replace light FIAT PANDA 2009 169 / 2.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2009, Model line: PANDA, Model: FIAT PANDA 2009 169 / 2.GPages: 226, PDF Size: 5.29 MB

Page 122 of 226

121KNOW

YOUR VEHICLE

SAFETYCORRECT USE

OF THE CARWARNING LIGHTS

AND MESSAGES

IN

AN EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

SNOW TYRESUse snow tyres of the same size as the normal tyres pro-

vided with the car.

Fiat Dealership will be happy to provide advice concern-

ing the most suitable type of tyres for the customer’s re-

quirements.

For the type of tyre to be used, inflation pressures and the

specifications of snow tyres, follow the instructions given

in paragraph “Wheels” in section “Technical specifica-

tions”.

The winter features of these tyres are reduced consider-

ably when the tread depth is below 4 mm. Replace them

in this case.

Due to snow tyre features, under normal conditions of

use or on long motorway journeys, the performance of

these tyres is much lower than that of standard tyres. Lim-

it performance according to the use for which they were

certified.

IMPORTANT When snow tyres are used with a max.

speed index below the one that can be reached by the

car (increased by 5%), place a notice in the passenger’s

compartment, plainly in the driver’s view which states the

max. permissible speed of the snow tyres (as per EC

Directive).

The max. speed of snow tyres with “Q”

marking is 160 km/h. The Highway Code

speed limits must however be always complied

with.

WARNING

All four tyres should be the same (brand and track) to

ensure greater safety when driving and braking and bet-

ter driveability.

Remember that it is inappropriate to change the rotation

direction of tyres.

111-122 PANDA EN 7-10-2009 15:01 Pagina 121

Page 138 of 226

137KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGESIN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

REPLACING A WHEELGENERAL INSTRUCTIONS

The car can be delivered (upon request/where provided)

with standard spare wheel or space-saver wheel; see

changing instructions on the following paragraphs. Wheel

changing and correct use of the jack and spare wheel call

for some precautions as listed below.

The space-saver wheel (where provided) is

specific to your car, do not use it on other

models, nor use the spare wheel of other models

on your car. The space-saver wheel must only be

used in case of emergency. It shall only be used for

the distance necessary to reach a service point and

the car speed shall not exceed 80 km/h. The spare

wheel has an orange sticker that summarises the

main cautions for use and limitations. The sticker

should never be removed or covered. Never apply

a wheel cup on a space-saver wheel. The sticker

gives the following information in four languages:

Caution! For temporary use only! 80 km/h max.!

Replace by standard wheel as soon as possible. Do

not cover this label in use. If you change the type

of wheel (alloy rims instead of steel rims) you will

have to change the entire set of fastening bolts with

another set of suitably sized bolts.

WARNING

Alert other drivers that the car is station-

ary in compliance with local regulations:

hazard warning lights, warning triangle, etc. Any

passengers on board should leave the car, espe-

cially if it is heavily laden. Passengers should stay

away from on-coming traffic while the wheel is

being changed. If parked on a slope or rough sur-

face, chock the wheels with wedges or other suit-

able devices.

WARNING

The driving features of the car may change

when a space-saver wheel is fitted. Avoid

sudden acceleration and braking, sudden steering

and fast cornering. The total life of a space-saver

wheel is approximately 3000 km, after which it

must be replaced by another wheel of the same

type. Never attempt to fit a conventional tyre on

a rim designed for use as a space-saver wheel.

Have the punctured wheel repaired and replaced

as soon as possible. Two or more space-saver

wheels should never be used together. Do not

grease the threads of bolts before installing them:

they might slip out.

WARNING

135-168 PANDA EN 7-10-2009 14:06 Pagina 137

Page 139 of 226

138KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGES

IN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

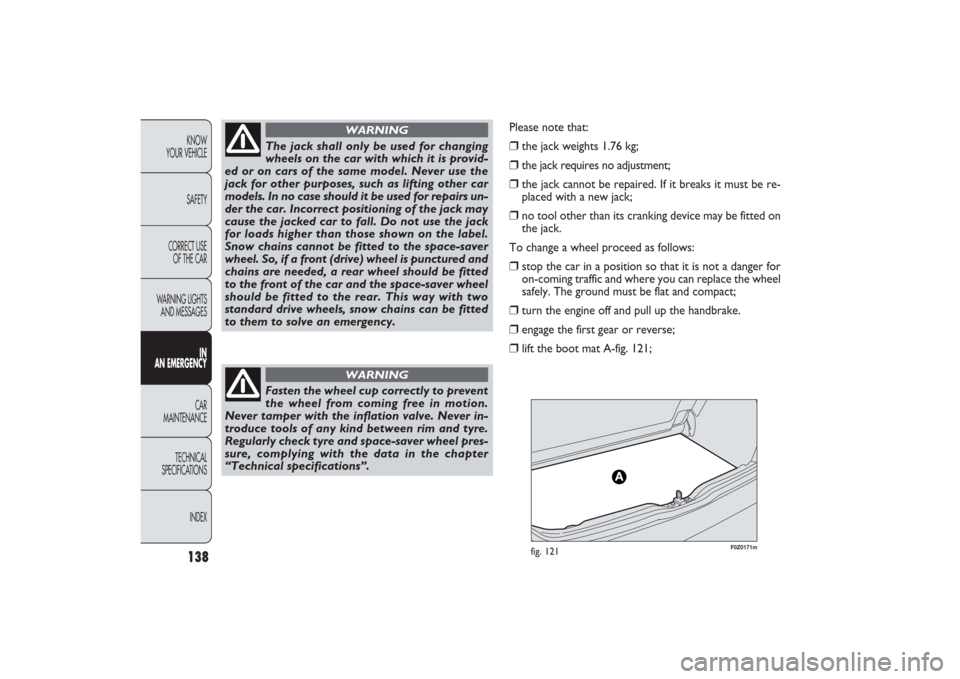

F0Z0171m

fig. 121

Please note that:❒

the jack weights 1.76 kg;

❒

the jack requires no adjustment;

❒

the jack cannot be repaired. If it breaks it must be re-

placed with a new jack;

❒

no tool other than its cranking device may be fitted on

the jack.

To change a wheel proceed as follows:

❒

stop the car in a position so that it is not a danger for

on-coming traffic and where you can replace the wheel

safely. The ground must be flat and compact;

❒

turn the engine off and pull up the handbrake.

❒

engage the first gear or reverse;

❒

lift the boot mat A-fig. 121;

Fasten the wheel cup correctly to prevent

the wheel from coming free in motion.

Never tamper with the inflation valve. Never in-

troduce tools of any kind between rim and tyre.

Regularly check tyre and space-saver wheel pres-

sure, complying with the data in the chapter

“Technical specifications”.

WARNING

The jack shall only be used for changing

wheels on the car with which it is provid-

ed or on cars of the same model. Never use the

jack for other purposes, such as lifting other car

models. In no case should it be used for repairs un-

der the car. Incorrect positioning of the jack may

cause the jacked car to fall. Do not use the jack

for loads higher than those shown on the label.

Snow chains cannot be fitted to the space-saver

wheel. So, if a front (drive) wheel is punctured and

chains are needed, a rear wheel should be fitted

to the front of the car and the space-saver wheel

should be fitted to the rear. This way with two

standard drive wheels, snow chains can be fitted

to them to solve an emergency.

WARNING

135-168 PANDA EN 7-10-2009 14:06 Pagina 138

Page 140 of 226

139KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGESIN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

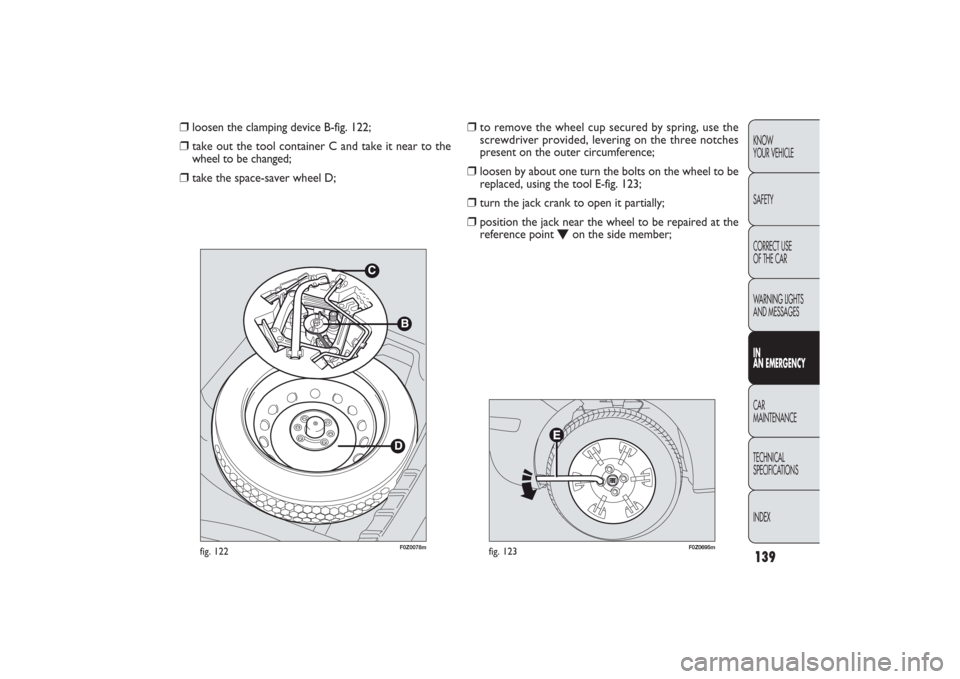

F0Z0078m

fig. 122

F0Z0695m

fig. 123

❒

to remove the wheel cup secured by spring, use the

screwdriver provided, levering on the three notches

present on the outer circumference;

❒

loosen by about one turn the bolts on the wheel to be

replaced, using the tool E-fig. 123;

❒

turn the jack crank to open it partially;

❒

position the jack near the wheel to be repaired at the

reference point

O

on the side member;

❒

loosen the clamping device B-fig. 122;

❒

take out the tool container C and take it near to the

wheel to be changed;

❒

take the space-saver wheel D;

135-168 PANDA EN 7-10-2009 14:06 Pagina 139

Page 144 of 226

143KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGESIN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

At the end of the procedure❒

stow the space-saving wheel D-fig. 122 in the space pro-

vided in the boot;

❒

fit the partially-open jack in its box C by forcing it slight-

ly to prevent it from vibrating when travelling;

❒

put the tools back into their locations;

❒

arrange the container and tools in the spare wheel and

secure the clamping device B;

❒

correctly reposition the boot stiff cover.

IMPORTANT Do not use inner tubes with tubeless tyres.

Check the inflation pressure of the tyres and the space-

saving wheel regularly.

IMPORTANT You will need to change the set of bolts if

you want to change the type of wheels fitted (alloy rims

instead of steel rims, and vice versa).The whole set of fas-

tening bolts must be replaced by another set of suitably

sized bolts and use a special space-saving wheel having dif-

ferent building characteristics.

You should keep the bolts and space-saving wheel in case

you decide to use the original type of wheel later on.

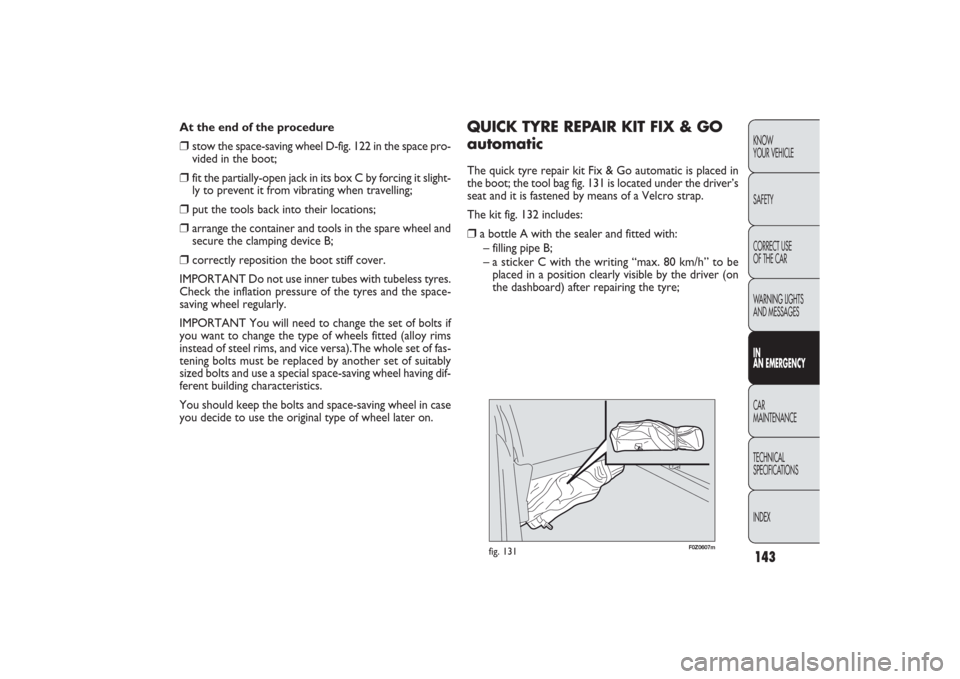

F0Z0607m

fig. 131

QUICK TYRE REPAIR KIT FIX & GO

automaticThe quick tyre repair kit Fix & Go automatic is placed in

the boot; the tool bag fig. 131 is located under the driver’s

seat and it is fastened by means of a Velcro strap.

The kit fig. 132 includes:❒

a bottle A with the sealer and fitted with:

– filling pipe B;

– a sticker C with the writing “max. 80 km/h” to be

placed in a position clearly visible by the driver (on

the dashboard) after repairing the tyre;

135-168 PANDA EN 7-10-2009 14:06 Pagina 143

Page 147 of 226

146KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGES

IN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0Z0697m

fig. 134

F0Z0672m

fig. 135

❒

make sure that the compressor switch D-fig. 135 is in

position 0 (off), start the engine, fit the plug E-fig. 136

in the 12 V-socket in the central tunnel and operate the

compressor turning the switch D-fig. 135 to position I

(on). Inflate the tyre at the pressure value specified in

paragraph “Inflation pressure” in chapter “Technical

specifications”.

For a more accurate reading, check pressure gauge

F-fig. 135 with the compressor off;

❒

if after five minutes it is still impossible to reach at least

1.5 bar, disengage the compressor from the valve and

current socket, then move the car forth for approx. ten

metres in order to distribute the sealing fluid inside

the tyre evenly, then repeat the inflation operation;

INFLATING PROCEDURE

Replace the bottle containing out of date

sealant fluid. Dispose of the bottle and the

sealant liquid properly. Dispose according

to the national and local regulations in force.Put on the protection gloves provided to-

gether with quick tyre repair kit.

WARNING

❒

Ensure that the handbrake is engaged. Remove the tyre

valve cap, extract the flexible filler tube A-fig. 134 and

fasten the ring B onto the tyre valve;

135-168 PANDA EN 7-10-2009 14:07 Pagina 146

Page 149 of 226

148KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGES

IN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0Z0699m

fig. 138

F0Z0676m

fig. 139

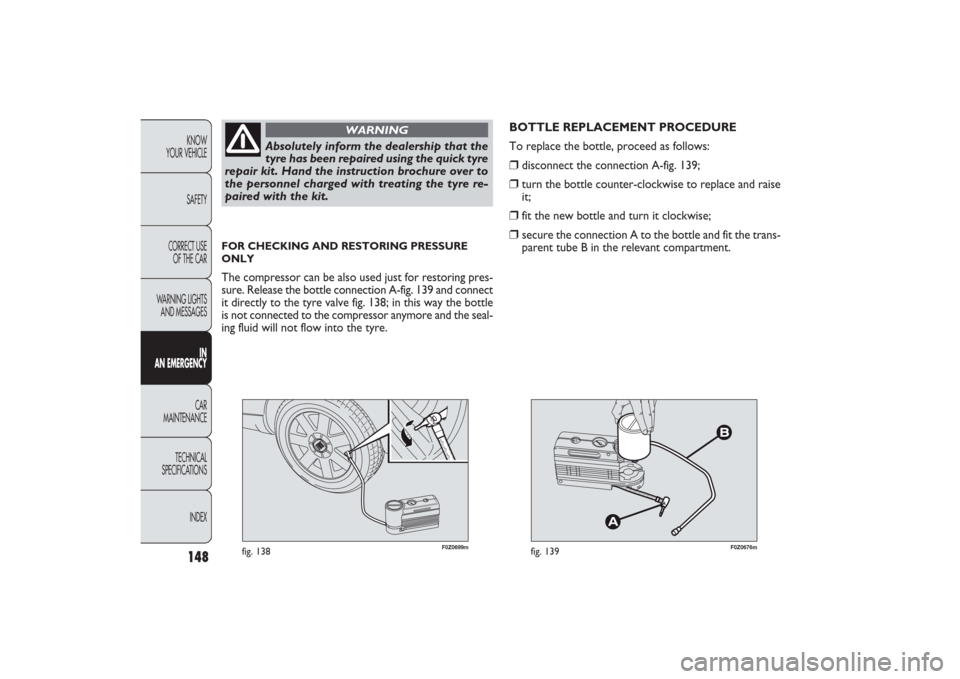

BOTTLE REPLACEMENT PROCEDURE

To replace the bottle, proceed as follows:❒

disconnect the connection A-fig. 139;

❒

turn the bottle counter-clockwise to replace and raise

it;

❒

fit the new bottle and turn it clockwise;

❒

secure the connection A to the bottle and fit the trans-

parent tube B in the relevant compartment.

Absolutely inform the dealership that the

tyre has been repaired using the quick tyre

repair kit. Hand the instruction brochure over to

the personnel charged with treating the tyre re-

paired with the kit.

WARNING

FOR CHECKING AND RESTORING PRESSURE

ONLYThe compressor can be also used just for restoring pres-

sure. Release the bottle connection A-fig. 139 and connect

it directly to the tyre valve fig. 138; in this way the bottle

is not connected to the compressor anymore and the seal-

ing fluid will not flow into the tyre.

135-168 PANDA EN 7-10-2009 14:07 Pagina 148

Page 150 of 226

149KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGESIN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

CHANGING A BULBGENERAL INSTRUCTIONS❒

Before changing a bulb check the contacts for oxidation;

❒

burnt bulbs must be replaced by others of the same type

and power;

❒

always check the headlight beam aiming after changing

a bulb;

❒

when a light is not working, check that the corre-

sponding fuse is intact before changing a bulb. For the

location of fuses, refer to the paragraph “Replacing fus-

es” in this chapter.

Modifications or repairs to the electric sys-

tem that are not carried out properly or

do not take the system technical specifications in-

to account can cause malfunctions leading to the

risk of fire.

WARNING

Halogen bulbs contain gas under pressure;

if they break, glass fragments may be dis-

persed.

WARNING

When handling halogen bulbs, only touch

the metal part. If the transparent bulb is

touched with the fingers, its lighting inten-

sity is reduced and life of the bulb may be com-

promised. In the event of accidental contact, wipe

the bulb with a cloth moistened with alcohol

and leave it to dry.

IMPORTANT The headlight inner surface might be slight-

ly misted: this should not be considered irregular rather

a natural phenomenon due to low temperature and the air

humidity level. Misting will disappear as soon as the head-

lights are turned on. The presence of drops inside the

headlights indicates infiltration of water. Contact a Fiat

Dealership.

Where possible, it is advisable to have bulbs

changed at a Fiat Dealership. The correct

operation and aiming of the outer lights are

absolutely important to the safety of the car and

its passengers and the subject of specific laws about

road traffic.

135-168 PANDA EN 7-10-2009 14:07 Pagina 149

Page 154 of 226

153KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGESIN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0Z0092m

fig. 144

F0Z0094m

fig. 146

F0Z0093m

fig. 145

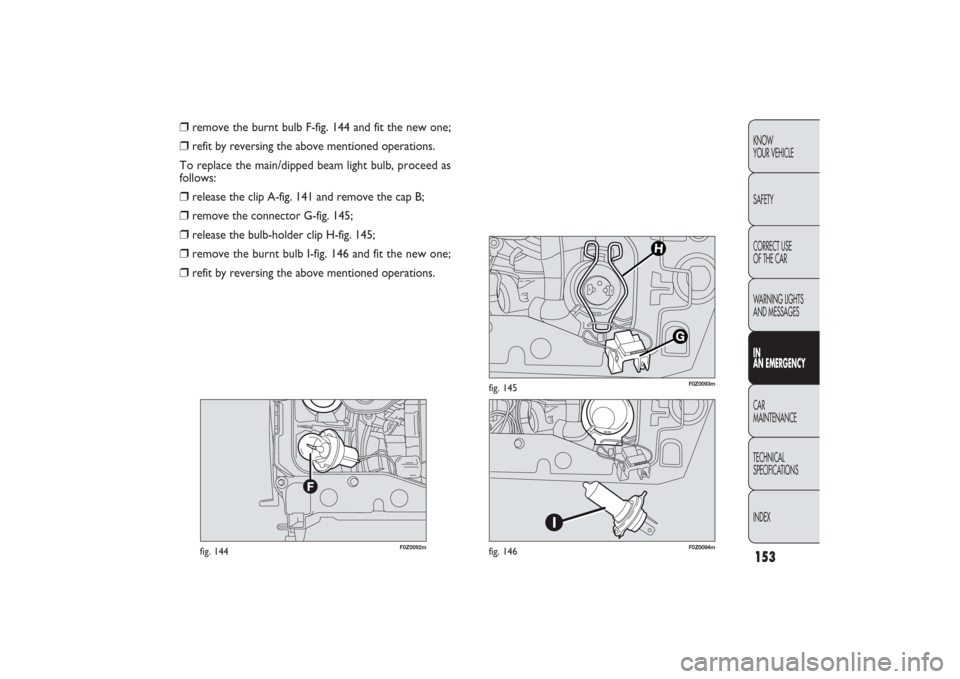

❒

remove the burnt bulb F-fig. 144 and fit the new one;

❒

refit by reversing the above mentioned operations.

To replace the main/dipped beam light bulb, proceed as

follows:

❒

release the clip A-fig. 141 and remove the cap B;

❒

remove the connector G-fig. 145;

❒

release the bulb-holder clip H-fig. 145;

❒

remove the burnt bulb I-fig. 146 and fit the new one;

❒

refit by reversing the above mentioned operations.

135-168 PANDA EN 7-10-2009 14:07 Pagina 153

Page 155 of 226

154KNOW

YOUR VEHICLE

SAFETY

CORRECT USE

OF THE CAR

WARNING LIGHTS

AND MESSAGES

IN

AN EMERGENCYCAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

F0Z0095m

fig. 147

F0Z0227m

fig. 149

F0Z0604m

fig. 148

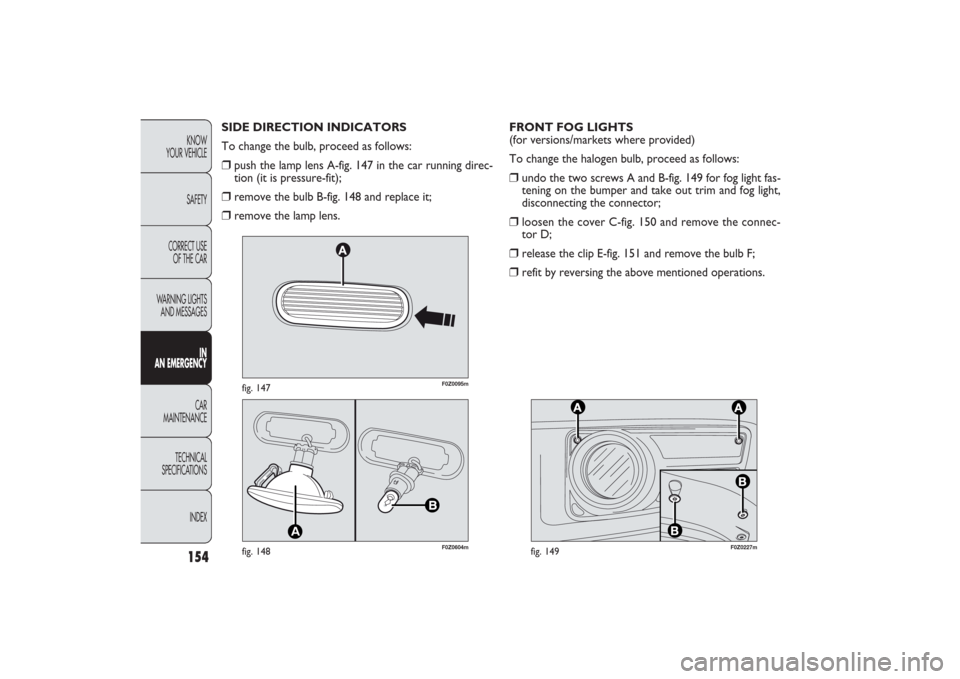

FRONT FOG LIGHTS

(for versions/markets where provided)

To change the halogen bulb, proceed as follows:❒

undo the two screws A and B-fig. 149 for fog light fas-

tening on the bumper and take out trim and fog light,

disconnecting the connector;

❒

loosen the cover C-fig. 150 and remove the connec-

tor D;

❒

release the clip E-fig. 151 and remove the bulb F;

❒

refit by reversing the above mentioned operations. SIDE DIRECTION INDICATORS

To change the bulb, proceed as follows:

❒

push the lamp lens A-fig. 147 in the car running direc-

tion (it is pressure-fit);

❒

remove the bulb B-fig. 148 and replace it;

❒

remove the lamp lens.

135-168 PANDA EN 7-10-2009 14:07 Pagina 154