gearbox FIAT UNO 1983 Service User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 217 of 303

11 Clutch

Clutch pedal - adjustment

(cable clutch)

Á

1The method of adjusting the clutch has

been revised.

2Fully depress the clutch pedal two or three

times.

3Using a suitable measuring stick placed in

contact with the floor panel (carpet peeled

back), measure dimension “X” in Fig. 13.87.

This dimension must be taken between the

centre of the pedal pad and the floor, first withthe pedal in the fully depressed position, and

then in the fully released position.

4The dimension measured should fall within

the range quoted in the Specifications for this

Supplement.

5Any adjustment which may be required

should be carried out by slackening the

locknut on the cable at the release lever (on

top of the gearbox) and turning the adjusting

nut. Tighten the locknut on completion.

Hydraulic clutch - description

6Some later models are fitted with an

hydraulically operated clutch in place of the

cable operated type. The main components of

the system are a master cylinder, with

separate hydraulic fluid reservoir, and the

operating cylinder. The master cylinder is

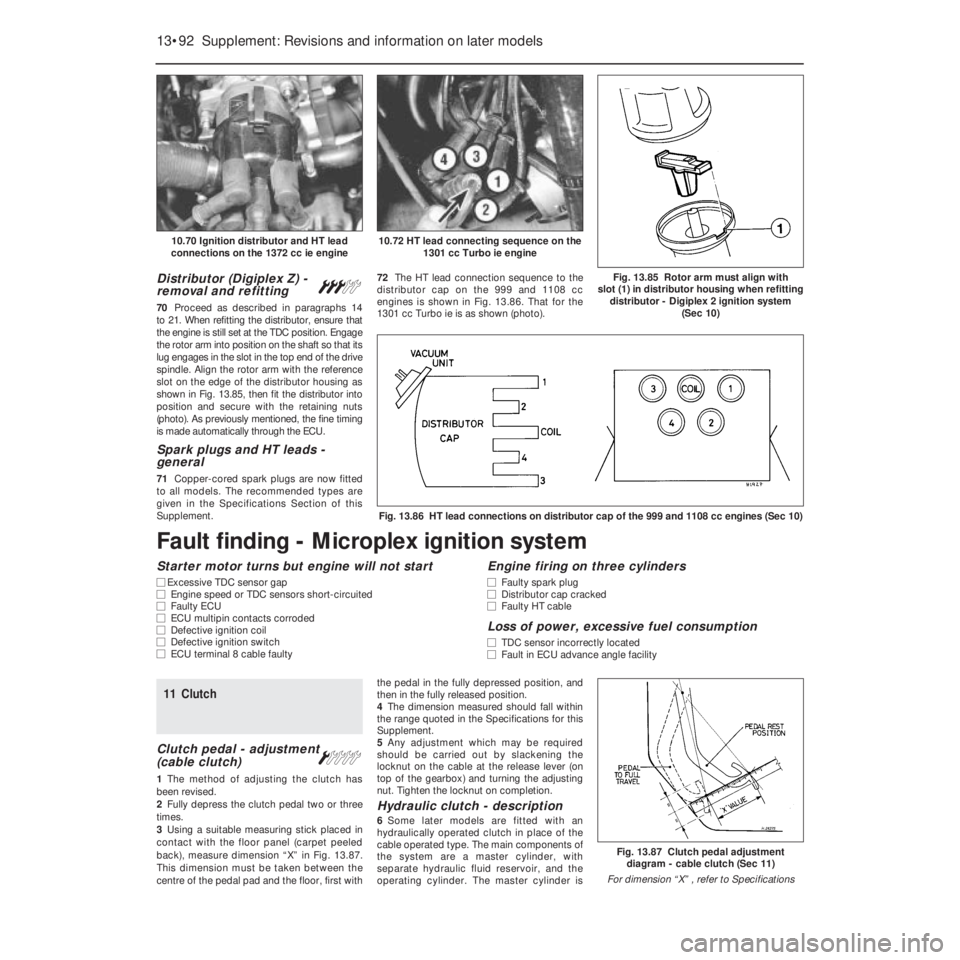

Distributor (Digiplex Z) -

removal and refitting#

70Proceed as described in paragraphs 14

to 21. When refitting the distributor, ensure that

the engine is still set at the TDC position. Engage

the rotor arm into position on the shaft so that its

lug engages in the slot in the top end of the drive

spindle. Align the rotor arm with the reference

slot on the edge of the distributor housing as

shown in Fig. 13.85, then fit the distributor into

position and secure with the retaining nuts

(photo). As previously mentioned, the fine timing

is made automatically through the ECU.

Spark plugs and HT leads -

general

71Copper-cored spark plugs are now fitted

to all models. The recommended types are

given in the Specifications Section of this

Supplement.72The HT lead connection sequence to the

distributor cap on the 999 and 1108 cc

engines is shown in Fig. 13.86. That for the

1301 cc Turbo ie is as shown (photo).

13•92 Supplement: Revisions and information on later models

Fig. 13.87 Clutch pedal adjustment

diagram - cable clutch (Sec 11)

For dimension “X” , refer to Specifications

Fig. 13.86 HT lead connections on distributor cap of the 999 and 1108 cc engines (Sec 10)

Fig. 13.85 Rotor arm must align with

slot (1) in distributor housing when refitting

distributor - Digiplex 2 ignition system

(Sec 10)

10.72 HT lead connecting sequence on the

1301 cc Turbo ie engine10.70 Ignition distributor and HT lead

connections on the 1372 cc ie engine

Fault finding - Microplex ignition system

Starter motor turns but engine will not start

m mExcessive TDC sensor gap

m mEngine speed or TDC sensors short-circuited

m mFaulty ECU

m mECU multipin contacts corroded

m mDefective ignition coil

m mDefective ignition switch

m mECU terminal 8 cable faulty

Engine firing on three cylinders

m

mFaulty spark plug

m mDistributor cap cracked

m mFaulty HT cable

Loss of power, excessive fuel consumption

m

mTDC sensor incorrectly located

m mFault in ECU advance angle facility

Page 220 of 303

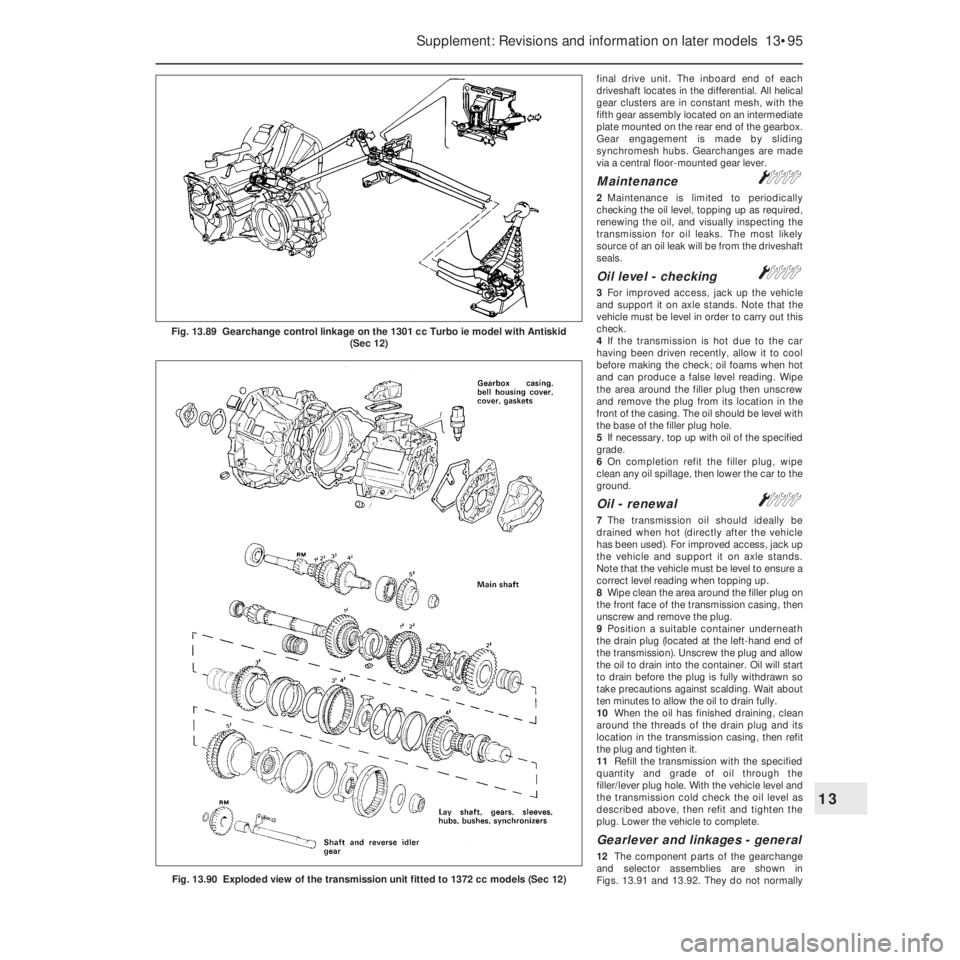

final drive unit. The inboard end of each

driveshaft locates in the differential. All helical

gear clusters are in constant mesh, with the

fifth gear assembly located on an intermediate

plate mounted on the rear end of the gearbox.

Gear engagement is made by sliding

synchromesh hubs. Gearchanges are made

via a central floor-mounted gear lever.

MaintenanceÁ

2Maintenance is limited to periodically

checking the oil level, topping up as required,

renewing the oil, and visually inspecting the

transmission for oil leaks. The most likely

source of an oil leak will be from the driveshaft

seals.

Oil level - checkingÁ

3For improved access, jack up the vehicle

and support it on axle stands. Note that the

vehicle must be level in order to carry out this

check.

4If the transmission is hot due to the car

having been driven recently, allow it to cool

before making the check; oil foams when hot

and can produce a false level reading. Wipe

the area around the filler plug then unscrew

and remove the plug from its location in the

front of the casing. The oil should be level with

the base of the filler plug hole.

5If necessary, top up with oil of the specified

grade.

6On completion refit the filler plug, wipe

clean any oil spillage, then lower the car to the

ground.

Oil - renewalÁ

7The transmission oil should ideally be

drained when hot (directly after the vehicle

has been used). For improved access, jack up

the vehicle and support it on axle stands.

Note that the vehicle must be level to ensure a

correct level reading when topping up.

8Wipe clean the area around the filler plug on

the front face of the transmission casing, then

unscrew and remove the plug.

9Position a suitable container underneath

the drain plug (located at the left-hand end of

the transmission). Unscrew the plug and allow

the oil to drain into the container. Oil will start

to drain before the plug is fully withdrawn so

take precautions against scalding. Wait about

ten minutes to allow the oil to drain fully.

10When the oil has finished draining, clean

around the threads of the drain plug and its

location in the transmission casing, then refit

the plug and tighten it.

11Refill the transmission with the specified

quantity and grade of oil through the

filler/lever plug hole. With the vehicle level and

the transmission cold check the oil level as

described above, then refit and tighten the

plug. Lower the vehicle to complete.

Gearlever and linkages - general

12The component parts of the gearchange

and selector assemblies are shown in

Figs. 13.91 and 13.92. They do not normally

Supplement: Revisions and information on later models 13•95

Fig. 13.90 Exploded view of the transmission unit fitted to 1372 cc models (Sec 12)

13

Fig. 13.89 Gearchange control linkage on the 1301 cc Turbo ie model with Antiskid

(Sec 12)

Page 292 of 303

Fault FindingREF•9

REF

Introduction

The vehicle owner who does his or her own

maintenance according to the recommended

schedules should not have to use this section

of the manual very often. Modern component

reliability is such that, provided those items

subject to wear or deterioration are inspected

or renewed at the specified intervals, sudden

failure is comparatively rare. Faults do not

usually just happen as a result of sudden

failure, but develop over a period of time.

Major mechanical failures in particular are

usually preceded by characteristic symptoms

over hundreds or even thousands of miles.

Those components which do occasionally fail

without warning are often small and easily

carried in the vehicle.

With any fault finding, the first step is to

decide where to begin investigations.

Sometimes this is obvious, but on other

occasions a little detective work will be

necessary. The owner who makes half a

dozen haphazard adjustments or

replacements may be successful in curing a

fault (or its symptoms), but he will be none the

wiser if the fault recurs and he may well have

spent more time and money than was

necessary. A calm and logical approach will

be found to be more satisfactory in the long

run. Always take into account any warning

signs or abnormalities that may have been

noticed in the period preceding the fault –

power loss, high or low gauge readings,

unusual noises or smells, etc – and remember

that failure of components such as fuses or

spark plugs may only be pointers to some

underlying fault.

The pages which follow here are intended

to help in cases of failure to start or

breakdown on the road. There is also a Fault

Diagnosis Section at the end of each Chapter

which should be consulted if the preliminary

checks prove unfruitful. Whatever the fault,

certain basic principles apply. These are as

follows:Verify the fault. This is simply a matter of

being sure that you know what the symptoms

are before starting work. This is particularly

important if you are investigating a fault for

someone else who may not have described it

very accurately.

Don’t overlook the obvious. For example,

if the vehicle won’t start, is there petrol in the

tank? (Don’t take anyone else’s word on this

particular point, and don’t trust the fuel gauge

either!) If an electrical fault is indicated, look

for loose or broken wires before digging out

the test gear.

Cure the disease, not the symptom.

Substituting a flat battery with a fully charged

one will get you off the hard shoulder, but if

the underlying cause is not attended to,the

new battery will go the same way. Similarly,

changing oil-fouled spark plugs for a new set

will get you moving again, but remember that

the reason for the fouling (if it wasn’t simply an

incorrect grade of plug) will have to be

established and corrected.

Don’t take anything for granted.

Particularly, don’t forget that a ‘new’

component may itself be defective (especially

if it’s been rattling round in the boot for

months), and don’t leave components out of a

fault diagnosis sequence just because they

are new or recently fitted. When you do finally

diagnose a difficult fault, you’ll probably

realise that all the evidence was there from

the start.

Electrical faults

Electrical faults can be more puzzling than

straightforward mechanical failures, but they

are no less susceptible to logical analysis if

the basic principles of operation are

understood. Vehicle electrical wiring exists in

extremely unfavourable conditions – heat,

vibration and chemical attack and the first

things to look for are loose or corroded

connections and broken or chafed wires,especially where the wires pass through holes

in the bodywork or are subject to vibration.

All metal-bodied vehicles in current

production have one pole of the battery

‘earthed’, ie connected to the vehicle

bodywork, and in nearly all modern vehicles it

is the negative (–) terminal. The various

electrical components – motors, bulb holders,

etc – are also connected to earth, either by

means of a lead or directly by their mountings.

Electric current flows through the component

and then back to the battery via the

bodywork. If the component mounting is

loose or corroded, or if a good path back to

the battery is not available, the circuit will be

incomplete and malfunction will result. The

engine and/or gearbox are also earthed by

means of flexible metal straps to the body or

subframe; if these straps are loose or missing,

starter motor, generator and ignition trouble

may result.

Assuming the earth return to be

satisfactory, electrical faults will be due either

to component malfunction or to defects in the

current supply. Individual components are

dealt with in Chapter 9. If supply wires are

broken or cracked internally this results in an

open-circuit, and the easiest way to check for

this is to bypass the suspect wire temporarily

with a length of wire having a crocodile clip or

suitable connector at each end. Alternatively,

a 12V test lamp can be used to verify the

presence of supply voltage at various points

along the wire and the break can be thus

isolated.

If a bare portion of a live wire touches the

bodywork or other earthed metal part, the

electricity will take the low-resistance path

thus formed back to the battery: this is known

as a short-circuit. Hopefully a short-circuit will

blow a fuse, but otherwise it may cause

burning of the insulation (and possibly further

short-circuits) or even a fire. This is why it is

inadvisable to bypass persistently blowing

fuses with silver foil or wire.

Page 295 of 303

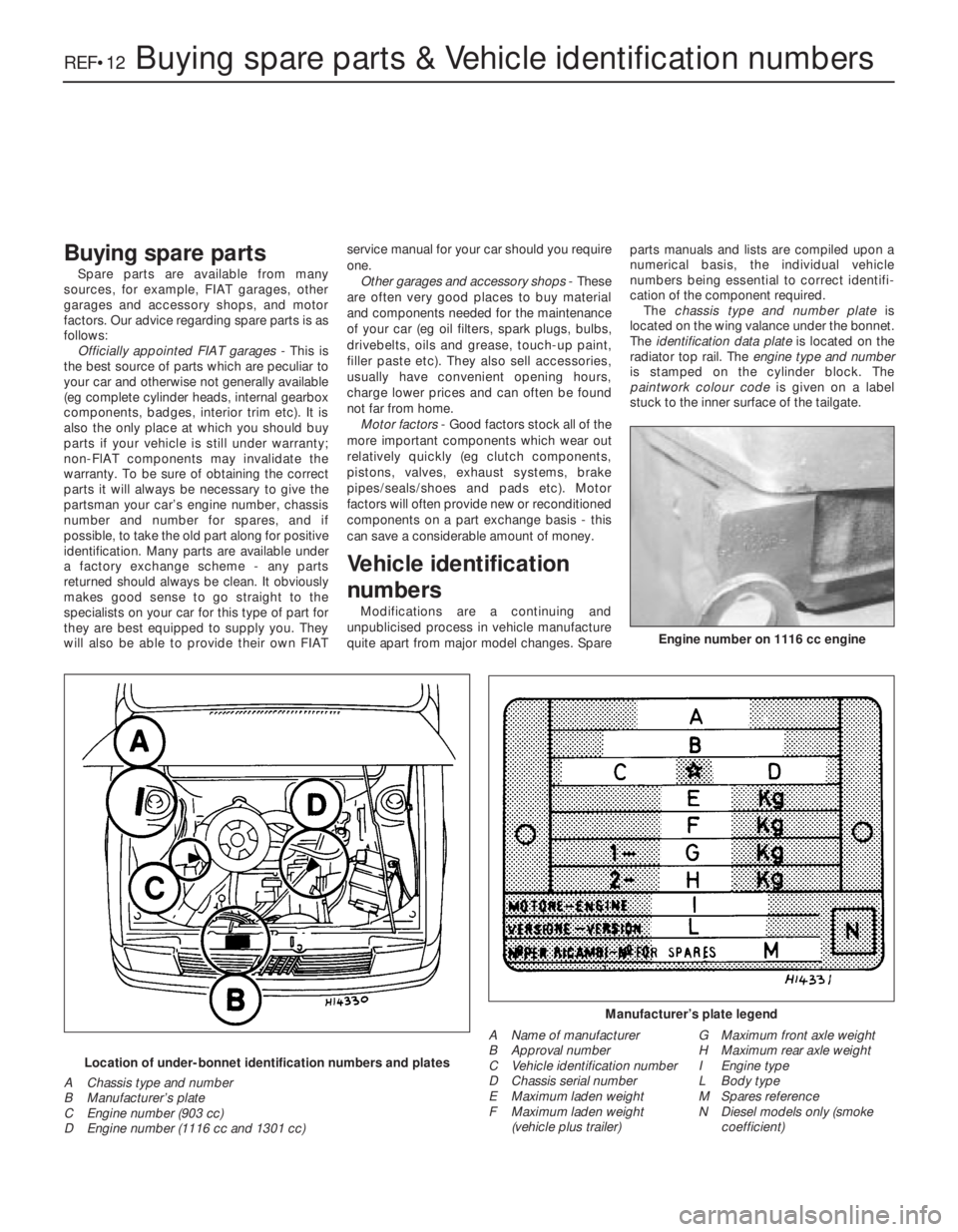

Buying spare parts

Spare parts are available from many

sources, for example, FIAT garages, other

garages and accessory shops, and motor

factors. Our advice regarding spare parts is as

follows:

Officially appointed FIAT garages -This is

the best source of parts which are peculiar to

your car and otherwise not generally available

(eg complete cylinder heads, internal gearbox

components, badges, interior trim etc). It is

also the only place at which you should buy

parts if your vehicle is still under warranty;

non-FlAT components may invalidate the

warranty. To be sure of obtaining the correct

parts it will always be necessary to give the

partsman your car’s engine number, chassis

number and number for spares, and if

possible, to take the old part along for positive

identification. Many parts are available under

a factory exchange scheme - any parts

returned should always be clean. It obviously

makes good sense to go straight to the

specialists on your car for this type of part for

they are best equipped to supply you. They

will also be able to provide their own FIATservice manual for your car should you require

one.

Other garages and accessory shops - These

are often very good places to buy material

and components needed for the maintenance

of your car (eg oil filters, spark plugs, bulbs,

drivebelts, oils and grease, touch-up paint,

filler paste etc). They also sell accessories,

usually have convenient opening hours,

charge lower prices and can often be found

not far from home.

Motor factors - Good factors stock all of the

more important components which wear out

relatively quickly (eg clutch components,

pistons, valves, exhaust systems, brake

pipes/seals/shoes and pads etc). Motor

factors will often provide new or reconditioned

components on a part exchange basis - this

can save a considerable amount of money.

Vehicle identification

numbers

Modifications are a continuing and

unpublicised process in vehicle manufacture

quite apart from major model changes. Spareparts manuals and lists are compiled upon a

numerical basis, the individual vehicle

numbers being essential to correct identifi-

cation of the component required.

The chassis type and number plate is

located on the wing valance under the bonnet.

The identification data plate is located on the

radiator top rail. The engine type and number

is stamped on the cylinder block. The

paintwork colour code is given on a label

stuck to the inner surface of the tailgate.

REF•12Buying spare parts & Vehicle identification numbers

Manufacturer’s plate legend

Location of under-bonnet identification numbers and plates

A Chassis type and number

B Manufacturer’s plate

C Engine number (903 cc)

D Engine number (1116 cc and 1301 cc)

Engine number on 1116 cc engine

A Name of manufacturer

B Approval number

C Vehicle identification number

D Chassis serial number

E Maximum laden weight

F Maximum laden weight

(vehicle plus trailer)G Maximum front axle weight

H Maximum rear axle weight

I Engine type

L Body type

M Spares reference

N Diesel models only (smoke

coefficient)

Page 301 of 303

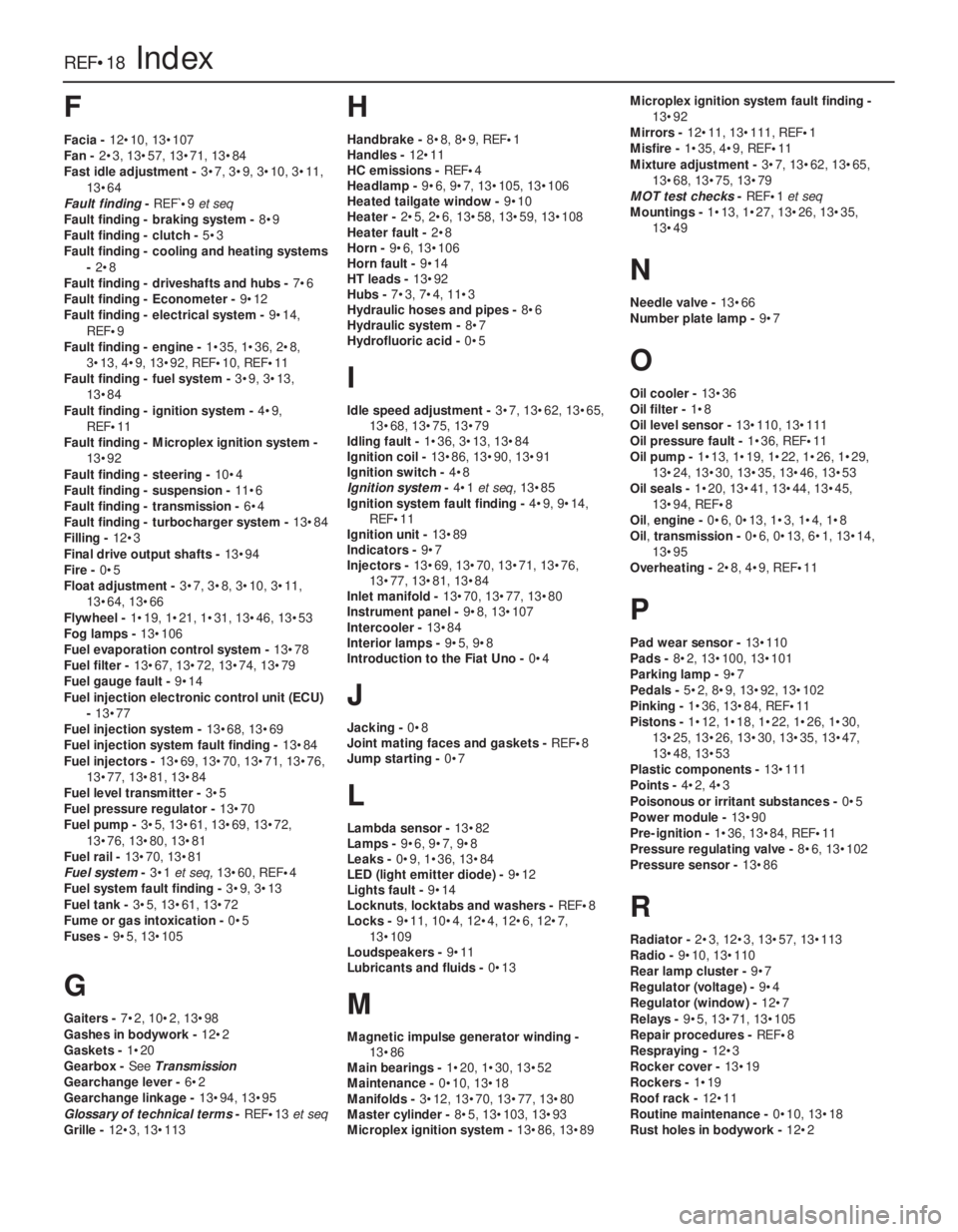

F

Facia - 12•10, 13•107

Fan -2•3, 13•57, 13•71, 13•84

Fast idle adjustment -3•7, 3•9, 3•10, 3•11,

13•64

Fault finding- REF`•9et seq

Fault finding - braking system -8•9

Fault finding - clutch -5•3

Fault finding - cooling and heating systems

-2•8

Fault finding - driveshafts and hubs -7•6

Fault finding - Econometer -9•12

Fault finding - electrical system -9•14,

REF•9

Fault finding - engine -1•35, 1•36, 2•8,

3•13, 4•9, 13•92, REF•10, REF•11

Fault finding - fuel system -3•9, 3•13,

13•84

Fault finding - ignition system -4•9,

REF•11

Fault finding - Microplex ignition system -

13•92

Fault finding - steering - 10•4

Fault finding - suspension - 11•6

Fault finding - transmission -6•4

Fault finding - turbocharger system - 13•84

Filling - 12•3

Final drive output shafts - 13•94

Fire -0•5

Float adjustment -3•7, 3•8, 3•10, 3•11,

13•64, 13•66

Flywheel -1•19, 1•21, 1•31, 13•46, 13•53

Fog lamps - 13•106

Fuel evaporation control system - 13•78

Fuel filter - 13•67, 13•72, 13•74, 13•79

Fuel gauge fault -9•14

Fuel injection electronic control unit (ECU)

- 13•77

Fuel injection system - 13•68, 13•69

Fuel injection system fault finding - 13•84

Fuel injectors - 13•69, 13•70, 13•71, 13•76,

13•77, 13•81, 13•84

Fuel level transmitter -3•5

Fuel pressure regulator - 13•70

Fuel pump -3•5, 13•61, 13•69, 13•72,

13•76, 13•80, 13•81

Fuel rail - 13•70, 13•81

Fuel system-3•1et seq, 13•60, REF•4

Fuel system fault finding -3•9, 3•13

Fuel tank -3•5, 13•61, 13•72

Fume or gas intoxication -0•5

Fuses -9•5, 13•105

G

Gaiters -7•2, 10•2, 13•98

Gashes in bodywork - 12•2

Gaskets -1•20

Gearbox - SeeTransmission

Gearchange lever -6•2

Gearchange linkage - 13•94, 13•95

Glossary of technical terms- REF•13et seq

Grille - 12•3, 13•113

H

Handbrake -8•8, 8•9, REF•1

Handles - 12•11

HC emissions - REF•4

Headlamp -9•6, 9•7, 13•105, 13•106

Heated tailgate window -9•10

Heater -2•5, 2•6, 13•58, 13•59, 13•108

Heater fault -2•8

Horn -9•6, 13•106

Horn fault -9•14

HT leads - 13•92

Hubs -7•3, 7•4, 11•3

Hydraulic hoses and pipes -8•6

Hydraulic system -8•7

Hydrofluoric acid -0•5

I

Idle speed adjustment -3•7, 13•62, 13•65,

13•68, 13•75, 13•79

Idling fault -1•36, 3•13, 13•84

Ignition coil - 13•86, 13•90, 13•91

Ignition switch -4•8

Ignition system-4•1et seq, 13•85

Ignition system fault finding -4•9, 9•14,

REF•11

Ignition unit - 13•89

Indicators -9•7

Injectors - 13•69, 13•70, 13•71, 13•76,

13•77, 13•81, 13•84

Inlet manifold - 13•70, 13•77, 13•80

Instrument panel -9•8, 13•107

Intercooler - 13•84

Interior lamps -9•5, 9•8

Introduction to the Fiat Uno -0•4

J

Jacking -0•8

Joint mating faces and gaskets - REF•8

Jump starting -0•7

L

Lambda sensor - 13•82

Lamps -9•6, 9•7, 9•8

Leaks -0•9, 1•36, 13•84

LED (light emitter diode) -9•12

Lights fault -9•14

Locknuts,locktabs and washers - REF•8

Locks -9•11, 10•4, 12•4, 12•6, 12•7,

13•109

Loudspeakers -9•11

Lubricants and fluids -0•13

M

Magnetic impulse generator winding -

13•86

Main bearings -1•20, 1•30, 13•52

Maintenance -0•10, 13•18

Manifolds -3•12, 13•70, 13•77, 13•80

Master cylinder -8•5, 13•103, 13•93

Microplex ignition system - 13•86, 13•89Microplex ignition system fault finding -

13•92

Mirrors - 12•11, 13•111, REF•1

Misfire -1•35, 4•9, REF•11

Mixture adjustment -3•7, 13•62, 13•65,

13•68, 13•75, 13•79

MOT test checks- REF•1et seq

Mountings -1•13, 1•27, 13•26, 13•35,

13•49

N

Needle valve - 13•66

Number plate lamp -9•7

O

Oil cooler - 13•36

Oil filter -1•8

Oil level sensor - 13•110, 13•111

Oil pressure fault -1•36, REF•11

Oil pump -1•13, 1•19, 1•22, 1•26, 1•29,

13•24, 13•30, 13•35, 13•46, 13•53

Oil seals -1•20, 13•41, 13•44, 13•45,

13•94, REF•8

Oil,engine -0•6, 0•13, 1•3, 1•4, 1•8

Oil,transmission -0•6, 0•13, 6•1, 13•14,

13•95

Overheating -2•8, 4•9, REF•11

P

Pad wear sensor - 13•110

Pads -8•2, 13•100, 13•101

Parking lamp -9•7

Pedals -5•2, 8•9, 13•92, 13•102

Pinking -1•36, 13•84, REF•11

Pistons -1•12, 1•18, 1•22, 1•26, 1•30,

13•25, 13•26, 13•30, 13•35, 13•47,

13•48, 13•53

Plastic components - 13•111

Points -4•2, 4•3

Poisonous or irritant substances -0•5

Power module - 13•90

Pre-ignition -1•36, 13•84, REF•11

Pressure regulating valve -8•6, 13•102

Pressure sensor - 13•86

R

Radiator -2•3, 12•3, 13•57, 13•113

Radio -9•10, 13•110

Rear lamp cluster -9•7

Regulator (voltage) -9•4

Regulator (window) - 12•7

Relays -9•5, 13•71, 13•105

Repair procedures - REF•8

Respraying - 12•3

Rocker cover - 13•19

Rockers -1•19

Roof rack - 12•11

Routine maintenance -0•10, 13•18

Rust holes in bodywork - 12•2

REF•18Index