FIAT SCUDO 2011 Owner handbook (in English)

Manufacturer: FIAT, Model Year: 2011, Model line: SCUDO, Model: FIAT SCUDO 2011Pages: 210, PDF Size: 3.29 MB

Page 171 of 210

170

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

❒Spraying of plastic parts, with a protec-

tive function in the more exposed

points: underdoor, inner fender parts,

edges, etc;

❒ Use of “open” boxed sections to pre-

vent condensation and pockets of mois-

ture from triggering rust inside.

BODY AND UNDERBODY

WARRANTY

Your vehicle is covered by warranty

against perforation due to rust of any orig-

inal element of the structure or body.

For the general terms of this warranty, re-

fer to Fiat Warranty Booklet.

ADVICE FOR PRESERVING THE

BODYWORK

Paintwork

The paintwork is not only to make your

vehicle look attractive but also to protect

the steel.

In the case of deep scrapes or scores, you

are advised to have the necessary touching

up carried out immediately to avoid the for-

mation of rust. For touching up use only

original products (see “Bodywork paint

identification plate” in section “Technical

specifications”).

BODYWORK

PROTECTION FROM

ATMOSPHERIC AGENTS

The main causes of corrosion are the fol-

lowing:

❒ atmospheric pollution;

❒ salty air and humidity (coastal areas, or

hot humid climates);

❒ seasonal environment conditions.

Not to be underestimated is also the abra-

sive action of wind-borne atmospheric

dust and sand and mud and gravel raised

by other vehicles.

On your vehicle, Fiat implemented the

best manufacturing technologies to effec-

tively protect the bodywork against cor-

rosion.

These are the most important:

❒ Painting products and systems which

give the vehicle particular resistance to

corrosion and abrasion;

❒ Use of galvanised (or pretreated) steel

sheets, with high resistance to corro-

sion;

❒ Spraying the underbody, engine com-

partment, wheelhouse internal parts

and other parts with highly protective

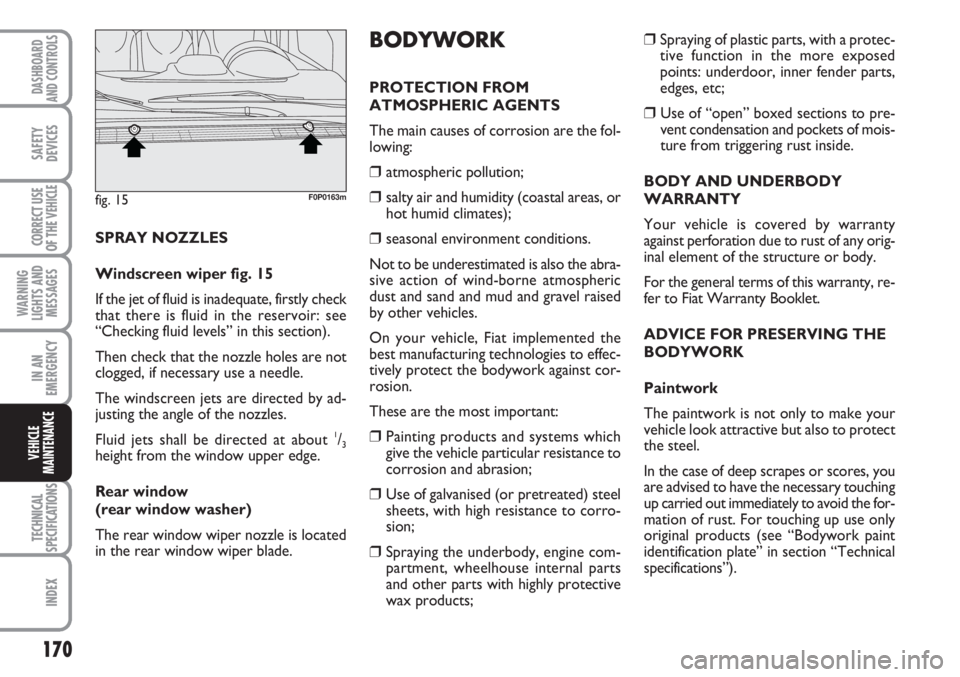

wax products; SPRAY NOZZLES

Windscreen wiper fig. 15

If the jet of fluid is inadequate, firstly check

that there is fluid in the reservoir: see

“Checking fluid levels” in this section).

Then check that the nozzle holes are not

clogged, if necessary use a needle.

The windscreen jets are directed by ad-

justing the angle of the nozzles.

Fluid jets shall be directed at about

1/3height from the window upper edge.

Rear window

(rear window washer)

The rear window wiper nozzle is located

in the rear window wiper blade.

fig. 15F0P0163m

Page 172 of 210

171

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

Normal paint maintenance consists in

washing at intervals depending on the con-

ditions and environment of use. For exam-

ple, in highly polluted areas, or if the roads

are sprayed with salt, it is wise to wash the

vehicle more frequently.

To correctly wash the vehicle:

❒ remove the aerial from the roof to pre-

vent damage to it if the vehicle is

washed in an automatic system;

❒ wash the body using a low pressure jet

of water;

❒ wipe a sponge with a slightly soapy so-

lution over the bodywork, frequently

rinsing with the sponge;

❒ rinse well with water and dry with a jet

of air or a chamois leather.

When drying, take particular care with the

less visible parts like door surrounds, bon-

net and around the headlights where wa-

ter may stagnate. The vehicle should not

be taken to a closed area immediately, but

left in the open so that residual water can

evaporate.Do not wash the vehicle after it has been

parked in the sun or while the bonnet is

hot: it could take the shine off the paint.

Outside plastic parts must be cleaned fol-

lowing the usual vehicle washing proce-

dure.

Where possible, do not park under trees;

the resinous substance many species re-

lease give the paint a dull appearance and

increase the possibility of triggering rust

processes.

IMPORTANT Bird droppings must be

washed off immediately and thoroughly as

the acid they contain is particularly ag-

gressive.

Detergents cause water pollu-

tion. Therefore the engine

compartment should be

washed in areas equipped for

collecting and purifying the liquid used

in the washing process.

Windows

Use specific window cleaner product. Use

also clean cloths to avoid scratching the

glass or damaging the transparency.

IMPORTANT The inside of the

rearscreen should be wiped gently with a

cloth in the direction of the filaments to

avoid damaging the heating device.

Engine compartment

At the end of the winter the engine com-

partment should be carefully washed,

without directing the jet against electron-

ic control units. Contact a specialised

workshop to have this done.

IMPORTANT The vehicle should be

washed with the engine cold and the ig-

nition key at S. After washing make sure

that the various protections (e.g. rubber

caps and various covers) have not been

damaged or removed.

Front headlights

IMPORTANT Never use aromatic sub-

stances (e.g.: petrol) or ketones (e.g.: ace-

tone) for cleaning front headlight plastic

lens.

Page 173 of 210

172

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

Fabric upholstery of your ve-

hicle is purpose-made to

withstand common wear re-

sulting from normal use of the

vehicle. It is however absolutely neces-

sary to prevent hard and/or prolonged

scratching/scraping caused by clothing

accessories like metallic buckles, studs,

“Velcro” fixings, etc. that stressing lo-

cally the fabric could break yarns and

damage the upholstery as a conse-

quence. CLEANING SEATS

AND FABRICS

Remove dust with a soft brush and vacu-

um cleaner. For velvet seats use a damp

brush.

Rub the seats with a sponge moistened

with a solution of water and neutral de-

tergent.Never use flammable prod-

ucts like oil ether or rectified

petrol for cleaning vehicle interiors.

Electrostatic discharges generated by

rubbing during cleaning operations

could cause fire.

WARNING

Do not keep aerosol cans in

the vehicle: they might ex-

plode. Aerosol cans must never be ex-

posed to a temperature above 50° C.

The temperature inside the vehicle

exposed to the sun may go well be-

yond that figure.

WARNING

INTERIORS

Periodically check that water is not trapped

under the mats (due to water dripping off

shoes, umbrellas, etc.) which could cause

oxidisation of the sheet metal.STEERING WHEEL/GEAR LEVER

KNOB WITH GENUINE

LEATHER COVERING

These components shall only be cleaned

with water and neutral soap.

Never use spirit or alcohol-based prod-

ucts.

Before using special products for clean-

ing interiors, read carefully label instruc-

tions and indications to make sure they

are free from spirit and/or alcohol-based

substances.

If when cleaning the windscreen with spe-

cial glass products, some drops fall on the

leather covering of the steering wheel/gear

lever knob remove them immediately and

then clean with water and neutral soap.

IMPORTANT Take the utmost care when

engaging the steering lock to prevent

scratching the leather covering.

INTERIOR PLASTIC PARTS

For routine cleaning of interior plastic parts

use a soft cloth moistened with water and

neutral soap. Remove grease or persisting

stains using appropriate solvent-free prod-

ucts designed to preserve appearance and

colour of plastic components.

IMPORTANT Never use spirit or petro-

leum to clean the instrument panel.

Page 174 of 210

173

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IDENTIFICATION DATA ................................................. 174

ENGINE CODES - BODYWORK VERSIONS .............. 177

ENGINE .................................................................................. 179

FUEL FEED/IGNITION ....................................................... 180

TRANSMISSION .................................................................. 180

BRAKES .................................................................................. 181

SUSPENSIONS ...................................................................... 181

STEERING .............................................................................. 181

WHEELS ................................................................................. 182

DIMENSIONS ....................................................................... 185

SIZE OF LOADING COMPARTMENT .......................... 189

PERFORMANCE .................................................................. 189

WEIGHTS AND TOWABLE LOADS ............................. 190

CAPACITIES .......................................................................... 196

FLUIDS AND LUBRICANTS ............................................. 197

FUEL CONSUMPTION ...................................................... 199

CO

2EMISSIONS .................................................................. 201

T T

E E

C C

H H

N N

I I

C C

A A

L L

S S

P P

E E

C C

I I

F F

I I

C C

A A

T T

I I

O O

N N

S S

Page 175 of 210

174

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

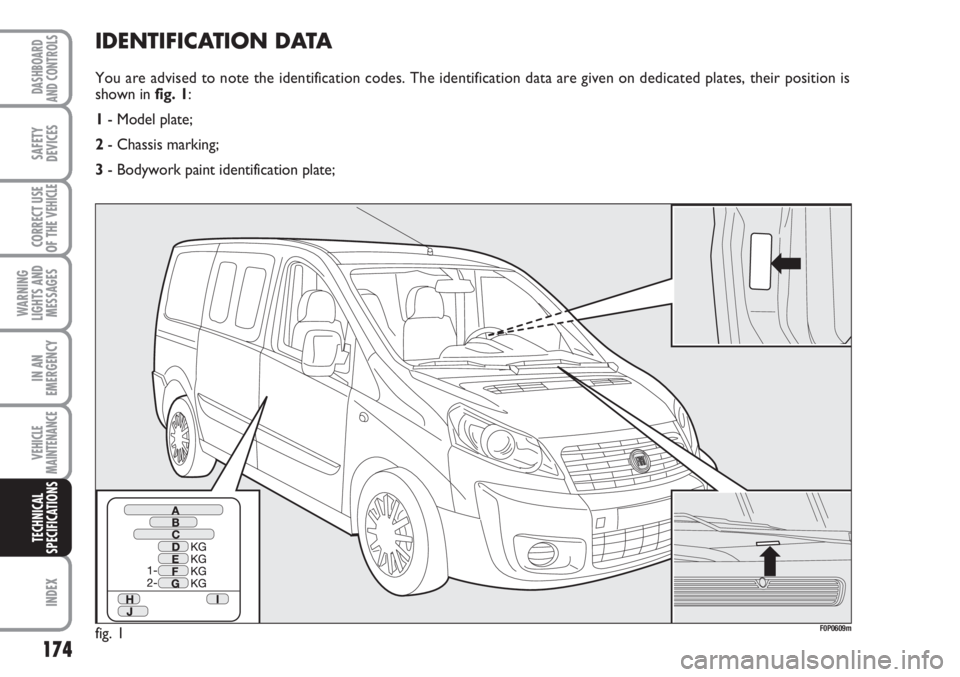

IDENTIFICATION DATA

You are advised to note the identification codes. The identification data are given on dedicated plates, their position is

shown in fig. 1:

1- Model plate;

2- Chassis marking;

3- Bodywork paint identification plate;

fig. 1F0P0609m

Page 176 of 210

175

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

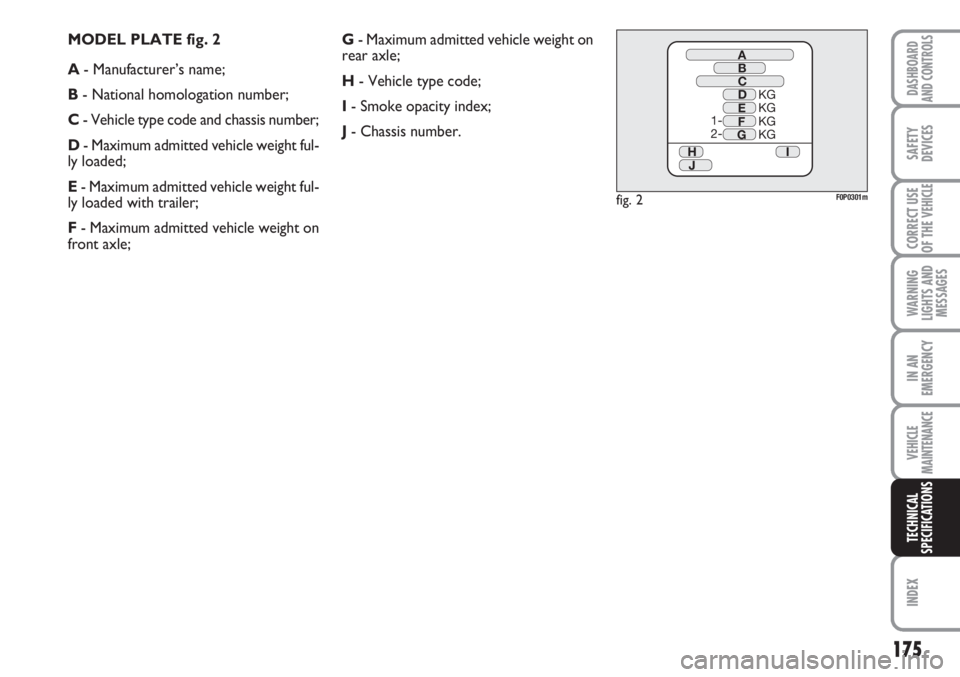

MODEL PLATE fig. 2

A- Manufacturer’s name;

B- National homologation number;

C- Vehicle type code and chassis number;

D- Maximum admitted vehicle weight ful-

ly loaded;

E- Maximum admitted vehicle weight ful-

ly loaded with trailer;

F- Maximum admitted vehicle weight on

front axle;G- Maximum admitted vehicle weight on

rear axle;

H- Vehicle type code;

I- Smoke opacity index;

J- Chassis number.

fig. 2

A

B

C

D

E

F

G

H

JI 1-

2-KG

KG

KG

KG

F0P0301m

Page 177 of 210

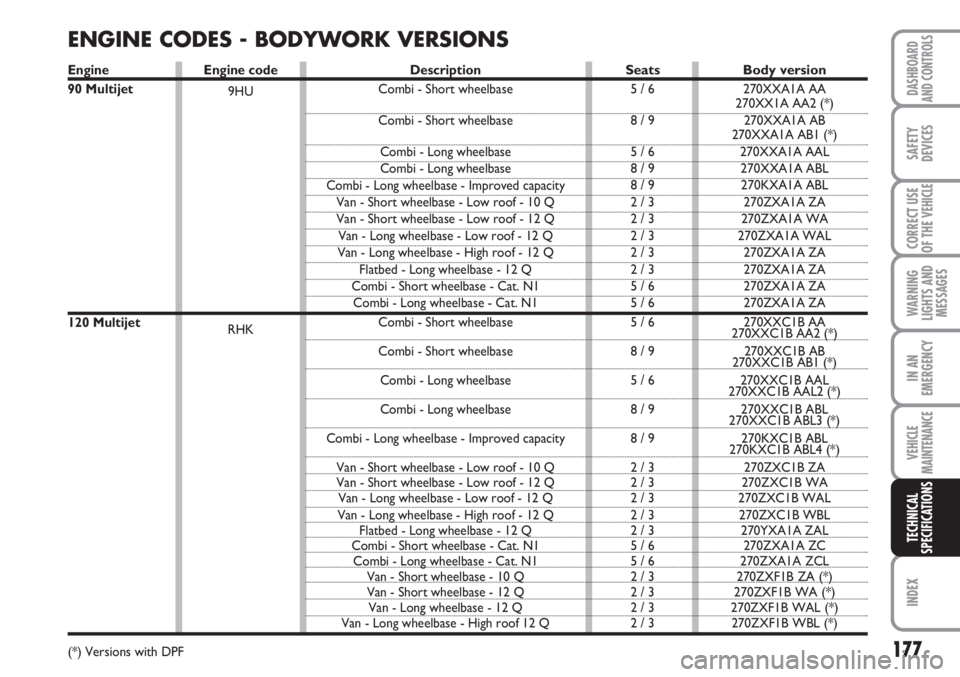

IDENTIFICATION PLATE

BODYWORK PAINT AND

TYRES fig. 4

The label attached to the upright, driver’s

side, indicates:

– The size of the wheel rims and the tyres;

– The brand of the tyres certified by the

manufacturer;

– The inflating pressure (the control of the

inflating pressure must be carried out

when stationary and at least once a

month):

– Paint colour code.

176

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

fig. 4

Bar Bar

PRESSIONS CONTROLLER PNEUS FROIDS (

0,05 bar)

A

B

C

D

E

F

G

H

I

F0P0304m

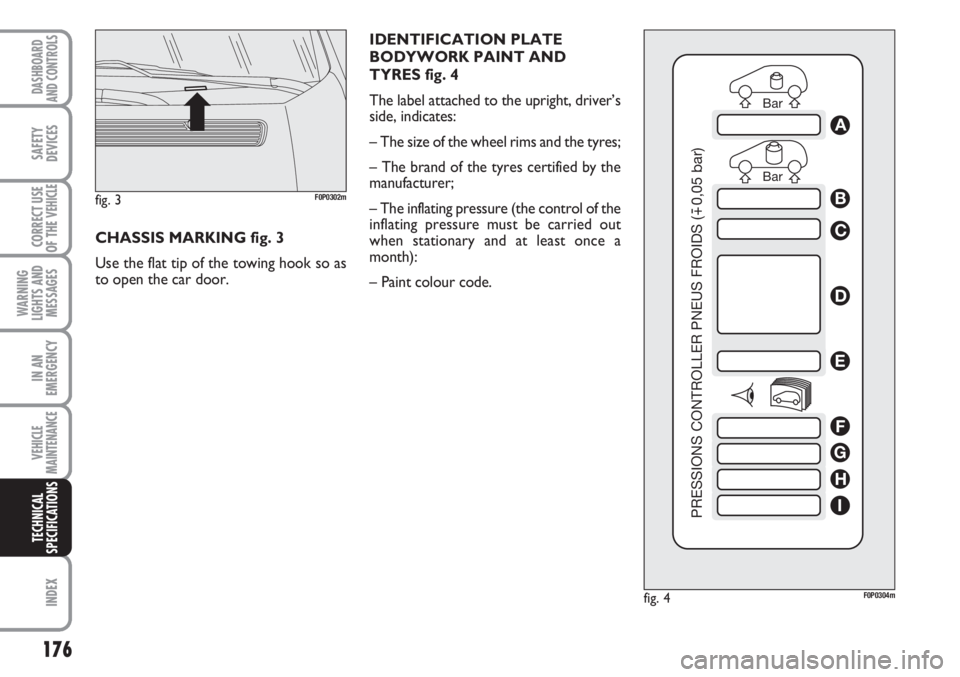

CHASSIS MARKING fig. 3

Use the flat tip of the towing hook so as

to open the car door.

fig. 3F0P0302m

Page 178 of 210

177

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

ENGINE CODES - BODYWORK VERSIONS

Engine code

9HU

RHKDescription

Combi - Short wheelbase

Combi - Short wheelbase

Combi - Long wheelbase

Combi - Long wheelbase

Combi - Long wheelbase - Improved capacity

Van - Short wheelbase - Low roof - 10 Q

Van - Short wheelbase - Low roof - 12 Q

Van - Long wheelbase - Low roof - 12 Q

Van - Long wheelbase - High roof - 12 Q

Flatbed - Long wheelbase - 12 Q

Combi - Short wheelbase - Cat. N1

Combi - Long wheelbase - Cat. N1

Combi - Short wheelbase

Combi - Short wheelbase

Combi - Long wheelbase

Combi - Long wheelbase

Combi - Long wheelbase - Improved capacity

Van - Short wheelbase - Low roof - 10 Q

Van - Short wheelbase - Low roof - 12 Q

Van - Long wheelbase - Low roof - 12 Q

Van - Long wheelbase - High roof - 12 Q

Flatbed - Long wheelbase - 12 Q

Combi - Short wheelbase - Cat. N1

Combi - Long wheelbase - Cat. N1

Van - Short wheelbase - 10 Q

Van - Short wheelbase - 12 Q

Van - Long wheelbase - 12 Q

Van - Long wheelbase - High roof 12 QBody version

270XXA1A AA

270XX1A AA2 (*)

270XXA1A AB

270XXA1A AB1 (*)

270XXA1A AAL

270XXA1A ABL

270KXA1A ABL

270ZXA1A ZA

270ZXA1A WA

270ZXA1A WAL

270ZXA1A ZA

270ZXA1A ZA

270ZXA1A ZA

270ZXA1A ZA

270XXC1B AA

270XXC1B AA2 (*)

270XXC1B AB

270XXC1B AB1 (*)

270XXC1B AAL

270XXC1B AAL2 (*)

270XXC1B ABL

270XXC1B ABL3 (*)

270KXC1B ABL

270KXC1B ABL4 (*)

270ZXC1B ZA

270ZXC1B WA

270ZXC1B WAL

270ZXC1B WBL

270YXA1A ZAL

270ZXA1A ZC

270ZXA1A ZCL

270ZXF1B ZA (*)

270ZXF1B WA (*)

270ZXF1B WAL (*)

270ZXF1B WBL (*)

Seats

5 / 6

8 / 9

5 / 6

8 / 9

8 / 9

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

5 / 6

5 / 6

5 / 6

8 / 9

5 / 6

8 / 9

8 / 9

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

5 / 6

5 / 6

2 / 3

2 / 3

2 / 3

2 / 3

Engine

90 Multijet

120 Multijet

(*) Versions with DPF

Page 179 of 210

178

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

Engine

120 Multijet

140 Multijet

165 Multijet

(*) Versions with DPF

Seats

2 / 3

5 / 6

5 / 6

8 / 9

8 / 9

5 / 6

5 / 6

5 / 6

8 / 9

5 / 6

8 / 9

8 / 9

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

5 / 6

5 / 6

8 / 9

8 / 9

8 / 9

2 / 3

2 / 3

2 / 3

2 / 3

2 / 3

5 / 6

5 / 6 Engine code

RHK

RHR

RHHDescription

Flatbed - Long wheelbase - 12 Q

Combi - Short wheelbase - 10 Q

Combi - Long wheelbase - 10 Q

Combi - Short wheelbase - 10 Q

Combi - Long wheelbase - 10 Q

Combi - Short wheelbase - 10 Q - Cat. N1

Combi - Long wheelbase - 10 Q - Cat. N1

Combi - Short wheelbase

Combi - Short wheelbase

Combi - Long wheelbase

Combi - Long wheelbase

Combi - Long wheelbase - Improved capacity

Van - Short wheelbase - Low roof - 10 Q

Van - Short wheelbase - Low roof - 12 Q

Van - Long wheelbase - Low roof - 12 Q

Van - Long wheelbase - High roof - 12 Q

Flatbed - Long wheelbase - 12 Q

Combi - Short wheelbase - Cat. N1

Combi - Long wheelbase - Cat. N1

Combi - Short wheelbase

Combi - Long wheelbase

Combi - Long wheelbase - Improved capacity

Van - Short wheelbase - Low roof - 10 Q

Van - Short wheelbase - Low roof - 12 Q

Van - Long wheelbase - Low roof - 12 Q

Van - Long wheelbase - High roof - 12 Q

Flatbed - Long wheelbase - 12 Q

Combi - Short wheelbase - Cat. N1

Combi - Long wheelbase - Cat. N1

Body version

270YXF1B WAL (*)

270XXF1B AA1 (*)

270XXF1B AAL1 (*)

270KXF1B AB1 (*)

270KXF1B AB2 (*)

270ZXF1B ZC (*)

270ZXF1B ZCL (*)

270XXD1B AA

270XXD1B AA2 (*)

270XXD1B AB

270XXD1B AB1 (*)

270XXD1B AAL

270XXD1B AAL2 (*)

270XXD1B ABL1

270KXD1B ABL1

270KXD1B ABL4 (*)

270KXD1B ABL5 (*)

270ZXD1B ZA

270ZXD1B WA

270ZXD1B WAL

270ZXD1B WBL

270YXD1B ZAL

270ZXD1B ZC

270ZXD1B ZCL

270KXG1B AB

270KXG1B ABL

270KXG1B ABL1

270ZXG1B ZA

270ZXG1B WA

270ZXG1B WAL

270ZXG1B WBL

270YXG1B WAL

270ZXG1B ZC

270ZXG1B ZCL

Page 180 of 210

179

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

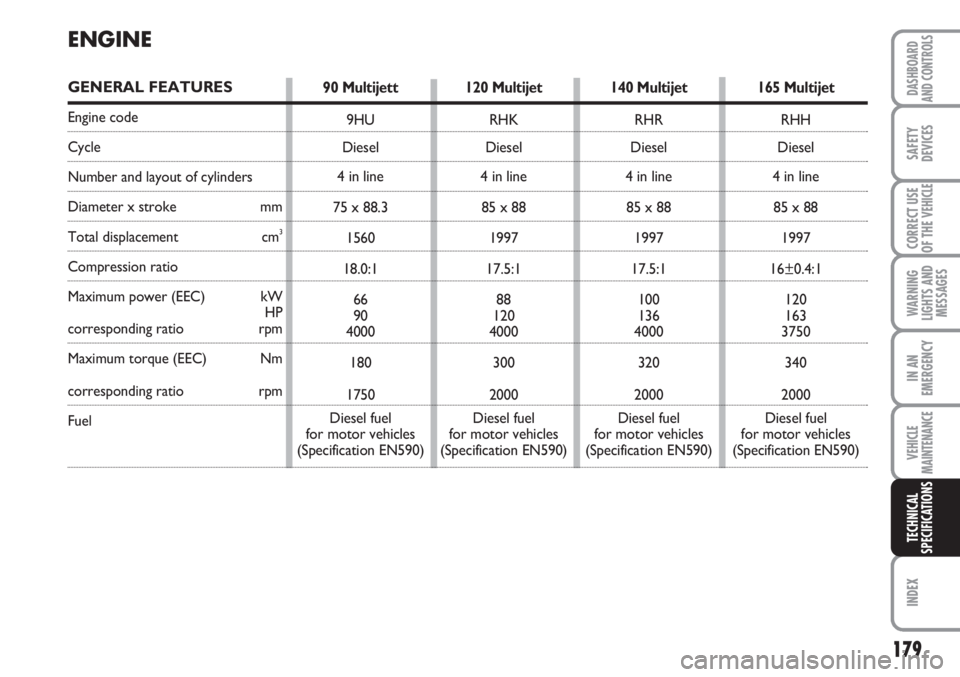

ENGINE

GENERAL FEATURES

Engine code

Cycle

Number and layout of cylinders

Diameter x stroke mm

Total displacement cm3

Compression ratio

Maximum power (EEC) kW

HP

corresponding ratio rpm

Maximum torque (EEC) Nm

corresponding ratio rpm

Fuel

90 Multijett

9HU

Diesel

4 in line

75 x 88.3

1560

18.0:1

66

90

4000

180

1750

Diesel fuel

for motor vehicles

(Specification EN590)

120 Multijet

RHK

Diesel

4 in line

85 x 88

1997

17.5:1

88

120

4000

300

2000

Diesel fuel

for motor vehicles

(Specification EN590)

140 Multijet

RHR

Diesel

4 in line

85 x 88

1997

17.5:1

100

136

4000

320

2000

Diesel fuel

for motor vehicles

(Specification EN590)

165 Multijet

RHH

Diesel

4 in line

85 x 88

1997

16±0.4:1

120

163

3750

340

2000

Diesel fuel

for motor vehicles

(Specification EN590)