engine FORD CAPRI 1974 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 65 of 205

64 Chapter 2 Cooting system

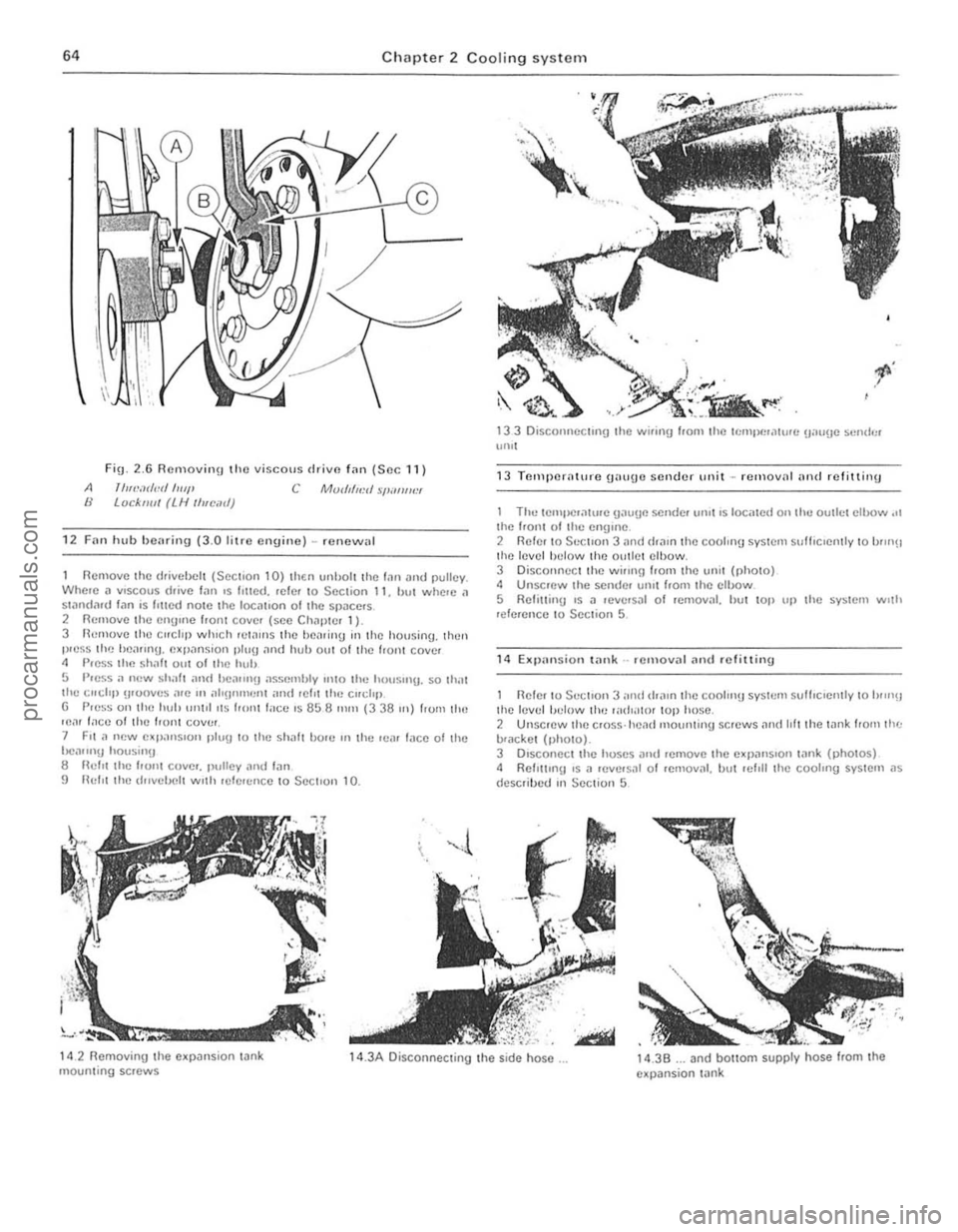

FiO_ 2.6 Rernovino tho viscous drivn '"n (Sec'1)

A 8 ,,,,,',1/1..·(/ ""f' lock/WI (LH /lorr.;,,') c Mudd"," SIIIIJ!III.'/

1 2 F"n hub bC1lr illg (3.0 litre engine) _ renew .. ,t

Remove

th e drivel>el t (Section 10) then unholt th e 1,111 and pulley. Where il v,scous drive 1,111 ,s j,ued. reler t o Sect ion 1 1. but where ,1 st .. m d;ud Ian is I.Uo

7 F,t;r new a~lr.'I1S'OIl "Iug 10 Ih e 5h

"', '

-.'. c

'

13 3 Disconncchng the wiring hom the l(,rllp .. ",lh "C " .. "tic sellt!.:: . WI't

13 TClllporll\"ro !.F'lIgo sonder ullit -rCr1lov(l1 (lnd refilting

Th ... ICIU IIC'J\U'C UauUc scndc. UII '\'S IOCillcd all the ou\le elbow ,II the f,ont 01 t he cnglllC. 2 H(llc r 10 S "C 110n 3 .. nd d';lllllhc coolm9 system s"H 'Clcrllly 10 bWl!! I he level hclow the auilel elbow 3 Disconnect the w irmS) from the unit (photo)

14 EHpimsion liHlk·· .ernOllill .. nd Icfiu ing

Rohlf \0 Sec tIon 3 "nd d'i"" the coolm!1 system suH,c'Cll1ly 10 hun\] the IOllel billow lhu ""honor la p hose. 2 Unscrew the cross ·hcnd rI10urliing screws ,lfl(t 1I1I the lank from t ht: lIIi1cket (photo).

3 D,sconeet the hoses .. m d remove the e~p;ms'on wnk (photos) 4 RellwnU IS iI reyer s,,' 01 re moy"l. but rel,n th e coohng system as oescr ibeu 'n Section 5

142 Removing th e e~pansion ta nk mounting soews 14.3A Disconnecting the side hose ... 14.36 ... and bottom suppl y hose flom lhe

c~pansion t"nk

procarmanuals.com

Page 68 of 205

)

Chapter 3 Fuel and exhaust systems 67

Torque wrenc h setting s Fuel P\JlllP Inlet n'

G ene ra l SyS1c'" Iype Idl e sp ce d CO "o,

) Chapter 3 Fuel and exhaust systems

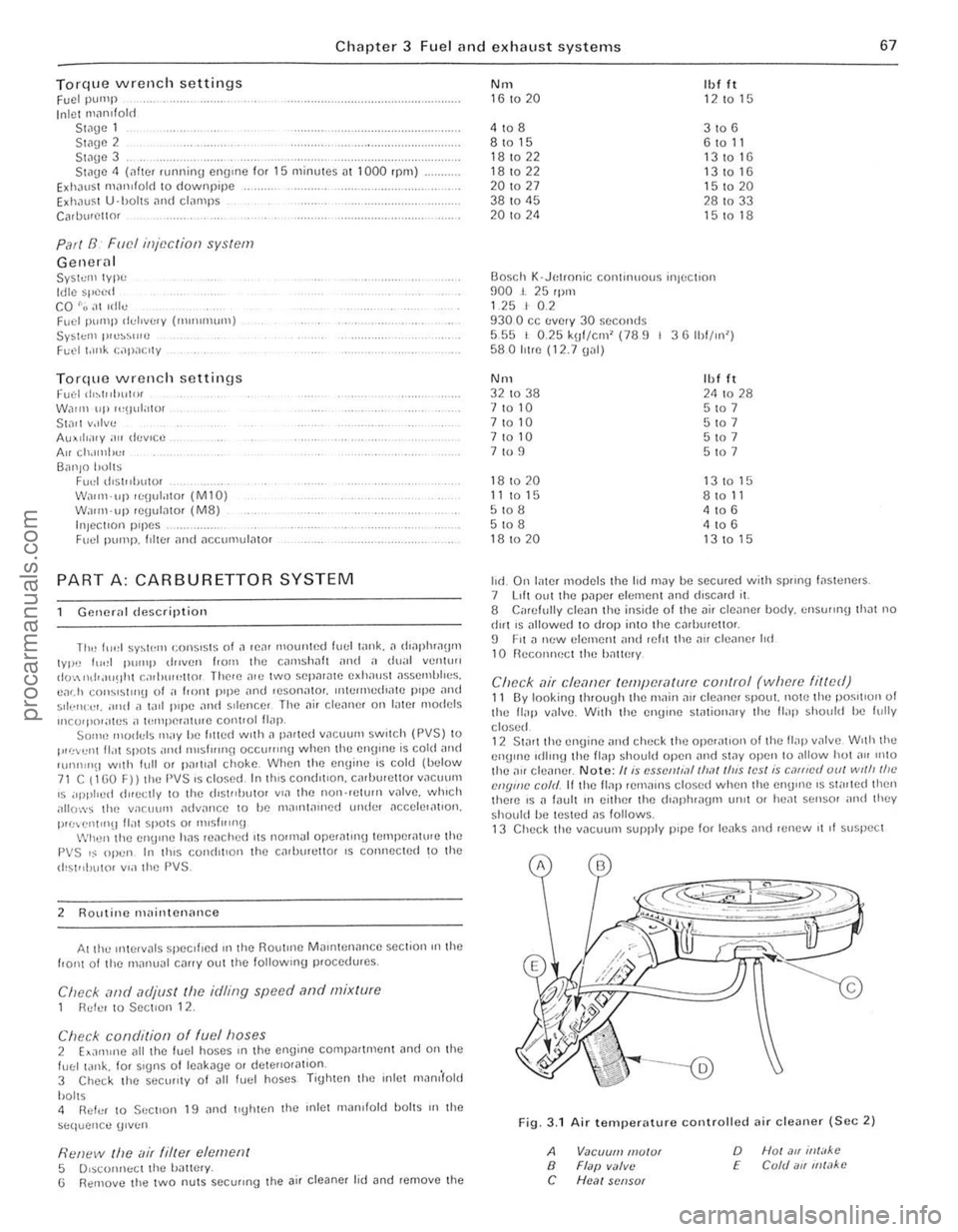

FiU _ 3.13 Components to he checked (Sec 9)

A

8

C/u':(:A fur wP.olf alJd (/illlli'f/I.l Clwck '(If .~/I"lIitJfJ

C CI)(xk for hd,ill{J {) Check (Of spfrlling

10 Weller cnrhurettor ""tom,lIie choke - rcmov,]L overhaul

and refitlinu

1 DlsconlH!~1 Ihe i)illicry nC\j

le"sselllhly. 11 Ik"ssemhle the choke meCh'1I11SI11. 12 Relit ll1e v"CUUIll til"phl1'lI)lIl alld hOUSII1,). enslllinu th"t lhe (hilphl,l()fIl IS lIolt before lile housing IS fllted. 13 Ensure thm the O-IIllg is correctly locmed in the choke housinU then reCOllnect the lower choke I",k Position the assembly and secure il WIth the thr ee sClews . ensure thnt the upper choke link loc"tes

cOlrectly tluouUh the c"rlJlJretlOf body 111 RecOllllec t the upper choke Imk to the choke Sp"l(tie. 15 Check the V"CUUIll pull· down

Note: lile pfOccc/

.l.I. .... , •• ,. ••. • .. .• . ,,~ ......... , •• , •• .;..,.: .•• ' •.•••• 1 . ;."

.,.', .,1,,/. 1,,' .. 1 . .. . , 1.,.: .. 1,.1.1,.1 .•. : ...

J

Fig. 3.1 4 F loat level adjustment t

.------

./ /' (

Fig.

/

3 .16 Automatic c hoke h ousing alignment (Sec 10)

A Rich c B Normal scl/lllg

marks

71

procarmanuals.com

Page 74 of 205

Chapter 3 Fuel and exhaust systems 73

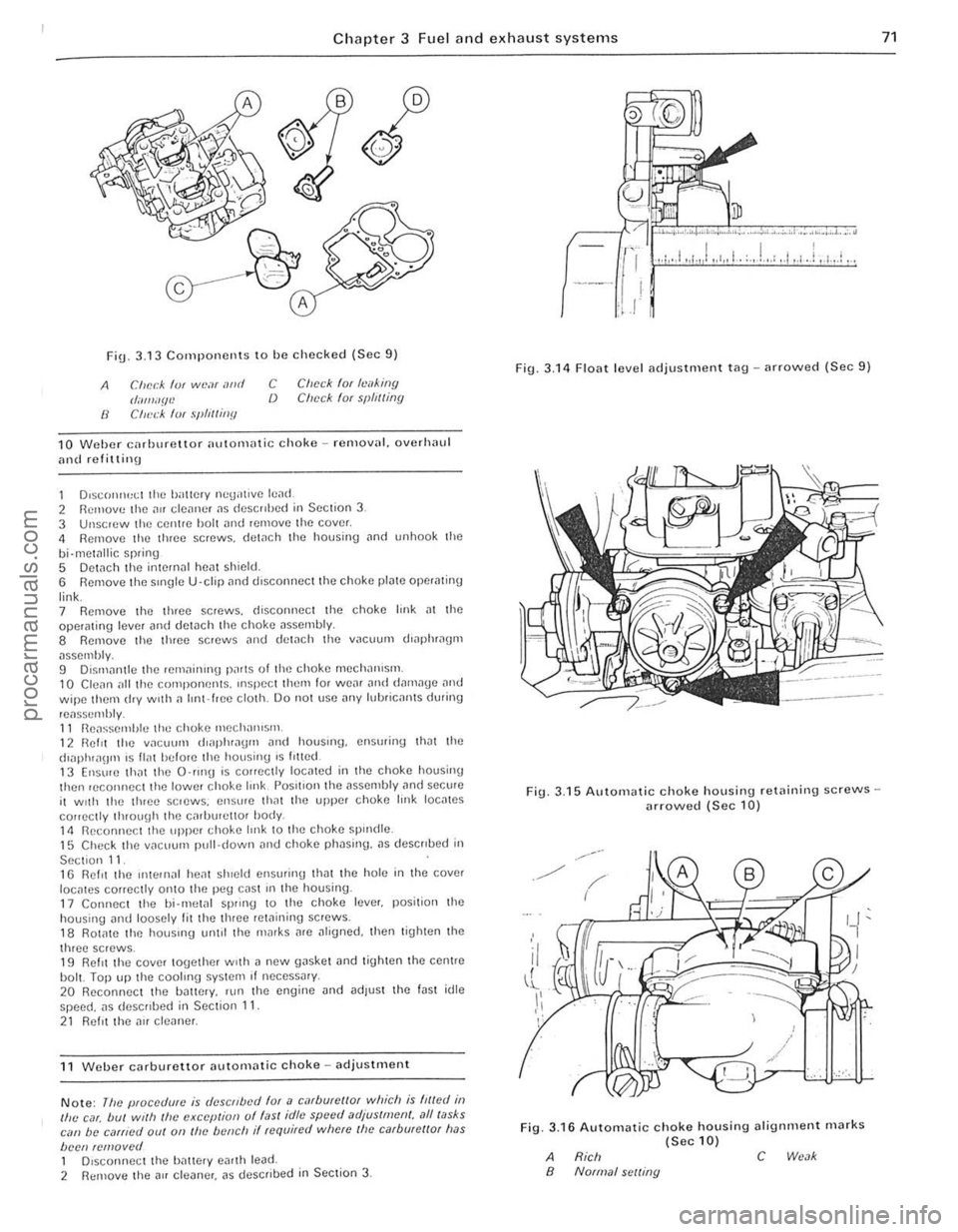

Fig 3.21 Adjusting the fast idle speed (Sec 11)

A Clloke f(llly Olwn ()

the 1:1l!)1I1" alld ;HI)"~;1 lhe lasl ,die s<:rew as llecess;uy 10 ohlain lhe COlleCI la~l I(llf~ 'Ilill 11 Finally felll lhe ,\(I cif,.1ne,.

1 2 Weber carburettor ~ id lilllJ ndjustment

N ote: III view of lfoe illcfem;illg ,1WmeIJeSS ollile d,lI/flefS of exh.lflsl pol/ulioll olml Ihe vefY low levels of cmbol! //Ionuxirle (CO) emission fOI which Ihis e,,,burel/o, is dcsiW!N/. IIIe: slow fUnlling mix/ute: se:l/ill9 ,wd tin' b,lsie idle svlling all WCbt'f e,ltborcl/OfS shoufllllu/lw "djus/cd Wililoll! OW (ISO of a {!fop!"!, CO flfv/ef (c·Xll,lOS! fI"s iflf'lfyser). Bdum CUfluHencillY work ,1150 f(;o1(/ /he flO/t' .11 til<: IW9innilly of Sl'CltOn 9 1 Walm LIp lh(l (ll1gU)(l 10 ilS nounal operalinu If:l1lpCrailH(l 2 COlIIlCCl .1 CO nleler ilnd " lolchol1l(llel. ,I lhe Iilller ,s nOl aire

IUSlrnent of lho mixture (CO levol) w,lIb(l requll(ld. It howevel the CO levcl is lound to be II1COHCCt thc 10110willII p locedwe should be ,ulnp!Cd 7 Rcmove lhe plast,c C

corr(lCl readings me ohwined. 9 Whe,e applicable f it new plas tic cnps 10 the mixture sc,ews. Remove th(l taChOmeler .1nd CO meter.

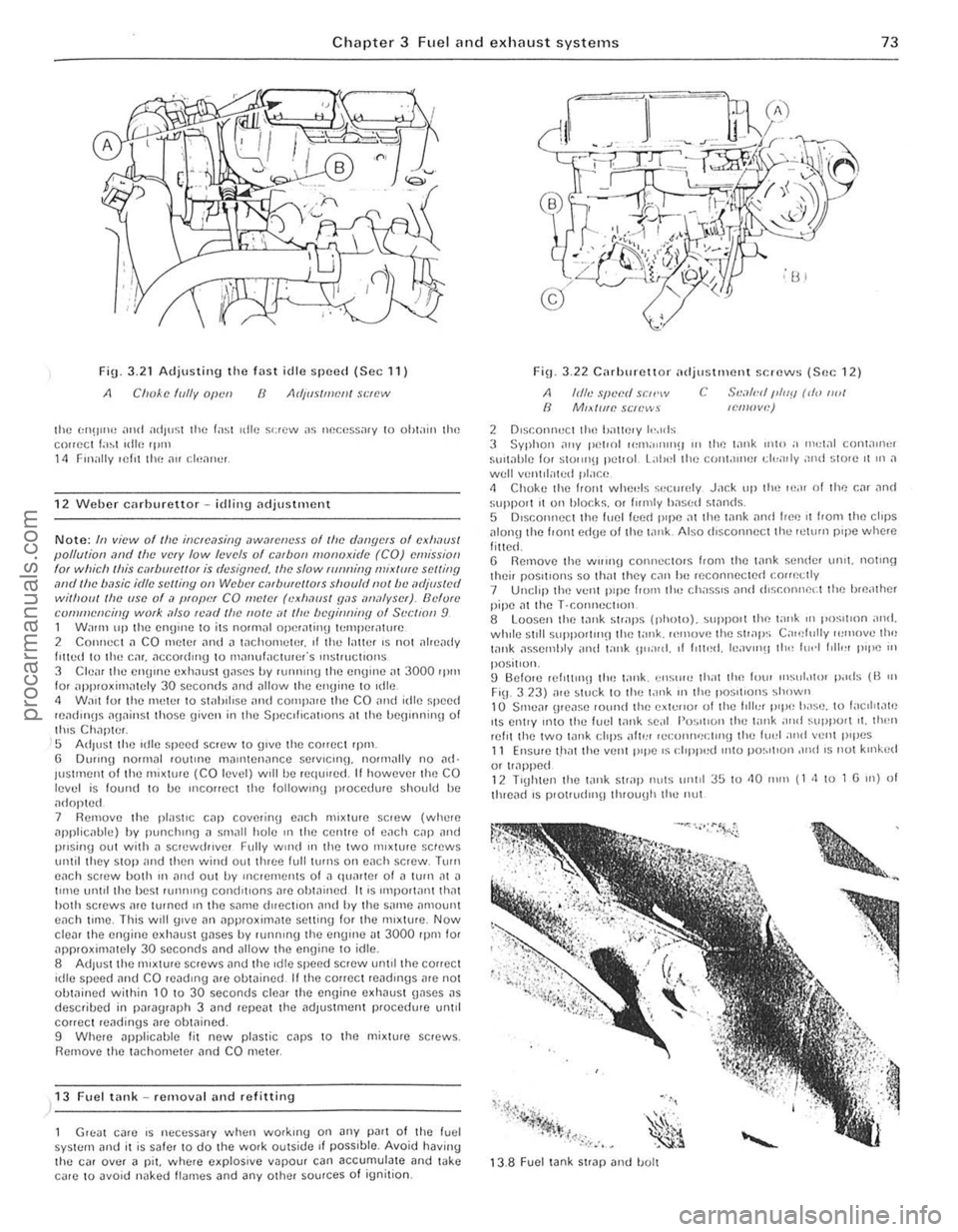

)13 Fuel tilnk ~ removill .lIld re fittin g

Gn;at c

2 O,sr.onnuct tho !Jallf)ry I,·"ds

c S,.',l/,·" /J/IIY rd,) ,wI lemow.')

3 Syphon o1"y petlOl Ii,,,,a"u!)!) III Ihl"! t,lnk min a 1",,1<11 conwu'"r sUlt

~.* ..... ·0 ~'.~',":L: :~ .. ~" :".~ r~r· .. '.~ . . ' . -

.... ', . ~ , . .

iil~);-< .~:a

1 3 .8 F uel tank StrllP lInd 1!OIt

procarmanuals.com

Page 76 of 205

![FORD CAPRI 1974 Service Manual )

Chapter 3 Fuel and exhaust systems 75

;\1.325 Prisillll oul tho re l<lin in\] clip (A) when removing IIIH acceluralOr callie (n) (Sec 1 7 )

~ fl""",V<: Ilw au eli!.",u. ;IS d .. ,~r."'J( FORD CAPRI 1974 Service Manual )

Chapter 3 Fuel and exhaust systems 75

;\1.325 Prisillll oul tho re l<lin in\] clip (A) when removing IIIH acceluralOr callie (n) (Sec 1 7 )

~ fl""",V<: Ilw au eli!.",u. ;IS d .. ,~r."'J(](/img/11/56932/w960_56932-75.png)

)

Chapter 3 Fuel and exhaust systems 75

;\1.325 Prisillll oul tho re l

cOlll,,,1 IIIIK"!I" G I'll'." Ih" ",,,,,,1 '''','UHrI!l <:lIp hom the IlIi,,;k"l 7 U~"'!I a ~,:",wd"v"r. d"I"CSS tile pl

'o le: If /I" ., IU:(/"I ",!ly ,.~ to "(~ /f.'/!/oVI:1I /("1,:, (0 1""""1';'1"" 12 [)I~.,:,,,,,,,'cl (h" 1",lle,y lea(ls ? r",," liNd" t lw C,II lemove Ihe 1;)(;';1 It""", 1';,,,,,1 II I, '''WII\l:d hy ,,<'I(:W~ (IlHO) OIII""e S{;WWS (LHD) "IIIII!I Ihe ''',II "dUI! ami C;1Il tJ" IUH:lopp"d l,ulll lhe hont l~d\)c 3 n"lllove th" ,u;cole'''lot cilhlc hom Ihe p"dal sha h olS ((e~""h"d III

Secll"" 113

RI-IO variilnls 4 DI~(u"ncct Ihe IHake ope',IiIl1\J IOd ill Ihe b'ake ped;rl. thcn 'enluve tio" I"aslcr cylinder ,lilt! sc,vo lllHI nell" to Ch,lpl!!' 9 101 lUll lol'l

'nl')lll1alI1111

5 WO,kllll) I I"OIl\)h (he ,e,l' bulkhead III the C "IJ"'C vo"'p,"t""!1I1. pull Ollt lire sh;rft "nd S"CUI1I1() chp () Rotate Ihe I1\)ht·h,,,,d Shil l I IIIO'"ltlll\) bush Ih,ou\)h 45' ,n e'lhe' d1lCC1l011 ;)nd pull II Out 7 DetaCh Ihe

AI/models 11 Oetach II", 'em;lIl\ll\Y bush ;rm] clIp hOIll lire shalt. ) To re11l0V" the pedill, pl1se the f!;ln\Je ilway Irom the SPIYO( on lire snail. lhell ,emove the p"dal and sp"ng 13 WI,en ,eflll"'!! tire pedal. locilte the sp''''U on Ihe SPIUOI shall, lilr,, clop th" 11""\)"$ 01110 Ihe SP'\JOIS ilnt! check lhilt Ihe pcd;)1 I"vots

cO"lIetl),

Fig. 3.26 Accele ra to r cable rc moval 1001 (Sec 1 7 )

A _ 250",,,,(10,,,)

() ~ Cell(fe IlUlidl /11 /J!Uv;d" ',1,SL'd -'''ullld ... ,

14 ncllll"'() the pud.ll shilft ,s Ihe ,eve,su 01 Ihc lelllov,,1 IHocerhllC, lolinwlllU whIch It w ,lI he 'H!CUssa,y to ;ullllS I It,,) cailic. "5 d"scllt)IJ d 11 Si,(.t'OIl 16 OIL Rill) v;",allts. dlcck lh;ot the I)(:d;oll"'$ 6 tn 14 ",m (02" 1{) 0 55 'Il) I,ft 110'" the nflu posit 'on If IIo,,"ss.u y ild)"st Ih!! pedal

Iofl up ~!Op !O ach'"ve I h,s

19 1"lc t Ill[l"il o ld -rClllov;l1 ilnd rcfitting

1 DIsconnect (he biltlc,y ne(),1Ilve IUild. 2 D'illli Ihe coolm\) syslem (Chapter 2). ,emovc Ihe d'StllIJU1{)I (Chapl", 4), and remove the C.llilll'et!O' (SectIon 8) ] DI~<:OIlI,,:ct til!! rl!m,IIIiUlI) hoses ;rlld Willi'\) <1 UllSV,P.W the 'nlet m;r,ulold holl~ p'ouress,vd), III II", ",v,,'~r: oldl)I 10 that lflvell II, 1"1) 327 5 LIft 11'1) II,let Ill;H"lold frum tlH! o:yhlHit;, hr:;lds ;",(1 II''''

\)IVCll '" the Spec,fr~.lt'ons 10 The '''lllillll'''\) proced",e IS" 'eve,s,,1 01 ,elHoval rlefrlllhc cool",'J s)'stem WIth Icfe'cnce 10 CI"lpte, 2

Fig. 3.27 Inlet III,mifold bolt tightening sequcnce fo r 3.0 litre engines (Sec 19)

procarmanuals.com

Page 78 of 205

-

Chapter 3 Fuel and exhaust systems 77

Fig. 3.29 CUlling the reM o f tho exhaust system to facilitate its removal (Sec 21 )

6 Usu a hadsa w 10 CII I II"Ul'!lh Ihe .e:!. Cxh:!ust p'pe ilhoul 240 mm (94 .n) ItOm Iho! ''';]' ollho I.onl tI:S(HlilIO' (r.O 329) 7 Removtlihe IHII sl:(:IIIIIl!llhe I.:a. sllrm cm hlolt:kel clamp. SWU1!llhc hl"ck,,1 ell,;" ot 1111, sol"nc", :tni! ,,",I ,lcll lit" ",n, e xhausl ~(,CII"n. 8 Ot.lt.1Ch ,1", 11"'110VI) Iho I"a. IIIOUnlll'!IIIIIIlw. :tnd IIIa(.k,,1 clallip 9 Rell1uve Iho hont P'P" LJ r:lallip and dill I oH 1111) Iron I pipe . D"t;tcll Ihe f(:sonn lo' 1I100mlll'!! h.ack", and Ih" wll plpt: 111111. If filled 10 Slilll 1e!11!1Il!j hy SCllhlll\j il nlo"k 115 I'"'' (1 8 III) 1,0m Ih', CIII ends ollhe ,csonnto. 10 Silence. pipe I I POSition Ihc .csonnlOl and ltont II'IX! ilSS(lmhly. loosely SUCIIIC ,110 the hr,'CkC I and man,Iold connCCIoOIi 12 Slide a se.vice sleeve (FlU. 3.30) 01110 Ihe .eson ;IIOf I"I)C. pos,"on,nu lI S end In Ime with Ihe s O lhed ma.k m,llle p.eviously. 13 F'llhe Silence. l)lpe mlO Ihe sleeve up 10 lI S sCli hed ma.k and .ehl Ihe .e:!. StiOIlCt" c l."up ItJo~ly Wilcil hlhll!llhe clamp. ensutc Ihm liS

;IIlUlet! end .s IIpp • .:tlnn~1 111 1\l1!II'lhe I!xhatls l syst"m sn Ih;11 .. I tin 1IOilit IS 'I Ile;u,,' Ih;)l 1 25 "'''' (1 III) 10 "lty i:Oll'pOllelll. o. 1',111 01 Ihe t,,,dywn,k TI!lilteli th\)

• J. ,

.) '. ,

FiU . 3.30 F itting the service sleeve to Ihe eKhausl system -arrowod (Sec 21)

II1n n llol(1 conn(:(:tlon and Ihen screw on Ihe nUlS of Ihe .esonnIO' clnlllflllll111 13 mm (0. 5 m) of Ih.end Pfotrudes Ih,ough Ihe nulS. 15 1'0SIlion Ihe IWO U·dmllps on Iho service steeve and li!Jhlen the n\llS 10 thu IO'IIIHl w.ench sc1ttng Uiven in lite SPCClhC,ltions 1 G [1"" 1 lit,) 1;111 pIpe 111m of "pP'OP".1W thon reconnect Ihe b.ll\e'y. M:ttllhe OllOine and chock 10' 10,lk 5 17 Low,,, the c," 10 Ihe Wound.

PART B, FUEL INJECTION SYSTEM

22 Goneril! description

The 111,,1 "'1"Cllon sySlem fitted 10 Ihe 2 .8 hIre engIne IS o f the COllltlllHlIlS '''IL'Cllon Iype ;tnd sttppltes " p.ecisely conuolled (IUnllllly (II ;I\()lII,":d hll:1 10 "nch c ylt1lde. undo. fill Ollo.nttng condItions.

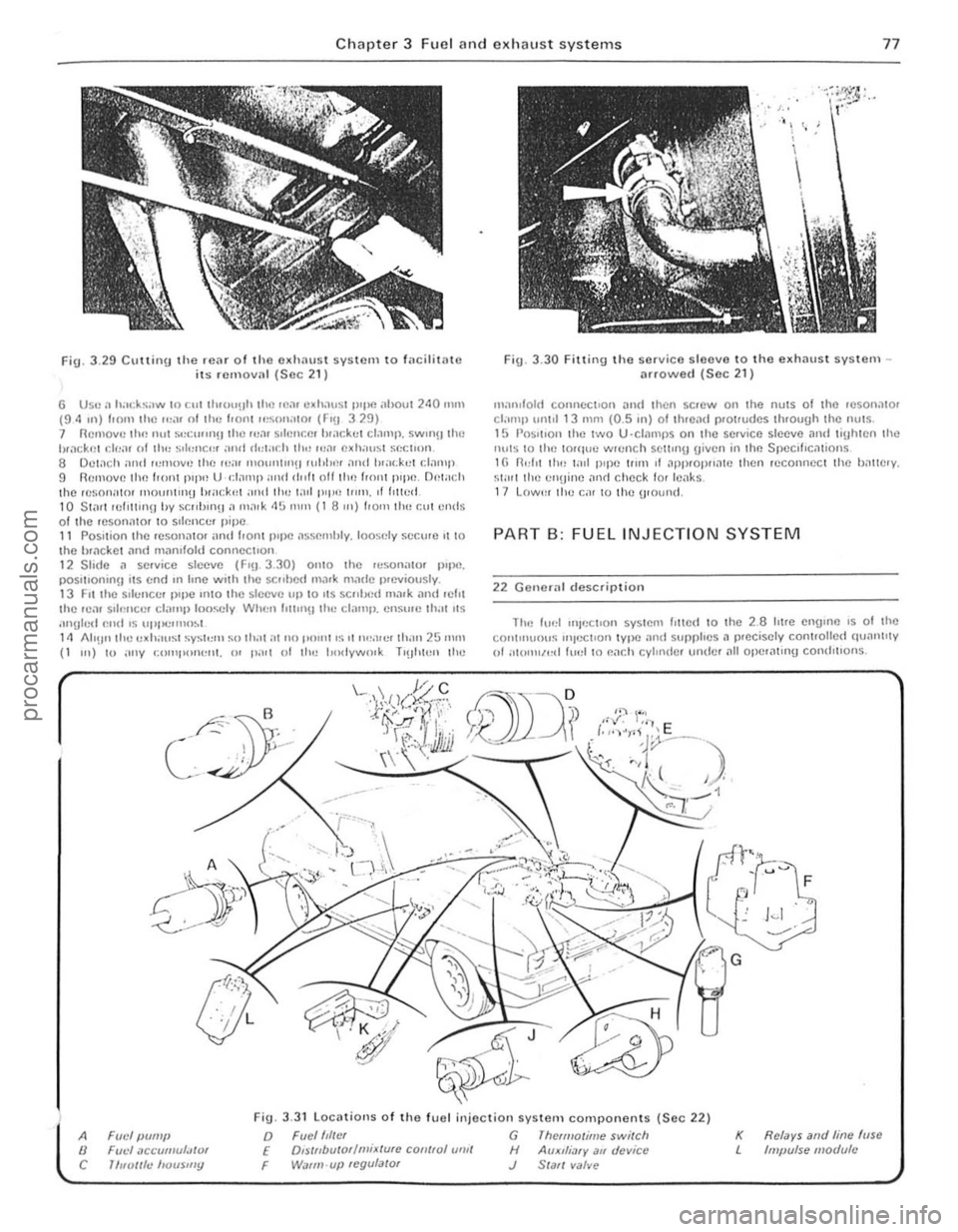

A U C

Fllel plllllJl FII~·1.1C'·''''IUI •• tul '''mUIr) IWlls",!}

Fi g.

D f F

3.31 Locations o f the fuel illjection system compo non IS

Fuel "'WI G rhemlolime switch

(Sec 22)

K

L Relays ilnd line (lise Im,lu'se module OrstllbulQr/mixture cO/wol "",I W,l. m·up leguliltol H Allxrfi,lfV illf device J Stilll valve

procarmanuals.com

Page 80 of 205

)

Chapte r 3 Fu el an d exhau st systems 79

Ii

0) G

\E )

' .. ~ ee)

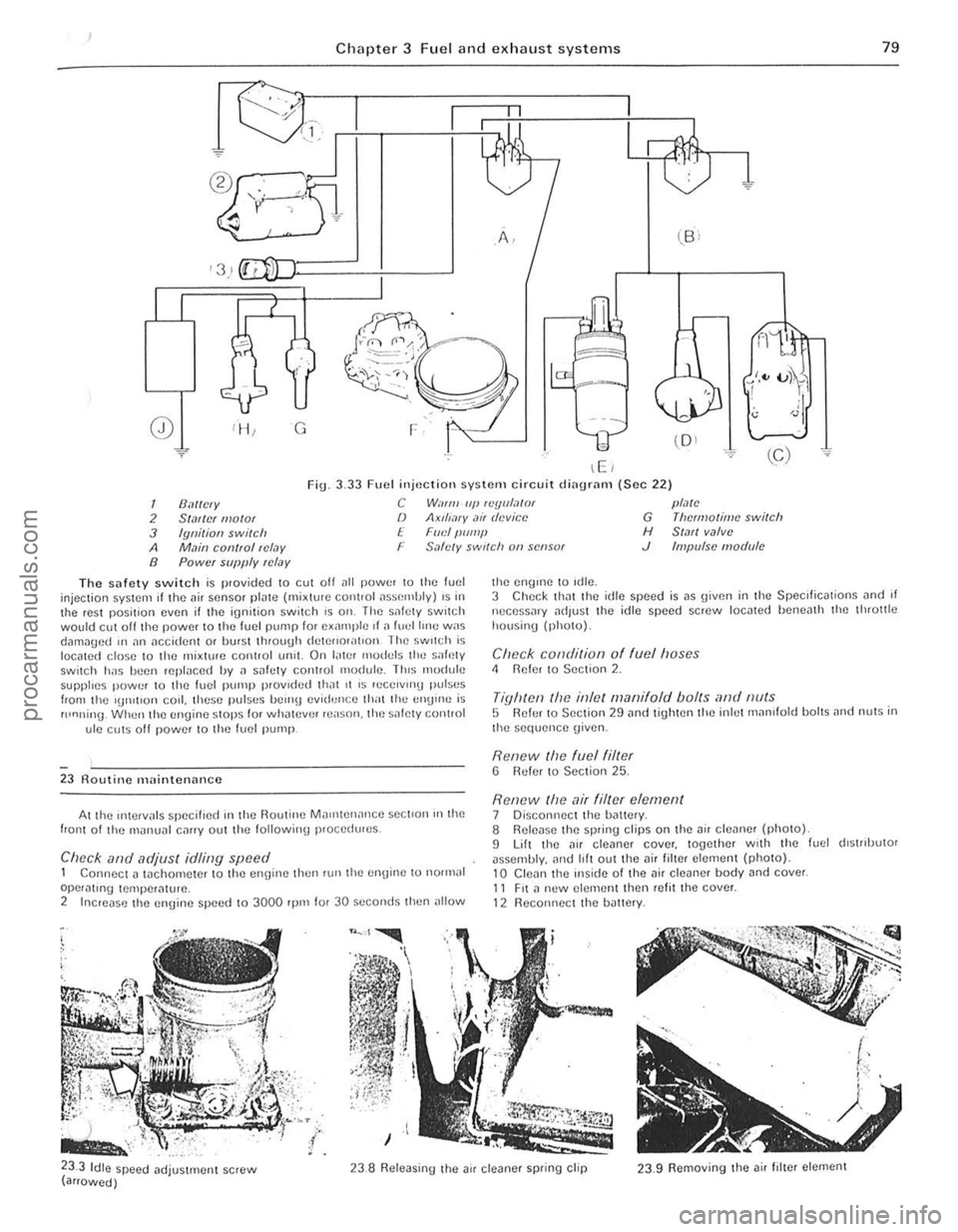

Fig. 3.33 Fuel injuctiOIl system circuit di

2 Sialicr I/Iolor /) Axll/,-"y ,1i, device G Theo1lO/lmc switch

3 fgnitioll switch E FIII;I/Iump H St,lfl valve

A M,lin con(Iol r(;/,)y F S

8 Power supply rcl.1Y

Tho safety switch is provided to cut olf illl power !O the fuel injection sySl(!m if the air sensor plJIC (mixt\HC COlllrol assemhly) IS il the rest position even if the ignition switch IS all. The s[lfcly switch would ell! off the power to the fuel pump for oillllpic ,I il fllOJllmu W

AI the IntelV

,. ,

< '(:,,~ , • . . ;::~t,·· . , ,

.' ) . ;~ ~~;:;: ~iJ" .. ,

n fr.X l

the engllle 10 'die.

3 Check Ihill I he idle speed is lIS given in the Specificmions ilnd il nccnssary "dlust the idle speed screw 10cllted heneillh Ihe Ihrottle housinv {photo).

Check conditiorl o f fuel hoses " Reier to SeClion 2.

Tighte/l the inlel manifold boilS and /luis 5 Refur 10 Section 29 and lighten the inlel rll

Renew the air filter element 7 Disconnect the h

-

I',

I t, ' .

;

!

" , ' .• I

! 1 I'

: 1'1 1 . ,

I

I '

I

procarmanuals.com

Page 81 of 205

80 Chapter 3 ~lIel and exhaust systems

24 Ai r cloanor -removal and re filling

1 Remove Iho elomerll as dllsc"hed III Sect,on 23. 2 Work,nn under Iht! left ·hand honl wheel arch. unboll the illr clenne, hOdy f,om Ih e s,de of the engmo compnl1lllen\. 3 Rohuil1g IS n rove rsal 01 tho lomova l I)rocodule wl lh relelence 10 $(1(;11011 23,

25 Main system compono n ts -rellloval "l1d rofitling

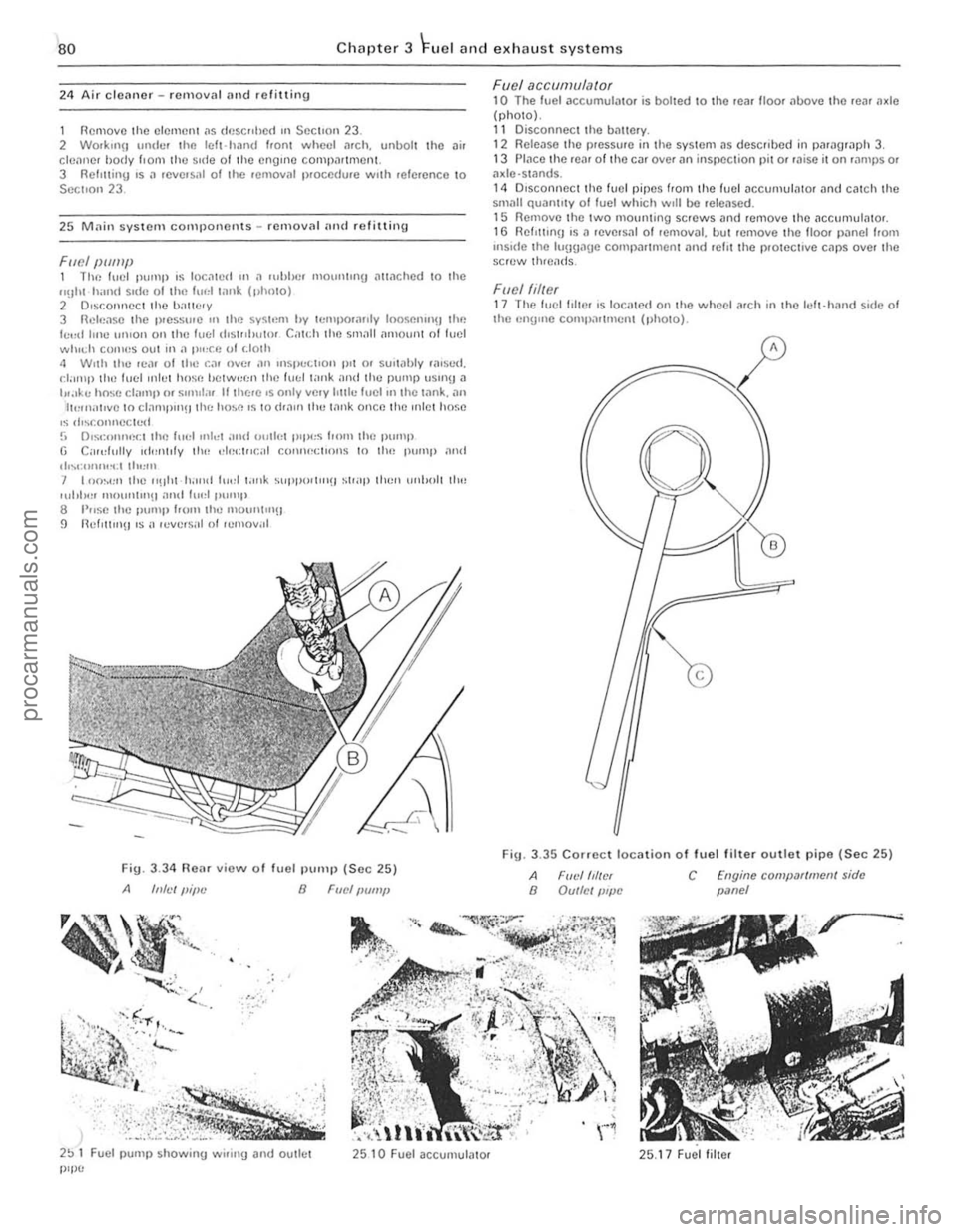

Fllel p /llllP 1 Thn hll)1 pump IS loc.lwd "' " lI,hlw.. 1ll011111111U .lUflchod 10 Ihe "!Ihl h"n{1 51th! 01 lhe 11I/,llal1k (phnIO) ') D,sC:OllllCCI Ihe h

'''~t:un'''~.1 11",," 7 I ,.,,.,~'''' the 1I!l11l hoilid Illd 1'lIlk SUPI)(Jl IIII(f Sl'ilP Illell unh(lll ll,,~ lul,I)". mOlllllll'H ami 111,,1 JlUlll!' 8 !'IISf) the pllmll "("n the "'OIull"'!! !) Ilcfllllll!j 's il IUliers,, 1 01 ,emOVi.1

FiU. 3 .34 R Oilr viow o f

A Ink'1 pi,ll}

fuel,HIIl'I) (Soc 25)

8 Fucl'WIII/'

..

) 2~ 1 Fllel pump showing Wlflflg ond oul'el pipe

~ .. . . ~ ~ ... ,

2510 Fuel accumulatO'

Fuel accumulator 10 The fuel accumulatO I is bolted to the Ical 11001 above Iho lear "Klc (phOIO). 11 Disconnect the bflltCly . 12 Releaso the preSSIJle in the system as descllbed in PfllfltJlilph 3, 13 I'lilCO the leal of th e car ovel ,1n inspection pit o. lilise il on ' ilmps O. fldo·stands. 1 4 D,sconnectlhe fucl pipes I,om the lu el accumul,110r and catch Ihe s

Fi U. 3.35 ConeCI 10Ciliion o f fuel filler oullel pipe (Sec 25)

A B Fuel "'ICf Ou/lelll'lle c Engine comporlmenl side p,wel

procarmanuals.com

Page 83 of 205

,

~ Chilpter 3 Fuel and exhaust systems

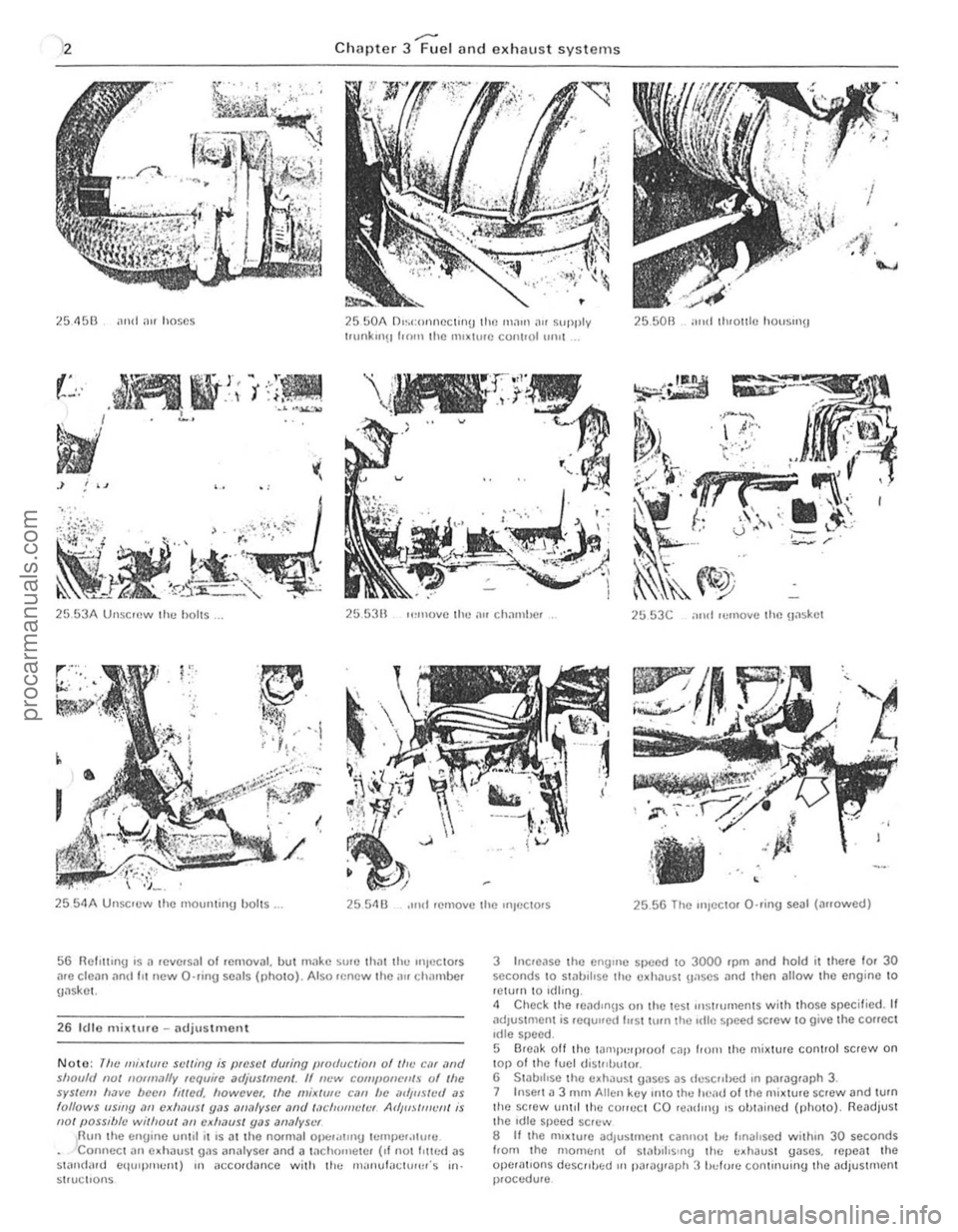

~5 4513 ,111<1 "'f hose s 2550A D",conneclinu the maUl "" supply t.unkul!! 1.011 the 1111~hue cont.ol 111111 25501l mid th'OI1I C houslIlU

"",'

25 53A UnsCII)w the holts. 255311 ,,,"U)IIC the ~'" chal11bcr ~5 53C ;11111 'cmoY(: the Haskct

,

25 5 4A UlIsc'ew the 11101l1lt;IIU bolts. 2554 U ,lIld remove the UIIL'CtOrs 2556 The "'Jecto, Q·rinU seal (a"owed)

56 Rcl,llll.g IS 11 reve rsal 01 rcmoval. hut mtlke SUiO Iha l til.., "l)OC Iors .IIC clea n and III new O'lIng seals (pholo). Also rencw the;IU chamber gtlskel.

26 I( H o mixture -adjustment

Noto: 11!e miJllllfe s"/liIl9 is preset during (!for/actiOIl of II", eM ,'nd shOll1ll 1101 "ofllwll~ require "djIISlment. If I!~'W r:QfIIl'O"Cllf.~ l)f 'he sys({)m ""VI! bccn flllCd. IlOwever. tile mix/IIII! (;,1/1 be mi,l/steil as lollows "Silly /II) cxlwlls/ y,l$

3 Incroase the enyulC speed 10 3000 'pm and hold it the,e 10' 30 seconds to Sl

5 Break oft the lalllpl:q)lOol cap 110111 the mj~ture conlrol screw on lap 01 Ihe fuel uistllbulOi. 6 S tabilise the cxhausl Ua ses as dcscllhc·d ,n paragraph 3. 7 In sert 11 3 r1\I AUcn key onto Ihe heau 01 the mixture SCfew and tum the SCfew urlld the COlfeCI CO re

procarmanuals.com

Page 84 of 205

·s

Chapter 3 Fuel and exhaust sys tems 83

1.6 7 I\dJ"~IIII!J II", n"~h"" ~ t:"'w

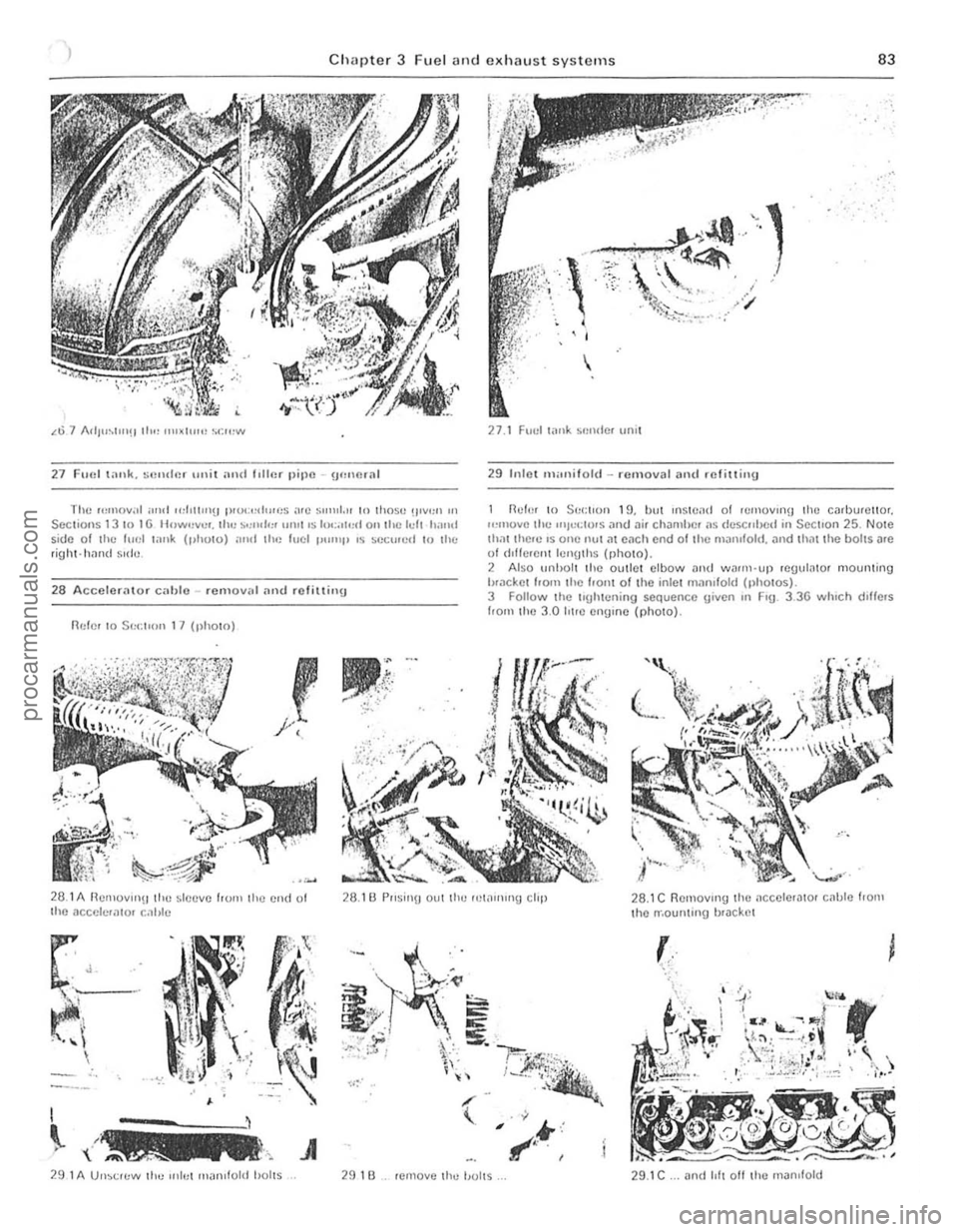

27 F"HII;Hlk. $1)I"ll)r ,Uli( and Idll)r pipr. -Ufm() r(ll

The 1(,11101.',.1 ,11111 "dlu",U pH.II.",hJlf:S ;1Ii! SII"II,II III Ihose !I'V"'I III

Sec lions 13 10 16 Ilow'IV<:f. Ih., ~.:",h:r "nlt.s 1 ... :;.1.,,1 o n ti,e letl h"tHl side 01 lhe "ml tank (phOIO) "lid Ihl) luel I'UIIII' 'S ~l'C"" .. d 10 lh(: righl·h"ml $ 1110 .

28 ACGelerilto r c;thlO -removl.1 "nu relitling

27.1 F tHlll(1l1k ~'!tldef "nil

29 Inlel manifold -rcmoval and re li inU

Ilclm In S')(:tlon 19. bUI Irl sJ(w d 01 ,.,((\01.'11'(1 thc cilllnllc1l0f,

" ,movc Ihe "'I"I:IOIS (Inti iii. chilmhef as dc-sc"hed in SeC t.on 25. N Ole th,,1 the.c IS one nul ill eilch end of Ihe m(ln,Iol(l. ;md 111m the bOltS (lIe of d,ife.enl Icn(jlhs (phow). 2 Also unbolt Ihe oUlle t elbOW and will/n·U)) .e(jul"lo, 1ll0unlin(j hlilckct hOIll I he "onl of the inlet nI(lIl ,lold (phOl0S). 3 Follow the I'ghtening seQuence uiven III Fig. 3.36 w hich d,lIels IrOIll the 3 ,0 hIr e engine (photo)

28.1/ llel110vlll\l the sleeve hom Ihe end 0 1 the (lCceh:r.lI0r c"hle 28,1 B Plisinn O\'! til " 11,1,,11\I0 chp 2a.le Removmg tile ilccclcrmOI cntJle 110111 Ihe IT,oull ting bracko l

---,

I

~ =-~==) ,

~. ,

,

'1,'

29 1 A Un~(.:r1:w the Inh,t m,llulol( l ho lls

J

29 10 (emove tilt) IW!IS

r " ' , , '~;

29, I C ... 1If1(11,/t off the ma(\, Iold

I

procarmanuals.com