FIAT UNO 1983 Service Repair Manual

Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 171 of 303

new oil seal, ensuring that it is correctly

orientated, and drive it squarely into position.

149Refit all disturbed components.

Flywheel - removal,

inspection and refitting#

150If not already done, remove the clutch as

described in Chapter 5.

151Prevent the flywheel from turning by

jamming the ring gear teeth, or by bolting a

strap between the flywheel and the cylinder

block.

152Make alignment marks on the flywheel

and the end of the crankshaft, so that the

flywheel can be refitted in its original position.

153Unscrew the securing bolts and remove

the washer plate, then withdraw the flywheel.

Do not drop it, it is very heavy.

154With the flywheel removed, the ring gear

can be examined for wear and damage.

155If the ring gear is badly worn or has

missing teeth it should be renewed. The old

ring gear can be removed from the flywheel by

cutting a notch between two teeth with a

hacksaw and then splitting it with a cold

chisel. Wear eye protection when doing this.

156Fitting of a new ring gear requires heating

the ring to a temperature of 80ºC (176ºF). Do

not overheat, or the hard-wearing properties

will be lost. The gear has a chamfered inner

edge which should fit against the shoulder on

the flywheel. When hot enough, place the gear

in position quickly, tapping it home ifnecessary, and let it cool naturally without

quenching in any way.

157Ensure that the mating faces are clean,

then locate the flywheel on the rear of the

crankshaft, aligning the previously made

marks on the flywheel and crankshaft.

158Fit the washer plate, and insert the

securing bolts, then prevent the flywheel from

turning as described in paragraph 151 whilst

the bolts are tightened progressively to the

specified torque setting in a diagonal

sequence (photos).

159If applicable, refit the clutch as described

in Chapter 5.

Sump -

removal and refittingÁ

160Drain the engine oil from the sump as

described in Chapter 1.

161Disconnect the lead from the engine oil

level sensor in the sump.

162Unscrew and remove the bolts retaining the

gear linkage mounting bracket (where applicable)

and the clutch housing lower cover bolts.

Remove the cover from the clutch housing.

163Unscrew and remove the sump retaining

bolts and nuts and lower the sump from the

crankcase. Recover the gasket.

164Clean all traces of old gasket from the

sump, crankcase and both oil seal housing

mating surfaces.

165Commence reassembly by applying

sealing compound (FIAT No. 5882442 orequivalent) to the joints between the

crankshaft front and rear oil seal housings and

the mating face of the crankcase (photo).

166Locate the new gasket in position on the

crankcase then fit the sump. As it is fitted it

will need to be twisted to avoid fouling the oil

pump unit. Refit the retaining bolts and nuts

and tighten them to the specified torque

(photos).

167Check that the sump drain plug is refitted

and fully tightened. If the engine is in the car,

top up the engine oil level.

Oil pump - removal,

checking and refittingª

168Drain the engine oil and remove the

sump as described in the previous

sub-Section.

169Unscrew the retaining bolts then

withdraw the oil pump and intake pipe/filter

from its location within the crankcase.

Remove the gasket.

170If oil pump wear is suspected, first check

the cost and availability of new parts and the

cost of a new pump. Then examine the pump

as described below and decide whether

renewal or repair is the best course of action.

171Unscrew the three securing bolts and

remove the oil pump cover (photo). Note that

as the cover is removed, the oil pressure relief

valve components will be released.

172Recover the oil pressure relief valve,

spring and spring seat.

13•46 Supplement: Revisions and information on later models

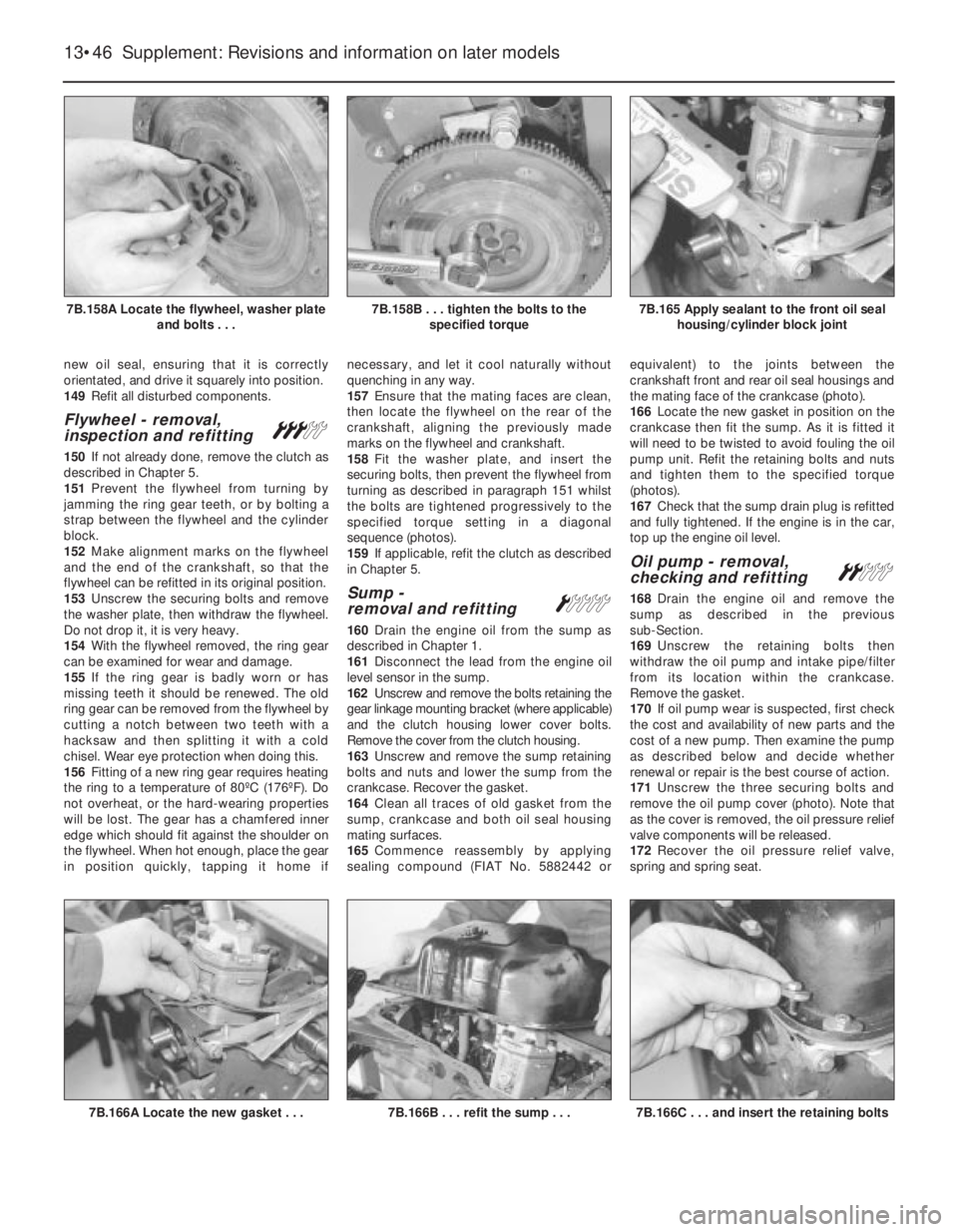

7B.166C . . . and insert the retaining bolts7B.166B . . . refit the sump . . .7B.166A Locate the new gasket . . .

7B.165 Apply sealant to the front oil seal

housing/cylinder block joint7B.158B . . . tighten the bolts to the

specified torque7B.158A Locate the flywheel, washer plate

and bolts . . .

Page 172 of 303

173Lift the intermediate plate from the oil

pump body.

174The gears can now be removed from the

oil pump body. Inspect them for obvious signs

of wear or damage, and renew if necessary.

175Commence reassembly by lubricating

the gears with clean engine oil, and refitting

them to the casing. Note that the scribed

marks on the top faces of the gears should

face each other with the gears installed

(photo).

176Using a feeler gauge, check that the

clearance between the gears and the pump

body is within the limits given in the Specifica-

tions (photo).

177Using a straight-edge placed across the

top of the pump body and the gears, and a

feeler gauge, check that the gear endfloat is

within the limits given in the Specifications

(photo).

178If either the gear-to-body clearance, or

the gear endfloat is outside the specified

limits, both gears should be renewed.

179Locate the intermediate plate on the

pump body (photo).

180Place the pressure relief valve and spring

over the pressure relief hole in the

intermediate plate, and locate the spring seat

over the boss in the pump cover, then refit the

pump cover, ensuring that the pressure relief

valve components seat correctly (photos).

181Refit and tighten the pump cover

securing bolts.

182Thoroughly clean the mating faces of thepump and crankcase before refitting the

pump. Prime the pump by injecting clean

engine oil into it and turning it by hand.

183Fit the pump using a new gasket, then

insert the securing bolts and tighten them.

184Refit the sump and top up the engine oil

level.

Pistons/connecting rods -

removal and refitting#

185Remove the sump and the cylinder head

as described previously in this Section.

186The big-end caps and connecting rods

normally have identification marks stamped

into their sides, facing the coolant pump side

of the cylinder block. If no marks are present,

use a centre-punch to identify the bearing

caps and the connecting rods for location.187Turn the crankshaft so that No. 1

crankpin is at its lowest point, then unscrew

the nuts and tap off the bearing cap. Keep the

bearing shells in the cap and the connecting

rod if they are to be re-used, taping them in

position if necessary to avoid loss.

188Using the handle of a hammer, push the

piston and connecting rod up the bore and

withdraw it from the top of the cylinder block.

Loosely refit the cap to the connecting rod.

189Repeat the procedure given in

paragraphs 187 and 188 on No. 4 piston and

connecting rod, then turn the crank-

shaft through half a turn and repeat the

procedure on Nos 2 and 3 pistons and

connecting rods.

190The pistons and connecting rods and the

big-end bearings can be examined and if

Supplement: Revisions and information on later models 13•47

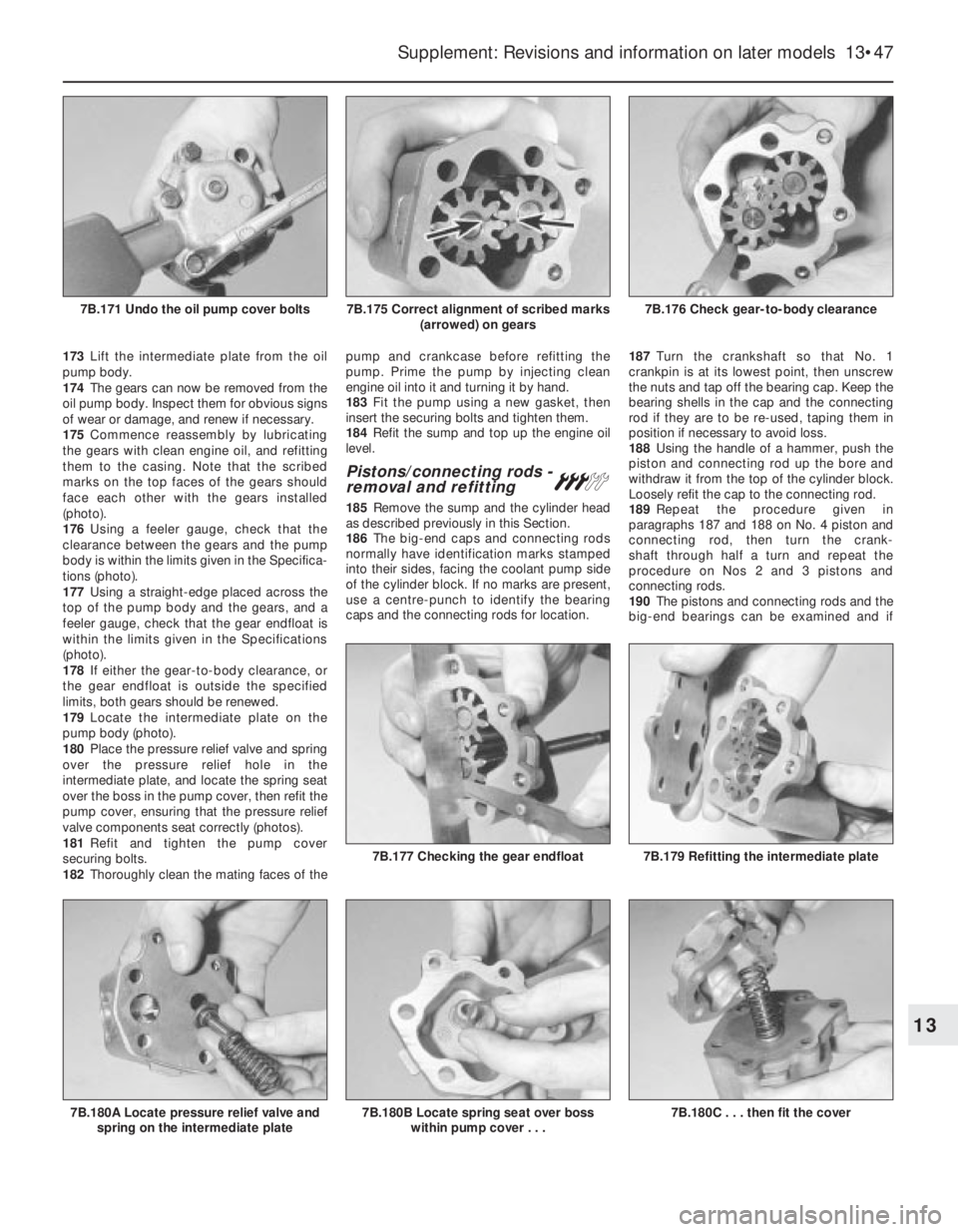

7B.176 Check gear-to-body clearance7B.175 Correct alignment of scribed marks

(arrowed) on gears7B.171 Undo the oil pump cover bolts

7B.180C . . . then fit the cover7B.180B Locate spring seat over boss

within pump cover . . .

7B.179 Refitting the intermediate plate7B.177 Checking the gear endfloat

7B.180A Locate pressure relief valve and

spring on the intermediate plate

13

Page 173 of 303

necessary renovated as described later in this

Section.

191Commence refitting as follows.

192Clean the backs of the bearing shells and

the recesses in the connecting rods and

big-end caps.

193Lubricate the cylinder bores with engine

oil.

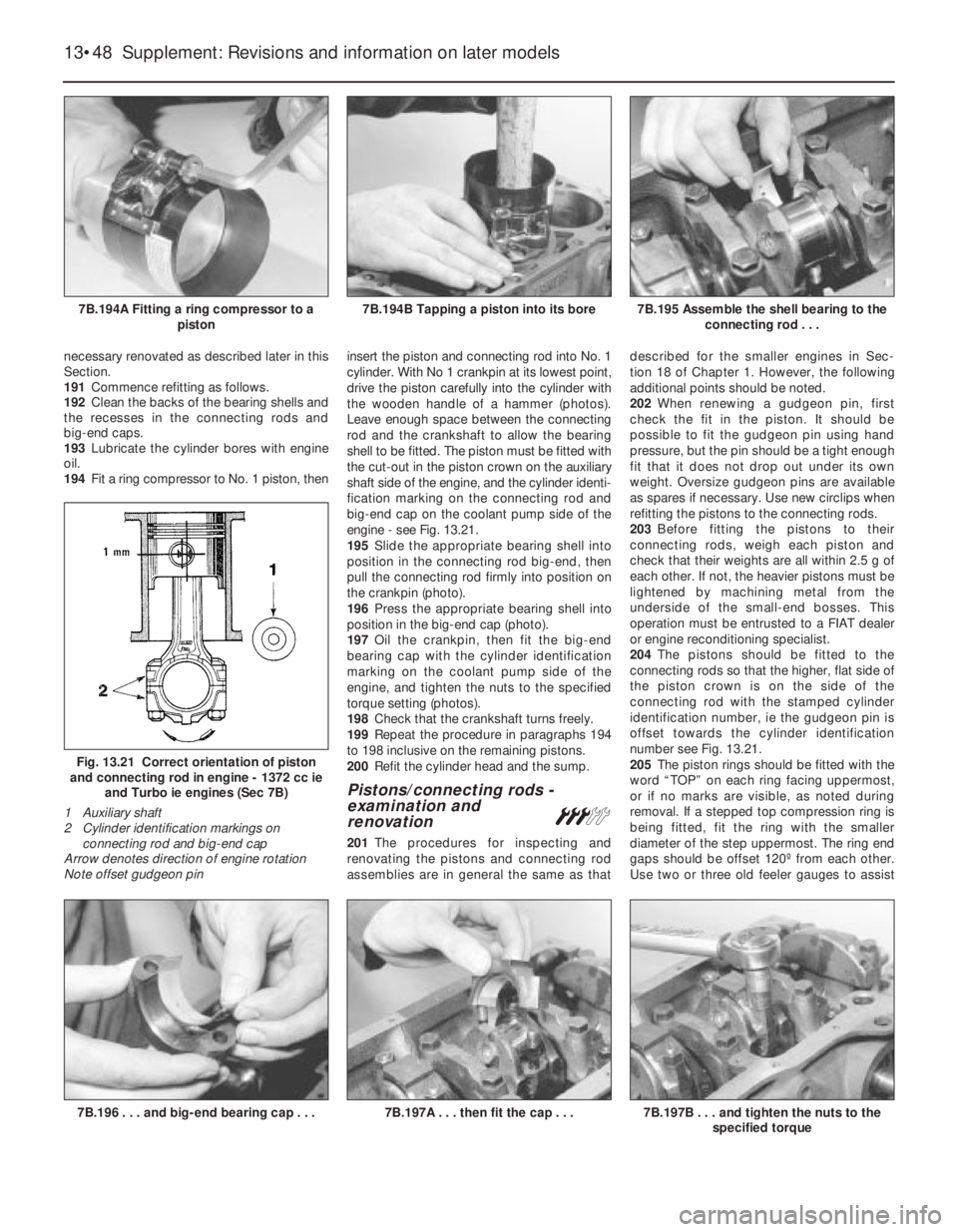

194Fit a ring compressor to No. 1 piston, theninsert the piston and connecting rod into No. 1

cylinder. With No 1 crankpin at its lowest point,

drive the piston carefully into the cylinder with

the wooden handle of a hammer (photos).

Leave enough space between the connecting

rod and the crankshaft to allow the bearing

shell to be fitted. The piston must be fitted with

the cut-out in the piston crown on the auxiliary

shaft side of the engine, and the cylinder identi-

fication marking on the connecting rod and

big-end cap on the coolant pump side of the

engine - see Fig. 13.21.

195Slide the appropriate bearing shell into

position in the connecting rod big-end, then

pull the connecting rod firmly into position on

the crankpin (photo).

196Press the appropriate bearing shell into

position in the big-end cap (photo).

197Oil the crankpin, then fit the big-end

bearing cap with the cylinder identification

marking on the coolant pump side of the

engine, and tighten the nuts to the specified

torque setting (photos).

198Check that the crankshaft turns freely.

199Repeat the procedure in paragraphs 194

to 198 inclusive on the remaining pistons.

200Refit the cylinder head and the sump.

Pistons/connecting rods -

examination and

renovation

#

201The procedures for inspecting and

renovating the pistons and connecting rod

assemblies are in general the same as thatdescribed for the smaller engines in Sec-

tion 18 of Chapter 1. However, the following

additional points should be noted.

202When renewing a gudgeon pin, first

check the fit in the piston. It should be

possible to fit the gudgeon pin using hand

pressure, but the pin should be a tight enough

fit that it does not drop out under its own

weight. Oversize gudgeon pins are available

as spares if necessary. Use new circlips when

refitting the pistons to the connecting rods.

203Before fitting the pistons to their

connecting rods, weigh each piston and

check that their weights are all within 2.5 g of

each other. If not, the heavier pistons must be

lightened by machining metal from the

underside of the small-end bosses. This

operation must be entrusted to a FIAT dealer

or engine reconditioning specialist.

204The pistons should be fitted to the

connecting rods so that the higher, flat side of

the piston crown is on the side of the

connecting rod with the stamped cylinder

identification number, ie the gudgeon pin is

offset towards the cylinder identification

number see Fig. 13.21.

205The piston rings should be fitted with the

word “TOP” on each ring facing uppermost,

or if no marks are visible, as noted during

removal. If a stepped top compression ring is

being fitted, fit the ring with the smaller

diameter of the step uppermost. The ring end

gaps should be offset 120º from each other.

Use two or three old feeler gauges to assist

13•48 Supplement: Revisions and information on later models

7B.197B . . . and tighten the nuts to the

specified torque

Fig. 13.21 Correct orientation of piston

and connecting rod in engine - 1372 cc ie

and Turbo ie engines (Sec 7B)

1 Auxiliary shaft

2 Cylinder identification markings on

connecting rod and big-end cap

Arrow denotes direction of engine rotation

Note offset gudgeon pin

7B.197A . . . then fit the cap . . .7B.196 . . . and big-end bearing cap . . .

7B.195 Assemble the shell bearing to the

connecting rod . . .7B.194B Tapping a piston into its bore7B.194A Fitting a ring compressor to a

piston

Page 174 of 303

fitting, as during removal. Note that the

compression rings are brittle, and will snap if

expanded too far.

206If new pistons are to be fitted, they must

be selected from the grades available, after

measuring the cylinder bores. Normally, the

appropriate oversize pistons are supplied by

the dealer when the block is rebored.

207Whenever new piston rings are being

installed, the glaze on the original cylinder

bores should be removed using either

abrasive paper or a glaze-removing tool in an

electric drill. If abrasive paper is used, use

strokes at 60º to the bore centre-line, to

create a cross-hatching effect.

Engine/transmission

mountings - renewalÁ

208The engine/gearbox assembly is

suspended in the engine compartment on

three mountings, two of which are attached to

the gearbox, and one to the engine.

Right-hand mounting

209Apply the handbrake, then jack up the

front of the vehicle and support it securely on

axle stands.

210Suitable lifting tackle must now be

attached to the engine in order to support it as

the engine mounting is removed. No lifting

brackets are provided, so care must be taken

when deciding on an engine lifting point. In the

workshop, a right-angled bracket was made up

by bending a suitable piece of steel plate. The

bracket was then bolted to the engine using the

rear right-hand camshaft housing securing bolt

with suitable packing washers.

211Attach the lifting tackle to the bracket on

the engine and just take the weight of the

assembly.

212Working under the vehicle, unbolt the

engine mounting bracket from the cylinder

block, and unbolt the mounting from the

body, then withdraw the bracket/mounting

assembly.

213Unscrew the nut and through-bolt,

counter holding the bolt with a second

spanner or socket, and separate the mounting

from the bracket.

214Fit the new mounting to the bracket, and

tighten the nut to the specified torque, while

counterholding the through-bolt using a

suitable spanner or socket.

215Refit the mounting bracket to the cylinder

block, and tighten the securing bolts to the

specified torque.

216Refit the mounting to the body and

tighten the securing bolts to the specified

torque.

217Disconnect the lifting tackle from the

engine, and remove the engine lifting bracket.

218Lower the vehicle to the ground.

Left-hand mountings

219Apply the handbrake, then jack up the

front of the vehicle and support it securely on

axle stands.

220Suitable lifting tackle must now be

attached to the gearbox lifting bracket inorder to support the weight of the assembly

as the mounting is removed.

221Attach the lifting tackle to the bracket on

the gearbox, and just take the weight of the

assembly.

222Working under the vehicle, unbolt the

mounting bracket from the gearbox, and

unbolt the mounting from the body, then

withdraw the bracket/mounting assembly.

223Proceed as described in paragraphs 213

and 214.

224Refit the mounting bracket to the

gearbox, and tighten the securing bolts to the

specified torque.

225Refit the mounting to the body and

tighten the mounting bolts to the specified

torque.

226Disconnect the lifting tackle from the

engine.

227Lower the vehicle to the ground.

PART C: ENGINE REMOVAL

AND DISMANTLING

Method of removal - general

1The engine (complete with transmission) is

disconnected and lowered downwards

through the engine compartment, then

withdrawn from the front underside of the car.

1372 cc engine/

transmission - removal

and separation

#

Warning: Refer to the beginning

of Section 9 before starting any

work.

2Depressurize the fuel system as described

in Section 9 of this Chapter.

3Disconnect the battery negative lead.

4Mark the position of the hinges on the

underside of the bonnet, then with the aid of

an assistant, unscrew the hinge bolts and lift

the bonnet clear of the car. Store the bonnet

in a safe area.

5Drain the engine coolant.

6Drain the engine and transmission oils.

7Disconnect and remove the air filter.

8Disconnect the coolant hoses from the

engine, including the hose to the inlet

manifold.

9Detach the ignition coil (HT) lead from the

distributor.10Compress the retaining clip and detach

the engine idle speed actuator lead from the

SPi unit (photo).

11Disconnect the brake servo vacuum pipe

from its connector on the inlet manifold.

12Disconnect the throttle cable from the SPi

unit.

13Disconnect the engine speed sensor lead.

14Release and detach the reversing light

lead from the switch on the transmission

(photo).

15Before disconnecting the hydraulic hose

from the clutch slave cylinder, remove the

filler cap from the reservoir and place a piece

of polythene sheet over the filler neck, then

refit the cap; this will help prevent excess fluid

loss. Once disconnected, plug the hose and

its cylinder connection to prevent the ingress

of dirt into the hydraulic system.

16Disconnect the wiring connector from the

alternator.

17Position a clean rag under the fuel supply

and return hose connections to the SPi unit,

then slowly unscrew the hose clips to release

the system pressure; catch fuel leakage in the

rag and dispose of it safely. Detach the hoses

and plug them to prevent ingress of dirt and

any further fuel leakage. Position the hoses

out of the way.

18Detach the wiring connector from the

engine coolant temperature sender unit

(photo).

19Release the retaining clip and detach the

wiring connector from the throttle position

switch. Also detach the associated earth

leads from the cylinder head.

Supplement: Revisions and information on later models 13•49

7C.14 Reversing light switch and lead7C.18 Engine coolant temperature sender

and wiring connector

7C.10 Engine idle speed actuator/SPi unit

lead connection (arrowed)

13

Page 175 of 303

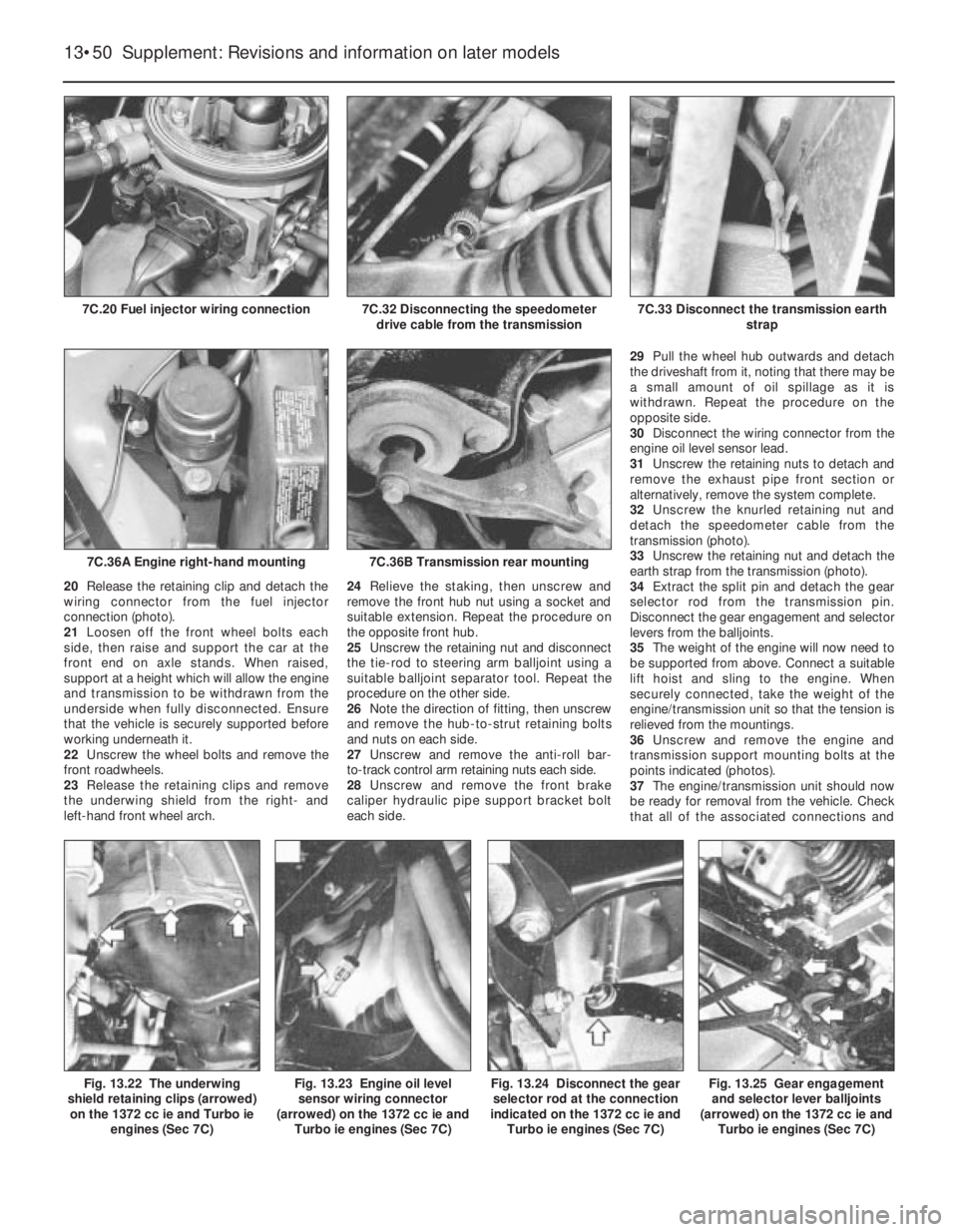

20Release the retaining clip and detach the

wiring connector from the fuel injector

connection (photo).

21Loosen off the front wheel bolts each

side, then raise and support the car at the

front end on axle stands. When raised,

support at a height which will allow the engine

and transmission to be withdrawn from the

underside when fully disconnected. Ensure

that the vehicle is securely supported before

working underneath it.

22Unscrew the wheel bolts and remove the

front roadwheels.

23Release the retaining clips and remove

the underwing shield from the right- and

left-hand front wheel arch.24Relieve the staking, then unscrew and

remove the front hub nut using a socket and

suitable extension. Repeat the procedure on

the opposite front hub.

25Unscrew the retaining nut and disconnect

the tie-rod to steering arm balljoint using a

suitable balljoint separator tool. Repeat the

procedure on the other side.

26Note the direction of fitting, then unscrew

and remove the hub-to-strut retaining bolts

and nuts on each side.

27Unscrew and remove the anti-roll bar-

to-track control arm retaining nuts each side.

28Unscrew and remove the front brake

caliper hydraulic pipe support bracket bolt

each side.29Pull the wheel hub outwards and detach

the driveshaft from it, noting that there may be

a small amount of oil spillage as it is

withdrawn. Repeat the procedure on the

opposite side.

30Disconnect the wiring connector from the

engine oil level sensor lead.

31Unscrew the retaining nuts to detach and

remove the exhaust pipe front section or

alternatively, remove the system complete.

32Unscrew the knurled retaining nut and

detach the speedometer cable from the

transmission (photo).

33Unscrew the retaining nut and detach the

earth strap from the transmission (photo).

34Extract the split pin and detach the gear

selector rod from the transmission pin.

Disconnect the gear engagement and selector

levers from the balljoints.

35The weight of the engine will now need to

be supported from above. Connect a suitable

lift hoist and sling to the engine. When

securely connected, take the weight of the

engine/transmission unit so that the tension is

relieved from the mountings.

36Unscrew and remove the engine and

transmission support mounting bolts at the

points indicated (photos).

37The engine/transmission unit should now

be ready for removal from the vehicle. Check

that all of the associated connections and

13•50 Supplement: Revisions and information on later models

Fig. 13.22 The underwing

shield retaining clips (arrowed)

on the 1372 cc ie and Turbo ie

engines (Sec 7C)Fig. 13.25 Gear engagement

and selector lever balljoints

(arrowed) on the 1372 cc ie and

Turbo ie engines (Sec 7C)Fig. 13.23 Engine oil level

sensor wiring connector

(arrowed) on the 1372 cc ie and

Turbo ie engines (Sec 7C)Fig. 13.24 Disconnect the gear

selector rod at the connection

indicated on the 1372 cc ie and

Turbo ie engines (Sec 7C)

7C.33 Disconnect the transmission earth

strap7C.32 Disconnecting the speedometer

drive cable from the transmission7C.20 Fuel injector wiring connection

7C.36B Transmission rear mounting7C.36A Engine right-hand mounting

Page 176 of 303

fittings are disconnected from the engine and

transmission and positioned out of the way.

Enlist the aid of an assistant to help steady

and guide the power unit down through the

engine compartment as it is removed, If

available, position a suitable engine trolley or

crawler board under the engine/transmission

so that when lowered, the power unit can be

withdrawn from the front end of the vehicle

and moved to the area where it is to be

cleaned and dismantled.

38Carefully lower the engine and

transmission unit, ensuring that no fittings

become snagged. Detach the hoist and

withdraw the power unit from under the

vehicle.

39To separate the engine from the

transmission, unbolt and remove the starter

motor, then unscrew the retaining bolts and

withdraw the transmission from the engine. As

it is withdrawn, do not allow the weight of the

engine or transmission to be taken by the

input shaft.

40To remove the clutch unit, refer to

Chapter 5 for details.

1372 cc Turbo ie

engine/transmission -

removal and separation

#

41The engine and transmission removal and

refitting details for Turbo-engined models are

similar to those described for the non-Turbo

models in the previous sub-Section, but the

following differences should be noted.

42To provide access for the disconnection

of the turbo and related components, first

remove the inlet manifold. Removal of the inlet

manifold and the turbocharger is described in

Section 9 of this Chapter.

43The ignition distributor on the Turbo

engine is driven from the auxiliary shaft and is

mounted at the front of the engine, towards

the timing cover end.

44The right-hand driveshaft has a steady

bearing and this will need to be unbolted and

detached.

Engine dismantling - general

45Refer to Chapter 1, Section 14 for details.

Auxiliary shaft - removal,

inspection and refitting #

46Remove the engine and transmission from

the vehicle as described previously in this

Section part.

47Drain the engine oil and remove the sump

as described in Part B of this Section.

48Remove the oil pump as described in Part

B of this Section.

49Remove the timing belt and the auxiliary

shaft sprocket as described in Part B of this

Section.

50Unscrew the three retaining bolts and

remove the auxiliary shaft cover. Remove the

gasket.

51Withdraw the auxiliary shaft from the

cylinder block.

52Examine the shaft and its bearing bushes

in the cylinder block for signs of excessive

wear and/or damage and renew it if

necessary. Bush renewal is described in

paragraph 79 in this Section.

53The cover gasket and the oil seal should

always be renewed whenever the cover is

removed. To renew the seal, support the

cover on blocks of wood and drive out the old

seal using a suitable drift inserted in the

cut-out in the back of the cover. Clean the

seal location in the housing. Drive the new

seal into place using a suitable metal tube or

socket (photo). The sealing lip must face

towards the cylinder block. Smear the sealing

lips with clean engine oil before installation.

54Commence refitting by lubricating theauxiliary shaft journals with clean engine oil,

then insert the shaft into the cylinder block

(photo).

55Refit the auxiliary shaft cover, using a new

gasket, and tighten the securing bolts

(photos).

56Refit the auxiliary shaft sprocket, timing

belt, cover and crankshaft pulley as described

in Part B of this Section.

57Refit the engine and transmission with

reference to Part D of this Section.

Engine -

complete dismantling#

Warning: Refer to the beginning

of Section 9 before starting any

work.

58Detach and remove the following ancillary

items. Where applicable, refer to the

appropriate Chapter or Section within this

Chapter for more detailed removal instructions.

Engine oil dipstick

Ignition distributor and HT leads

Fuel pump

Alternator

Oil filter

Oil vapour recovery unit

Inlet and exhaust manifolds and associated

fuel injection components (as applicable)

Clutch unit

59Refer to Part B of this Section for details

and remove the timing cover and drivebelt.

60Refer to Part B of this Section for details

and remove the cylinder head unit.

Supplement: Revisions and information on later models 13•51

7C.54 Inserting the auxiliary shaft into the

cylinder block (rear timing belt cover

removed)7C.53 Driving a new oil seal into the

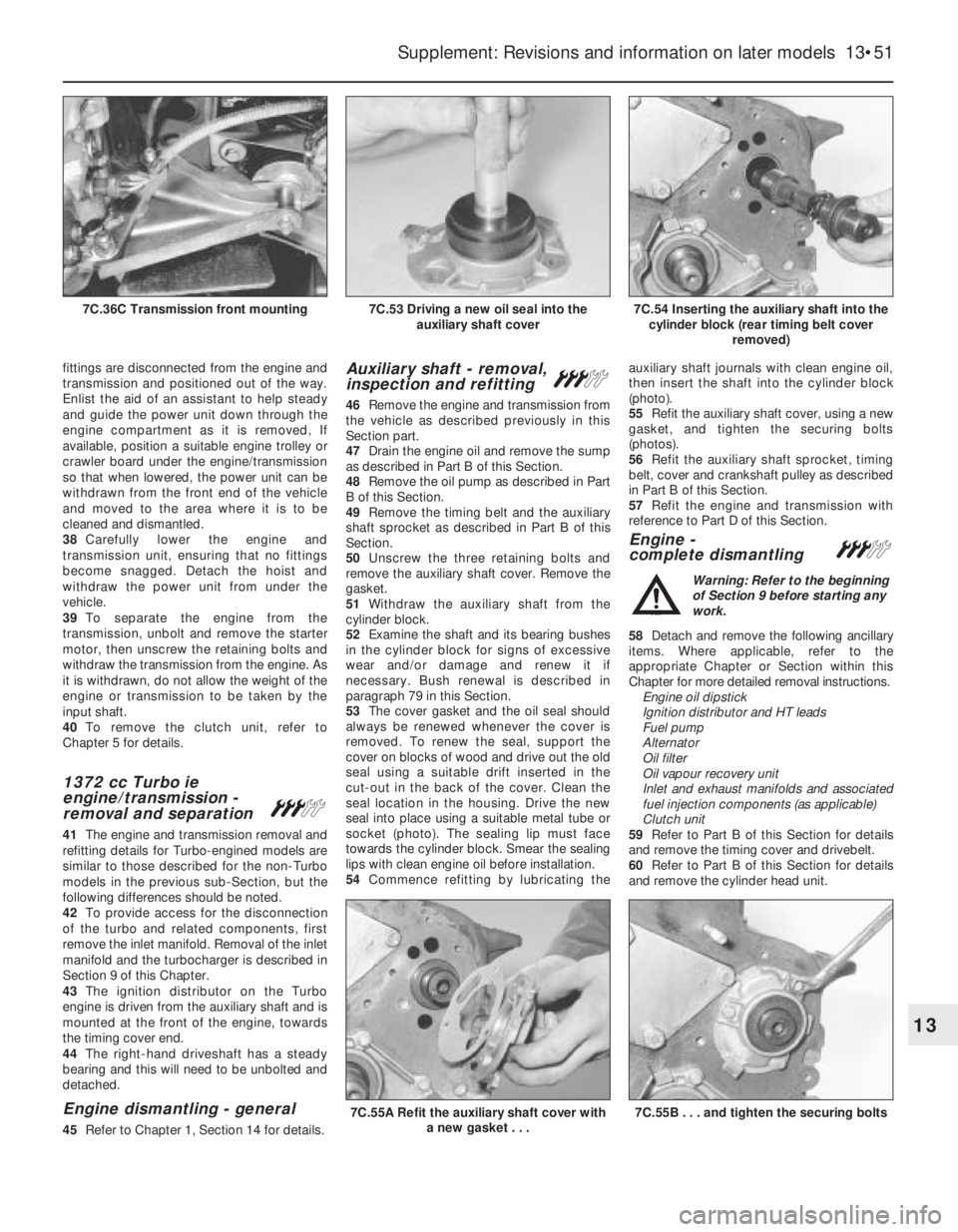

auxiliary shaft cover7C.36C Transmission front mounting

7C.55B . . . and tighten the securing bolts7C.55A Refit the auxiliary shaft cover with

a new gasket . . .

13

Page 177 of 303

61Refer to Part B of this Section for details

and remove the flywheel.

62Refer to the previous sub-Section for

details and remove the auxiliary shaft.

63Refer to Part B of this Section for details

and remove the sump.

64Refer to Part B of this Section for details

and remove the oil pump unit.

65Refer to Part B of this Section for details

and remove the front and rear crankshaft oil

seals.

66Refer to Part B of this Section and remove

the piston/connecting rod assemblies.

67Refer to Part B of this Section for details

and remove the crankshaft and main bearing

assemblies.

Crankshaft and main

bearings - removal#

68Unscrew the securing bolts and remove

the front and rear crankshaft oil seal housings.

Recover the gaskets.

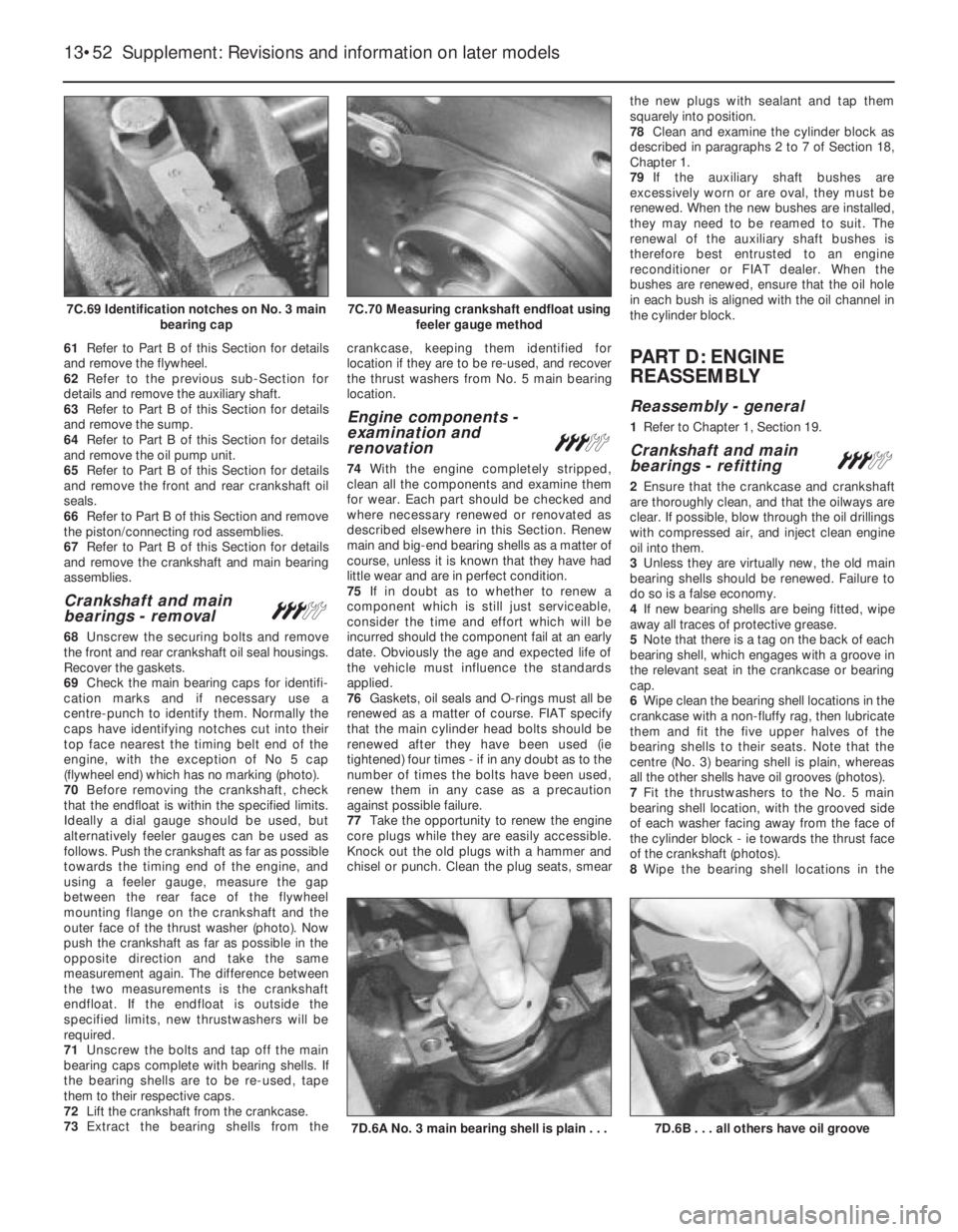

69Check the main bearing caps for identifi-

cation marks and if necessary use a

centre-punch to identify them. Normally the

caps have identifying notches cut into their

top face nearest the timing belt end of the

engine, with the exception of No 5 cap

(flywheel end) which has no marking (photo).

70Before removing the crankshaft, check

that the endfloat is within the specified limits.

Ideally a dial gauge should be used, but

alternatively feeler gauges can be used as

follows. Push the crankshaft as far as possible

towards the timing end of the engine, and

using a feeler gauge, measure the gap

between the rear face of the flywheel

mounting flange on the crankshaft and the

outer face of the thrust washer (photo). Now

push the crankshaft as far as possible in the

opposite direction and take the same

measurement again. The difference between

the two measurements is the crankshaft

endfloat. If the endfloat is outside the

specified limits, new thrustwashers will be

required.

71Unscrew the bolts and tap off the main

bearing caps complete with bearing shells. If

the bearing shells are to be re-used, tape

them to their respective caps.

72Lift the crankshaft from the crankcase.

73Extract the bearing shells from thecrankcase, keeping them identified for

location if they are to be re-used, and recover

the thrust washers from No. 5 main bearing

location.

Engine components -

examination and

renovation

#

74With the engine completely stripped,

clean all the components and examine them

for wear. Each part should be checked and

where necessary renewed or renovated as

described elsewhere in this Section. Renew

main and big-end bearing shells as a matter of

course, unless it is known that they have had

little wear and are in perfect condition.

75If in doubt as to whether to renew a

component which is still just serviceable,

consider the time and effort which will be

incurred should the component fail at an early

date. Obviously the age and expected life of

the vehicle must influence the standards

applied.

76Gaskets, oil seals and O-rings must all be

renewed as a matter of course. FIAT specify

that the main cylinder head bolts should be

renewed after they have been used (ie

tightened) four times - if in any doubt as to the

number of times the bolts have been used,

renew them in any case as a precaution

against possible failure.

77Take the opportunity to renew the engine

core plugs while they are easily accessible.

Knock out the old plugs with a hammer and

chisel or punch. Clean the plug seats, smearthe new plugs with sealant and tap them

squarely into position.

78Clean and examine the cylinder block as

described in paragraphs 2 to 7 of Section 18,

Chapter 1.

79If the auxiliary shaft bushes are

excessively worn or are oval, they must be

renewed. When the new bushes are installed,

they may need to be reamed to suit. The

renewal of the auxiliary shaft bushes is

therefore best entrusted to an engine

reconditioner or FIAT dealer. When the

bushes are renewed, ensure that the oil hole

in each bush is aligned with the oil channel in

the cylinder block.

PART D: ENGINE

REASSEMBLY

Reassembly - general

1Refer to Chapter 1, Section 19.

Crankshaft and main

bearings - refitting#

2Ensure that the crankcase and crankshaft

are thoroughly clean, and that the oilways are

clear. If possible, blow through the oil drillings

with compressed air, and inject clean engine

oil into them.

3Unless they are virtually new, the old main

bearing shells should be renewed. Failure to

do so is a false economy.

4If new bearing shells are being fitted, wipe

away all traces of protective grease.

5Note that there is a tag on the back of each

bearing shell, which engages with a groove in

the relevant seat in the crankcase or bearing

cap.

6Wipe clean the bearing shell locations in the

crankcase with a non-fluffy rag, then lubricate

them and fit the five upper halves of the

bearing shells to their seats. Note that the

centre (No. 3) bearing shell is plain, whereas

all the other shells have oil grooves (photos).

7Fit the thrustwashers to the No. 5 main

bearing shell location, with the grooved side

of each washer facing away from the face of

the cylinder block - ie towards the thrust face

of the crankshaft (photos).

8Wipe the bearing shell locations in the

13•52 Supplement: Revisions and information on later models

7D.6B . . . all others have oil groove7D.6A No. 3 main bearing shell is plain . . .

7C.70 Measuring crankshaft endfloat using

feeler gauge method7C.69 Identification notches on No. 3 main

bearing cap

Page 178 of 303

bearing caps with a soft non-fluffy rag, then fit

the lower halves of the bearing shells to their

seats. Again, note that the centre (No. 3)

bearing shell is plain, whereas all the other

shells have oil grooves (photo).

9Lubricate the crankshaft journals and the

upper and lower main bearing shells with

clean engine oil (photo).

10Carefully lower the crankshaft into the

crankcase (photo). If necessary, seat the

crankshaft using light taps with a

rubber-faced hammer on the crankshaft

balance webs.

11Lubricate the crankshaft main bearing

journals again, the fit the No. 1 bearing cap.

Fit the two securing bolts, and tighten them as

far as possible by hand.

12Fit the No. 5 bearing cap, and as before

tighten the bolts as far as possible by hand.

13Fit the centre and then the intermediate

bearing caps, and again tighten the bolts as

far as possible by hand.

14Check that the markings on the bearing

caps are correctly orientated as noted during

dismantling - ie the identification grooves

should face towards the timing side of the

engine, then working from the centre cap

outwards in a progressive sequence, finally

tighten the bolts to the specified torque

(photo).

15Check that the crankshaft rotates freely.

Some stiffness is to be expected with new

components, but there should be no tight

spots or binding.16Check that crankshaft endfloat is within

the specified limits, as described in paragraph

70 of Part C in this Section.

17Examine the condition of the front and

rear crankshaft oil seals and renew if

necessary with reference to Part B of this

Section. It is advisable to renew the oil seals

as a matter of course unless they are in

perfect condition.

18Lubricate the oil seal lips with clean

engine oil, then carefully fit the front and rear

oil seal housings using new gaskets.

Pistons and connecting rods -

refitting

19Refer to Part B of this Section.

Oil pump - refitting

20Refer to Part B of this Section.

Sump - refitting

21Refer to Part B of this Section.

Flywheel - refitting

22Refer to Part B of this Section. When the

flywheel is bolted in position, refer to Chapter

5 for details and refit the clutch unit.

Auxiliary shaft - refitting

23Refer to Part C of this Section.

Cylinder head - refitting

24Refer to Part B of this Section. Note that

this procedure describes cylinder head

refitting complete with the camshaft housingassembly and manifolds as a complete unit.

Details of refitting the camshaft housing (and

followers) to the cylinder head will be found

separately in Part B.

Timing belt and covers -

refitting

25Refer to Part B of this Section.

Engine/transmission -

reconnection and refitting#

Note: A suitable hoist and lifting tackle will be

required for this operation. New locktabs will

be required for the exhaust

downpipe-to-manifold nuts, and suitable

exhaust assembly paste, will be required when

reconnecting the downpipes to the exhaust

manifold.

26Before attempting to reconnect the

engine to the gearbox, check that the clutch

friction disc is centralised as described in

Chapter 5, Section 8. This is necessary to

ensure that the gearbox input shaft splines

will pass through the splines in the centre of

the friction disc.

27Check that the clutch release arm and

bearing are correctly fitted, and lightly grease

the input shaft splines.

28Mate the engine and gearbox together,

ensuring that the engine adapter plate is

correctly located, and that the gearbox

locates on the dowels in the cylinder block,

then refit the engine-to-gearbox bolts and the

single nut, but do not fully tighten them at this

stage. Ensure that any brackets noted during

Supplement: Revisions and information on later models 13•53

7D.8 Locate the bearing shells into the

main bearing caps . . .7D.7B . . . sliding them into position each

side of the No. 5 main bearing

7DS.14 Tighten the main bearing cap bolts

to the specified torque setting7D.10 Lower the crankshaft into position7D.9 . . . and lubricate the shells

13

7D.7A Locate the thrust washer . . .

Page 179 of 303

removal are in place under the

engine-to-gearbox bolts. Do not allow the

weight of the gearbox to hang on the input

shaft as it is engaged with the clutch friction

disc.

29Refit the starter motor, ensuring that the

wiring harness bracket is in position on the

top bolt.

30Locate the engine/transmission unit at the

front of the car and move it into position under

the engine compartment. Attach the lifting

sling and hoist as during removal.

31Enlist the aid of an assistant to help

steady the combined units as they are raised

into position and to locate the mountings in

the engine compartment.

32Once they are located, tighten the

mountings to the specified torque settings,

then disconnect the lifting hoist and sling.

33The remainder of the refitting and

reconnection procedures are a reversal of the

removal procedure described in Part C. For

further details on reconnecting the

suspension and driveshaft components,

refer to Chapter 7 and Section 13 of this

Chapter.

34Ensure that the exhaust downpipe-to-

manifold connection is clean and renew the

gasket when reconnecting this joint. Use a

smear of exhaust assembly paste on the jointfaces. Use new lockwashers and tighten the

flange nuts securely.

35Ensure that all fuel and coolant

connections are cleanly and securely made.

36Ensure that all wiring connections are

correct and securely made.

37Top up the engine and transmission oil

levels.

38Refill the cooling system.

39Check that all connections are securely

made, then reconnect the battery negative

lead.

Initial start-up after major

overhaul

40Refer to Chapter 1, Section 45.

8 Cooling system

PART A:

999 AND 1108 CC ENGINES

Description

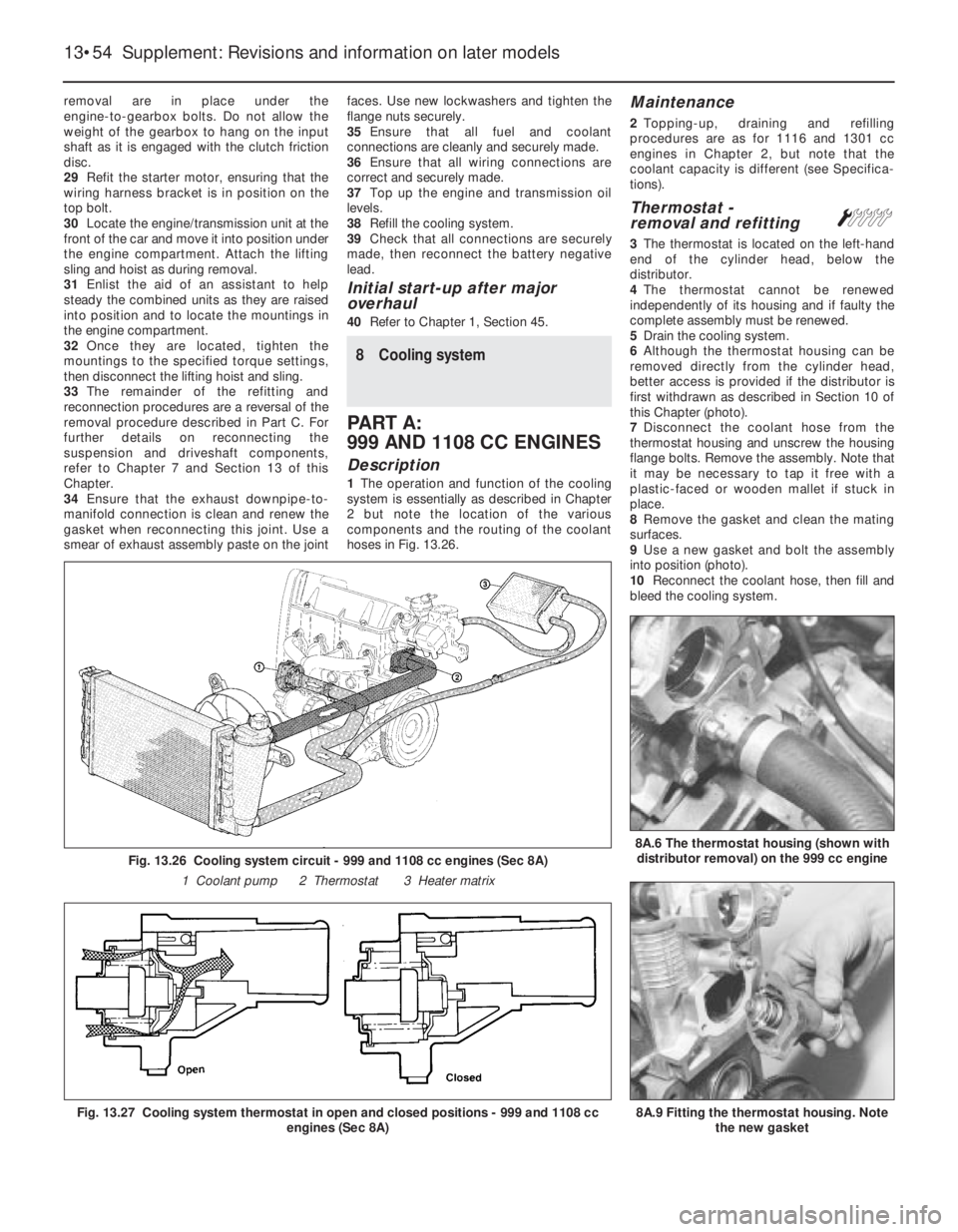

1The operation and function of the cooling

system is essentially as described in Chapter

2 but note the location of the various

components and the routing of the coolant

hoses in Fig. 13.26.

Maintenance

2Topping-up, draining and refilling

procedures are as for 1116 and 1301 cc

engines in Chapter 2, but note that the

coolant capacity is different (see Specifica-

tions).

Thermostat -

removal and refittingÁ

3The thermostat is located on the left-hand

end of the cylinder head, below the

distributor.

4The thermostat cannot be renewed

independently of its housing and if faulty the

complete assembly must be renewed.

5Drain the cooling system.

6Although the thermostat housing can be

removed directly from the cylinder head,

better access is provided if the distributor is

first withdrawn as described in Section 10 of

this Chapter (photo).

7Disconnect the coolant hose from the

thermostat housing and unscrew the housing

flange bolts. Remove the assembly. Note that

it may be necessary to tap it free with a

plastic-faced or wooden mallet if stuck in

place.

8Remove the gasket and clean the mating

surfaces.

9Use a new gasket and bolt the assembly

into position (photo).

10Reconnect the coolant hose, then fill and

bleed the cooling system.

13•54 Supplement: Revisions and information on later models

Fig. 13.26 Cooling system circuit - 999 and 1108 cc engines (Sec 8A)

1 Coolant pump 2 Thermostat 3 Heater matrix

Fig. 13.27 Cooling system thermostat in open and closed positions - 999 and 1108 cc

engines (Sec 8A)8A.9 Fitting the thermostat housing. Note

the new gasket

8A.6 The thermostat housing (shown with

distributor removal) on the 999 cc engine

Page 180 of 303

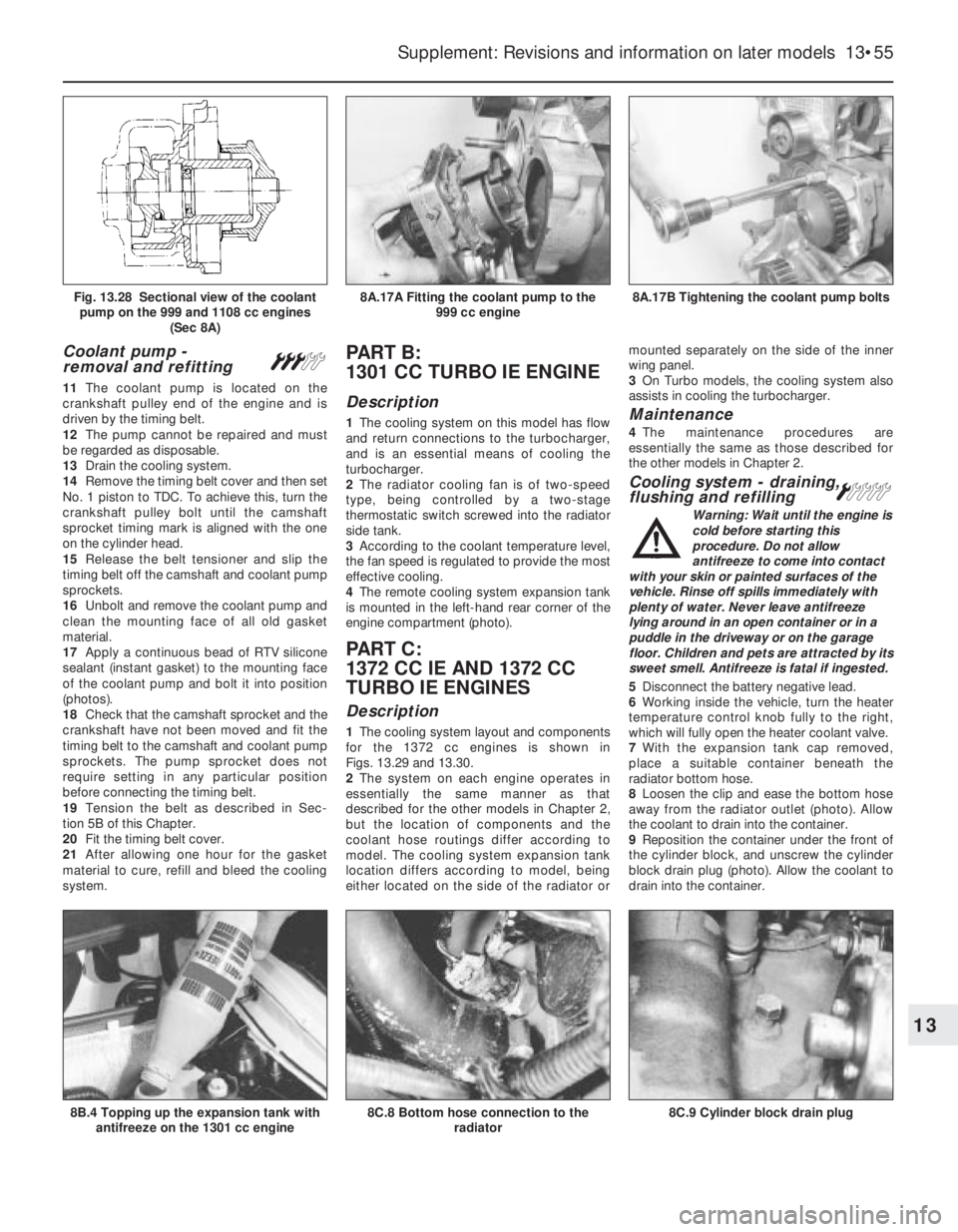

Coolant pump -

removal and refitting#

11The coolant pump is located on the

crankshaft pulley end of the engine and is

driven by the timing belt.

12The pump cannot be repaired and must

be regarded as disposable.

13Drain the cooling system.

14Remove the timing belt cover and then set

No. 1 piston to TDC. To achieve this, turn the

crankshaft pulley bolt until the camshaft

sprocket timing mark is aligned with the one

on the cylinder head.

15Release the belt tensioner and slip the

timing belt off the camshaft and coolant pump

sprockets.

16Unbolt and remove the coolant pump and

clean the mounting face of all old gasket

material.

17Apply a continuous bead of RTV silicone

sealant (instant gasket) to the mounting face

of the coolant pump and bolt it into position

(photos).

18Check that the camshaft sprocket and the

crankshaft have not been moved and fit the

timing belt to the camshaft and coolant pump

sprockets. The pump sprocket does not

require setting in any particular position

before connecting the timing belt.

19Tension the belt as described in Sec-

tion 5B of this Chapter.

20Fit the timing belt cover.

21After allowing one hour for the gasket

material to cure, refill and bleed the cooling

system.

PART B:

1301 CC TURBO IE ENGINE

Description

1The cooling system on this model has flow

and return connections to the turbocharger,

and is an essential means of cooling the

turbocharger.

2The radiator cooling fan is of two-speed

type, being controlled by a two-stage

thermostatic switch screwed into the radiator

side tank.

3According to the coolant temperature level,

the fan speed is regulated to provide the most

effective cooling.

4The remote cooling system expansion tank

is mounted in the left-hand rear corner of the

engine compartment (photo).

PART C:

1372 CC IE AND 1372 CC

TURBO IE ENGINES

Description

1The cooling system layout and components

for the 1372 cc engines is shown in

Figs. 13.29 and 13.30.

2The system on each engine operates in

essentially the same manner as that

described for the other models in Chapter 2,

but the location of components and the

coolant hose routings differ according to

model. The cooling system expansion tank

location differs according to model, being

either located on the side of the radiator ormounted separately on the side of the inner

wing panel.

3On Turbo models, the cooling system also

assists in cooling the turbocharger.

Maintenance

4The maintenance procedures are

essentially the same as those described for

the other models in Chapter 2.

Cooling system - draining,

flushing and refillingÁ

Warning: Wait until the engine is

cold before starting this

procedure. Do not allow

antifreeze to come into contact

with your skin or painted surfaces of the

vehicle. Rinse off spills immediately with

plenty of water. Never leave antifreeze

lying around in an open container or in a

puddle in the driveway or on the garage

floor. Children and pets are attracted by its

sweet smell. Antifreeze is fatal if ingested.

5Disconnect the battery negative lead.

6Working inside the vehicle, turn the heater

temperature control knob fully to the right,

which will fully open the heater coolant valve.

7With the expansion tank cap removed,

place a suitable container beneath the

radiator bottom hose.

8Loosen the clip and ease the bottom hose

away from the radiator outlet (photo). Allow

the coolant to drain into the container.

9Reposition the container under the front of

the cylinder block, and unscrew the cylinder

block drain plug (photo). Allow the coolant to

drain into the container.

Supplement: Revisions and information on later models 13•55

8A.17B Tightening the coolant pump bolts8A.17A Fitting the coolant pump to the

999 cc engineFig. 13.28 Sectional view of the coolant

pump on the 999 and 1108 cc engines

(Sec 8A)

8C.9 Cylinder block drain plug8C.8 Bottom hose connection to the

radiator8B.4 Topping up the expansion tank with

antifreeze on the 1301 cc engine

13