auxiliary battery FIAT UNO 1983 Service Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 38 of 303

5In practice, if several shims have to be

changed, they can often be interchanged, so

avoiding the necessity of having to buy more

new shims than is necessary.

6If more than two or three valve clearances

are found to be incorrect, it will be more

convenient to remove the camshaft carrier for

easier removal of the shims.

7Where no clearance can be measured, even

with the thinnest available shim in position,

the valve will have to be removed and the end

of its stem ground off squarely. This will

reduce its overall length by the minimum

amount to provide a clearance. This job

should be entrusted to your dealer as it is

important to keep the end of the valve stem

square.

8On completion, refit the camshaft cover and

gasket.

27 Camshaft and camshaft

carrier- removal and refitting

3

1Disconnect the battery.

2Remove the air cleaner (see Chapter 3).

3Disconnect the fuel filter hose from the fuel

pump and tie it back, out of the way.

4Identify and then disconnect any electrical

leads which must be moved away to enable

the camshaft cover to be withdrawn.

5Identify and disconnect any vacuum gases

which must be moved away to enable the

camshaft cover to be withdrawn.

6Unscrew the securing nuts and remove the

camshaft cover.

7Turn the crankshaft pulley nut until No. 4

piston is at TDC. This can be established as

described in Section 28.

8Unbolt and remove the timing belt cover.

9Check that the timing mark on the camshaft

sprocket is aligned with, and adjacent to the

pointer on the timing belt cover backplate.

10Restrain the timing belt with the hand and

release but do not remove the camshaft

sprocket bolt. Release the belt tensioner

pulley by slackening the pulley centre nut.

Push the timing belt evenly from the

sprockets, noting which way round the belt isfitted if it is to be completely removed. The

lettering on the belt is normally legible from

the crankshaft pulley end of the engine when

the belt is as originally fitted.

11Unbolt the camshaft carrier and lift it

sufficiently from the cylinder head to break the

seal of the mating faces. Note: It is important

not to allow the cam followers to pull out; they

must be retained in their original locations.

This can be done if the carrier is raised very

slowly, until the fingers can be inserted to

prise the cam followers onto their respective

valve spring retainers. It is unlikely that the

valve clearance adjusting shims will be

displaced from their recesses in the cam

followers because of the suction of the

lubricating oil, but watch that this does not

happen; the shims must also be retained in

their originally fitted sequence.

12Remove the previously loosened

camshaft sprocket bolt and take the sprocket

from the camshaft.

13Unbolt and remove the camshaft end

cover with its gasket. Withdraw the camshaft

(photos).

14Refitting is a reversal of the removal

process, but observe the following points.

15Use new gaskets.

16Retain the cam followers and shims in

their bores in the camshaft carrier with thick

grease; they must not be allowed to drop out

when the carrier is lowered onto the cylinder

head.

17If the crankshaft or camshaft have been

moved from their set positions, re-align the

sprocket timing mark with the pointer on the

belt cover and the crankshaft pulley or

flywheel with the TDC mark. This must be

observed otherwise the valves may impinge

upon the piston crowns when the camshaft

lobes compress any of the valve springs

during bolting down of the carrier.

18Screw in the carrier bolts and tighten

them to the specified torque (photo).

19Refit and tension the timing belt as

described in Section 28.

20Refit the camshaft cover and gasket.

21Refit the hose and air cleaner.

22Reconnect the battery.

28 Timing belt- renewal

3

1Set No. 4 piston at TDC. Do this by turning

the crankshaft pulley nut or by jacking up a

front roadwheel, engaging a gear and turning

the wheel until the mark on the flywheel is

opposite to the TDC mark on the flywheel

bellhousing aperture. Remove No. 4 spark

plug, place a finger over the plug hole and feel

the compression being generated as the

crankshaft is rotated and the piston rises up

the cylinder bore.

2On some models the TDC marks on the

crankshaft pulley and belt cover may be

visible and can be used instead.

3Remove the alternator drivebelt (Chapter 2,

Section 8). Unbolt and remove the timing belt

cover.

4Check that the timing mark on the camshaft

sprocket is aligned with the pointer on the belt

cover backing plate (photo).

5Slacken the nut in the centre of the

tensioner pulley and push in on the support to

release the tension on the belt, then retighten

the nut. Slide the drivebelt off the pulleys.

6Check that the crankshaft and camshaft

pulleys have not been moved from their

previously aligned positions.

7To check that the auxiliary shaft sprocket

has not moved, take off the distributor cap

and check that the contact end of the rotor

arm is aligned with No. 4 HT lead contact in

the cap.

1•24 1116 cc and 1301 cc engine

28.4 Camshaft sprocket alignment marks

27.18 Tightening a camshaft carrier bolt27.13B Withdrawing camshaft from carrier27.13A Removing camshaft end cover

Page 39 of 303

8Fit the new belt. Start at the crankshaft

drive pulley and, taking care not to kink or

strain the belt, slip it over the camshaft pulley.

The camshaft may have to be turned slightly

to mesh the pulley with the teeth on the belt.

Fit the belt on the tensioner pulley last; if this

is difficult, do not lever or force the belt on,

recheck the belt (photo).

9Release the tensioner nut and rotate the

crankshaft through two complete revolutions.

Retighten the nut. The belt tension may be

checked by twisting it through 90º with the

finger and thumb. It should just turn through

this angle without undue force. Note: The

above procedure serves only as a rough guide

to setting the belt tension - having it checked

by a FIAT dealer at the earliest opportunity is

recommended.

10Refit the timing belt cover (photo). Fit and

tension the alternator drivebelt (Chapter 2,

Section 8).

29 Cylinder head-

removal and refitting

3

1Drain the cooling system (see Chapter 2).

2Disconnect the battery.

3Disconnect and plug the carburettor fuel

hoses.

4Disconnect the throttle and choke linkage

from the carburettor. 5Disconnect the HT leads from the spark

plugs.

6Disconnect the brake servo vacuum hose

from the intake manifold.

7Disconnect the coolant hoses from the

thermostat housing.

8Disconnect the crankcase ventilation

system hoses from the rocker cover and

carburettor.

9Unbolt and remove the timing belt cover.

10Release the timing belt tensioner pulley

bolt, then lever the pulley against the spring

plunger and retighten the bolt to retain the

tensioner pulley in the non-tensioned position.

Slip the belt from the camshaft sprocket.

11Disconnect the coolant hoses from the

carburettor and intake manifold.

12Disconnect the exhaust downpipes from

the manifold.

13If a crowfoot type wrench is available, the

cylinder head nuts and bolts can be removed

and the complete cylinder head camshaft

carrier assembly withdrawn (photo).

14If this type of wrench is not available

however, remove the carrier first as described

in Section 27.

15If a crowfoot is available, unscrew the

cylinder head nuts and bolts evenly and

progressively starting with the centre ones

and working towards both ends.

16Rock the cylinder head by gripping the

manifolds. Note: Do not insert a lever in

the gasket joint to prise the head from the

block.17Pull the head off the studs and remove it

to the bench. Remove and discard the old

cylinder head gasket.

18Unbolt and remove the hot air collecting

shield for the air cleaner from the exhaust

manifold. The exhaust and inlet manifolds can

now be unbolted. The carburettor may remain

on the inlet manifold.

19Overhaul and decarbonising of the

cylinder head is described in Section 39.

20Refitting is a reversal of the removal

process, but make sure the crankshaft and

camshaft timing marks are set as described in

Section 28 to avoid the valve heads digging

into the piston crowns when the head is

refitted.

21Always use new gaskets. The cylinder

1116 cc and 1301 cc engine 1•25

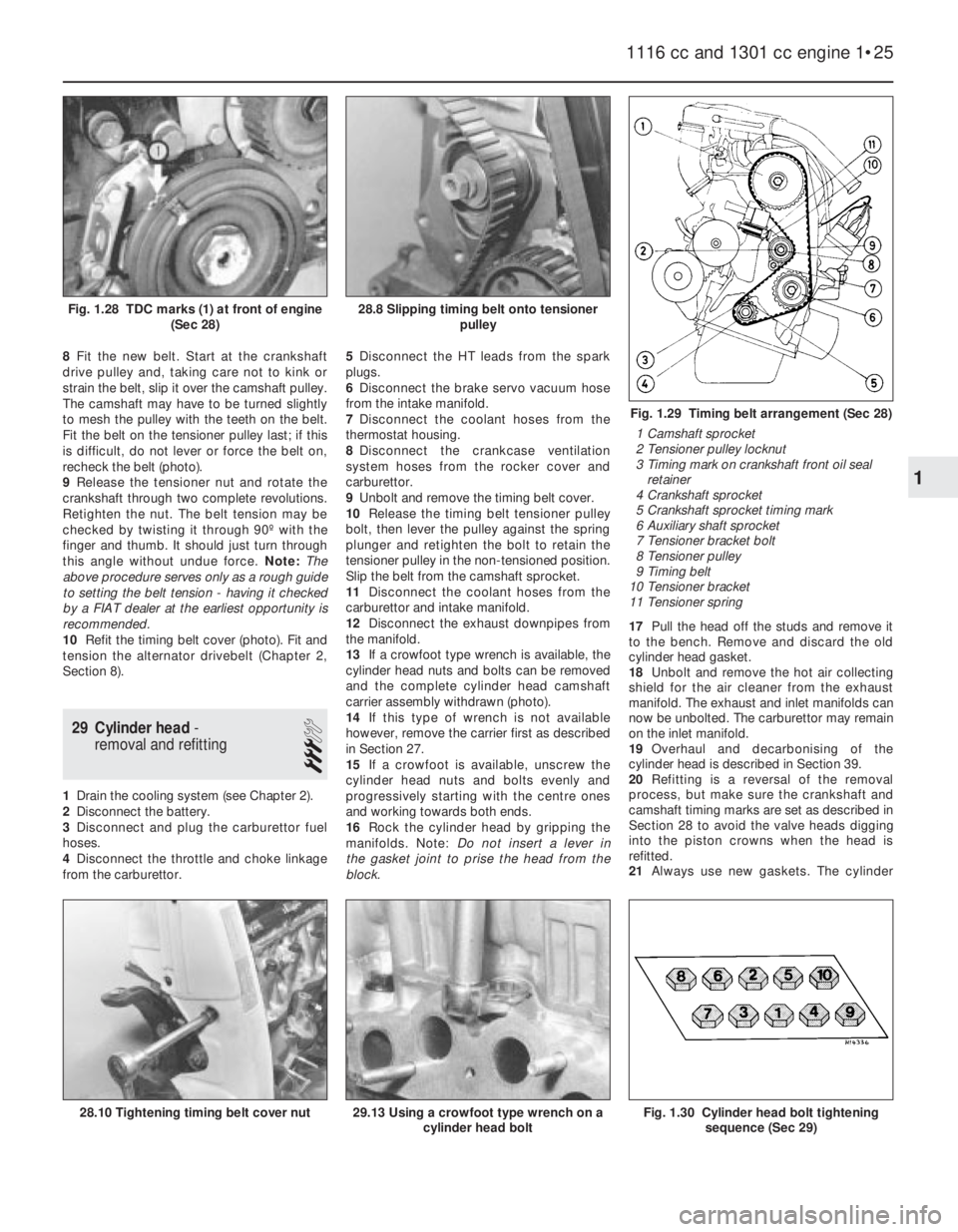

Fig. 1.29 Timing belt arrangement (Sec 28)

1 Camshaft sprocket

2 Tensioner pulley locknut

3 Timing mark on crankshaft front oil seal

retainer

4 Crankshaft sprocket

5 Crankshaft sprocket timing mark

6 Auxiliary shaft sprocket

7 Tensioner bracket bolt

8 Tensioner pulley

9 Timing belt

10 Tensioner bracket

11 Tensioner spring

28.8 Slipping timing belt onto tensioner

pulleyFig. 1.28 TDC marks (1) at front of engine

(Sec 28)

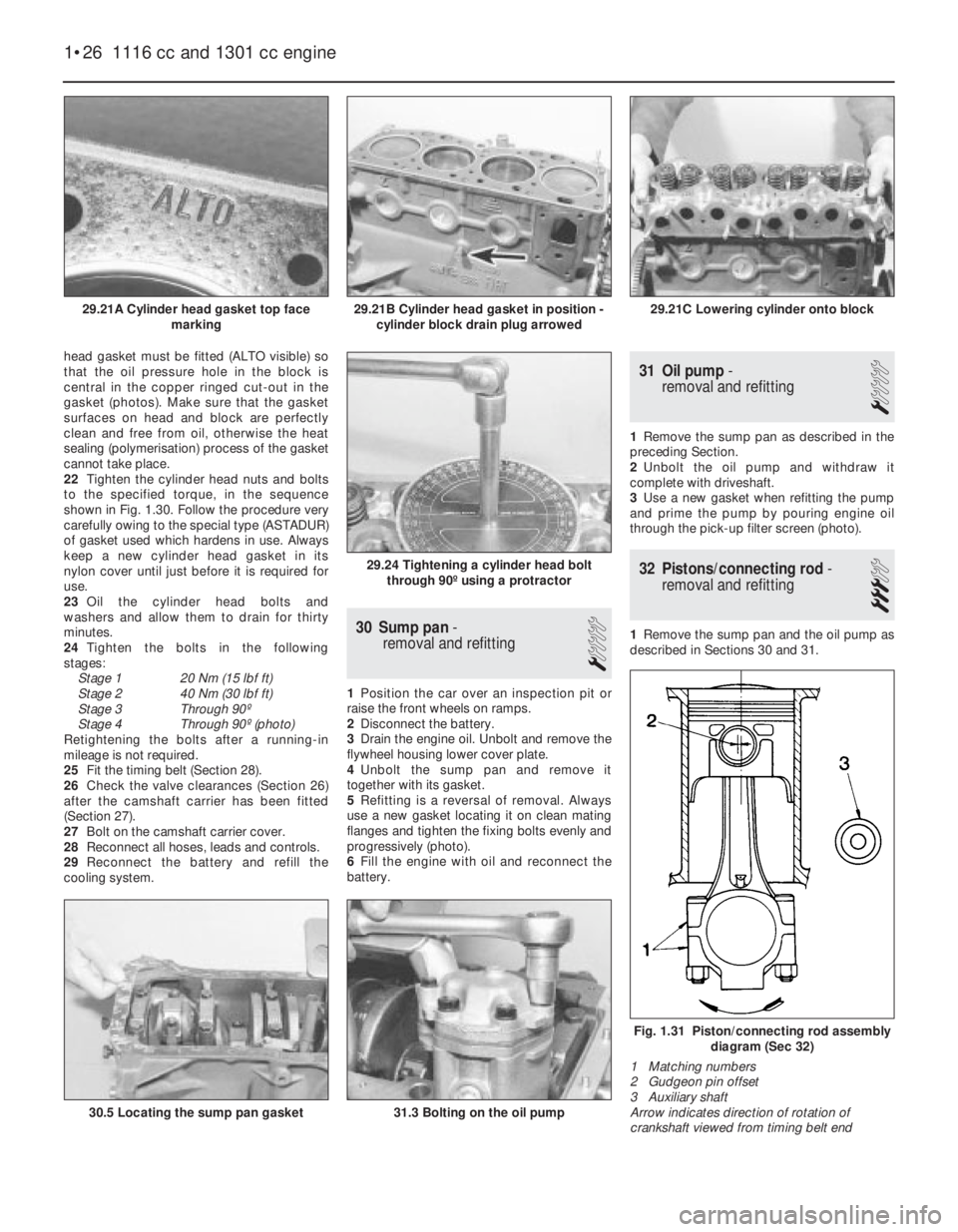

Fig. 1.30 Cylinder head bolt tightening

sequence (Sec 29)28.10 Tightening timing belt cover nut29.13 Using a crowfoot type wrench on a

cylinder head bolt

1

Page 40 of 303

head gasket must be fitted (ALTO visible) so

that the oil pressure hole in the block is

central in the copper ringed cut-out in the

gasket (photos). Make sure that the gasket

surfaces on head and block are perfectly

clean and free from oil, otherwise the heat

sealing (polymerisation) process of the gasket

cannot take place.

22Tighten the cylinder head nuts and bolts

to the specified torque, in the sequence

shown in Fig. 1.30. Follow the procedure very

carefully owing to the special type (ASTADUR)

of gasket used which hardens in use. Always

keep a new cylinder head gasket in its

nylon cover until just before it is required for

use.

23Oil the cylinder head bolts and

washers and allow them to drain for thirty

minutes.

24Tighten the bolts in the following

stages:

Stage 1 20 Nm (15 lbf ft)

Stage 2 40 Nm (30 lbf ft)

Stage 3 Through 90º

Stage 4 Through 90º (photo)

Retightening the bolts after a running-in

mileage is not required.

25Fit the timing belt (Section 28).

26Check the valve clearances (Section 26)

after the camshaft carrier has been fitted

(Section 27).

27Bolt on the camshaft carrier cover.

28Reconnect all hoses, leads and controls.

29Reconnect the battery and refill the

cooling system.

30 Sump pan-

removal and refitting

1

1Position the car over an inspection pit or

raise the front wheels on ramps.

2Disconnect the battery.

3Drain the engine oil. Unbolt and remove the

flywheel housing lower cover plate.

4Unbolt the sump pan and remove it

together with its gasket.

5Refitting is a reversal of removal. Always

use a new gasket locating it on clean mating

flanges and tighten the fixing bolts evenly and

progressively (photo).

6Fill the engine with oil and reconnect the

battery.

31 Oil pump-

removal and refitting

1

1Remove the sump pan as described in the

preceding Section.

2Unbolt the oil pump and withdraw it

complete with driveshaft.

3Use a new gasket when refitting the pump

and prime the pump by pouring engine oil

through the pick-up filter screen (photo).

32 Pistons/connecting rod-

removal and refitting

3

1Remove the sump pan and the oil pump as

described in Sections 30 and 31.

1•26 1116 cc and 1301 cc engine

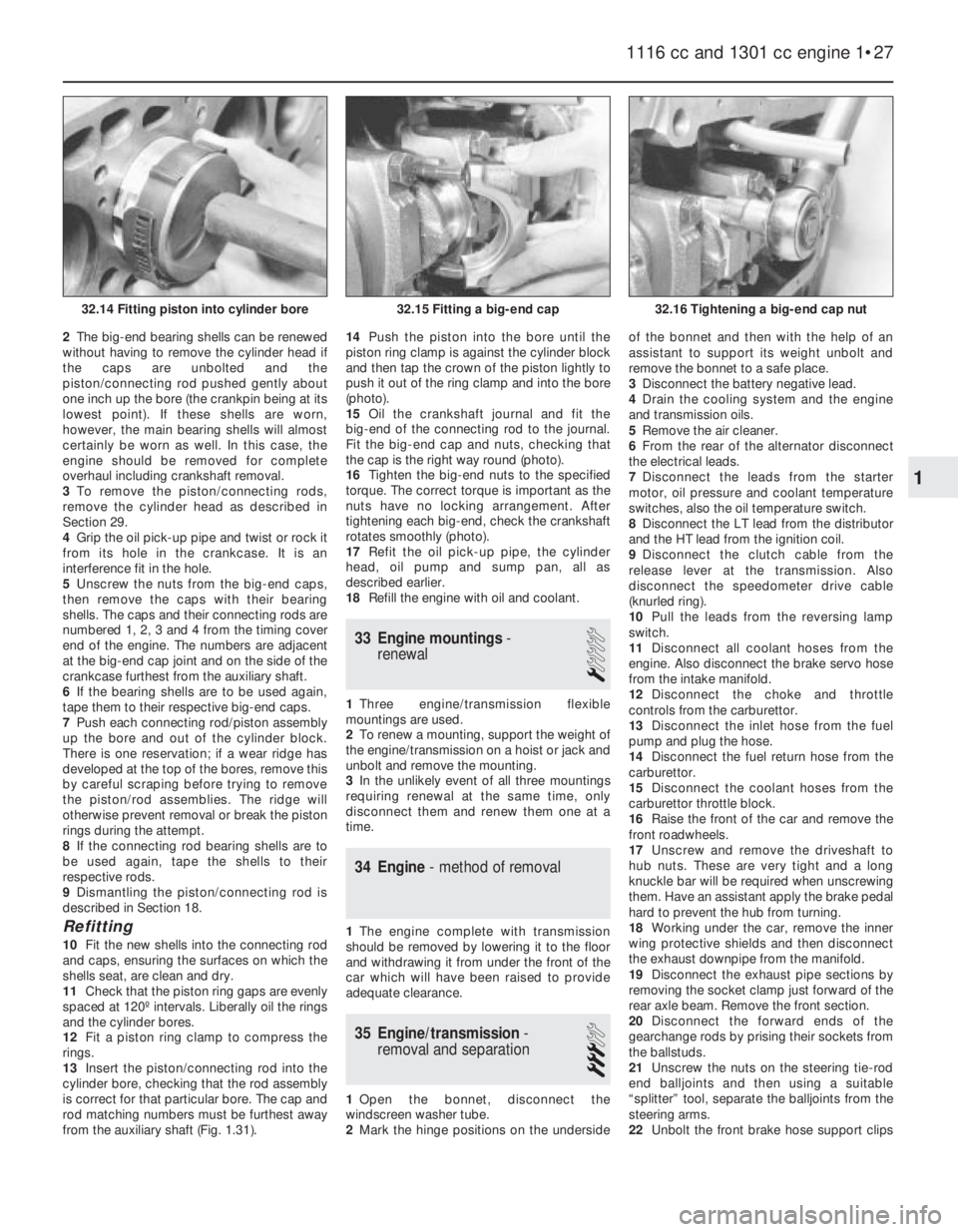

Fig. 1.31 Piston/connecting rod assembly

diagram (Sec 32)

1 Matching numbers

2 Gudgeon pin offset

3 Auxiliary shaft

Arrow indicates direction of rotation of

crankshaft viewed from timing belt end

29.24 Tightening a cylinder head bolt

through 90º using a protractor

31.3 Bolting on the oil pump30.5 Locating the sump pan gasket

29.21C Lowering cylinder onto block29.21B Cylinder head gasket in position -

cylinder block drain plug arrowed29.21A Cylinder head gasket top face

marking

Page 41 of 303

2The big-end bearing shells can be renewed

without having to remove the cylinder head if

the caps are unbolted and the

piston/connecting rod pushed gently about

one inch up the bore (the crankpin being at its

lowest point). If these shells are worn,

however, the main bearing shells will almost

certainly be worn as well. In this case, the

engine should be removed for complete

overhaul including crankshaft removal.

3To remove the piston/connecting rods,

remove the cylinder head as described in

Section 29.

4Grip the oil pick-up pipe and twist or rock it

from its hole in the crankcase. It is an

interference fit in the hole.

5Unscrew the nuts from the big-end caps,

then remove the caps with their bearing

shells. The caps and their connecting rods are

numbered 1, 2, 3 and 4 from the timing cover

end of the engine. The numbers are adjacent

at the big-end cap joint and on the side of the

crankcase furthest from the auxiliary shaft.

6If the bearing shells are to be used again,

tape them to their respective big-end caps.

7Push each connecting rod/piston assembly

up the bore and out of the cylinder block.

There is one reservation; if a wear ridge has

developed at the top of the bores, remove this

by careful scraping before trying to remove

the piston/rod assemblies. The ridge will

otherwise prevent removal or break the piston

rings during the attempt.

8If the connecting rod bearing shells are to

be used again, tape the shells to their

respective rods.

9Dismantling the piston/connecting rod is

described in Section 18.

Refitting

10Fit the new shells into the connecting rod

and caps, ensuring the surfaces on which the

shells seat, are clean and dry.

11Check that the piston ring gaps are evenly

spaced at 120º intervals. Liberally oil the rings

and the cylinder bores.

12Fit a piston ring clamp to compress the

rings.

13Insert the piston/connecting rod into the

cylinder bore, checking that the rod assembly

is correct for that particular bore. The cap and

rod matching numbers must be furthest away

from the auxiliary shaft (Fig. 1.31).14Push the piston into the bore until the

piston ring clamp is against the cylinder block

and then tap the crown of the piston lightly to

push it out of the ring clamp and into the bore

(photo).

15Oil the crankshaft journal and fit the

big-end of the connecting rod to the journal.

Fit the big-end cap and nuts, checking that

the cap is the right way round (photo).

16Tighten the big-end nuts to the specified

torque. The correct torque is important as the

nuts have no locking arrangement. After

tightening each big-end, check the crankshaft

rotates smoothly (photo).

17Refit the oil pick-up pipe, the cylinder

head, oil pump and sump pan, all as

described earlier.

18Refill the engine with oil and coolant.

33 Engine mountings-

renewal

1

1Three engine/transmission flexible

mountings are used.

2To renew a mounting, support the weight of

the engine/transmission on a hoist or jack and

unbolt and remove the mounting.

3In the unlikely event of all three mountings

requiring renewal at the same time, only

disconnect them and renew them one at a

time.

34 Engine- method of removal

1The engine complete with transmission

should be removed by lowering it to the floor

and withdrawing it from under the front of the

car which will have been raised to provide

adequate clearance.

35 Engine/transmission-

removal and separation

3

1Open the bonnet, disconnect the

windscreen washer tube.

2Mark the hinge positions on the undersideof the bonnet and then with the help of an

assistant to support its weight unbolt and

remove the bonnet to a safe place.

3Disconnect the battery negative lead.

4Drain the cooling system and the engine

and transmission oils.

5Remove the air cleaner.

6From the rear of the alternator disconnect

the electrical leads.

7Disconnect the leads from the starter

motor, oil pressure and coolant temperature

switches, also the oil temperature switch.

8Disconnect the LT lead from the distributor

and the HT lead from the ignition coil.

9Disconnect the clutch cable from the

release lever at the transmission. Also

disconnect the speedometer drive cable

(knurled ring).

10Pull the leads from the reversing lamp

switch.

11Disconnect all coolant hoses from the

engine. Also disconnect the brake servo hose

from the intake manifold.

12Disconnect the choke and throttle

controls from the carburettor.

13Disconnect the inlet hose from the fuel

pump and plug the hose.

14Disconnect the fuel return hose from the

carburettor.

15Disconnect the coolant hoses from the

carburettor throttle block.

16Raise the front of the car and remove the

front roadwheels.

17Unscrew and remove the driveshaft to

hub nuts. These are very tight and a long

knuckle bar will be required when unscrewing

them. Have an assistant apply the brake pedal

hard to prevent the hub from turning.

18Working under the car, remove the inner

wing protective shields and then disconnect

the exhaust downpipe from the manifold.

19Disconnect the exhaust pipe sections by

removing the socket clamp just forward of the

rear axle beam. Remove the front section.

20Disconnect the forward ends of the

gearchange rods by prising their sockets from

the ballstuds.

21Unscrew the nuts on the steering tie-rod

end balljoints and then using a suitable

“splitter” tool, separate the balljoints from the

steering arms.

22Unbolt the front brake hose support clips

1116 cc and 1301 cc engine 1•27

32.16 Tightening a big-end cap nut32.15 Fitting a big-end cap32.14 Fitting piston into cylinder bore

1

Page 132 of 303

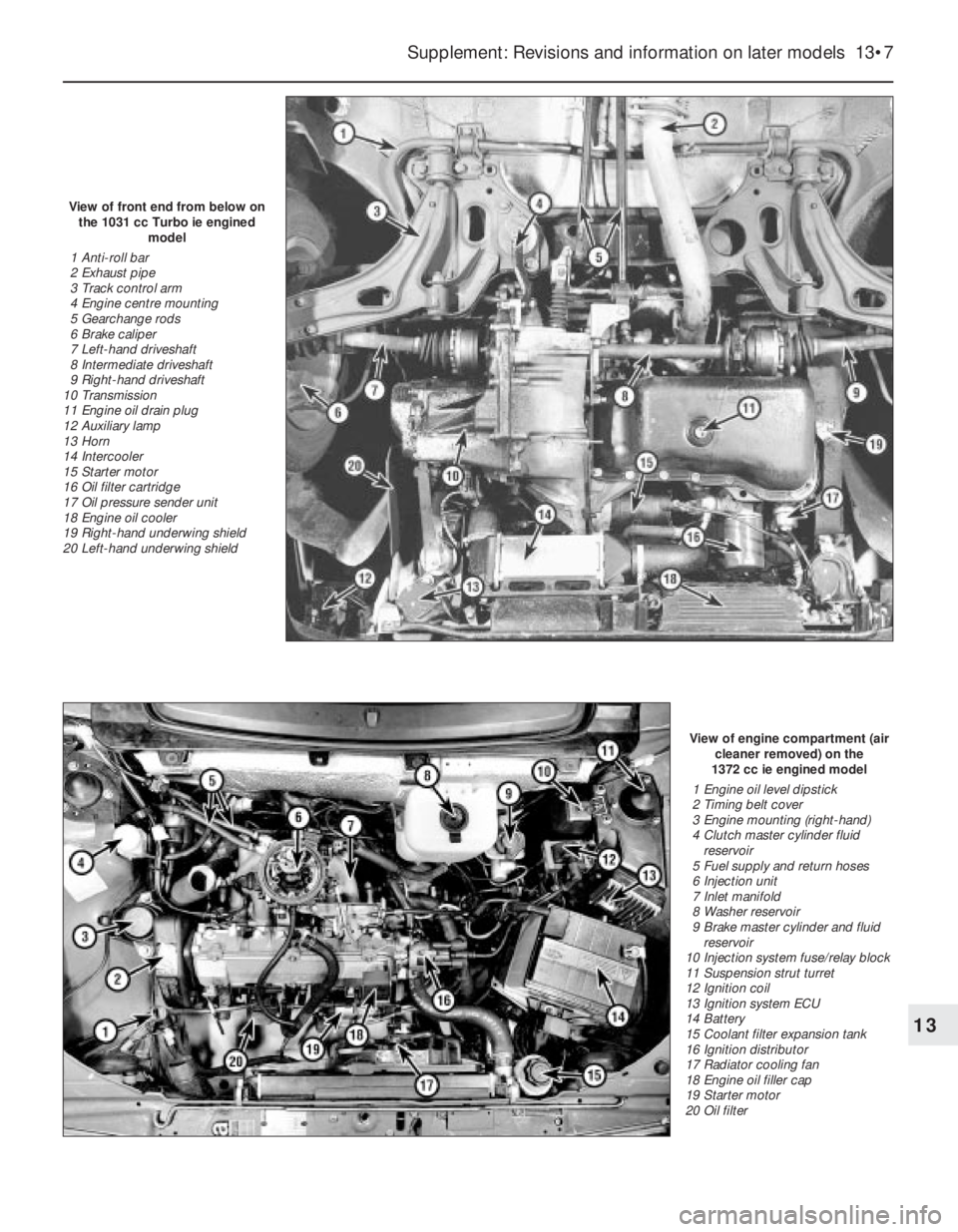

Supplement: Revisions and information on later models 13•7

View of engine compartment (air

cleaner removed) on the

1372 cc ie engined model

1 Engine oil level dipstick

2 Timing belt cover

3 Engine mounting (right-hand)

4 Clutch master cylinder fluid

reservoir

5 Fuel supply and return hoses

6 Injection unit

7 Inlet manifold

8 Washer reservoir

9 Brake master cylinder and fluid

reservoir

10 Injection system fuse/relay block

11 Suspension strut turret

12 Ignition coil

13 Ignition system ECU

14 Battery

15 Coolant filter expansion tank

16 Ignition distributor

17 Radiator cooling fan

18 Engine oil filler cap

19 Starter motor

20 Oil filter

View of front end from below on

the 1031 cc Turbo ie engined

model

1 Anti-roll bar

2 Exhaust pipe

3 Track control arm

4 Engine centre mounting

5 Gearchange rods

6 Brake caliper

7 Left-hand driveshaft

8 Intermediate driveshaft

9 Right-hand driveshaft

10 Transmission

11 Engine oil drain plug

12 Auxiliary lamp

13 Horn

14 Intercooler

15 Starter motor

16 Oil filter cartridge

17 Oil pressure sender unit

18 Engine oil cooler

19 Right-hand underwing shield

20 Left-hand underwing shield

13

Page 166 of 303

thumb and forefinger at the centre of the run

between the auxiliary shaft sprocket and the

camshaft sprocket. Using this method it

should just be possible to twist the belt

through 90º using moderate pressure.

55To adjust the tension, loosen off the

tensioner pulley nut then insert two rods (or

screwdrivers) into position in the pulley holes

and position a lever between them.

56Gently lever the tensioner pulley in the

required direction to set the tension as

described, then initially tighten the pulley nut

to lock the tensioner in the required position.

57Remove the tools from the tensioner,

recheck the tension and then tighten the

tensioner pulley nut securely.

58Rotate the crankshaft clockwise through

two complete turns using a socket or spanner

on the crankshaft pulley nut, then recheck the

belt tension. To avoid the possibility of

unscrewing the pulley nut, remove the spark

plugs to enable the engine to be turned over

easier.

59If further adjustment is required, repeat

the previously mentioned procedures. If in

doubt, err on the slightly tight side when

adjusting the tension. If the belt is set too

loose, it may jump off the sprockets resulting

in serious damage.

60Remove the crankshaft pulley retaining

nut, fit the timing belt cover, then refit and

tighten the pulley nut to the specified torque

setting.

61Refit the remaining components in the

reverse order of removal. Tighten the retaining

nuts/bolts to the specified torque settings

where given. Adjust the tension of the

alternator drivebelt as described in Section 8.

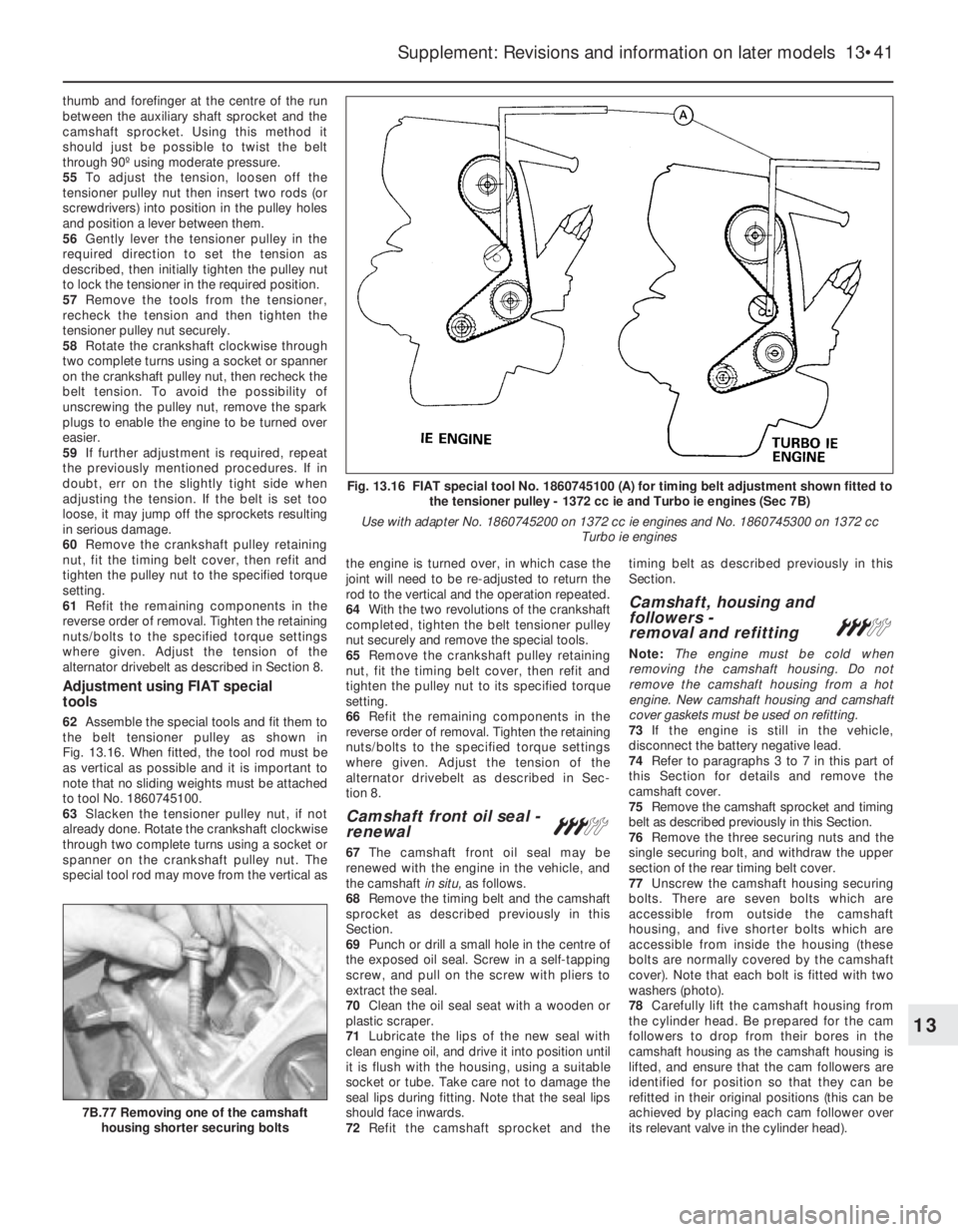

Adjustment using FIAT special

tools

62Assemble the special tools and fit them to

the belt tensioner pulley as shown in

Fig. 13.16. When fitted, the tool rod must be

as vertical as possible and it is important to

note that no sliding weights must be attached

to tool No. 1860745100.

63Slacken the tensioner pulley nut, if not

already done. Rotate the crankshaft clockwise

through two complete turns using a socket or

spanner on the crankshaft pulley nut. The

special tool rod may move from the vertical asthe engine is turned over, in which case the

joint will need to be re-adjusted to return the

rod to the vertical and the operation repeated.

64With the two revolutions of the crankshaft

completed, tighten the belt tensioner pulley

nut securely and remove the special tools.

65Remove the crankshaft pulley retaining

nut, fit the timing belt cover, then refit and

tighten the pulley nut to its specified torque

setting.

66Refit the remaining components in the

reverse order of removal. Tighten the retaining

nuts/bolts to the specified torque settings

where given. Adjust the tension of the

alternator drivebelt as described in Sec-

tion 8.

Camshaft front oil seal -

renewal#

67The camshaft front oil seal may be

renewed with the engine in the vehicle, and

the camshaft in situ, as follows.

68Remove the timing belt and the camshaft

sprocket as described previously in this

Section.

69Punch or drill a small hole in the centre of

the exposed oil seal. Screw in a self-tapping

screw, and pull on the screw with pliers to

extract the seal.

70Clean the oil seal seat with a wooden or

plastic scraper.

71Lubricate the lips of the new seal with

clean engine oil, and drive it into position until

it is flush with the housing, using a suitable

socket or tube. Take care not to damage the

seal lips during fitting. Note that the seal lips

should face inwards.

72Refit the camshaft sprocket and thetiming belt as described previously in this

Section.

Camshaft, housing and

followers -

removal and refitting

#

Note: The engine must be cold when

removing the camshaft housing. Do not

remove the camshaft housing from a hot

engine. New camshaft housing and camshaft

cover gaskets must be used on refitting.

73If the engine is still in the vehicle,

disconnect the battery negative lead.

74Refer to paragraphs 3 to 7 in this part of

this Section for details and remove the

camshaft cover.

75Remove the camshaft sprocket and timing

belt as described previously in this Section.

76Remove the three securing nuts and the

single securing bolt, and withdraw the upper

section of the rear timing belt cover.

77Unscrew the camshaft housing securing

bolts. There are seven bolts which are

accessible from outside the camshaft

housing, and five shorter bolts which are

accessible from inside the housing (these

bolts are normally covered by the camshaft

cover). Note that each bolt is fitted with two

washers (photo).

78Carefully lift the camshaft housing from

the cylinder head. Be prepared for the cam

followers to drop from their bores in the

camshaft housing as the camshaft housing is

lifted, and ensure that the cam followers are

identified for position so that they can be

refitted in their original positions (this can be

achieved by placing each cam follower over

its relevant valve in the cylinder head).

Supplement: Revisions and information on later models 13•41

Fig. 13.16 FIAT special tool No. 1860745100 (A) for timing belt adjustment shown fitted to

the tensioner pulley - 1372 cc ie and Turbo ie engines (Sec 7B)

Use with adapter No. 1860745200 on 1372 cc ie engines and No. 1860745300 on 1372 cc

Turbo ie engines

7B.77 Removing one of the camshaft

housing shorter securing bolts

13

Page 183 of 303

35Clean the mating faces of the thermostat

cover and cylinder head, and use a new

gasket when refitting the cover.

36Refill the cooling system as described

earlier in this Section.

Coolant pump -

removal and refittingÁ

Note: A new coolant pump gasket must be

used on refitting. If the pump is found to be

worn it must be renewed as a complete unit as

dismantling and repair is not possible.

37Disconnect the battery negative lead.

38Drain the cooling system as described

earlier in this Section.

39Remove the coolant/alternator drivebelt

as described in the next sub-Section.

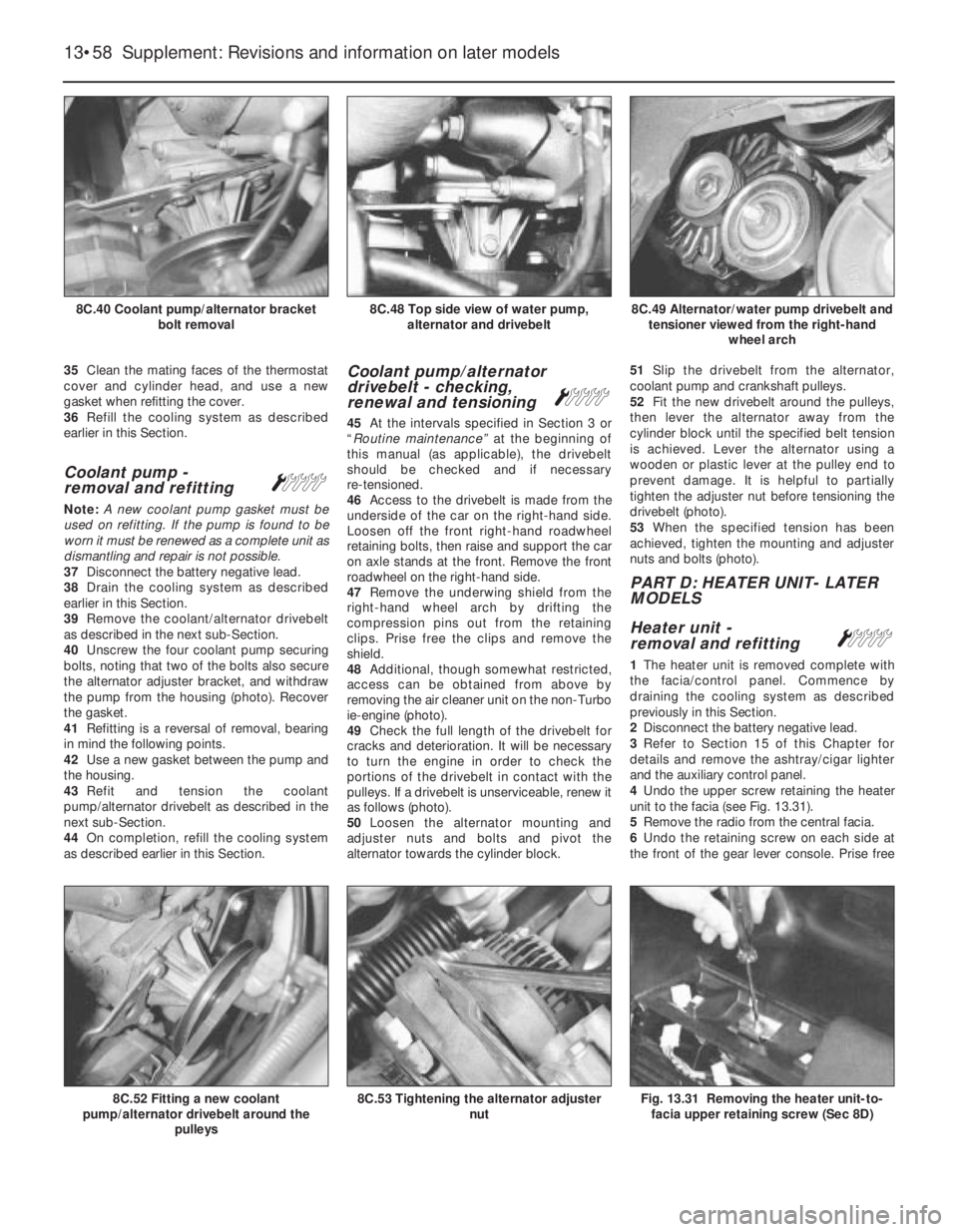

40Unscrew the four coolant pump securing

bolts, noting that two of the bolts also secure

the alternator adjuster bracket, and withdraw

the pump from the housing (photo). Recover

the gasket.

41Refitting is a reversal of removal, bearing

in mind the following points.

42Use a new gasket between the pump and

the housing.

43Refit and tension the coolant

pump/alternator drivebelt as described in the

next sub-Section.

44On completion, refill the cooling system

as described earlier in this Section.

Coolant pump/alternator

drivebelt - checking,

renewal and tensioning

Á

45At the intervals specified in Section 3 or

“Routine maintenance” at the beginning of

this manual (as applicable), the drivebelt

should be checked and if necessary

re-tensioned.

46Access to the drivebelt is made from the

underside of the car on the right-hand side.

Loosen off the front right-hand roadwheel

retaining bolts, then raise and support the car

on axle stands at the front. Remove the front

roadwheel on the right-hand side.

47Remove the underwing shield from the

right-hand wheel arch by drifting the

compression pins out from the retaining

clips. Prise free the clips and remove the

shield.

48Additional, though somewhat restricted,

access can be obtained from above by

removing the air cleaner unit on the non-Turbo

ie-engine (photo).

49Check the full length of the drivebelt for

cracks and deterioration. It will be necessary

to turn the engine in order to check the

portions of the drivebelt in contact with the

pulleys. If a drivebelt is unserviceable, renew it

as follows (photo).

50Loosen the alternator mounting and

adjuster nuts and bolts and pivot the

alternator towards the cylinder block.51Slip the drivebelt from the alternator,

coolant pump and crankshaft pulleys.

52Fit the new drivebelt around the pulleys,

then lever the alternator away from the

cylinder block until the specified belt tension

is achieved. Lever the alternator using a

wooden or plastic lever at the pulley end to

prevent damage. It is helpful to partially

tighten the adjuster nut before tensioning the

drivebelt (photo).

53When the specified tension has been

achieved, tighten the mounting and adjuster

nuts and bolts (photo).

PART D: HEATER UNIT- LATER

MODELS

Heater unit -

removal and refitting

Á

1The heater unit is removed complete with

the facia/control panel. Commence by

draining the cooling system as described

previously in this Section.

2Disconnect the battery negative lead.

3Refer to Section 15 of this Chapter for

details and remove the ashtray/cigar lighter

and the auxiliary control panel.

4Undo the upper screw retaining the heater

unit to the facia (see Fig. 13.31).

5Remove the radio from the central facia.

6Undo the retaining screw on each side at

the front of the gear lever console. Prise free

13•58 Supplement: Revisions and information on later models

Fig. 13.31 Removing the heater unit-to-

facia upper retaining screw (Sec 8D)8C.53 Tightening the alternator adjuster

nut8C.52 Fitting a new coolant

pump/alternator drivebelt around the

pulleys

8C.49 Alternator/water pump drivebelt and

tensioner viewed from the right-hand

wheel arch8C.48 Top side view of water pump,

alternator and drivebelt8C.40 Coolant pump/alternator bracket

bolt removal

Page 211 of 303

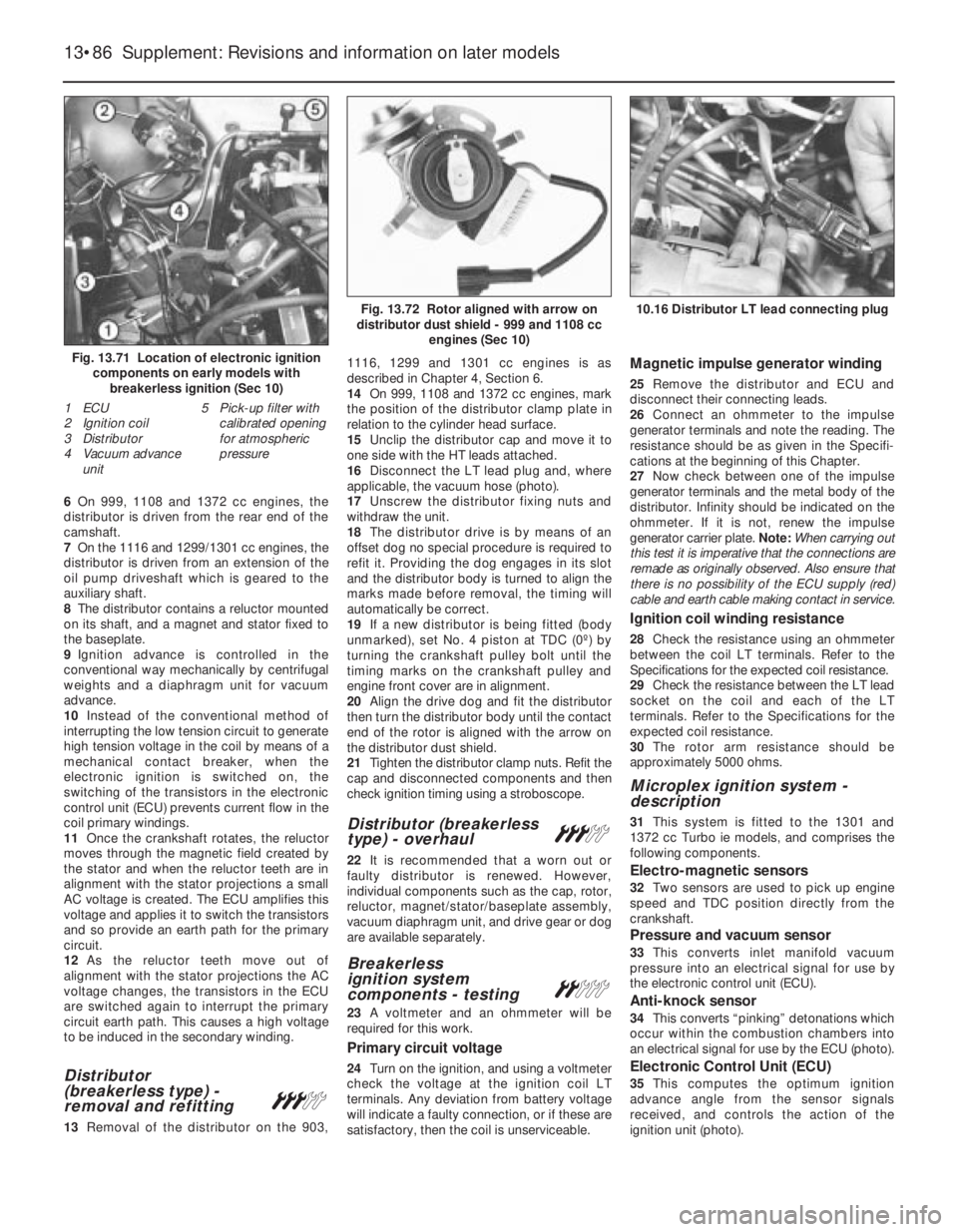

6On 999, 1108 and 1372 cc engines, the

distributor is driven from the rear end of the

camshaft.

7On the 1116 and 1299/1301 cc engines, the

distributor is driven from an extension of the

oil pump driveshaft which is geared to the

auxiliary shaft.

8The distributor contains a reluctor mounted

on its shaft, and a magnet and stator fixed to

the baseplate.

9Ignition advance is controlled in the

conventional way mechanically by centrifugal

weights and a diaphragm unit for vacuum

advance.

10Instead of the conventional method of

interrupting the low tension circuit to generate

high tension voltage in the coil by means of a

mechanical contact breaker, when the

electronic ignition is switched on, the

switching of the transistors in the electronic

control unit (ECU) prevents current flow in the

coil primary windings.

11Once the crankshaft rotates, the reluctor

moves through the magnetic field created by

the stator and when the reluctor teeth are in

alignment with the stator projections a small

AC voltage is created. The ECU amplifies this

voltage and applies it to switch the transistors

and so provide an earth path for the primary

circuit.

12As the reluctor teeth move out of

alignment with the stator projections the AC

voltage changes, the transistors in the ECU

are switched again to interrupt the primary

circuit earth path. This causes a high voltage

to be induced in the secondary winding.

Distributor

(breakerless type) -

removal and refitting

#

13Removal of the distributor on the 903,1116, 1299 and 1301 cc engines is as

described in Chapter 4, Section 6.

14On 999, 1108 and 1372 cc engines, mark

the position of the distributor clamp plate in

relation to the cylinder head surface.

15Unclip the distributor cap and move it to

one side with the HT leads attached.

16Disconnect the LT lead plug and, where

applicable, the vacuum hose (photo).

17Unscrew the distributor fixing nuts and

withdraw the unit.

18The distributor drive is by means of an

offset dog no special procedure is required to

refit it. Providing the dog engages in its slot

and the distributor body is turned to align the

marks made before removal, the timing will

automatically be correct.

19If a new distributor is being fitted (body

unmarked), set No. 4 piston at TDC (0º) by

turning the crankshaft pulley bolt until the

timing marks on the crankshaft pulley and

engine front cover are in alignment.

20Align the drive dog and fit the distributor

then turn the distributor body until the contact

end of the rotor is aligned with the arrow on

the distributor dust shield.

21Tighten the distributor clamp nuts. Refit the

cap and disconnected components and then

check ignition timing using a stroboscope.

Distributor (breakerless

type) - overhaul#

22It is recommended that a worn out or

faulty distributor is renewed. However,

individual components such as the cap, rotor,

reluctor, magnet/stator/baseplate assembly,

vacuum diaphragm unit, and drive gear or dog

are available separately.

Breakerless

ignition system

components - testing

ª

23A voltmeter and an ohmmeter will be

required for this work.

Primary circuit voltage

24Turn on the ignition, and using a voltmeter

check the voltage at the ignition coil LT

terminals. Any deviation from battery voltage

will indicate a faulty connection, or if these are

satisfactory, then the coil is unserviceable.

Magnetic impulse generator winding

25Remove the distributor and ECU and

disconnect their connecting leads.

26Connect an ohmmeter to the impulse

generator terminals and note the reading. The

resistance should be as given in the Specifi-

cations at the beginning of this Chapter.

27Now check between one of the impulse

generator terminals and the metal body of the

distributor. Infinity should be indicated on the

ohmmeter. If it is not, renew the impulse

generator carrier plate. Note: When carrying out

this test it is imperative that the connections are

remade as originally observed. Also ensure that

there is no possibility of the ECU supply (red)

cable and earth cable making contact in service.

Ignition coil winding resistance

28Check the resistance using an ohmmeter

between the coil LT terminals. Refer to the

Specifications for the expected coil resistance.

29Check the resistance between the LT lead

socket on the coil and each of the LT

terminals. Refer to the Specifications for the

expected coil resistance.

30The rotor arm resistance should be

approximately 5000 ohms.

Microplex ignition system -

description

31This system is fitted to the 1301 and

1372 cc Turbo ie models, and comprises the

following components.

Electro-magnetic sensors

32Two sensors are used to pick up engine

speed and TDC position directly from the

crankshaft.

Pressure and vacuum sensor

33This converts inlet manifold vacuum

pressure into an electrical signal for use by

the electronic control unit (ECU).

Anti-knock sensor

34This converts “pinking” detonations which

occur within the combustion chambers into

an electrical signal for use by the ECU (photo).

Electronic Control Unit (ECU)

35This computes the optimum ignition

advance angle from the sensor signals

received, and controls the action of the

ignition unit (photo).

13•86 Supplement: Revisions and information on later models

Fig. 13.72 Rotor aligned with arrow on

distributor dust shield - 999 and 1108 cc

engines (Sec 10)

1 ECU

2 Ignition coil

3 Distributor

4 Vacuum advance

unit5 Pick-up filter with

calibrated opening

for atmospheric

pressure

Fig. 13.71 Location of electronic ignition

components on early models with

breakerless ignition (Sec 10)

10.16 Distributor LT lead connecting plug

Page 230 of 303

Starter motor brushes

(later models) - renewal#

25When renewing the starter motor brushes

on later models, the old brushes will need to

be crushed (in a vice or with a hammer) and

their leads then soldered to the new brushes.

Fuses - later models

26The fuse arrangement is slightly different

on later models, but the circuits protected are

still identified by a symbol. Refer to the

Specifications Section for full details. Note

also the terminal block with plastic cover,

which can be used to isolate the battery from

the electrical system by disconnecting the

leads from the terminals (photos).

Relays (Turbo ie models) -

general

27On Turbo ie models, the relays mounted

in the fuse block are as shown in Fig. 13.103.

Additional relays are located as follows:

Headlamp relay - on lead under main fuse

blockFuel injection system main control relay -

adjacent to airflow meter

Headlamps later models

28The headlamp units fitted on later models

differ according to model, but the bulb and

unit replacement details are generally the

same as described for previous models in

Chapter 9. Note that the rubber cover can

only be fitted with the tab to the top as shown

(photo).

Headlamp beam adjusters for

load compensation - later

models

29Some later models are fitted with

headlamp beam adjusters which allowtemporary resetting to be made (such as

when the car is fully loaded). Access to these

adjusters is made by lifting the bonnet (photo).

30Turn the adjusters anti-clockwise to lower

the beam to the normal level or clockwise to

raise the beam (when the car is unloaded).

Repeat the procedure on the opposite

headlamp unit an equal amount.

31Other later models have separate

horizontal and vertical beam adjusters,

positioned as shown (photos). A load

compensating lever is attached to the

adjusters to enable temporary resetting of the

headlamp beams, without changing the

normal adjustment. Turn the lever to the

appropriate side (right or left) to make the

adjustment as required. The normal setting

Supplement: Revisions and information on later models 13•105

15.26B Battery lead terminal block on the

1301 cc Turbo ie model15.23B Starter motor and wiring

connections on the 1372 cc ie engine

15.31B Headlamp vertical beam alignment

adjuster screw on a 1372 cc ie model. Note

the load compensator lever which is set in

the “O” (normal load) setting position15.31A Headlamp horizontal beam

alignment adjuster screw on a 1372 cc ie

model

15.29 Headlamp beam adjuster on the

999 cc Turbo ie model15.28 Headlamp unit fitted to the 1372 cc ie

model

15.26A Fuse block on the 1301 cc Turbo ie

model

13

Fig. 13.103 Auxiliary fuses and relays on

1301 cc Turbo ie models (Sec 15)

1 Horn relay

2 Heated rear screen relay

3 Foglamps relay

4 Radiator fan relay

5 Electric windows relay

6 Foglamps fuse

7 Radiator fan second speed fuse

8 Fuel injector fan fuse

9 Electric windows fuse

10 Electric fuel pump fuse

Page 233 of 303

Auxiliary control panel

(later models) -

removal and refitting

Á

61Disconnect the battery negative lead.

62Insert the flat of a screwdriver under the

trim piece at the end of the auxiliary panel as

shown and prise it free. Repeat the procedure

and remove the trim piece at the other end of

the panel (photo).

63Undo the retaining screws, withdraw the

panel from the facia. Disconnect the wiring

connectors from the panel switches to

remove the panel completely (photo).

64A switch bulb can be renewed by

untwisting the holder and removing the holder

and bulb.

65A switch unit can be removed from the

panel by unscrewing the four retaining screws.66Refitting is a reversal of the removal

procedure. Ensure that the wiring connections

are securely made and check for satisfactory

operation of the switches on completion.

Heater control panel

(later models) -

removal and refitting

Á

67Disconnect the battery negative lead.

68Pull free the heater/fresh air and blower

control knobs (photo).

69Undo the two retaining screws and

withdraw the control panel from the facia

(photos). Detach the wiring connectors from the

panel illumination lights and remove the panel.

70Refitting is a reversal of the removal

procedure. Ensure that the wiring connections

are securely made and on completion check

that the operation of the controls is satisfactory.

Trip master Á

71This electronic instrument is fitted into the

check panel of 1100SL and 1300SL models

from 1986.

72The device provides information on fuel

consumption, range, speed and elapsed time.

73With the ignition key turned to MAR,

figures are displayed in respect of the last

journey - average fuel consumption, average

speed and elapsed time (up to switching off

the ignition).

74As soon as the engine is started, the

instrument processes the current values to

include fuel consumption, range and the

actual time. 75Fuel consumption is only displayed when

the road speed exceeds 8.0 km/h (5.0 mph).

76The fuel range is only displayed after a

road speed of between 25.0 and 70.0 km/h

(15.0 to 44.0 mph) has been maintained for at

least 90 seconds or at higher speeds for

22 seconds.

77A reset button is provided, also a display

change button (from instant to average or

total values). Should the instrument reading

exceed 99 hours, 59 minutes or 1000 km

(622 miles) depressing the display change

button will display all zeros. Depress button E

to resume normal function.

78Refer to the end of the manual for a wiring

diagram of the check panel, incorporating the

trip master.

Interior roof mounted spotlamp,

switch and/or clock -

removal and refitting

Á

79Disconnect the battery negative lead.

80Prise free the lamp unit from its aperture

in the roof panel using a thin-bladed

screwdriver. The lamp bulb can be inspected

by untwisting the holder and withdrawing it

from the rear of the unit (photos). Extract the

bulb from the holder if it requires renewal.

81To remove the lamp switch from the

panel, reach through the lamp aperture and

press it free from the roof panel (photo).

Detach the wiring connectors.

82To remove the clock, reach through the

lamp aperture and undo the retaining screws

(photo). Withdraw the clock and detach the

wiring connectors.

13•108 Supplement: Revisions and information on later models

15.69B . . . and withdraw the heater control

panel15.69A . . . undo the retaining screws

(arrowed)15.68 Remove the control knobs . . .

15.63 . . . and withdraw the auxiliary

control panel

15.62 Prise free the trim covers for access

to retaining screws . . .15.59B . . . and disconnect the

speedometer cable15.59A . . . withdraw the instrument

panel . . .