engine FORD CAPRI 1974 Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 162 of 205

Chapter 10 Suspension and steering 161

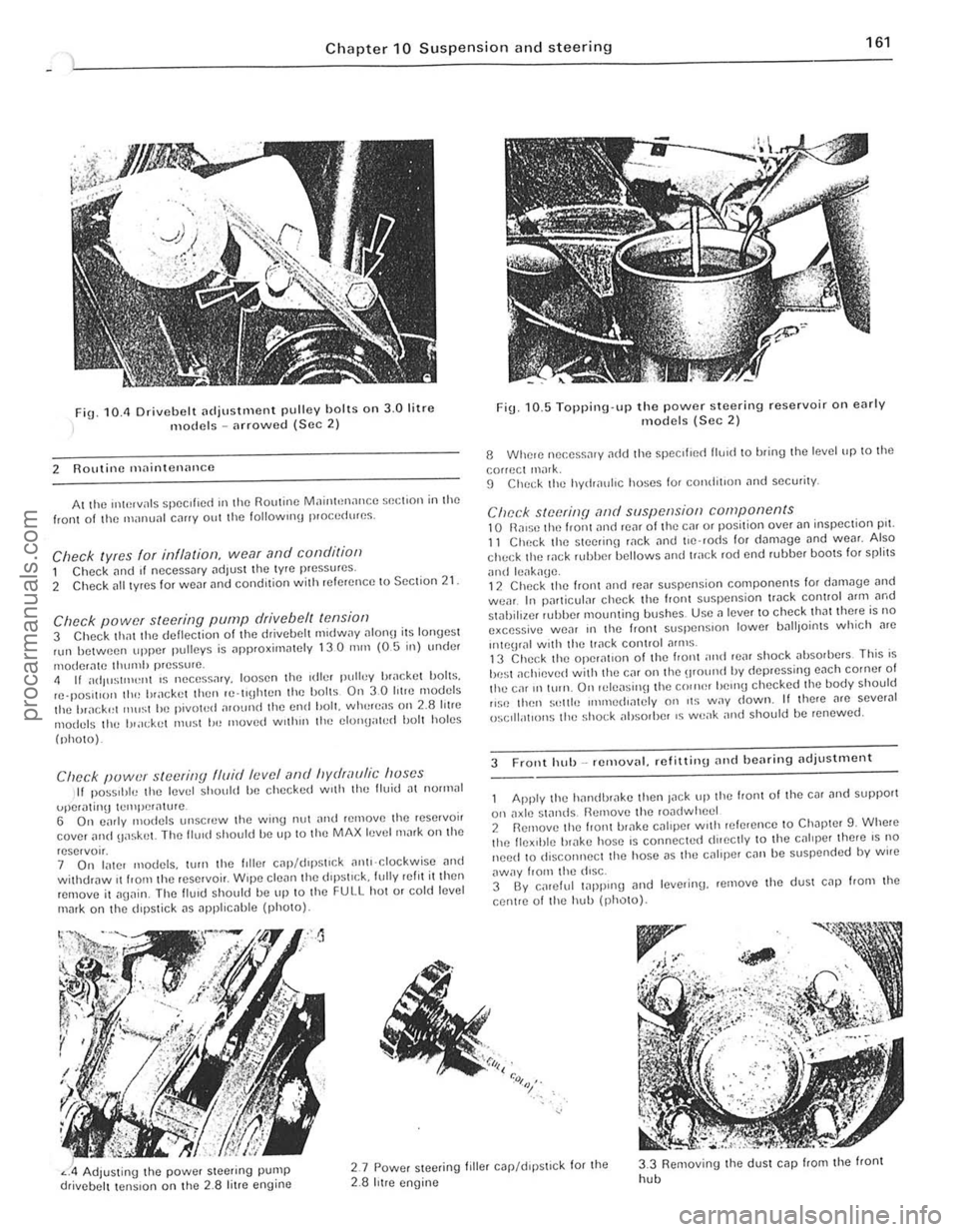

fig. 10.11 Drivebelt [ldjustlllent pulley holts on 3.0 litre models -arrowed (Sec 2)

2 Routine maintenance

At the "*',vals spec ,f,ed III the Routine MainhHlance $()(;t,on in the front of til() manunl c,lIIy out the 101l0wlIl\j p,o(;cdures.

Check lyres for illflalioll, wear and conditioll 1 Check [lnd If necessary adjust the tyre pressures .

2 Check [III t yres for WC[lr and condition with referenc e to Section 21

Check power steering pump drive belt tensiof) 3 Check thm the deflection of the drivebelt m,dway ulon!) its lonyest nlll between upper pulleys is approxirn

(photo).

Clwck puwer steering fluid levef (lnd hydraulic huses II pOSStble the level should be checked w,th the Buid [It nOll1lal

uper,\!mg tClIll)Cr[lture . 6 On c;lrly modcls unscrcw the wing nut nnd relnove Ihe rese,voir cover ilild uaskel. The flu,d should be up 10 Ihe MAX level mark on the

reservo". 7 On later models, wrn tht! hiler C

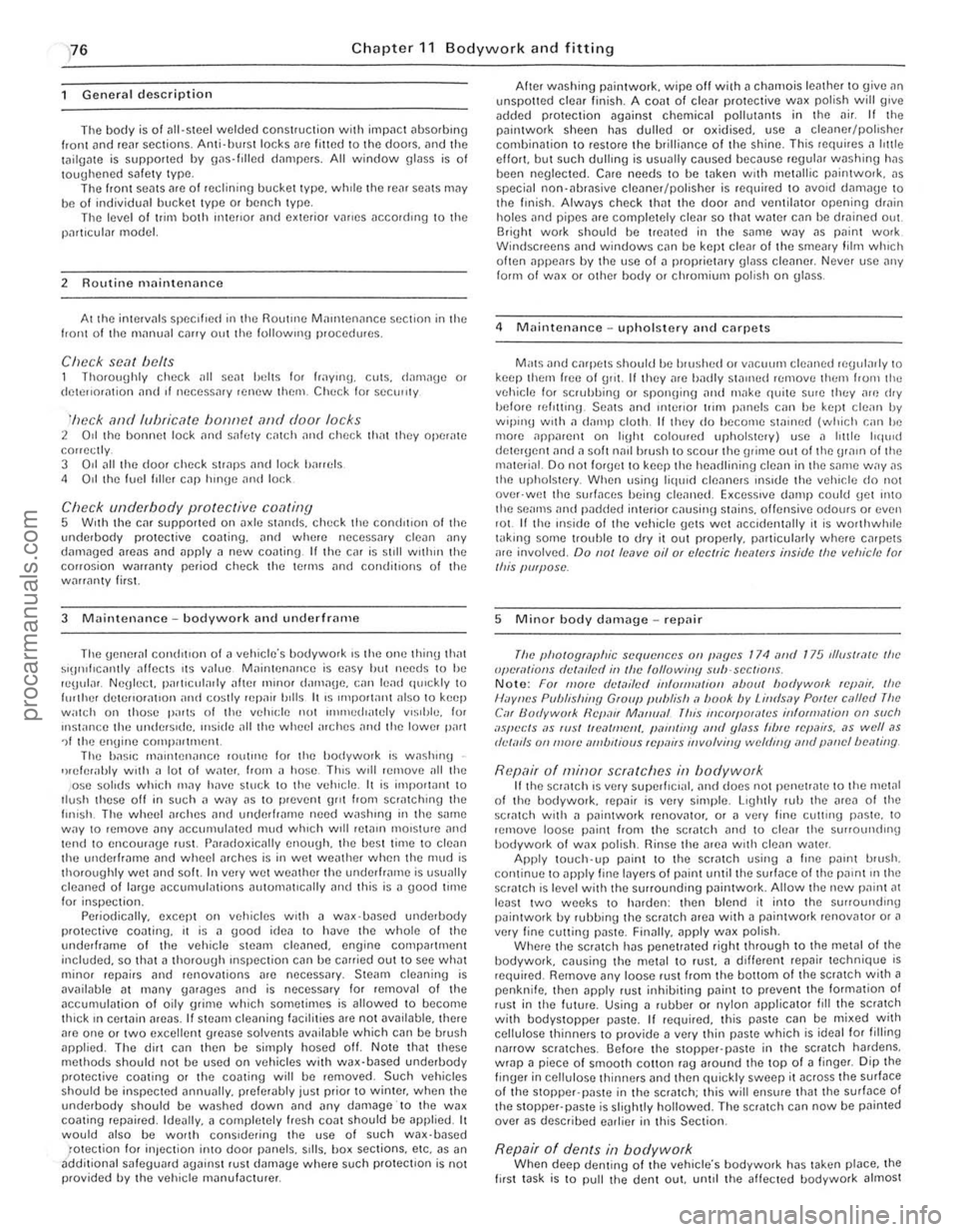

Fig. 10. 5 Topping·up the power steering reservoir on early models (Sec 2)

8 Whele nec.ess.1'y ~dd Ihe ~pccilled lIU1d to bring Ihe level up to the

correct ,nilrk. 9 ChC(;k the hydr[luhc hoses for comJit,on and security.

Check steerinfj ,-md suspension components 10 n,ll$O tilt) front ilno reM 01 the Cill or position over an inspeclion pn. 11 Check the SleetinlJ wck and t'e 'rods for d[lm3ge und weM. Also check the wek HJbber bellows and track rod end rubber bOOIS for spfilS

ilnd leilk[lge. 12 Chec k the front ,md reilr suspension components lor d"m.Jge [lnd wear. In particuf;lr check the front suspension tr.Jck control Mm ilrod stahiliwr r"bber mounling bushes. Usc a lever to check that there is no excessive we[lr III the Iron I slispenSlon lower IJ[ll lJoints which Me

"'\()\JIill wnh the track conlrol ilflllS . 13 Check the operat,on of the I,ont ;IIHt rear shock absorbers This is

be st ilchievcd with thO} Cilr on the \lfOlind by depressing euch corner of the ca' 1111\I1. On 'ele[lsil\ljthe C()"H~r helllU checked Ihe body should ,,~c thell s"llie IIlIl11ed,mely on ,t~ way down. II there nrc sever.J1 ()sclll;ot'ons the sho(;k absorber IS weilk nnd should be renewed.

3 Front hub _ removal. refitliny and bearing adjustillent

Apply the h[llldhr[lke then Jilek tip the front 01 the cm ilnd support

on axlt! standS Remove til(! rOildwhecl 2 Rernove the front ul;lke CJllper With ,elerence 10 Ch.Jpter 9. Whele the flex,ble br[lke host! is connecte(t dueclly to the cililper ther e IS no need 10 disconnect the hose i1S thO} caliper can be suspcnded by wire

aWily from the diSC. 3 By calelul 1

" :<>,:,~,.

Adjusting the power Sleering pump drivebelt tension on the 2.8 litre engine

2.7 Powcr steeling filler c.Jp/d,pstlck for the 2.8 hIre engine

3.3 Removing the dUSI cap from the front

hob

i

i ,

~ !

procarmanuals.com

Page 177 of 205

)76 Chapter 11 Bodywork and fitting

General description

The body is of all-s teel welded construction with impact ilbsorbing hont Dnd rear sections . Anli-burSllocks nrc lilted 10 the doors, ilnd the

t ailgDte is supponcd by \J

AI the in1erVills speCIfIed in the Routine M"IIl\cnilnCe section in the front 0 1 the nl

Check underbody protective coatiog 5 W,th the CM supponed on i1xle stilnds. check the cond,tlon 01 the un(lelbody protcctivc coating. i1nd wherc neceSSilry clean

M,,;ntcll

Wily to remove any aCCUIllUI,lted mud whIch WIll retillll mOlslu re

Mats and C

very line culling pils te. Finally, opply wax polish. WhNe the scrotch has penctrDt(ld right through to the metill of the bodywork. causing the mowl \0 rust. iI d ifferent repa ir lechnique is

required. Remove any loosc rus t fronl the bottom 01 the scra tch with a penknile. then apply rUSI inhibiting paint 10 prevent the lormation 01 rust in Ihe future. Using n rubber or nylon appliCiltor fill the scratch with bodystopper paste. II requ ired. this paste Ciln be mixed with cellulose thinners to provide a very thin paste which is ideal for filling narrow scratches. Before t he stopper·paSI(l in the scratch hardens. wrilp il piece 01 smooth COllon rJg i1round the lOp 01 J linger. Dip the finger in cellulose thinners and then quickly sweep it i1CIOSS the surlace of the 5topper-pJste in the scratCh: this will ensure tha t the surfilce 01 the stopper,pilste is slightly hollowed. The scratch can now be p

first wsk is to pull the dent out, untrl t he affected bodywork almost

procarmanuals.com

Page 194 of 205

Chapter 11 B odywork an d fitting 1 93

)~--------------------------~-- ------------

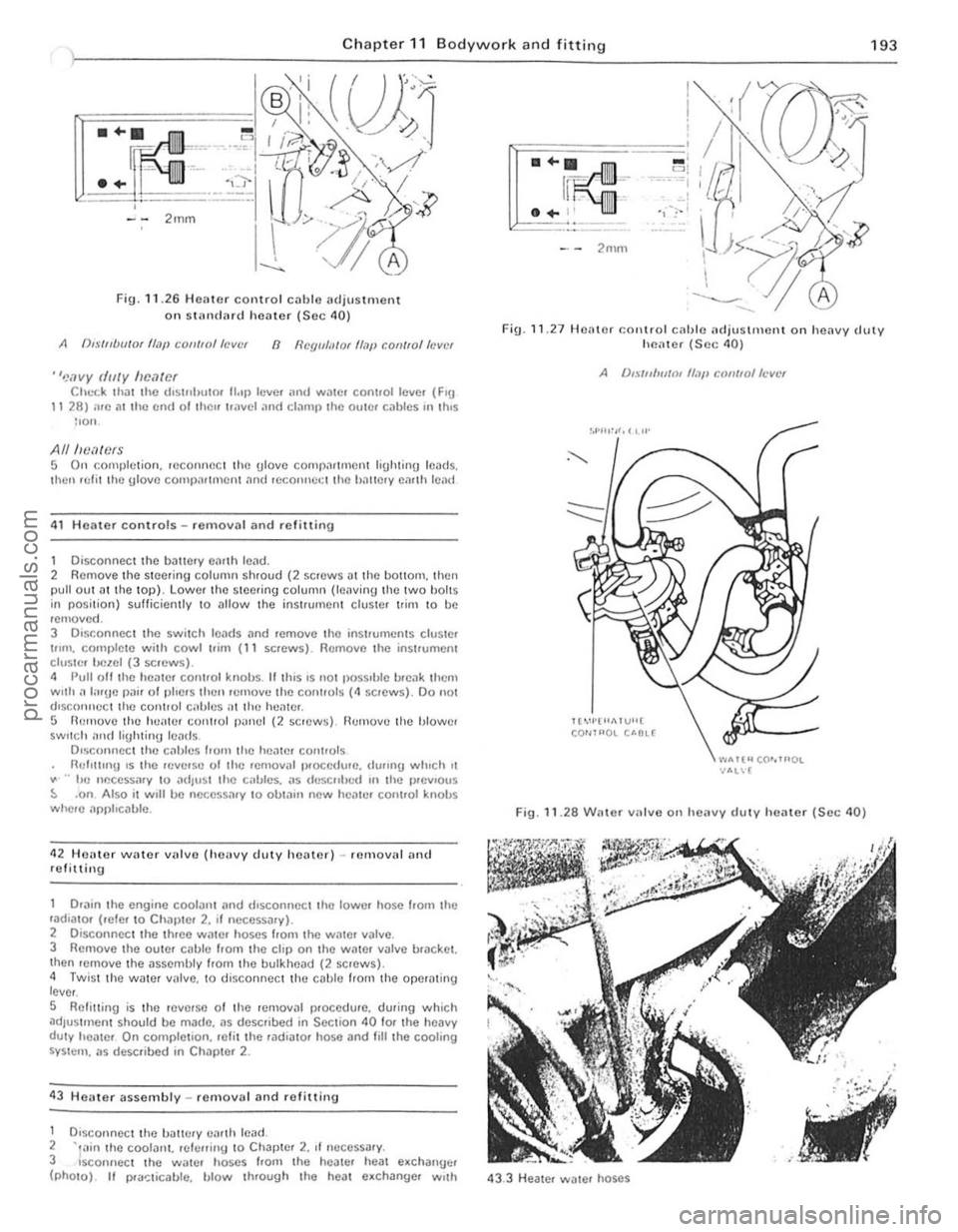

Fig . 11 .2 6 Heilter control cil blc 1Hljus tm ent

on SlHn (IMd heilter (S ec 40)

A (),.\·/"UlI/Ot flajl COII/ro//aVllr 8 I/Cgll/;I/O( Il.7p con/fo/h'vt'f

"'!ovy dilly IIfHltOf Chl.-r.k thilt Ihe d'Slflhutor 1I"p levc. ,HId WilIC, cont.ollcve. (FlU 11 28) we 011 Ihc cnd ollhl)" Ir,"vel ilnd clamp Ihe oulC, cablcs "I \IllS lIon.

AlllwMCfS 5 On complct ion. reconrWC I Ihe ulove comp;lr llllent liUhtinU leads.

Ihen lelil Ihe Ulove COllll)nltrllell1 nnd reconnet;1 Ihe hnllelY emlh len {1

41 H OMe r controls - removal and refittinu

1 Disconnect Ihe ballery eimh lend. 2 Rcmove Ihe s teer ing column shroud (2 screws D tthe bOliO",. then pull oul .lIlhe lOp). Lo wer thc stee.ing column (lel\Ving Ihe twO bOltS in position) sufficiently to ullow t he inst.umenl cluster I rim to be remOve d. 3 DIsconnect Ihc switch 10MIs ;lnd remove the instruments cluSIO' t"m. COllll)lot e with cowl "im (11 screws). Rcmovc the instrumont clusle r l!clOI (3 scrcws). 4 Pull oil Ihe hOiltor control knobs. II t his IS 1I0t possIble I>

.. hc neccssmy 10 adjust th e callies. as dl.'SCfllled III the p.evlous ::. .on Also it w,1I be necessary to obtall1 new hCille. control knobs where npphcable.

42 HCHte r

water villve (hellvy duty heater) -IC lll oval an( 1

refittin g

Drilin

the engine coolant ilnd dlsconncct tho lowe. hosc !rom th c ,aulato. (,efe. to Chapter 2. II necessary). 2 Disconnect Ihe th.ee water hoses f,olll tho Wille. valve. 3 Removo the OUWr cilble from the clip on the WilWr v~lve bracket.

Ihen lenlOve the assembly from the bulkhead (2 screws). 4 Twis t the wate r valve. to disconnect the cable IrOI11 the operilt ing

l ever .

S Relilling is Ihe reve'so of the removal p.occdure. during which ~dJustl\lcnt should be m~do. as described in Section 40 fOf the heavy duty healCf On completion. re li t the rudiutor hose and fililhe cooling SYSt(:rll . us described in Chapler 2 .

43 Heater assembly -re mova l and re fillin u

1 DlsconnOCl lhc tJiltH:ry ea.th ICild. 2 -,,,in the COOIIlI1l. rei!;fliny 10 Chllpte. 2. II neCCSSilry. 3 sconnect th e Wiltcr hoscs from the hoale. he;!t e.chanuc. (phOtO). II I>

- ' = 1 --·-~··""I c,

'1,:-1

F ig .

11 .27 Heale r COl\trol cilhle ncJju stm ont on heilvy cJllty hl"latot (Sec 40)

A /),., ·{n/w/III If,}!, CQII/lo/ft'vct

Il"'·I·"1>.1 VU[ CO""'OL U·OL(

".."Tt"CO""'OL -NIL\[

Fig. 11.28 Willer varv e o n heavy duty heilter (Sec 40)

43.3 H eiltel water hoses

i , , . ,,

"

procarmanuals.com

Page 199 of 205

)

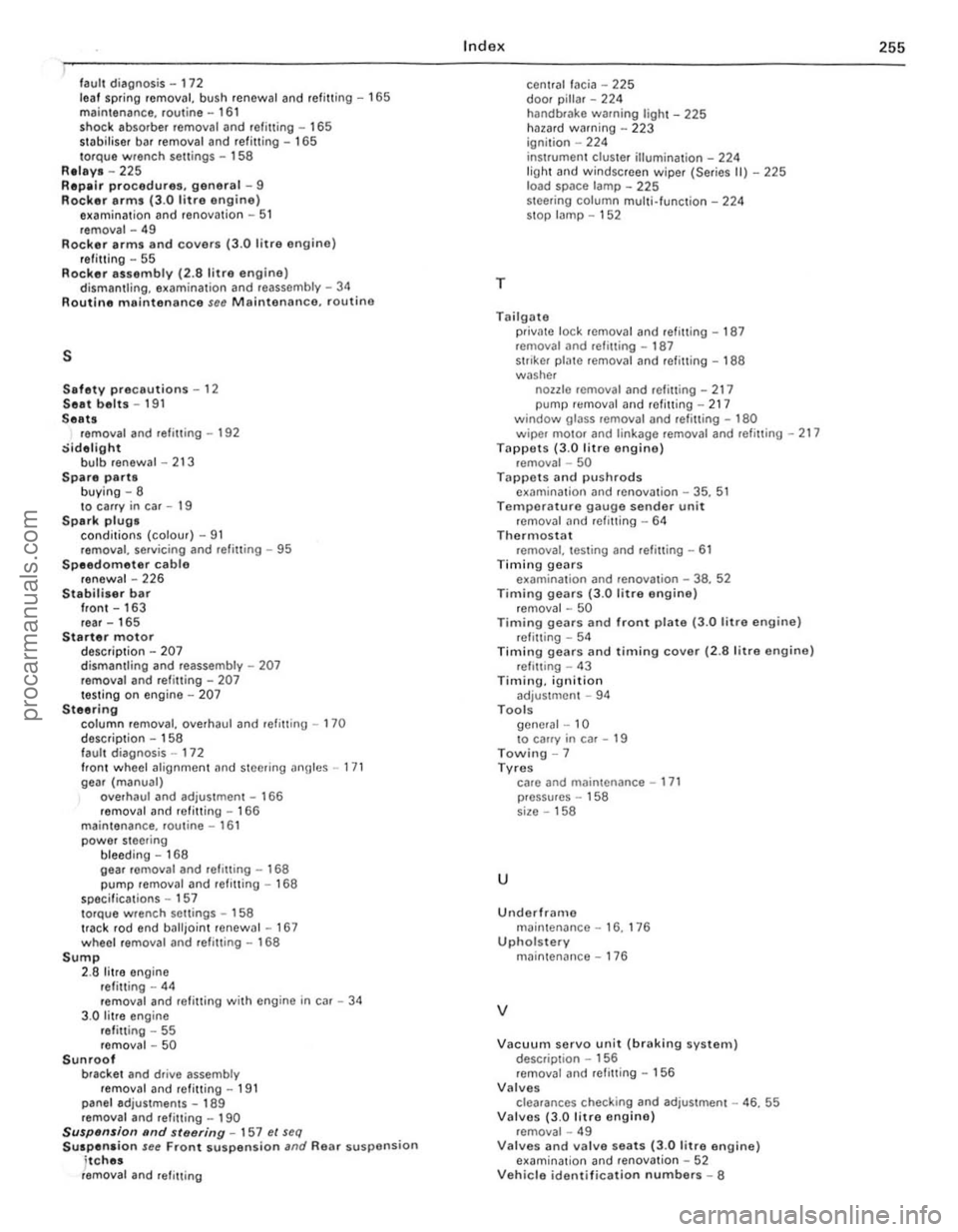

Index

A

Accelerator cilble removal ilnd refining -14 shnft ilnd pedal removal and refining -75 Air cleaner removill Jnd ref,nrng cal buren or mod cis -68 fuel injecllon models -80

P rnator .,rushes inspecllon. removal and refilling Bosch -202 Femsa -203 Lucas - 202

dismantling and rcassembly -203

removal and refining -201 Antifreeze mixture -60 Automatic transmission descrip tion -122

B

downshift cable removal. refi11ing and adjustment -121 extension housing oil seal renewal -121 faull diagnosis -127

maintenance. routine -123

removal and refOlting -123

selector mechanism ildjustment - 126 rcmovill. overhaul ilnd refl11lng -125 speclflf:iltions -103 SI.1r1er IIlh'bilm/reVerse lamp switch remov

demister

noules reOlov

doms-178.180. 18210 185 face level vents removal and refItting -197 facia panel -188 fuel filler flap -188 heater -192 to 194. 196 10

uphOISlCry

and carpets -176 mirrors

-

192 open rem quarter glass assembly

removal and refitting -186

re~r qllMlcr trim panel removal and refitting -185 repi'lir millor damaue -178 minor damage -176 sent belts -191 seats -192 sunroof-189la 191 lailgate -180. 187. 188 torque wrench scuings -173 windscreen -180 Bodywork repair sequence (colour) -174, 175 Bonnet release c

Camshaft (3.0 litre engine) retitting -54 removal -50 Camshaft and camshaf t bearings examination and renovation 2 _8 litre engine -35

3 .0 litre engine -51 Camshah and front intermediate plate (2.8 litre engine) refilling -41 Capacities. general -6 Carburetlor (Weber) aulomat ic choke

adjustment -71 removal. overhaul and retitting -71

dismantling and reassembly -69 general -68 idling adjustment -73

procarmanuals.com

Page 200 of 205

)

rernoy .. ' and refl Uing -69 spcc,'iC

(IlIvchells

G3 e~p:mSloll I nnk 6<1 Ian hub l)()nllllH (30 hilI] 1110<1111,;) 64 f~ull (II;)Ul1osl~ 65

flll".U -

60 lIush"'9 59

",nmlen,lncc. roullllC 59

'ild,nlOr

GO speclficn llon5 57 lem,)er;!lurc unuuc Sf:n(Ie. unil -134 IhcrmOSl<11 -61 10Htlle wrench selll ngs 57 VISCOUS drlv\! 11'111 -63 W1)ler IWIllP 61 Crankca se ventiln tion system 2.8 tol'c engine -39 3.0 rillC engine 53 Cranksh1)ft 2.8 li l.e engine examinat ion nnd rcnoviuion -37 refilling -<10

3 .0 til.e cn gine examination lind renOV1'l110n -52 Crankshilft and main bearings (3.0 litr o engino) removal -51 Crankshllft pulley refitting (2.8 hIre engine) -44

removal ( 3 .0 litre engine) -50 Crankshaft r ear oil seal (3.0 litre engine) .efllling - 55 .emova l -51 Cylinder bores ~xaminalion and .enovation -36. 51 Indo r heads 2.8 titre engine dismanll ing .• cnova lion and .eassembl y -35

Index

D

refining - 45

3.0 litre engin e

. eassembly -55 refining -55 .emoval wilh engIne -49

removal wil h engine in car -49

Decarhonising -52 Dimensions. vehicle _ 6 Dim-dip lighting system _ 226 Disc br1lke s scc Front disc brakes Distributor overhaul 2.8 hlle engIne -93 3 a !r1l0 cng,ne -92 rcmoval and r efIlling _ 90 Doors eXle.io. hllndle ,emoval and refilling - 183 lock 1Issernbly removal and .efilling -184 pillar swi lc h -224

priVill e lock ,ernovill and ref'lIing -185 fnllics tracing nnd feCllik al ion -178 remOle conlroi hnndle removal and refilling -180 Hlmoval and rell\1l11g _ 185 Irim j>ilnel removal and ,efi ning _ 182 window Irnm c

moul(II ng nnd door wealhcrSlrips

removal and refining -185 rcmoval and relining -185 wmdow glass removal and retilling - 184 window regulnlor nssembly

r emoval and relilling -183 Drivebelt s .emov,,1 ilnd refil ling -63 Drum brakes sce Renl drum brakes

E

Eloc triclIl.system -198 e/ seq Electrical systcm altell11110, -201 10 203

ilu xiha.y driving "ghl -212 bmlery -200. 201 bulbs -199.21310217 ciga. IighlOf -225

clock -223

d escrip llon -200 dim-dip ligh ling syslem -226 laull diilgnOSIS -19. 233 ""sher unils and rel1lys -225

fuse s -199. 220

headligllls -211 10213 horn -220

inSI.ument clUSler -22 1 inSI.ument vollage .egula lor - 226 Inmp5 -21410217 mninlenance. fOUline w 200 mobite r"dio equIpment - 226

precautions - 200

rildio /casse tte player -226 specif ications - 198

speedomeler cab le -226 Slmte . mOlOr -207 swi tches -223 10 22 5 lailgall) wash er -217 laHgme wipef -217 to.que wrench sell ings -199

w indscree n washer -219 windscreen wiper -21810 220 wi.ing diagrams -235 10 249

25'

Ii

procarmanuals.com

Page 201 of 205

" .... Index

------ --------------------------------------

Engine -23 cl $cq Engine (2 .8 litro) lmcillllries -29. 36 camshaft -35, 41 components e~aminlltion for wear -34 connecting rods -37. 42 crankcase ventilation system -39 crankshllft -37, 40 crankshaft pulley -44 cylinder bores -36 cylinder heads -35. 45 description -26 dismantling -29 fault dingnOSlS -20. 56 flywheel -38. 42 front interm!.lt hate plme -41 gudgeon pins -37 lubriClllion system·-39 main Il!ld big·end bellrings -37 rll(lintenance, routine -26 OIl pump -38. 42 operations possible with eng :ne in car -22 op(!r;lIions rC'quiring engine remov,,' -22 iSlOn rings -36 pistons -36. 42 rC(lssembly -40 refining -46 removal -22 removal methods -22

rocker asscmbly -34. 45 spec ifications -23 start· up after overhau l-4 6 sump -34, 44 lappets ;:and pushrods -35 timing covcr -43 timing gears - 38. 43

l orque wrench senings -24 valvcs -46 Engino (3.0 litro) ilO)cill:lr ies • 49. 55 camshalt •. 50. 51. 54 componcnlS e~.-.minlllion lor WC:lr -34. 51 connecting rods -37. 42. 51. 52. 54 cr.-.nkshMt ventoilltion system --53 Crank~hllh -52. 54 Crtlnkshllh pulley -50

c .t1nkshaft rear oil seal -51. 55 cylillde. bores -36. 51 ylinde. hoad s -49. 55 decarbonising -52 descrif)1ion _ 47 dism.-.ntling -29. 49 faull dingnosis -20. 56 lIywhecl/d.ivepl(lte -50. 52 . 55 Iront covc. -50 hOn! plate -54 gudgeon pins -37. 52 IUbricntion system -53 main and big·end bcarings -37, 52 mainten(lnce. routine -48 oil pump -50. 52. 54 operations possible with engine in ca. -48 operations requiring engine .emov,)1 _ 48

piston rings -36. 51 pistons -36. 42. 51, 54 push.ods -35. 51 reassembly -40. 54

refining -56

removal _ 48

removn! methods -48

rocker arms - 49. 51. 55

specifications -25

sump -

50. 55 pppels -35. 50. 51 !lming gears -38. 50. 52. 54 torquo wrcnch sellings -25

.

villvcs -46. 49. 52. 55 Exhaus t syste m remova l and refining -76 EMpnfls ion tank ( coolin g sys tem) removal and refilling -64

F

Facia pilnel t(!mov,)1 and rcfining -188 Fan hub bearing (3.0 lit r e models) .encwal -64

Fan. viscous d rive remov,,1 and refinmg -63 Fnllli (Jingnosis -19 et seq Fault di,)gnosis

lIulOtl1allC lrnnsmrssion -127 tJ,nkmg system -156 Clutch -101 coolmg system -65 clectf1clll system -19. 233 cnlline -20. 56 fuel system cilrbure uor - 85 lucl inlCCho n -85 IHn,hon system -96 mllnu .. 1 !Je.l,hox 122 p.npeller shaft -131 1f!.1f

oved'lIul -

145 remov

rcmoval ilnd rcfilling -2 I 5 Front suspen sio n COIl sprinU removal and refIning -162 duscnp tlon -158 fault dIagnosis -172 h\,bs-161.162 milintenance. routine -161 stabiliscr bar removal and rcfming -163 Strut removal and refilling -162 lorque wrench sellings - 158 track control arm removal and .elilling -164 Fuel (/lid exhaust systems -66 el $eq Fuel filler cap .cmoval and refining -188 Fuo l injection syste m ')CCclcflltor cable -74. 83

air Cleilller -80 deSCri ption - 77 exhaust manifold - 85 fault diagnosis -85 fuel lank. s&nder unit and filler pipe -83 idle mixture ,)djustment -82

procarmanuals.com

Page 202 of 205

inlet manifold - 83

main system components remova l and refilling -80 m~intenilnce, routine -79

specificiltions -67 to rque wrench settings -67 Fuel pump carburettor system cleaning - 68 re moval and refilling - 68

testing -68

fuel inject ion system removal and refining -80 Fuel system (carbureUor) accelera tor cable -74

accelerator shah and pedal - 75 air cleaner - 68

carburetlor -66, 68 to 73

description -67 e~ haust manifold - 76 lault diagnosis -85 luel pump -68 fu el wnk -73, 74 fu el lan k fille r pipe -74 fuel tank sender unit -74 inle l manifold -75 mainte nance, routine -67 specifiCiltions -66 torque wrench senings - 67 Fue l tank cleaning and repai r -74

filler pipe removal and re fi\ling .-74 remova l and refilling -73

sender uni t removal and ref il\in g -74 Fuel tank sender unit (fuel injection models) -83 Fuses

G

general -220 specifica tio ns - 199

Gearbo~ see Manual gearbO K Gudgeon pins - 37. 52

pdbrake adjus tment -153 cable(s} and rod removal and refilling 155 lever removal and refitting -154

warnin g hght switc h -225 Headlights alignment - 212 assembl y: removal and refilling ~ 211 bulbs renewal-2 13 Heater assembly: diSI11(lntting and reassembly 8ehr - 19 4 Smiths standard and heavy duty -196 assembly: removal and ret.tting -193 contlols

adjustmen t -192 removal and refilling ~ 1 93 water valve (heavy dUly heater)

removal and re fitting - 193 History o f tho nlodal-5 Horn faul t tra cing . remova l and refilling -220 Hubs, front

bearings renewal -162 removal. ret lu in g and bearing adjustment -16 1 Iraulic systam (brakes) bleed ing - 152 pipes and hoses removal and refilling -151

Index

Ignition switch and lock -224 Ignition system -87 el seq Ignition sys tem amplrlier module (2 .8 l i\(e mode ls)

r emova l and refilling - 94

condenser (3. 0 litre models) -90 COntact bre aker points (3.0 litre models) - 89

description -88

dis tributo r -

90. 92. 93 fau lt diagnosis -96

firing order -87 mainteMnce. routine -88

spare plugs - 91. 95 speci fications -87

t im ing -94

torque wrench settings -87 In strument cluster ill umina tion switch -224 removal and refitting _ 221 Instrument voltage regulator removal and refilling -226 Interior lamp and bulb

removal and refilling -217

J

Jacking -7

L

lubricants and fluids recommended - 17 lubrication chart - 17 lubrication system

M

2.8 litre engine -39 3.0 litre engi ne -53

Main and big·eOld bO(lrings e~amination and renovation -37, 52 Main bearings (3.0 litro engine) removal - 51 Maintenanco , routine bodywork and fillings d oor ch ec k straps security check - 16 locks, door chec k Straps. tuellilte r C

h andbrake linkage lubricat ion -16, 144

h ydraulic fluid levul check /lap up - 16 . 143 hydraulic flu id renewal -16. 144

line s and hoses check -16

pads ilnd shoes we." check -16 , 14 3 servo check -16 . 144 vacuum hose check -16 Clutch adjustment chock -16, 98 cooling syslem

coolan l leve l chec k/top up -16, 59 coolant renewal -16, 59 drivebelt condl tion/wnsion check -16, 59 leaks check - 59 electrical system

ballery elec tro lyt e leve l cheek /top up - 16. 200 equ ipmen t opera tio n check -16. 200 headlamps cleaning -16

253

'i

'" , '.;.l

•

procarmanuals.com

Page 203 of 205

2"4 Index

",-----------------------------------------------------------------1 -

ligh\s operation check -16 w~she( fluid levels check/lop up - 16, 217, 219

engine

crankcase emission valve renewal -16, 27

fluid leaks check -16 oil i1nd filter change -16, 26 oil filler cap clClIning -16. 26 oil level check/lop up -16 1I;llvo clearances check/adjust -16. 46

exhaust system condition check -16

fuel sySlCm

removlll and relltting lldjustllble exter ior -192 interior -192

Oil pump

p

28 Iotre engine dismantling. examination and re~sselllhly -38 ref in in 9 -42 3 0 li tre englllc dismantling. eX~lllinmion ilnd reass embly .-52 [elit\lng -54 removill 50

Pedal ,1cceler,ltOr 75 bra k e · 152 clutch -101 Pisto n an d connec ting rods ref,nin\j -42. 51 Pistons and pisto n rin\js exanllna\lon ,1nd rcoova\lon 36,51 Pi sto ns. connecting rod s il11d bearin\js (3.0 litre cngine) [lmlov,11 51 Propeller shaft 128 d s, .'r/ Prop elle r shaft cenlre bcarln!J r()"l]w~1 12!J

descrip1l011 28 I"ul l (i iaunosis - 131 removat and rel,UlI1U -128 10rque wrench seHlIlgs -128 univers~1 10lllts inspection 130 Pushrods 35< 51

R

Rndi,lto r rel11ov~I, Inspcctoon, cie

Rear lamp and b ulb removal and refttling - 216 Rear number plilte lamp and bulb removal ilnd relilling -216 R ear su spension description - 158

procarmanuals.com

Page 204 of 205

fault diagnosis -172 leaf spling .emoval. bush renewal and refitting -165 maintllnance. louline -161 shock absorber remoyal and refitting -165 stabiliser bar removal and refitting -165 lorque wrenCh settings -158 R"ays -225 Rep.ir procedures, general - 9

Rocker e rms (3.0 litre engine) examinat ion and renovation -51 removal - 49 Rocker arms and coverl (3.0 litre engine) ref itting -55 Rocker assembly (2.8 litre engine) dismantling. examina tion and reassembly -34 Routine maintenance stt Maintenance. routine

5

Safety precautions - 12 Seat belts -191 Seats .emoval and refining -192 Sidelight bulb renewal -213 Spare parta buying -8

to carry in ca. - 19 Spark p lugs conditions (colour) -91 lemoval. servicing and .elilling -95 Speedometer cable renewal - 226 Stabiliur bar Iront -163 rear -165 Starter moto r

description -207

d ismant ling and reassembly -207

removal and refi tting -207 testing on engine -207 Steering column removal. overhaul and refitt ino -170 desc.iption -158 faull diagnosis -172 f,on t wheel alignmenl ~nd steering angles -171 gear (manual)

ove,haul and adjustment -166 removal and refittin g -166 maintenance. rouline -161 power steering bleeding -168 gear removal and refitting -168

pump femoval and refining - 168

specifications _ 157 torque wlench senings -158 track rod end balljoint renewal-167

whea' removal and refitt ing -168 Sump 2.8 litra engine

refining -44

removal and refining with engine in car -34 3.0 litre engine refitting -55 removal -50 Sunroof bracket and dr ive assembly lemoval and refitting -191 panel adjustments -189 removal and refining _ 190 Suspension lfnd steering _ 15 7 tl seq Suspension see Front suspension Imd Re ar suspension jtches removal and relining

Index

T

central facia - 225

door p illar - 224 handbrake warning light _ 225 hazard warning -223

ignition -224

instr um

ent cluster illum ination _ 224 light and windscreen wiper (Series II) -225 load sp':)ce lamp -225 steerin g column multi-Iunction -224

s top lamp - 152

Tailgate priv ate lock removal and relining -187 .emoval and refilling -187 striker plate removal and relin ing - 188 wnsher

nozzle removal and refitting -217

pump rllmov31 and refitting -217 window glass removal and relitting -180 wiper mOlOr and linkage remoyal and refitting -217 Tappets (3.0 litre engine) remoyal -50 Tappets and push rods el

care and maintenance -171 presswes -158 size -15 8

Underframe

maintenance -16. 176 Upholstery maintenance -176

v

Vacuum servo unit (braking system) description -156 lemov~! and refining -156 Valves clearances checking and adjustment -46 . 55 Valves (3.0 titre engine) removat -49 Valves and va lv e seats (3.0 litre engine) examination and renovation -52 Vehicle identification numbers - 8

255

procarmanuals.com