cooling FIAT UNO 1983 Service Manual PDF

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 253 of 303

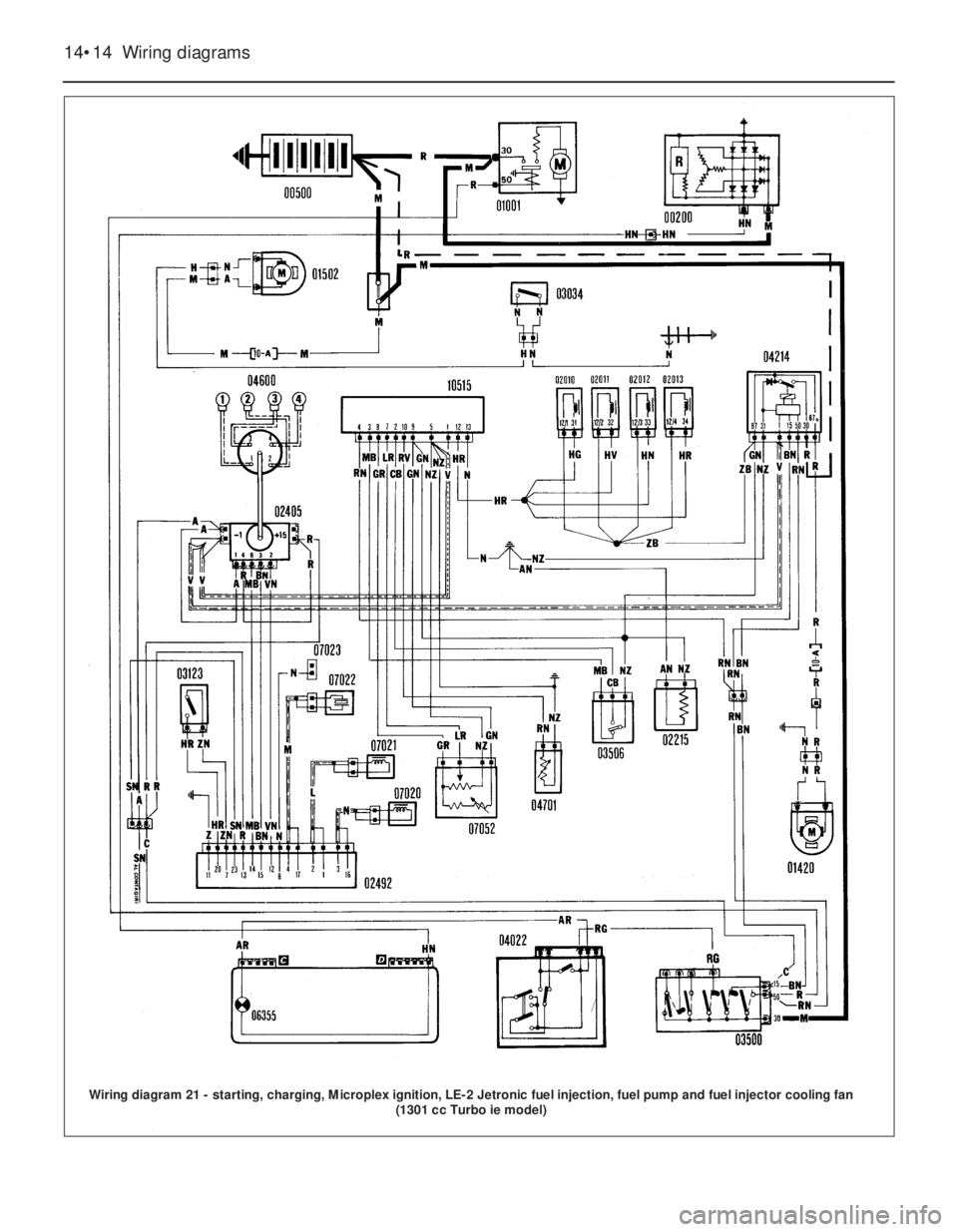

14•14 Wiring diagrams

Wiring diagram 21 - starting, charging, Microplex ignition, LE-2 Jetronic fuel injection, fuel pump and fuel injector cooling fan

(1301 cc Turbo ie model)

Page 259 of 303

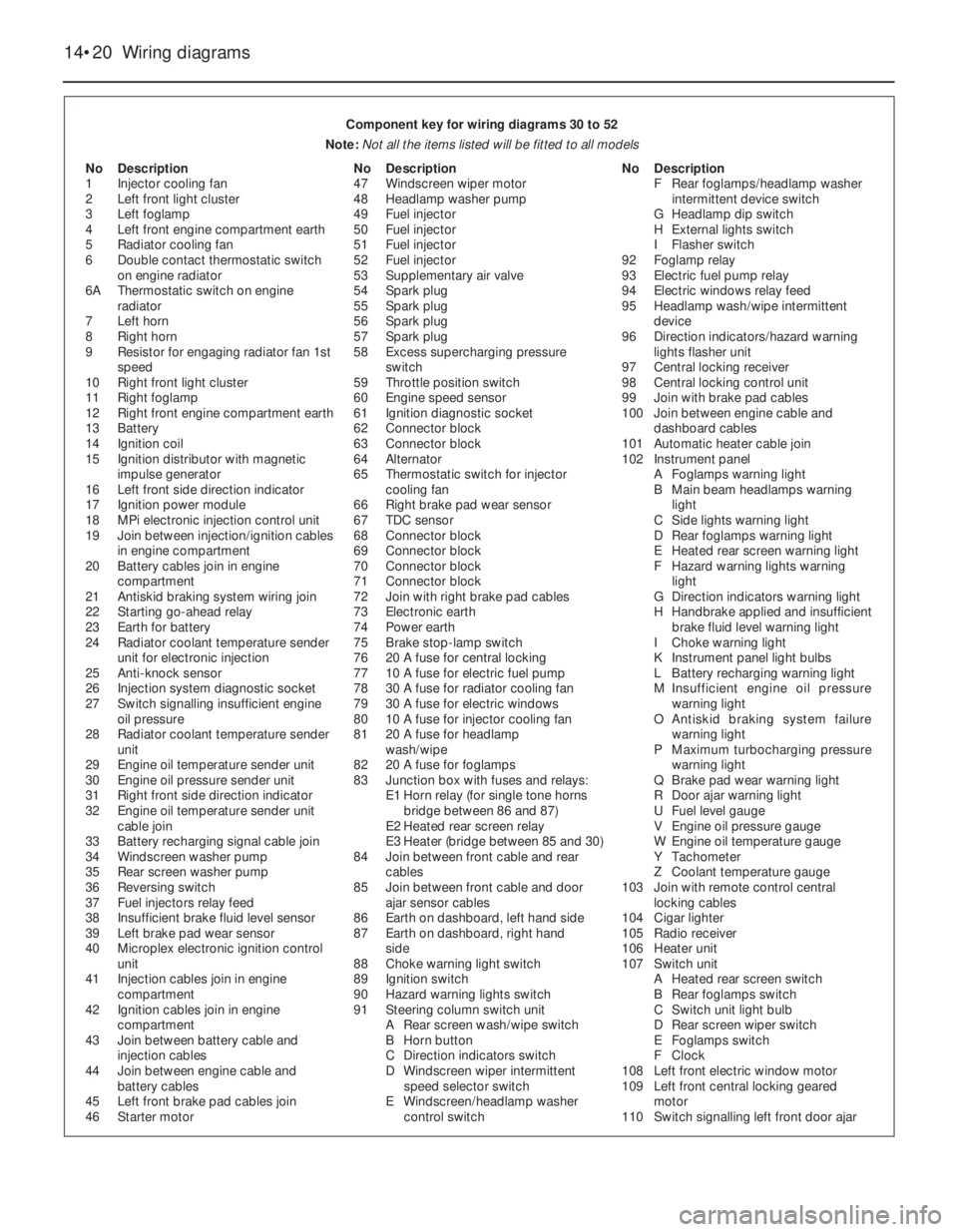

14•20 Wiring diagrams

Component key for wiring diagrams 30 to 52

Note: Not all the items listed will be fitted to all models

No Description

1 Injector cooling fan

2 Left front light cluster

3 Left foglamp

4 Left front engine compartment earth

5 Radiator cooling fan

6 Double contact thermostatic switch

on engine radiator

6A Thermostatic switch on engine

radiator

7 Left horn

8 Right horn

9 Resistor for engaging radiator fan 1st

speed

10 Right front light cluster

11 Right foglamp

12 Right front engine compartment earth

13 Battery

14 Ignition coil

15 Ignition distributor with magnetic

impulse generator

16 Left front side direction indicator

17 Ignition power module

18 MPi electronic injection control unit

19 Join between injection/ignition cables

in engine compartment

20 Battery cables join in engine

compartment

21 Antiskid braking system wiring join

22 Starting go-ahead relay

23 Earth for battery

24 Radiator coolant temperature sender

unit for electronic injection

25 Anti-knock sensor

26 Injection system diagnostic socket

27 Switch signalling insufficient engine

oil pressure

28 Radiator coolant temperature sender

unit

29 Engine oil temperature sender unit

30 Engine oil pressure sender unit

31 Right front side direction indicator

32 Engine oil temperature sender unit

cable join

33 Battery recharging signal cable join

34 Windscreen washer pump

35 Rear screen washer pump

36 Reversing switch

37 Fuel injectors relay feed

38 Insufficient brake fluid level sensor

39 Left brake pad wear sensor

40 Microplex electronic ignition control

unit

41 Injection cables join in engine

compartment

42 Ignition cables join in engine

compartment

43 Join between battery cable and

injection cables

44 Join between engine cable and

battery cables

45 Left front brake pad cables join

46 Starter motorNo Description

47 Windscreen wiper motor

48 Headlamp washer pump

49 Fuel injector

50 Fuel injector

51 Fuel injector

52 Fuel injector

53 Supplementary air valve

54 Spark plug

55 Spark plug

56 Spark plug

57 Spark plug

58 Excess supercharging pressure

switch

59 Throttle position switch

60 Engine speed sensor

61 Ignition diagnostic socket

62 Connector block

63 Connector block

64 Alternator

65 Thermostatic switch for injector

cooling fan

66 Right brake pad wear sensor

67 TDC sensor

68 Connector block

69 Connector block

70 Connector block

71 Connector block

72 Join with right brake pad cables

73 Electronic earth

74 Power earth

75 Brake stop-lamp switch

76 20 A fuse for central locking

77 10 A fuse for electric fuel pump

78 30 A fuse for radiator cooling fan

79 30 A fuse for electric windows

80 10 A fuse for injector cooling fan

81 20 A fuse for headlamp

wash/wipe

82 20 A fuse for foglamps

83 Junction box with fuses and relays:

E1 Horn relay (for single tone horns

bridge between 86 and 87)

E2 Heated rear screen relay

E3 Heater (bridge between 85 and 30)

84 Join between front cable and rear

cables

85 Join between front cable and door

ajar sensor cables

86 Earth on dashboard, left hand side

87 Earth on dashboard, right hand

side

88 Choke warning light switch

89 Ignition switch

90 Hazard warning lights switch

91 Steering column switch unit

A Rear screen wash/wipe switch

B Horn button

C Direction indicators switch

D Windscreen wiper intermittent

speed selector switch

E Windscreen/headlamp washer

control switchNo Description

F Rear foglamps/headlamp washer

intermittent device switch

G Headlamp dip switch

H External lights switch

I Flasher switch

92 Foglamp relay

93 Electric fuel pump relay

94 Electric windows relay feed

95 Headlamp wash/wipe intermittent

device

96 Direction indicators/hazard warning

lights flasher unit

97 Central locking receiver

98 Central locking control unit

99 Join with brake pad cables

100 Join between engine cable and

dashboard cables

101 Automatic heater cable join

102 Instrument panel

A Foglamps warning light

B Main beam headlamps warning

light

C Side lights warning light

D Rear foglamps warning light

E Heated rear screen warning light

F Hazard warning lights warning

light

G Direction indicators warning light

H Handbrake applied and insufficient

brake fluid level warning light

I Choke warning light

K Instrument panel light bulbs

L Battery recharging warning light

M Insufficient engine oil pressure

warning light

O Antiskid braking system failure

warning light

P Maximum turbocharging pressure

warning light

Q Brake pad wear warning light

R Door ajar warning light

U Fuel level gauge

V Engine oil pressure gauge

W Engine oil temperature gauge

Y Tachometer

Z Coolant temperature gauge

103 Join with remote control central

locking cables

104 Cigar lighter

105 Radio receiver

106 Heater unit

107 Switch unit

A Heated rear screen switch

B Rear foglamps switch

C Switch unit light bulb

D Rear screen wiper switch

E Foglamps switch

F Clock

108 Left front electric window motor

109 Left front central locking geared

motor

110 Switch signalling left front door ajar

Page 276 of 303

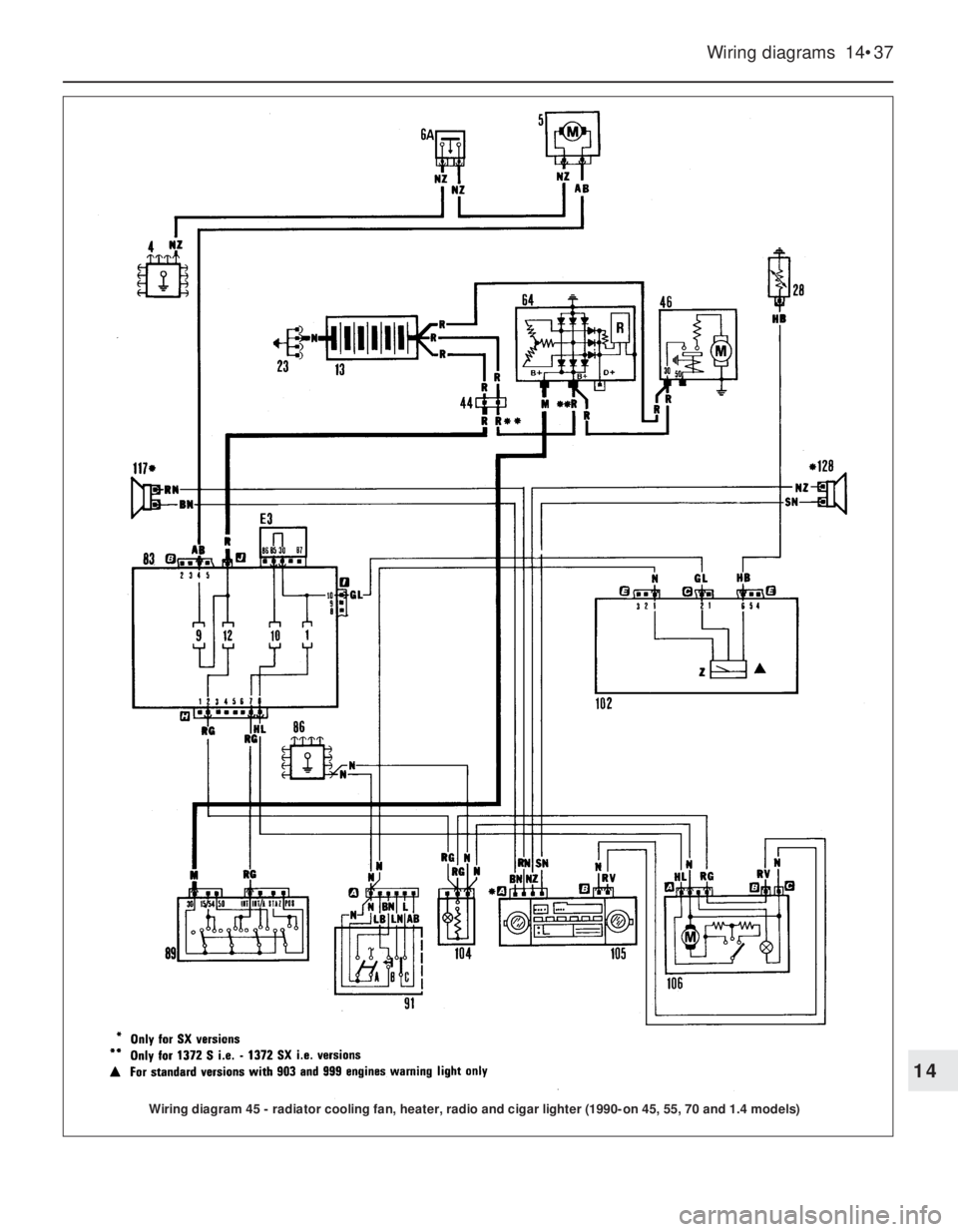

Wiring diagrams 14•37

14

Wiring diagram 45 - radiator cooling fan, heater, radio and cigar lighter (1990-on 45, 55, 70 and 1.4 models)

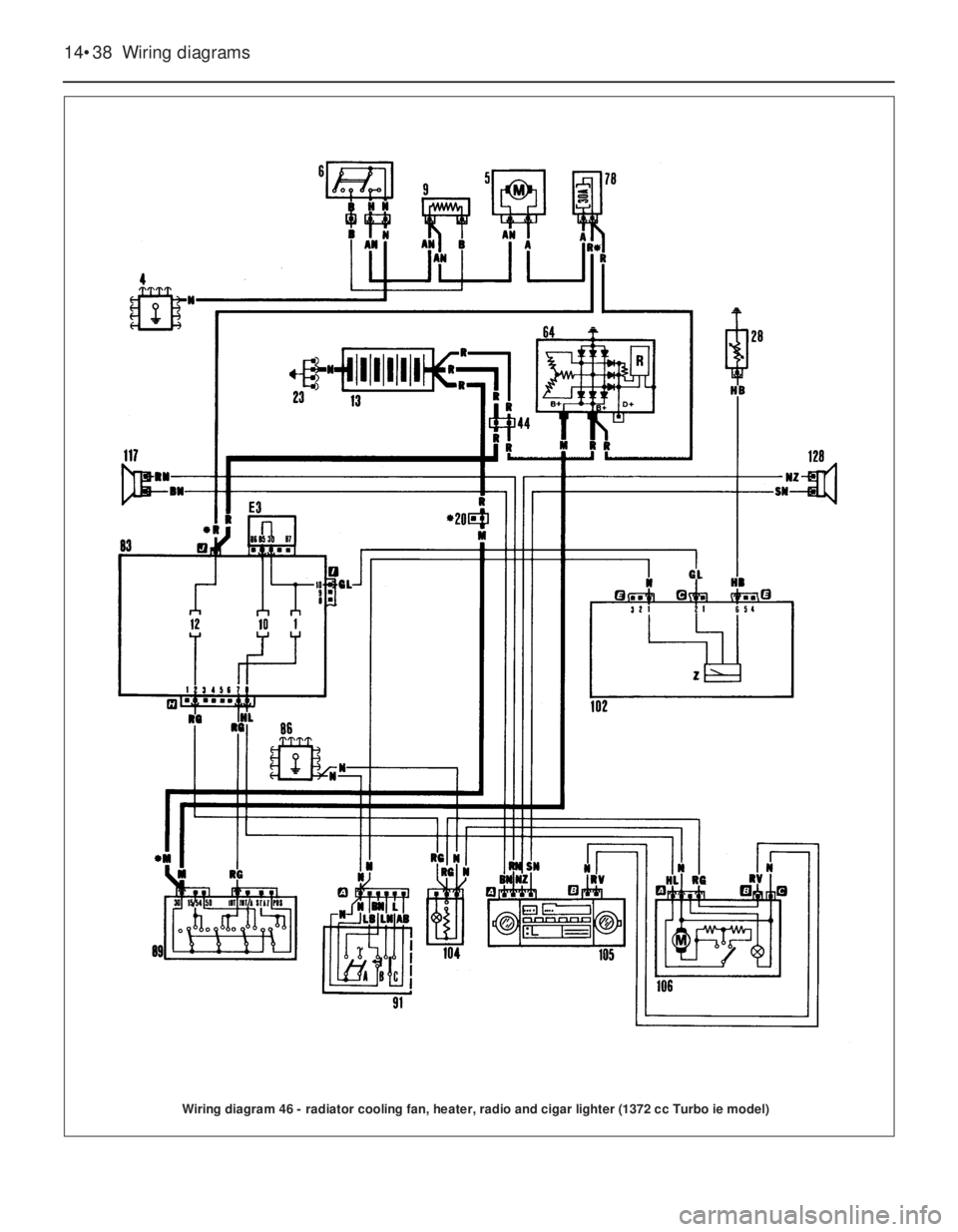

Page 277 of 303

14•38 Wiring diagrams

Wiring diagram 46 - radiator cooling fan, heater, radio and cigar lighter (1372 cc Turbo ie model)

Page 294 of 303

Engine cuts out suddenly –

ignition fault

m mLoose or disconnected LT wires

m mWet HT leads or distributor cap (after

traversing water splash)

m mCoil failure (check for spark)

m mOther ignition fault (see Chapter 4)

Engine misfires before cutting out

– fuel fault

m mFuel tank empty

m mFuel pump defective or filter blocked

(check for delivery)

m mFuel tank filler vent blocked (suction will be

evident on releasing cap)

m mCarburettor needle valve sticking

m mCarburettor jets blocked (fuel contami-

nated)

m mOther fuel system fault (see Chapter 3)

Engine cuts out – other causes

m

mSerious overheating

m mMajor mechanical failure (eg camshaft

drive)

Ignition (no-charge) warning light

illuminated

m mSlack or broken drivebelt — retension or

renew (Chapter 9)

Ignition warning light not

illuminated

m mCoolant loss due to internal or external

leakage (see Chapter 2)

m mThermostat defective

m mLow oil level

m mBrakes binding

m mRadiator clogged externally or internally

m mElectric cooling fan not operating correctly

m mEngine waterways clogged

m mIgnition timing incorrect or automatic

advance malfunctioning

m mMixture too weak

Note: Do not add cold water to an overheated

engine or damage may result

Note: Low oil pressure in a high-mileage

engine at tickover is not necessarily a cause

for concern. Sudden pressure loss at speed is

far more significant. In any event check the

gauge or warning light sender before

condemning the engine.

Gauge reads low or warning light

illuminated with engine running

m mOil level low or incorrect grade

m mDefective gauge or sender unit m mWire to sender unit earthed

m mEngine overheating

m mOil filter clogged or bypass valve defective

m mOil pressure relief valve defective

m mOil pick-up strainer clogged

m mOil pump worn or mountings loose

m mWorn main or big-end bearings

Pre-ignition (pinking) on

acceleration

m mIncorrect grade of fuel

m mIgnition timing incorrect

m mDistributor faulty or worn

m mWorn or maladjusted carburettor

m mExcessive carbon build-up in engine

Whistling or wheezing noises

m

mLeaking vacuum hose

m mLeaking carburettor or manifold gasket

m mBlowing head gasket

Tapping or rattling

m

mIncorrect valve clearances (where appli-

cable)

m mWorn valve gear

m mWorn timing chain or belt

m mBroken piston ring (ticking noise)

Knocking or thumping

m

mUnintentional mechanical contact (eg fan

blades)

m mWorn drivebelt

m mPeripheral component fault (generator,

water pump, etc)

m mWorn big-end bearings (regular heavy

knocking, perhaps less under load)

m mWorn main bearings (rumbling and

knocking, perhaps worsening under load)

m mPiston slap (most noticeable when cold)

Engine noises

Low engine oil pressure

Engine overheatsEngine cuts out and will not restart

Fault FindingREF•11

REF

Crank engine and check for spark. Note

use of insulated tool

Page 296 of 303

Glossary of Technical TermsREF•13

REF

A

ABS (Anti-lock brake system)A system,

usually electronically controlled, that senses

incipient wheel lockup during braking and

relieves hydraulic pressure at wheels that are

about to skid.

Air bag An inflatable bag hidden in the

steering wheel (driver’s side) or the dash or

glovebox (passenger side). In a head-on

collision, the bags inflate, preventing the

driver and front passenger from being thrown

forward into the steering wheel or windscreen.

Air cleanerA metal or plastic housing,

containing a filter element, which removes

dust and dirt from the air being drawn into the

engine.

Air filter elementThe actual filter in an air

cleaner system, usually manufactured from

pleated paper and requiring renewal at regular

intervals.

Allen keyA hexagonal wrench which fits into

a recessed hexagonal hole.

Alligator clipA long-nosed spring-loaded

metal clip with meshing teeth. Used to make

temporary electrical connections.

AlternatorA component in the electrical

system which converts mechanical energy

from a drivebelt into electrical energy to

charge the battery and to operate the starting

system, ignition system and electrical

accessories.

Ampere (amp)A unit of measurement for the

flow of electric current. One amp is the

amount of current produced by one volt

acting through a resistance of one ohm.

Anaerobic sealerA substance used to

prevent bolts and screws from loosening.

Anaerobic means that it does not require

oxygen for activation. The Loctite brand is

widely used.

AntifreezeA substance (usually ethylene

glycol) mixed with water, and added to a

vehicle’s cooling system, to prevent freezing

of the coolant in winter. Antifreeze also

contains chemicals to inhibit corrosion and

the formation of rust and other deposits that

would tend to clog the radiator and coolant

passages and reduce cooling efficiency.

Anti-seize compoundA coating that

reduces the risk of seizing on fasteners that

are subjected to high temperatures, such as

exhaust manifold bolts and nuts.

AsbestosA natural fibrous mineral with great

heat resistance, commonly used in the

composition of brake friction materials.Asbestos is a health hazard and the dust

created by brake systems should never be

inhaled or ingested.

AxleA shaft on which a wheel revolves, or

which revolves with a wheel. Also, a solid

beam that connects the two wheels at one

end of the vehicle. An axle which also

transmits power to the wheels is known as a

live axle.

AxleshaftA single rotating shaft, on either

side of the differential, which delivers power

from the final drive assembly to the drive

wheels. Also called a driveshaft or a halfshaft.

BBall bearingAn anti-friction bearing

consisting of a hardened inner and outer race

with hardened steel balls between two races.

BearingThe curved surface on a shaft or in a

bore, or the part assembled into either, that

permits relative motion between them with

minimum wear and friction.

Big-end bearingThe bearing in the end of

the connecting rod that’s attached to the

crankshaft.

Bleed nippleA valve on a brake wheel

cylinder, caliper or other hydraulic component

that is opened to purge the hydraulic system

of air. Also called a bleed screw.

Brake bleedingProcedure for removing air

from lines of a hydraulic brake system.

Brake discThe component of a disc brake

that rotates with the wheels.Brake drumThe component of a drum brake

that rotates with the wheels.

Brake liningsThe friction material which

contacts the brake disc or drum to retard the

vehicle’s speed. The linings are bonded or

riveted to the brake pads or shoes.

Brake padsThe replaceable friction pads

that pinch the brake disc when the brakes are

applied. Brake pads consist of a friction

material bonded or riveted to a rigid backing

plate.

Brake shoeThe crescent-shaped carrier to

which the brake linings are mounted and

which forces the lining against the rotating

drum during braking.

Braking systemsFor more information on

braking systems, consult the Haynes

Automotive Brake Manual.

Breaker barA long socket wrench handle

providing greater leverage.

BulkheadThe insulated partition between

the engine and the passenger compartment.

CCaliperThe non-rotating part of a disc-brake

assembly that straddles the disc and carries

the brake pads. The caliper also contains the

hydraulic components that cause the pads to

pinch the disc when the brakes are applied. A

caliper is also a measuring tool that can be set

to measure inside or outside dimensions of an

object.

CamshaftA rotating shaft on which a series

of cam lobes operate the valve mechanisms.

The camshaft may be driven by gears, by

sprockets and chain or by sprockets and a

belt.

CanisterA container in an evaporative

emission control system; contains activated

charcoal granules to trap vapours from the

fuel system.

CarburettorA device which mixes fuel with

air in the proper proportions to provide a

desired power output from a spark ignition

internal combustion engine.

CastellatedResembling the parapets along

the top of a castle wall. For example, a

castellated balljoint stud nut.

CastorIn wheel alignment, the backward or

forward tilt of the steering axis. Castor is

positive when the steering axis is inclined

rearward at the top.

Canister

Brake bleeding

Bearing

Air filter

Page 298 of 303

Glossary of Technical TermsREF•15

REF

GGapThe distance the spark must travel in

jumping from the centre electrode to the side

electrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.

Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful to

the ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

Adjusting spark plug gap

Plastigage

Gasket

Page 300 of 303

A

Accelerator cable - 3•12, 13•80

Accelerator control system - 13•75

Accelerator pump -3•7, 3•8, 3•11, 13•66

Acknowledgements - 0•4

Aerial -9•10

Air bags - 0•5

Air cleaner -3•4, 13•60, 13•69, 13•67,

13•75, 13•79

Air pressure switch - 13•70

Air temperature sensor - 13•76

Airflow meter - 13•67, 13•69, 13•80

Alternator -9•3, 13•58, 13•103, 13•104

Alternator fault -9•14

Anti-flooding device -3•8, 3•9, 3•10, 3•11,

13•64

Anti-knock sensor - 13•86, 13•90

Anti-roll bar - 13•111

Antifreeze - 0•6, 0•13, 2•1, 2•2

Antiskid system - 13•103

Armrest - 13•112

Asbestos - 0•5

Auxiliary shaft -1•29, 1•30, 13•51, 13•53

B

Battery -0•5, 9•2

Battery fault -9•14

Bleeding brakes -8•7

Bleeding clutch - 13•94

Bodywork- 12•1et seq, 13•111, REF•4

Bonnet - 12•3, 12•4

Boots -7•2, 10•2, 13•98

Brake fluid -0•13, 8•1, 13•110, 13•111

Braking system-8•1et seq, 13•100,

REF•1, REF•2, REF•3

Braking system fault finding -8•9

Breakerless ignition system - 13•85, 13•86

Bumpers - 12•4, 12•11, 13•113

Burning -0•5

C

Cables -3•12, 5•1, 8•9, 9•8, 13•80

Calipers -8•3, 13•101, 13•102Camshaft -1•19, 1•21, 1•24, 1•29, 1•32,

13•21, 13•30, 13•34, 13•41, 13•42

Capacities -0•6, 13•17

Carburettors -3•6 to 3•11, 13•62 to 13•66

Carpets - 12•2

Cassette player-9•10

Catalytic converter - 13•77

Central door locking -9•11, 13•109

Centre console - 12•9

Check control (warning module) system -

9•12, 9•13, 13•110, 13•111

Choke -3•11, 3•12

Cigar lighter -9•13, 13•109

Clock -9•13, 13•108

Clutch-5•1et seq, 13•83, 13•92, 13•94

Clutch fault finding -5•3

Clutch fluid -0•13

CO emissions (mixture) - REF•4

Coil -4•6, 13•86, 13•90, 13•91

Coil spring - 11•3, 11•4

Condenser -4•5

Connecting rods -1•12, 1•18, 1•22, 1•26,

1•30, 13•25, 13•26, 13•30, 13•35,

13•47, 13•48, 13•53

Console - 12•9

Constant velocity joint -0•13, 7•3, 13•98,

13•99

Contact breaker points -4•2, 4•3

Contents -0•2

Control panel - 13•108

Conversion factors -0•14

Coolant -0•6, 0•13, 2•1, 2•2, 13•69, 13•70,

13•110, 13•111

Coolant pump -2•4, 13•55, 13•58

Cooling and heating systems-2•1et seq,

13•54, 13•55

Cooling and heating systems fault finding -

2•8

Courtesy lamp -9•5, 9•8

Crankcase -1•17

Crankcase ventilation system -1•8

Crankshaft -1•18, 1•20, 1•30, 1•31, 13•44,

13•45, 13•52

Crossmember - 11•4

Crushing -0•5

CV joints -0•13, 7•3, 13•98, 13•99

Cylinder block -1•17Cylinder head -1•10, 1•16, 1•19, 1•22,

1•25, 1•28, 1•32, 13•19, 13•22, 13•30,

13•34, 13•43, 13•44, 13•53

D

Dents in bodywork - 12•2

Depressurisation (fuel system) - 13•75

Digiplex 2 ignition system - 13•90

Dim-dip system - 13•106

Dimensions -0•6, 13•17

Direction indicators -9•7

Discs -8•4, 13•101, 13•102

Distributor -4•3, 4•5, 13•86, 13•89, 13•90,

13•92

Doors -9•11, 12•5, 12•6, 12•7, 13•111,

13•112, 13•114, REF•2

Drivebelts -2•3, 13•58

Driveshaft

Driveshafts and hubs fault finding -7•6

Driveshafts,hubs,roadwheels and tyres-

0•13, 7•1et seq, 10•4, 11•3, 11•6,

13•98, 13•99, REF•3, REF•4

Drums -8•4

Dwell angle -4•4

E

Economy gauge (Econometer) -3•11, 9•12

Electric shock -0•5

Electric windows -9•11, 13•109

Electrical control circuit (ECU) - 13•67,

13•71, 13•81, 13•86, 13•90

Electrical system-9•1et seq,13•103,

REF•2

Electrical system fault finding -9•14,

REF•9

Electronic ignition -4•3, 4•6, 4•7

Engine-1•1et seq, 13•19, 13•33, 13•37

Engine fault finding -1•35, 1•36, 2•8, 3•13,

4•9, 13•92, REF•10, REF•11

Engine oil -0•6, 0•13, 1•3, 1•4, 1•8

Engine speed sensor -4•7, 13•89, 13•91

Environmental considerations - REF•8

Exhaust emission checks - REF•4

Exhaust manifold - 13•77

Exhaust system -3•12, REF•3

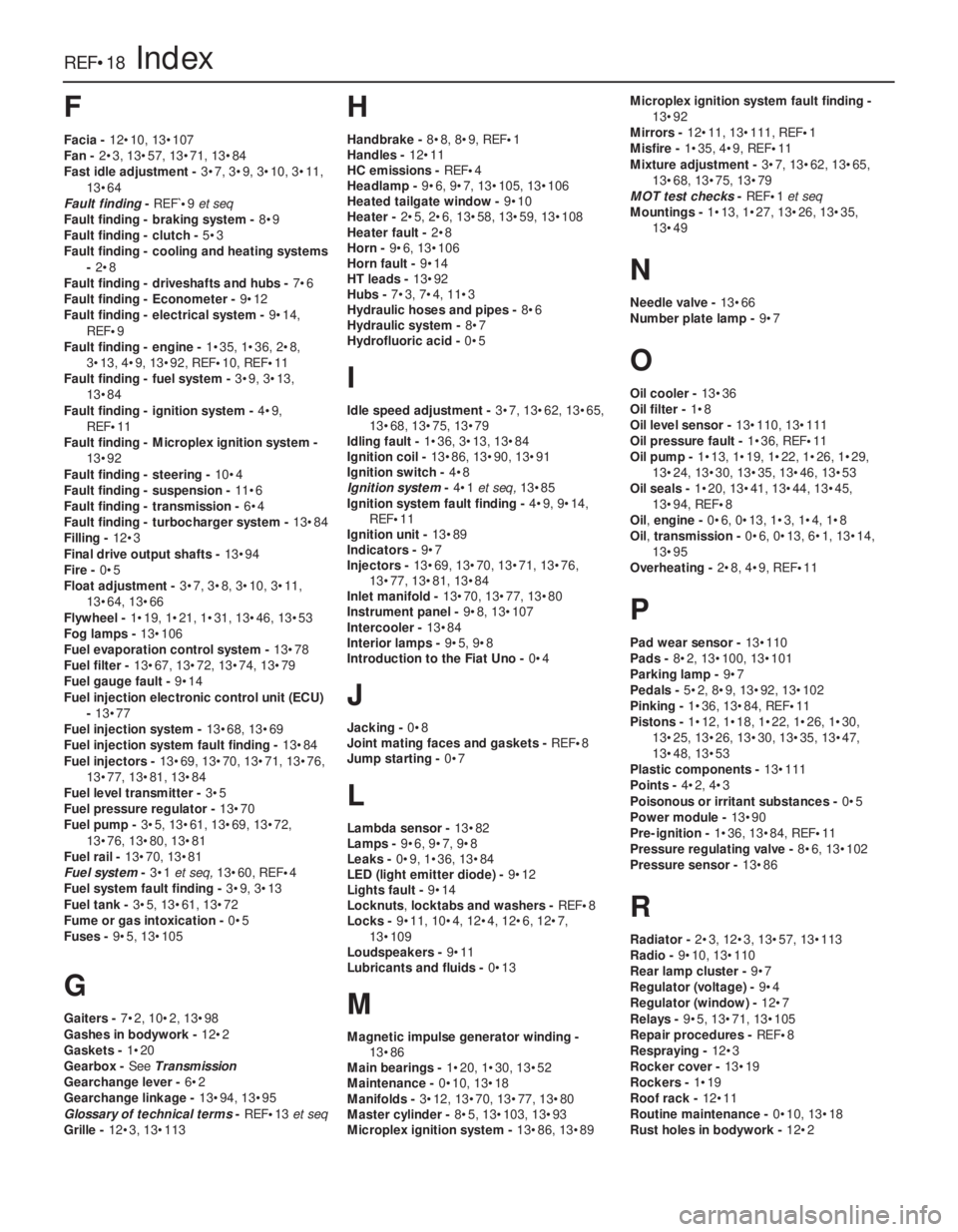

IndexREF•17

REF

Note: References throughout this index relate to Chapter•page number

Page 301 of 303

F

Facia - 12•10, 13•107

Fan -2•3, 13•57, 13•71, 13•84

Fast idle adjustment -3•7, 3•9, 3•10, 3•11,

13•64

Fault finding- REF`•9et seq

Fault finding - braking system -8•9

Fault finding - clutch -5•3

Fault finding - cooling and heating systems

-2•8

Fault finding - driveshafts and hubs -7•6

Fault finding - Econometer -9•12

Fault finding - electrical system -9•14,

REF•9

Fault finding - engine -1•35, 1•36, 2•8,

3•13, 4•9, 13•92, REF•10, REF•11

Fault finding - fuel system -3•9, 3•13,

13•84

Fault finding - ignition system -4•9,

REF•11

Fault finding - Microplex ignition system -

13•92

Fault finding - steering - 10•4

Fault finding - suspension - 11•6

Fault finding - transmission -6•4

Fault finding - turbocharger system - 13•84

Filling - 12•3

Final drive output shafts - 13•94

Fire -0•5

Float adjustment -3•7, 3•8, 3•10, 3•11,

13•64, 13•66

Flywheel -1•19, 1•21, 1•31, 13•46, 13•53

Fog lamps - 13•106

Fuel evaporation control system - 13•78

Fuel filter - 13•67, 13•72, 13•74, 13•79

Fuel gauge fault -9•14

Fuel injection electronic control unit (ECU)

- 13•77

Fuel injection system - 13•68, 13•69

Fuel injection system fault finding - 13•84

Fuel injectors - 13•69, 13•70, 13•71, 13•76,

13•77, 13•81, 13•84

Fuel level transmitter -3•5

Fuel pressure regulator - 13•70

Fuel pump -3•5, 13•61, 13•69, 13•72,

13•76, 13•80, 13•81

Fuel rail - 13•70, 13•81

Fuel system-3•1et seq, 13•60, REF•4

Fuel system fault finding -3•9, 3•13

Fuel tank -3•5, 13•61, 13•72

Fume or gas intoxication -0•5

Fuses -9•5, 13•105

G

Gaiters -7•2, 10•2, 13•98

Gashes in bodywork - 12•2

Gaskets -1•20

Gearbox - SeeTransmission

Gearchange lever -6•2

Gearchange linkage - 13•94, 13•95

Glossary of technical terms- REF•13et seq

Grille - 12•3, 13•113

H

Handbrake -8•8, 8•9, REF•1

Handles - 12•11

HC emissions - REF•4

Headlamp -9•6, 9•7, 13•105, 13•106

Heated tailgate window -9•10

Heater -2•5, 2•6, 13•58, 13•59, 13•108

Heater fault -2•8

Horn -9•6, 13•106

Horn fault -9•14

HT leads - 13•92

Hubs -7•3, 7•4, 11•3

Hydraulic hoses and pipes -8•6

Hydraulic system -8•7

Hydrofluoric acid -0•5

I

Idle speed adjustment -3•7, 13•62, 13•65,

13•68, 13•75, 13•79

Idling fault -1•36, 3•13, 13•84

Ignition coil - 13•86, 13•90, 13•91

Ignition switch -4•8

Ignition system-4•1et seq, 13•85

Ignition system fault finding -4•9, 9•14,

REF•11

Ignition unit - 13•89

Indicators -9•7

Injectors - 13•69, 13•70, 13•71, 13•76,

13•77, 13•81, 13•84

Inlet manifold - 13•70, 13•77, 13•80

Instrument panel -9•8, 13•107

Intercooler - 13•84

Interior lamps -9•5, 9•8

Introduction to the Fiat Uno -0•4

J

Jacking -0•8

Joint mating faces and gaskets - REF•8

Jump starting -0•7

L

Lambda sensor - 13•82

Lamps -9•6, 9•7, 9•8

Leaks -0•9, 1•36, 13•84

LED (light emitter diode) -9•12

Lights fault -9•14

Locknuts,locktabs and washers - REF•8

Locks -9•11, 10•4, 12•4, 12•6, 12•7,

13•109

Loudspeakers -9•11

Lubricants and fluids -0•13

M

Magnetic impulse generator winding -

13•86

Main bearings -1•20, 1•30, 13•52

Maintenance -0•10, 13•18

Manifolds -3•12, 13•70, 13•77, 13•80

Master cylinder -8•5, 13•103, 13•93

Microplex ignition system - 13•86, 13•89Microplex ignition system fault finding -

13•92

Mirrors - 12•11, 13•111, REF•1

Misfire -1•35, 4•9, REF•11

Mixture adjustment -3•7, 13•62, 13•65,

13•68, 13•75, 13•79

MOT test checks- REF•1et seq

Mountings -1•13, 1•27, 13•26, 13•35,

13•49

N

Needle valve - 13•66

Number plate lamp -9•7

O

Oil cooler - 13•36

Oil filter -1•8

Oil level sensor - 13•110, 13•111

Oil pressure fault -1•36, REF•11

Oil pump -1•13, 1•19, 1•22, 1•26, 1•29,

13•24, 13•30, 13•35, 13•46, 13•53

Oil seals -1•20, 13•41, 13•44, 13•45,

13•94, REF•8

Oil,engine -0•6, 0•13, 1•3, 1•4, 1•8

Oil,transmission -0•6, 0•13, 6•1, 13•14,

13•95

Overheating -2•8, 4•9, REF•11

P

Pad wear sensor - 13•110

Pads -8•2, 13•100, 13•101

Parking lamp -9•7

Pedals -5•2, 8•9, 13•92, 13•102

Pinking -1•36, 13•84, REF•11

Pistons -1•12, 1•18, 1•22, 1•26, 1•30,

13•25, 13•26, 13•30, 13•35, 13•47,

13•48, 13•53

Plastic components - 13•111

Points -4•2, 4•3

Poisonous or irritant substances -0•5

Power module - 13•90

Pre-ignition -1•36, 13•84, REF•11

Pressure regulating valve -8•6, 13•102

Pressure sensor - 13•86

R

Radiator -2•3, 12•3, 13•57, 13•113

Radio -9•10, 13•110

Rear lamp cluster -9•7

Regulator (voltage) -9•4

Regulator (window) - 12•7

Relays -9•5, 13•71, 13•105

Repair procedures - REF•8

Respraying - 12•3

Rocker cover - 13•19

Rockers -1•19

Roof rack - 12•11

Routine maintenance -0•10, 13•18

Rust holes in bodywork - 12•2

REF•18Index