tow FORD CAPRI 1974 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 4 of 205

)

Contents

Introductory pages

About th is manual 5

Introduction to the Capri VB 5

General dimensions, weights and capacities 6

Jacking and towing 7

Buying spare P M 'S and vehicle identification numb ers 8

G en eral rep air procedures 9

Tools and workrllU facilIties 10

Safety f irs t! 12

Routine main tenance

Recommended lullricants and flUids

Conv ersion !,I CIOIS

F aull dlilgn osis

Chapter 1

EIlUlne

C[Hlple r 2

Coolin\) system

Ch

Chapter 4

Ignition sys!Cm

Chapter 5

Clutch

Chllptcr 6

Manllill IJCil,hox a nd 'llltonlil!'!.: lrililsn'IS~IOII

Chopler 7

Propeller shalt

Ch(liltcr 8

IlCilr ilxl<:

Chapter 9

l3ulklilU sy~lem

Chapter 10

Suspension ilnd SluCIIIIU

Chapter 1 1

Bodyw or k and trl1il19S

Chapter 12

Electrical s y s!Cm

In de x

13

17

18

19

23

57

66

87

"

102

12 8

132

142

1 [is

171

196

248

procarmanuals.com

Page 8 of 205

![FORD CAPRI 1974 Workshop Manual Jacking and towing

Jilckillg poillls To chan!IC ,I WhUt:1 111 ,11 ,-,"W!ICIICY. usc the t:]ck slIpplled wilh the velIe!!.!. Ensurf! 1hal the Hhldwh,:cl nuIS;OH! ,ciC;lSCd Imlole Ii, cklll\j up thO FORD CAPRI 1974 Workshop Manual Jacking and towing

Jilckillg poillls To chan!IC ,I WhUt:1 111 ,11 ,-,"W!ICIICY. usc the t:]ck slIpplled wilh the velIe!!.!. Ensurf! 1hal the Hhldwh,:cl nuIS;OH! ,ciC;lSCd Imlole Ii, cklll\j up thO](/img/11/56932/w960_56932-7.png)

Jacking and towing

Jilckillg poillls To chan!IC ,I WhUt:1 111 ,11 ,-,"W'!ICIICY. usc the t:]ck slIpplled wilh the ve'lIe!!.!. Ensurf! 1hal the Hhldwh,:cl nuIS;OH! ,ciC;lSCd Imlole Ii, cklll\j up thO ca. and make SlUe Ih;u the .lOIn of the 1,1Ck IS luU.,. cnua\Jcd wI,h the body bracket and thatlhe hase allhe Jilek IS st;lIldlt '!J on a 111111 surface. The Jilek supplied w!lh lhe vehIcle IS 1101 $",,;,l)le lor lISC when laislflg the ve!.iclc lor U\;J",l()II;IIlCC or 'Cp,1If up,:r;J110ns. For this walk, use a trol ley. hyd'ilui,c Of screw-Iype tad IOCille(1 und!:. thO f,OIll crOSSlllcmbcr. bodylrame s,(ic-mcmbcls 01 ,ea, il~le cnsing, .1$ ,UuSlr

Fronl IOwin9 pain I S (ll • • owed )

Towing poillls II you/ vehIcle ,s bCIIl9 IOWl;d, m,lke SUfe lhal the lOw rope IS auached to Iho 110111 cmssmembcr or, where Ilued. the towlog eye auachcd 10 Iho 11001 ClOssmember II Ihe vehicle IS equipped wilh atilOma llC Iraosrlllsslon, the d.slanCe lowed rnuSI nOI exceed 15 miles (24 km). 00' Ihe speed 30 mph (48 km/h), olhe.wise sefious damage 10 Ihe Ir

10Wlflg eye.

, 'I I -J ' ,;

~)

'J

: .. ': .... 111"'"' ..... _-.___ •• _...:. __ ... ,

Jacking l)oinl S

Rear towing I)oio \s (arrowe d )

procarmanuals.com

Page 10 of 205

General repair procedures

Whenever scrvie,,,U. repair or overhaul work ,$ c;nric

Joinl mating ftlces ,7l1d gaskets Where 1'1 gasket IS lIsed tmlwl:CIl the ",,,,ill\1 [

Make SUfi) lh,,[ tnppcd holes nrc ciedncd WIth il pI pc clcilncr, and kcep thcm flcc 01 101l1llng compound If tillS IS helll\) used unless

speCIfIcally Instructed otherWIse Ensure that "II ollfrtes. (:hannels 0 1 pIpes ,lie Clt'ill ilnd blow thlough Ihelll. p,eleriluly llsing compressed ill(

ai/ seal s

Wheneve, nn od sCill is removed flom its wOlkll1\1 10Ciliion, eIther mdlvidu"lly or "s p"rt of iln assemhly, It should be lencwcd The very finc sc"lIng IIp of the sei'll IS e"slly dama\Jcd and WIll not seal If the surface it COI11<1(:15 IS not completely c lean and free frOlll

SCHl\ches, nicks 0' grooves. If the o'iginal scaling surfi'lce of the COlnponern cannOI he restorCd, Ihe component shoul d he renewed, PrOlect lhe lips of the scal from any surlace which mi'lY damage them in the course of fmlng. Usc wpe or a conical sleeve where POSSIble, LUb ricate the senl lips WIth 011 befole fruing and, on dual lipped se"ls, fill the space be twcen the hps With grease. Unless otherwise stated. all seills must be hlled with then sealing hps toward the lubricilrH to he seillcd Use iI\ubuli'l' <111ft 01 block 01 wood 01 the npploprime sIze to II1sta ll

) I he scal ilnd, lithe sCi,1 housing IS ~houldeleu. drive the seill down to the shoulue,. If the scal hOUSIng is unshouldcred, the seal Should be fItted with its lace flush W ith the hou$lIlg top face,

Screw IhrCiU/s and lasleoings Always cnsurc that a blind t"pped hole is completely free from orl. U

reilSe,

wilte, or other flUId hcfore instatllng the hott a' stud. Fililu'e 10 do tillS could C,luse thc housm\) to c"lck due to the hydrilulic <1ction of the bolt or slud ilS It IS sc,ewed '" When tluhtenlllU ,1 cilswllilled nut to ilCCCpt iI spht pin, tIghten the nut to the speCIfIed torque, whele ilpphcilh le, and then lIghten furthe, to the next split pin hole Ncver slilckenlhe nulla "lrgn a spirt pin hole unless ~t

SOllle Inswnces, where no a lterniltlve IS poss ible. II hilS been necessary 10 resort to the use of a manufilclurer"S tool and thIS has been done for reilsons of safety as well as Ihe eHlcien! completion of the repair

operation. Unless you are highly Skilled ilnd hilve a thorough unde,standlng of the procedure desc(lbed, neve, " tWlllpl to bypass the use of any specl,,1 tool when the procedure descrIbed specllies ils use, Not only IS I here a ve,y great risk of pe,sonal Injury, but expensive dillllage could be causJd 10 Ihe components involved

procarmanuals.com

Page 21 of 205

a

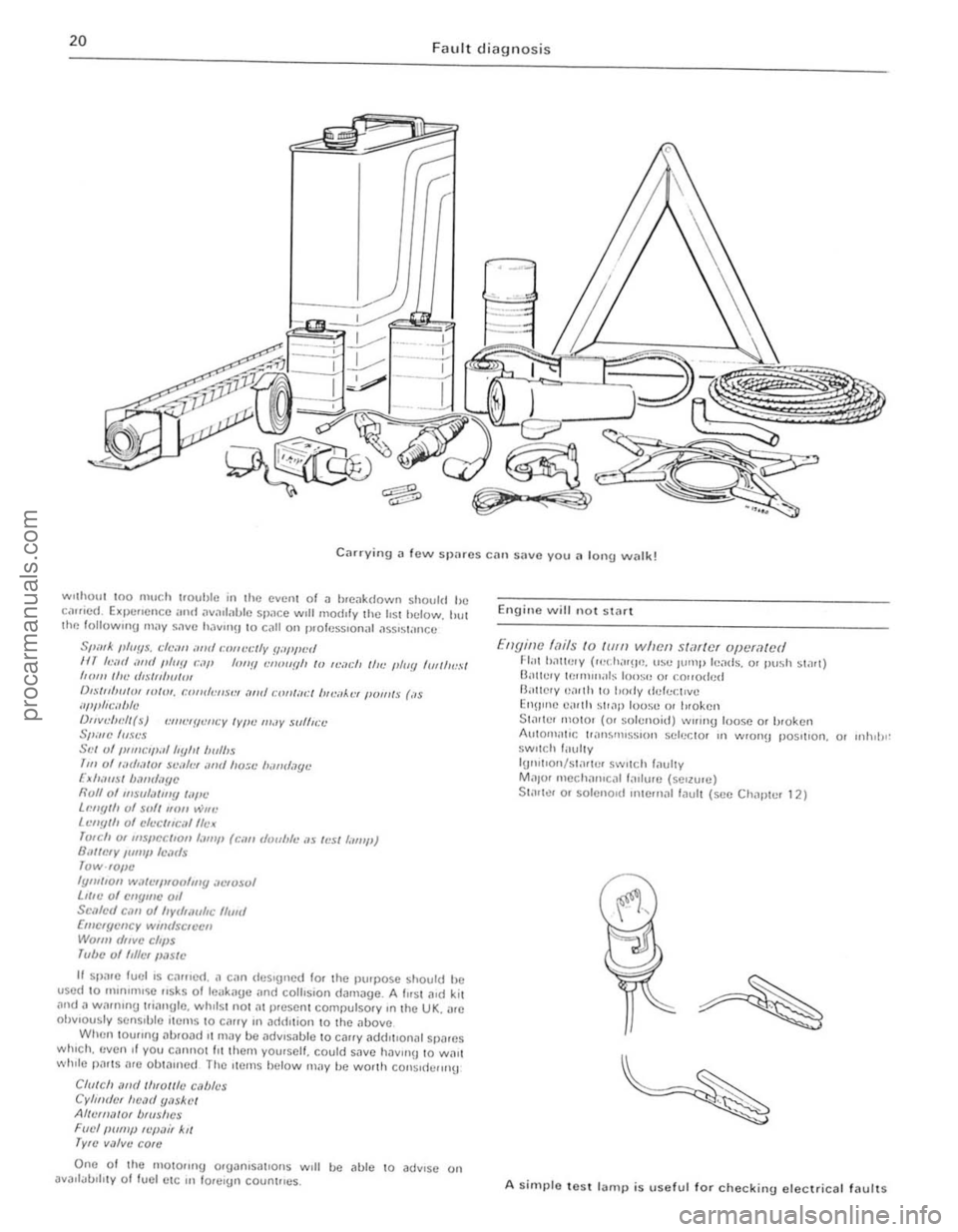

20 Fault diagnosis

Carrying a lew spares eM) :\l1VO you a lono walk!

WHhou t 100 ,ulIeh trouhle in the event o f il hrC

DrHII/mim [(JIm, (:lIlIdulI.~VI IIlId C""Ii":II"'HI~'." I'omls (;'s ;,/I/lII(.','I/)/e

IJllv/.'lmll(s) ,.'/I11:II/VJlCY IYl't' m"y suffu;t, SlIill!! {(I,ft'S S •. '/ of //111//:'/1,,1 "ylll bill/,S 1/1/ 0/ ",dlll/Ol 5<:;,11:, ,mil IlOst: '>,md.1UI! t"~II;III.1'1 /),111(1I1!IC Roll OlllllilJIMlt/y IIIl'l' Lf>llylll of sulillflll WIIC Lc"yllt of ci.:cIIlC,llllt·.

rUiC" Of mSIICC/IQIII;III'11 (eilllliot/blt' ;,S II.'S( I;IIIJIJ) OMlt'IY 111111/1 Il'mls Tow" Q/IC Iym(/Oll WJiClllloo/lllY ,ow/osol Llfll! 01 c"Yllle Oil SeMcI I eMI olltyr/wlIll(: /f",d Emeif/CoCY WII/({SCIt'ell W(JIm ({live cl'II$ Tube 01 Idlel IJ,1S((;

II Sllilro IU(l 1 IS Cil",c< I .• 1 Ciln dcs'Ollod for th(l pu'pose should hc uscd 10 m"l",l(~e rrsks of le

WhiCh, evon 'f you cnnnOi III thcm yowscll, could snve hav'"(J 10 Willi wh,le p

One of Ihe 111010llng 0'ganlSilll0ns w

Ellgillc taits 10 ((IIf) W/IL'II slilrlc r ()p vra le d 1' 1;11 h~lll.'ry (.ud,;,,!!,!, u~.., rlmlll'uolds, 01 push Sl.1rt) nnllclY 1(:rnllll.,ls Ions!! 01 cntlod,!d BaltelY ll.1,tll to hody dd"cl'vu Enwnc e(utll S I,,1)) 100Sll 01 broken Sl.1rtel 1II0lO r (or so lulloid) "",,,ng loose or IJroken

l\ulOn1 ;II,e II1!11srllr~s,()" seleClor ,n W'OIlIl pos",on, or Inhd)!' sW/lcli fHur,y '11""'Oll/SI (lr lu, sw,'ch folUllY

M i'ror mech:u"C.11 ,,,,lure (Se'lUre)

Sli"!~1 Or sole"ord 'ntorrloll rilul! (seo Chaplllr 12)

A

simple les t lamp is useful fot checking electrical fault s

procarmanuals.com

Page 70 of 205

)

-

Clwpter 3 Fuel

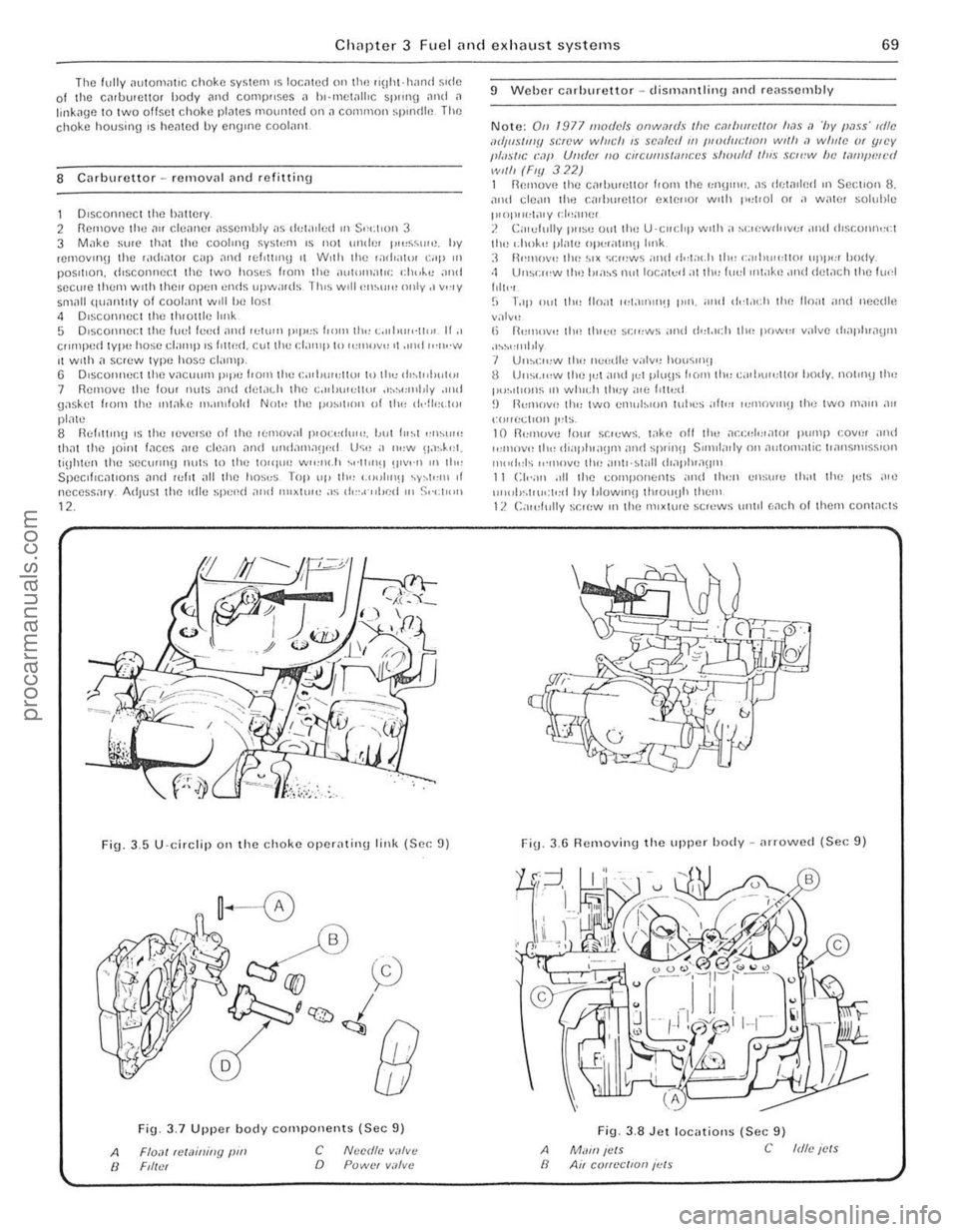

Fig. 3,5 U·circlip 011 the choke operatil\g link (Sec: 9)

A /I

Fi9 3_7 Upper body components (Sec 9)

Flo,lI telaininy pm Ftll.'t c o NlJcdto V;I/V(!

POWCI v.1lvc

9 Weber Cilrhurettor -dismilntlinu [lnd reas~ernhly

Note: On 1977 mod(!/s onw,lf(II /lIP. cmlll/id/ot 11,15 ,1 '/Jy PilIS' tdle IIdIItS/IIIY SP~'W willch IS sc,l/r:iI //I l!lodl/cllOn wl/h <1 willie (}f ljlCY 1,/,'sIIC (:,11' UlI(ler /10 CItC(ff!!s/a/lces should {/II.~ SCI('"W h e /,)t!J/JlNl'd wi/h (Fly 322) 1 R(!II1Ov(! the C.1,h"n;llor I! O"l th e ':Ol!)""' . ,1~ dr;w,lp.oI ,n Section 8. an d cl(!,lIl th.) f:ilrl""etlor extC"Of w'lh 1'.,['01 or a walt' soluhle t"OI",,:l;\,y 1'/,,;)11(:1 J. C;, rdully I"'S" 0,,1 Ihe U'CIIClrp w,th a hC,(lWII"v" •• lIul ,h~COIUlo:cl til" '.ilok" pl"w oj)l:(allnulrnk :I 1\""10\"" tire ~I X ·,,:,,'ws ;'"It ,i,-(;" .h II" , GIl1"""llor "Ill"" body. ·1 Uns';",w llr,) h'n~s nul locnl"d:ot th" ((",I ,nwk,) .'nd d el.1cll Ihe flU'l

Iolt"1 (; T"II Ollt tlo" lIo;i! ,,,t.1"lII'!J pm. ;,nd dd.1{,1r II,,) 110;11 ,Hl d needh~

v:otv" I, R"",,,v,, tlon th,c" ~c,,:ws and d"t.u:1r tlw po","", valvc d';lpl"a!)1ll .'~h,,"'tJly 7 U"hl:",W thn ncedle ~"Iv" ho,,~,nu 8 U"suo:w the It)( and Io:t pt"\Js I. o r" til" c."jJ\""l1m Imdy. not"l\) th .. , p"~.'I'o"s III wh",h 11,,;y ;0,(, f'lll:d ~) I~l"ll()v" (h" two cn ,"b,on luhes ;011'" ,,,'IIOVIII\) the two lll,lIn "" l"II rt<.:t,on t,;ts 10 1l<:!lIUVC lorn sr.'l:ws. t;JkC nil II", ,1co:"I,;r.lto , j)"Il'P co"", ,,,,d ,,,,,,,-.vOl ttl<, d',Ij,lua!l1l> ;Hld 5P(in'l SUlul,,

Fi\j. 3.6 Removing the upper h ody -nrrowed (Sec 9)

A II

Fig. 3,8 Jet locatiolls (Sec 9)

Mwn ICIS C Idlc ICIS Air COtt~'CIIOIl ;"IS

procarmanuals.com

Page 86 of 205

Chapter 3 Fuel and exhaust systems

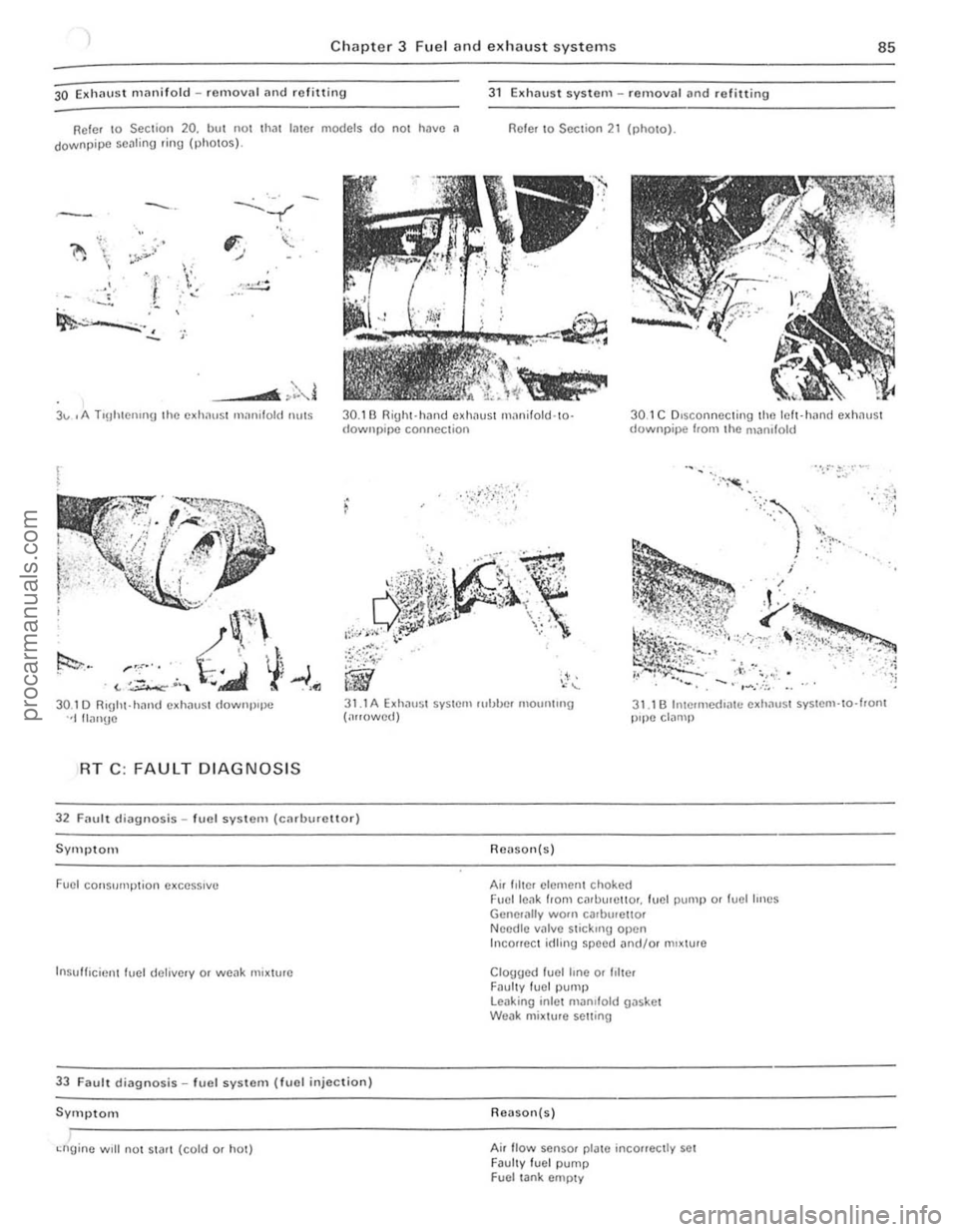

30 E~haust manifold -rOllloval nnd r e fitting

Rcle . \0 Section 20. but not that 1,11C' models do nOI have n downpipo scaling ring (photos)

~ ..

y

" ..:

';.

__ +.,,",l

31 E~haust system -removal and ro fitting

Reier to Section 21 (pholO).

85

3" ,A TI!Jhlenrrl!J Iho O~hilUSI mnnilold nuts 30.1 BRight hnnd e~hnust rn.1nilold ·todownpipc connection 30.1 C Dl sconnec tirrg the lell hnnd e~hnusl downp;,Je hom Ihe manIfOld

. ;/~}":"~"":'. ,

\"~'"

} ·':t-

i

31.1A hhnust system ,ubbe. mountIng (;,,,owed) 31.1 B Irnermed'ilttl oxhilu st system-to-honl pIpe clamp

RT C , FAULT D IAGNOSIS

32 Fault diagnosis -fuel sys tem (CMuurottor)

Symptom

Fuel COlls!ll11ption e~cesslve

Insu llicienl fuel detrvery or weak mi~lure

33 Fault diagnosis -fuel system (fuol injection)

Symptom

~ngine will no t starl (cold 0' hot)

Reason(s)

Ai . 1,ltel clement choked Fuel lenk flom cmbulellor. fuel pump Of luellrlles Gene.ally waUl ca,bu,ettor Needle vnlve StickIng open Incorrec t idling speed

o. hiler

F

llason(s)

Ai. !tow sensa. plale incorroctly sel FauilY fu el pump Fuel lank omply

'J

----------------------------......

procarmanuals.com

Page 91 of 205

90 ) Chapter 4 Ignition sys tem

' .

. ' =-,,":.

:f/~jI

iJ -~

, .. '

k~

~

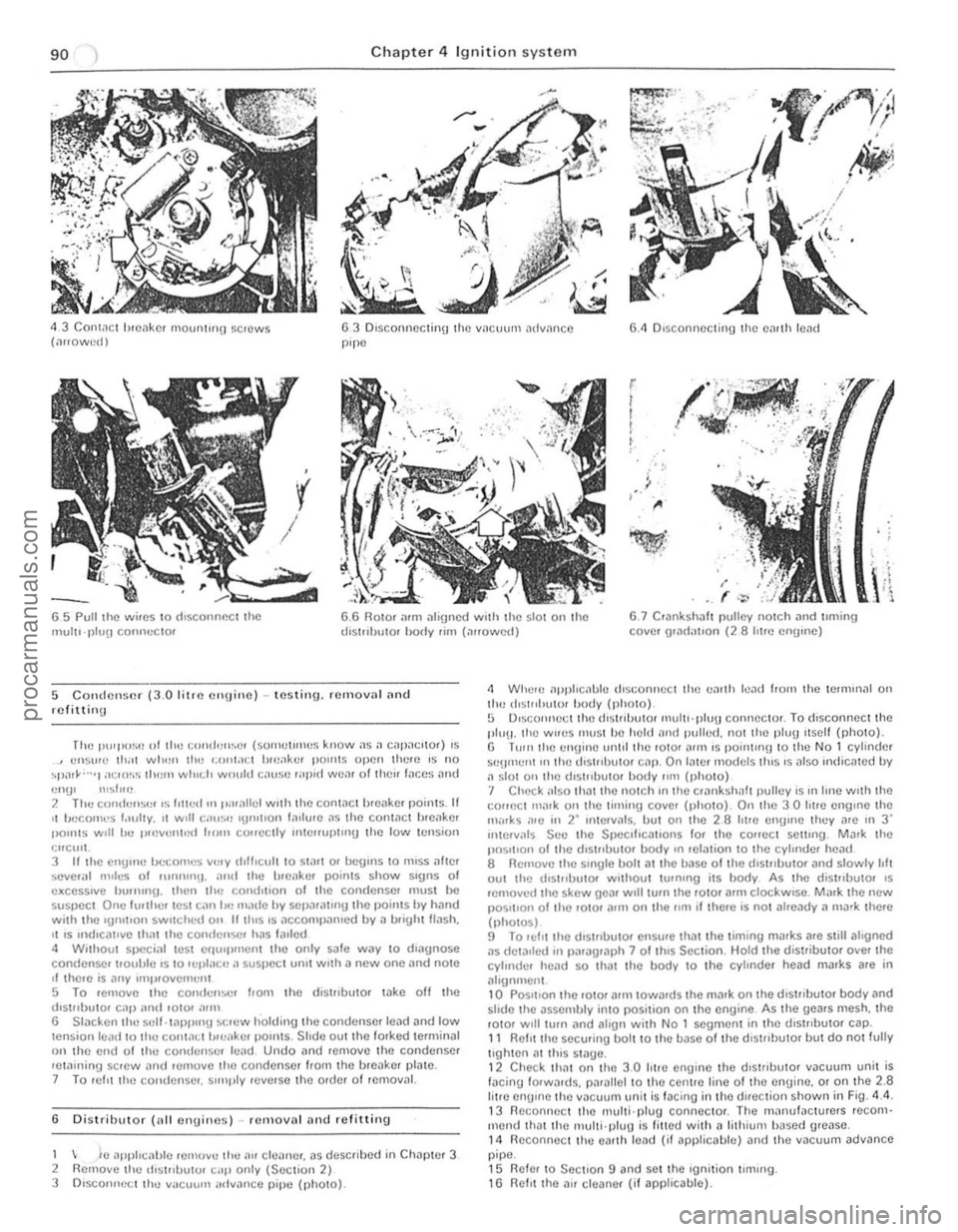

<1 3 Contact hlcnkc. mOUIlJrrlO ~CH)WS (,lrrowcd) 63 Dlsconncclinu the V

(

/

r

I

I

I

,

. '. f

'1,j , , , ,

65 Pull tile wires 10 rhSCOlll1CCl the mull"I)I.,\) COlll1eClor 6.6 flOIO. arm al;\jncd with the slOI on t he d,strlhutor hrnly rim (allowed) 6 .7 C'ilnkshall polley nOlch and Imling covel gr,1(lahOn (28 hIre cn!l'ne)

5 Condenser (3.0 l itrf~ rnllJillo) -testing. removal (lnd rcf ittinu

The PU'I'OSI) 01 tilt) ccmd"",.er (sorllclull(!S know .15 .1 capacItor) IS ensure lh.1I wli,m II", ',()IIi."; ( I!UJakcr POUllS open thew IS no ~po1'~""1 a~Hl"S ilWlll whIch would C,llIlie ,ap,d weill 011hcu r .. ees ilnd

'!I'Il' ",slue 2 The CUIHIUIlSt" .s hUed !II I>luallel wnh the conlJCI h,e;)kc. points. II '1 becomes r""lly, ,1 w,lI C;II,,'" 'IJ'''IIOI' fa,lure ,15 the conlilCl hreaker 1'011115 1'0',11 he pH)VI!fIl,:ti hom cOllcclly 1Il1elfurlcmu che low ccnsion qrCIIIL 3 II Ihe en!)'lIe becomes very dlHlcul1 co SWrl 01 begins to I11ISS afrer

severill null'S of I lInl1l11\l . and che I)lcilker poinls show signs 01 e l\ceSSlve blllllllll/. Chen chI) condlu o n of Ihe condenser muSI be suspecI One f".ther !C:.t can II" milde hy sepa,ahl1U che points by hilnd wilh the ,umtlon 5WIICtl(:(1 on IItl"5 IS ilCCOoul),,"Il1led by a mighl trash. II IS ,ndu;:allve Ih .... 1 the comlcuscr has I0111cd

6 D istributor (illi en\)ines) -rcmoval and relittin\)

1 k ,1pphcablo II.HlH>VU the 1111 ele,me" ilS descllbed in Chapler 3

2 Remove Ihl! dl ~l"bulo' C;Ij> only (SeClion 2) 3 D,sconlle\:t Ill.., V

1 1 Relit the securing bolt 10 the bnse of Iha dlSlrrbulor bUI do nOt fully Ilghlen ;IllhlS Slage. 12 Check 11I11t on Ihe 3.0 hlr a engme the dlstrlbulo, VJcuum unil is lilcing fo,wilrds. parilliellO the centrO line of Ihe el1\)ine. or on Ihe 2.8 lil,e engine Ihe VilCUIIIll unil is lacing in Ihe duection shown in F ig. 4 .4 . 13 Reconnect Ihe IllUlli·plu\) conneClor. The manlJf~Clurers recom· mend Illill Ihe Illulli·plu!) is 'illed wilh il lilhium hased grease. 14 fleconneCllllu earlh lead (it applicable) and t he vJCUUm advance pipe. 15 Reier 10 Section 9 and se l Ihe 'gnition IlmlllO. 16 Refll Ihe all cleane. (if applicable).

procarmanuals.com

Page 107 of 205

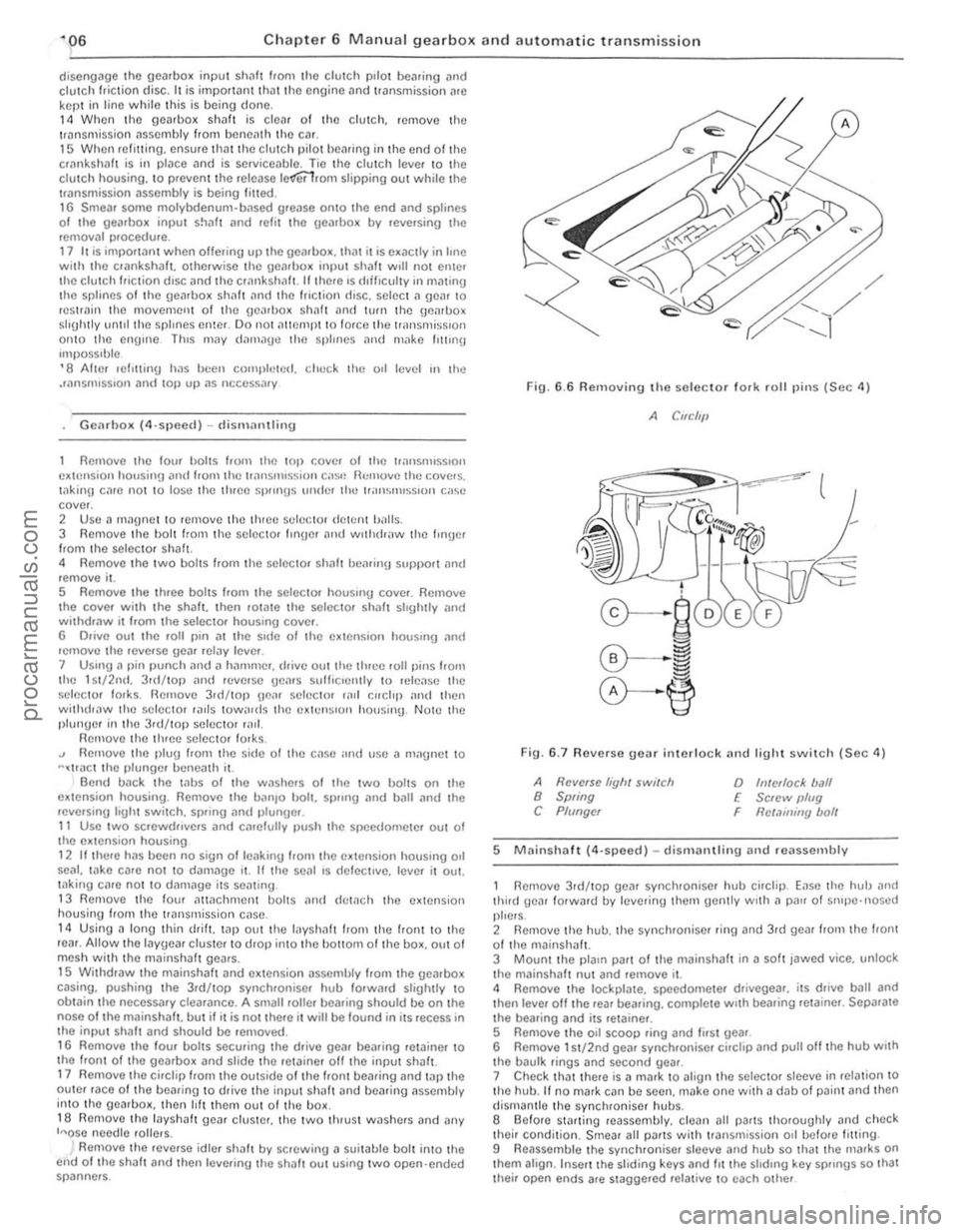

·06 Chapter 6 Manual gearbox and automatic transmiss io n

disengilge the gearbox inpu t Shill! hom ,ho clutch p,Iot bearing ,111(1 clu tc h friction disc. I, is imporlanllhal,hc engine and transmi ssion <'lre kept in lino while this is being done. 14 When the gearbox shaft is cleDr of the clutch, remove th e

tran smissio n assembly from bCn(!illh the car.

15 When refiuing, ensure 1il1 the clut ch pilot h earing in the end althe tfilnksha h is ill plilce Jncl is scrviceDble. Tic the clutch lever 10 the clutch housing, 1 0 pr(!venllhe release le.rertrolll slipping out while the ,Wnsmission assembly is being lined. 16 Smear some molybdenum-based grease OntO the end and splines 0' the gearbox input s!mh lind refit the gearbox by reversing the fcmovili p.ocedure. 17 II is impO.IMll when offering up the {jOMOO)(. th,lt il is e~

slightly until the splines enter Do not iluempltO lo.ce the tfilllsmisslOn

ontO thO enlJlnO ThiS Illay (i

'8 Ahe •• el,uinn has been completed. chuck the 011 level Ifl t he .r

Romoye the lou. bolts hom the 1011 cove. 01 the t.ansm.sslon c~t()"sion housin!J ilnd f.om the lri"'snHs~ir)Ol eo'S<' Ilcmovflthc \:oye. s.

t.1king c

R emoYo the .eyerse idle , shah by sc.ewing a suitable bolt into Ihe end of Iho shah and then leye.ing the Sh;'lit Out uSing Iw o open ·ended spanne.s. Fi\)

.

6.6 Removing the seleclor 10lk rolillins (Sec 4)

A CIfC/'11

Fin. 6 .7 Revorso gear interlock nnd light swil c h (Sec 11)

A Ravelse liyh, switch 8 Swing C Plf/ngcr

o h!/ellocl< ball E Sc,ew IJlug

Rct.1ininy bolt F

5 M

thud gear lotwald lly lel/erinu the,n gently wrth a p

their condition. Smear all Pi/ItS wilh tr3nsmission 011 befo.e fitting .

9 Reassemble the synchroniser sleeve and hub so that the nlafks on thorn align . Inse.t the sliding keys and 1IIIhe shdrn\) key sp"ngs so Ihat Ihei. open ends afe stagge.ed re lat ive 10 each other

procarmanuals.com

Page 111 of 205

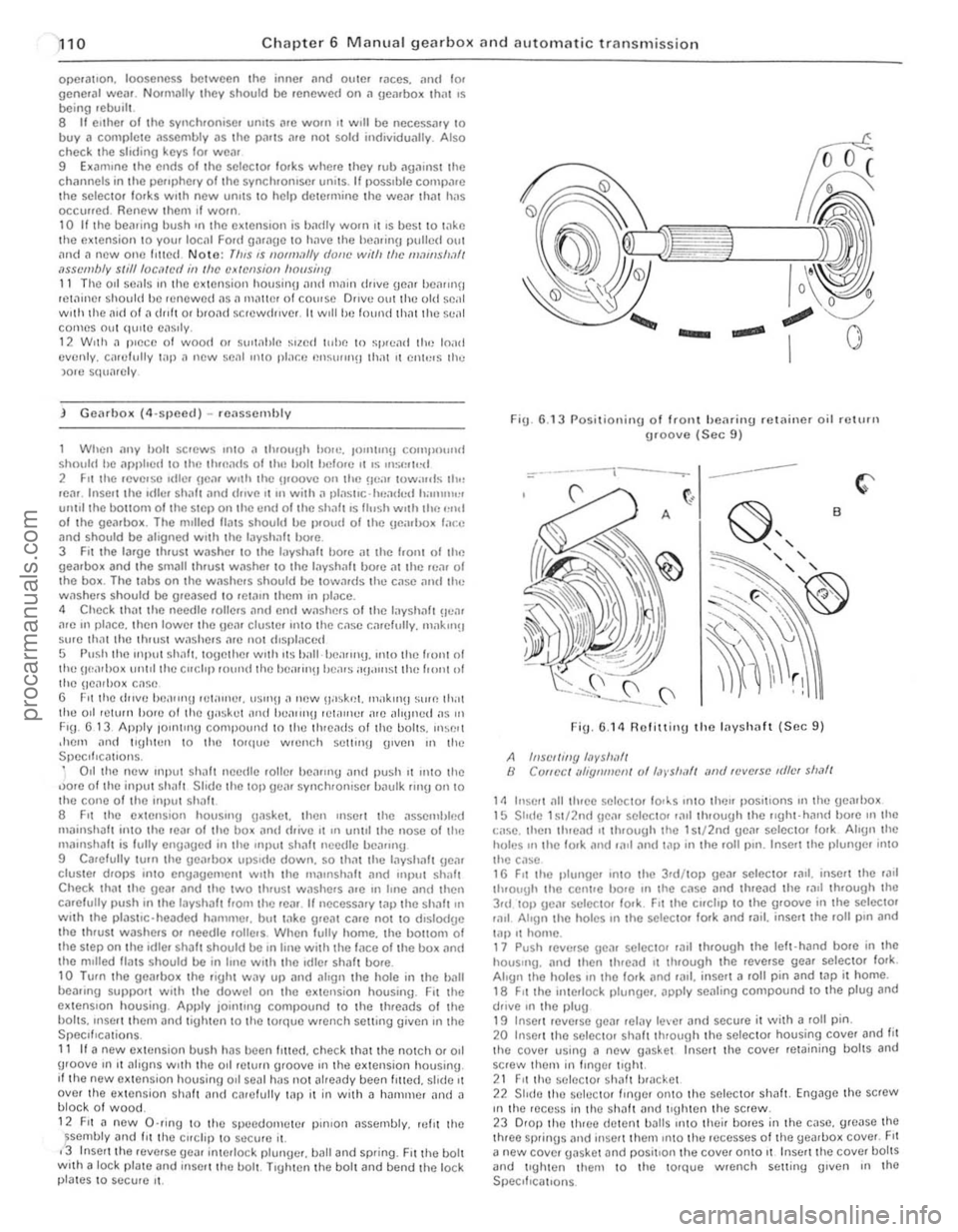

~10 Chap ter 6 Manual gearbo)( an d automatic transm iss io n

operlltlon. looseness between the inner ;mel oulC. ';)ces. imd 10f genera' wear. NOfIll.llly they should be .enewed on a gearbox lh<11 IS being .ebuil l. 8 II Clther 0' the synchrOnise. unllS ;nc WOUl II w Ill be ncccssmy 10 buy" complete assembly as the Pill ts ,lIC not sold individually. Also check the sliding keys 10' we;'!. 9 Examine tho ends 0' IhO scl(!C I(ll' lor ks where they rub "g.1In51 the channels in the peJiphery of the synchrOntSfl f units_If I)()Ss,ble cOIllp.."e the sclecw. lorks with new Units to hell) dC1Crminc the weill lh,,1 h,IS occtJUcd Renew thelll " worn. 10 If the bCilring bUSh ,n Ihe CXI(mSlon is b;uliy worn II,s OOS110 [

When any hOlt screws "110 a throuUh hor". JOllll11\!J COlllpnulI/t Should hc nj)lllted to I he lhwads 011l11! holl helorc It ," InS/"h~1 2 Fit Ihe /cve.so Idle. He"r WIlli Ihc It,oolle on the !le;1I tuw;IId,. Ih,' lenr.lnsel! Ihe .dle, s h ah nnll dlllle 11111 with .1 pla~t.c·IIIl:IIIt].1 h;""""" unllllhc OOltOnl ollhe Slel) on the end ollhe shalt.s IIIIsh WIth lhl! ,,11.1 0 1 the gCJloox. Thc mIlled "

FlU. 6 13 Apply 101ll1lng compoullll to the threilds 0 1 Ihe bolts. lIl~e

0,1

the new IIlput sh,ll! ncedle rollel heilrlllg ilnd push I t 11)10 tllC oJorc 01 the input sha ft Slide the lOP gC(lr synchroniser baulk IInu on to the cone olthe IIlJ)u I sha h 8 FIt the extension houSll19 gnske!. lhen InSerl the ,1s~",hlcd mainsha/t into Ihe rca. 01 the box anll (frille II III untIl the nose 01 Ihe Illalnsh~h is fully engaucd in I he II1PUI shilh necdle l>c,l11nU 9 Carefully lu.n the ge;ubox upSIde down. so thilt the layshalt \}e,lr elusler dIOI)S mto engJgelllenl with the malnshillt Jnd IIlpIII shalt Check thilt the gear and the two lluust wilshe.s il.e III line and then c,l.elully push in the layshalt from thc leal. If necessary till) Ihe S h ,ll! In with the p lasuc·headed IHI/llmer. bllt take grC;lI CJre not to dlslodUe Ihe thruSI washels or needle .olle.s . When fully home. the h Ollom of Ihe slep on the .dlel shalt shOuld be In hnc with Ihe face 01 the box and Ihe mIlled flats should be in IIno wllh the Idler shalt oo.e. 10 Turn the geilrbo~ the lighl w;ly UI) Jnd align the hole in the 1>.111 bemll1g SUpj)Orl WIth the dowcl on Ihc cxtcnsion housing. Fit the eXlenSlon housing. Apply jOlllllnu coml)ound to the ttlle<1ds of Ihe bolts. InSClt them and tightcn 10 thO torQuc wrench seHlng gillen In the SpeCll l

C3tions . 11 1/ a new cxtension bush has been fllle(1. check Ih~t the notch 01 011 groolle III II ilhgns wllh lhe o ll,elurn grOOlle In thoJ extension housing. If thc now exlension housinU 011 senl hilS not illready been filled. slide It Ollel the extension Shill t and enrelully tap it in wilh n h~nllller and n

b lock 01 wood.

1 2 FIt J ncw O ·ring to the spcedomeler pll110n assembly. relit the ~Sembly and f it the C llcli l) to socure i1. ,3 Inser t the r(,lIerse gear interlock plungel. ball and spring. Fllihe boll with aloek plate and lIl$crl tI,c l.Iol t. TIghten the boll and bend Ihe lock plilles to seCure ,to

Fig. 6.1 3 Posilionin g of Iront hearin\} .e lainer oil return \}Ioove (Sec 9)

=-*.------t---.---- ---

FiU . 6.14 R olitting the Inyshaft (Sec 9 )

A hlSC//ing /,1vs/!I!f/ B ClJflec / lIi1:qlll!!efl/ of /,J)'$/I,III illld 'fJve.se IdlfJf sl!,lfl

1/1 Insert ~II Ihrce selecto, 10l~s Into Ihcn I)ositlons 111 lhe gearl)o~ 15 Shllc 1~1/2n(1 \le,1r selector ,,111 through Ihe r,ghl-hilll(1 bo.e mille

I:ilse. Ihell tluead ,t through the 1 S I/2nd gCM selector lo.k Align Ihe holes 111 tile lo.k and r~11 ,111(/ t<1l) in the 101l1)ln. Insert the plunUe/ into thc c,lse 16 FIt Ihe pltlllgc/ '1110 Iho 3rd /lOI) ge,ll selecto. lad. inscrt lhe 'illl

t h .ough Ihe ccnHe hore III the C,lse ;lnd Ihread the raIl Ihrough Ihe 3rd 101) gea. sel()(: tor lo.k. Fit the clfchp to Ihe groolle ;n the se lecta' lilll Ahon Ihe holcS III the selectol 100k and ,;lil. insert the loll pIn and lal) .t home. 17 PUSh lellerSC gc,'1 seleelo, r;llt Ih/ough Ihe lelt·hand bore in the hou$"'g. and then thread 11 through the rellerse gear seleclol fork. Align Ihe holes III Iho IOrk and 101.1. inserl a roll pin and tap it home. 18 FIt Ihe interlock plungC/< apply sealing compound to the plug and dfille In Ihe plug 19 Inse!! ICllerSe ueJI ,clay lever and secu/c it wilh a roll pin. 20 Inse't thO sCleCtOr shalt ItHough the selcctol housing COllel and fit the co~er using a new gaskel Insert the COlier rewining bolts and screw them in Iingel lIghl. 21 FII the sel/lCIO' sh:lh b'lIcket 22 Shdo lhe S(lIOClOr flnge. onto the selec tol shalt. Eng~gc the strew III the ,ece~~ in th O shaft ~nd tIghten the sc rew. 23 0101) lhe Ihloo dctent ba lls 1I1tO thcir bores in t he casc. g1Case the thleo sprinus alld Ilise rt thcm Into the recesses 01 tile yeJ.1>ox COllel. FII

a new COlier gasket and positIon Ihe COllcr onto II Insert the COllel holtS and tlghtcn Ihem to tho 10Ique wrench suiting (Jillen III lhO SpeClf,callons

procarmanuals.com

Page 121 of 205

)20 Chapter 6 M anual gearbox and automatic transmissio n

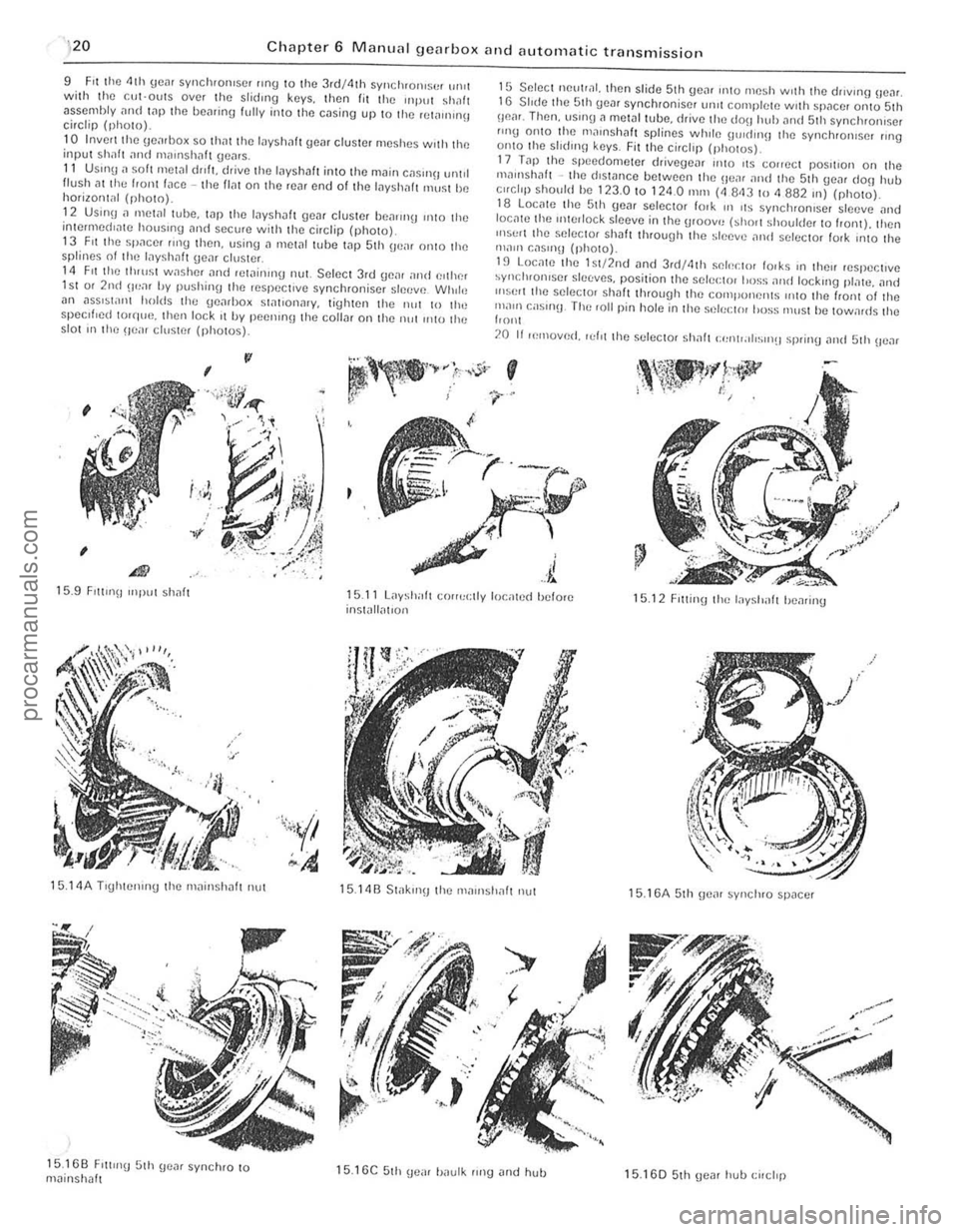

9 F it the 4th gCill syncluolliser "n9 to the 3rd/4lh sym;luOI"s(1f 'HUI with lhe c:ul-outs over the slidlllg k(lYs. then fit the UlPUl shalt asscnlhly i]n(l lilP the bearing fully into tho casing up 10 the rclo1llunu circtip (photo).

10 Invert Ihe \jCo1rilox so Ihil! the l

12 Us;n!).1 mel,lilllbe. lilfl the Inyshaf gear cluster be,IIPI'!J 11110 the inlcrmcd'

15 Seleci neulrnl. then slide 5th ge", IlItO mesh WIth the driVing Be",. 16 Slide the 51h gem synchroniser unll complete with sp"ce[ Onto 51h Oll"r. Then. usrng.l metal tube, drive Ihe dO\1 huh "lid 51h synchronlser flng OnlO Ihe 1ll",nsh,,11 splines whIle UlOld"l!) the synchronIse! 111111 onto Ihe shdlll[J keys. Fit the circhp (pholUs).

17

T"p Ihe sp eedometer drivegeilr "HO ItS COrreCI poslilon on Ihe mollllsh"ft -the dlsWllce belwoon Ihe HeM 'Illd the 5th gO,l[ dOll hub c"cllp should be 123.0 to 1 24 .0 111m (4 843 10 <1 882 Ill) (nhoto). lB Loc"le Ihc 5th He", selector fOlk In liS syn ch ronlSN sleeve "nd loc"le Ihe Interlock sleeve in Ihe uroov", hhol! Shollider 10 front). then InSurt the seleClor sh~1t through the sleeve ,1nd SeleCIOr fOlk InlO the "'aOll r.,lsll1\J (photo).

19 LocnlC the lSI/2nd "nd 3rd/4th Sf)I'~rIOr IOlks 1(1 Ihell respecllve ~Yllcillonlser sleeves. posilion the selectOl !ross

20 If If!rnoverl. 'ef'l Ihe seleCIOr sh,,11 (:"nlr,, 11~1I1!1 sprinU ",ui 51h \Ie",

.' /

15.9 FI1l1I1\1 Inpul shnl1 15.11 L;,ysh;r!t corruc tly located hefore inst,111,11101l 15.12 F,ltintllile Inysllilft hearing

15. 14A Tlghtelllng thc rn"insha fl nut

15.16B F'lllI'\) 5th genr synchlO to m~inshalt

15.148 Slak,n\1 the rH.lloslrall nul

15.16C 5th \le,,, haulk flng Jod hull

15.16A 5th gem synchro spacer

15. 160 51h gear hub {:ilchp

procarmanuals.com