fulfilling the requirements, the

warranty expires.

AdBlue tank topping (UREA) in cold

environments

Since AdBlue (UREA) starts to freeze

around the -11 °C, the vehicle is

equipped with an automatic system of

heating UREA that allows the system to

function properly at temperatures

below -11 °C.

If the vehicle remains idle for a long

period at temperatures below the -11

°C, the UREA in the tank might freeze.

If the tank UREA was filled beyond

the maximum level and freezes, it can

be damaged; for this reason it is

advisable not to exceed the maximum

level of the tank.

Pay extra attention to avoid exceeding

the maximum level when you use

portable containers for topping up.

135

Page 142 of 304

LOADING ADVICE

The Fiat Ducato version used by you

has been designed and type approved

on the basis of certain maximum

weights (see "Weights" table in the

"Technical Data" chapter): kerb weight,

payload, total weight, maximum weight

on front axle, maximum weight on

rear axle, towable weight.

IMPORTANT The maximum permitted

load on the floor fastenings is 500

kg; the maximum permitted load on the

side panel is 150 kg.

IMPORTANT For versions with right and

left side flaps, it is advisable to

reposition the release lever in the closed

position before lowering the sides.

134) 135) 136)

40)

In addition to these general

precautions, some simple precautions

can improve driving safety, travelling

comfort and vehicle durability:

distribute the load evenly over the

platform: if it is necessary to

concentrate it in a single area, choose

an area mid-way between both axles;

lastly, remember that the vehicle’s

dynamic behaviour is affected by the

weight transported: in particular, the

stopping distances are longer,

especially at high speed.

WARNING

134)Bumpy roads and abrupt braking may

cause unexpected load shifting with

consequently hazardous situations for the

driver and passengers: before setting

off, secure the load tightly using the

partition and appropriate hooks, steel

cables, ropes or chains strong enough to

hold the items to be secured.

135)Even when the car is stopped on a

steep hill or side slope, opening the rear or

side doors could cause unsecured goods

to fall out.

136)If you wish to carry a reserve of petrol

in a can, observe the legal restrictions

and only use a can that is type-approved

and properly secured to the load

anchorage eyebolts. In the event of a

collision the fire risk is increased all the

same.

WARNING

40)Each of these must be strictly

observed and MUST NEVER BE

EXCEEDED in any case. In particular,

ensure that you never exceed the

maximum permitted weights on the front

and rear axles when arranging the load on

the vehicle (particularly if the vehicle is

equipped with a specific trim level).

140

STARTING AND DRIVING

Page 147 of 304

INSTRUCTIONS FOR

USING THE REMOVABLE

BALL HEAD TOW BAR

41) 42) 43) 44) 45) 46)

Before setting off, check the correct

locking of the removable ball head tow

bar, as follows:

The green mark of the flywheel must

coincide with the green mark on the

tow bar.

The flywheel is in the stop position

on the tow bar (without slot).

Locked lock and key removed. The

flywheel cannot be removed.

Ball head bar firmly secured to the

housing pipe. Check by shaking with a

hand.

The fitting procedure must be repeated

if any of the 4 checked requirements

is not met.

If even only one of the requirements is

not met the tow hook must not be

used, as in this case there is risk of

accidents. Contact the joint

manufacturer.

The ball head tow bar can be fitted and

removed manually, without needing

any tool.

Never use working tools or means, as

the mechanism could be damaged.

Never unlock in the case of trailer

attached to the vehicle or fitted rack.When driving without trailer or rack the

ball head tow bar must be removed

and the closing plug must always

be inserted in the housing pipe. This

applies particularly if the visibility of the

number plate characters or of the

lighting system is reduced.

Removable ball head tow bar fig.

144 - fig. 145 - fig. 146

1. Mounting pipe - 2. Ball head tow bar

- 3. Locking ball - 4. Release lever -

5. Handwheel - 6. Cap - 7. Wrench - 8.

Red mark (handwheel) - 9. Green

mark (handwheel) - 10. Green mark

(tow bar) - 11. Symbol (release control)

- 12. Closing plug - 13. Coupling pin

- 14. No gaps between 2 and5-15.

Gap of about 5 mm

Installing the ball head tow bar

1. Remove the plug from the mounting

pipe.

The ball head tow bar is usually in the

released position when taken out from

the boot. This can be observed by

the flywheel spaced from the tow bar,

corresponding to a slot of approx. 5

mm (see figure) and by the red mark on

the flywheel directed to the green

mark on the tow bar.

144F1A0380

145 - Locked position, drivingF1A0381

146 - Released position, removedF1A0382

145

Page 151 of 304

REPLACING A BULB

GENERAL

INSTRUCTIONS

140) 141)

47)

When a light is not working, check

that the corresponding fuse is intact

before changing a bulb. For the location

of fuses, refer to the paragraph

"Replacing fuses" in this chapter.

before changing a bulb check the

contacts for oxidation;

burnt bulbs must be replaced by

others of the same type and power;

always check the headlight beam

direction after changing a bulb;

IMPORTANT A slight misting may

appear on the internal surface of the

headlight: this does not indicate a fault

and is caused by low temperature

and the degree of humidity in the air.

Misting will rapidly disappear when the

headlights are switched on. The

presence of drops inside the headlights

indicates infiltration of water. Contact

a Fiat Dealership.

WARNING

140)Modifications or repairs to the

electric system that are not carried out

properly or do not take the system

technical specifications into account can

cause malfunctions leading to the risk

of fire.

141)Halogen bulbs contain pressurised

gas, in the case of breakage they may

burst causing glass fragments to be

projected outwards.

WARNING

47)Halogen bulbs must be handled

holding the metallic part only. Touching the

transparent part of the bulb with your

fingers may reduce the intensity of the

emitted light and even reduce the lifespan

of the bulb. In the event of accidental

contact, wipe the bulb with a cloth

moistened with alcohol and let the bulb

dry.

149

Page 177 of 304

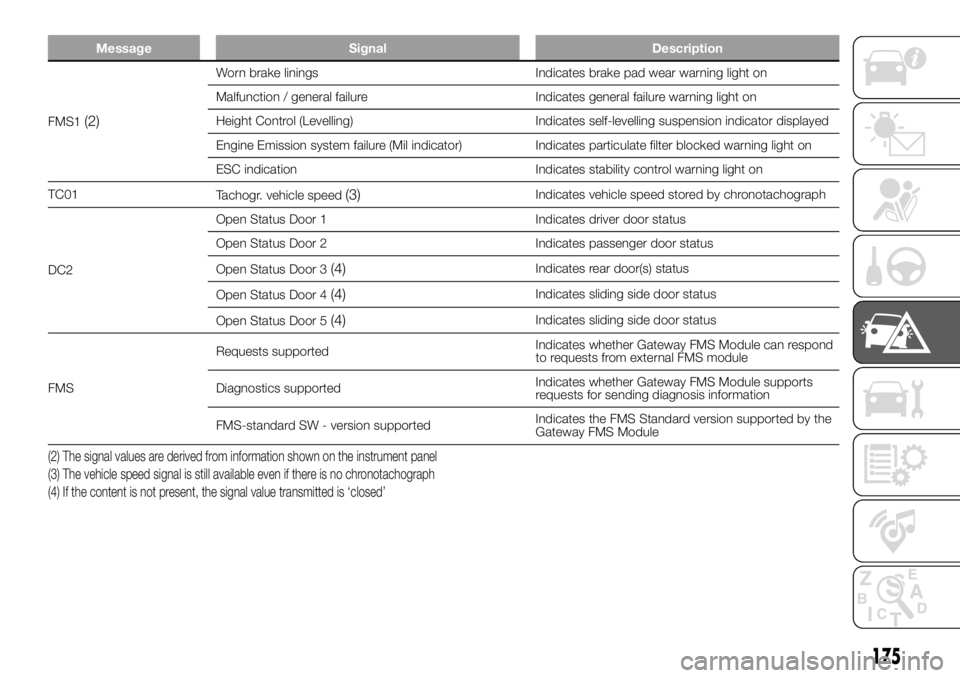

Message Signal Description

FMS1(2)

Worn brake linings Indicates brake pad wear warning light on

Malfunction / general failure Indicates general failure warning light on

Height Control (Levelling) Indicates self-levelling suspension indicator displayed

Engine Emission system failure (Mil indicator) Indicates particulate filter blocked warning light on

ESC indication Indicates stability control warning light on

TC01

Tachogr. vehicle speed

(3)Indicates vehicle speed stored by chronotachograph

DC2Open Status Door 1 Indicates driver door status

Open Status Door 2 Indicates passenger door status

Open Status Door 3

(4)Indicates rear door(s) status

Open Status Door 4

(4)Indicates sliding side door status

Open Status Door 5

(4)Indicates sliding side door status

FMSRequests supportedIndicates whether Gateway FMS Module can respond

to requests from external FMS module

Diagnostics supportedIndicates whether Gateway FMS Module supports

requests for sending diagnosis information

FMS-standard SW - version supportedIndicates the FMS Standard version supported by the

Gateway FMS Module

(2) The signal values are derived from information shown on the instrument panel

(3) The vehicle speed signal is still available even if there is no chronotachograph

(4) If the content is not present, the signal value transmitted is ‘closed’

175

Page 180 of 304

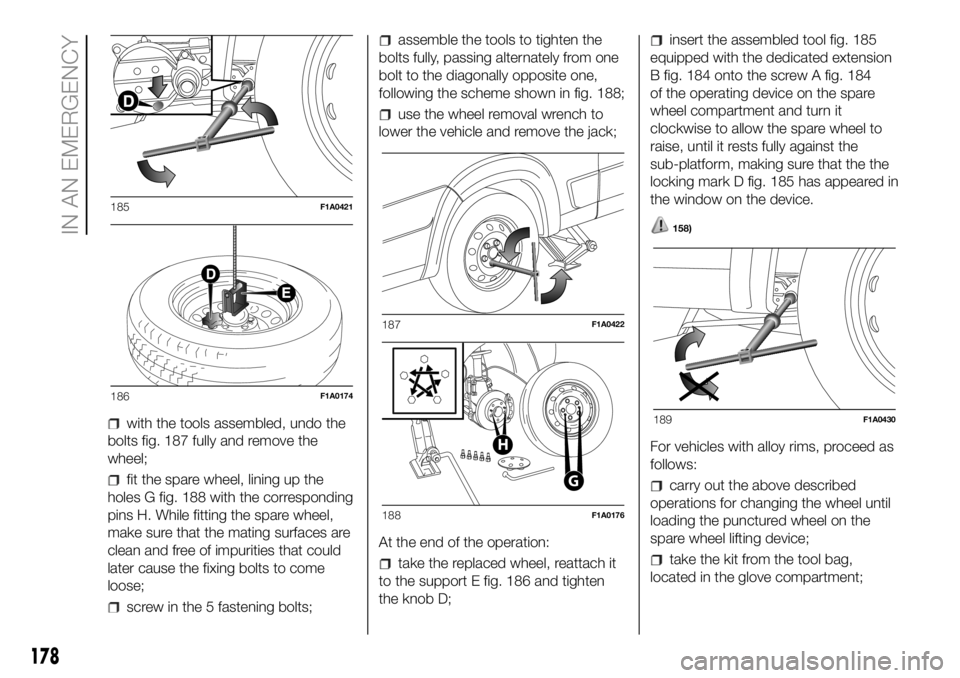

with the tools assembled, undo the

bolts fig. 187 fully and remove the

wheel;

fit the spare wheel, lining up the

holes G fig. 188 with the corresponding

pins H. While fitting the spare wheel,

make sure that the mating surfaces are

clean and free of impurities that could

later cause the fixing bolts to come

loose;

screw in the 5 fastening bolts;

assemble the tools to tighten the

bolts fully, passing alternately from one

bolt to the diagonally opposite one,

following the scheme shown in fig. 188;

use the wheel removal wrench to

lower the vehicle and remove the jack;

At the end of the operation:

take the replaced wheel, reattach it

to the support E fig. 186 and tighten

the knob D;

insert the assembled tool fig. 185

equipped with the dedicated extension

B fig. 184 onto the screw A fig. 184

of the operating device on the spare

wheel compartment and turn it

clockwise to allow the spare wheel to

raise, until it rests fully against the

sub-platform, making sure that the the

locking mark D fig. 185 has appeared in

the window on the device.

158)

For vehicles with alloy rims, proceed as

follows:

carry out the above described

operations for changing the wheel until

loading the punctured wheel on the

spare wheel lifting device;

take the kit from the tool bag,

located in the glove compartment;

185F1A0421

186F1A0174

187F1A0422

G

H

188F1A0176

189F1A0430

178

IN AN EMERGENCY

Page 196 of 304

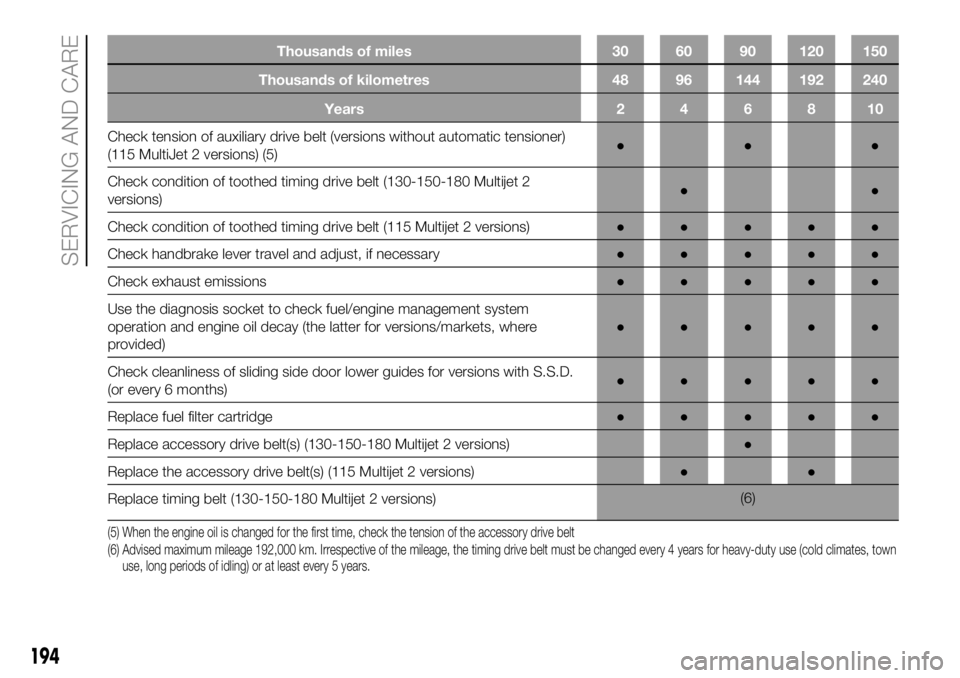

Thousands of miles 30 60 90 120 150

Thousands of kilometres 48 96 144 192 240

Years 2 4 6 8 10

Check tension of auxiliary drive belt (versions without automatic tensioner)

(115 MultiJet 2versions) (5)●●●

Check condition of toothed timing drive belt (130-150-180 Multijet 2

versions)●●

Check condition of toothed timing drive belt (115 Multijet 2 versions)●●●●●

Check handbrake lever travel and adjust, if necessary●●●●●

Check exhaust emissions●●●●●

Use the diagnosis socket to check fuel/engine management system

operation and engine oil decay (the latter for versions/markets, where

provided)●●●●●

Check cleanliness of sliding side door lower guides for versions with S.S.D.

(or every 6 months)●●●●●

Replace fuel filter cartridge●●●●●

Replace accessory drive belt(s) (130-150-180 Multijet 2 versions)●

Replace the accessory drive belt(s) (115 Multijet 2 versions)●●

Replace timing belt (130-150-180 Multijet 2 versions)(6)

(5) When the engine oil is changed for the first time, check the tension of the accessory drive belt

(6) Advised maximum mileage 192,000 km. Irrespective of the mileage, the timing drive belt must be changed every 4 years for heavy-duty use (cold climates, town

use, long periods of idling) or at least every 5 years.

194

SERVICING AND CARE

Page 197 of 304

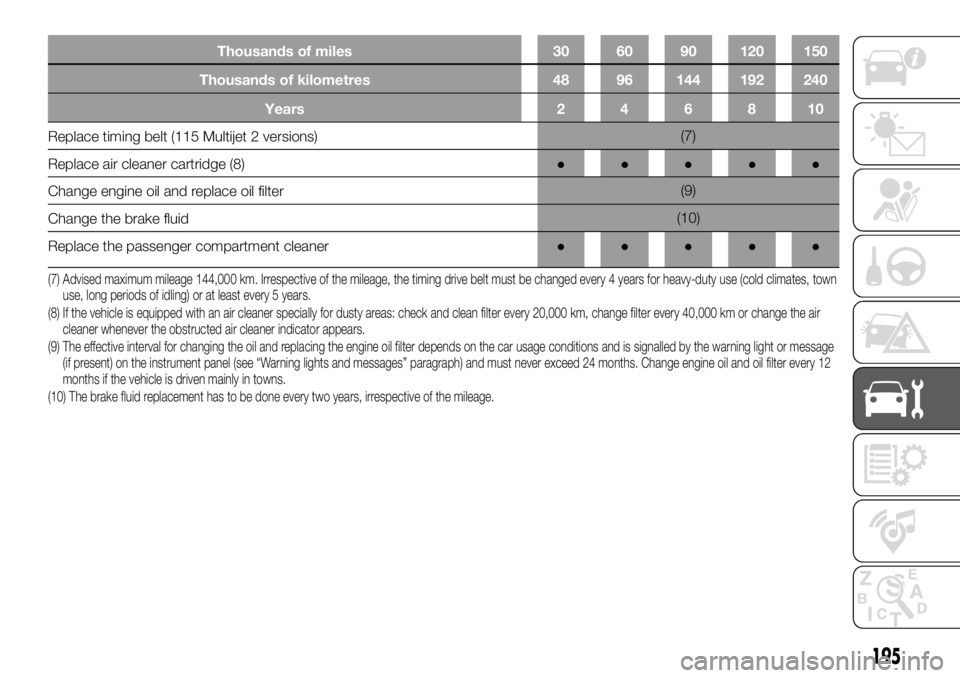

Thousands of miles 30 60 90 120 150

Thousands of kilometres 48 96 144 192 240

Years 2 4 6 8 10

Replace timing belt (115 Multijet 2 versions)(7)

Replace

air cleanercartridge (8)●●●●●

Change engine oil and replace oil filter(9)

Change the brake fluid(10)

Replace the passenger compartment cleaner●●●●●

(7) Advised maximum mileage 144,000 km. Irrespective of the mileage, the timing drive belt must be changed every 4 years for heavy-duty use (cold climates, town

use, long periods of idling) or at least every 5 years.

(8) If the vehicle is equipped with an air cleaner specially for dusty areas: check and clean filter every 20,000 km, change filter every 40,000 km or change the air

cleaner whenever the obstructed air cleaner indicator appears.

(9) The effective interval for changing the oil and replacing the engine oil filter depends on the car usage conditions and is signalled by the warning light or message

(if present) on the instrument panel (see “Warning lights and messages” paragraph) and must never exceed 24 months. Change engine oil and oil filter every 12

months if the vehicle is driven mainly in towns.

(10) The brake fluid replacement has to be done every two years, irrespective of the mileage.

195