FIAT UNO 1983 Service Repair Manual

Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 151 of 303

99Tighten the big-end bolts to the specified

torque (photo). The correct torque is

important as the bolts have no locking

arrangement. After tightening each big-end,

check that the crankshaft rotates smoothly.

100Repeat the operations on the remaining

piston/rod assemblies.

101Refit the oil pump pick-up assembly

using a new sealing ring.

102Refit the sump pan and the cylinder head

as described in earlier sub-Sections.

103Fill the engine with oil and coolant.

Pistons/connecting rods -

separation and piston

ring renewal

ª

104If the piston/connecting rods have been

removed in order to renew the piston rings,

refer to Chapter 1, Section 18, but note thatthe piston rings should be fitted so that the

word TOP is uppermost.

105If new pistons are to be fitted, it is

recommended that the gudgeon pins are

removed and refitted by a FIAT dealer as the

connecting rods must be carefully heated in

order to be able to push the gudgeon pin out

of the rod small-end, change the piston and

push the pin back into position. Locating the

gudgeon pin will require a special tool. The

gudgeon pin is a sliding fit in the piston but an

interference fit in the connecting rod.

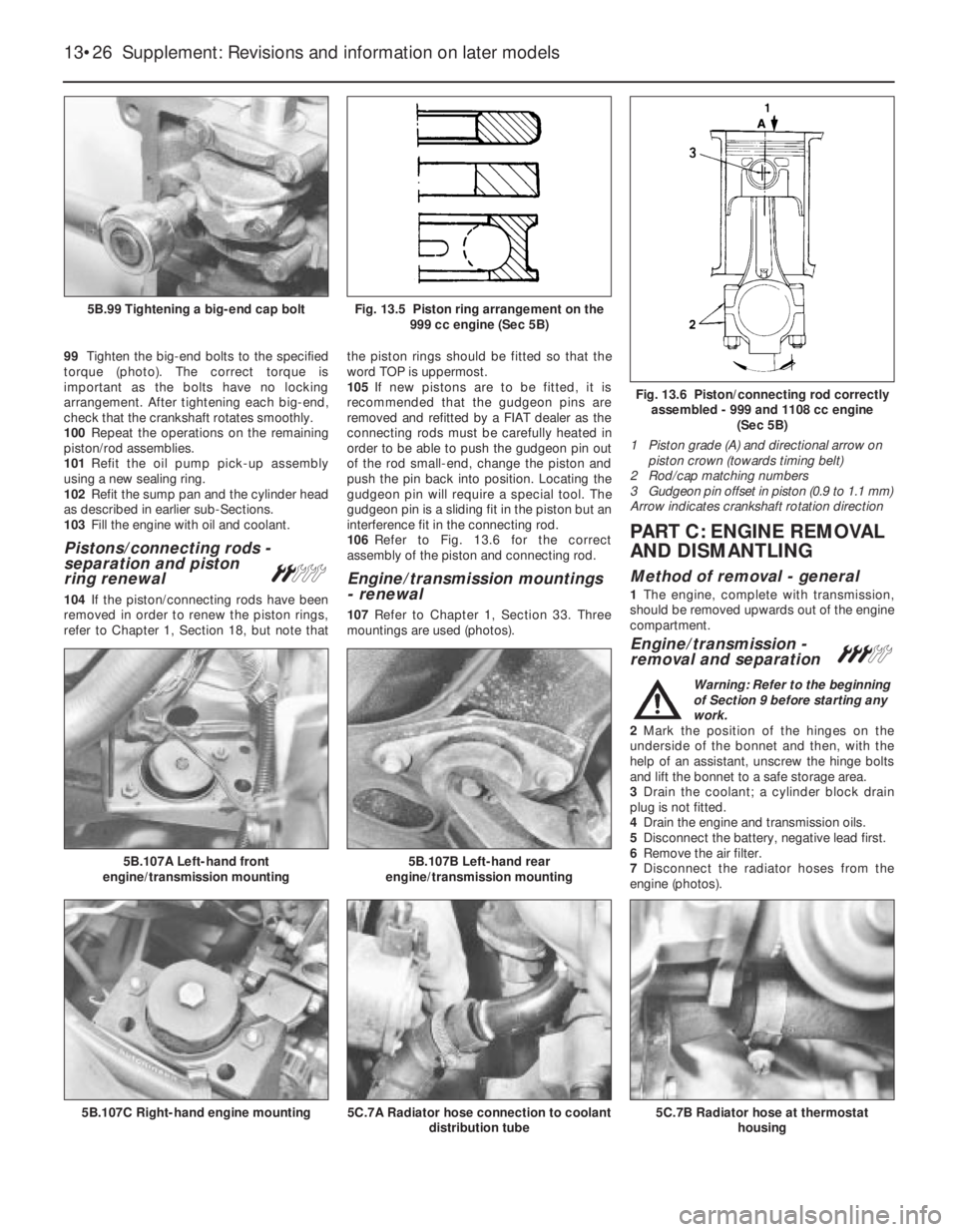

106Refer to Fig. 13.6 for the correct

assembly of the piston and connecting rod.

Engine/transmission mountings

- renewal

107Refer to Chapter 1, Section 33. Three

mountings are used (photos).

PART C: ENGINE REMOVAL

AND DISMANTLING

Method of removal - general

1The engine, complete with transmission,

should be removed upwards out of the engine

compartment.

Engine/transmission -

removal and separation #

Warning: Refer to the beginning

of Section 9 before starting any

work.

2Mark the position of the hinges on the

underside of the bonnet and then, with the

help of an assistant, unscrew the hinge bolts

and lift the bonnet to a safe storage area.

3Drain the coolant; a cylinder block drain

plug is not fitted.

4Drain the engine and transmission oils.

5Disconnect the battery, negative lead first.

6Remove the air filter.

7Disconnect the radiator hoses from the

engine (photos).

13•26 Supplement: Revisions and information on later models

5C.7B Radiator hose at thermostat

housing5C.7A Radiator hose connection to coolant

distribution tube5B.107C Right-hand engine mounting

5B.107B Left-hand rear

engine/transmission mounting5B.107A Left-hand front

engine/transmission mounting

Fig. 13.6 Piston/connecting rod correctly

assembled - 999 and 1108 cc engine

(Sec 5B)

1 Piston grade (A) and directional arrow on

piston crown (towards timing belt)

2 Rod/cap matching numbers

3 Gudgeon pin offset in piston (0.9 to 1.1 mm)

Arrow indicates crankshaft rotation direction

Fig. 13.5 Piston ring arrangement on the

999 cc engine (Sec 5B)5B.99 Tightening a big-end cap bolt

Page 152 of 303

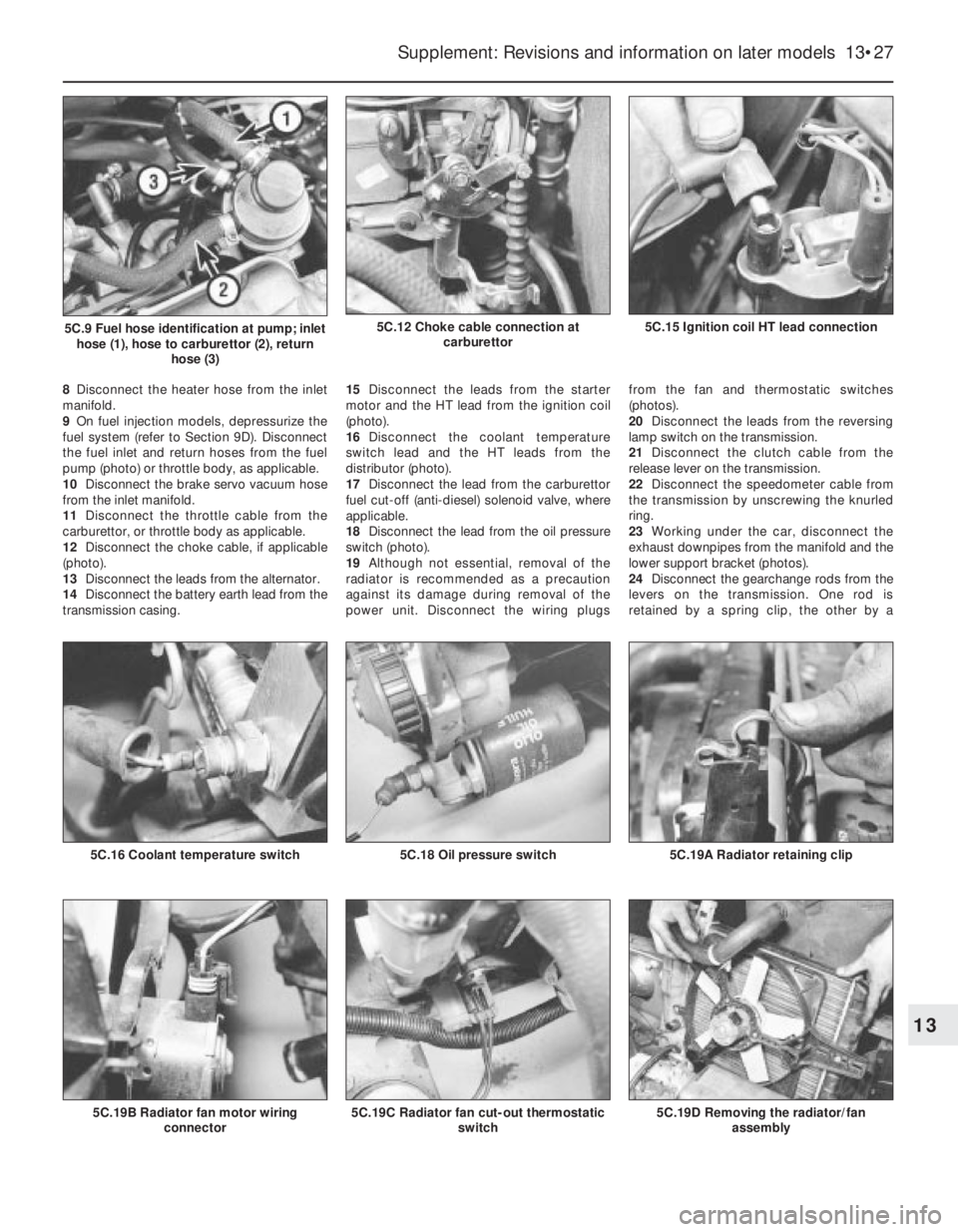

8Disconnect the heater hose from the inlet

manifold.

9On fuel injection models, depressurize the

fuel system (refer to Section 9D). Disconnect

the fuel inlet and return hoses from the fuel

pump (photo) or throttle body, as applicable.

10Disconnect the brake servo vacuum hose

from the inlet manifold.

11Disconnect the throttle cable from the

carburettor, or throttle body as applicable.

12Disconnect the choke cable, if applicable

(photo).

13Disconnect the leads from the alternator.

14Disconnect the battery earth lead from the

transmission casing.15Disconnect the leads from the starter

motor and the HT lead from the ignition coil

(photo).

16Disconnect the coolant temperature

switch lead and the HT leads from the

distributor (photo).

17Disconnect the lead from the carburettor

fuel cut-off (anti-diesel) solenoid valve, where

applicable.

18Disconnect the lead from the oil pressure

switch (photo).

19Although not essential, removal of the

radiator is recommended as a precaution

against its damage during removal of the

power unit. Disconnect the wiring plugs from the fan and thermostatic switches

(photos).

20Disconnect the leads from the reversing

lamp switch on the transmission.

21Disconnect the clutch cable from the

release lever on the transmission.

22Disconnect the speedometer cable from

the transmission by unscrewing the knurled

ring.

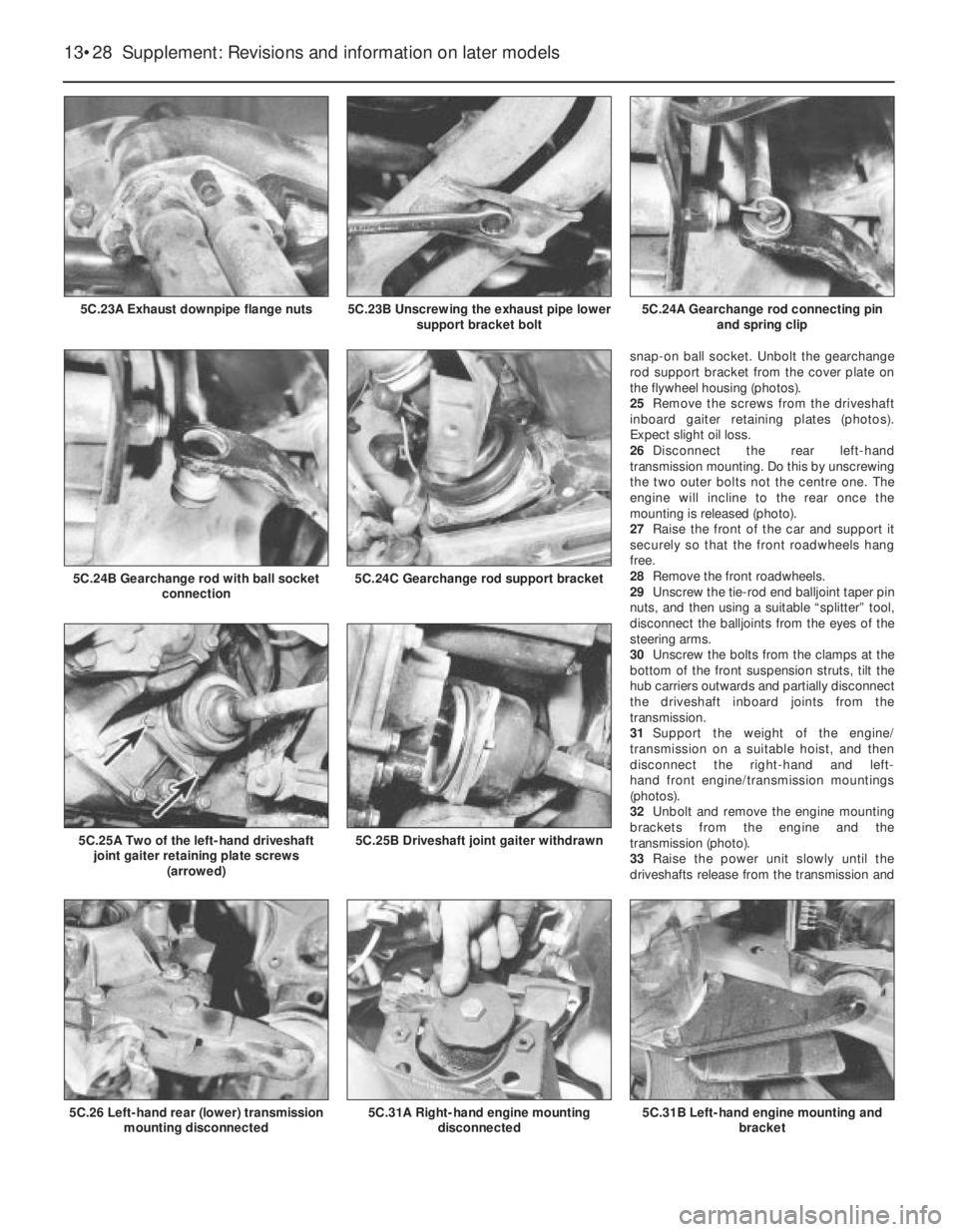

23Working under the car, disconnect the

exhaust downpipes from the manifold and the

lower support bracket (photos).

24Disconnect the gearchange rods from the

levers on the transmission. One rod is

retained by a spring clip, the other by a

Supplement: Revisions and information on later models 13•27

5C.15 Ignition coil HT lead connection5C.12 Choke cable connection at

carburettor5C.9 Fuel hose identification at pump; inlet

hose (1), hose to carburettor (2), return

hose (3)

5C.19D Removing the radiator/fan

assembly5C.19C Radiator fan cut-out thermostatic

switch5C.19B Radiator fan motor wiring

connector

5C.19A Radiator retaining clip5C.18 Oil pressure switch5C.16 Coolant temperature switch

13

Page 153 of 303

snap-on ball socket. Unbolt the gearchange

rod support bracket from the cover plate on

the flywheel housing (photos).

25Remove the screws from the driveshaft

inboard gaiter retaining plates (photos).

Expect slight oil loss.

26Disconnect the rear left-hand

transmission mounting. Do this by unscrewing

the two outer bolts not the centre one. The

engine will incline to the rear once the

mounting is released (photo).

27Raise the front of the car and support it

securely so that the front roadwheels hang

free.

28Remove the front roadwheels.

29Unscrew the tie-rod end balljoint taper pin

nuts, and then using a suitable “splitter” tool,

disconnect the balljoints from the eyes of the

steering arms.

30Unscrew the bolts from the clamps at the

bottom of the front suspension struts, tilt the

hub carriers outwards and partially disconnect

the driveshaft inboard joints from the

transmission.

31Support the weight of the engine/

transmission on a suitable hoist, and then

disconnect the right-hand and left-

hand front engine/transmission mountings

(photos).

32Unbolt and remove the engine mounting

brackets from the engine and the

transmission (photo).

33Raise the power unit slowly until the

driveshafts release from the transmission and

13•28 Supplement: Revisions and information on later models

5C.31B Left-hand engine mounting and

bracket5C.31A Right-hand engine mounting

disconnected5C.26 Left-hand rear (lower) transmission

mounting disconnected

5C.25B Driveshaft joint gaiter withdrawn5C.25A Two of the left-hand driveshaft

joint gaiter retaining plate screws

(arrowed)

5C.24C Gearchange rod support bracket5C.24B Gearchange rod with ball socket

connection

5C.24A Gearchange rod connecting pin

and spring clip5C.23B Unscrewing the exhaust pipe lower

support bracket bolt5C.23A Exhaust downpipe flange nuts

Page 154 of 303

can be lowered to rest on the exhaust and

bodymember.

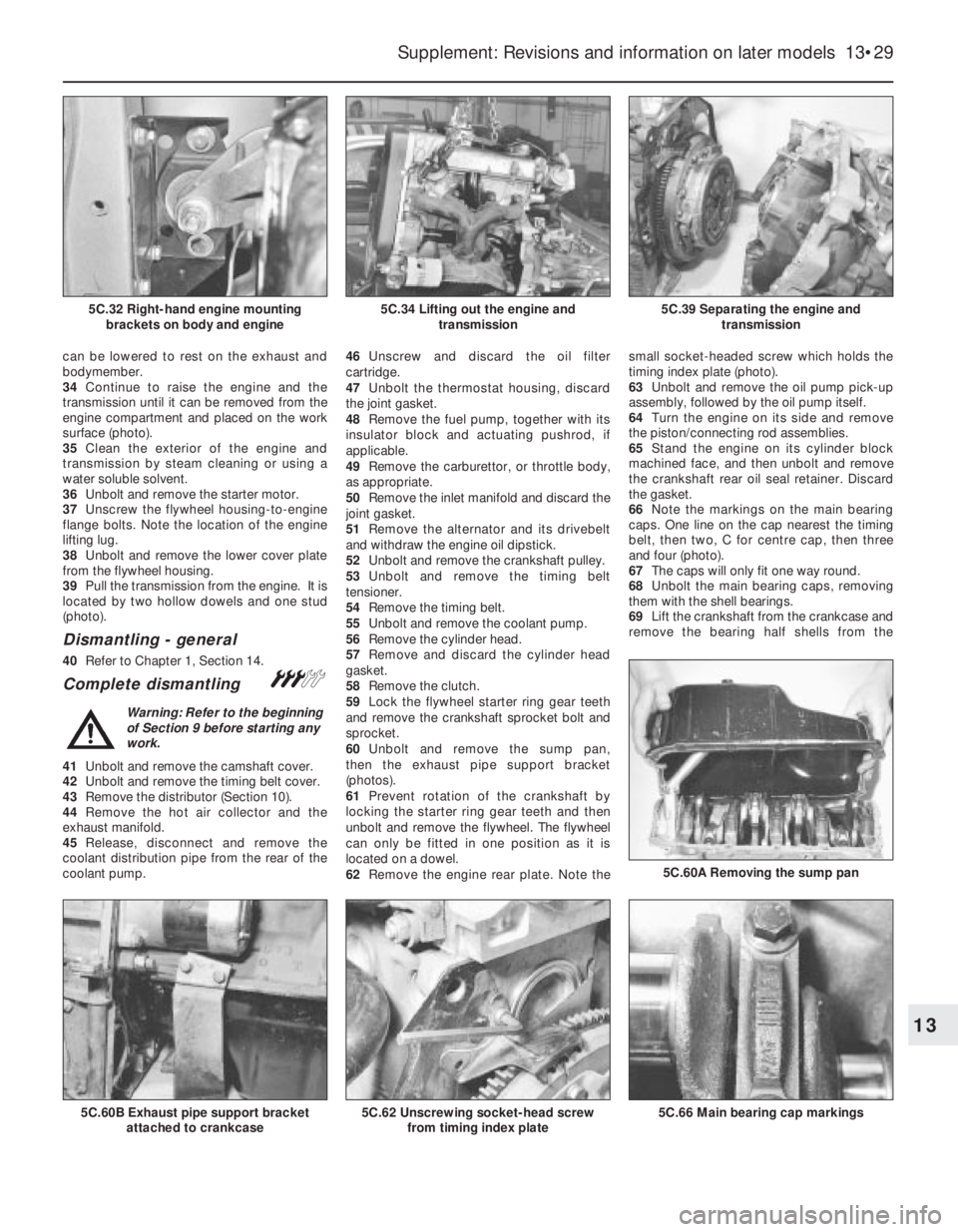

34Continue to raise the engine and the

transmission until it can be removed from the

engine compartment and placed on the work

surface (photo).

35Clean the exterior of the engine and

transmission by steam cleaning or using a

water soluble solvent.

36Unbolt and remove the starter motor.

37Unscrew the flywheel housing-to-engine

flange bolts. Note the location of the engine

lifting lug.

38Unbolt and remove the lower cover plate

from the flywheel housing.

39Pull the transmission from the engine. It is

located by two hollow dowels and one stud

(photo).

Dismantling - general

40Refer to Chapter 1, Section 14.

Complete dismantling#

Warning: Refer to the beginning

of Section 9 before starting any

work.

41Unbolt and remove the camshaft cover.

42Unbolt and remove the timing belt cover.

43Remove the distributor (Section 10).

44Remove the hot air collector and the

exhaust manifold.

45Release, disconnect and remove the

coolant distribution pipe from the rear of the

coolant pump.46Unscrew and discard the oil filter

cartridge.

47Unbolt the thermostat housing, discard

the joint gasket.

48Remove the fuel pump, together with its

insulator block and actuating pushrod, if

applicable.

49Remove the carburettor, or throttle body,

as appropriate.

50Remove the inlet manifold and discard the

joint gasket.

51Remove the alternator and its drivebelt

and withdraw the engine oil dipstick.

52Unbolt and remove the crankshaft pulley.

53Unbolt and remove the timing belt

tensioner.

54Remove the timing belt.

55Unbolt and remove the coolant pump.

56Remove the cylinder head.

57Remove and discard the cylinder head

gasket.

58Remove the clutch.

59Lock the flywheel starter ring gear teeth

and remove the crankshaft sprocket bolt and

sprocket.

60Unbolt and remove the sump pan,

then the exhaust pipe support bracket

(photos).

61Prevent rotation of the crankshaft by

locking the starter ring gear teeth and then

unbolt and remove the flywheel. The flywheel

can only be fitted in one position as it is

located on a dowel.

62Remove the engine rear plate. Note thesmall socket-headed screw which holds the

timing index plate (photo).

63Unbolt and remove the oil pump pick-up

assembly, followed by the oil pump itself.

64Turn the engine on its side and remove

the piston/connecting rod assemblies.

65Stand the engine on its cylinder block

machined face, and then unbolt and remove

the crankshaft rear oil seal retainer. Discard

the gasket.

66Note the markings on the main bearing

caps. One line on the cap nearest the timing

belt, then two, C for centre cap, then three

and four (photo).

67The caps will only fit one way round.

68Unbolt the main bearing caps, removing

them with the shell bearings.

69Lift the crankshaft from the crankcase and

remove the bearing half shells from the

Supplement: Revisions and information on later models 13•29

5C.39 Separating the engine and

transmission5C.34 Lifting out the engine and

transmission5C.32 Right-hand engine mounting

brackets on body and engine

5C.66 Main bearing cap markings

5C.60A Removing the sump pan

5C.62 Unscrewing socket-head screw

from timing index plate5C.60B Exhaust pipe support bracket

attached to crankcase

13

Page 155 of 303

crankcase. If the shells are to be used again,

keep them with their respective bearing caps.

70The thrust washers which control

crankshaft endfloat are located in the

crankcase, and retained by the turned-over

edges of the centre main bearing shell.

71The engine is now fully stripped.

Examination and renovation

72The procedures for the following items are

essentially as described in Chapter 1, Sec-

tion 18.

Cylinder block and crankcase

Crankshaft and bearings

Flywheel

Oil seals and gaskets

Cylinder head

73Using a straight-edge, check the cylinder

head gasket surface for distortion. If it

exceeds the specified tolerance, it must be

surface ground by your dealer.74Refer to Chapter 1, Section 39, for

dismantling and renovation operations. Note

that single valve springs are fitted.

Oil pump

75Checking operations are described in

sub-Section B.

Pistons and connecting rods

76Refer to sub-Section B.

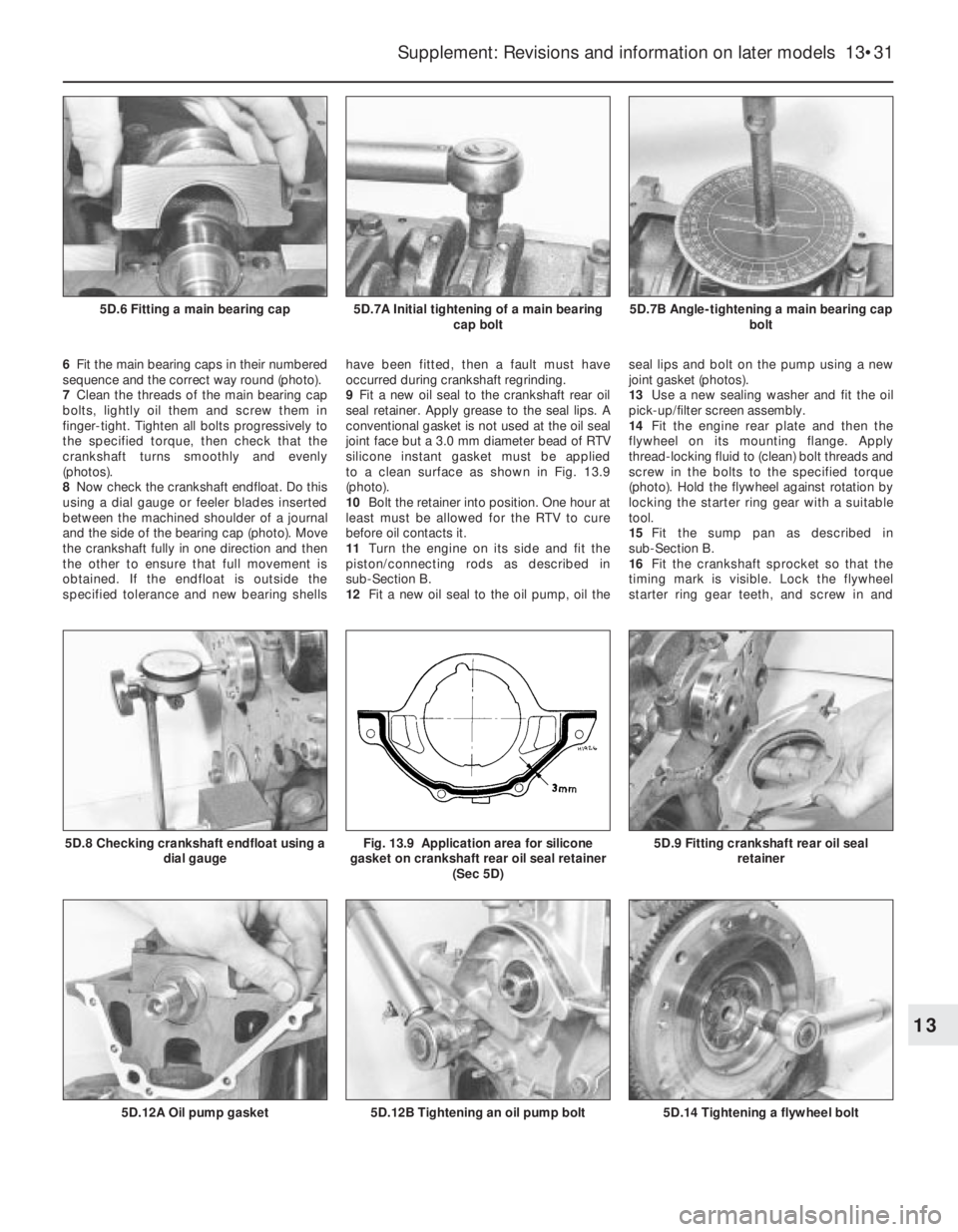

77If one or more connecting rods are

changed, it is important that its weight is

identical to that of the original. Use an

accurate balance to weigh them and remove

metal if necessary from the new rod in the

areas indicated in Fig. 13.7.

Camshaft and cam followers

78If the camshaft journals or bearings show

any sign of wear or scoring, then the

camshaft, or cylinder head, or both must be

renewed.

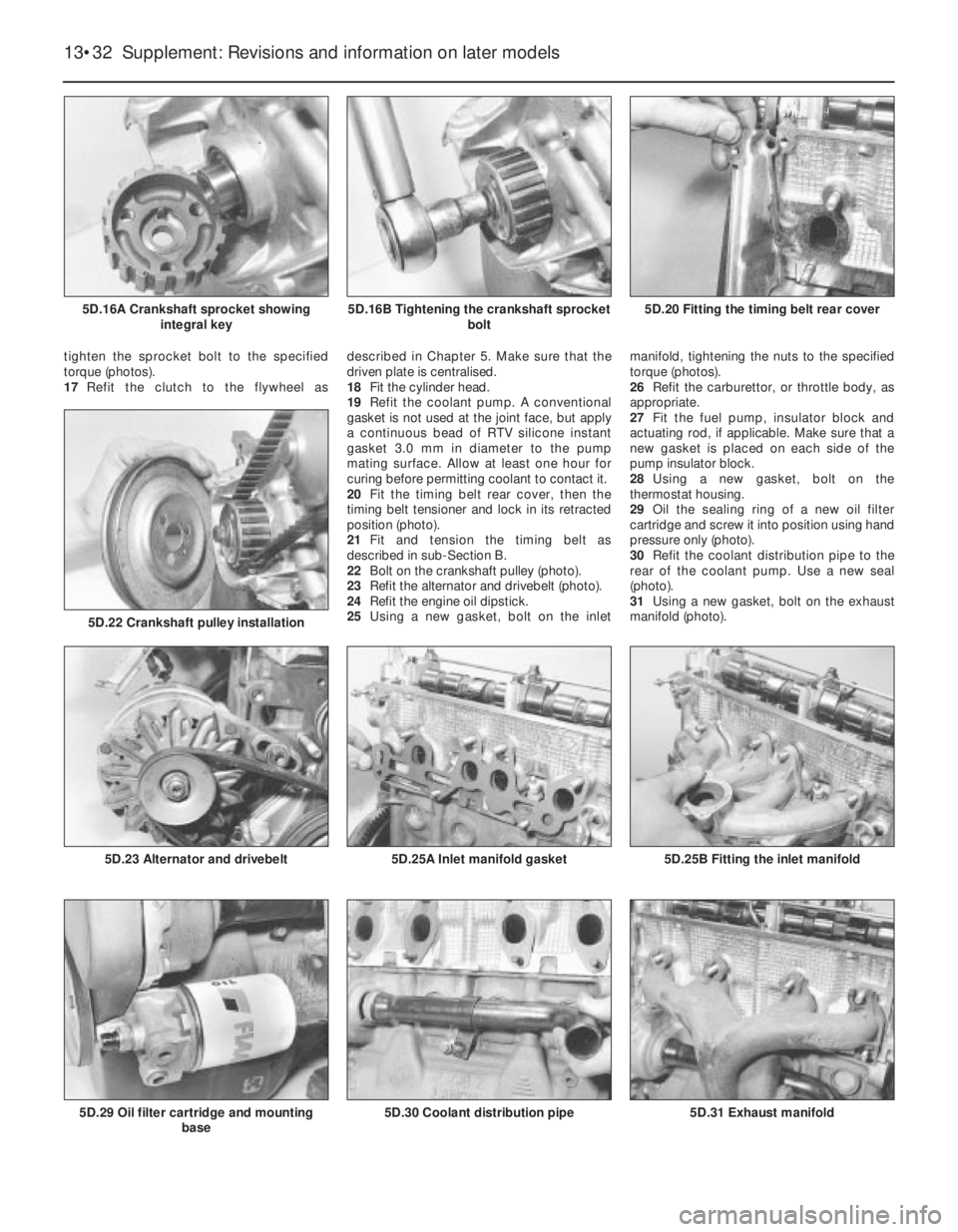

79The cam followers should be checked for

ovality using a micrometer. Unless unworn

they should be renewed.

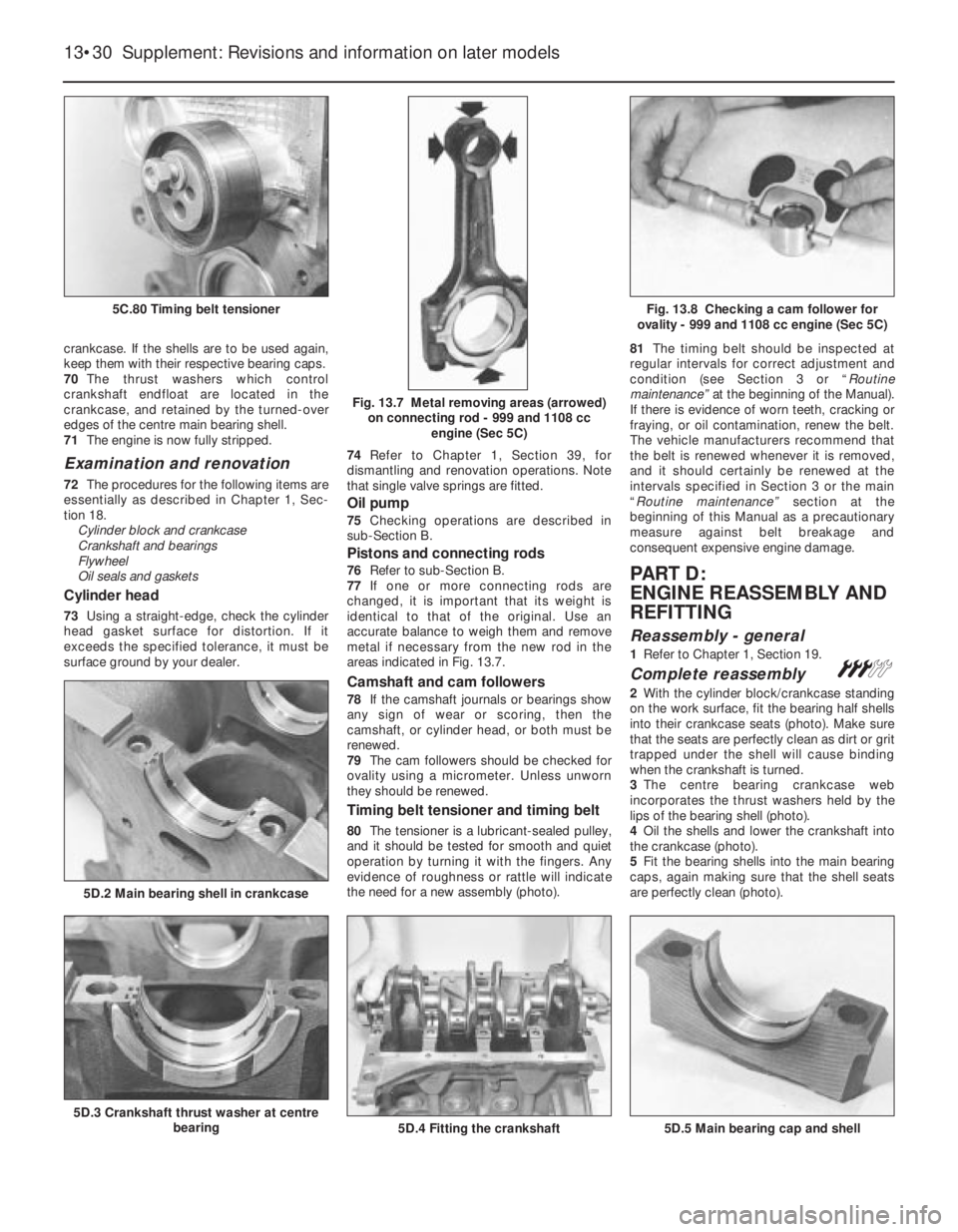

Timing belt tensioner and timing belt

80The tensioner is a lubricant-sealed pulley,

and it should be tested for smooth and quiet

operation by turning it with the fingers. Any

evidence of roughness or rattle will indicate

the need for a new assembly (photo).81The timing belt should be inspected at

regular intervals for correct adjustment and

condition (see Section 3 or “Routine

maintenance” at the beginning of the Manual).

If there is evidence of worn teeth, cracking or

fraying, or oil contamination, renew the belt.

The vehicle manufacturers recommend that

the belt is renewed whenever it is removed,

and it should certainly be renewed at the

intervals specified in Section 3 or the main

“Routine maintenance” section at the

beginning of this Manual as a precautionary

measure against belt breakage and

consequent expensive engine damage.

PART D:

ENGINE REASSEMBLY AND

REFITTING

Reassembly - general

1Refer to Chapter 1, Section 19.

Complete reassembly#

2With the cylinder block/crankcase standing

on the work surface, fit the bearing half shells

into their crankcase seats (photo). Make sure

that the seats are perfectly clean as dirt or grit

trapped under the shell will cause binding

when the crankshaft is turned.

3The centre bearing crankcase web

incorporates the thrust washers held by the

lips of the bearing shell (photo).

4Oil the shells and lower the crankshaft into

the crankcase (photo).

5Fit the bearing shells into the main bearing

caps, again making sure that the shell seats

are perfectly clean (photo).

13•30 Supplement: Revisions and information on later models

5D.5 Main bearing cap and shell5D.4 Fitting the crankshaft5D.3 Crankshaft thrust washer at centre

bearing

5D.2 Main bearing shell in crankcase

Fig. 13.8 Checking a cam follower for

ovality - 999 and 1108 cc engine (Sec 5C)

Fig. 13.7 Metal removing areas (arrowed)

on connecting rod - 999 and 1108 cc

engine (Sec 5C)

5C.80 Timing belt tensioner

Page 156 of 303

6Fit the main bearing caps in their numbered

sequence and the correct way round (photo).

7Clean the threads of the main bearing cap

bolts, lightly oil them and screw them in

finger-tight. Tighten all bolts progressively to

the specified torque, then check that the

crankshaft turns smoothly and evenly

(photos).

8Now check the crankshaft endfloat. Do this

using a dial gauge or feeler blades inserted

between the machined shoulder of a journal

and the side of the bearing cap (photo). Move

the crankshaft fully in one direction and then

the other to ensure that full movement is

obtained. If the endfloat is outside the

specified tolerance and new bearing shellshave been fitted, then a fault must have

occurred during crankshaft regrinding.

9Fit a new oil seal to the crankshaft rear oil

seal retainer. Apply grease to the seal lips. A

conventional gasket is not used at the oil seal

joint face but a 3.0 mm diameter bead of RTV

silicone instant gasket must be applied

to a clean surface as shown in Fig. 13.9

(photo).

10Bolt the retainer into position. One hour at

least must be allowed for the RTV to cure

before oil contacts it.

11Turn the engine on its side and fit the

piston/connecting rods as described in

sub-Section B.

12Fit a new oil seal to the oil pump, oil theseal lips and bolt on the pump using a new

joint gasket (photos).

13Use a new sealing washer and fit the oil

pick-up/filter screen assembly.

14Fit the engine rear plate and then the

flywheel on its mounting flange. Apply

thread-locking fluid to (clean) bolt threads and

screw in the bolts to the specified torque

(photo). Hold the flywheel against rotation by

locking the starter ring gear with a suitable

tool.

15Fit the sump pan as described in

sub-Section B.

16Fit the crankshaft sprocket so that the

timing mark is visible. Lock the flywheel

starter ring gear teeth, and screw in and

Supplement: Revisions and information on later models 13•31

5D.7B Angle-tightening a main bearing cap

bolt5D.7A Initial tightening of a main bearing

cap bolt5D.6 Fitting a main bearing cap

5D.14 Tightening a flywheel bolt5D.12B Tightening an oil pump bolt5D.12A Oil pump gasket

5D.9 Fitting crankshaft rear oil seal

retainerFig. 13.9 Application area for silicone

gasket on crankshaft rear oil seal retainer

(Sec 5D)5D.8 Checking crankshaft endfloat using a

dial gauge

13

Page 157 of 303

tighten the sprocket bolt to the specified

torque (photos).

17Refit the clutch to the flywheel asdescribed in Chapter 5. Make sure that the

driven plate is centralised.

18Fit the cylinder head.

19Refit the coolant pump. A conventional

gasket is not used at the joint face, but apply

a continuous bead of RTV silicone instant

gasket 3.0 mm in diameter to the pump

mating surface. Allow at least one hour for

curing before permitting coolant to contact it.

20Fit the timing belt rear cover, then the

timing belt tensioner and lock in its retracted

position (photo).

21Fit and tension the timing belt as

described in sub-Section B.

22Bolt on the crankshaft pulley (photo).

23Refit the alternator and drivebelt (photo).

24Refit the engine oil dipstick.

25Using a new gasket, bolt on the inletmanifold, tightening the nuts to the specified

torque (photos).

26Refit the carburettor, or throttle body, as

appropriate.

27Fit the fuel pump, insulator block and

actuating rod, if applicable. Make sure that a

new gasket is placed on each side of the

pump insulator block.

28Using a new gasket, bolt on the

thermostat housing.

29Oil the sealing ring of a new oil filter

cartridge and screw it into position using hand

pressure only (photo).

30Refit the coolant distribution pipe to the

rear of the coolant pump. Use a new seal

(photo).

31Using a new gasket, bolt on the exhaust

manifold (photo).

13•32 Supplement: Revisions and information on later models

5D.31 Exhaust manifold5D.30 Coolant distribution pipe5D.29 Oil filter cartridge and mounting

base

5D.25B Fitting the inlet manifold5D.25A Inlet manifold gasket5D.23 Alternator and drivebelt

5D.22 Crankshaft pulley installation

5D.20 Fitting the timing belt rear cover5D.16B Tightening the crankshaft sprocket

bolt5D.16A Crankshaft sprocket showing

integral key

Page 158 of 303

32Fit the hot air collector plate for the air

cleaner (photo).

33Refer to Section 10 and fit the distributor.

34Bolt on the timing belt cover.

35Fit the camshaft cover, using a new

gasket unless the original one is in perfect

condition.

Engine/transmission -

reconnection and refitting#

36Locate the engine in an upright position

on wooden blocks to allow for the greater

depth of the transmission flywheel housing

when it is joined to the engine.

37Make sure that the clutch driven plate has

been centralised, offer the transmission to the

engine and locate the flywheel housing on the

single stud and dowels.

38Tighten the connecting bolts to specifiedtorque, having located the lifting eye (photo).

39Bolt on the starter motor.

40Refit the cover plate to the flywheel

housing, but do not insert the lower bolts at

this stage as they retain the support bracket

for the gearchange rod.

41The engine and transmission are now

ready for refitting. The operations are a direct

reversal of the operations described earlier,

but observe the following points.

42Have the engine/transmission perfectly

horizontal and suspended on the hoist.

43Lower it into position very slowly until it is

possible to engage the driveshaft inboard

joints with the transmission.

44Continue lowering until the driveshafts

can be fully engaged and the mountings

reconnected. Remove the hoist.

45Tighten all nuts and bolts to the specifiedtorque. Note the method shown for

connecting the gearchange rod ball socket

using pliers (photo).

46Refill the engine with oil and coolant and

replenish the transmission oil.

Initial start-up after major

overhaul

47Refer to Chapter 1, Section 45.

6 Engine-

1301 cc Turbo ie

PART A: GENERAL

Description

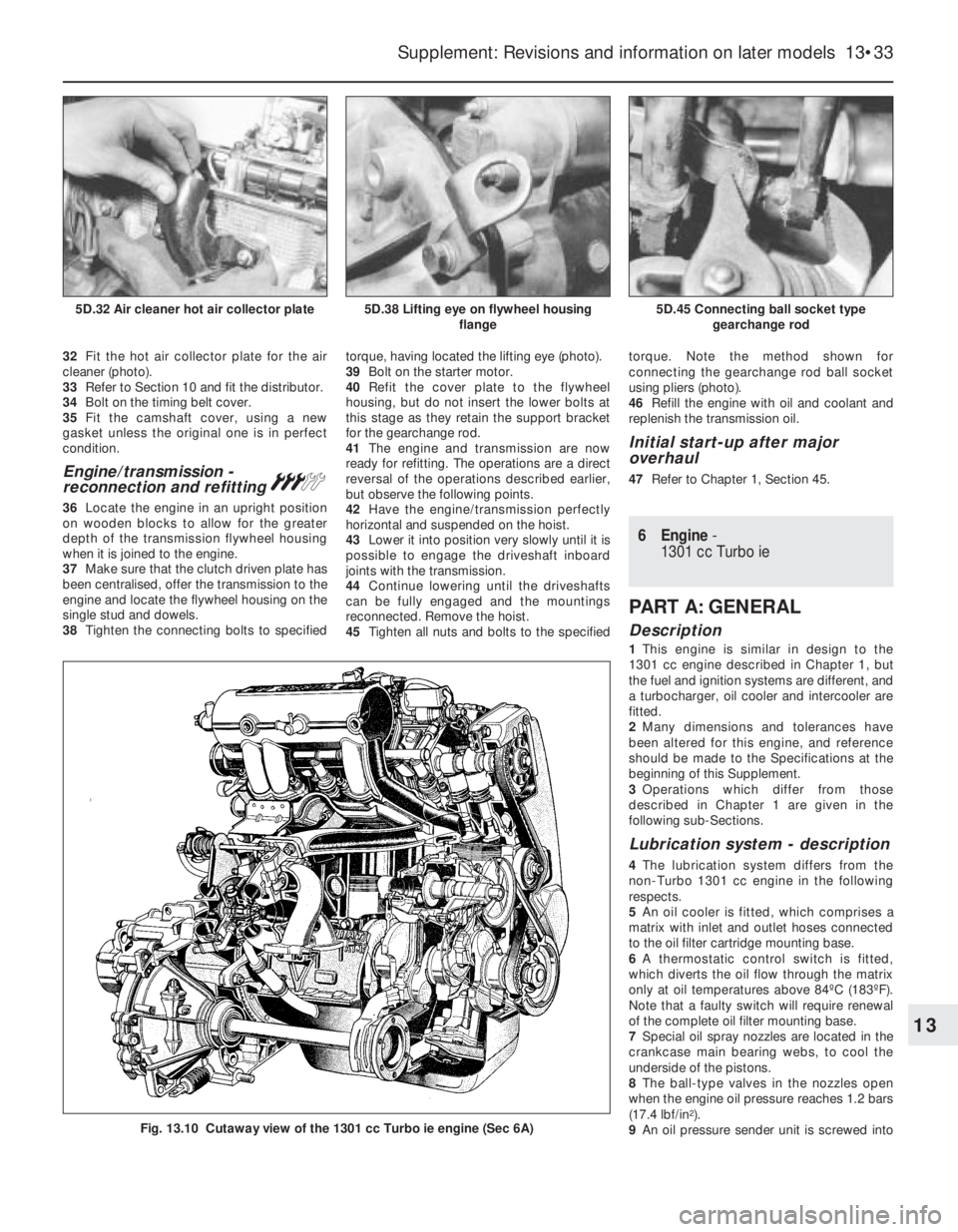

1This engine is similar in design to the

1301 cc engine described in Chapter 1, but

the fuel and ignition systems are different, and

a turbocharger, oil cooler and intercooler are

fitted.

2Many dimensions and tolerances have

been altered for this engine, and reference

should be made to the Specifications at the

beginning of this Supplement.

3Operations which differ from those

described in Chapter 1 are given in the

following sub-Sections.

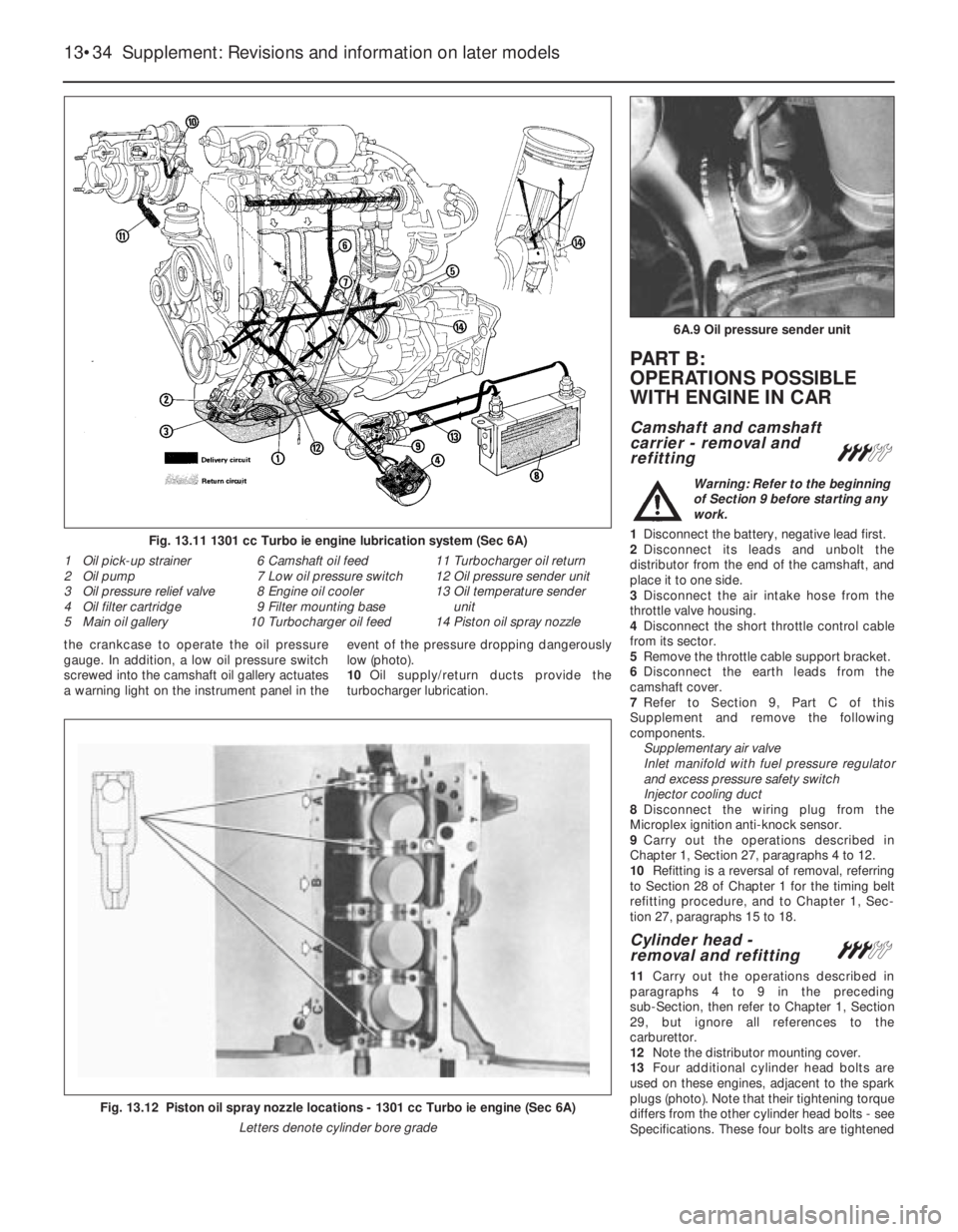

Lubrication system - description

4The lubrication system differs from the

non-Turbo 1301 cc engine in the following

respects.

5An oil cooler is fitted, which comprises a

matrix with inlet and outlet hoses connected

to the oil filter cartridge mounting base.

6A thermostatic control switch is fitted,

which diverts the oil flow through the matrix

only at oil temperatures above 84ºC (183ºF).

Note that a faulty switch will require renewal

of the complete oil filter mounting base.

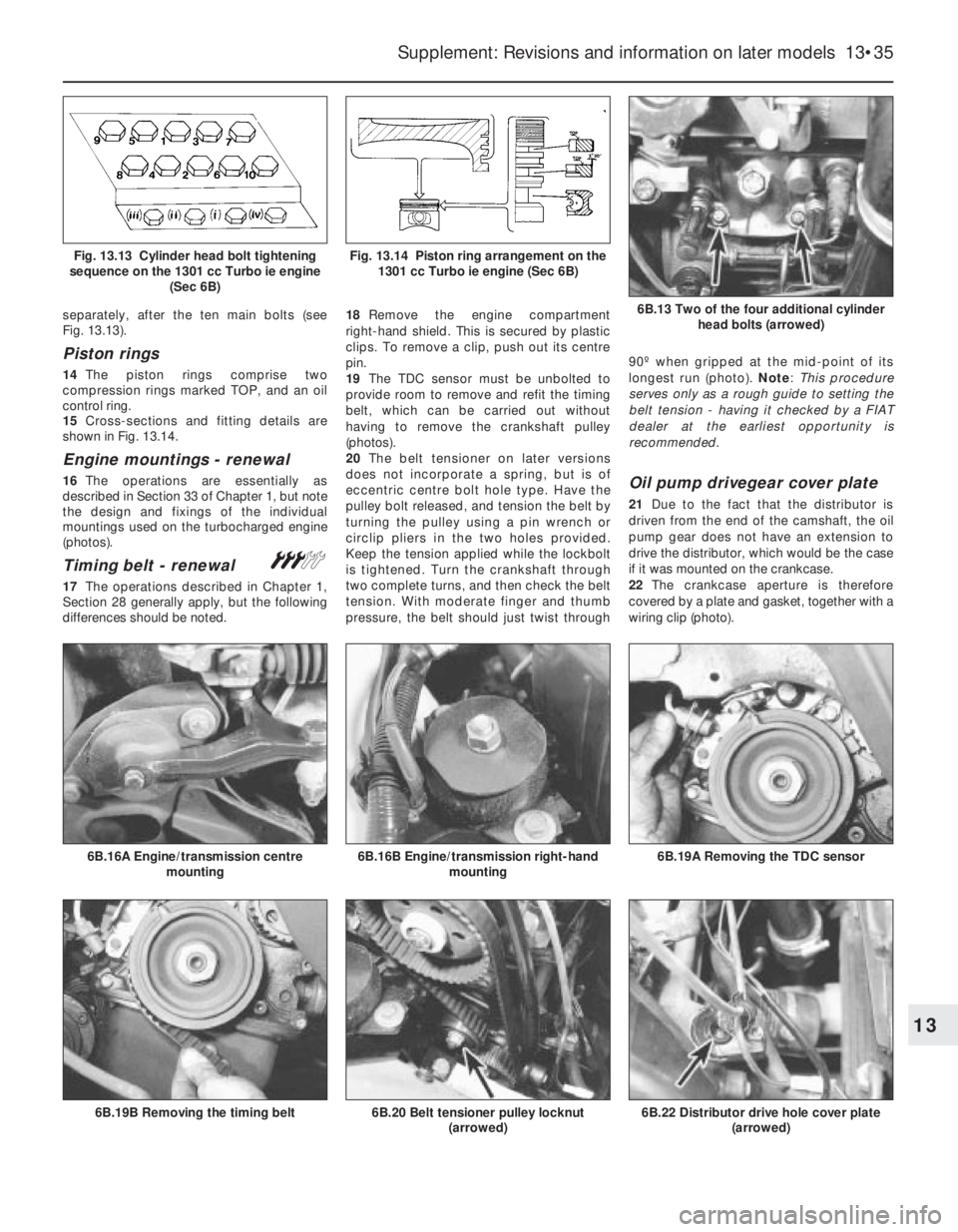

7Special oil spray nozzles are located in the

crankcase main bearing webs, to cool the

underside of the pistons.

8The ball-type valves in the nozzles open

when the engine oil pressure reaches 1.2 bars

(17.4 lbf/in

2).

9An oil pressure sender unit is screwed into

Supplement: Revisions and information on later models 13•33

5D.45 Connecting ball socket type

gearchange rod5D.38 Lifting eye on flywheel housing

flange5D.32 Air cleaner hot air collector plate

Fig. 13.10 Cutaway view of the 1301 cc Turbo ie engine (Sec 6A)

13

Page 159 of 303

the crankcase to operate the oil pressure

gauge. In addition, a low oil pressure switch

screwed into the camshaft oil gallery actuates

a warning light on the instrument panel in theevent of the pressure dropping dangerously

low (photo).

10Oil supply/return ducts provide the

turbocharger lubrication.

PART B:

OPERATIONS POSSlBLE

WITH ENGINE IN CAR

Camshaft and camshaft

carrier - removal and

refitting

#

Warning: Refer to the beginning

of Section 9 before starting any

work.

1Disconnect the battery, negative lead first.

2Disconnect its leads and unbolt the

distributor from the end of the camshaft, and

place it to one side.

3Disconnect the air intake hose from the

throttle valve housing.

4Disconnect the short throttle control cable

from its sector.

5Remove the throttle cable support bracket.

6Disconnect the earth leads from the

camshaft cover.

7Refer to Section 9, Part C of this

Supplement and remove the following

components.

Supplementary air valve

Inlet manifold with fuel pressure regulator

and excess pressure safety switch

Injector cooling duct

8Disconnect the wiring plug from the

Microplex ignition anti-knock sensor.

9Carry out the operations described in

Chapter 1, Section 27, paragraphs 4 to 12.

10Refitting is a reversal of removal, referring

to Section 28 of Chapter 1 for the timing belt

refitting procedure, and to Chapter 1, Sec-

tion 27, paragraphs 15 to 18.

Cylinder head -

removal and refitting#

11Carry out the operations described in

paragraphs 4 to 9 in the preceding

sub-Section, then refer to Chapter 1, Section

29, but ignore all references to the

carburettor.

12Note the distributor mounting cover.

13Four additional cylinder head bolts are

used on these engines, adjacent to the spark

plugs (photo). Note that their tightening torque

differs from the other cylinder head bolts - see

Specifications. These four bolts are tightened

13•34 Supplement: Revisions and information on later models

1 Oil pick-up strainer

2 Oil pump

3 Oil pressure relief valve

4 Oil filter cartridge

5 Main oil gallery6 Camshaft oil feed

7 Low oil pressure switch

8 Engine oil cooler

9 Filter mounting base

10 Turbocharger oil feed11 Turbocharger oil return

12 Oil pressure sender unit

13 Oil temperature sender

unit

14 Piston oil spray nozzle

Fig. 13.12 Piston oil spray nozzle locations - 1301 cc Turbo ie engine (Sec 6A)

Letters denote cylinder bore grade

Fig. 13.11 1301 cc Turbo ie engine lubrication system (Sec 6A)

6A.9 Oil pressure sender unit

Page 160 of 303

separately, after the ten main bolts (see

Fig. 13.13).

Piston rings

14The piston rings comprise two

compression rings marked TOP, and an oil

control ring.

15Cross-sections and fitting details are

shown in Fig. 13.14.

Engine mountings - renewal

16The operations are essentially as

described in Section 33 of Chapter 1, but note

the design and fixings of the individual

mountings used on the turbocharged engine

(photos).

Timing belt - renewal#

17The operations described in Chapter 1,

Section 28 generally apply, but the following

differences should be noted.18Remove the engine compartment

right-hand shield. This is secured by plastic

clips. To remove a clip, push out its centre

pin.

19The TDC sensor must be unbolted to

provide room to remove and refit the timing

belt, which can be carried out without

having to remove the crankshaft pulley

(photos).

20The belt tensioner on later versions

does not incorporate a spring, but is of

eccentric centre bolt hole type. Have the

pulley bolt released, and tension the belt by

turning the pulley using a pin wrench or

circlip pliers in the two holes provided.

Keep the tension applied while the lockbolt

is tightened. Turn the crankshaft through

two complete turns, and then check the belt

tension. With moderate finger and thumb

pressure, the belt should just twist through90º when gripped at the mid-point of its

longest run (photo). Note: This procedure

serves only as a rough guide to setting the

belt tension - having it checked by a FIAT

dealer at the earliest opportunity is

recommended.

Oil pump drivegear cover plate

21Due to the fact that the distributor is

driven from the end of the camshaft, the oil

pump gear does not have an extension to

drive the distributor, which would be the case

if it was mounted on the crankcase.

22The crankcase aperture is therefore

covered by a plate and gasket, together with a

wiring clip (photo).

Supplement: Revisions and information on later models 13•35

6B.13 Two of the four additional cylinder

head bolts (arrowed)

Fig. 13.14 Piston ring arrangement on the

1301 cc Turbo ie engine (Sec 6B)Fig. 13.13 Cylinder head bolt tightening

sequence on the 1301 cc Turbo ie engine

(Sec 6B)

6B.22 Distributor drive hole cover plate

(arrowed)6B.20 Belt tensioner pulley locknut

(arrowed)6B.19B Removing the timing belt

6B.19A Removing the TDC sensor6B.16B Engine/transmission right-hand

mounting6B.16A Engine/transmission centre

mounting

13