clutch FORD CAPRI 1974 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 4 of 205

)

Contents

Introductory pages

About th is manual 5

Introduction to the Capri VB 5

General dimensions, weights and capacities 6

Jacking and towing 7

Buying spare P M 'S and vehicle identification numb ers 8

G en eral rep air procedures 9

Tools and workrllU facilIties 10

Safety f irs t! 12

Routine main tenance

Recommended lullricants and flUids

Conv ersion !,I CIOIS

F aull dlilgn osis

Chapter 1

EIlUlne

C[Hlple r 2

Coolin\) system

Ch

Chapter 4

Ignition sys!Cm

Chapter 5

Clutch

Chllptcr 6

Manllill IJCil,hox a nd 'llltonlil!'!.: lrililsn'IS~IOII

Chopler 7

Propeller shalt

Ch(liltcr 8

IlCilr ilxl<:

Chapter 9

l3ulklilU sy~lem

Chapter 10

Suspension ilnd SluCIIIIU

Chapter 1 1

Bodyw or k and trl1il19S

Chapter 12

Electrical s y s!Cm

In de x

13

17

18

19

23

57

66

87

"

102

12 8

132

142

1 [is

171

196

248

procarmanuals.com

Page 9 of 205

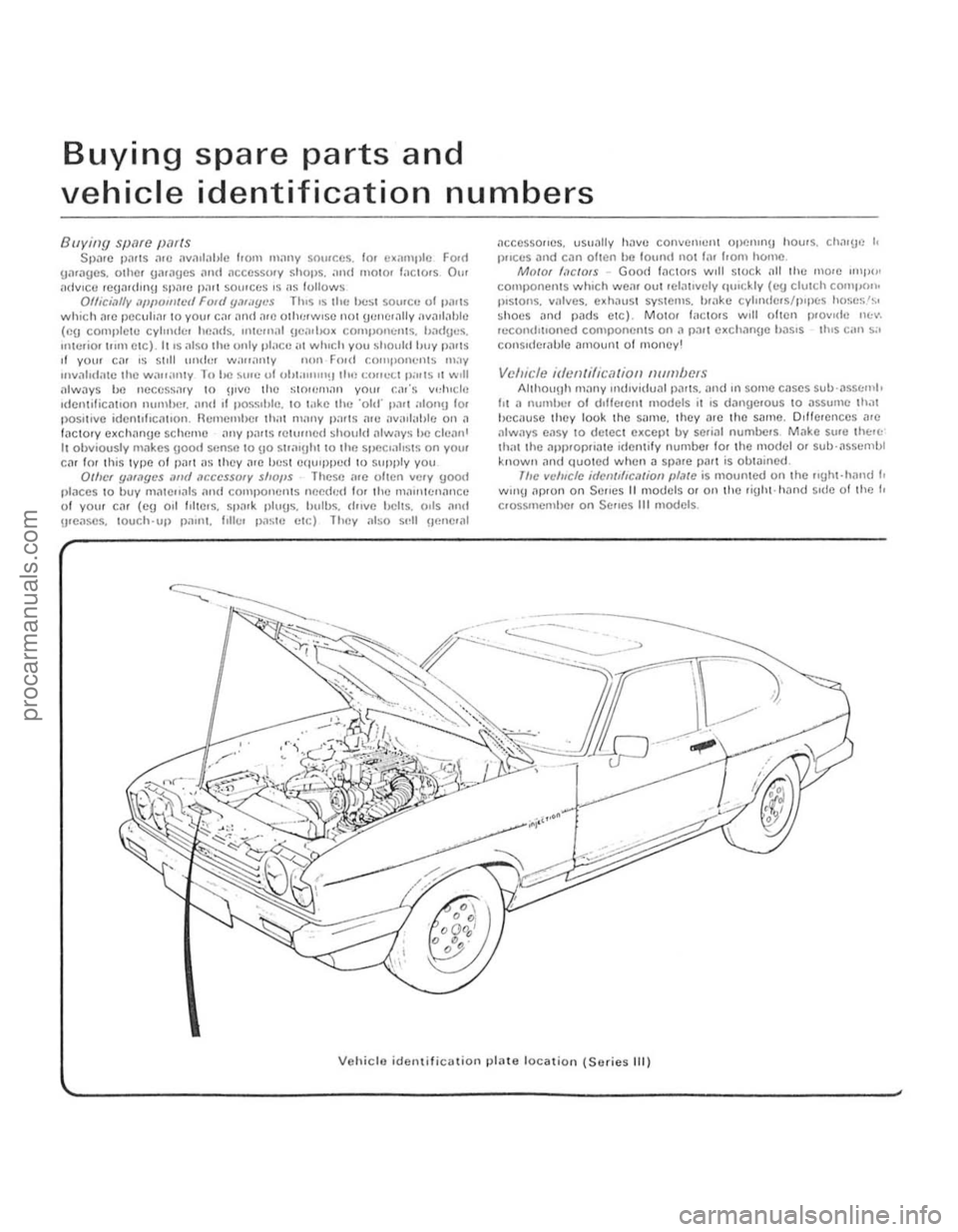

Buying spare parts and

vehicle identification numbers

Bllyillg spare parts Sp;'1rc p"rlS ;lre ilwul.1!Jlc from momy sources. Jo. exam ple FOHI uar"gcs. oliler gil':lgCS ,-mtl ncccssu.y shOIIS. im(i mOlor ';.elms 0", a

I lOSII.ve idenlil leallol1, Bumcml)C. ,h;'1 .,,;,ny p;rrlS illt) ;'Yirrl;.hle on a InelOry exclHlnge schelllC illly PililS .elurne(1 should nlw,1ys he clennl II obviously makes oood snnse 10 go S\""Uhl \0 Ihn SIICel.1hsts on you. CM lor this Iype 01 PMI as Ihey n.e besl equipped Il) supply you O/hef yM,'yes Im.1 m:cesSOlr shops These a.e ollen ye'Y goot! plnces 10 buy Illate".lls al1

ileccssoflcs, uSlIillly l \.lye conyenlent opcnUlU hours, Ch.11Ue I, prices and can often be lound nOI la. hom home MOlor 1,7C(0IS ~ Good lacto.s will stock illl Ihe mOle Illlp,,, comllOnen lS which wea. oul .elilhycly qUI ckly ((..'9 Clutch COIllI,cm. PISIOI1S. villyes. e~hilusl systems. IJr;lku cyhnlie

Vehicle itlenlificc1l;OIl numbers Altholl!lh milny uuhviduill pa.ls. 1md ill some cases sub-ass/:mlo III a lIU1nlJm 01 dlflerent models II IS dallge,ou$ 10 a ssUllle tll;1 \JCCilU5e they look the 5,lIn e, Ihey a.e the same. Dillelences n.e nlwilys e.1sy 10 detect excepl l.Iy serial numtJCrs Make su.e the.e th;otille ilPI),op"ale identify number for the mode! or suh-asseml.lt known .1n(l Quoled when a spare PMt is obtained. '"c v(!/m;fc irlCl!lrfrc.lfioll "IMe is mounted on the rIght-hand tr Will\! ilpron on SCries II models or on the righl·hand Side of Ihe f, Cfossmemher on Selles III models.

Vehiclo ident ifictltion philO location (Series III)

procarmanuals.com

Page 15 of 205

14,-------------------------------------------------------------

"

-. . . { .' ~I ~ " : . ',\' ,.~ ~ . . -,. ','. ;,:! ---. , ." .. ~

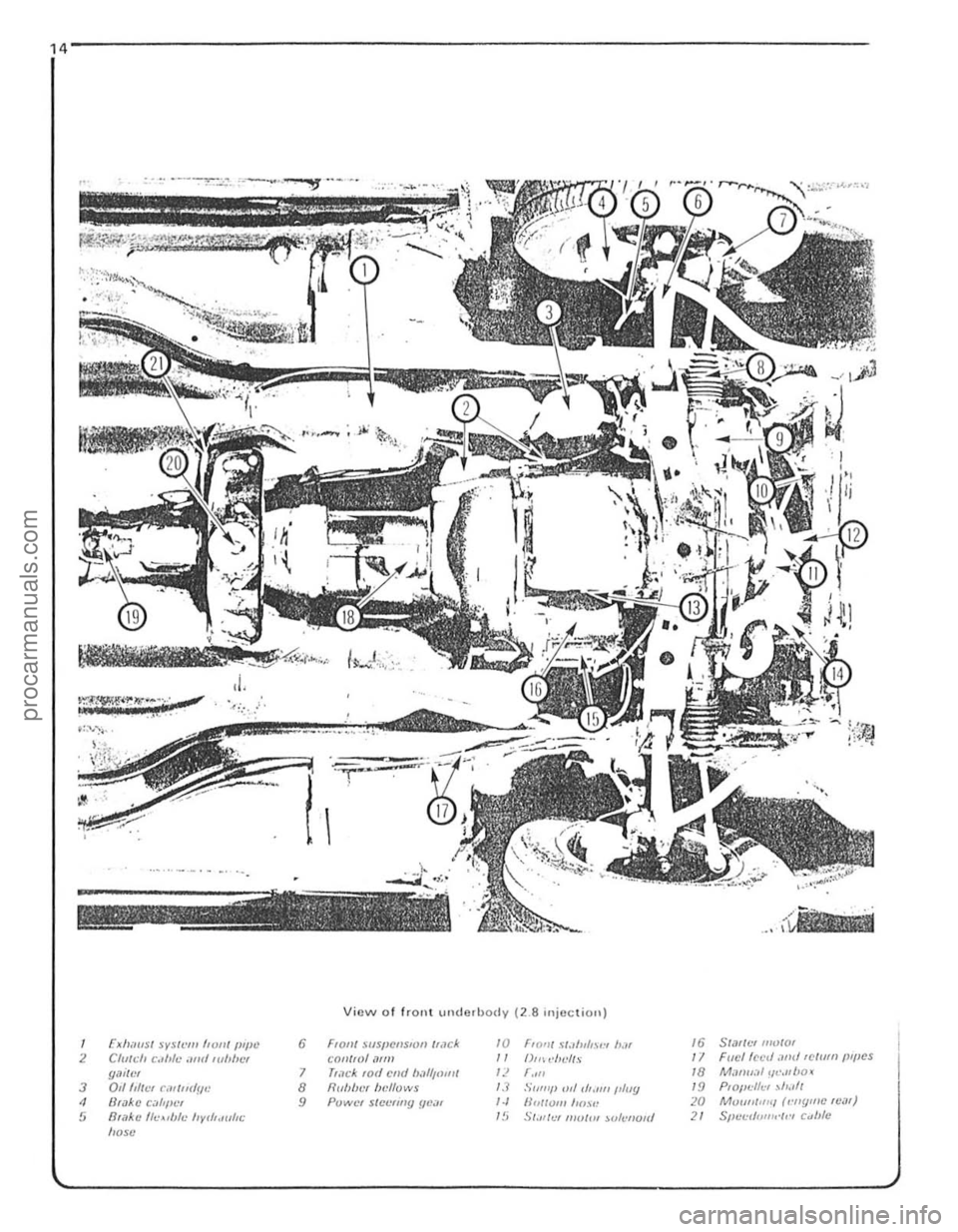

View o f frOll t undo. body (2 _8 injection)

,

1

3 4 ,

Exhilllsl sys/t'''' {,uIII II'Pol Clutch c.,hI,· ,w'/mi!lJt'f g.li/l:( Od /rU,H Cd,llIdy" Brake c.l/,/uN OWkt· fie.d)l" "yllt,IIII,,; hese

6

7 8 9

F,QII! SIl$/lellSIOII {""Ie t 'ollitolmm Tr,lt'1!. (0(/ emf IMII/mlll RulJ/"" IJdfows Pt)Wf!( s/f!f!,lIIg !leal

'0 Fam l SI",,,II.\I." " .l(

" f)1II d}d{.~

" r.", .., Sump "" ,h,,,,, Iduy , ., U!lIIOIII 1m,,...

'" " S(.JI/"', 11/(1/01' lV/,'/w/11

16 SMile, "'''IQI 17 Fuel !ct-" ,1m/te/llm ,)'pes /8 M,1"'1.1I,!",,,v ox 19 Plopell,·, _,,,,,11

20 MUI"'('''', ("IIYllle IC,ll) 21 511<:1:1/"""

procarmanuals.com

Page 43 of 205

42 Chapter 1 Engine

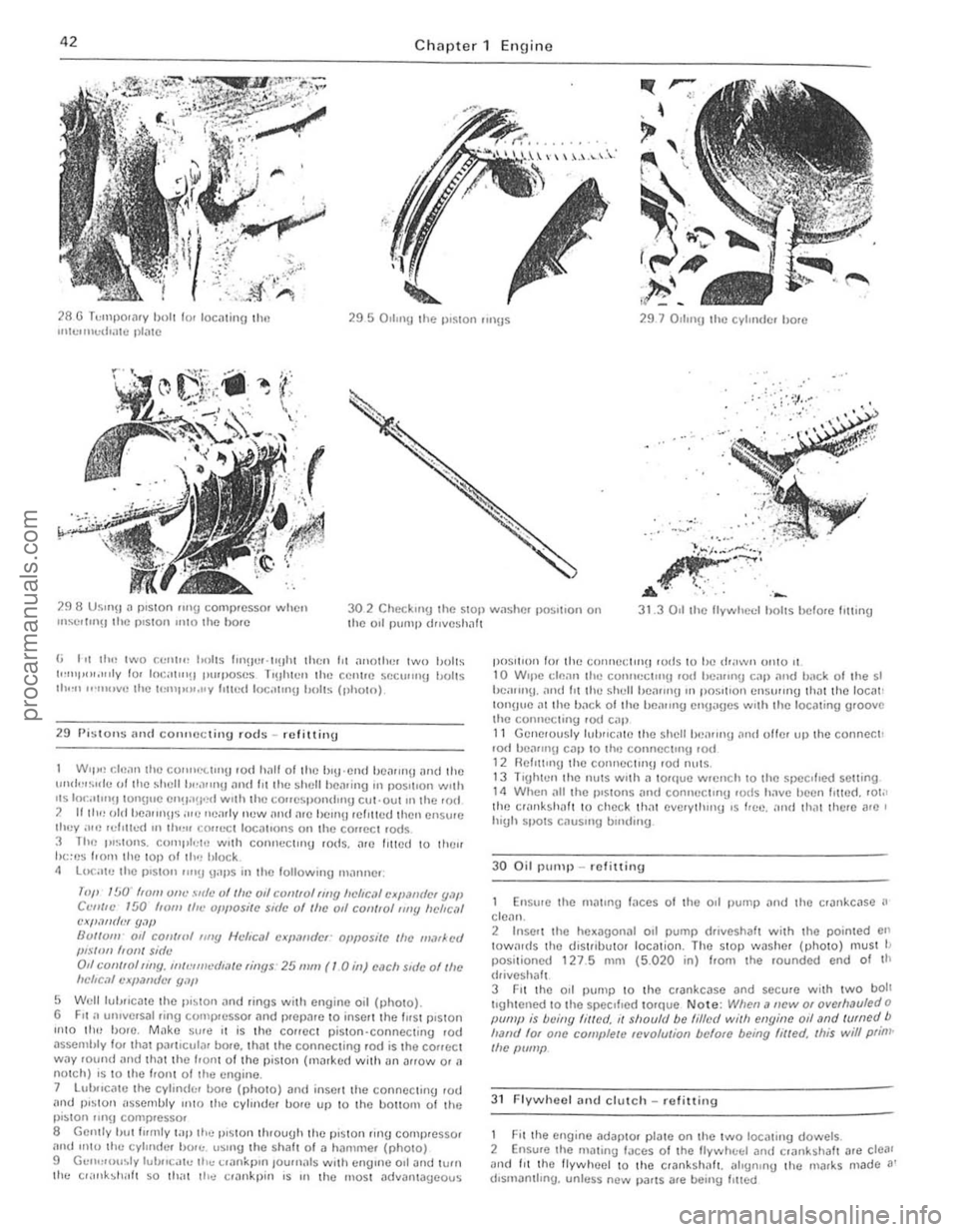

28 G TempO'i1'y holl 101 IOC;l1inO the mlc""t:thiUo: plale 29 5 0'1111(1 the )l'~10n linUS 29 7 0,11I1{J the cyllnde. hOlo

";; '. '''' . :~ .,

.. : .

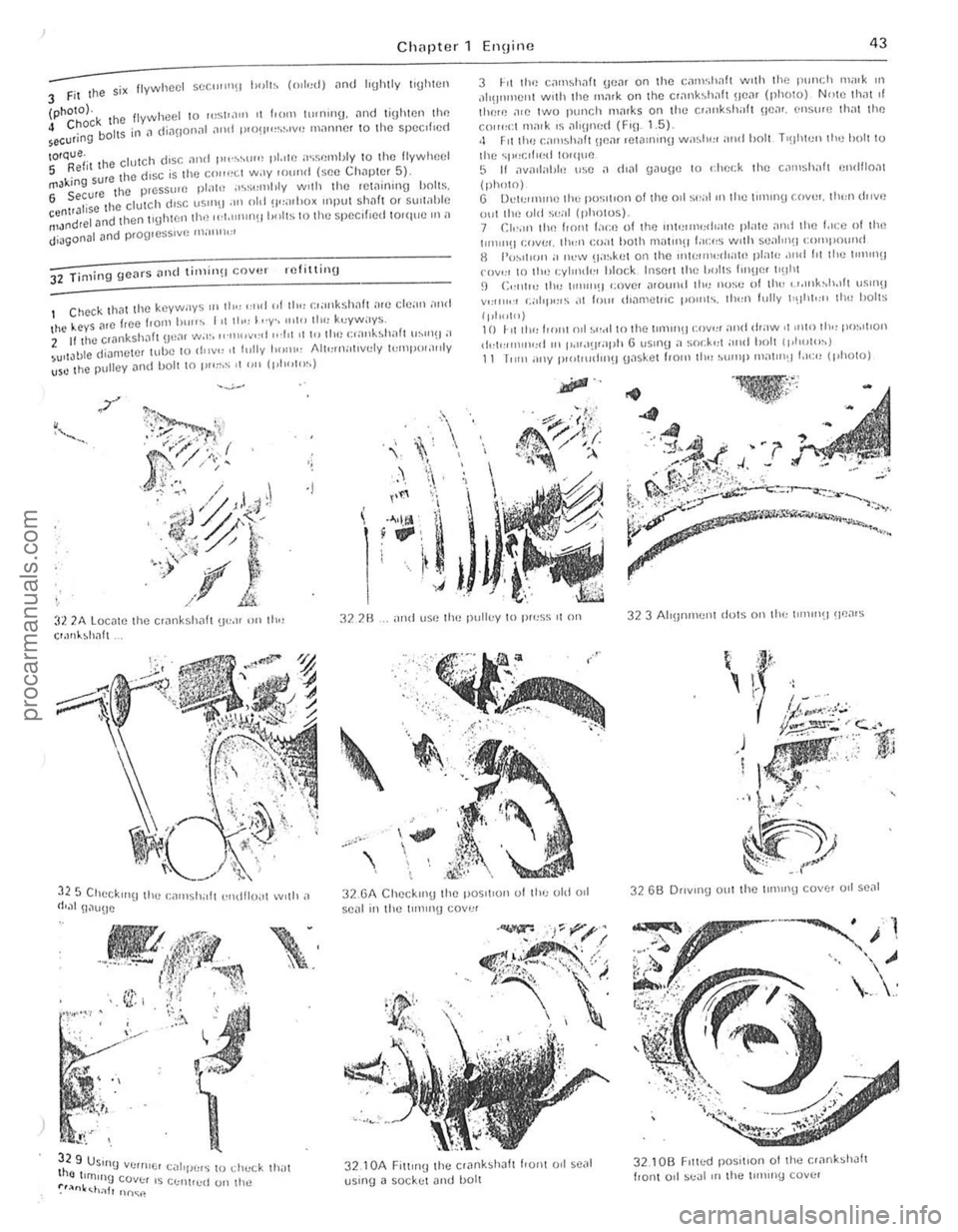

..-2 9 8 US'''H (I plSl0n "l1g compressor when uiSerhn!llhc p,ston "110 the hore 30 2 Chet;kln~1 the Sial) washer I)OS'['OIl on the 0,1 pump d""csh"fl 31.3 O,llhe tlywheel holls bel o re ',",ng

(j 1,1 II", two f.t:"11'~ holts ItI1!jl.:r·"!lhl then 101 ;Hlorlm' two holls t'''''IHH""ly 1o. IIU:"I"'!I purposes T'!Jhtcli the CCIllle sec"""!J hails th.·" It''''"Yll the '"ml""'''Y Io,u "d 1000,umU bulh (photo)

29 P istons Hnd COIH1(!cli"g rods -refitting

WI, ... , ('.101,1" the COIU1I;:(.I,n\l ,ad h"U of tll c !l0U·end bO il'lIlll 1111d rh e IInde,sulu ollh(l ~hcll h .... "l1y ;lnd IIIIhe sh ell hc"rlllU "' pO$IIIOn WIth It S Im :, IIUI!llonuuc OIl!"'!I'!!! with the COH CSpo tUhnU CU[-OU1 ",the lad :1 If II", old hC.l.II'!)S 'lrllnea.ly n.;w nlld nrc hell'U re!ltu:d Ih en ensure Ihey inn ,dlll"d III Ih"" cO"I.'Cr 1000.UioilS on the COUOCI ,ods :1 The 1%lOn5 , c:;()n ll'l",,~ With c:;onm;c:;t"'u ,ods. mo f,tted 10 the" IH,::es from th(l lOP 01 Ih'! block

'1 luc ilte the p'stoll ""u Hap s III th e 101i0w inU rllilnnCI .

TOil 1['0' fr Olll Ollt· sir/e of /l,e Oil conl,o l 'IllY "ehc.1/ t'xf/8mle. y,l!) Cellt", 150 /tom lire O/Jilosi/e SI(/e of fire Oil cOII(101 ""Y l,el,cM cx,r.lnr/

Bo/lom or! cOll/,,,1 ""9 HeI,cal eXI',lIIdel' 01l 110s,/ e I/IC /II,lfAed {J,S/OII "on / side

ad cOIl/,OI ''''y, III/':"llrHI',J/c lings 25 film (1 0 ill) c.,,1/ sie/e of tllC /Jchcall;xl1amh'l 9,7/'

5 Well lulJllc~le Ihe pl~lon iln d ring s w il h e ngine oil (phOlo).

6 Fit n unlve.salring compressor Imd I>'epalc 10 insell Ihe fllsl p'Slo n IIItO IIw ho,e. Mnke sure 11 is Ihe corrcct piSlon·conneClinu lod ilSse'l.hly 101 Ihill par',culil' boro. Ihillthe c onnecting lad is Iho COII(.'(:I Wily .ound and th3tthe fron t of Ihe piston (mmkcd with an arro w 01 11 notch) ,s 10 Ihe fronl ollhe engine. 7 Lul )l'Ciltc Ihe Cylmd,:r \)o,e (photo) and inserllhe conncCllIlU ro d a"d p, ston nsse ",!;ly ,nlO Ihe cylinder !loro up 10 Ihe botlom of the pislon IIIllJ com plessor 8 Genlly hUI f,,"'ly Illp Ih~ l/ls!On Ihrough Ihe piston "ng compressor nllu "'I u Ihe cyhnd er 1)(.1'''' uSlI'g Iho shah 01 a hammer (phOtO) 9 G".""nu~ly luh",c"I" 11,,, ,,"ank,),,) 10U"",ls with engllle 0,1 JII{ltu.n Ille ClI,nbh;,lt so 11\1,1 III" e'

30 Oil pump -re fitting

Ensure the l1lillmg lilces 01 Ihe 0,1 pump ;Jnd Ihe clankcase n cle'lIl . 2 Inse.1 the hexilgo nal 0.1 pum p drivesh"fl wilh Ihe pointed en lowil,ds the <1ist"bulor localion. The SlOP washer (photo) must IJ posil ioned 127.5 mm (5.020 in) foom the lounded end 01 t h driveshilll 3 FII th o od pump 10 tho cfankcose and secure wilh t wO boll "9hle llcd to Ihe spec,f,ed 1 0'(lUe N ote: When a flew or overhaoled 0 pump is bl!illY IiI/cd. II should be /illed wilh enyine Olll1l1d lurned . b hand 101 om: comple/e ,evolution before being fil/ed. I his will po"" /he plm.p

3 1 F lywheel and clutch _ refilling

1 Fir Ihe engino IIdap lol pla le on Ihe twO localing dowels 2 Ensure Ihe milling faces of Ihe lIywhc(;1 and crank shaft arc cleal

,lnd fit t he flywh eel 10 tho Cliln kshnll. aliUn",U Ihe nla,ks made ii' (hsrn;Jnthny. unless n ew l>arlS a.e being lilted

procarmanuals.com

Page 44 of 205

)

Ch

4 Chock the secur ing boilS

flywheel 10 "'~1'.111' ,I fro", tll,nlll\J. <1nd tighlen Ihe in il (li<1110I1ill <111(1 plO!i'''~~''VU l11<1ntJer 10 the speclf,ed

IOf~:iil l he clutch (Iosf: ilnd p"'~"'l"" pl.rle iI~s"mbly 10 Ihe flywheel 5 . ,ure Ihe disc ,s I he co"",:1 w.,y lo"nd (see Ch<1plor 5) rTlJk,ng . 6 Secure the pr~ssum pl"h~ "~~I:mhly Wllh the ,ct.1U1Ing boIlS. enl'Jlise Ille clulch dISC "Sill\) .11' old !i,,,"I>OX ,npul slwh 0' sul\ahle ~1Jnd,el Jnd thel1llghten Ih,~ ",I""'II1(II,,,IIS to Ihe sp~clfl()d tOlque III

32 TiOling geMS ilild li,nin(1 COVIH refitting

I Check Ih

';

. ,

. -\.

...

I't'

3 hI Ih'~ c,"n~h

,111(I'"nOIlI with the mark on tho cr,ll1bh.1ft HO

(1'1",1") 10 1 " 1 11,,, f'''111 n,l ~(, .. I tn the 11111111(j .:ov"r .111tl .haw 01 11,10 lh" 1'()~'IIOI\ ,h.I""))II,,,

~ ..

:U 'lA Loc"lo the cr,lnksh<1fl U", II 01 111" e ,.",hhilh

322B ,. ,HId uSO Ihc pull"y In pruss It on 323 Alryn"".",t d01S 0" lhu III\lII1~) \le

~ .. ,

..,

, ,

., ' ,

32 .61 Checklllg Ihe pOS,I'Oli of Ihu old 0,1 se

32 6B OflVII1!j 0111 the ""'lIlg COV(:r 0,1 se<11

32. 10B F,tluU posItion o f Ihe e

procarmanuals.com

Page 51 of 205

\.

50 C hapter 1 Engine

51 T llp pcts -removat

Remove the 1

5 2 Crnnksh

4 Wilhdraw Ih~ Wood'uH key hom the end of th(! CllInk5hah and pl,lC,(! " w'lh Ihe pulley. til(! holl alld its washer 5 The C'.1nk~h;)h p"lIey m;oy he ICliloved wilh Ihe eno,,,e III Ihe C:\I. hilt ,I 'S IIIsl tU!Ccss;o,y 10 ,emove Ihe ',ld'illO' :lI1d thc rh'vehelts

53 Flyw heel -remov[ll

P,even llhe flywhcel hum 101m",!) by FHlHllln\J Ihe lin!) !lcal ;ollain~1 ;In imp.ovised SIOI). 2 On nlodels willi nl;lnu:ol 1I;o"$""S5'01i. Icmove Ihe Clulch plessure 1)1;lle and disc :os described in Ch:op!Cr 5. 3 Rele.lse Ihe s,~ bolts secu.in!1 Ihe flywheel 10 Ihe CllInksh;oll .lnd lefl\OVC I,ve of Ihenl.

4 Whilc supporling Ihe tJywheel III pl;ll':e .• emove Ihc Sixlh hoi' ,'11d Iolt Ihe lIywheel otl c;o,elully. so 111:01 Ihe m;lllllg su.lilccs of flywheel [lild c.;onksh;oit ;o.e 1101 dllm,'ged

5 4 Sump -removal

W"h lhe '''1(1'''') oul fli the e,". CII~"'C Ihal Ihe sump has 1o('CIl d,amvd ;ond then lilln the engll1C ()VCI so tl1011 Ihe sump's U l)I)ClmOSI F" wOOr1CII bloc"s tn Slll)lmrl tim en!l'ne 'n Ih,s POSIIiOIl . 2 Remove 11m h()IIS seCUlln( J the oil Sump 10 Ihe CI.1nkColSe o1nd rClllOVO Ihe SUll1p_ 11 the sump IS stuck 10 the c r;ollkcasc . II should be reh;lIsctl hy 1"'SII1\1 olle SIde wllh 11 sClcw drover. 3 To !Cn,ovtl .Ile sump wllh Ihc CIIU"HJ Hl tloe eM. 11151 IcnlUVC Ihe

d'l)S llck :ond d'SCOIlII(!Ct Ihe hatlery 4 Remove Ihe luur holts ;ond lou. Ch,)S ;ond dCI.leh Ihe OIl splash

shIeld.

5 Pl;oce a Con'"lIlcr 01 at lellst 6lttre (106 JlIllI) cal,,-.elly heneath Ihe SUml). remove Ihe d,ain pl\l(l ;ond d,aln Iha sump. Reflilhe d.am plull and (11)hlen II 10 Ihe 10lqUO wrench seilIng gtven In the SIXlClflC;JIIons G Del:och the engme fubl)CI mounllngs, by lemovlng the" nuts an(1 w:oshe!s. 7 Romove the ciampinI) bolt hom the tal) ;oml bOIlOI11 endS 01 the Steellll!.) intellnediate sh(lil. rush Ihe lap end 0 1 Ihe shlilt upwollds unlll Ihe lowcr ell(1 Clin be dlsenga\led 8 PI

55 FrOllt cover -removlll

If Ihe engHle IS In the CM. II wllllnSI he necessaly 10 dlsc()nneC lthe l!allefY. drll'" 11m coolll1\) sys tem ;ond lel110lle Iho radiillor. 2 loosen the alternalol mounllrlg bOilS. SWlrlg the aitemalor downwilids .0w:Olds the cyltnder block and lemove Ihe drive belt

3 Remove the bolt Irom the cenlro of Ihe cooling Ian .. nd pull (

Ian and clutch assembly. 4 Remove Ihc boil an d wilsher from Ihe centre of the cran pulley .. nd I hen use ., claw puller 10 drilw Ihe I)ulley ofllhe sha nOI anempllO lelle, Ihe pulley ott. t)Ccause Ihis may .esull in dllm. t he Irani covcr.

5 Rcmove the si~ bolts secuung Ihe sump 1 0 Ihe honl cover an, t he cleven bolts securing Ihe I ront cover 10 the Cylllldcl block . G lIlt Ihe cover ott ;ond remove Ihe g;oskel.

5 6 Tillling gears -relllov;ol

1 Remove the honl cover 10 e xpose Ihe IImlnu ueo1/S 2 Removc Ihe bolt and washer sccu"I1IJ Ihe fat!Je gear I,

cn,nsIl1'll t. IhCIi pull.he geill ol! and Icmovc tho Woodllll! key. 3 Dlllw the ileal hOI11 Ihe cr;onk!;h:oh am! remove Ihe Wood'utl

57 Carllshaft -r erllov;ol

The camsh:olt nwy be rCUlovfld wllh the cll!JlIle 1<1 Ihe car •• lollowlng p!Cpol.aloIY wo,k IS co1med out. 2 0,,,,,. Ihe cootong syStelll nnd .emove Ihe .ad,mOl 3 Dlsconneci the ballery. 1 Remove Iho sp.1lk pili!! IC.1ds 1,om Ihe spalk 11lugs. 5 D,s':Ol

eCI the le;ods I,ull' Ihe :l lt'!11\.110r. remove Ihc allelllalo·

l i S (hivebell. G Undo "nd rem ovC tho screws S()CIIIII1U Ihe .0dcl covers and It Ihe rocke. covels and Iheir ilaskcls 7 Sincken lhe nulS secullnu the rocker ~"ns unlollhe locke' arm, he swung aside . 8 Remove the pushrods. idenlllylllg each one as .. IS lemoved. so 1 Ciln be rell1l ed in Ihe same position 9 Remove the cylmde. heads,

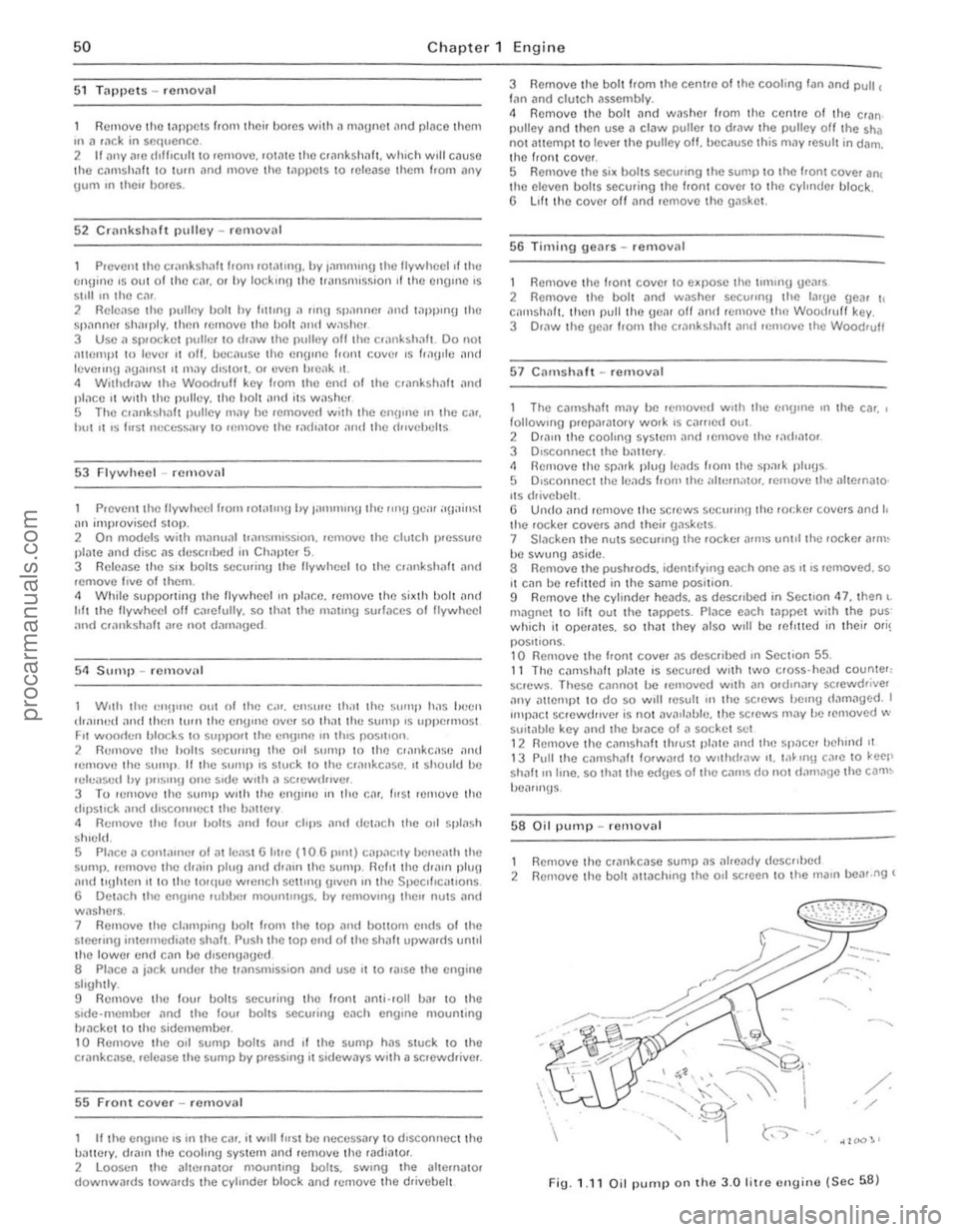

58 O il pump -r e m oval

Remove Ihe crill1kc:ose sump as ;olleady dcsc"hed 1 2 Remove Ihe boll aUJchmg the 011 scrcen 10 the Illalll 00111.119 (

/ /

Fig. 1.11 Oil pump o n tho 3.0 f itre efluill(l (Se c 58)

F

procarmanuals.com

Page 57 of 205

56 Chapter 1 Engine

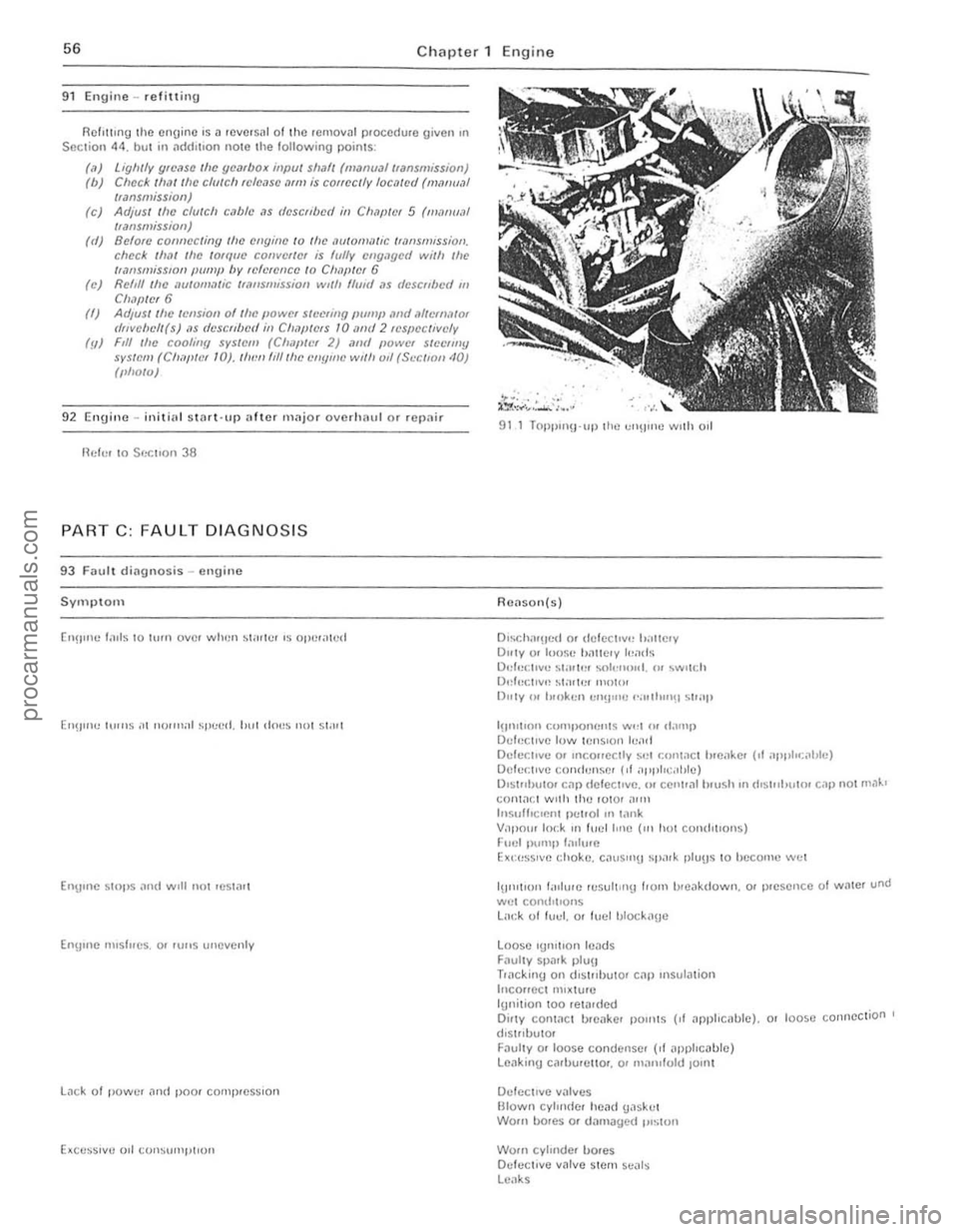

91 Engine -refilting

Rcf'tlIng the engine is a rCllcrsnl alth e removJI procedure given In Section 44. bUI in addrhon note the following 1)O;I1IS:

(,,) Ugh/I)' 9(0"50 Ihe ycar/)QIC ;npu{ Sh,ll{ (m,lI/v.,1 transmission) (b) Check tlMllhe dlileh fc/c,He .7Im is cOIf(!clly loentcd (m,lllu,)1 (fiJn$miSS;OIl) (e) Adiusl (he clutch cClbfll ,15 (/(!sCllbcri ill Clwp/fN 5 (m,mu,,1 flilMmission) (d) BelOfc COfl/weliny the engine /0 {I!(! ,W{omMIC {MOSl/tllSion check 111M /he /O((/lle con vet/or is fully 01l9,19N/ wilh lite /f,lfI smiSSI()II pump by reh'/(!IICa to CIWp/Of 6 (e) Refll' file ,)II/QIII,llie ("'''lllltHiOIl WillI 1141/11 ,15 dcsCfI/)t'd III Ch,lpWI 6 (/) Ad/usllhe lellsioll 01 the IJowor steeling IIlIfIIll MId .11/emMa. !lnvalid/(s) ,15 d(!scfI/)ml in Ch,?pICIS 10 i/lld 2 f(!SpcC/lv(!/y (!I) Fill Ihc cooJillfl sys/cm (el,.l/'/C' 2) ,md /lOW,!' Slcc/IIIY

SVS/l:tII (ella,'/Cf 10), 1111:11 fIIlllle mlylllc Willi od (SeC/lOll ti~) ("ho/Q)

92 E n £line -initial start-u p after major overlwul or re pair

Hel",

10 Sect Ion 38

PART C, FAULT D IAGNOSIS

93 Faull diagnosis -engine

Sympto m

(n!Jlne f.111s to tllm OVCI whim ~t;llt", IS Opc,;) lcd

Enll"n) lUIIIS ill no.",al ~pced. hili dous not 51,IIt

E"u'ne SlOp s ilnd Will not 'estill t

Enll'Ile

.",slucs, O. lUll S unevenly

L~ck of powc. illlt! poo, comp.esslo ll

91 1 T OPPln! 1 lIl) tile ""'II"") wIth od

ReilSOn(S)

DI~ch.1'Hed 01 delec tlv" 1o:,lle.y

Dilly 01 lI)os" lI.11tc.y le.,ds

O"f '!I:llve sl; IIt", soL"",,,, I. ,II SW'II: " Odl'ctlvl' s lillte. "UIIOf

Dilly 0 ' III"ken e"!I"IC "'''1111''11 SIt;IP

1\I1'"111 ':Ol1lpOlu",ts Will (If ,1;""1) DefectIve low te nSIOIi le"d Detective o. InCOllec,ly :,,, 1 ,:"III"C I h,e;oke. (,I "PI.I,,:a"fe)

Oe f"ctlve condense. (If '11'lllIo,;.,"lc) O'st"hulor cal) defec tIve. or celltral h,ush HI (irs l,,"uto ' cap Ilot m,,~, COfltilf.t w'th th e .otor a"n Ifls.ulhc,em petrol "' tilllk V.1pOOf Iud '11 luel hlle (," hut cOl1{lIuolls)

Fuet pump I:uhlfe E~O:Hs51ve c hoke, caus,,,u spillk pluUs 10 hccolllt) wet

IU"I1I(HI 1,,,IUle result Ill!.! 110111 b.cakdown. or prescncc o t w;'1ler \,Inti w(: 1 cOnthllOIlS l:n:k 1.11 tud. at luel IJlock, l!Je

loose 19111tlon Icads F(luIIV s J)n. k 1)Iuli T'(1ckin£l on d,slllbuto. cnjl IIlsuliltion

InCOIICCll11lxtu'e 'Ullilion 100 telilldcd Dilly con[,lCI blcakc. POlll1S (,I ajlplPcablc). or loose connection'

D"lectlve v.,lves Blown cyIP"de . head £lasket

WOlll bo.es OJ dilm ilye

Page 98 of 205

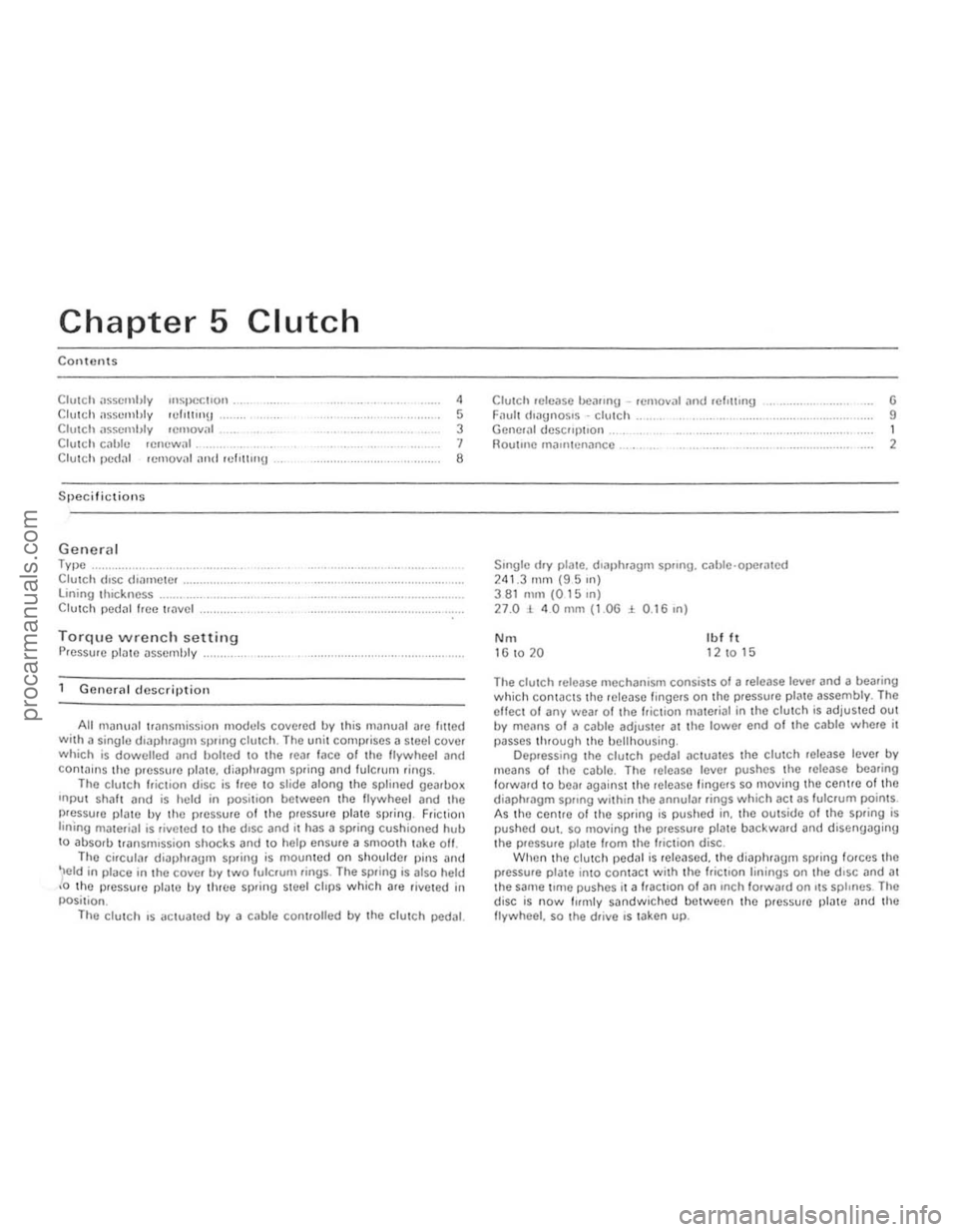

Chapter 5

Contents

CIUICh il$scmhty '"SIJoCcl'Qn . Clu\(;11 assembly 'Urn!!ll!) Clutch llsscmhly lemOY," C lutc h cilhle .efluwal._

Clutch

Clutch !Jedal rClllovnl illld ,cflltl"U

Specifictions

Genera l Type ..... Clutch (lise (hamClcr lining tlnckncss Clutch pedal hcc "

Gene.al description

,

5 3 1 8

All manu:!1 transmission madllis covered by this manual nrc lilted Wilh a singlo dl3phrilgll SpllJlg clutch. The unit COlllt)riscs il steel cover which is dowelled and bolted to the tear lace of the lIywheci ilnd conla i.lS the pressure plnte. diaphragm spring and fulCrum .ings . The clutc h " iClio n disc is

ee to slice along the splineJ gearllox

Inpu t Shillt and is held in posi t,on between the flywheel and the pressure plate by the pressure of the pressure plate spring , Friction linIng materiill is riveled 10 the d,sc and II has a spring cushioned hull to absorb transmission shocks and to help ensure a smoo th take oft. The circular diaphrilUm spring is mounted on shoulder pins ilnd

'Ield in place in the cover b.,. two fulcrum rings . The spring is also held ,0 th e pressure platc by three spling steel clips which are rive ted in

posi tion .

The

clu tC h ,s aCluated b.,. a cable controlled b.,. the clulCh pedal.

Clutch '0Ie,150 bCilfl"U -remova' and wl,u,"g Filult (ioilU"OS'S -clutch Generill descllptlon . noutlilc rn,untenanco .

SlIlgle (Iry plate. dlill)hragm sprong. cilhle ·ope.ated 241,3 rnm (95 Ill) 381 nun (0 15 In) 27.01 40mm (1.OG:i 0 .16,n)

No. Ib l It 16 to 20 12 10 15

G 9 1 2

The clutch release mechanism consists 01 a .elease leve. and a bearing which conwcts the lelease Imgers on the pressure plilte assembl.,.. The eHect of an.,. wear of the friction ma terial in the clutch is adjuSled out b.,. means 01 a cable adjuster at the lowel end 01 the cable where it

passes through the bell housing .

Dep.ess lng the clutch pedal actuates the clutch release leve. b.,. means of the cable . The lelease level pushes the lelease bearing

forward to bear against thO release l ingels so moving the centre of the diaphf()gm sprong within the annular rings which act as fulcrum points.

A s th e centrO of thO spring is pushed in. the outside of the Spling is pushed OUI. so Illoving Ihe pressure plme backward and disengaging the p.essu.e plate flom the /tielion disc . When the Clutch pedJI is Icleased. the diaptllaglll spring torces the plessule plate into contac t w ith the frictIon linings on the d,sc and at the saIne t,me pushes it a flactlon 01 an InCh fOlward on I\S splines . The

disc is now fuml.,. sandwic h ed between the plcsswe plnte Dnd the

flywheel. so the d.ive IS laken up.

procarmanuals.com

Page 99 of 205

Chapter 5 Clutch

?

4 7

/ ,

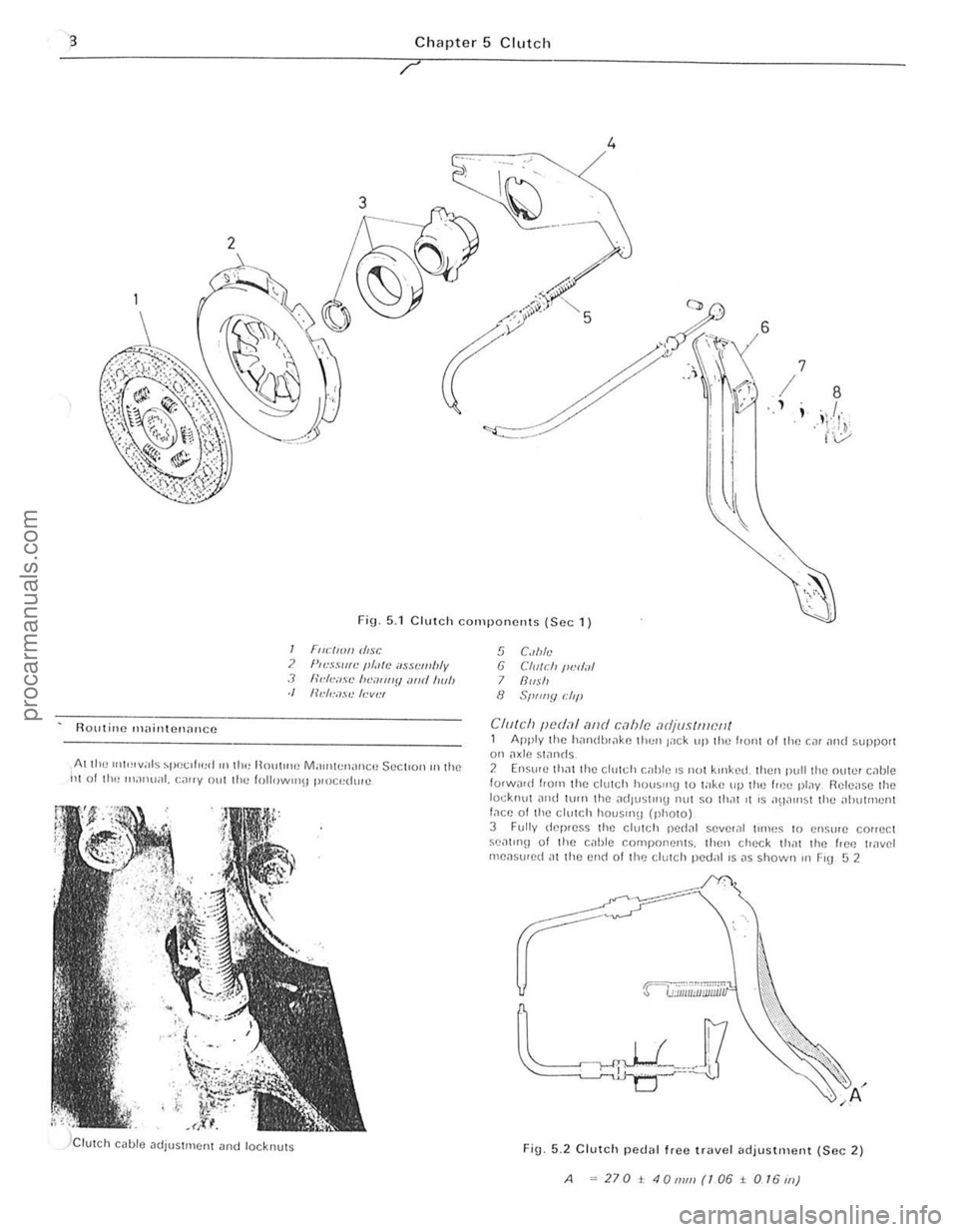

Fig 5.1 Clutch components (Sec 1)

Ruutine 1\1,lintC!1aIlCC

I FrwllO" d,sc ? }"".HIlfL' II/"'e ilHL'wlJly J "''''I.·o'R' /II .'''''''fJ oml 1001, ./ 11"',.""se /,."w"

AI tl1" U(itHv;lls spec(hud ((1 lh" llolll((1(J M ,((ntcnanCI! SeCI(OIlIll Ihe 111 of 11((1 Inilnu;!l. callY (Jut Ihe follow,,,\) pI<)c"dUlu

5 C"Ma 6 CI(I((:/' /1I:d,d 7 Rllsh 8 SI>tJlly dil'

CII/teh pUdo1l and c,1hle adjustment 1 Apply the handlH,lke til(:" J'lck lip the h01l1 ulthe Cill iII ld support 011 ilxle sl,lnds 2 Ensure thilt the c illtd, c;Jble 'S not klilked. Ihell pull the nllwr cilbt e 10lWilid hum the ch,tch houslI1g to lake up the f rec pl,lY Release the locknut ,1ud lurn the a(illlstln9 Ilut ~o thilt 11 IS an,lulst thc "i>utl1lenl f,Ke of the clutch houslnU (photo) 3 Fu lly dcp,e~s Ihe clutch pedill seve'ill ulnes 10 en~u'e correct seat ln\! of Ihe cable components. then check thilt the hOI! t(<

A .. 270t40mm(106± O/6J1l)

procarmanuals.com

Page 100 of 205

Chapter 5 Clutch 99

--.;,:;.~.--.

. '

3 I V,,'W 01 Ihe clutch wIth the Ue,IIbox r~movcd

1 If IH,<:~SS;lIy. ill'" Ihe

I Remove the ~Jenrbox .. 5 described in Chapter G (photo). 2 Ma,k Ihe chltd, cove,

II", ~1'''I'·r ""!I Uoar (photo).

1 Cili lch assemhly -inspectioll

Ex;"nIlIO IllI] 1", :lio n dISC lor we,ll ollhe In<:lIon 1ll'lIe"al. for bwkell .j ,;pllilUS. (ilSlull rOll of the rilll "ml we;lr all the splmos Unless the

. 1I:h plate IS In ve'y \Jood condlliull II is ;I false "cono"'y not 10 hi J

II""" ono ? The I"ctron d,sc should he ren ewed as as "ssemhly II IS adviscd Ih.ll th,s co\m;r~ IS prelelahle to lIymB 10 1'1 .. IIew I"ctlon IIIHIlU· :3 Chec k tho tnJchlned Iilces 01 Ihe flywheel "nd p'essure plate . lithe Ilywheells scoled. II should he relllove<1 "lid m~ch",cd Illhe preSSIJle pl.lIe IS scored.

cluic h nnd II si9nS 01 le"ks "re found. rec t,ly Ihe le"ks be/Ole hlling Ihe

clutch.

5 E x nmlllC Ihe diapl""9fll sprinu lor wear ,lIld <1

., Ch eck Ihe comt.tion ollhe dolCh spigol be .. ring in Ihe end 01 Ihe o""kshillt. Further inlorlllillion on this is given in Ch;lpICr 1.

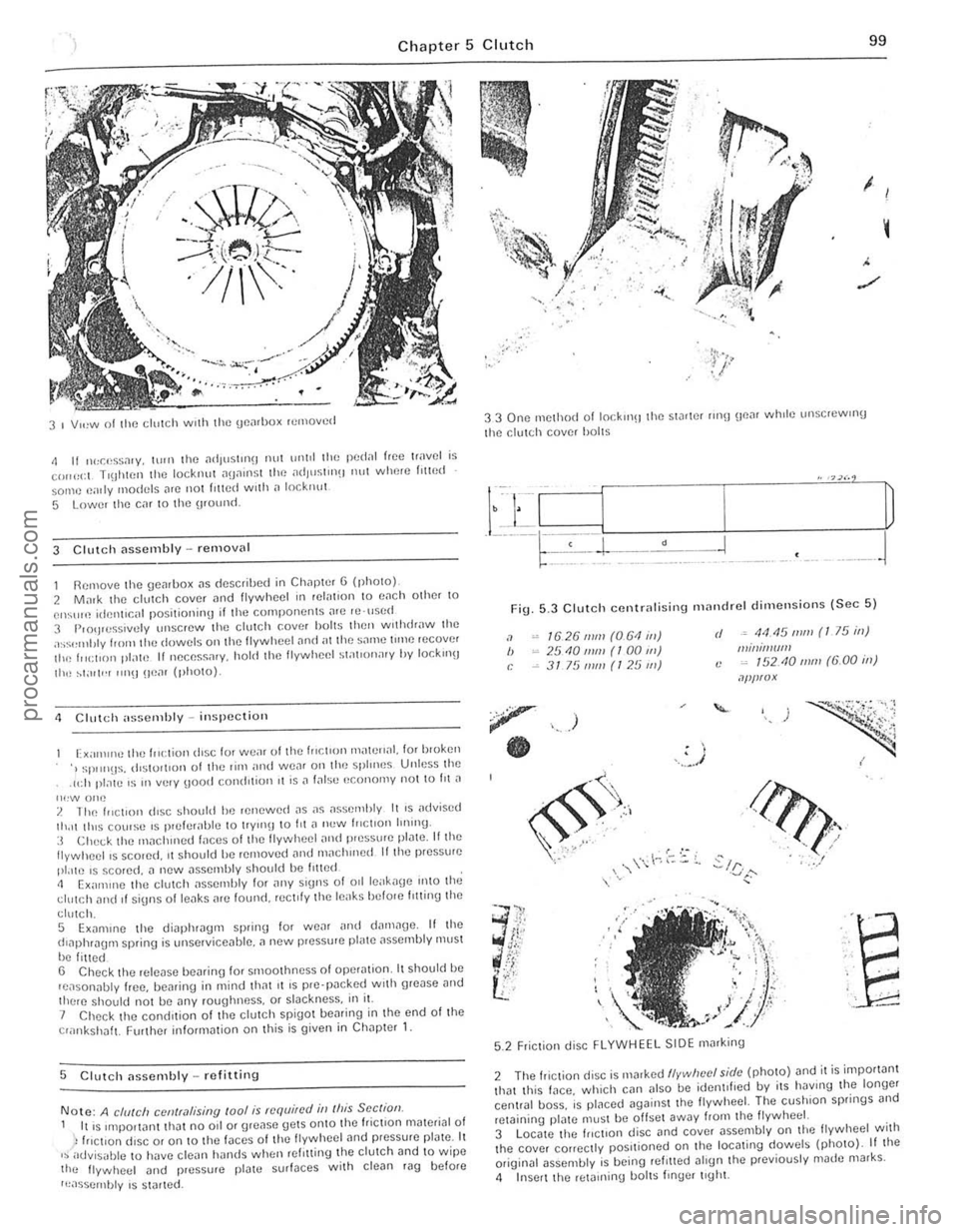

5 Clu tc h assembly _ relitting

Note: A chI/eli CCII(r,l/ising roo/ is required in (his See (ion. I IllS IInpOllanllhal no od or gre.lse gelS onlO th(l friction mated,,1 01 h,c t,on diSC 01 on 10 the laces of Ihe lIywheel find pressure plalc. It ,~advisi,llle to have clean hands when rel'lIing the dolCh and 10 w ipe lho lIywheel ;lIld pressure [lla\\! surfaces wilh clean rag belore

I~assernhly IS s1

.... , ... "

'.

33 One method 01 10cklllH the Slarter lin!) \lo"r wlHle \II1SCleWll1U

the clulCh cover hailS

•

Fig . 5.3 Clulc h centr" lising nHllldrel dimellsio ns ISec 5 )

"

" ,

1626 111111 (061 ill) 25101ll11! (100 1ft) 3175 mill (125 1ft)

)

.. , . I .. ~ .

rI .• 44.15 mm (I 75 ill) IIImil!l(IfII (: ~ 15210111111 (6.00 ill)

.l/lf!f(!X

./J?f1. ' ,

.?!<'. , , ..... /

~/ r .... :./ .:..1('":'

'''r' ....... , .

. )i";; , i ,

. . ~:.. • j • ,

/'" , , -..

··E

"

.. . -

5.2 Friction disc FLYWHEEL SIDE marking

2 The friClion disc is Il,arkcd flvwlwcl shit· (photo) and il i$ impol1anl Ihal th is face . which can 11150 be idenl,lled by ils haVing the longe, cenllal boss. ;s plnced againSI Ihe lIywheel. The cushion springs and reJaining pl"te muSI b(l ollsel away hom lhe Ilywheei. 3 Loca te the Inctlon disc "nd cover "ssembly on t he lIywheel with the cover cOlleclly positioned on J he loc .. ting dowels (phOto) . If lhe oliginal assembly is being , efllled .. lIgn Ihe previously made marks .

<1 Insell Ihe reta,ning boilS I"'ger Ilghl.

,

I

I

I

I,

procarmanuals.com