check oil FORD CAPRI 1974 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 53 of 205

, ,

52 Chapter 1 Engin e

68 Connecting rods and gudgeon pins -Il~nmination a nd renovation

Refer 10 Sccuo n 18.

69 Cr,lIlkshnft -e~(lrl1in

70 Mail' and biu·end heafinUs -olwillinmion and H)!1ovation

Ilelo,r to Seo.:lIOIl 20

71 TilninU oellrs -e~i1miniltion find renOVlltio n

Re f

el to Sec t,on 21.

72 Flywhee l/ d riveplale -Okamitliltiotl lind ronovtttion

Inspf:CI lhu ffywhf)l)I 0 ' ([ttvl'pl,,": fOI (!;U";'\lC ilnd 1:I".1I:k Ih;'1 Ihe ""!I H".u docs uol have .IIlY \)Iok"n o. l);Idly wOtn teeth. :1 On ''''''''';11 I'''"''''US~IO'' mnd"b ,I IS pOSSII.Il) 10 'CHew the I"'!l \]C,II .'S Ilesl:

[xallutle Ihl} v,tlves 101 IlIls "lid !l,ooves lind the valve SIems to. e~c,'SslV') we,l' III d'~loIIIOII' 2 Ek,""l1ltJ Ihe v,oIVil hf)"d 10' SI!.!"S 01 hu",u,U of the vOllvo seillS lind ch .. !ck Ihe ht 01 Ihl) villves III Iho v,llve UUldes . 10 SCl) II Ihe villve uu,des il,e WO!ll

3 We"" valve U",dcs c;'" be r l),lIned O\It lind vlIlves w'th overs.~e Siems lilted II iI v

S To 1,1P the valves. In tt s u ction Iype gnmlonu 1001 to Ihe villvc hettd. smeil' a lu tle COil.se c;ubo.unllulll urmdmu pOIste on to I he sealing I~c e 01 Ihe vnlve ond inserllhe valve 11110 the cyJonder he"d. Rub Ihe stern of the v al ve gundlng 1001 hetween the palms 0 1 the hands. so Ihal Ihe valve,s ,otllle(l hHckwards 1I11d lo.wa.ds When II IS lelt lhOlI culling has

ceased. loft Ihe villvc. rotate It th.ough 90·, lowe. 1 and fepCill the u"n(llnu o.:.e.atlon . • e dlslllbulill9 the g"nd,ng pas!O on Ihe seal if necessilry. Conlinue Ihe process unlll a mllll gwy bOlnd IS pfoduced OIloun d the complete pe"phclY of hoth the vlllvc and t he valve seil l G RepoiJl Ihe opcrilllO" US" 'U fine o""d,nU I).Jsle. 10 ohtil'"

IInlsh. then clean lJoth Ihe valvcs and Ille v alve seals 10 ,emove IIU \llIces 01 u"ndlno pash:! 7 II 'I IS convenl,,1lI 10 liIke Ihe eyhndc. he

When Ihe cyllnde. heilds (li e removed. eilhe. in Ihe Course ovelhJul Of for inspection 01 bows 0. villve condllion when the e IS in Ihe CM . il IS nO'''1

Ihe eiliite. dilys 01 10nU stroke low .eVYlnO en!)lIles tJUllllodern enUil fuels ilnd Itrb"canlS C,1use less cOIIOOn deposils OInyway and any. b ehind lend merely 10 cause h O I .SpO IS.

75 Oil PU"',) -disnwntlino. eknmin"liOil ,,"d reOlssembly

The Oil pump mm"Itt;"S a I)ressure 0 1 ilbout 2 8 kgl/cm' (3 Ihf/in') lInd unless Ihere is ,1 sIo",IIcanl (hop In 001 P'(lSsuro willel ,)loved to he due 10 the Pllln,). rillhn. Ih;", 10 wo", heil'm!)s. 11 IS be .

t o le"ve Ihe 011 pump und'S hilhed. 2 To d'smanlle Ihe pump. fll:.1 ,emove II hOln the en!l'ne ns desc,,1 III SUClion 58 3 Remove Ihe IWO bolts seCulII1!J Ihe en d cover 10 the body 1 'emove the covel ilnd 1he .ehel v;" ve "sscmhly. Ihen Ihe Iwo P"

fOIOI assembly.

" Remove ,he IWO bolts lind ,,,ke Ihe p,ck·up w he lind SCIl' lIssembly oft Ihe pump housin!1 S Wilsh all lhe pilrlS In petlo'. usc iI hlllsh 10 cleol" Ihe Inside 01 1 pump ho usinu ilnd lhe p.cssu,.., .elle' vil've eh'!lnbel. ilnd milke 5' Ihilt ,111 p,tltlClcs 01 dill ilnd mewl n,e ,emoved Allow the pttrlS 10'~ n;IIUf,lllyor blow them d.y G Check Ihe Illslde ollho Puml) houSII'9. Ihe OilIer .;w:e ilnd Ihe 101 101 dilfllilUe and e~cesSIve weill 7 E~ll'''Ule the I111lling su.lace 01 lhe I)Ump cove. 101 we,lr It Ihe CO' IS sco,ed. o rooved. a. shows ilny s'g ns o f wea •. a new covef must I hlled 8 W,lh the ,otor assembly filted in the hOuSing. place a straighl·ed!. over Ihe end 0 1 the housing

Page 55 of 205

) 54 Chapter 1 Engine

,n the "Oill hand ror;ke. covc. ~nd mlO Ihl) en!IHlC Ih'ouUh .111 .1(1,1pl0' bene,.!!> the (.1,hl"l)ll01 The sys\cm '!nSlI.ct; 11\.11 !lIlhurnl lIilSCS ille .ChunNt to Ihe enU'"e fOI fUllher (:orlllJ\'~I'OIl

78 Engine reassernbly - gcner

79 C,lInsllllll -re';II'I1I)

SI"h, Illc SpM.,<1 "",th li S ChitrllfCI1'" "ml [""I onin Ill" r:;HlI:.hall ;oml ,, the kr,y 2 LlIb",':"I" lh" c"m~h,111 lo",.,als w,lh <:Ill)"") nd ,llld ~I,d" Ihe ' ·.IIlI~hah "' hOln\h" hOIl!. 1.II-IItH C;UI~ 10 ~""P ,1 ~1',IO!lhl. SO ,I', nvt III rl.mlil!1" II", /:.III1,h,,11 I)","'IIO~ 3 rr! th., (.l", ~h"h 11""~1 ,)1",,, wuhou! ;, !1.'~"('1 fIt lI,e two (,(lInl\I:!,,,nk hr',lei rr,!,'"lll'!! serews ;1I,d 11\lhl"" III"",

80 Cranksh .. ft reblti,,!!

~V'lh lilt: "II\IIIH' "p',ul" ,low". I. 'v ";I, h "I II", "1'1"'11"',""'0 h.,I,,",s ''''10 Ih" "1'1""1''''''1: u.",ll .• '~" wI·h. 111,'''''''1 ~,,,,, Ih." Ih" 1<" ""'!II.IIIO 0" II", I""""'!I '~P"'I""IV ""!!,,!!,,,I '" ,II" ':C"":~I"""h"!I ~I{)I '" II,,: 1; • • u'"c;I~" WI'!> Illh., "Id I""""'!I~ .,," I"""!I ",!tW:Il. ItI.lk" .;",1.111,,10:01 e.lch I .. """,!! hill! IS '''Iud • III III.., 1'1.,, ;11 h"ll wh";h,, W.IS ",mo"..,d Fn Iht:: Ih'u~1 w.lsh".s 10 <1;lcl. ~,,11l 01 11", CI:'II • .., I...,a''''!I. Ih" 0''''''''''([ l;lI;"s 01 Ihe wa~I'e.s IJelll!! Oulw;!lds (1"11 1 16) n"I.""II,c II"tI~1 w.l~I""s 11 1)lar.r. w,lh UH}.1SC 2 FII Ihe low ll anO "!1 halv",s 10 the app,op""h: I>";'''''!I ,;nps 1"1 Ihl1 IllIuSI wM,h.."s on ellll(!' S,dCl "r Ihe <""'"11 I>e;"'I1!l ':"1', Wllh Iho 1.," 01 Ihe w" she. Iitied "1i0 Ihe slOI It' IluI be''''''!1 <;;'1' Rel

RclC' 10 $CCI'O" ;:t!)

82 Oil pump -refillin U

P"lTle

Ihe oilllUlllp L>V 1IIIol1g Ihe IlIlel 1101l wnh Cl1g,"e 0,1 and Ihen flJlat,ng Iho dllvcshilh 10 d,sl"L>ule Ihe 011 wllh," the I'lI"'P hodv 2 Inselllhp. pOll1led end ollhe dliveshMI "'to Ihe PWIlP hodv and III Ihe clop 10 .etain II 3 Place Ih o pUIliP U1 I)051110n . cngnU!! Ihe d""e~h;JII and Iheo inseH Ihe ' .... 0 llitallung IJolls r'\lhlet1ll1.., holts to thC lo.que w'lInch SCII,ng

\I,,,(:n III Ihc SpClcol,c,lIIons < Rell lihu boll SClCU.IIlU Ihe 0,1 pick up luhe 10 IhCl ",nln I)C;UU1U cap ",,(I "U"l"" II 10 Ihe ~j}ec"H,d 10'ljue. F

ig. 1

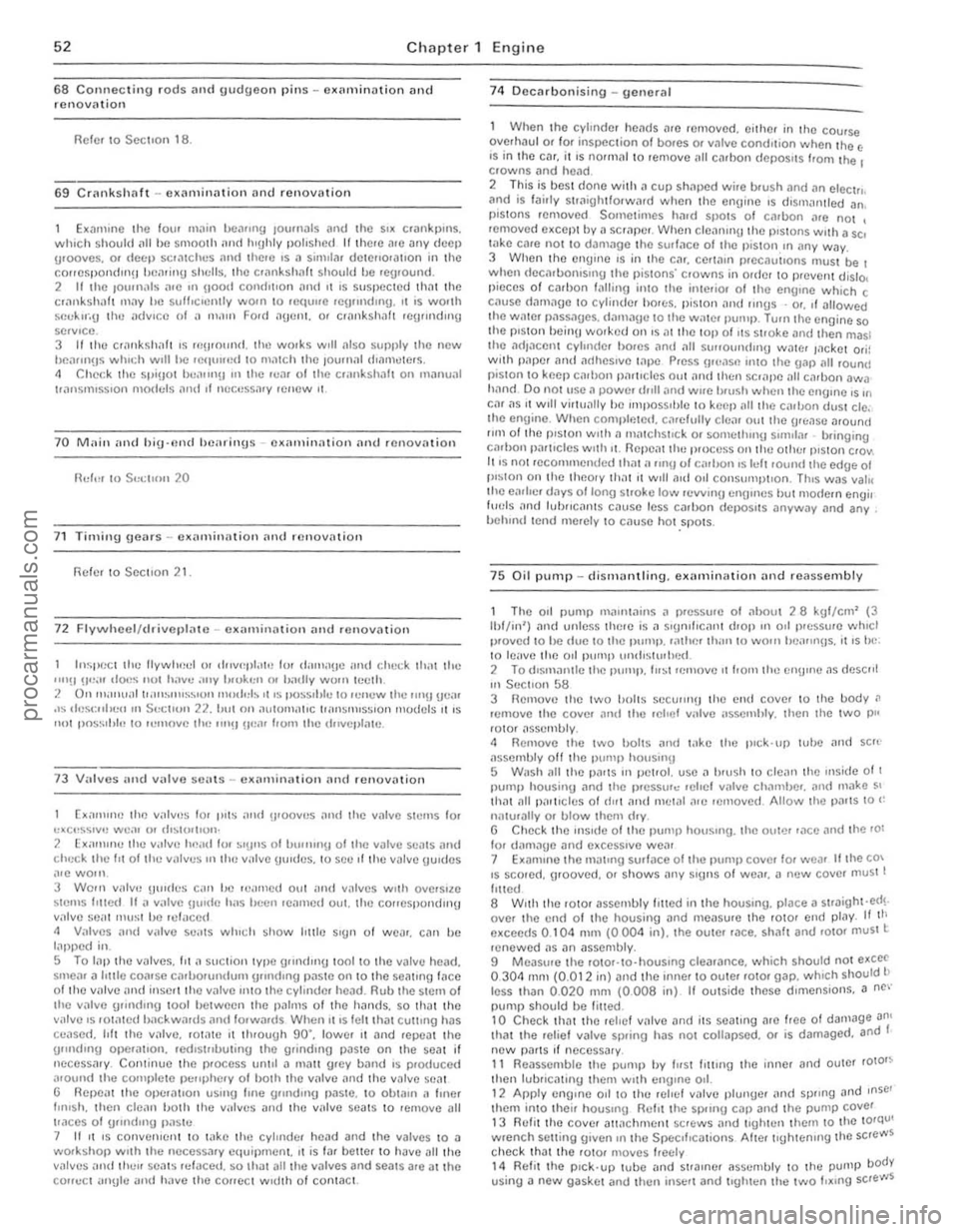

.16 Cr.1J1 kshilft Ihru st wash ers ~ ;orrowed (Sec 80)

83 T illl i,,!! !I ClH'S illid I rOll 1 pla to rclillill!!

Apply 1""'III'!1 1:1>"'1","11<1 In Ih " (11,1,,1 ""!I" nllh" 1"'''1 "n,loI Ih. <,yin""" hl(1{.k ;"HI l

1o"lh < no:l,1 the e:"nlsl1.1 lt ge".. Sf> Ih.ll Iho kP.VW.1VS "I I>ulh Ihl} CI.lnkshall ill1Illlol: e:.1t11sh"'1 "H) In lone ;11111 Ih,: ",,,,ks on Ihe tW,lIS .1,Q on 11m Silllll

I",,, II", <.I:'l1ksllo1ft \1";11 hilS IWO "';IIks Oil 'I alII I " " mipOIWnl Ih;n 111"V iIIe l'OSI\loncd as ~hown ,,' f.U I!; [) M""~,,,e Ir." I:lldllo.1l 01 II", <:.1I1l~hall ;,ft,,, '"~"'IIIIII Ihe t:alllsh;oIl "''''''''''!I hull ami lI\1hl"IIIlI\1 , 10 Iho: 111"1'''' wII,I1I:h ~I:H"'!I U,,,e,, III 1111, SI'"",I,,;;llll)lIS 11", cillll:;h:.11 1;"dllu"l e:"" I", ;111",'01"01 lIy f,ItIl'lI .'

Ilelf'·I,".1 1''''lIlh ~I'.".'·I G M""~,,,e'II": 1"".ll.l~h ul II,,, 1:O",,,h.111 !I",,, ill 1"lIl ··'IIl.,lly ~1'.1(:",1 PIII"i'. .",,,,,,,1 "s I""'I"""V lh.~ ~hull"ll", 0 7.2 In 0 32 """ (000910 001:l "I) 7 AIII,IV 1"'''h''!1 (:O"'P(111,,<1 II! Ihe cII(:uII11r:"",ce ollhe 1",uIIU CO"..,, 101111 I.",,~ .IIHI It) l hl) 100111 01 Ille ;"I.'pIO' pl.'le JI,d oil." up Ihe 1I1l11r'>{'

co"el 8 1l,,1'1 Ih" ",,"'kshall j)l11l!:V to pO~'I'IHI Ih.., IIIIIIII!} '.0"'1<. rhcll mSCIl III" 1""'''11 CO"", hOlls alld t'H"I"" Ih..,111 10 Ihll 10'<1"(: .·"~IIe:h Sr:l1Illg

11''' 1)'' UI Ihe SI'I1t:o/'C;l\'OllS

9 Apply ,0"lIuIII C0111llOll11d In 01111 f.,.:c 01 Ihl! e:,.,,,1 ~11i,11 llullllV w;o~I"", pl.lcc Ihls s,de 10w",US 111(; I'tlilev . ItISC.I Ihl! pull,;V SCCUH"!I holl ,,"(1 ilUhlCIl II 10 Ihc SP':Cllll1d tOlqllC

Fi

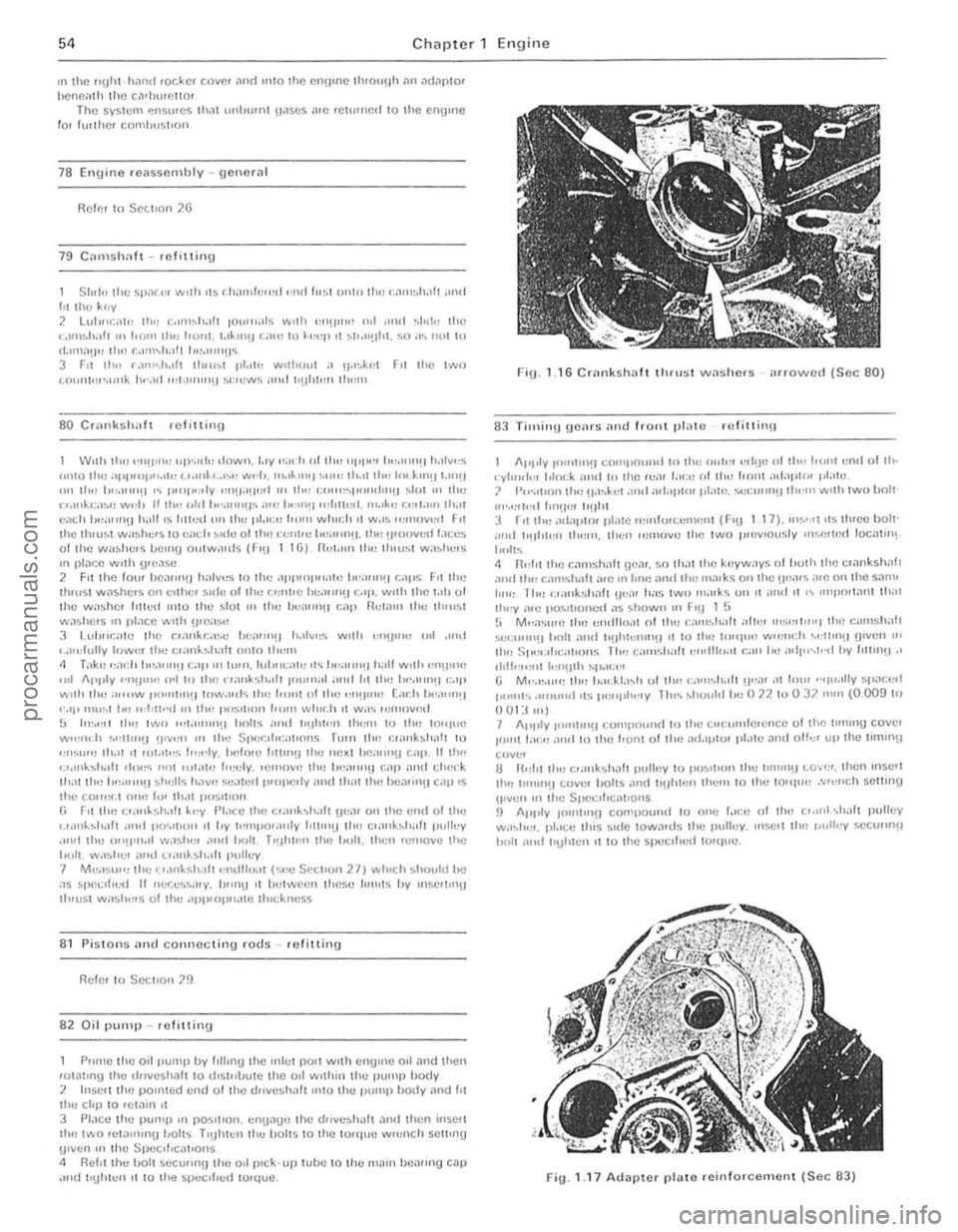

U.1 .17 Adap te r plato reinlo lcclllcnt (Sec 83)

procarmanuals.com

Page 56 of 205

7

Chapter 1 Engine

Fig . 1.1 8 R ear oil sen I ilnd ildaptcr pliltc (Sec 84)

84 Renr oil se;1i ,,,,(I lIywheel - rc fitti"u

1 I'll the ()n!J"I(~ .r,," ,,(1"1'10' pla1<:1 and s(:clIre ,I wllh 'I S IIv(: holls. 2 Smenr en\J1ne (ld OlltO the CI,mkshah '''". Smear 0,1 on the lip 01 the sea l tlnd pos(( lon tlon ';".11 on th e cran hha ll. 3 Align the seil l c;""er holos wllh Ihose 011 the cylrnd(:, hlock . Insell the loul bolts and 11!lhlCll Ihem 10 the SpeCifIed 10lqUfl 4 F it the flywher.:l . or dllveplalc on au lOlllallC lwnsrnis sion Illodels.

InSerll h e six holl S ;",d u\llole rllhem 10 Ihe 10 lque w rench sell"'U Uiven in lhe Speclllcm'olls

8 5 Sump -rciiuill!)

En~",,, lh;ol Ill" ru,rI "'!) ',u.l,u :e s 01 hoth IllI.! Slimp a"d t h e c(,1nkcilsc ,lie cl ea" ,mol IIi,1I n", '.""I",!) SlIrJ ,u;e 01 the Sli mp IS not d'S lo lte d. 2 Apply IO" ,I,,,!! c"'''pollnd 1 0 the pOUltS wllel(~ Ihe l"llllll) cover ablilS lhu ,;yir r"lr" 1,Io ck .lIId where Ihe rea' 001 $u,,1 carr.(:r "dIOIllS II 3 Pln ce tloo \J,,~k"l '" fJo~.t.on, lIt tlo" SlIm l} ,'Ild IIlS(). 1 lhe r0Io1111il1l)

bolts ImUO I tl!lhl 4 PrO!lres~lvely 1I!llIt,," llw sump holt s 011 opposIte I'ilr ts lIllt,1 all 0 1

t

hem ,H" il l tl", ~ 1"":lllI"d IOlllUU , 5 FII ,1 now w;,~h", 10 Ihe ~Ul1lp II"'UI pili!) , IIlscrl lhe dl,lIll pllll) and

t ,uhlen ,t

8 6 Cylinder h e"ds re;rssernbly

L~y the cylrnd" r h",.\! on .IS s Ide. luhrrcnt e cvcry valve Uu ide with eng;l1(! oil. ,lilt! ,"~,,"t the valves 11110 the \Ju, dc Irom whIch lh ey wele remov(:d 2 To ,WOld d

lhero.s dilnlJC' oltl1<.: ~I""IU rcW""C' dillllil\)IIlU tllC villve SHlm 011 sen l

G Ahcr "lsert")!J tit" ~pllt collets. r eleilSo the spllny compressor (111(1

rcmove II 7 C hcc k th"t lh..: ~pl'l cull":IS hilve seilled properly and t

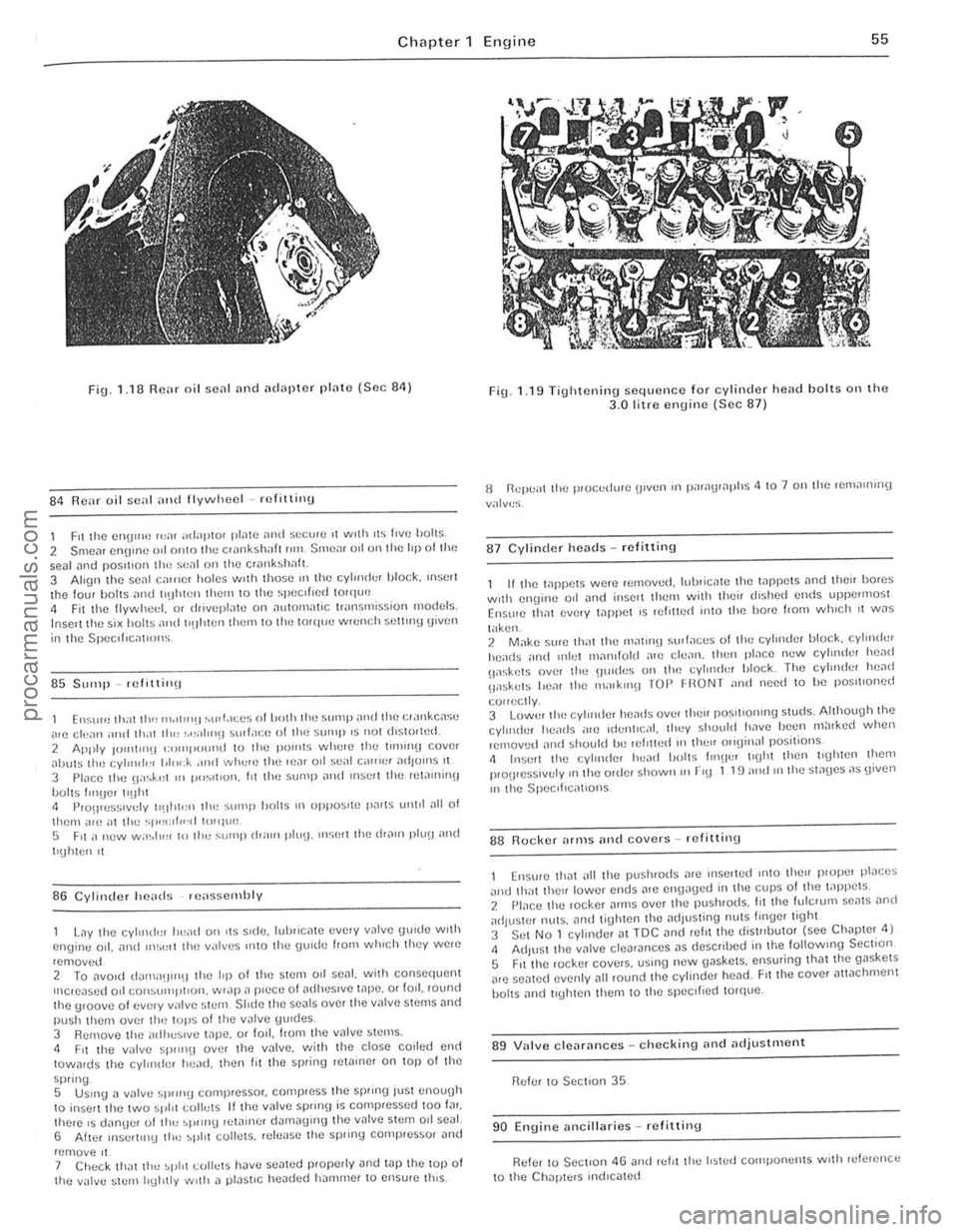

Fi g. 1.1 9 Tightening sequenc e for cylinde r head bolts on the 3.0 litre enuine (Sec 8 7)

a Repe"l liln pruccdwn orven III p;ua!Jrnphs 1 to 7 o n the (CmJlnlllU

v,llv"s

87 Cylinder heads - re fitt;nu

11 the tappels w ere rcmoved. luiJricnle lhe lilppets nnd I heu hores wnh enoine orl nnd insor t thOlll wilh lhc;, d Ished cnds uppermost Ensule lha l every tappet ,s rclltlcd Into lhe hore hom whIch II wns

t nkcl1

2 Mak e sure tha t Ihe rna t"'!1 surlaccs o f lhe cylinder block. cyl lndor henrJs ;Uld 1111,,1 Ill,lIlIlold ;lIe de;"l. then plnce new cyhndcr head \Ja~kets ove, the Wildes un thn cylrmh" block. Tho cyirnder head \I,,~k ~IS beilr thO malkln\! TOP f:nON T ilnd nced to h e pOSII,oned

cOII(:ct ly .

3 Low ul Ille cyl ""lcr he,1ds ov"r the" posl tlonrngst u(!s, Although t he cyhlld\~r headS ,"0 Id entlc;,I, they should h,lVe been Illtlrke d when remuved ilnd should be lehllUd III thcrr ()IIUinal positions t1 Inse rt the cyirndcf 11I)"d boilS f"'!I(:r t.!Jh l then tIghten lhelll prUglC SSlv(: ty OIl the olde, shown III r,U I l!J and III llle stnucs",s U iven

m the SpcelirC;lt'OnS

88 Rocker arms and cover

s -refiUing

Ensure Ihm "II Ihe puslllOlls ,lie ,nselwd I!ltO the" p'llpor placos ;II1

)olt S nntl lighten them t o the spec ,f led torque.

89 Valve clearnnees -checking nnd adjustment

R eier

to SeC!lon 3 5

90 Engine ancillaries -refitting

R eier 10 Sec tIon 46 and ref, t lhe I. ste d componenlS w,th refercnce

to th e Chaptels ind,cilte(f

procarmanuals.com

Page 57 of 205

56 Chapter 1 Engine

91 Engine -refilting

Rcf'tlIng the engine is a rCllcrsnl alth e removJI procedure given In Section 44. bUI in addrhon note the following 1)O;I1IS:

(,,) Ugh/I)' 9(0"50 Ihe ycar/)QIC ;npu{ Sh,ll{ (m,lI/v.,1 transmission) (b) Check tlMllhe dlileh fc/c,He .7Im is cOIf(!clly loentcd (m,lllu,)1 (fiJn$miSS;OIl) (e) Adiusl (he clutch cClbfll ,15 (/(!sCllbcri ill Clwp/fN 5 (m,mu,,1 flilMmission) (d) BelOfc COfl/weliny the engine /0 {I!(! ,W{omMIC {MOSl/tllSion check 111M /he /O((/lle con vet/or is fully 01l9,19N/ wilh lite /f,lfI smiSSI()II pump by reh'/(!IICa to CIWp/Of 6 (e) Refll' file ,)II/QIII,llie ("'''lllltHiOIl WillI 1141/11 ,15 dcsCfI/)t'd III Ch,lpWI 6 (/) Ad/usllhe lellsioll 01 the IJowor steeling IIlIfIIll MId .11/emMa. !lnvalid/(s) ,15 d(!scfI/)ml in Ch,?pICIS 10 i/lld 2 f(!SpcC/lv(!/y (!I) Fill Ihc cooJillfl sys/cm (el,.l/'/C' 2) ,md /lOW,!' Slcc/IIIY

SVS/l:tII (ella,'/Cf 10), 1111:11 fIIlllle mlylllc Willi od (SeC/lOll ti~) ("ho/Q)

92 E n £line -initial start-u p after major overlwul or re pair

Hel",

10 Sect Ion 38

PART C, FAULT D IAGNOSIS

93 Faull diagnosis -engine

Sympto m

(n!Jlne f.111s to tllm OVCI whim ~t;llt", IS Opc,;) lcd

Enll"n) lUIIIS ill no.",al ~pced. hili dous not 51,IIt

E"u'ne SlOp s ilnd Will not 'estill t

Enll'Ile

.",slucs, O. lUll S unevenly

L~ck of powc. illlt! poo, comp.esslo ll

91 1 T OPPln! 1 lIl) tile ""'II"") wIth od

ReilSOn(S)

DI~ch.1'Hed 01 delec tlv" 1o:,lle.y

Dilly 01 lI)os" lI.11tc.y le.,ds

O"f '!I:llve sl; IIt", soL"",,,, I. ,II SW'II: " Odl'ctlvl' s lillte. "UIIOf

Dilly 0 ' III"ken e"!I"IC "'''1111''11 SIt;IP

1\I1'"111 ':Ol1lpOlu",ts Will (If ,1;""1) DefectIve low te nSIOIi le"d Detective o. InCOllec,ly :,,, 1 ,:"III"C I h,e;oke. (,I "PI.I,,:a"fe)

Oe f"ctlve condense. (If '11'lllIo,;.,"lc) O'st"hulor cal) defec tIve. or celltral h,ush HI (irs l,,"uto ' cap Ilot m,,~, COfltilf.t w'th th e .otor a"n Ifls.ulhc,em petrol "' tilllk V.1pOOf Iud '11 luel hlle (," hut cOl1{lIuolls)

Fuet pump I:uhlfe E~O:Hs51ve c hoke, caus,,,u spillk pluUs 10 hccolllt) wet

IU"I1I(HI 1,,,IUle result Ill!.! 110111 b.cakdown. or prescncc o t w;'1ler \,Inti w(: 1 cOnthllOIlS l:n:k 1.11 tud. at luel IJlock, l!Je

loose 19111tlon Icads F(luIIV s J)n. k 1)Iuli T'(1ckin£l on d,slllbuto. cnjl IIlsuliltion

InCOIICCll11lxtu'e 'Ullilion 100 telilldcd Dilly con[,lCI blcakc. POlll1S (,I ajlplPcablc). or loose connection'

D"lectlve v.,lves Blown cyIP"de . head £lasket

WOlll bo.es OJ dilm ilye

Page 60 of 205

)

'tz

Chapter 2 Cooting system 59

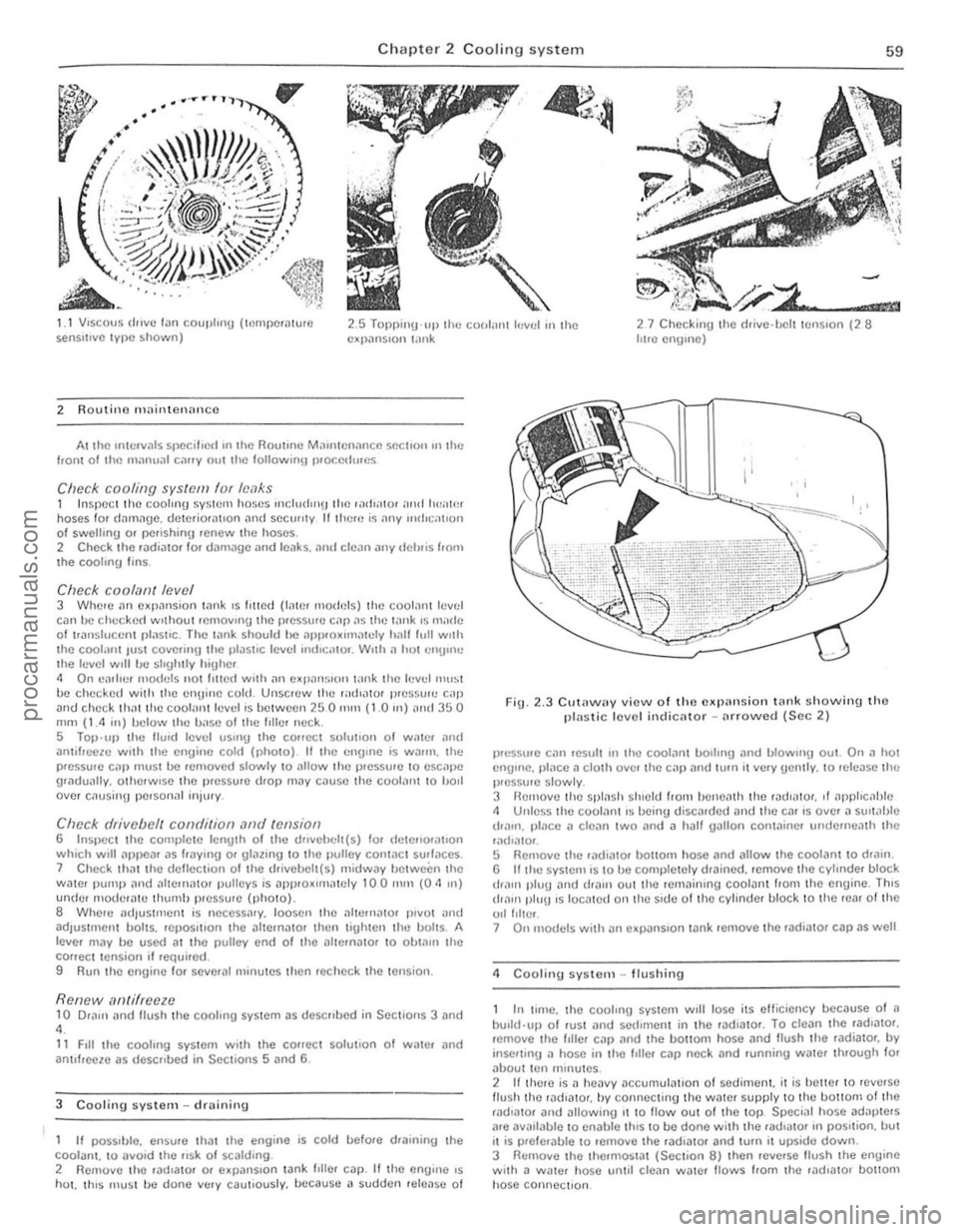

1 I VISCOUS (IPlVC I,m coupling (I,~mpc,alu,e sensitIve 1VIle shown) 2.5 Tuppill\l -lIplhc COlllilll1 h,vel in the c~J)alls,on \;lI\k 27 Checkin U the drive-belt IClls,on (28 hire CIlUulC)

2 Routino Illaintcnanco

Altho ,n1C, ... "ls SPOC""]!! utlhe Rouhnc M .. "UcnanCf! SOChOr! on Ihe 110111 01 the m;uu,a1 c;lrIy oul the lol1oWl!ljl p.occduoes

Check cnoling syslcm lor /c,1k.~ 1 In spe cl Iht! coolin!! sysh),l) hose s 'llcludlll!) the ,adIOiIO' :,"<1 Iwate. hoses for damage. detcriOlllll0n i1nd sccullly If Ihelt) is I'Irly IOulle;1I'01] of swelling 01 p

COf/ec t tension If .equir e d .

9 Run the enuine f o r severlll minutes Ihen rec hec k t he lension.

Renew,1/Jtilreeze 10 O.am i1nd flush Ihe CO(lhng System as descrlhed in Sections 3 and 4 . 11 F,II the coollllg system With Ihe correct solullon of watel and amlf,ccle as desc"hed in SeClions 5 and 6 .

3

Cooling sysl e m -drai"inU

If pOSSIble. ensu,e thilt the engine IS cold belo.t! d.al"i"lJ Ihe cool ant. 10 aVOid the fisk of scalding.

2 Remove Ihe .adlatOf or expanSIon tank IIlIe. cap. If the eflUlnc IS hot. Ih ls must be done vl;lry caul,ously, because a sudden release 0 1

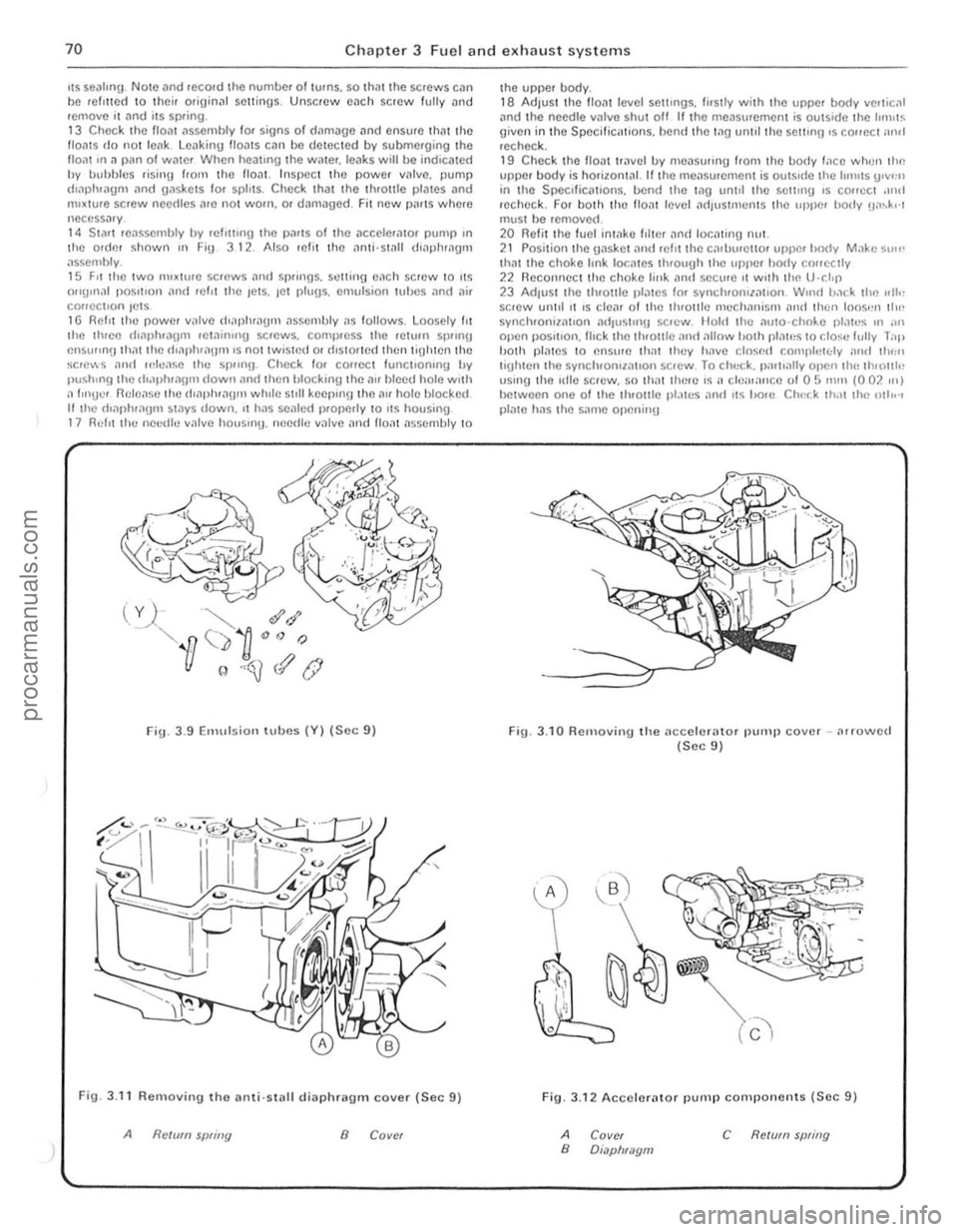

Fig. 2.3 Clltawa y view o f Iho expan sio n tlln k showin g tho plastic lovel indicator -tH rowed (Sec 2)

P'".'·S5U'0 CilIl ,esull II. the cool(lnl !.>oIling i1nd blOWing Oul. On ,1 hot enUlIle. plilce iI cluth ove, the caf} and lurn il ve. y uently. '0 release tim p,ess\lIe slowly. 3 flel110ve the SplilSh shield frOI11 b enomh the ra(II;IIOf. of i1pplrcilble

" Unless !he coolilnt IS beinu discarded and thc ca. 's over (I slilt illJle

d'illl1. ,,'"ce a deiln IWO i1nd a half gallon Conl;1ine. underneath the ,adlaIOl. !) Rel110ve the radlatOl bOllom hose lind allow the coo'al11 10 drili" . 6 If the SyStel1'IS to be completely d,ained. rcmove the cyhnde. block d.;1I1' pluU and draIn oul Iho .emainlng coolant hom tho engine . ThiS d'illf' plug IS locilted all the s,de of the cyl inder block to Ihe rear of the oiliolicr. 7 On 1I10deis wilh all eXJ}ilnSlon tank 'emove the rad.alO' cap as well

4 Cooling systom -ftushing

In IUlIe. !he cooling syStel11 Will lose ils efficiency because o f a bu,ld'lIp 01 .uSI and sedunen t in the radiator. To clean the .adliltol. .emove thc IllIer Cill) i1nd 'he bOllom hose ilnd !lush Ihe radialo" by inse.llng a hose in Iho f,lle. car> neck i1nd funninu Wille. th.ough fOf about tr.m I11mules . 2 If Ihere is a Ilea vy aCCUmuliltlOn 01 sediment. it is betler to .eve.se

flu sh Ihe .adl~tor. by connecting the water supply 10 Ih o boltom of the rilclmof alld allowinu II 10 flow oul of the tOIl. Speclnl hose adapters arc avai lable to enahle thIS to be done w ith the rild.ator In I)OSllion. but It is p,efe.able '0 removc the lad,ato. and tum il upside down.

3 Remove t he thernlos,a, (Section 8) then .eve.se lIush Ihe engine wi,h a W1l1e. hose u n lll clean waler flows from the .ndlat Of bottom h ose connectIon.

procarmanuals.com

Page 71 of 205

70 Chapter 3 Fucl and exhaust systems

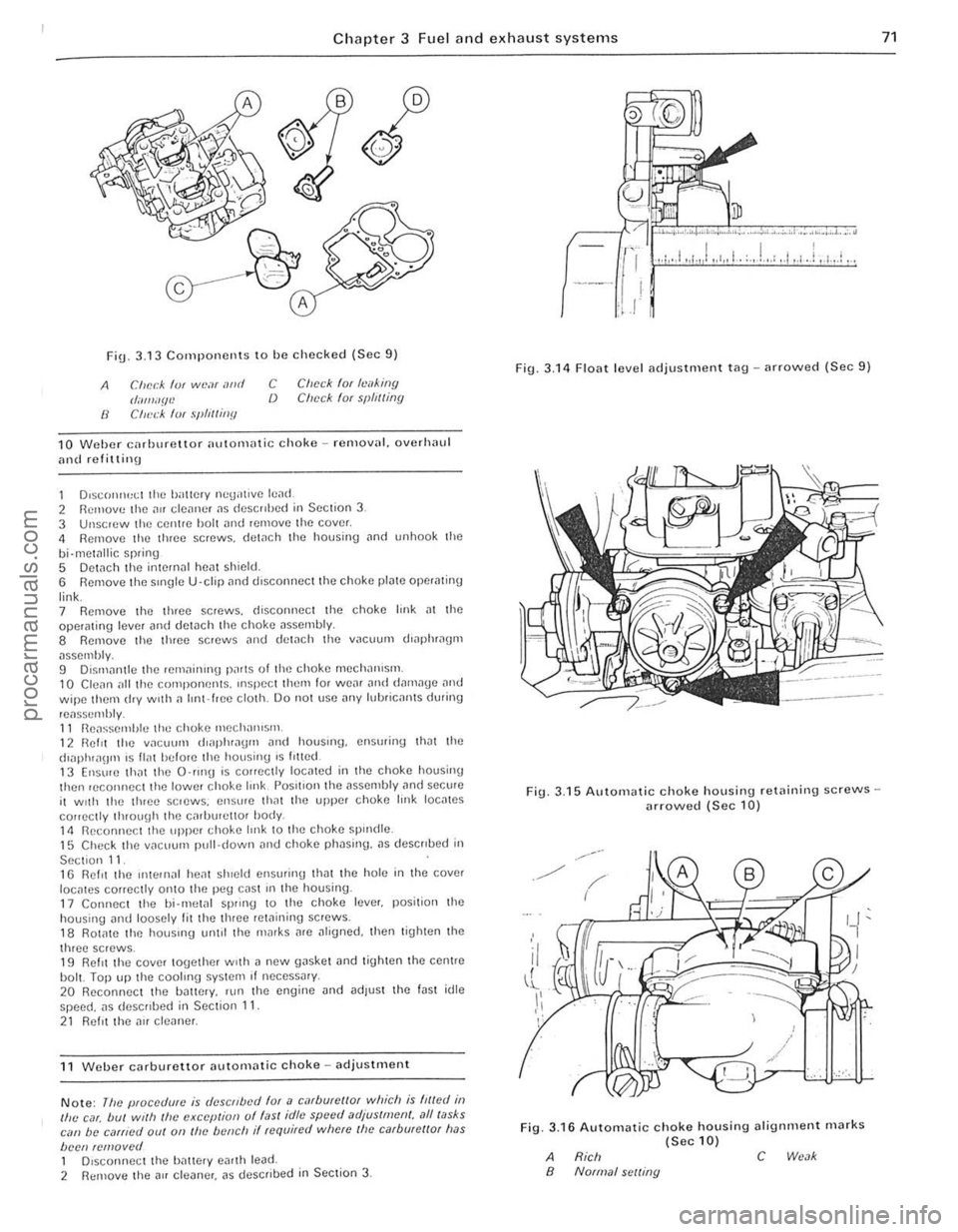

liS seatmu Note ,1nd reco.d the number of lurns, so th,11 the screws can be relltted 10 their orjuin~' settings . Unscrew cilch screw fully and remove it and its SPfing . 13 Che<:k the lIoat

Fig. 3 .9 Emulsion t u bes (V) (Sec 9)

Fig, 3.11 Removin!J tho IIlIli'Slilll dillphragm cover (Soc 9)

Refum sWing 8 Cover

the upper body. 18 Adjuslthe flo." level settings, fi,slly w;l h the upper body verlical .md I he needle villve s hut off lithe meilsurerneot is outsIde Ihe IInlllS given in the SpecifiC

Fig. 3.10 Relllovingllie IIccelcrillor pump cover -(lrrowcd (Sec 9)

..

Fig. 3.12 Accelerator pump components (Sec 9)

A B Covcr Diapl/mom c RC/(lfll swing

procarmanuals.com

Page 72 of 205

) Chapter 3 Fuel and exhaust systems

FiU _ 3.13 Components to he checked (Sec 9)

A

8

C/u':(:A fur wP.olf alJd (/illlli'f/I.l Clwck '(If .~/I"lIitJfJ

C CI)(xk for hd,ill{J {) Check (Of spfrlling

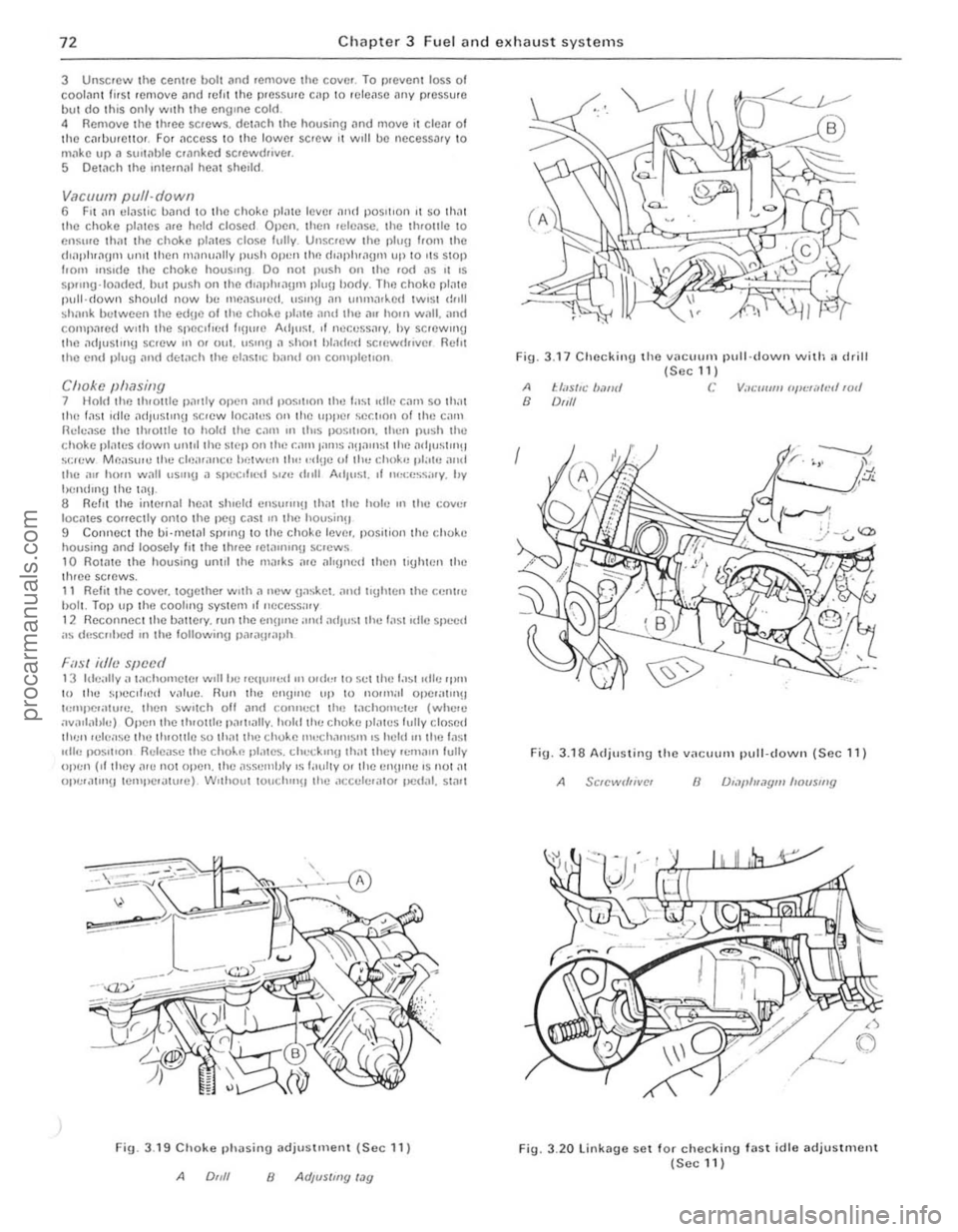

10 Weller cnrhurettor ""tom,lIie choke - rcmov,]L overhaul

and refitlinu

1 DlsconlH!~1 Ihe i)illicry nC\j

le"sselllhly. 11 Ik"ssemhle the choke meCh'1I11SI11. 12 Relit ll1e v"CUUIll til"phl1'lI)lIl alld hOUSII1,). enslllinu th"t lhe (hilphl,l()fIl IS lIolt before lile housing IS fllted. 13 Ensure thm the O-IIllg is correctly locmed in the choke housinU then reCOllnect the lower choke I",k Position the assembly and secure il WIth the thr ee sClews . ensure thnt the upper choke link loc"tes

cOlrectly tluouUh the c"rlJlJretlOf body 111 RecOllllec t the upper choke Imk to the choke Sp"l(tie. 15 Check the V"CUUIll pull· down

Note: lile pfOccc/

.l.I. .... , •• ,. ••. • .. .• . ,,~ ......... , •• , •• .;..,.: .•• ' •.•••• 1 . ;."

.,.', .,1,,/. 1,,' .. 1 . .. . , 1.,.: .. 1,.1.1,.1 .•. : ...

J

Fig. 3.1 4 F loat level adjustment t

.------

./ /' (

Fig.

/

3 .16 Automatic c hoke h ousing alignment (Sec 10)

A Rich c B Normal scl/lllg

marks

71

procarmanuals.com

Page 73 of 205

72 Chapter 3 Fuel and exhaust systems

3 Unsc.cw the cenlle bolt and .emovc the cove •. T o p

locmes COrfeclly 01110 Ihe t :le\] C

Filsl idlv speL'd 1 3 hlc;IlIy" tachomcte. wlIII,c .eq,,"ed !lllmlc. 10 sellhu t,'~1111l1! 'P'" 10 lhe ~peclllncl v.1Iuc . nUll lhc CnnUlc lip to no.,,,al opc.at"I!1 t,:'Upe."lu,e. then ~wO\ch oil ;Jml COllllect Ihn tachomete. (whe.e .wn"a"h,) OpCl1t he Iluollie pal\lally. hnhllhc chokc pl.1\(.)5 lully closed tI'"" 'ele,lse tht.! th,ollie $0 Ih.111he cho~e 1""ch.1111$I11 IS held 'n the fast "II" fK151\10" Relc"$c the cho~1"l pl.ltCS . d" . .:ckllll! lh;lllhcy .cmaln lully olwn (II they ".c not open. Ihe ,lsse rnlJly IS I"ully 01 Ihe cnU"lc ' S 1101 al 01Ie .,11111IJ len'I/C,,'lurc) Wlthoul louchl"H the ;lc c"le."to. ved"I. Sliltl

, ,

~A

Fig. 3.1 9 Choke phasing adjuSlme'lI (Sec 11)

A 0,,/1 8 AUjus/my'"y

Fig. 3 .17 Checking the Vllc .. "m pull·down with l' drill {Scc 111

A t:lils/lc Im",' C V;//:1I11111 ('I'~'f,~lmllull B DIJII

Fig. 3.18 AdjtlslinU the vacullm pull- down (Sec 11)

A 8

Fig. 3 .20 linkage SCI fo r checking fast idle adjustment (Secl1)

procarmanuals.com

Page 75 of 205

74 Chapter 3 Fuel and exhaust systems

, ;

1)'>

,

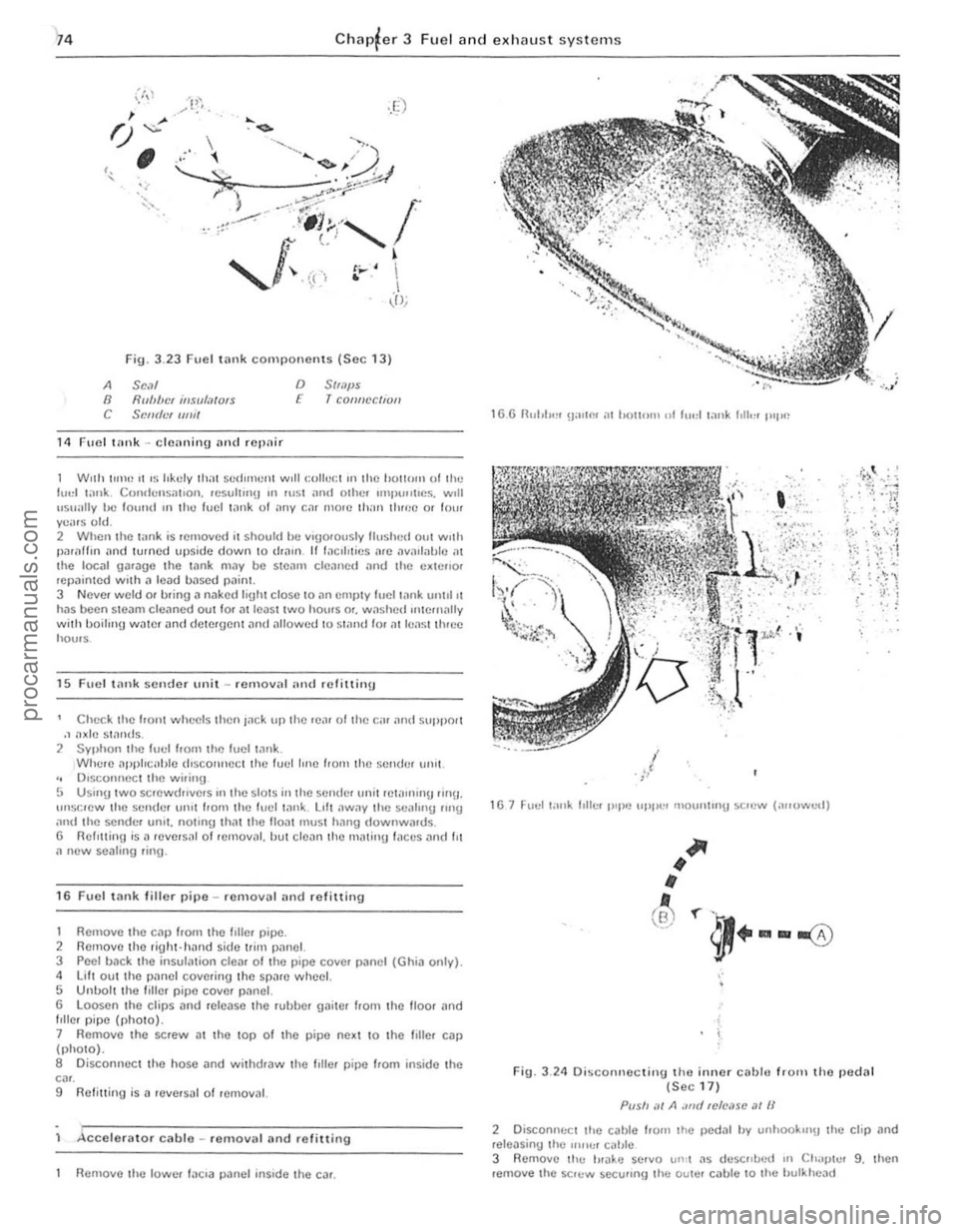

Fig. 3 .23 F el '

A

" C

Se.ll Ruhbcl ill,W/,lIQI S SI!IIIJ..'f lIoil

14 Fuel lank -cronning DrHI rcpl1ir

D SImps E , COllflcetiu"

W,lh IlI1m 11 I~ likely Ihal scd'lllcnl .... .11 COIiC(;1 1f1 the IJOIiUlIl u l the ruel wnk. Con

Check Ihe h01l1 whL'{)ls Ihen J;lc k ufllhe le;lr of Ihe 17;11 ;'Ind supporl ,1 ilxle sr,llids . 2 SYI/hon Ihe fllel hom Ih e tllcllim k. Wherc ;lpphcilhle d,scol,,'ecl Ihe fuel line hOIll the scnder unll.

" Discormoci Ihe wiring 5 USlllljlWO SC!(lw(i!lvers III Ihe 51015 inlhe sendcr unit ,e lirmlng 1111\1. unsr;'ew Ih o sender (mil loom Ihe tucllilnk Lilt ilW;lY Ihe scaling ling iln d Ihe sender unit. nO llng Ihill Ihe 110.11 must hilng downw;'IrrJs. G Re fill ing is a rever snl of .e moval . bUI clea n lile milling !;lces ;'Inel I II ;'I new sealing ring .

1 6

Fuel lank filler pipe -removal "nel refitting

I Remove the cap horn Ihe hiler pipe. 2 Re movo Ihe .ighl·twnd siele lIim p;'lllei. 3 Peel back Ih e in sul alion clear 0 1 Ih e pipe (:Over fliln cl (Ghia only). 4 Lift outlhe pimel coverinU Ihe spore wheel. 5 Unbolt Ihe IllIer pipe covor panel. 6 Lo osen th e clips and releilse Ihe rubl>C1 oail er from Ih e floor and f,llel pipo (phOIO) 7 Remove Ihe screw al Ihe lO P of Ih e pipo nexl 10 Iho filter cap (photo). 8 Disconnect the hoso and withdra w the I.ller pipe I rom in si de Ih e

car.

o Relill ing

is a rever sal 01 romov;lI,

A

cceleralor cabl o - removal and relining

Removo Ihe

lowe. lac.a panel inSide Ihe ca'.

166 Rull"'" !F"1I1';'I1 "otlom " I I"". la llk flU", l"llll

(

. ,'l

--.

. ~

1(; 7 Fuel lank flUc. Pll~ UppCI 1II0UIIIIII\I SClew (.lIwwL't I)

"

, I;'.' . :~, \;.;

: : i;. "j -' , ,' .... :r: , :'y~ it. ; '., :

Fig. 3.24 Disconnecling Ihe innor cabla from the pedal (Sec17)

Pusll M 11 ,mrl rcfc,uc ill IJ

2 Disconn(:cI Ihe cahle 1<0111 Ihe I)OOal hy unhookoug Ihe clip and rcleasing Ihe ""II:! cal,le 3 Rem oye Ihe IHal:.e servo un:1 a~ dcscfLb c(1 11 Ch;lll lcr 9. Ihen remove the SClew securrn~J Ih(: Oulcr cable to Ihe iJulkhc;'ld

-

procarmanuals.com

Page 76 of 205

![FORD CAPRI 1974 Owners Manual )

Chapter 3 Fuel and exhaust systems 75

;\1.325 Prisillll oul tho re l<lin in\] clip (A) when removing IIIH acceluralOr callie (n) (Sec 1 7 )

~ fl""",V<: Ilw au eli!.",u. ;IS d .. ,~r."'J( FORD CAPRI 1974 Owners Manual )

Chapter 3 Fuel and exhaust systems 75

;\1.325 Prisillll oul tho re l<lin in\] clip (A) when removing IIIH acceluralOr callie (n) (Sec 1 7 )

~ fl""",V<: Ilw au eli!.",u. ;IS d .. ,~r."'J(](/img/11/56932/w960_56932-75.png)

)

Chapter 3 Fuel and exhaust systems 75

;\1.325 Prisillll oul tho re l

cOlll,,,1 IIIIK"!I" G I'll'." Ih" ",,,,,,1 '''','UHrI!l <:lIp hom the IlIi,,;k"l 7 U~"'!I a ~,:",wd"v"r. d"I"CSS tile pl

'o le: If /I" ., IU:(/"I ",!ly ,.~ to "(~ /f.'/!/oVI:1I /("1,:, (0 1""""1';'1"" 12 [)I~.,:,,,,,,,'cl (h" 1",lle,y lea(ls ? r",," liNd" t lw C,II lemove Ihe 1;)(;';1 It""", 1';,,,,,1 II I, '''WII\l:d hy ,,<'I(:W~ (IlHO) OIII""e S{;WWS (LHD) "IIIII!I Ihe ''',II "dUI! ami C;1Il tJ" IUH:lopp"d l,ulll lhe hont l~d\)c 3 n"lllove th" ,u;cole'''lot cilhlc hom Ihe p"dal sha h olS ((e~""h"d III

Secll"" 113

RI-IO variilnls 4 DI~(u"ncct Ihe IHake ope',IiIl1\J IOd ill Ihe b'ake ped;rl. thcn 'enluve tio" I"aslcr cylinder ,lilt! sc,vo lllHI nell" to Ch,lpl!!' 9 101 lUll lol'l

'nl')lll1alI1111

5 WO,kllll) I I"OIl\)h (he ,e,l' bulkhead III the C "IJ"'C vo"'p,"t""!1I1. pull Ollt lire sh;rft "nd S"CUI1I1() chp () Rotate Ihe I1\)ht·h,,,,d Shil l I IIIO'"ltlll\) bush Ih,ou\)h 45' ,n e'lhe' d1lCC1l011 ;)nd pull II Out 7 DetaCh Ihe

AI/models 11 Oetach II", 'em;lIl\ll\Y bush ;rm] clIp hOIll lire shalt. ) To re11l0V" the pedill, pl1se the f!;ln\Je ilway Irom the SPIYO( on lire snail. lhell ,emove the p"dal and sp"ng 13 WI,en ,eflll"'!! tire pedal. locilte the sp''''U on Ihe SPIUOI shall, lilr,, clop th" 11""\)"$ 01110 Ihe SP'\JOIS ilnt! check lhilt Ihe pcd;)1 I"vots

cO"lIetl),

Fig. 3.26 Accele ra to r cable rc moval 1001 (Sec 1 7 )

A _ 250",,,,(10,,,)

() ~ Cell(fe IlUlidl /11 /J!Uv;d" ',1,SL'd -'''ullld ... ,

14 ncllll"'() the pud.ll shilft ,s Ihe ,eve,su 01 Ihc lelllov,,1 IHocerhllC, lolinwlllU whIch It w ,lI he 'H!CUssa,y to ;ullllS I It,,) cailic. "5 d"scllt)IJ d 11 Si,(.t'OIl 16 OIL Rill) v;",allts. dlcck lh;ot the I)(:d;oll"'$ 6 tn 14 ",m (02" 1{) 0 55 'Il) I,ft 110'" the nflu posit 'on If IIo,,"ss.u y ild)"st Ih!! pedal

Iofl up ~!Op !O ach'"ve I h,s

19 1"lc t Ill[l"il o ld -rClllov;l1 ilnd rcfitting

1 DIsconnect (he biltlc,y ne(),1Ilve IUild. 2 D'illli Ihe coolm\) syslem (Chapter 2). ,emovc Ihe d'StllIJU1{)I (Chapl", 4), and remove the C.llilll'et!O' (SectIon 8) ] DI~<:OIlI,,:ct til!! rl!m,IIIiUlI) hoses ;rlld Willi'\) <1 UllSV,P.W the 'nlet m;r,ulold holl~ p'ouress,vd), III II", ",v,,'~r: oldl)I 10 that lflvell II, 1"1) 327 5 LIft 11'1) II,let Ill;H"lold frum tlH! o:yhlHit;, hr:;lds ;",(1 II''''

\)IVCll '" the Spec,fr~.lt'ons 10 The '''lllillll'''\) proced",e IS" 'eve,s,,1 01 ,elHoval rlefrlllhc cool",'J s)'stem WIth Icfe'cnce 10 CI"lpte, 2

Fig. 3.27 Inlet III,mifold bolt tightening sequcnce fo r 3.0 litre engines (Sec 19)

procarmanuals.com