steering FIAT FULLBACK 2016 1.G Service Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: FULLBACK, Model: FIAT FULLBACK 2016 1.GPages: 312, PDF Size: 13.67 MB

Page 205 of 312

WARNING

281)If the vehicle is towed with the ignition

switch in the “ON” position or the operation

mode in ON and only the front wheels or

only the rear wheels raised off the ground,

the active traction control system may

operate, resulting in an accident.

282)If your vehicle equipped with the

Active Stability & Traction Control system

(ASTC), if the vehicle is towed with the

ignition switch in the “ON” position or the

operation mode in ON and only the front

wheels or only the rear wheels raised off

the ground, the active traction control

system may operate, resulting in an

accident.

283)Avoid sudden braking, acceleration

and steering wheel movements; such

driving operation could cause damage to

the towing hook or towing rope. People in

the vicinity could be injured as a result.284)When going down a long slope, the

brakes may overheat, reducing

effectiveness. Have your vehicle transport

by a tow truck.

285)The person in the vehicle being towed

must pay attention to the brake lamps of

the towing vehicle and make sure the rope

never becomes slack.

286)Do not use flexible cables for towing

and avoid jerking. During towing

operations, make sure that the fastened

joint does not damage adjoining

components.

287)When towing the vehicle comply with

the specific rules of the Highway Code

regarding the towing device and the

behaviour on the road.

288)Do not start the engine while towing

the vehicle.

289)Towing must be made exclusively on

roads/streets; the device must not be used

to recover the vehicle if it got off the road.

290)Towing must not be made for getting

past significant obstacles on the road (e.g.

heaps of snow or material on the road

surface).

291)Towing must take place with the two

vehicles (one towing, the other towed)

aligned as much as possible; towing by

roadside assistance vehicles, too, must

take place with the two vehicles aligned as

much as possible.

IMPORTANT

138)This vehicle must not be towed by a

tow truck using sling lift type equipment

(Type A) as illustrated. Using a sling lift will

damage the bumper and front end.

139)On 4WD vehicles, be sure to set the

drive mode-selector to “2H” position and

transport the vehicle with the driving wheels

on a carriage (Type D or E) as illustrated.

Never try to tow with the drive

mode-selector in “4H” or “4L” positions

(easy select 4WD), “4H”, “4HLc” or “4LLc”

positions (super select 4WD II) and with the

front or rear wheels on the ground (Type B

or C) as illustrated. This could result in the

driving system damage or vehicle may

jump at the carriage. If you cannot set the

drive mode-selector to “2H” position or the

transmission is malfunctioning or damaged,

transport the vehicle with the all wheels on

a carriage (Type D or E) as illustrated.

140)On 2WD vehicles, if the transmission

is malfunctioning or damaged, transport the

vehicle with the driving wheels on a

carriage (Type C, D or E) as illustrated.

141)If you tow the vehicles with automatic

transmission with the driving wheels on the

ground (Type B) as illustrated, make sure

that the towing speed and distance given

below are never exceeded, causing

damage to the transmission. Towing speed:

30 km/h Towing distance: 80 km For the

towing speed and the towing distance,

follow the local driving laws and

regulations.

340AHZ101027

203

Page 206 of 312

142)Never tow an automatic transmission

vehicle with the front wheels up (and the

rear wheels on the ground) (Type B) when

the automatic transmission fluid level is low.

This may cause serious and expensive

damage to the transmission.

143)When the engine is not running, the

brake booster and power steering pump do

not operate. This means higher brake

depression force and higher steering effort

are required. Therefore, vehicle operation is

very difficult.

144)Do not leave the ignition switch in the

“LOCK” position or the operation mode in

OFF. The steering wheel will lock, causing

loss of control.

145)On vehicles with super select 4WD II,

when you are going to tow another vehicle,

set the drive mode-selector to “4H”

position. Selecting “2H” drive may increase

the differential oil temperature, resulting in

possible damage to the driving system.

Further, the drive train will be subjected to

excessive loading possibly leading to oil

leakage, component seizure, or other

serious faults.OPERATION UNDER

ADVERSE DRIVING

CONDITIONS

On a flooded road

Avoid flooded roads. Water could enter

the brake discs, resulting in temporarily

ineffective brakes. In such cases, lightly

depress the brake pedal to see if the

brakes operate properly. If they do not,

lightly depress the pedal several times

while driving in order to dry the brake

pads.

When driving in rain or on a road with

many puddles a layer of water may

form between the tyres and the road

surface. This reduces a tyre’s frictional

resistance on the road, resulting in loss

of steering stability and braking

capability.

To cope with this, observe the following

items:

(a) Drive your vehicle at a slow speed.

(b) Do not drive on worn tyres.

(c) Always maintain the specified tyre

inflation pressures.On a snow-covered or frozen road

When driving on a snow-covered or

frozen road, it is recommended that you

use snow tyres or snow traction device

(tyre chains). Refer to the “Snow tyres”

and “Snow traction device (tyre chains)”

sections.

Avoid high-speed operation, sudden

acceleration, abrupt brake application

and sharp cornering.

Depressing the brake pedal during

travel on snowy or icy roads may cause

tyre slippage and skidding. When

traction between the tyres and the road

is reduced the wheels may skid and the

vehicle cannot readily be brought to a

stop by conventional braking

techniques. Braking will differ,

depending upon whether you have

anti-lock brake system (ABS). If you do

have ABS, brake by pressing the brake

pedal hard, and keeping it pressed. If

you do not have ABS, pump the brake

pedal with short rapid jabs, each time

fully applying and fully releasing for

greatest effect.

Allow extra distance between your

vehicle and the vehicle in front of you,

and avoid sudden braking.

Accumulation of ice on the braking

system can cause the wheels to lock.

Pull away from a standstill slowly after

confirming safety around the vehicle.

292)

204

IN CASE OF EMERGENCY

Page 214 of 312

Fuse replacement

294) 295) 296) 297) 298)

147)

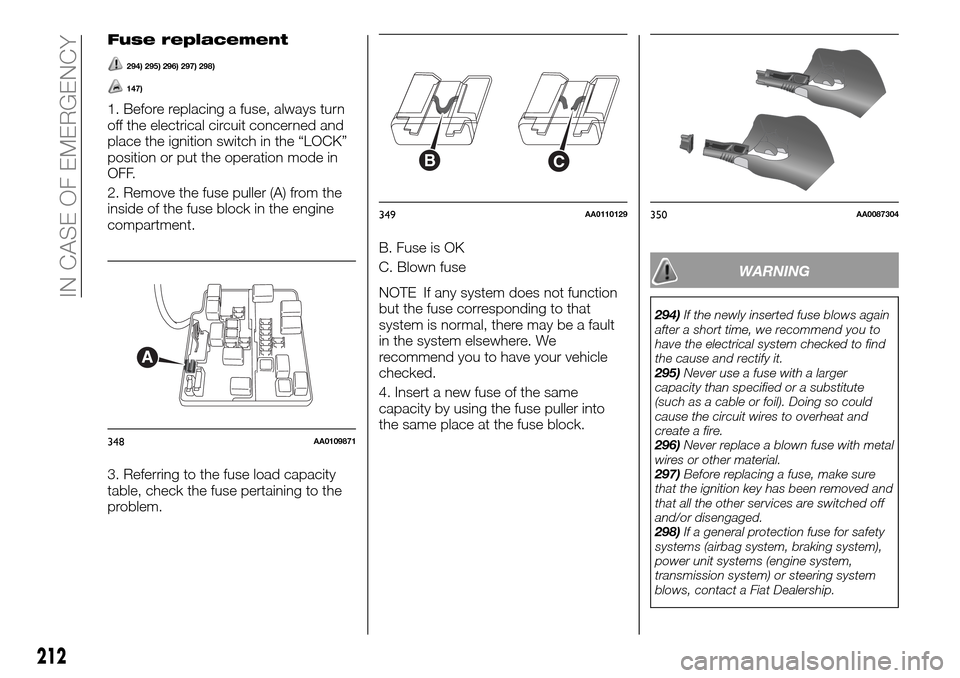

1. Before replacing a fuse, always turn

off the electrical circuit concerned and

place the ignition switch in the “LOCK”

position or put the operation mode in

OFF.

2. Remove the fuse puller (A) from the

inside of the fuse block in the engine

compartment.

3. Referring to the fuse load capacity

table, check the fuse pertaining to the

problem.B. Fuse is OK

C. Blown fuse

NOTE If any system does not function

but the fuse corresponding to that

system is normal, there may be a fault

in the system elsewhere. We

recommend you to have your vehicle

checked.

4. Insert a new fuse of the same

capacity by using the fuse puller into

the same place at the fuse block.

WARNING

294)If the newly inserted fuse blows again

after a short time, we recommend you to

have the electrical system checked to find

the cause and rectify it.

295)Never use a fuse with a larger

capacity than specified or a substitute

(such as a cable or foil). Doing so could

cause the circuit wires to overheat and

create a fire.

296)Never replace a blown fuse with metal

wires or other material.

297)Before replacing a fuse, make sure

that the ignition key has been removed and

that all the other services are switched off

and/or disengaged.

298)If a general protection fuse for safety

systems (airbag system, braking system),

power unit systems (engine system,

transmission system) or steering system

blows, contact a Fiat Dealership.

A

348AA0109871

BC

349AA0110129350AA0087304

212

IN CASE OF EMERGENCY

Page 218 of 312

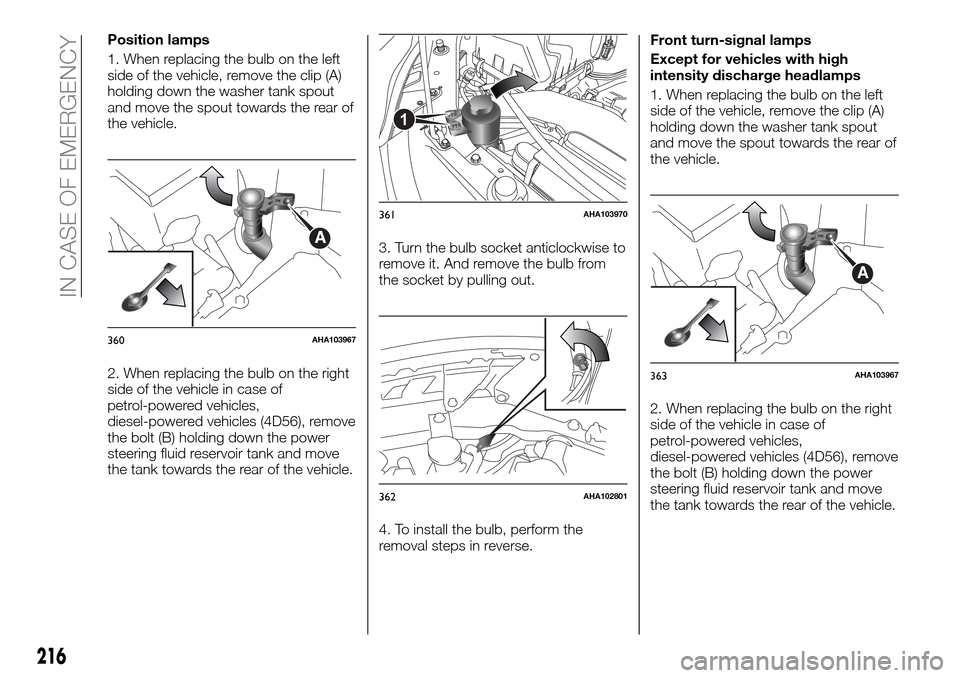

Position lamps

1. When replacing the bulb on the left

side of the vehicle, remove the clip (A)

holding down the washer tank spout

and move the spout towards the rear of

the vehicle.

2. When replacing the bulb on the right

side of the vehicle in case of

petrol-powered vehicles,

diesel-powered vehicles (4D56), remove

the bolt (B) holding down the power

steering fluid reservoir tank and move

the tank towards the rear of the vehicle.3. Turn the bulb socket anticlockwise to

remove it. And remove the bulb from

the socket by pulling out.

4. To install the bulb, perform the

removal steps in reverse.Front turn-signal lamps

Except for vehicles with high

intensity discharge headlamps

1. When replacing the bulb on the left

side of the vehicle, remove the clip (A)

holding down the washer tank spout

and move the spout towards the rear of

the vehicle.

2. When replacing the bulb on the right

side of the vehicle in case of

petrol-powered vehicles,

diesel-powered vehicles (4D56), remove

the bolt (B) holding down the power

steering fluid reservoir tank and move

the tank towards the rear of the vehicle.

A

360AHA103967

11

361AHA103970

362AHA102801

A

363AHA103967

216

IN CASE OF EMERGENCY

Page 219 of 312

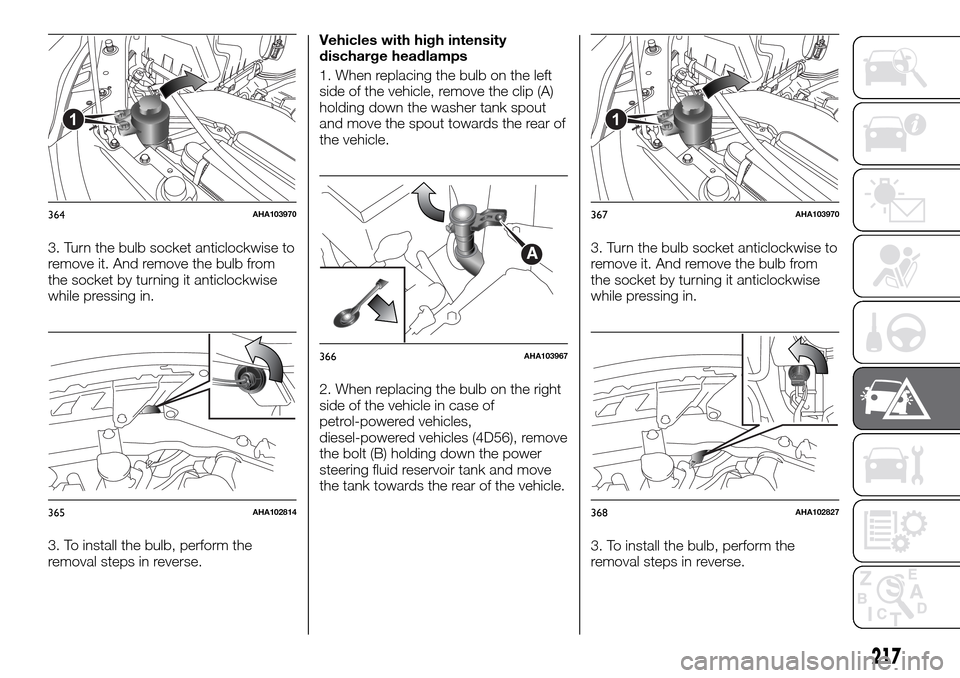

3. Turn the bulb socket anticlockwise to

remove it. And remove the bulb from

the socket by turning it anticlockwise

while pressing in.

3. To install the bulb, perform the

removal steps in reverse.Vehicles with high intensity

discharge headlamps

1. When replacing the bulb on the left

side of the vehicle, remove the clip (A)

holding down the washer tank spout

and move the spout towards the rear of

the vehicle.

2. When replacing the bulb on the right

side of the vehicle in case of

petrol-powered vehicles,

diesel-powered vehicles (4D56), remove

the bolt (B) holding down the power

steering fluid reservoir tank and move

the tank towards the rear of the vehicle.3. Turn the bulb socket anticlockwise to

remove it. And remove the bulb from

the socket by turning it anticlockwise

while pressing in.

3. To install the bulb, perform the

removal steps in reverse.

11

364AHA103970

365AHA102814

A

366AHA103967

11

367AHA103970

368AHA102827

217

Page 225 of 312

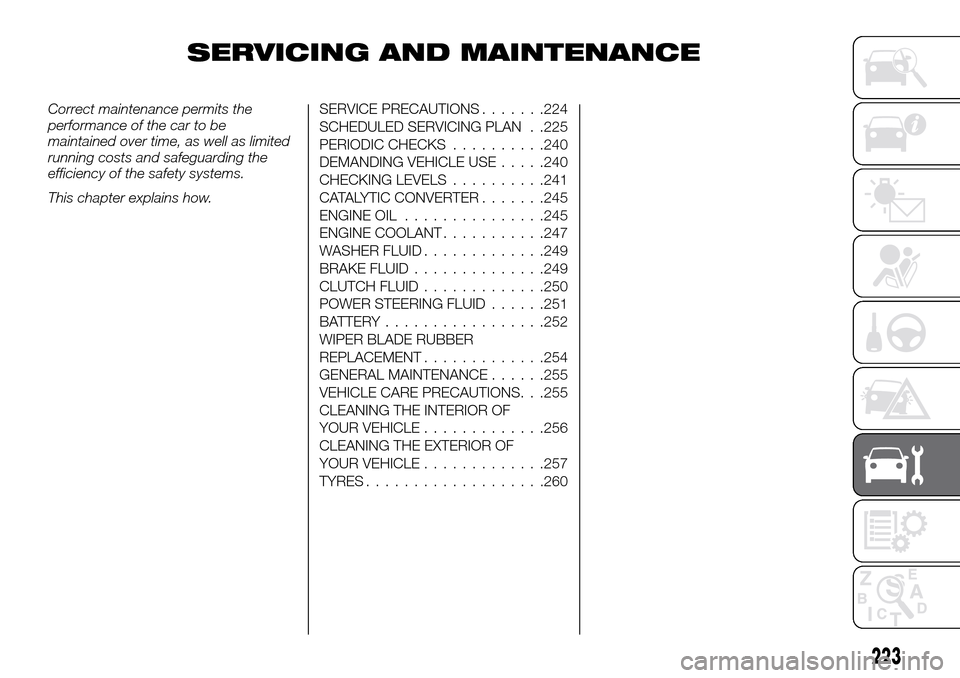

SERVICING AND MAINTENANCE

Correct maintenance permits the

performance of the car to be

maintained over time, as well as limited

running costs and safeguarding the

efficiency of the safety systems.

This chapter explains how.SERVICE PRECAUTIONS.......224

SCHEDULED SERVICING PLAN . .225

PERIODIC CHECKS..........240

DEMANDING VEHICLE USE.....240

CHECKING LEVELS..........241

CATALYTIC CONVERTER.......245

ENGINE OIL...............245

ENGINE COOLANT...........247

WASHER FLUID.............249

BRAKE FLUID..............249

CLUTCH FLUID.............250

POWER STEERING FLUID......251

BATTERY.................252

WIPER BLADE RUBBER

REPLACEMENT.............254

GENERAL MAINTENANCE......255

VEHICLE CARE PRECAUTIONS. . .255

CLEANING THE INTERIOR OF

YOUR VEHICLE.............256

CLEANING THE EXTERIOR OF

YOUR VEHICLE.............257

TYRES...................260

223

Page 228 of 312

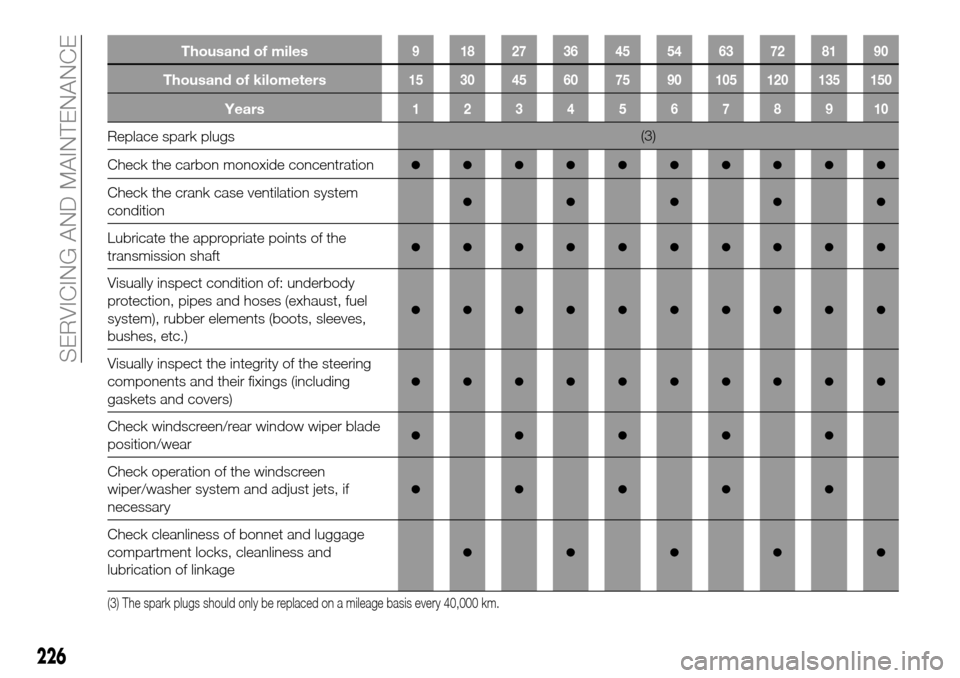

Thousand of miles9 182736455463728190

Thousand of kilometers15 30 45 60 75 90 105 120 135 150

Years12345678910

Replace spark plugs(3)

Check the carbon monoxide concentration

●●●●●●●●●●

Check the crank case ventilation system

condition●●●●●

Lubricate the appropriate points of the

transmission shaft●●●●●●●●●●

Visually inspect condition of: underbody

protection, pipes and hoses (exhaust, fuel

system), rubber elements (boots, sleeves,

bushes, etc.)

●●●●●●●●●●

Visually inspect the integrity of the steering

components and their fixings (including

gaskets and covers)

●●●●●●●●●●

Check windscreen/rear window wiper blade

position/wear●●●●●

Check operation of the windscreen

wiper/washer system and adjust jets, if

necessary

●●●●●

Check cleanliness of bonnet and luggage

compartment locks, cleanliness and

lubrication of linkage

●●●●●

(3) The spark plugs should only be replaced on a mileage basis every 40,000 km.

226

SERVICING AND MAINTENANCE

Page 233 of 312

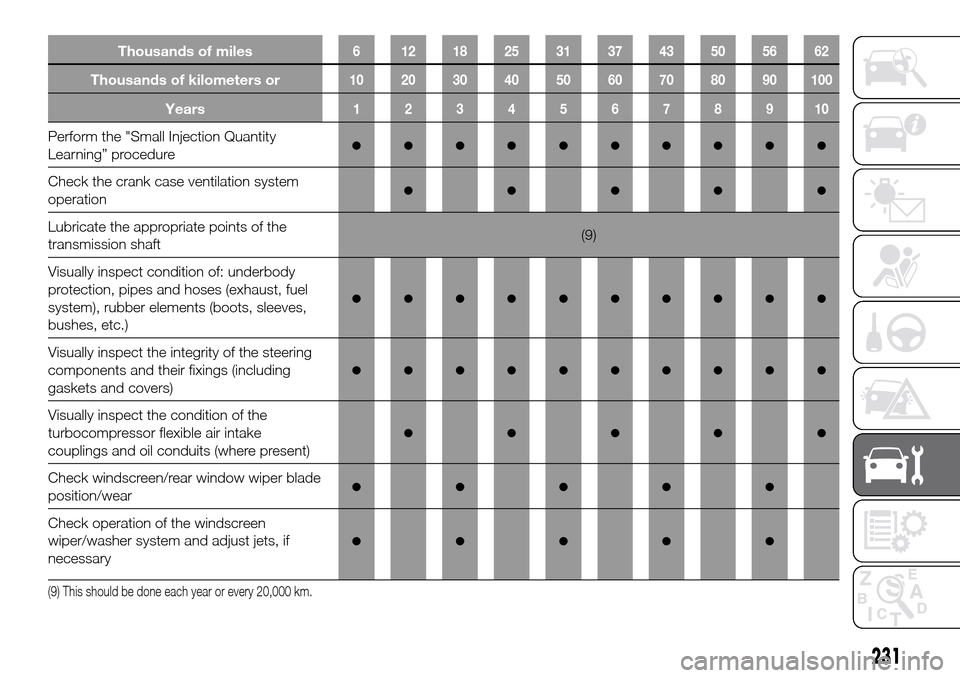

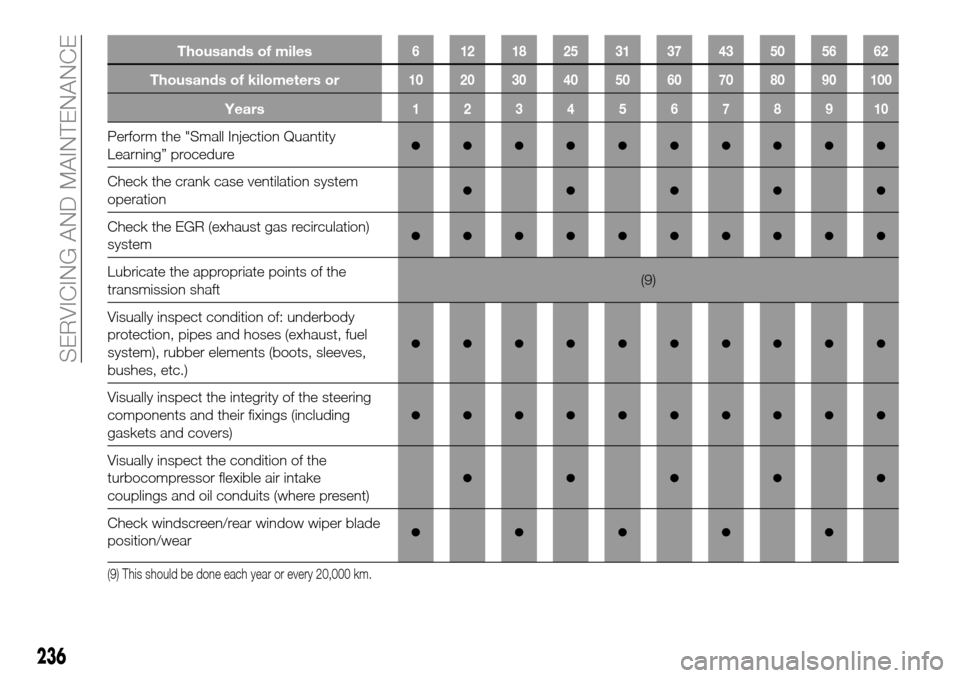

Thousands of miles6 121825313743505662

Thousands of kilometers or10 20 30 40 50 60 70 80 90 100

Years12345678910

Perform the "Small Injection Quantity

Learning” procedure●●●●●●●●●●

Check the crank case ventilation system

operation●●●●●

Lubricate the appropriate points of the

transmission shaft(9)

Visually inspect condition of: underbody

protection, pipes and hoses (exhaust, fuel

system), rubber elements (boots, sleeves,

bushes, etc.)

●●●●●●●●●●

Visually inspect the integrity of the steering

components and their fixings (including

gaskets and covers)

●●●●●●●●●●

Visually inspect the condition of the

turbocompressor flexible air intake

couplings and oil conduits (where present)

●●●●●

Check windscreen/rear window wiper blade

position/wear●●●●●

Check operation of the windscreen

wiper/washer system and adjust jets, if

necessary

●●●●●

(9) This should be done each year or every 20,000 km.

231

Page 238 of 312

Thousands of miles6 121825313743505662

Thousands of kilometers or10 20 30 40 50 60 70 80 90 100

Years12345678910

Perform the "Small Injection Quantity

Learning” procedure●●●●●●●●●●

Check the crank case ventilation system

operation●●●●●

Check the EGR (exhaust gas recirculation)

system●●●●●●●●●●

Lubricate the appropriate points of the

transmission shaft(9)

Visually inspect condition of: underbody

protection, pipes and hoses (exhaust, fuel

system), rubber elements (boots, sleeves,

bushes, etc.)

●●●●●●●●●●

Visually inspect the integrity of the steering

components and their fixings (including

gaskets and covers)

●●●●●●●●●●

Visually inspect the condition of the

turbocompressor flexible air intake

couplings and oil conduits (where present)

●●●●●

Check windscreen/rear window wiper blade

position/wear●●●●●

(9) This should be done each year or every 20,000 km.

236

SERVICING AND MAINTENANCE

Page 243 of 312

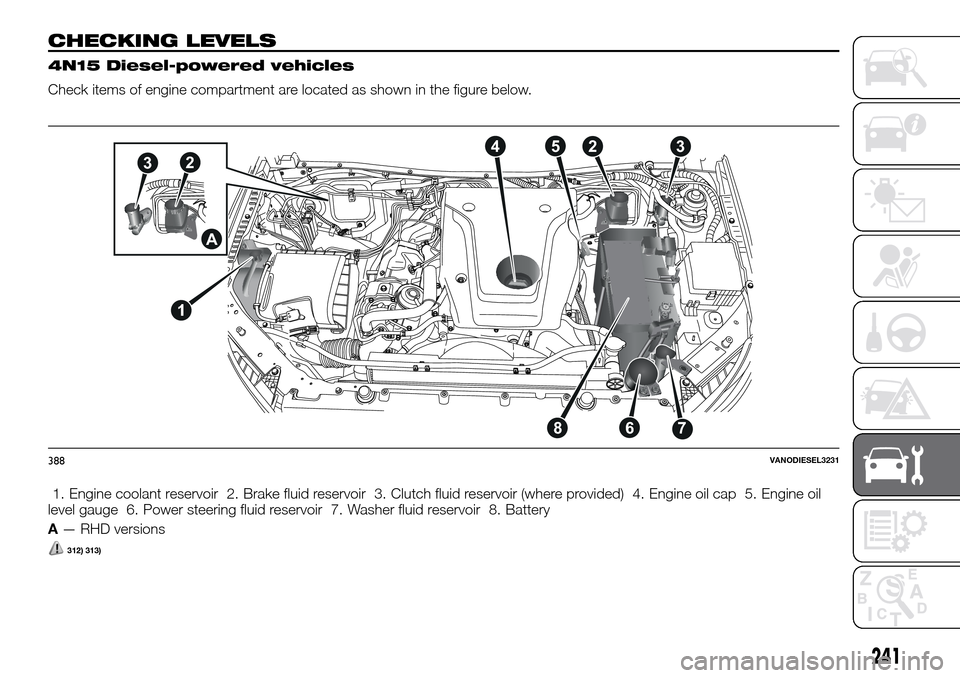

CHECKING LEVELS

4N15 Diesel-powered vehicles

Check items of engine compartment are located as shown in the figure below.

1. Engine coolant reservoir 2. Brake fluid reservoir 3. Clutch fluid reservoir (where provided) 4. Engine oil cap 5. Engine oil

level gauge 6. Power steering fluid reservoir 7. Washer fluid reservoir 8. Battery

A— RHD versions

312) 313)

A

1

42253

3

678

388VANODIESEL3231

241