lock FIAT DUCATO BASE CAMPER 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2018, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2018Pages: 304, PDF Size: 14.93 MB

Page 155 of 304

remove the bulb by pushing it

slightly and turning it anticlockwise

(bayonet mount);

refit the bulb holder B by turning it

clockwise and making sure that it locks

correctly

refit the protective rubber cover A

fig. 150.

MAIN BEAM HEADLIGHTSTo replace the bulb, proceed as follows:

remove the protective rubber cover

C fig. 150;

free the bulb holder A fig. 152 from

the side clips B and remove it;

disconnect the electrical connector;

fit the new bulb, ensuring that the

outline of the metal part coincides with

the grooves on the curve of the

headlight, pressing to engage it with the

side clips;

reconnect the electrical connector;

refit the protective rubber cover

C fig. 150.

DIPPED BEAM

HEADLIGHTS

With incandescent bulbs

To replace the bulb, proceed as follows:

remove the protective rubber cover

B fig. 150;

free the bulb holder A fig. 153 from

the side clips B and remove it;

disconnect the electrical connector;

fit the new bulb, ensuring that the

outline of the metal part coincides with

the grooves on the curve of the

headlight, pressing to engage it with the

side clips;

reconnect the electrical connector;

refit the protective rubber cover

B fig. 150.

DIRECTION INDICATORS

To replace the bulb, proceed as follows:

remove the protective rubber cover

A fig. 150;

turn the bulb holder B fig. 154

anticlockwise;

extract the bulb by pulling and

replace it;

remove the bulb by pushing it

slightly and turning it anticlockwise

(bayonet mount);

refit the bulb holder B by turning it

clockwise and making sure that it locks

correctly

refit the protective rubber cover A

fig. 150.

151F1A0386

152F1A0315

153F1A0316

153

Page 156 of 304

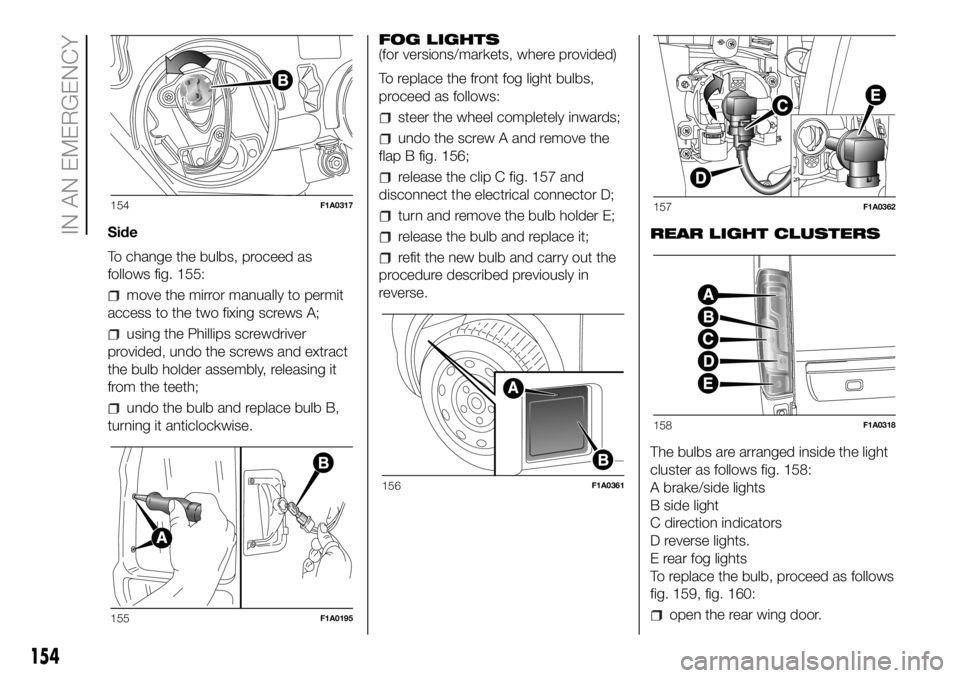

Side

To change the bulbs, proceed as

follows fig. 155:

move the mirror manually to permit

access to the two fixing screws A;

using the Phillips screwdriver

provided, undo the screws and extract

the bulb holder assembly, releasing it

from the teeth;

undo the bulb and replace bulb B,

turning it anticlockwise.FOG LIGHTS

(for versions/markets, where provided)

To replace the front fog light bulbs,

proceed as follows:

steer the wheel completely inwards;

undo the screw A and remove the

flap B fig. 156;

release the clip C fig. 157 and

disconnect the electrical connector D;

turn and remove the bulb holder E;

release the bulb and replace it;

refit the new bulb and carry out the

procedure described previously in

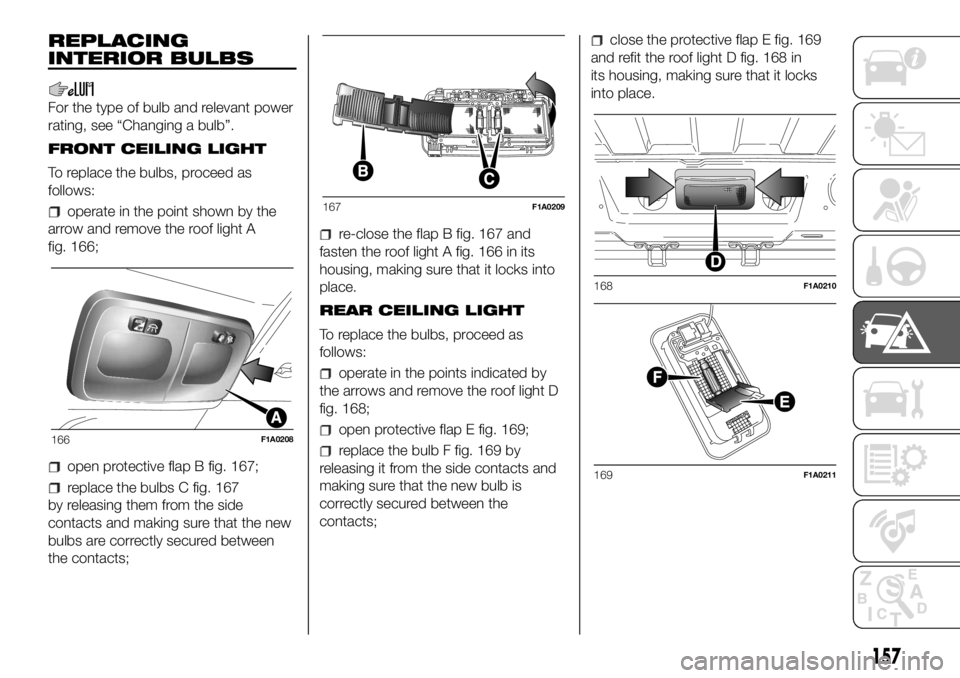

reverse.REAR LIGHT CLUSTERS

The bulbs are arranged inside the light

cluster as follows fig. 158:

A brake/side lights

B side light

C direction indicators

D reverse lights.

E rear fog lights

To replace the bulb, proceed as follows

fig. 159, fig. 160:

open the rear wing door.

154F1A0317

155F1A0195

156F1A0361

157F1A0362

158F1A0318

154

IN AN EMERGENCY

Page 157 of 304

undo the 7 fixing screws A of the

plastic cover;

undo the two fixing screws B;

extract the unit outwards and

disconnect the electrical connector;

unscrew the screws C using the

screwdriver provided and remove the

bulb holder;

remove the bulb D, E, F pushing it

gently and turning it anticlockwise

(“bayonet” locking), then replace it;

remove the bulb G, H pulling outwards;

refit the bulb holder and tighten the

screws C;

reconnect the electrical connector,

correctly reposition the unit on the body

of the vehicle and then tighten the

fixing screws B;

refit the plastic cover fastening it

with the 7 fixing screws A.For truck and chassis cab versions:

Undo the four screws H fig. 161 and

replace the bulbs:

I bulb for rear fog light

L bulb for reversing light

M bulb for side light

N bulb for brake light

O bulb for side light.

159F1A0319160F1A0320

161F1A0200

155

Page 159 of 304

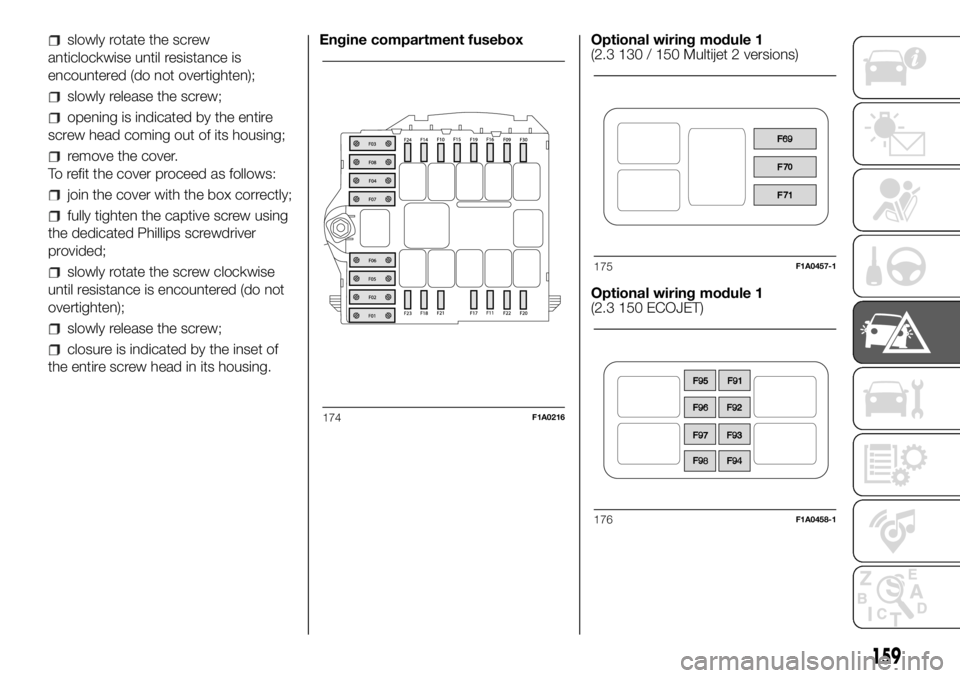

REPLACING

INTERIOR BULBS

For the type of bulb and relevant power

rating, see “Changing a bulb”.

FRONT CEILING LIGHT

To replace the bulbs, proceed as

follows:

operate in the point shown by the

arrow and remove the roof light A

fig. 166;

open protective flap B fig. 167;

replace the bulbs C fig. 167

by releasing them from the side

contacts and making sure that the new

bulbs are correctly secured between

the contacts;

re-close the flap B fig. 167 and

fasten the roof light A fig. 166 in its

housing, making sure that it locks into

place.

REAR CEILING LIGHT

To replace the bulbs, proceed as

follows:

operate in the points indicated by

the arrows and remove the roof light D

fig. 168;

open protective flap E fig. 169;

replace the bulb F fig. 169 by

releasing it from the side contacts and

making sure that the new bulb is

correctly secured between the

contacts;

close the protective flap E fig. 169

and refit the roof light D fig. 168 in

its housing, making sure that it locks

into place.

166F1A0208

167F1A0209

168F1A0210

169F1A0211

157

Page 161 of 304

slowly rotate the screw

anticlockwise until resistance is

encountered (do not overtighten);

slowly release the screw;

opening is indicated by the entire

screw head coming out of its housing;

remove the cover.

To refit the cover proceed as follows:

join the cover with the box correctly;

fully tighten the captive screw using

the dedicated Phillips screwdriver

provided;

slowly rotate the screw clockwise

until resistance is encountered (do not

overtighten);

slowly release the screw;

closure is indicated by the inset of

the entire screw head in its housing.Engine compartment fusebox Optional wiring module 1

(2.3 130 / 150 Multijet 2 versions)

Optional wiring module 1

(2.3 150 ECOJET)

174F1A0216

175F1A0457-1

176F1A0458-1

159

Page 163 of 304

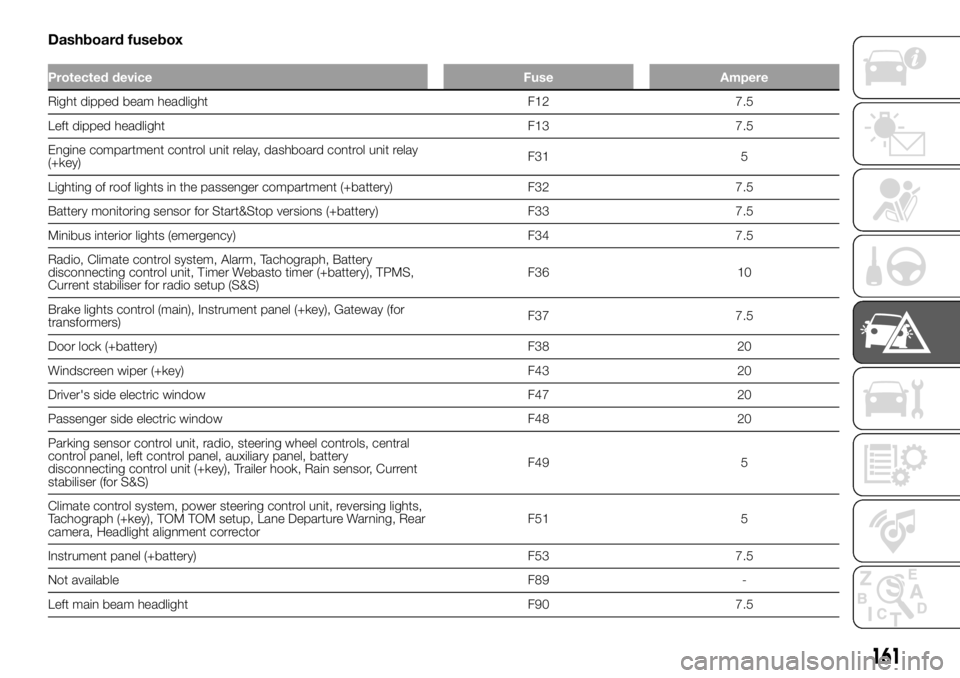

Dashboard fusebox

Protected device Fuse Ampere

Right dipped beam headlight F12 7.5

Left dipped headlight F13 7.5

Engine compartment control unit relay, dashboard control unit relay

(+key)F31 5

Lighting of roof lights in the passenger compartment (+battery) F32 7.5

Battery monitoring sensor for Start&Stop versions (+battery) F33 7.5

Minibus interior lights (emergency) F34 7.5

Radio, Climate control system, Alarm, Tachograph, Battery

disconnecting control unit, Timer Webasto timer (+battery), TPMS,

Current stabiliser for radio setup (S&S)F36 10

Brake lights control (main), Instrument panel (+key), Gateway (for

transformers)F37 7.5

Door lock (+battery) F38 20

Windscreen wiper (+key) F43 20

Driver's side electric window F47 20

Passenger side electric window F48 20

Parking sensor control unit, radio, steering wheel controls, central

control panel, left control panel, auxiliary panel, battery

disconnecting control unit (+key), Trailer hook, Rain sensor, Current

stabiliser (for S&S)F49 5

Climate control system, power steering control unit, reversing lights,

Tachograph (+key), TOM TOM setup, Lane Departure Warning, Rear

camera, Headlight alignment correctorF51 5

Instrument panel (+battery) F53 7.5

Not available F89 -

Left main beam headlight F90 7.5

161

Page 176 of 304

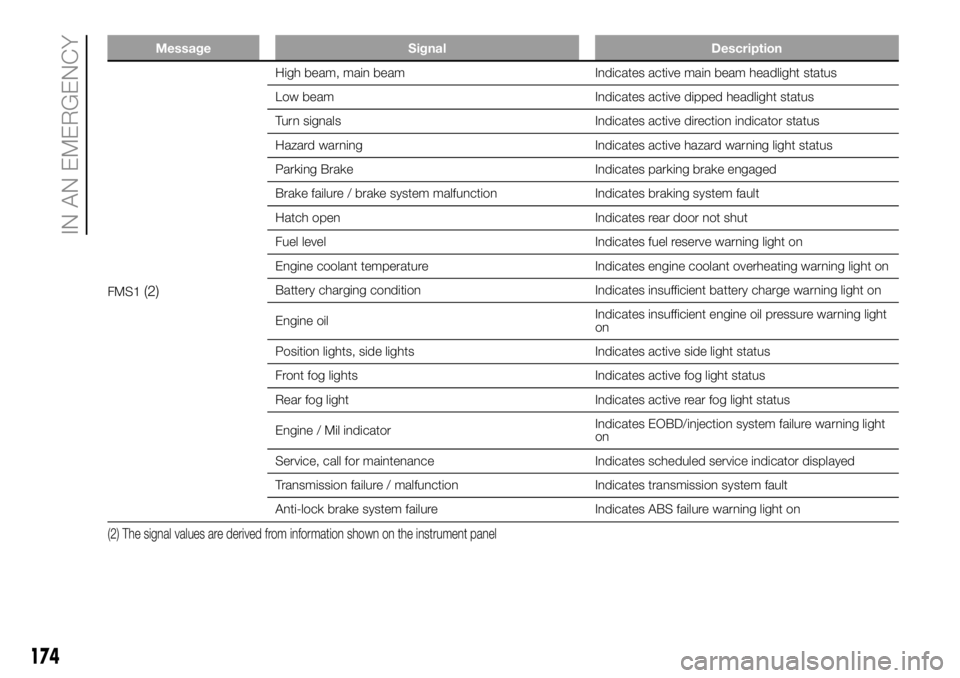

Message Signal Description

FMS1(2)

High beam, main beam Indicates active main beam headlight status

Low beam Indicates active dipped headlight status

Turn signals Indicates active direction indicator status

Hazard warning Indicates active hazard warning light status

Parking Brake Indicates parking brake engaged

Brake failure / brake system malfunction Indicates braking system fault

Hatch open Indicates rear door not shut

Fuel level Indicates fuel reserve warning light on

Engine coolant temperature Indicates engine coolant overheating warning light on

Battery charging condition Indicates insufficient battery charge warning light on

Engine oilIndicates insufficient engine oil pressure warning light

on

Position lights, side lights Indicates active side light status

Front fog lights Indicates active fog light status

Rear fog light Indicates active rear fog light status

Engine / Mil indicatorIndicates EOBD/injection system failure warning light

on

Service, call for maintenance Indicates scheduled service indicator displayed

Transmission failure / malfunction Indicates transmission system fault

Anti-lock brake system failure Indicates ABS failure warning light on

(2) The signal values are derived from information shown on the instrument panel

174

IN AN EMERGENCY

Page 177 of 304

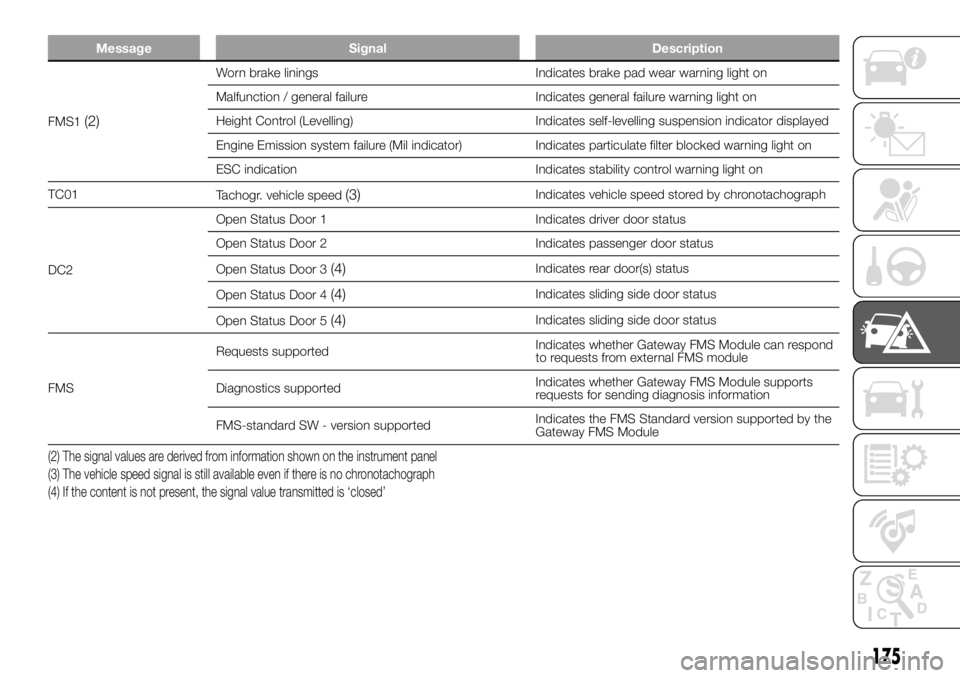

Message Signal Description

FMS1(2)

Worn brake linings Indicates brake pad wear warning light on

Malfunction / general failure Indicates general failure warning light on

Height Control (Levelling) Indicates self-levelling suspension indicator displayed

Engine Emission system failure (Mil indicator) Indicates particulate filter blocked warning light on

ESC indication Indicates stability control warning light on

TC01

Tachogr. vehicle speed

(3)Indicates vehicle speed stored by chronotachograph

DC2Open Status Door 1 Indicates driver door status

Open Status Door 2 Indicates passenger door status

Open Status Door 3

(4)Indicates rear door(s) status

Open Status Door 4

(4)Indicates sliding side door status

Open Status Door 5

(4)Indicates sliding side door status

FMSRequests supportedIndicates whether Gateway FMS Module can respond

to requests from external FMS module

Diagnostics supportedIndicates whether Gateway FMS Module supports

requests for sending diagnosis information

FMS-standard SW - version supportedIndicates the FMS Standard version supported by the

Gateway FMS Module

(2) The signal values are derived from information shown on the instrument panel

(3) The vehicle speed signal is still available even if there is no chronotachograph

(4) If the content is not present, the signal value transmitted is ‘closed’

175

Page 179 of 304

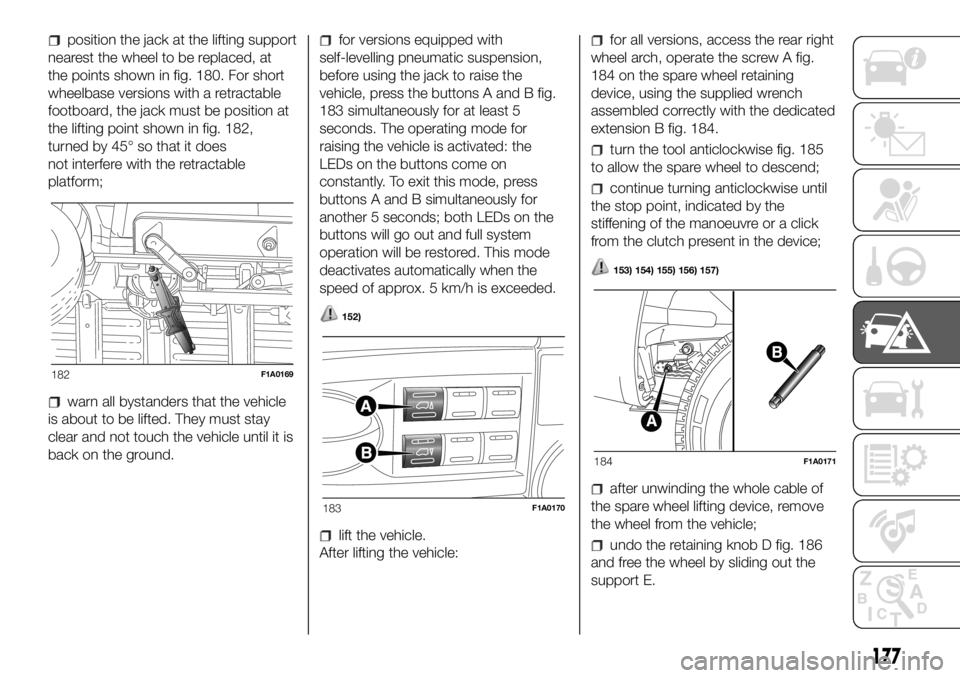

position the jack at the lifting support

nearest the wheel to be replaced, at

the points shown in fig. 180. For short

wheelbase versions with a retractable

footboard, the jack must be position at

the lifting point shown in fig. 182,

turned by 45° so that it does

not interfere with the retractable

platform;

warn all bystanders that the vehicle

is about to be lifted. They must stay

clear and not touch the vehicle until it is

back on the ground.

for versions equipped with

self-levelling pneumatic suspension,

before using the jack to raise the

vehicle, press the buttons A and B fig.

183 simultaneously for at least 5

seconds. The operating mode for

raising the vehicle is activated: the

LEDs on the buttons come on

constantly. To exit this mode, press

buttons A and B simultaneously for

another 5 seconds; both LEDs on the

buttons will go out and full system

operation will be restored. This mode

deactivates automatically when the

speed of approx. 5 km/h is exceeded.

152)

lift the vehicle.

After lifting the vehicle:

for all versions, access the rear right

wheel arch, operate the screw A fig.

184 on the spare wheel retaining

device, using the supplied wrench

assembled correctly with the dedicated

extension B fig. 184.

turn the tool anticlockwise fig. 185

to allow the spare wheel to descend;

continue turning anticlockwise until

the stop point, indicated by the

stiffening of the manoeuvre or a click

from the clutch present in the device;

153) 154) 155) 156) 157)

after unwinding the whole cable of

the spare wheel lifting device, remove

the wheel from the vehicle;

undo the retaining knob D fig. 186

and free the wheel by sliding out the

support E.

182F1A0169

183F1A0170

184F1A0171

177

Page 180 of 304

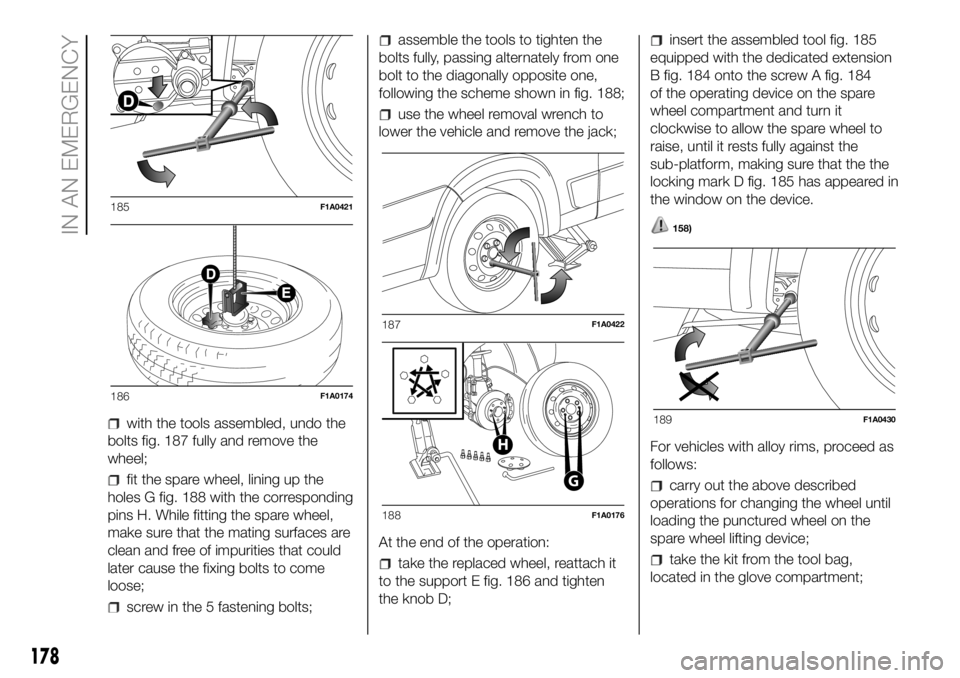

with the tools assembled, undo the

bolts fig. 187 fully and remove the

wheel;

fit the spare wheel, lining up the

holes G fig. 188 with the corresponding

pins H. While fitting the spare wheel,

make sure that the mating surfaces are

clean and free of impurities that could

later cause the fixing bolts to come

loose;

screw in the 5 fastening bolts;

assemble the tools to tighten the

bolts fully, passing alternately from one

bolt to the diagonally opposite one,

following the scheme shown in fig. 188;

use the wheel removal wrench to

lower the vehicle and remove the jack;

At the end of the operation:

take the replaced wheel, reattach it

to the support E fig. 186 and tighten

the knob D;

insert the assembled tool fig. 185

equipped with the dedicated extension

B fig. 184 onto the screw A fig. 184

of the operating device on the spare

wheel compartment and turn it

clockwise to allow the spare wheel to

raise, until it rests fully against the

sub-platform, making sure that the the

locking mark D fig. 185 has appeared in

the window on the device.

158)

For vehicles with alloy rims, proceed as

follows:

carry out the above described

operations for changing the wheel until

loading the punctured wheel on the

spare wheel lifting device;

take the kit from the tool bag,

located in the glove compartment;

185F1A0421

186F1A0174

187F1A0422

G

H

188F1A0176

189F1A0430

178

IN AN EMERGENCY