tow FORD CAPRI 1974 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 122 of 205

) Chapter 6 Manual gearbox and automatic transmissio n

121

"

i

...,

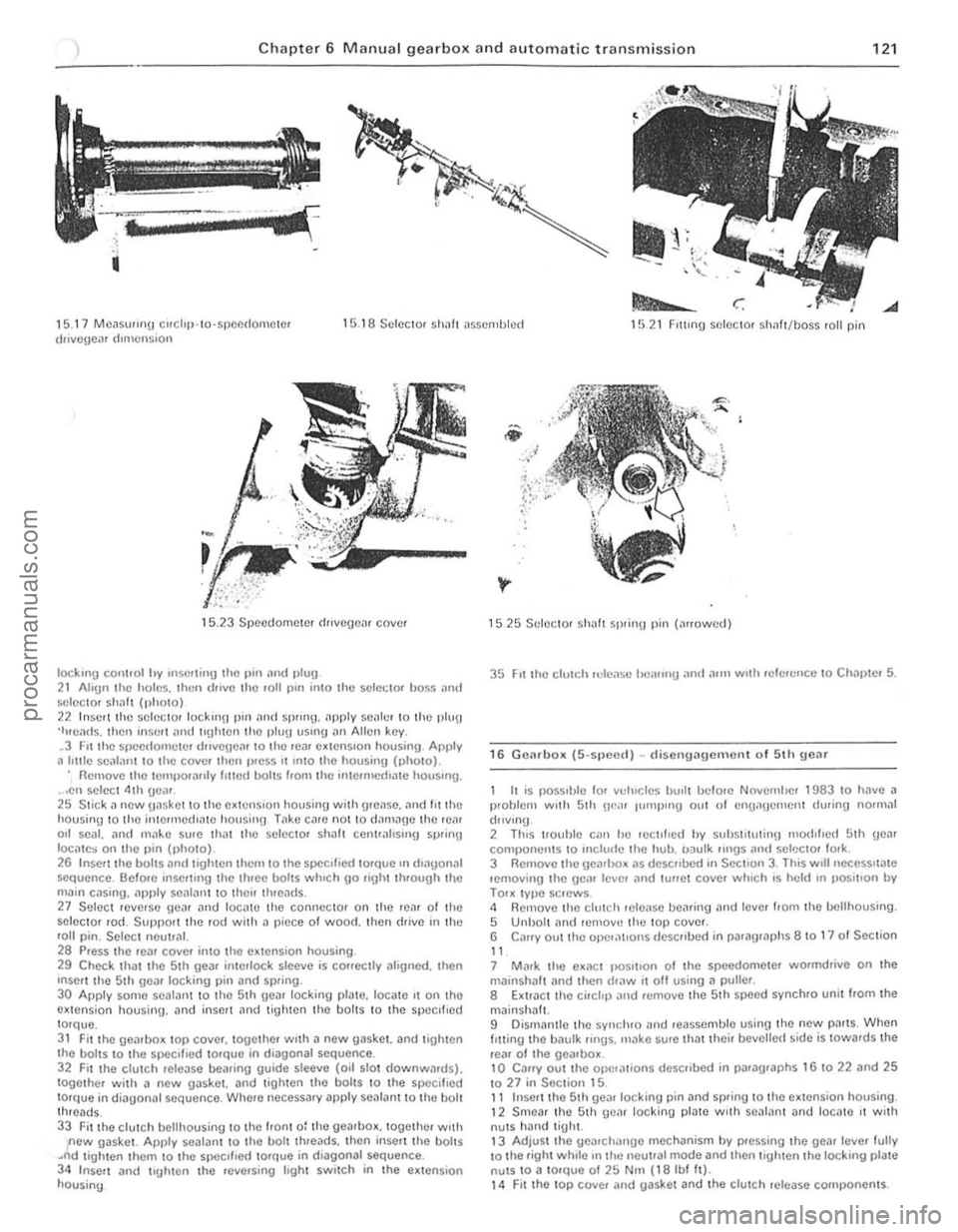

1 5. 17 MC~Sll"nu corchp· 10·SPCI1(lOIllClcr drivcgc,l' dImension 1 5 .1 8 Sc lcCl0f Sholl! t1sscmlJ lcct 1521 FIlling selector sh1lft/boss fall pin

15.23 Speedome ter dJlvcgcn, cove.

IOCkmg cOI1l,ol hy Inserl;"y the 1)111 ;lnd 1>lu9 2 1 Ahgn the holes. then (lillie Ihe roll pin il1lo the sc lcCIOf boss ;111\1 SI~ICC1Of s h

main c .. sing ... pply se

29 Check that the 5th gea. interlock slceve is corrcctly .11ognoo. then 'nscrt thc Sth geil' locking pin and spring.

30 Appl y some scalallt to the 5th geilr locking plate. 10Cilte It on thO extensio n housing. an d inselt nnd t igh ten th e bolts to I h e specIfIed torque. 31 Fit the Ueilrbo~ top covcr. together WIth a new gas\(et. and lighten

the boilS to t he sf1eclf.ed tOfQue in diagonal sequence. 32 F u the clulC h relCilSe bearing guide sleeve (oil slot dow nwllfd s). together with a new gilsket. and lighlen th o boi lS to the specillt~d torque in d;ilgon;11 sequence. Where neceSS;1ry apply seal,.nt to the bolt threads_ 33 Fitthe clutch bell housing to the Iron t 0: the gearhox. together woth new gaske t. Apply sealant to the bolt threads. thcn inse n the boilS .~d tigh ten them to Ihe SIXlcllled 10rQue in diagonal sequence. 34 Inscrt and trgh le n the .ev(usinl.l Ioght switch in Ihe ex tensio n housing

1525 Selec tor sh aft spring pin (arrowed)

35 FIt the clutch reLease l"l'lIIng and a.1Il wuh .efercnce 10 Chnl)\ el 5.

16 G e(lr box (5-spee{l) -d isellg i:lgem enl of 5th gear

I I

is possI ble 'or vducles hu,l t bclo.e NovcmiJer 1983 to have i:l p.oblem WIth 5th ne". Illillplllg Ollt of cnuanClllcn t during normal

(hlv lnu

2 ThiS 1I0uhle Cilll he rcc tl',cd hy suhstitutinu nlod,hc

3 Rem ove Ihe gearbo_ "s de$("bed in SectIon 3. This wrll nCCCSSlla te lemov ing the ge(l' Icvcr "nd lu"C I cove. whIch is held In ,)OSltlo n by TOOK typc sClews . 4 Removo the clutch Hlleilse bearing and tevcl 110m the bclthousing . 5 Unbolt ami lemovc the lOP covel. 6 C"ory out the opel,1t'0"S dcsc llbed in par "graphs 8 10 1" 01 Seclion

" 7 M"r\( Ihe ex.1Ct IIOS""o n of t he speedometcl wormdrive on the milinshil lt (lnd then draw it off using a pulter .

8 Extr"ct the ci. et,p "nd H)move the 5 th sp(lcd sync hro unil/rom Ihe

mJinsh"lt. 9 Dismanlle the synr.hro "nd reasscmble using the new p" rts, When I Itting t he b"ulk lings. m"ko sure that theil bevelle( 1 side is tOwa.ds the

re,,' o f Iho ge",box. 10 Caffy out the ope,,,,,ons desCfibed in jh"lfilgraphs 16 to 22 and 25 1027 in Section 15. 11 Inser t the 5 th ge

procarmanuals.com

Page 124 of 205

Chapter 6 Manual gearbox and automatic transmission 123

When towing a vehic le wIth automl11ic uansmission it is impoltllllt to observe the precautIons gIven til ,he 'Jading and Towing' se<:,ion at the Iront 01 the manual. Due to the complexity of the au'oma',c tran smission unit. If performance IS not up 10 s tandard, or overhaul is necessary, it IS impera tive that this be left to the locallllain agents who will have the special equipment for fault diagnosis and rectiflcallon. The content of the following sections is thereforc confined to supplying gener", Informl11ion 1'Ind any service information and ins t.uc tion tha i cnn be used by the owner.

19 Routine Illilinte,wno

At the i!lle.vnls SI)CClfiecllll Iho ROllllne Milintennnce seCIlOll in the I.onl 01 th e Illanllal cnllY Oul Ihe follOWIng p'ocp.dwe

Luuricow selector link'1[}() , Applv the h;rrldh.,lke th(:n J,lck \lp the front of Ihc Cill ,'lid Support

,n nxle Slnnds

2 Orlthe Irnkn!JCs at cndl end 01 Ihe genrsh ,h rml on the Icfl·hnnd "le 01 Ihe Iransnll~s,on lowel the cnr \0 Iho wound,

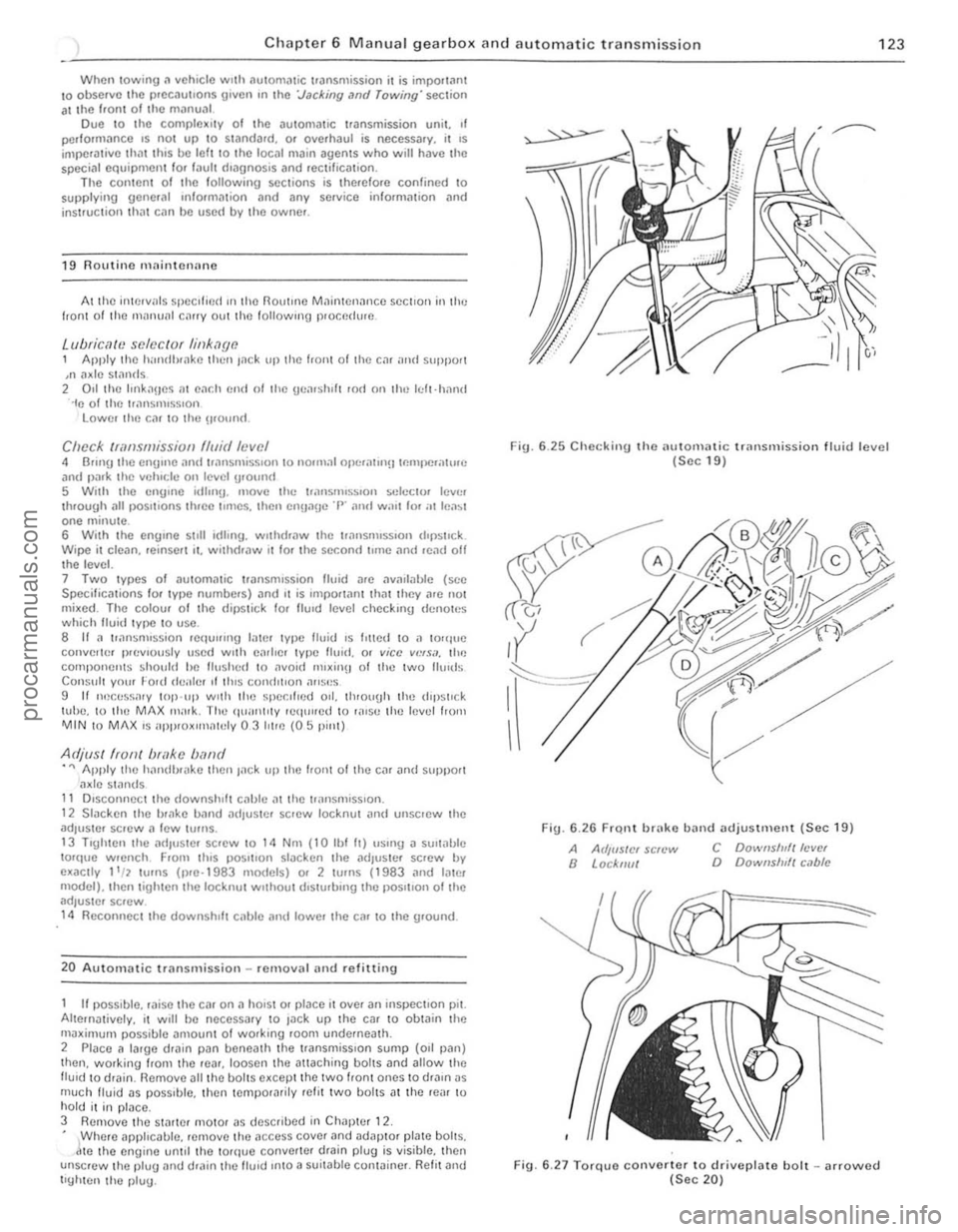

Check /mn.Wllissioll fluid level 4 Elrlll!! the engIne and trnnsnllSSlon to nOllllal ope.IlIUl!IIp.llIperillllfe

and I)alk tho vehlchl on le vel grOllnd 5 Wi,h Ihe engIne idllll(l. move tht: 1.,lnsnllSj"on St:leclt>r lev!]r through ill! pOSlllons 1!lIee lImes. Ihen onuaue '1" ,11111 wall for ;rt lea~t one minute. 6 With ,he engine 51111 idling, wllhd.ilW Ihe lr.1nSnllSSIOll d,psllck.

Wipe it dean, reinsert II, wilhd •• 1W 11 for Ihe second !line nnd read off the levol. 7 Two tv pes 01 automatic transnllssion fluid a.e nvarlilblc (sec SpccifiCiltions 10' tv,>c numbe.s) .1nd It is ImpO,I,ln , Ihilt IheV 'lIe nOI mixed. The colour 01 the dipstick. 10' flUId level checklllg denotes which fluid tvpe to use , 8 If a tlr1nsnllssion requlII"U 1,1ter tvpe fluid IS I'lled 10 " to'

adjus'or screw n lew h,fIlS . 13 Tlghlolllhe adJuslo, sOcw to 14 Nm (10 Ihl II) IISIilU a SUItable lo,que wrcnch From Ih,s poSlllon slaCken the adJusle r screw bv exact Iv I'll \Urns (pre·1983 models) or 2 Iwns ( 1983 and late,

model), Ihen tighten Ihe locknut Wllhoul diSlUrblllg Ihe pOsition of Ihe adjuster sc,ow .

14 R econnec t the downshift cable and lowe' Ihe car 10 Ihe ground.

20 Automalic transmission -removal (HId refining

If l)Osslble, ,aise the car on a hOlsl o. place it over an inspectIon pit. Alternatively, it WIll ho necessary 10 Jack up Ihe car to obtain the Illaximum possible amount of wOlking room undernealh. 2 Place a large d.ain pan benealh the transmiss.on sump (011 pan)

Ihen. working horll the ,car, loosen the a!laching boilS and allow ,he lIuld to drain. nemove all thO bohs excep t tho two I.onl ones to draIn as mIlch fluid as pOSSIble, th on temporarilV .efit Iwo bolls at th e re,1I 10 hold it in place . 3 Remove tho Slilrte. moto. as desc.ibed in Chapter 12 . • jWhero apphcable, rernove the access cover Dnd ad3pto, plale bolts,

Ie the engine untrl the to.qu e converter drain plug is visible, then

unsc.ew Iho plug and d.ain Iho Ihud Into a suit3ble con winer. Refl! and l'Uh ten Iho plug.

Fig. 6 .25 Checkill{J tho au tomatic transmission lIuid lovel (Soc 19)

Fig. 6.2 6 FrQ,1 bn'ko band adjustment (Sec 19)

A Arllf/SICI sc/t'w a Locknut

C Downslu/t Icvel D Downs/u/t c.lblc

Fig. 6.27 Torquo convorter to driveplato boll -arrowod (Sec 20)

'I

.' i

!

,

{ ,

I , .::

.1 , I, , i:

i 'i; ; I

:1

procarmanuals.com

Page 140 of 205

•

Chapter 8 Rear axle 139

ci,cumS«"Ulces mny only one pmt of the two be renewed. fnspect the dllfe,enti,ll pinions nnd side gems for signs of pitting. score mMks. Chipping nnd general wem. Obtain new gears as necessa,y . Inspect the th,ust washers lor signs of weM or deep sco,ing. Obwin new thrust wnshe,s as necessary. Once the pinion o il senl has been disturbed it must be discMded and a new one obtained. 20 When new pnrts have been obwined ns required. reassembly cnn begin. First lit the thrust washers to the side gems and place them in position in the differential housing. The ground side of the thrust washers IllUSt lace the side gC.Jrs. 21 Place tile thrust wilshers behind the dillelentini pinion genrs i1nd mesh these twO Oems with the Side gears through the tWI) ilpertores in the lilllerentlill housing. Milke sure they ilre diametlicilily opposite 10 each other. RO«l!e the clillerent'i11 pinion gears through 90' so brinUlI1\j them into line with the pinion genr shnlt bore 111 the housinlt 22 Insert the pinion genr shnft with the lock In!) p'n hole III line with the pill hole. 23 Usinu leeler 1),IU!Jcs. measure the en{lll(",t 01 ench s,de Be,,,. II the speclficd h\Jure IS excecrt"d. IU!W tl"u~t washlllS mu"t he olJt,uned

-omnlllie the a~~el)lhly ,lg,llll ,trld ht new thll,st wa:,lu'

28 Using soitable diameter tubes. fit the two Wper roller bearing cones into the finnl dlive housing. making sure that they ale litted the correct way round. 29 Slide the shim and spncer onlO the pinion shalt and insert inlo t he final drive housing. 30 Relit the second and smaller diameter wper loller bea,ino onto the end of the pinion shaft lind 101i0w Ihis Wilh a new oil seal. Sefore Ihe senl is nctually fitted. apply some grense to the inner Ince between the two lips of the seal. 31 Apply n little jOinting compoond to the outer Ince of the seD I. 32 Using n tuhulilr dllft 01 suitable dinmeter, carefully drive the oil seal into the fillal (hive housinlJ. Make quite sore thnt it is lilted squarely and flush with the housinU. 33 Refn the drive pinion IInnge nnd hold securely in n bench vice. It II fixed lenIJth spncCl is Itlted. fit ilnd tighten the pinion nut 10 the spec ,lied lorque. If a collapsihle spnce r is f,tte d. follow the prOCedlHe

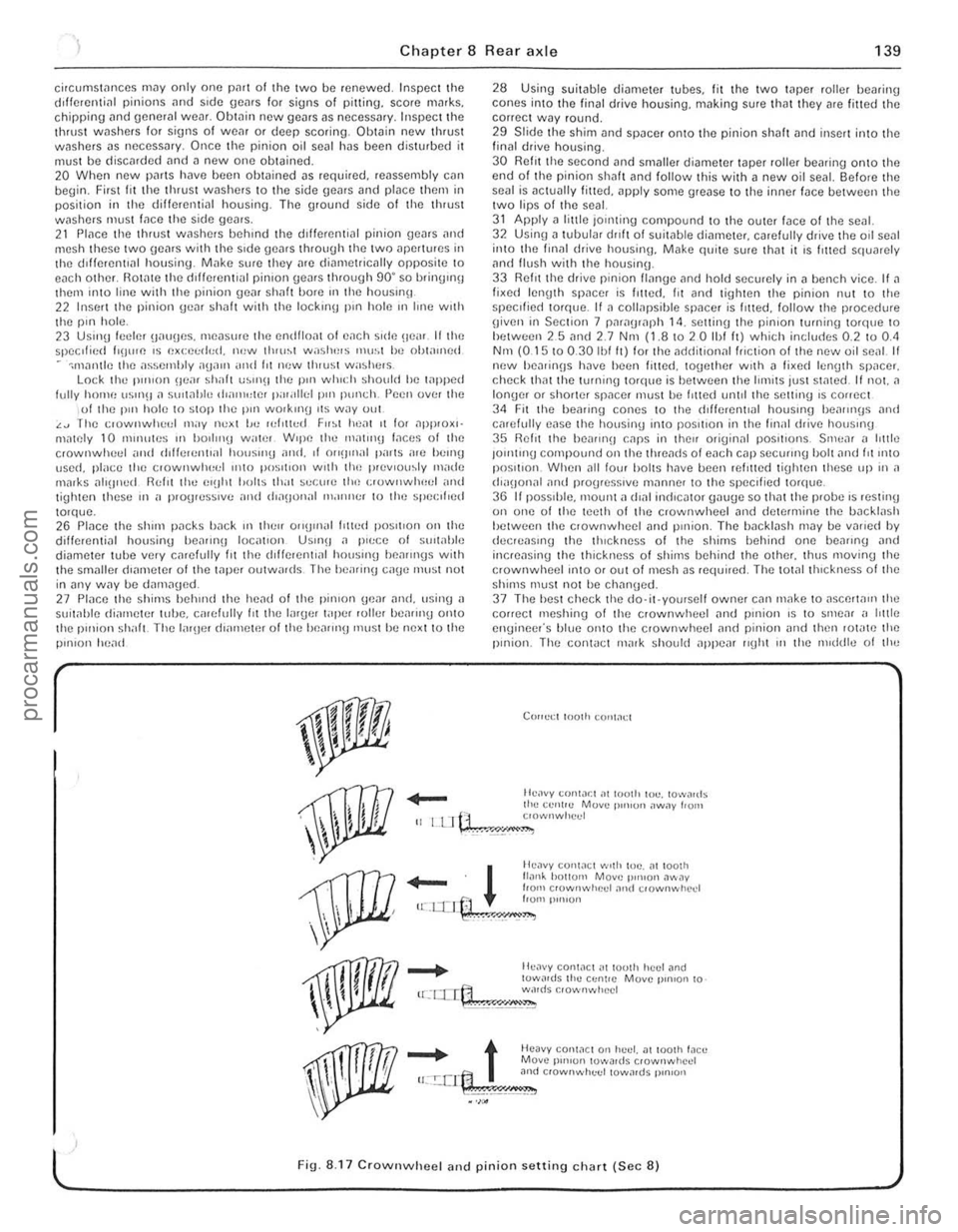

g iven in Section 7 paragraph 14. setting the pinion turning to'que to hetween 25 nnd 2.7 Nnt (1.810 2 0 Ihf It) which includes 0.2 to 0.<1 Nm (0.15 10 0.30 Ibl It) lor the ndriitional friction of the new oil senl II new hea,inns h~ve heen filted. logether With n li~e(l len(Jth SP,lCer. check thm the tOrlllllg torque is bel ween the limits just stmed. If not. a longer or shorter spilcer must he I,tted until the setting IS correct 34 Fit the healing cones to the cf,fierenllal houslIlg heallll(Js and carefully ease the housing Into posilion in the finill drive housmg 35 Relit the be,IIII'!J CilpS in thell originnl pOSitions. Srnc,ll n httle JOlntmg compound on the threilcfs 01 each cnp secuIII'O bolt nnd fit 11110 position. When ,111 low halts have bcen rein ted tiUhten these up in a (h"IJonal and progresSive milnne, to the speCi fied torque. 36 I I pOSSIble. 1Il00nt n dlnl in(licntor onu(Je so thnt the probe IS resting on one of the teeth of the crownwheel and determine the backlash hetween the clownwheel and pillion. The bileklash may be vMicd by elecreasll'\) the thickness of the shims bellind one beilling nnd incrensing the thickness of shirns behind the othcr. thus moving the crownwheel ;nlO or out ofmcsh as requi,ed. The tOt.llthlckness 01 the shims must not be chnn\)ed. 37 The hesl check the do·it·yourself owner cnn make to aSCerta", the correct meshinu of the crownwheel ilnd pinion is to smear ,I htt le engineer's blue onto the crownwheel and pinion iJnd then lot"te the pinion. The con1

_

t Heavy conWCl 0" huel. at 100lh !,leu Move p'",on lowa,ds crownwhcd u:.!:.crt:1 3nd c,ownwhuel towards p,n,on

.~\;!~" •. ,;.';,;,"",.,=,"--

l ' Fig. 8.17 CrownwheeJ and pinion setting chart (Sec 8)

, ,

, ,

"

procarmanuals.com

Page 167 of 205

,6 Chapter 10 Suspension and steering

A

l

I Lr;=::;;r""~Jj'Q l

G-cc;;;;-~---~~~~~

, " I : I 'II

'I' , ,

, ,

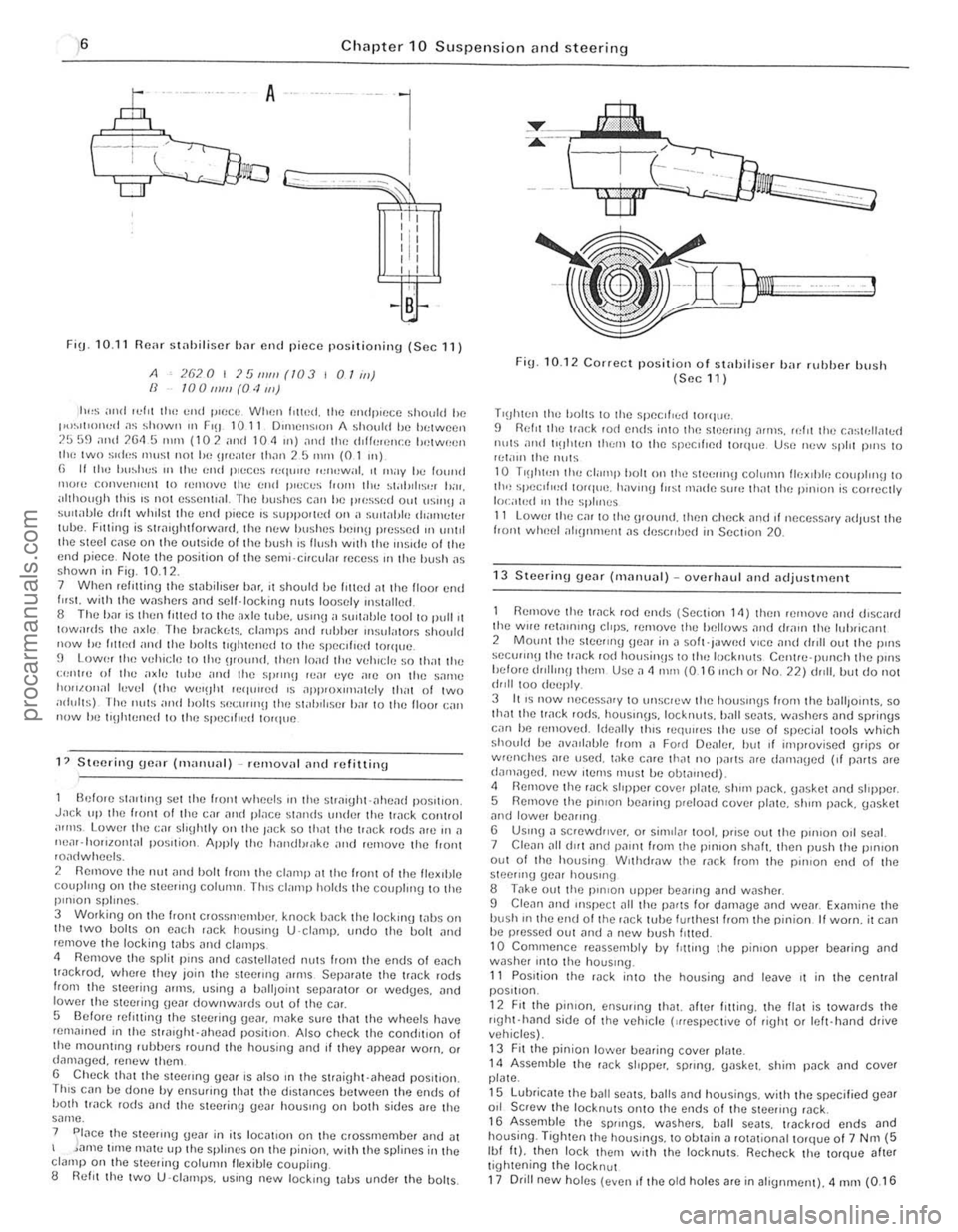

FiU · 10.11 Fl(Wr stniJiliscr b;H flnd piece positioning (Sec 11)

A IJ 2620 I J!J 111111 (/03 101m) 100111111 (0·1 mJ

1"'5 ;",(1 ,0.:1'1 tile t;1\{1 sHoec When l ilted. the wHip'cec should he 1'''~'ll'''H,,1 .15 shown III FlO 1011 DIIIlCIlS'Oll A should he betweell ?!.i 59 nlld 2Gtl 5 ""ll (102 ami 104 JI') :lnd Ih" (h(fmcncc IWlwr!f!1l IllI! two s"I"5 IIll1S! nOI he \l'catc, th.1rl 2 5 nUll (0 1 m)

(l II Ihe IJl,~hcs "' II", (,11(1 11".:';'$ "''1''''<) """,wi,I, II 'llaV I", found "'O'e COI1V"Il

h",,/.ul1,11 h.'vel (the wUIOht ",qlllred IS dpp'ox,m

J.!Ck lip the front 0 1 thn C,lr and place s1

2 Remove tile nul ~lId holt from the elnmp at the front of tile fleXIble COllpll ll(1 on the steerm!j colllllln, Tills cl,IInp hOlds the couplln(J to the pillion splines.

3 Working on the front crossmemlier, knock hilek the lockmg wbs orl the two bolts on each IJck houslllg U ·C lillllp. undo the bolt ~nd remove tbe locking tabs ~nd clamps

4 Remove Ihe split pillS

Th iS cnn be done by ensuflng that the d,swnces hetween Ihp. ends oj bOlh trllek rods 1111(1 the Stec1inu geilr hOllslng on both sides ~re the same .

7 Place the stee"ng Uear in it s 10c

-,

Fig. 10,12 COfrect position o f stnhiliser bar ruhher bush {Sec11 )

T'!jht(:n the holts to Ihe speclf,(:{! to"lne, 9 Relit the I.,lck rod ends into the stO)(:IIn!) illluS. refIt (he I:a';[ellolted nllts and II!Jhten them to the slleclfl{)d tOlque Use new spill pillS to '!:t.nn the nuts

10 T'!lhten tho I:I,II"P bolt (HI the steeru'!J COItIllHI lIex'hle couphllU to 1f1n spec""~d torque. h,)vIlI!) fll~t rnil(\e SlJlOl tholt tlul pin lOll is cOlfecily 10(;"101(1 III t he S"III1CS 1 1 Lower the cm to tho urOllnd. thcn check nrld If neceSSo1ly ildJlIst the front whlwl ;III(J 'Hncnr 015 descrd)ed in Sec lion 20.

13 Stcerinu geM (Illanual) -overhaul <111(1 adjustment

Remove tlllltr ilc k rod nnds (Section 14) then .elllove 1)nd discard the Wile retalnlllg cliPS. remove the hellows and drall1 the I"hricant 2 Mount the stee"ng Ijear in

15 LubrientIJ the ball Seilts. balls and housings. with the specified gear 011 Screw the locknuts OntO the ends of the steeling (1)ck. 1 G Assemble t he sprlllgs. waShers. bJIl seJts. track rOd ends and housing. Tighten the hOllsmgs. to obwin a rowtionnltorque of 7 N m (5 Ibf It). then lock them w ith the locknuts. Recheck the torque alter tiuhtening the locknut 17 Drill new holes (even If the o ld holes Jre in aliunment). 4 mm {O, 16

______________________________ .1

procarmanuals.com

Page 171 of 205

Chapter 10 S usp en sion" and steerin g

c

D

A

E

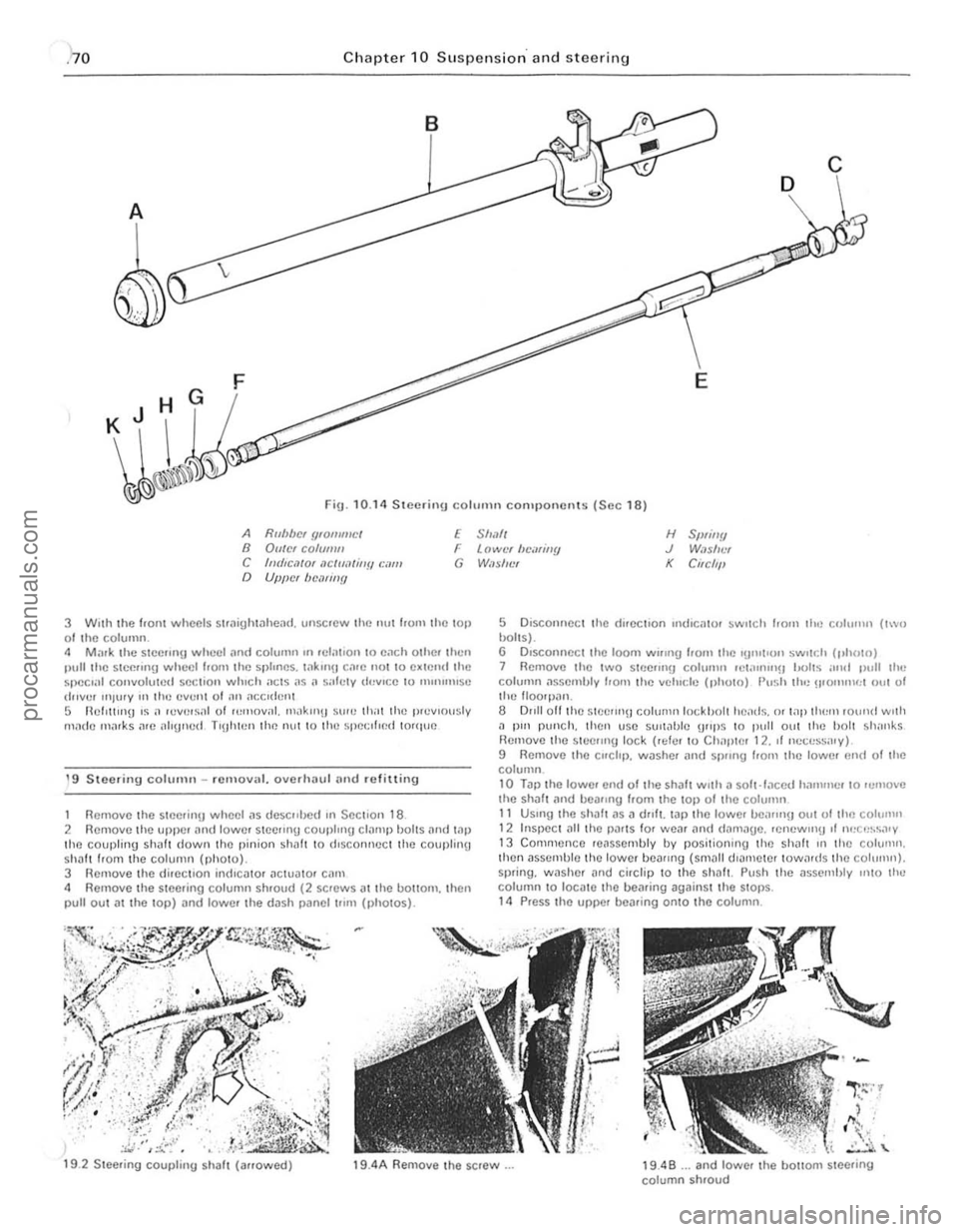

Fig. 10.14 Sleering column componenlS (Sec 18)

A Rllllbcl f/IOIIIIIICt n OutCI CO/U/IIII E Simll H SWill!! J W.n!u :, K Ci,cflfl C fmhC,ltOI ,1Ctuol(iIJ.II C,/11I o Upper f)CMIllf/

F lowt'l /)f:;lIiIlY G W.lslrtH

3 Wilh Ihe iron! wheels sl/aigh13he,ul, unse.ew Ihe nul from Ihe lOP of Ihe column. <1 Mi"k Ihe s!Celinu whecl and column m .eliliion 10 eilch olhe. Ihen 1".11 Ihe SI~"ng wlu • .'ci from thc spllncs. lilk",!! C illC nOI 10 cxtend Ihe ~pcclill convoluled SCC\lon which ;'CIS ilS it Si.rtlly d

dllVCI "'J"'Y II, IIHJ evenl o f 01" lIccldelll 5 nel,!!",\) IS a revClsal (ll "''''(lvill. m;lklllll su'e Ih;11 Ihe Jucvlnu sly mndc marks ... c ilhUned T'\Jhlell Ihe nUllO Ih\! spc,:l1lod torquc

1 9 S leerinu coilimn -remov,,1. overhaul (lnd refitting

1 Remove Ihe Sleer'n\J wheel ilS descllhed III SeCllo n 18-2 Remove Ihe upper and lowe. slee.lI1\J coupllll(l cl;Jmp 1)0115 ;Jnd 131) Ihc coupling sh;Jh down Ihe pinion shah 10 rhSC(lnneCI Ihe cO\lplin\J

sha ri f.om Ihe column (pholo).

3 Remove Ihe direCllon in(hcaIO' aCIUillOI C(lm 4 RemovC Ihe stee.ing column shroud (2 screws

"J . "\/ . ..::..J. \..

19 .2 S leering coupling shall (ar.owed) 19.4A Remove Ihe se,cw ... 19.48 ... and lower the bOllom slecring column shroud

procarmanuals.com

Page 181 of 205

.80 Chapter 11 B odywork and fitting

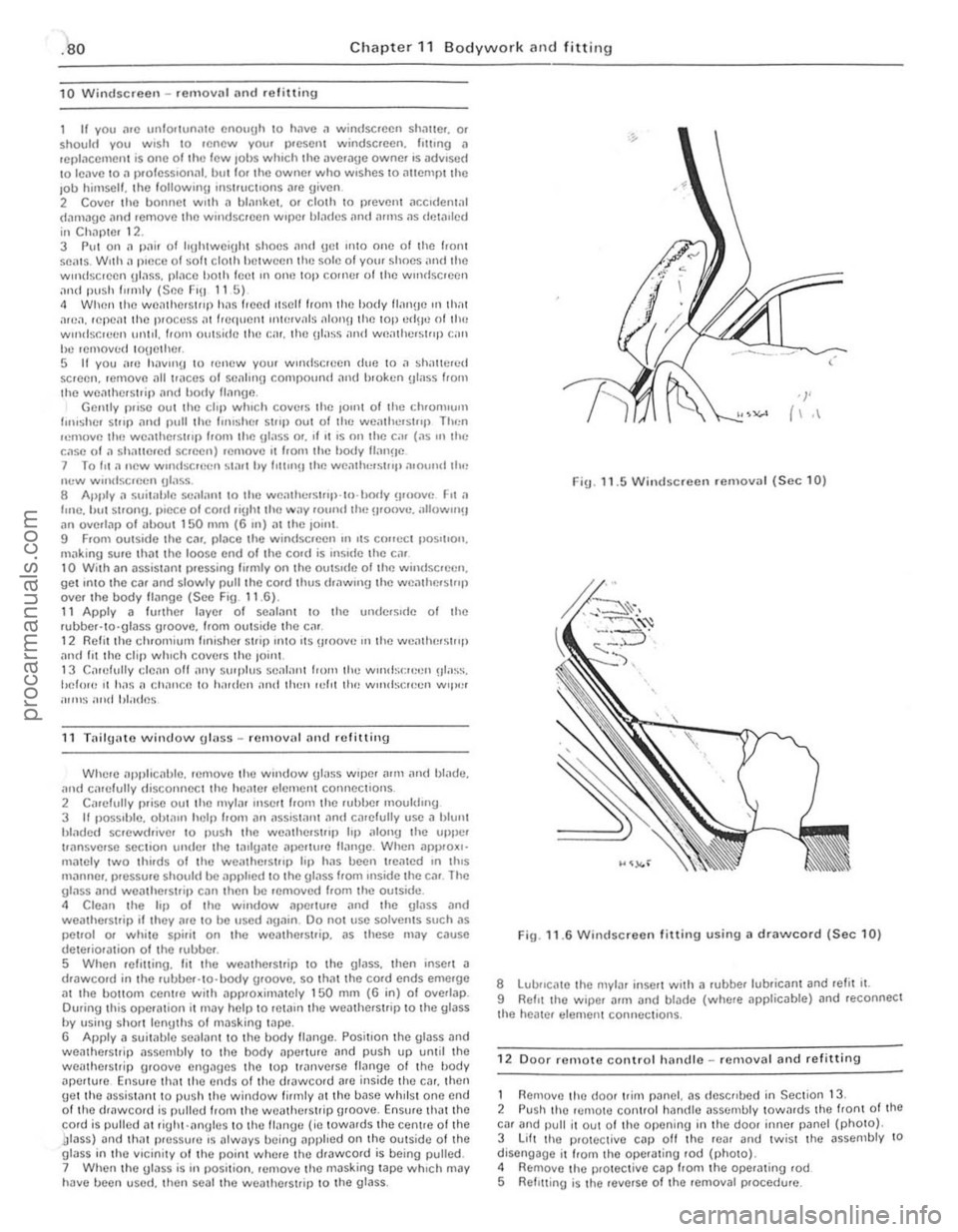

10 Windscreen -re rnavnl and re titting

II you ;lIe unlo,'unnlO enough 10 h:1\IO .1 wind$CICCIl shallC., 01 should you wIsh 10 . enew yOu. present windSClccn. humg J rel)lncemcnt is ono 0 1 the few Johs wluch lhe nvC'alJC owner IS advIsed 10 leave 10 n profeS SIon

1 0 Wilh an assis tant I>ressin g firml y on Ihe ouls.(Je of Ihe windscreen. gOI 1010 Ihe ca. and slowly puU the co.d Ihus d.,lwlng Ihe weathe.SllIll over Ihe body ffnnge (See FiU. 11.6). 11 Apply a lurlher Inye . 01 se"lilllI 10 Ihe omlelslde 01 Ihe lubber·lo·glass groove. from oOlside Ihe car. 1 2 Rellllh(l chromiom flnis hCI suit) Into I1S !!Joove In Ihe weallu"slliP ;"lIld 111 Ih(l clip which covers Ihe ,0inl. 1 3 CmefuHy clc,1 n all ;Iily SUiplus seal;mt 111)'" Ihe wlO\d~;"""..!" 1I';lss. ileJooe 1t ha s a Ch;'l"C!! to h;.,den ilild Ihell leflt the wtndscrecn WI",!r WillS ; IIId blades

11 T ailijato window g lnss -rem ov;,1 nnd rcfitting

Where applicnble. !elllove Ihe window ijl<1sS wipe. nrm and bln(l(l. and calefolly disconnCC I Ihe hunter elemenl conneCliOlls. 2 C,lr(lfully priso OUI Ih o myl;'l r Inser t from the rubber moullhng 3 If possIble. 01l1,1111 hell1110111 an nssist;1II1 nnd "nelolly usc a Illunt blnded scrcw(ffivcr 10 IlU sh the wenthc,slrop hi) "Ionu the u llpe. transverse sCGlion unde. th(l Inl lijnte aperl\lIe flange. When applOxl' Illately two Ihirds o f the wei'lherslllp hi) has been treated III Ihls manne •. pressu. e s holiid be apl>hed to the gl

G Apply a $uililhle seill,IIl1 to I he hody flilnijo . Posilion Ihe glass and w(lather$llip ;'I5sembly 10 Ihe body i1perlUre nnd pus h up unlil thO wemherstrip Oroove (lngnues tho top tl

, I '

I ,

FiU . 11.5 Win dscreen removal (Sec 10)

FiO . 11.6 Windscree" filting using a drawcor d (Sec 10)

8 LubflCillO the mylnr insert wilh a rubbel lobricanl and re lit il. 9 Refit Iho wi,>or arm and blado (whele applicable) and leconne<:t the heale. elemenl connections.

1 2 D

oor rClliote control handle -removal and .elitting

I Flcmovc Ihe door uim panel. as descflhed in SeCI;on 13.

2 Posh Iho rem OIO COnlrol h,lndl(l ilssembly low;"uds the lronl of 1110 C1ll and poll il oot o l lh e opening in Ih(l dool inner pan(ll (photo).

3 L ilt Ihe protec tive cap o ff the rea, and Iwis t Ih(l assembly 10 dis(lngago itlrom Iho operating .od {phOIO).

4 Removo t h(l prO leClivo cap hom Iho operating .od 5 Flel illing is Ihe reV(ltSe of the removal procedu.e.

----------------------------~~ 灲潣慲浡湵慬献捯m

Page 184 of 205

Chapter 11 Bodywork and fitting 183

.", .

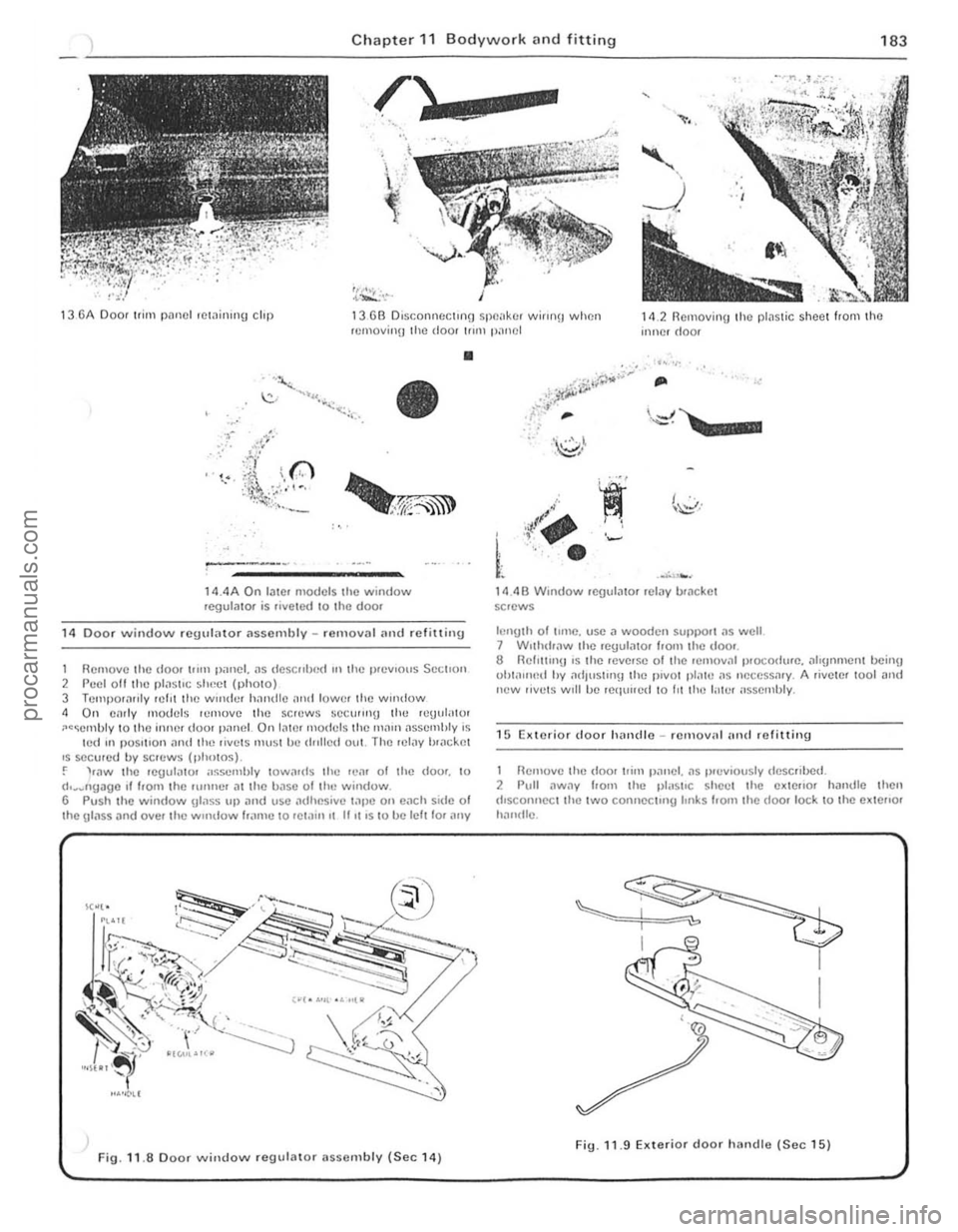

13 6A Door Ir;I" rwool lewining chp 136(3 Oisconll(:CIIIlg spen kOl WiWl!J when ICIllOV;"U Ihe dool Ir"ll p;lnel 14.2 Removing Iho plastic sheel from tho inllcr (Ioor

•

:, .. '

•

14.4A On l a tel models Ihe window IC9ullltor is I;ve ted 10 the doo.

14 Door window rcgul;otor (lsscf11b ly -r el1lov(l1 lmd refining

1 Remove Ihe dool II"n Ihlllei. liS dcscllb(~(1 III lhe preVIOUS Seclloll 2 Peel oH Ihe pl;1StiC shee t (phOto) 3 Teltll)Ol;111ly ICfl1 the wI"der h;1nd le and lowel the WII1(low 4 On emil' models lelllOve the screws SCC!ll"lU the reuul;rIOI ~<~ernbly to Ihe innel dool p;1l1el On l

Fig.l1. S Door window regulator assembly (Sec 14)

...r,

14.48 Window regulilto r relay b.acket

sc'ews

l e

nglh of '"lle. usc a wooden SUI>I>o.t ,,5 well 7 W,thdl

1 R eillove Ihe door 11;111 pam:l. ;15 plevlously deSCfibed . 2 Pull aw"y horn the pl"sII c sh ee . 'he cxtello, handle then dlsconncc. 'he .wo corlll&''''iJ hnks from 'he door lock \0 the extello, handlc .

Fig. 11.9 Ex te rior door hlllldle (Sec 15)

procarmanuals.com

Page 197 of 205

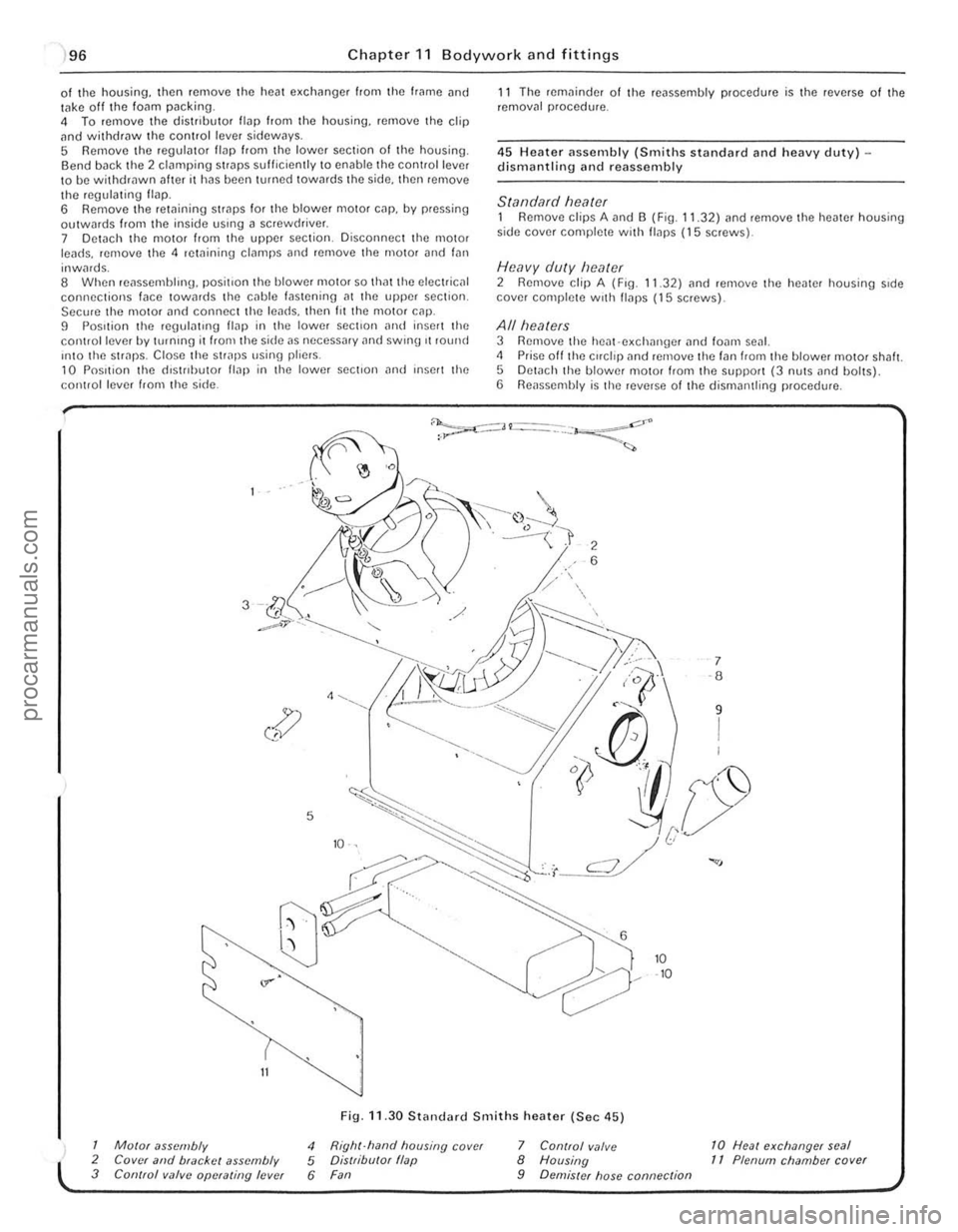

)96 Chapter 11 Bodywork an d fittings

of the housing, then remOlle the heal exchanger from the 1ramc and lake ott the fOilm pilcking. 4 To remove the distributor flap from the housing. remove the clip and withdraw the conlrollcvcr sideways. 5 Remove the rcgul<110r flap from the lower section of the housing, Bend bJck the 2 claillping straps sulticicnlly \0 enable the conlrollCIICI 10 be withdrawn (liter i, hilS been turned tow;1rds the side, then remove the regulating flilp. 6 Remove the retaining straps for the blower mOlor cap. by pressing outwards from the inside uSing 11 screwdriver. 7 Deweh the mOlOr from the upper sectioll. Disconnect the motor leads, remove til(! <1 rewining clumps and remove the motor and filiI inw,uds. a When reassembling. positIon thc blower mOlOr so that the clectric

11

11 The remainder 01 the reassembl y procedure is the reverse 01 the

r emova l procedure.

45 Heate r nssenlbly (Smiths standard and heavy duty) -dismantl ing and reassem bly

Standard he,1ler I Remove clips A and B (Fig. 11.32) ilnd remove lhe heater housing

sidc cover complete with flaps (15 screws) .

Heavy duty healer 2 Remove clip A (FIg . 11.32) olnd remove thc hcater housing SIde cover complete WIth flaps (15 screws)

All he,lIers 3 Remove thc heat e~chnnger nnd 10,1111 sen I. <1 Prise off the c"clip nnd remove the Ian I.om the blower motor shall. 5 Detach the blowe r motor from the support (3 nuts and holts). 6 Reassemhly is the reverse of the dismantl ing procedure.

Fig .

11.30 Stilndllrd Smiths h eater (Sec 4 5 )

1 M%r assembly

2 COVt·( and black!:t assembly 3 Control valve operatillg le vel

4 Righr·hand housing cover 5 Dis/ributor flap 6 Fan

7 Control v

-------------------------------~ 灲潣慲浡湵慬献捯m

Page 204 of 205

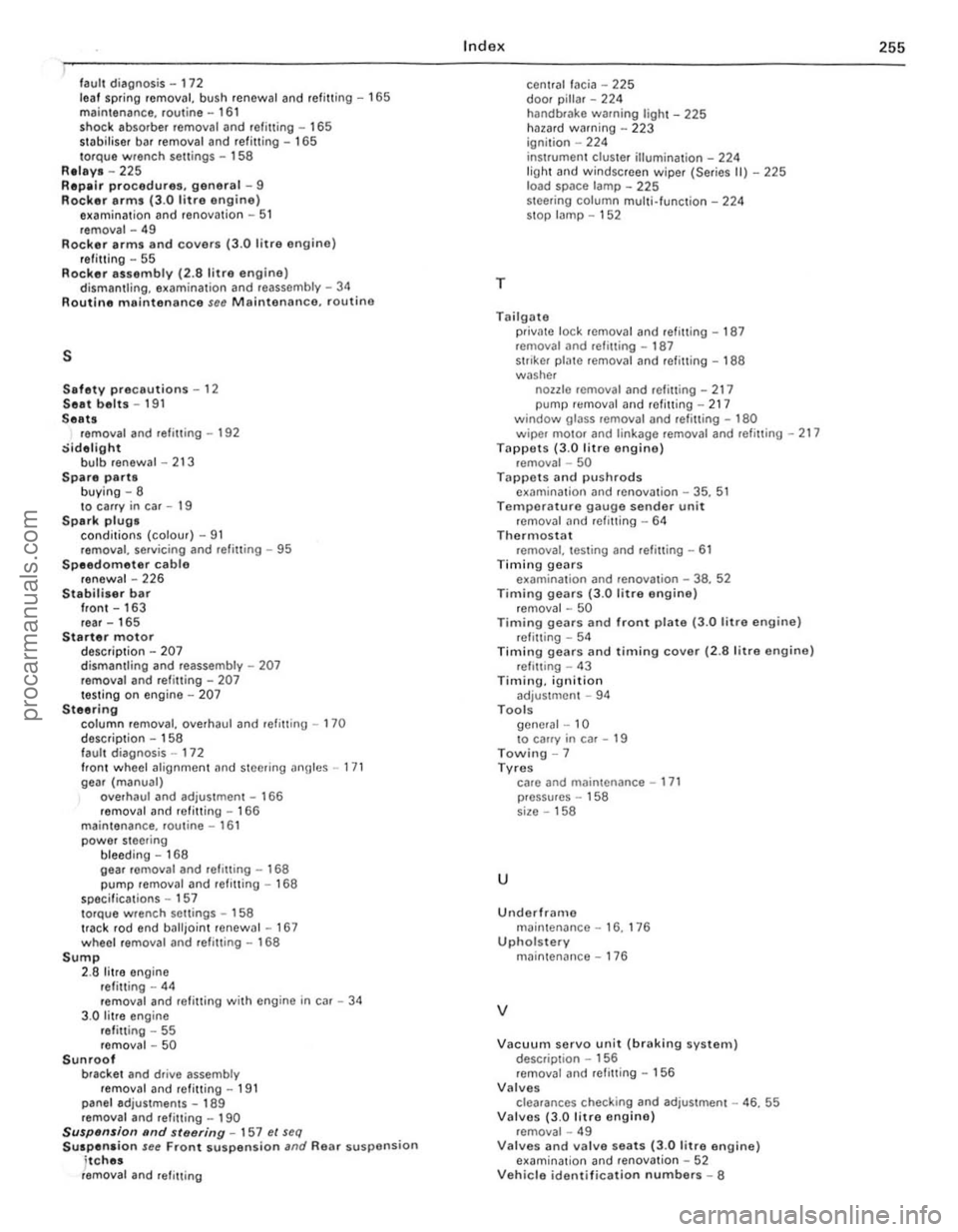

fault diagnosis -172 leaf spling .emoval. bush renewal and refitting -165 maintllnance. louline -161 shock absorber remoyal and refitting -165 stabiliser bar removal and refitting -165 lorque wrenCh settings -158 R"ays -225 Rep.ir procedures, general - 9

Rocker e rms (3.0 litre engine) examinat ion and renovation -51 removal - 49 Rocker arms and coverl (3.0 litre engine) ref itting -55 Rocker assembly (2.8 litre engine) dismantling. examina tion and reassembly -34 Routine maintenance stt Maintenance. routine

5

Safety precautions - 12 Seat belts -191 Seats .emoval and refining -192 Sidelight bulb renewal -213 Spare parta buying -8

to carry in ca. - 19 Spark p lugs conditions (colour) -91 lemoval. servicing and .elilling -95 Speedometer cable renewal - 226 Stabiliur bar Iront -163 rear -165 Starter moto r

description -207

d ismant ling and reassembly -207

removal and refi tting -207 testing on engine -207 Steering column removal. overhaul and refitt ino -170 desc.iption -158 faull diagnosis -172 f,on t wheel alignmenl ~nd steering angles -171 gear (manual)

ove,haul and adjustment -166 removal and refittin g -166 maintenance. rouline -161 power steering bleeding -168 gear removal and refitting -168

pump femoval and refining - 168

specifications _ 157 torque wlench senings -158 track rod end balljoint renewal-167

whea' removal and refitt ing -168 Sump 2.8 litra engine

refining -44

removal and refining with engine in car -34 3.0 litre engine refitting -55 removal -50 Sunroof bracket and dr ive assembly lemoval and refitting -191 panel adjustments -189 removal and refining _ 190 Suspension lfnd steering _ 15 7 tl seq Suspension see Front suspension Imd Re ar suspension jtches removal and relining

Index

T

central facia - 225

door p illar - 224 handbrake warning light _ 225 hazard warning -223

ignition -224

instr um

ent cluster illum ination _ 224 light and windscreen wiper (Series II) -225 load sp':)ce lamp -225 steerin g column multi-Iunction -224

s top lamp - 152

Tailgate priv ate lock removal and relining -187 .emoval and refilling -187 striker plate removal and relin ing - 188 wnsher

nozzle removal and refitting -217

pump rllmov31 and refitting -217 window glass removal and relitting -180 wiper mOlOr and linkage remoyal and refitting -217 Tappets (3.0 litre engine) remoyal -50 Tappets and push rods el

care and maintenance -171 presswes -158 size -15 8

Underframe

maintenance -16. 176 Upholstery maintenance -176

v

Vacuum servo unit (braking system) description -156 lemov~! and refining -156 Valves clearances checking and adjustment -46 . 55 Valves (3.0 titre engine) removat -49 Valves and va lv e seats (3.0 litre engine) examination and renovation -52 Vehicle identification numbers - 8

255

procarmanuals.com